Automatic stamping device

An automatic, sliding connection technology, applied in the direction of printing, stamping, etc., to achieve the effect of appropriate ink depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

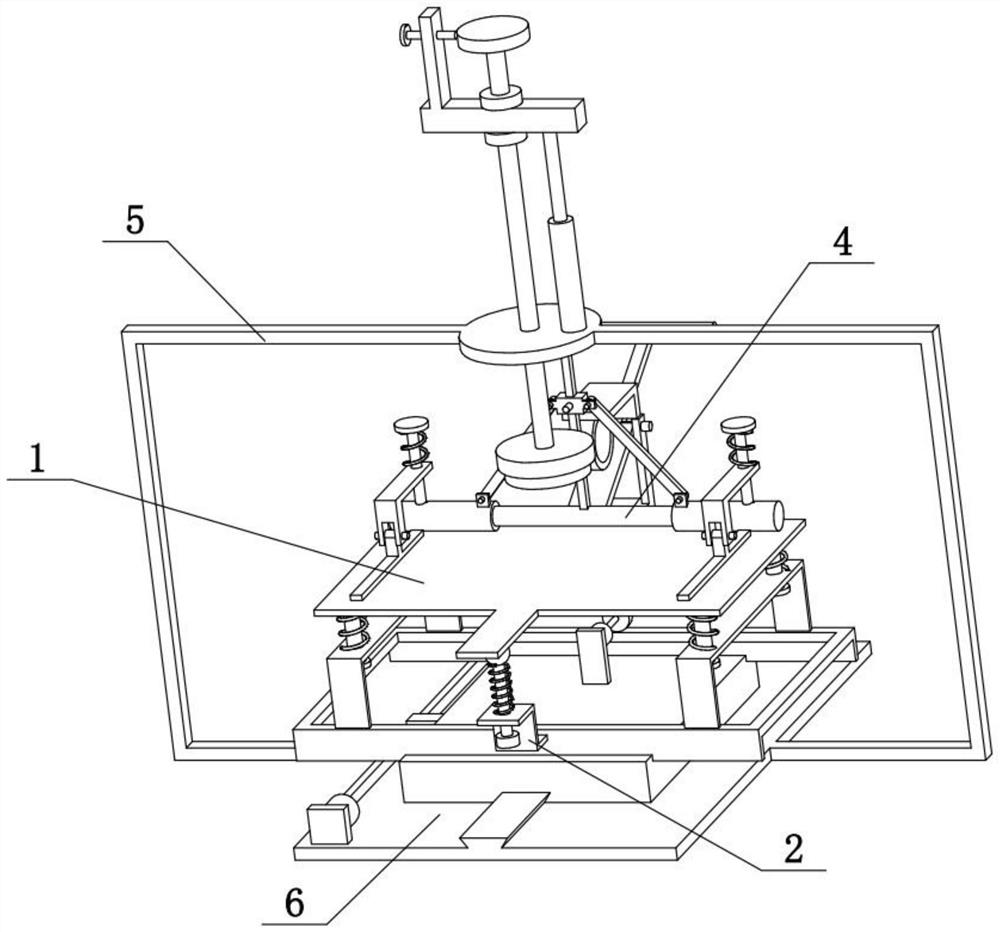

[0028] Combine below Figure 1-8 Describe this embodiment mode, the present invention relates to a kind of accounting appliance, more specifically a kind of automatic stamping device, including flat plate 1, door-shaped plate 102, rectangular frame 103, round baffle 1104 and vertical column 105, the present invention can There is a suitable strength when stamping, so that the ink depth is suitable.

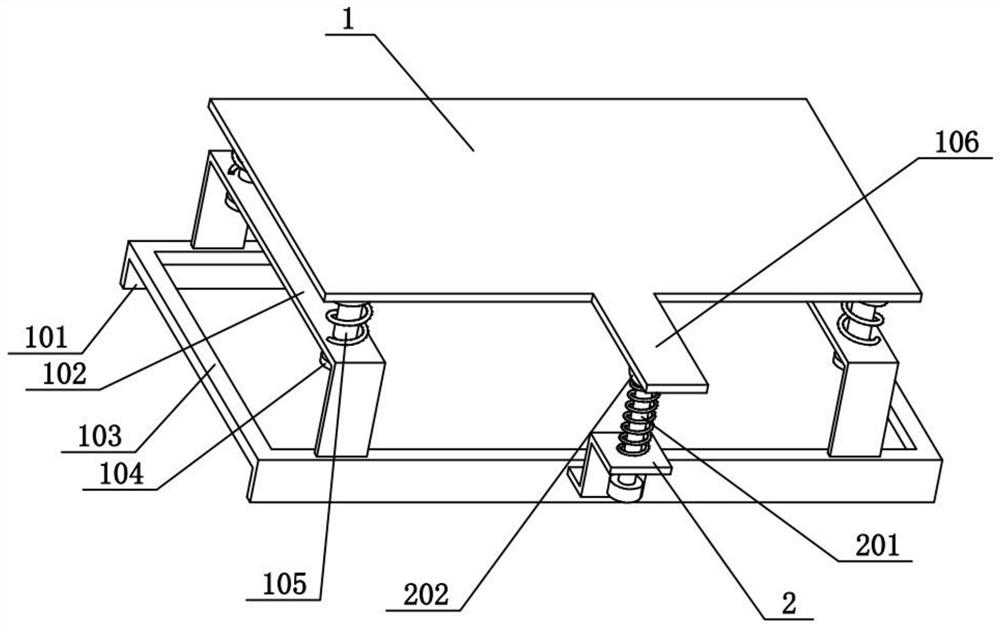

[0029] The left and right ends of the upper side of the rectangular frame 103 are fixedly connected with door-shaped plates 102, and the four corners of the lower side of the flat plate 1 are fixedly connected with vertical columns 105, and the two vertical columns 105 at the left end are slidably connected with each other at the left end. On the door-shaped plate 102, the two vertical columns 105 at the right end are slidably connected to the door-shaped plate 102 at the right end, and the four vertical columns 105 are sleeved with compression springs I, and the four compression ...

specific Embodiment approach 2

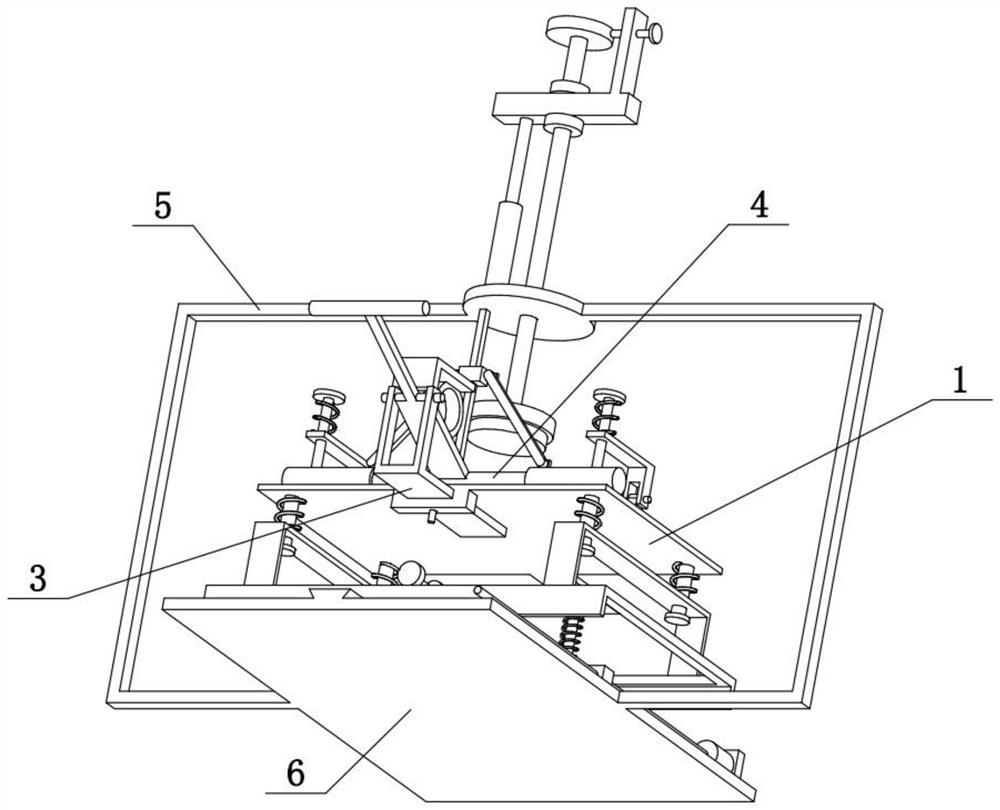

[0031] Combine below Figure 1-8 To illustrate this embodiment, the automatic stamping device also includes a front convex plate 106, a folding plate 2, a hammer post 201 and a ball 202, the front side of the flat plate 1 is fixedly connected with the front convex plate 106, and the front side of the rectangular frame 103 is fixed. The folding plate 2 is connected, the hammer column 201 is vertically slidingly connected to the folding plate 2, the upper end of the hammer column 201 is fixedly connected with a ball 202, the ball 202 is located under the front convex plate 106, and the hammer column 201 is sleeved with a compression Spring II, the compression spring II is located between the front flange 106 and the flap 2 . The compression spring II can be stored by pulling the hammer column 201, and then when the hammer column 201 is released, the ball 202 is pushed forward by the action of the compression spring II to the forward convex plate 106, so that the plate 1 vibrates...

specific Embodiment approach 3

[0033] Combine below Figure 1-8 To illustrate this embodiment, the automatic stamping device also includes a fixed seat 107, a front and rear moving plate 3, a lever 301, a hinged frame 302, an L-shaped seat 303 and a rubber ring 304, and the lower rear portion of the flat panel 1 is fixedly connected with a fixed seat 107, the front and rear moving plates 3 are slidably connected to the fixed seat 107 in the front and rear direction, and the front and rear moving plates 3 and the fixed seats 107 are fixed by means of screw compression, and the rear of the front and rear moving plates 3 is fixedly connected with a hinged frame 302, The middle part of the lever 301 is hinged on the upper part of the hinged frame 302, the upper end of the hinged frame 302 is fixedly connected with an L-shaped seat 303, the lower side of the L-shaped seat 303 is fixedly connected with a rubber ring 304, and the rubber ring 304 is pressed on the upper side of the front end of the lever 301 . The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com