Peanut harvester having stir-airing function

A harvester and functional technology, applied in the field of peanut harvesters, can solve problems such as insufficient drying, and achieve the effects of protecting the service life of the equipment, easy fruit picking, and improving the quality of peanuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

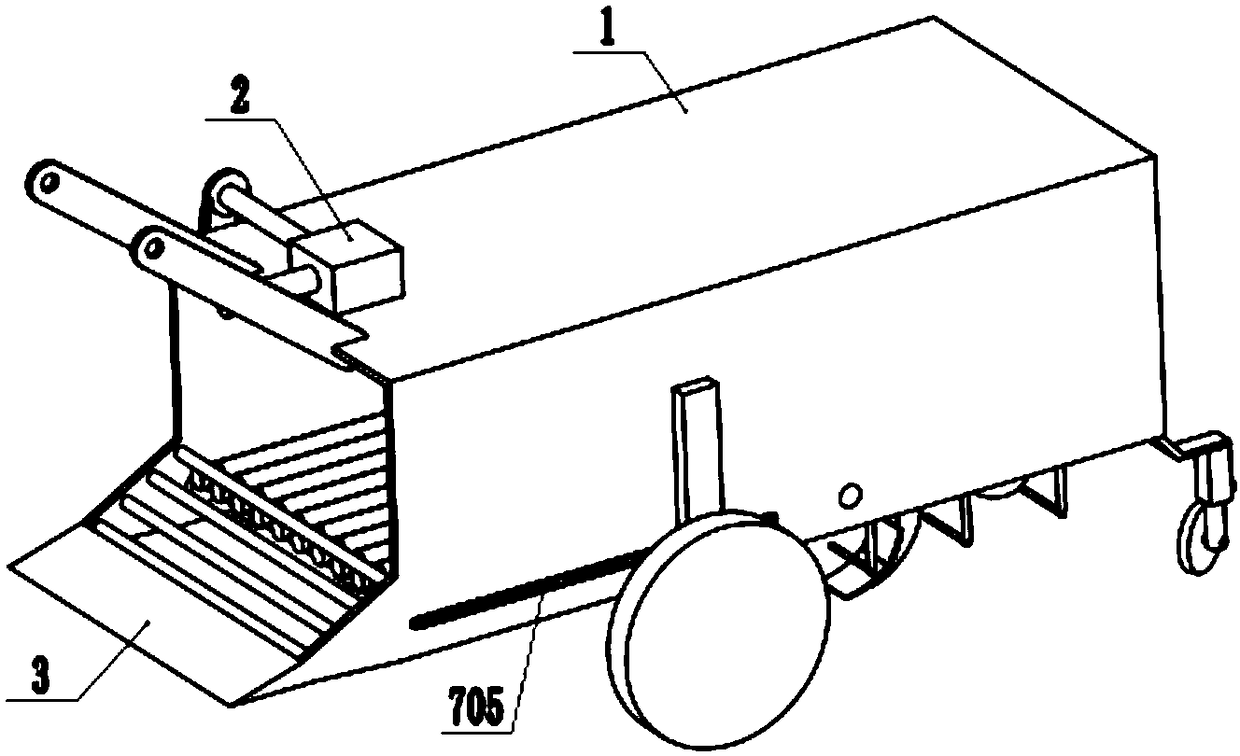

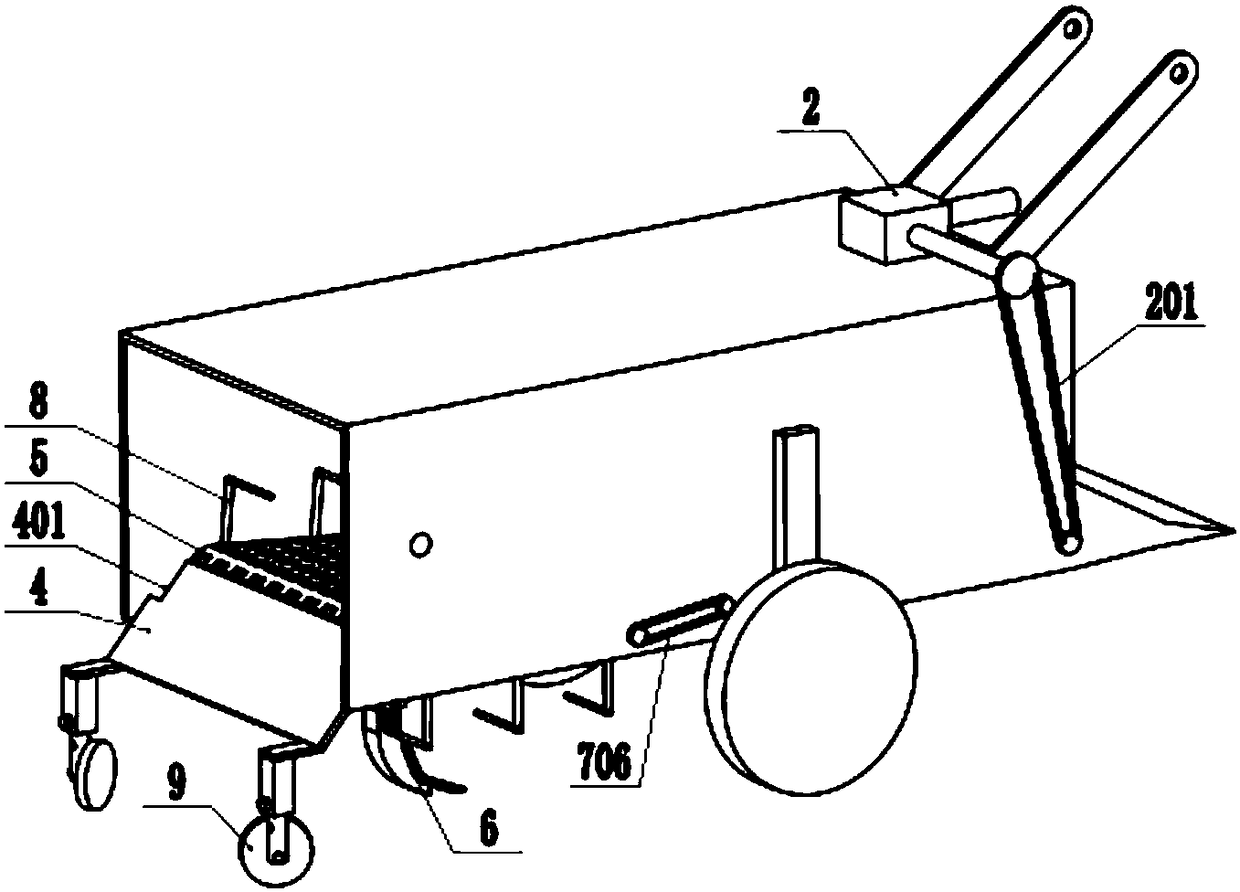

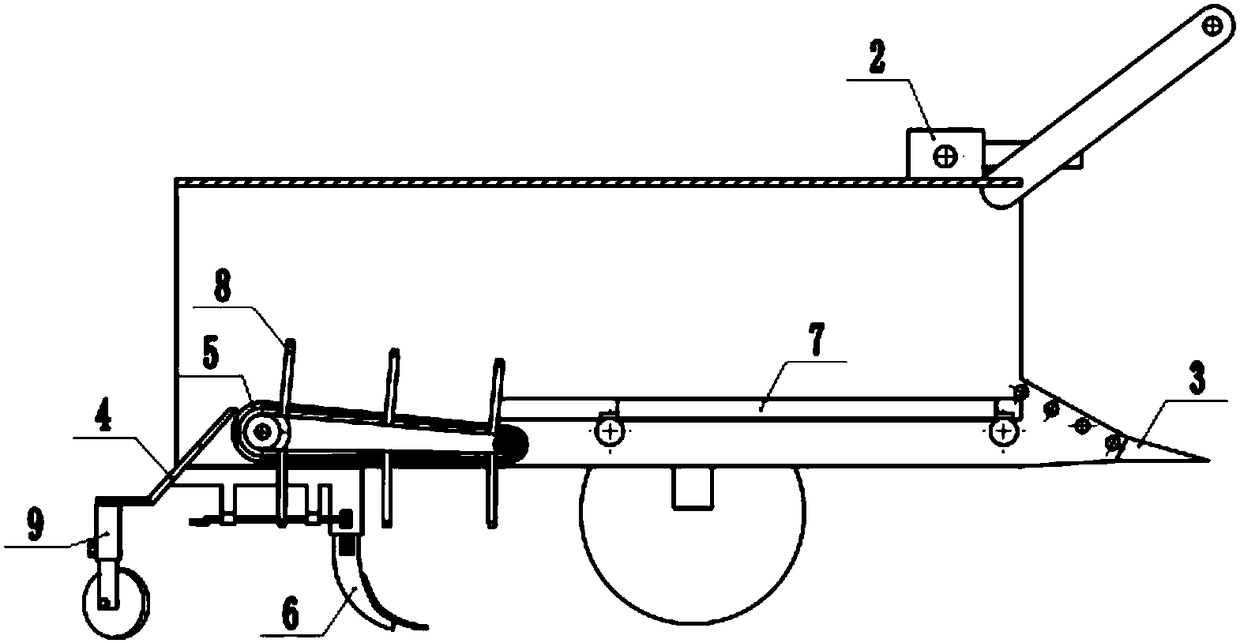

[0031] Such as Figure 1-3As shown, a peanut harvester with an overturning function includes a chassis 1, a gearbox 2 located at the upper end of the chassis 1, a vibrating screen 7 located inside the chassis 1, and a digging head 3. The power output shaft of the gearbox 2 passes through the power The transmission chain 201 is connected with the vibrating screen 7, the excavating head 3 is arranged on the lower side of the front end of the cabinet 1, the rear side of the vibrating screen 7 is provided with a seedling turning device 5, and the vibrating screen 7 and the seedling turning device 5 are driven by a chain 706 connected, the front end of the seedling turning device 5 is arranged on the bottom of the vibrating screen 7, the rear end of the seedling turning device 5 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com