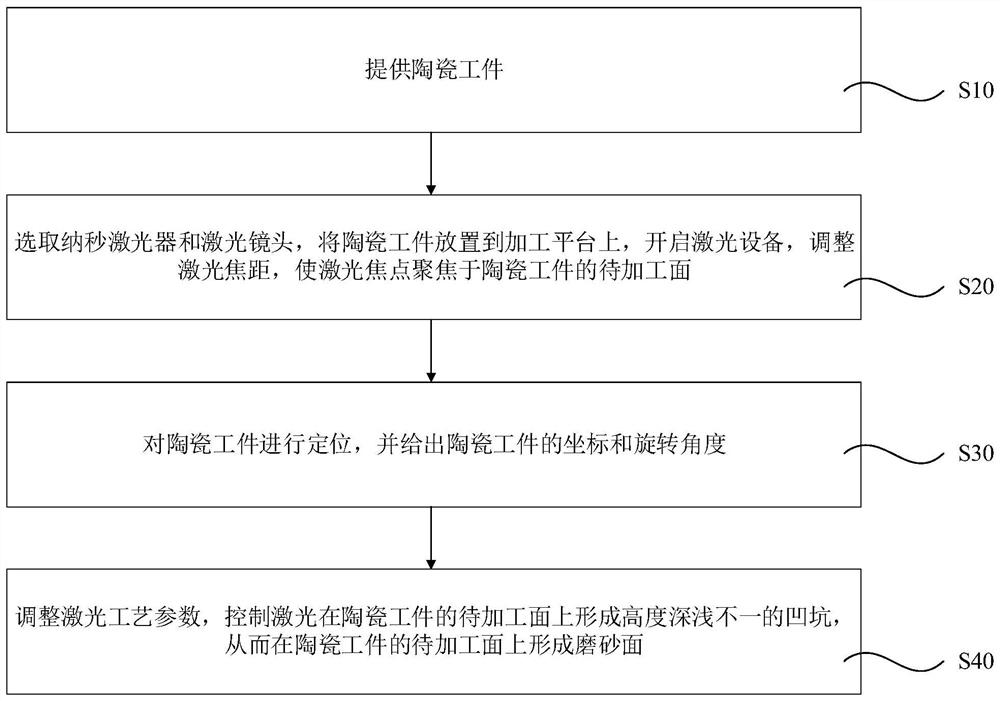

Laser polishing method for ceramic workpiece

A technology for workpieces and ceramics, which is applied in the field of laser grinding and sanding of ceramic workpieces, which can solve the problems of thermal deformation of the back cover of ceramic mobile phones, too smooth ceramic surface, unfavorable coating adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Provide zirconia ceramic mobile phone rear cover, sequentially with acetone, alcohol, deionized water to ultrasonic cleaning of zirconia ceramic mobile phone rear cover, and then dry with dust cloth.

[0049] The infrared nanosecond laser and laser range of 1064 nm and the pulse width of 60 ns are selected from 160 mm × 160 mm. The laser is placed on the precision machining platform, and the laser device is turned on, and the laser is adjusted. To make the laser focus focus on the upper surface of the zirconia ceramic phone back cover.

[0050]The two sets of CCD visual devices with large vision are selected, and the upper left edges of the ceramic mobile phone rear cover are positioned, and the coordinates and rotation angles of the rutzirconal ceramic phone rear cover are respectively positioned.

[0051] Setting the laser process parameters in the marking software, the power of laser processing is 15W, the processing speed is 800mm / s, the frequency is 40 kHz, the relea...

Embodiment 2

[0055] Embodiment 2 is substantially identical to Example 1, and the difference point is only in the selection of infrared nanosecond lasers having a wavelength of 1064 nm and a pulse width of 75 ns, and controls the power of the laser processing of 20W.

[0056] In this embodiment, the laser depth of the zirconia ceramic mobile phone rear cover is 30 μm, and the surface roughness is 6 μm.

Embodiment 3

[0058] Example 3 was substantially identical to Example 1, only an infrared nanosecond laser selected from 1064 nm and a pulse width of 90 ns, and controls the power of laser processing of 26W.

[0059] In this embodiment, the laser depth of the zirconia ceramic mobile phone rear cover is 60 μm, and the surface roughness is 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com