Method for preparing large-diameter diene-based rubber latex and acrylonitrile-butadiene-styrene graft copolymer including large-diameter diene-based rubber latex

A technology of diene rubber and latex, which is applied in the preparation of large-size diene rubber latex and the field of acrylonitrile-butadiene-styrene graft copolymer containing the rubber latex, which can solve the performance difficulties of rubber latex, etc. Problems, achieve the effect of improving industrial productivity, increasing polymerization conversion rate, and excellent impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In the preparation of the diene rubber latex applied to ABS resin, the invention provides a kind of preparation method of diene rubber latex, comprising:

[0027] Based on 100 parts by weight of conjugated diene monomer, add 50 parts by weight to 75 parts by weight of conjugated diene monomer, 1 part by weight to 3 parts by weight of emulsifier, 0.1 part by weight to 0.4 parts by weight Parts of polymerization initiator, 0.1 to 3 parts by weight of electrolyte, 0.1 to 0.5 parts by weight of molecular weight regulator and 65 to 100 parts by weight of ion-exchanged water while stirring, based on 100 parts by weight of conjugated Diene monomers, to which 0.05 to 0.3 parts by weight of a crosslinking agent is added, and then they are subjected to a first polymerization step (step 1);

[0028] When the polymerization conversion rate of (step 1) is 45% to 60%, add the remaining conjugated diene monomer, 0 to 0.1 parts by weight of emulsifier and 0 to 0.2 parts by weight of cr...

Embodiment 1

[0075] (Preparation of rubber latex)

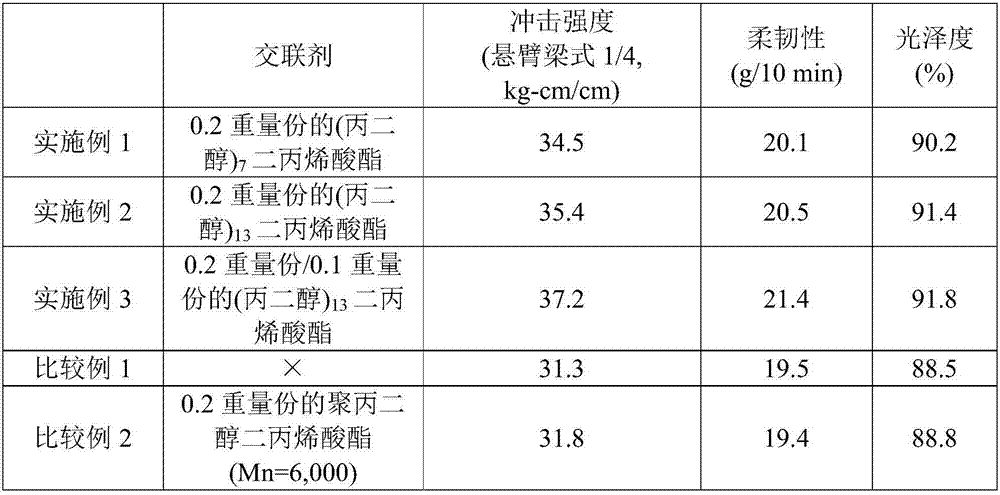

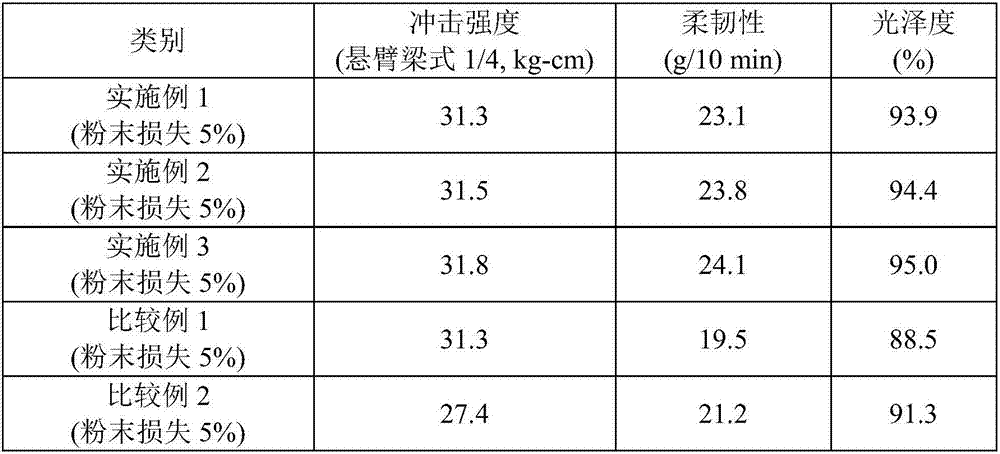

[0076] 65 parts by weight of ion-exchanged water, 75 parts by weight of 1,3-butadiene as a monomer, 1 part by weight of potassium rosinate, and 1.5 parts by weight of oil were simultaneously added to a nitrogen-substituted polymerization reactor (autoclave) potassium carbonate as an emulsifier, 0.3 parts by weight of potassium carbonate (K 2 CO 3 ) as electrolyte, 0.3 parts by weight of tertiary dodecyl mercaptan (TDDM) as molecular weight regulator, 0.3 parts by weight of potassium persulfate (K 2 S 2 o 8 ) as an initiator. As a crosslinking agent, add 0.2 parts by weight of (propylene glycol) 7 The diacrylate was then reacted at a reaction temperature of 70°C until the polymerization conversion reached 40% (first polymerization). Then, the remaining 1,3-butadiene and 0.3 parts by weight of potassium rosinate were respectively added thereto, heated to 82° C. and reacted (second polymerization). Then, when the polymerization conver...

Embodiment 2

[0082] (Preparation of rubber latex)

[0083] In addition to using (propylene glycol) 13 Diacrylate Substitute (Propylene Glycol) 7 Except that diacrylate is used as cross-linking agent, repeat the step of embodiment 1 to obtain the gel content with 76% and The larger size of rubber latex.

[0084] (Preparation of Acrylonitrile-Butadiene-Styrene Copolymer)

[0085] Except for using the above-prepared rubber latex instead of the rubber latex prepared in Example 1, the procedure of Example 1 was repeated to obtain an acrylonitrile-butadiene-styrene copolymer powder, and the copolymer powder was used to prepare a sample. The properties of the samples were measured, and the results are shown in Table 1 below, and then the numerical values were analyzed for comparison.

[0086] (acrylonitrile-butadiene-styrene thermoplastic resin)

[0087] 22.5% by weight of acrylonitrile-butadiene-styrene graft copolymer powder and 77.5% by weight of styrene-acrylonitrile resin (LG SAN 92H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com