Self-roughened porous meshed super-hydrophobic polyester fabric and preparation method thereof

A polyester fabric, self-roughening technology, used in textiles, papermaking, fiber processing, etc., to achieve good low surface energy properties, good abrasion resistance and solvent resistance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

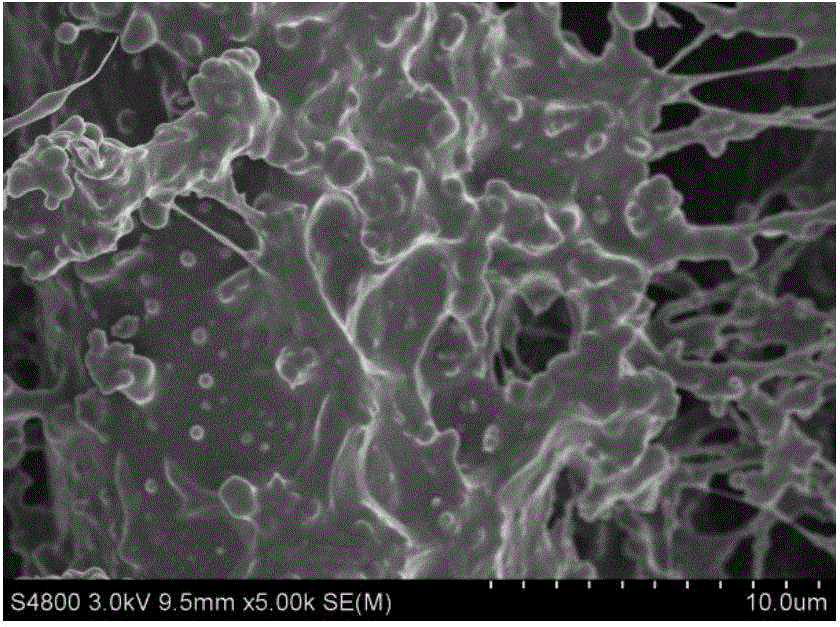

Image

Examples

Embodiment 1

[0017] Preparation of polyester fabric by phase separation method: first the polyester fabric is padded with ethanol solution (mass fraction 99.7%), then padded in mixed solution A, mixed solution A uses tetrahydrofuran as a solvent, and PDMS and PVC are dissolved in the solvent. Among them, the main agent of PDMS is 0.2g, the curing agent is 0.02g, the PVC is 0.2g, and the tetrahydrofuran is 19.58g. After drying at 40°C for 2 hours, the surface contact angle of the polyester fabric obtained by this method is 165.7°, and the static contact angles of the fabric with water droplets after washing and friction are 160.1° and 158.3° respectively.

Embodiment 2

[0019] Prepare polyester fabric by phase separation method: first the polyester fabric is padded with ethanol solution (mass fraction 99.7%), then padded in mixed solution A, mixed solution A is solvent with tetrahydrofuran, and PDMS and PVC are dissolved in this solvent, wherein , the main agent of PDMS is 0.2g, the curing agent is 0.02g, PVC is 0.1g, and tetrahydrofuran is 19.68g. After drying at 40°C for 2 hours, the surface contact angle of the obtained polyester fabric was 163.5°, and after the fabric was subjected to mechanical forces such as washing and friction, its static contact angles with water droplets were 159.6° and 156.4°, respectively.

Embodiment 3

[0021] Prepare polyester fabric by phase separation method: first the polyester fabric is padded with ethanol solution (mass fraction 99.7%), then padded in mixed solution A, mixed solution A is solvent with tetrahydrofuran, and PDMS and PVC are dissolved in this solvent, wherein , the main agent of PDMS is 0.2g, the curing agent is 0.025g, PVC is 0.05g, and tetrahydrofuran is 19.725g. After drying at 40°C for 2 hours, the surface contact angle of the obtained polyester fabric was 160.5°, and after the fabric was subjected to mechanical forces such as washing and friction, its static contact angles with water droplets were 157.6° and 154°, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com