Preparation methods and catalysis method of dimethyl maleate hydrogenation catalyst

A technology of dimethyl maleate and hydrogenation catalyst, which is applied in the chemical industry, can solve the problems of complex preparation process, complex process, and large equipment investment, and achieve good catalytic performance, reduced polymerization reaction, and low roasting temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

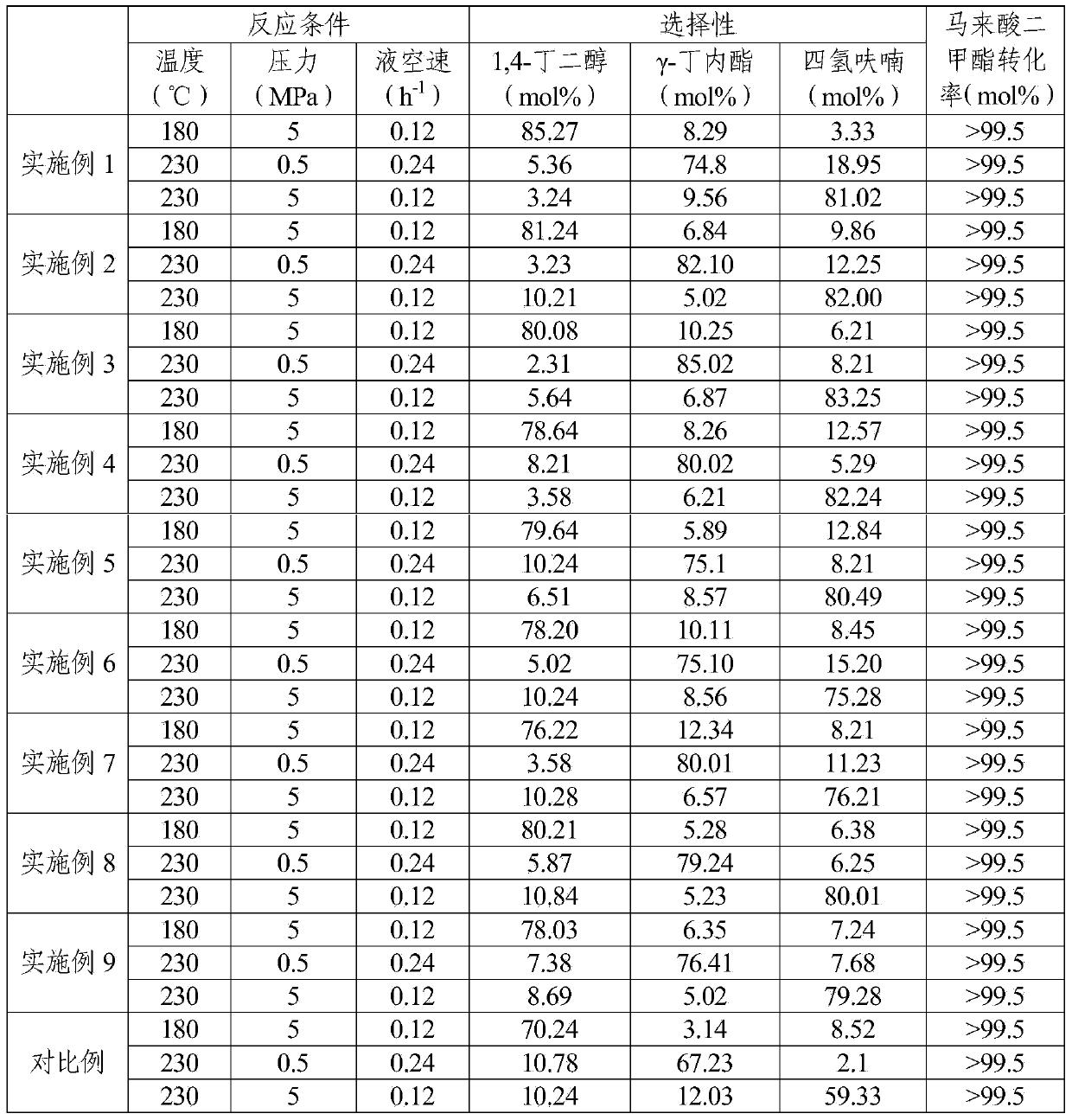

Examples

Embodiment 1

[0033] Step 1, 178.2g Cu(NO 3 ) 2 ·3H 2 O and 119.0g Zn(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to make 1100mL mixed aqueous solution, and 137g Na 2 CO 3 Dissolve in deionized water to make a precipitant aqueous solution with a concentration of 1.6M, preheat the precipitant aqueous solution to 60°C, and then add dropwise to the preheated precipitant aqueous solution under the stirring condition of 300r / min. ℃ mixed aqueous solution to a pH value of 7.2±0.5, the amount of metered mixed aqueous solution is 1025mL, to obtain copper and zinc co-precipitation material;

[0034] Step 2, mix 14.5g pseudo-boehmite powder with 145mL deionized water evenly, then drop into the mixture a dilute nitric acid with a mass concentration of 5%, stir for 2h to obtain a pseudo-boehmite sol; The ratio of the mass of nitric acid to the mass of alumina in the pseudo-boehmite powder is 0.2:1; the specific surface area of the pseudo-boehmite powder is >240m 2 / g, peptization index>...

Embodiment 2

[0038] Step 1, 151g Cu(NO 3 ) 2 ·3H 2 O and 185.33g Zn(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to form a 2.5L mixed aqueous solution, and 210g NaHCO 3 Dissolve in deionized water to make a concentration of 0.5M precipitant aqueous solution, preheat the precipitant aqueous solution to 80°C, and then add dropwise to the preheated precipitant aqueous solution under the stirring condition of 300r / min. The mixed aqueous solution to pH value is 7.0, and the amount of metered mixed aqueous solution is 2080mL, obtains the coprecipitation material of copper and zinc;

[0039] Step 2, mix 12.3g pseudo-boehmite powder with 98.4mL deionized water evenly, then drop into the mixture a dilute nitric acid with a mass concentration of 3%, and stir for 3h to obtain a pseudo-boehmite sol; the dilute nitric acid The ratio of the mass of nitric acid in medium to the mass of alumina in pseudo-boehmite powder is 0.05:1; the specific surface area of the pseudo-boehmite powder is >24...

Embodiment 3

[0043] Step 1, 151g Cu(NO 3 ) 2 ·3H 2 O and 185.33g Zn(NO 3 ) 2 ·6H 2 Dissolve O in deionized water to make a 2.5L mixed aqueous solution, dissolve 100g NaOH in deionized water to make a concentration of 0.5M precipitant aqueous solution, preheat the precipitant aqueous solution to 80°C, and then stir at 300r / min Add dropwise the mixed aqueous solution preheated to 80°C to the pH value of 7.0 into the preheated precipitant aqueous solution, and measure the amount of the mixed aqueous solution to 2080mL to obtain a coprecipitation material of copper and zinc;

[0044] Step 2, mix 6.3g pseudo-boehmite powder with 75.6mL deionized water evenly, then drop dilute nitric acid with a mass concentration of 10% into the mixture, stir for 2h to obtain pseudo-boehmite sol; the dilute nitric acid The ratio of the mass of nitric acid in medium to the mass of alumina in pseudo-boehmite powder is 0.05:1; the specific surface area of the pseudo-boehmite powder is >240m 2 / g, peptizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com