Synthesizing method for acrylate copolymers with hydrophobicity

An acrylate and synthesis method technology, which is applied in the field of synthesis of hydrophobic acrylate copolymers, can solve the problems of poor hydrophobicity, poor emulsification effect, and low polymerization efficiency of polymers, and achieve improved waterproof and antifouling properties, hydrophobic Outstanding performance and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Preparation of emulsifier water emulsion:

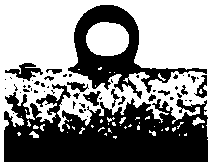

[0041] In the 250ml there-necked flask (reaction device such as figure 1 As shown), add 50ml deionized water, and add 0.606g SDS, 0.3578g OP-10, 0.1503g FS-3100. Stir at room temperature for 20 minutes at a rotational speed of 650 r / min, then ultrasonically disperse and stir in an ice-water bath for 20 minutes to obtain a uniform emulsifier water emulsion.

[0042] 2) Preparation of monomer mini-emulsion:

[0043] Weigh 0.1038g AIBN, 5.0018g formaldehyde methyl acrylate (MMA), 6.405g butyl acrylate (BA), 1.0292g hexadecane, mix well and add to the constant pressure dropping funnel, slowly drop to step 1) synthesis In the emulsifier aqueous emulsion, continue to stir at room temperature for 30 minutes after the dropwise addition, then ultrasonically disperse and stir in an ice-water bath for 20 minutes, take it out and let it stand until it returns to room temperature to obtain a monomer miniemulsion.

[0044] 3) Polymeri...

Embodiment 2

[0051] 1) Preparation of emulsifier water emulsion:

[0052] In the 250ml there-necked flask (reaction device such as figure 1 As shown), add 50ml deionized water, and add 0.6146g SDS, 0.3925g OP-10, 0.1793g FS-3100. Stir at room temperature for 20 minutes at a rotational speed of 650 r / min, then ultrasonically disperse and stir in an ice-water bath for 20 minutes to obtain a uniform emulsifier water emulsion.

[0053] 2) Preparation of monomer mini-emulsion:

[0054] Weigh 0.1039g AIBN, 0.9494g perfluorooctyl ethyl acrylate (FA), 4.9942g MMA, 6.5382gBA, 0.9936g hexadecane, mix well and add to the constant pressure dropping funnel, slowly drop to step 1 ) into the emulsifier water emulsion synthesized, after the dropwise addition, continue to stir at room temperature for 30 minutes, then ultrasonically disperse and stir in an ice-water bath for 20 minutes, take it out and let it stand until it returns to room temperature to obtain a monomer miniemulsion.

[0055] 3) Polymer...

Embodiment 3

[0062] 1) Preparation of emulsifier water emulsion:

[0063] In the 250ml there-necked flask (reaction device such as figure 1 As shown), add 50ml deionized water, and add 1.4651g DMC, 0.3298g OP-10, 0.1735g FS-3100. Stir at room temperature for 20 minutes at a rotational speed of 650 r / min, then ultrasonically disperse and stir in an ice-water bath for 20 minutes to obtain a uniform emulsifier water emulsion.

[0064] 2) Preparation of monomer mini-emulsion:

[0065] Weigh 0.1008g AIBN, 1.0347g FA, 5.2118g MMA, 6.4367g BA, 1.017g hexadecane, mix uniformly and add in the constant pressure dropping funnel, slowly add it dropwise to the emulsifier aqueous emulsion synthesized in step 1), After the dropwise addition, continue to stir at room temperature for 30 minutes, then ultrasonically disperse and stir in an ice-water bath for 20 minutes, take it out and let it stand until it returns to room temperature to obtain a monomer fine emulsion.

[0066] 3) Polymerization of minie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com