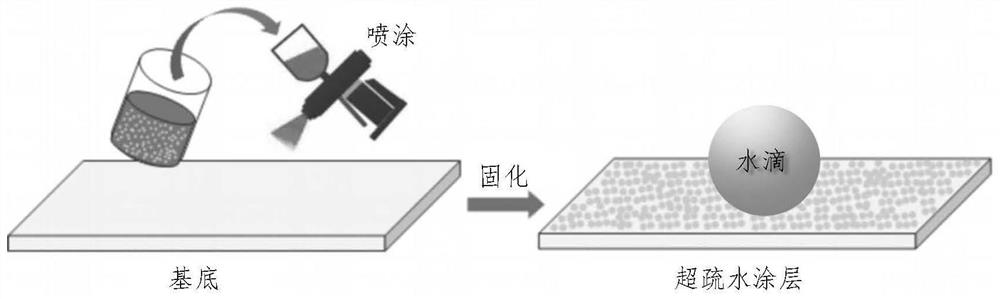

Preparation method and application of substrate-unlimited super-hydrophobic coating

A super-hydrophobic coating and solution technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of large-scale industrial preparation, cumbersome process, and high cost, and achieve excellent super-hydrophobicity, reduce surface energy, and high and low temperature resistance sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

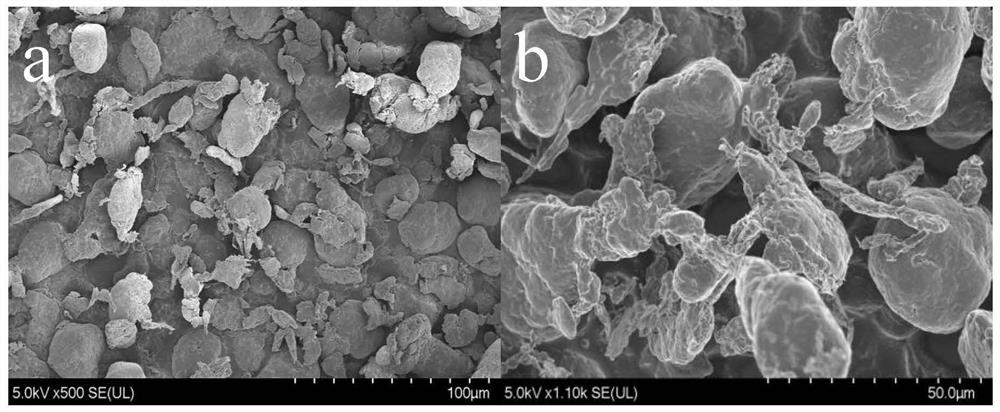

[0043] In this example, metal copper is used as the substrate, PFA (fusible polytetrafluoroethylene) is used as micro-nano particles, Dow Corning SJ-168 silicone weather-resistant sealant is used as adhesive, n-hexane is used as solvent, and no modifier is added. Prepare superhydrophobic copper surface, the steps are as follows:

[0044] (1) Take 0.5g of Dow Corning SJ-168 silicone weather-resistant sealant in 9.5g of n-hexane, dilute and stir until evenly mixed, and the resulting solution is named solution A;

[0045] (2) Get 2.5g of PFA hydrophobic micro-nano particles and put them into solution A, and mix them evenly to make a super-hydrophobic composite coating solution, which is called solution B;

[0046] (3) Use a spray gun to spray solution B onto the metal copper surface with a pressure of 0.3 MPa and a distance of 5 cm from the substrate. After the surface is dried, a superhydrophobic copper surface is obtained.

Embodiment 2

[0048] In this example, an iron plate is used as a substrate, FEP (perfluoroethylene propylene copolymer) is a micro-nano particle, Dow Corning SJ-168 silicone weather-resistant sealant is used as an adhesive, n-heptane is used as a solvent, and perfluorohexylethyltrimethoxy Silane is used as modifier to prepare superhydrophobic iron surface, and the steps are as follows:

[0049] (1) Take 0.5g of Dow Corning SJ-168 silicone weather-resistant sealant in 9.5g of n-heptane, dilute and stir until mixed evenly, and the resulting solution is named solution A;

[0050] (2) Add 0.1 g of perfluorohexylethyltrimethoxysilane modifier into solution A, and stir to obtain solution B;

[0051] (3) Get 2.5g FEP hydrophobic micro-nano particles and put them into solution B, and mix them evenly to make a super-hydrophobic composite coating solution, which is called solution C;

[0052] (4) Spray the solution C onto the surface of the iron plate with a pressure of 0.5 MPa and a distance of 7 cm ...

Embodiment 3

[0054] In this example, an aluminum plate is used as the substrate, PTFE (polytetrafluoroethylene) is used as micro-nano particles, Dow Corning LDC-737 silicone sealant is used as an adhesive, cyclohexane is used as a solvent, and Shanghai Ziyi ZY-FC327 fluorocarbon surfactant is Modifier prepares superhydrophobic aluminum surface, the steps are as follows:

[0055] (1) Take 0.5g of Dow Corning LDC-737 silicone sealant in 9.5g of cyclohexane, dilute and stir until mixed evenly, and the resulting solution is named solution A;

[0056] (2) Take 0.1g ZY-FC327 fluorocarbon surfactant and add it to solution A, and stir to obtain solution B;

[0057] (3) Get 2.5g PTFE hydrophobic micro-nano particles and put them into solution B, and mix them evenly to make a superhydrophobic composite coating solution, which is called solution C;

[0058] (4) Spray the solution C onto the surface of the aluminum plate with a pressure of 0.3 MPa and a distance of 6 cm from the substrate, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com