Patents

Literature

78results about How to "Smooth routing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

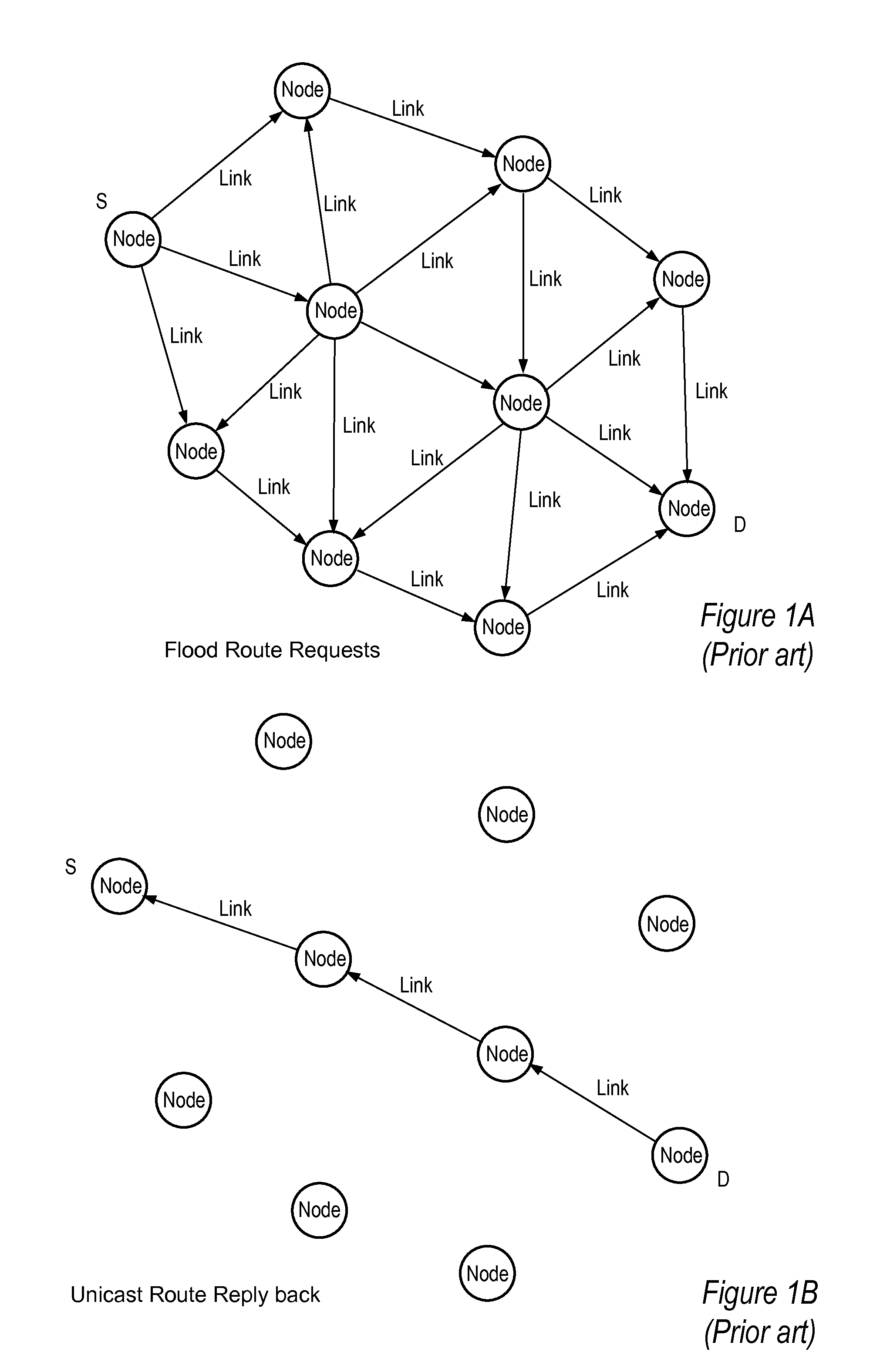

Method and Apparatus for Mesh Routing

ActiveUS20090168653A1Good for healthProlong lifeError preventionTransmission systemsCost metricMesh routing

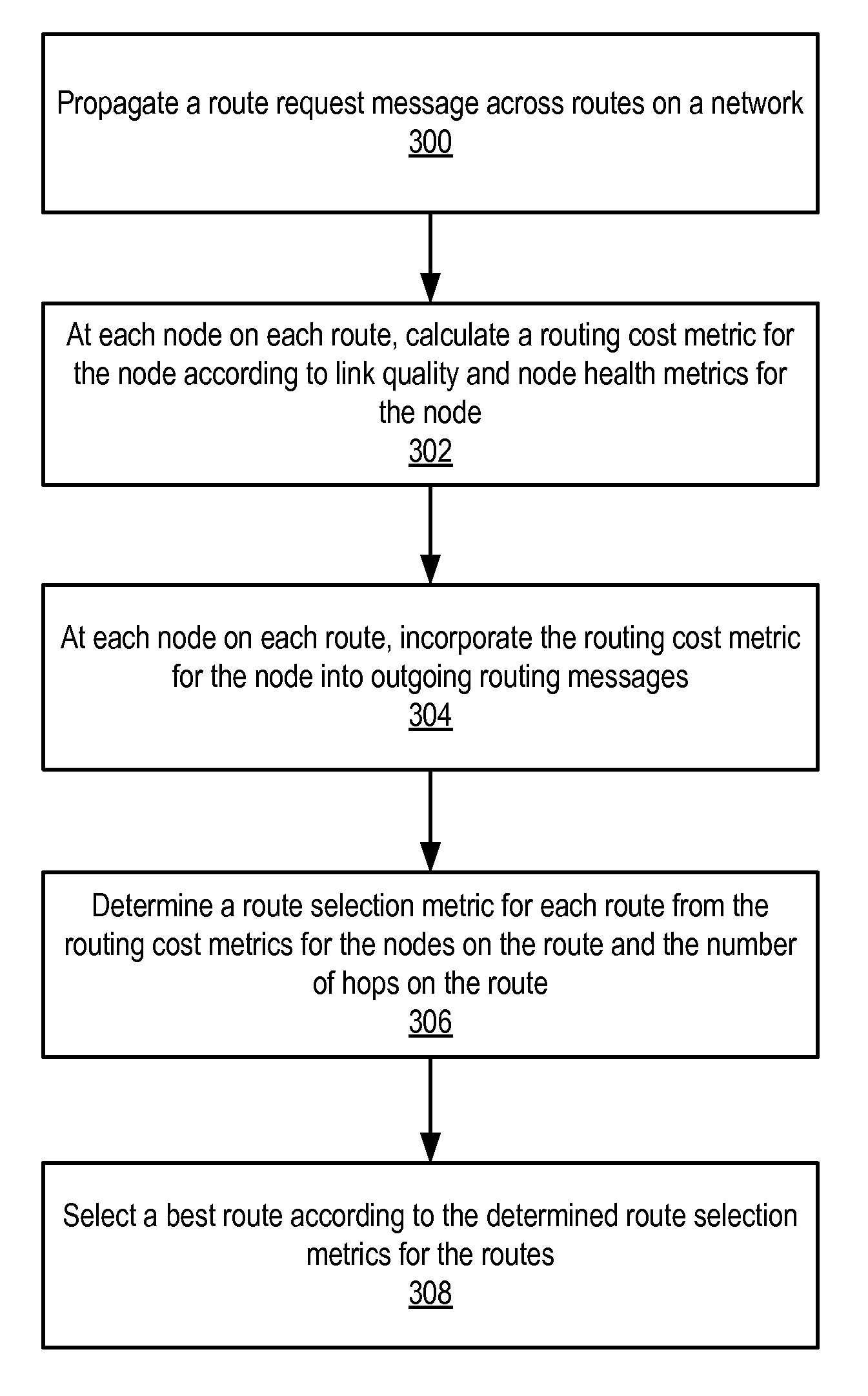

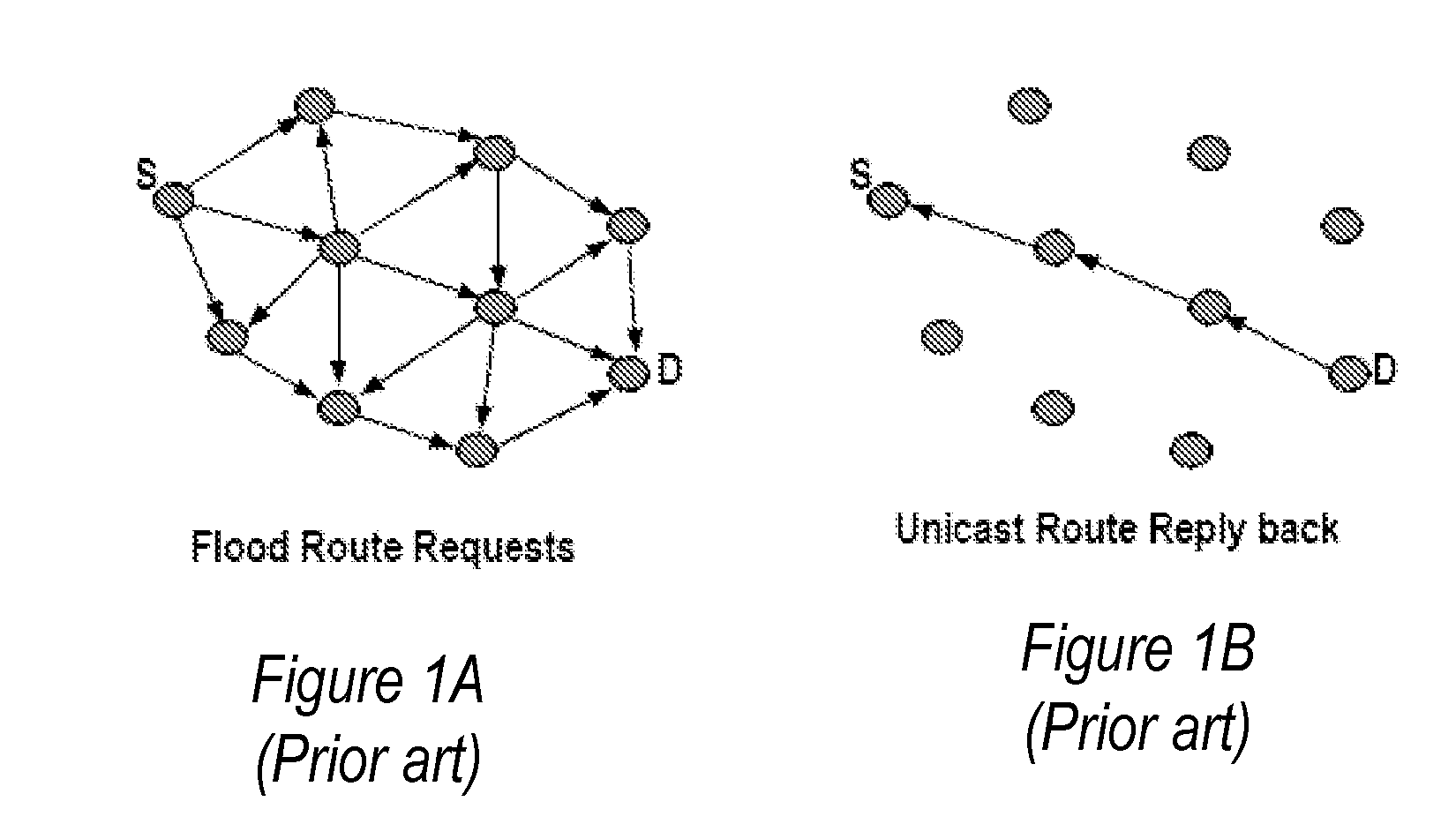

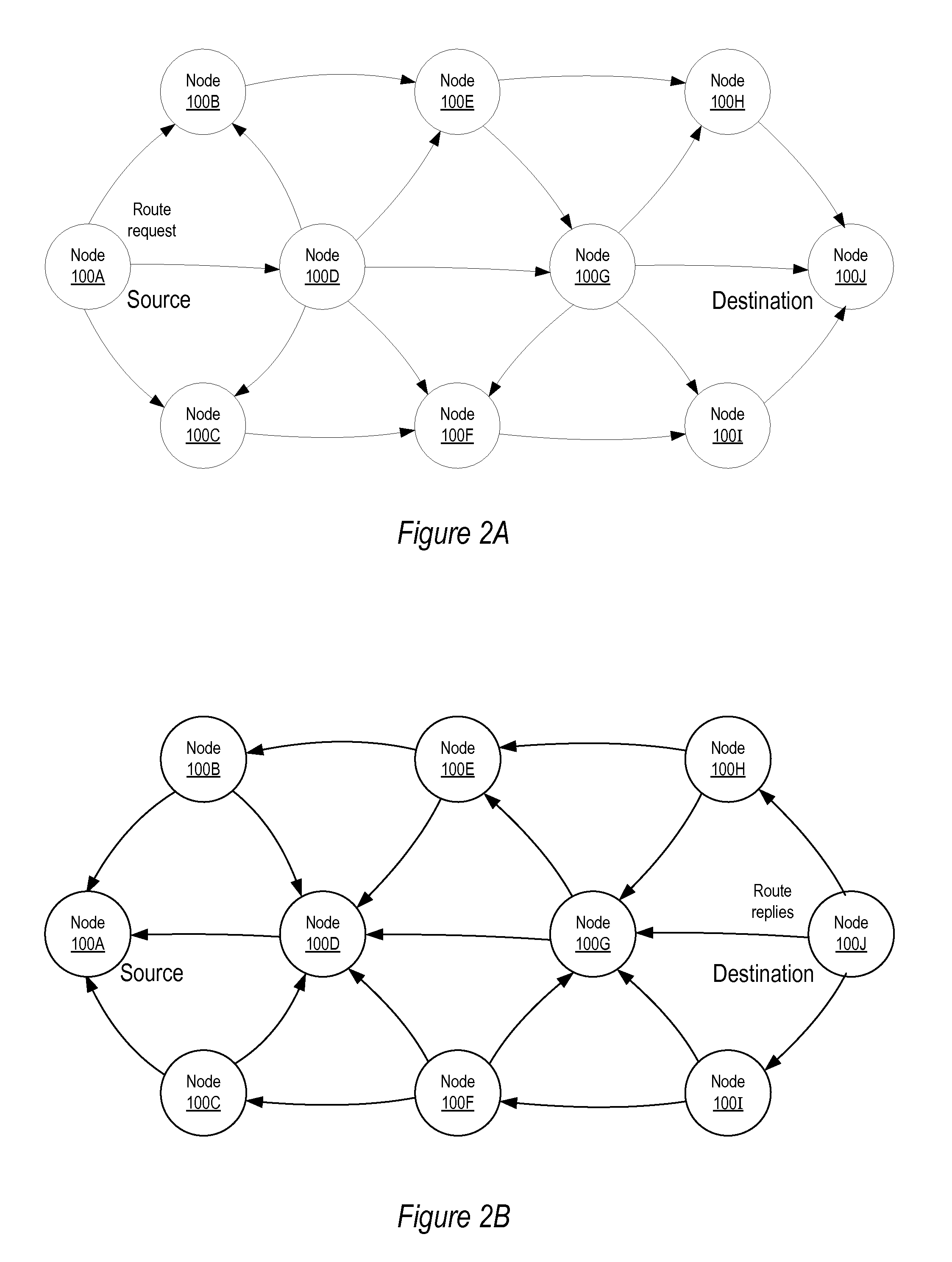

Method and apparatus for optimizing mesh routing for stability and system lifetime maximization in networks, for example in wireless networks. A routing module may be instantiated in nodes on the network. The routing module may implement a link quality and node health aware routing protocol on the network that considers a combination of link quality and node health / residual lifetime metrics in the calculation of the desirability of nodes and links between nodes as parts of an overall route. A route selection metric for each route may be determined from routing cost metrics for the nodes on the route and the number of hops on the route. A node may then select a best route according to the determined route selection metrics for the routes.

Owner:ORACLE INT CORP

Method and apparatus for mesh routing

ActiveUS7881206B2Good for healthProlong lifeError preventionTransmission systemsCost metricMesh routing

Method and apparatus for optimizing mesh routing for stability and system lifetime maximization in networks, for example in wireless networks. A routing module may be instantiated in nodes on the network. The routing module may implement a link quality and node health aware routing protocol on the network that considers a combination of link quality and node health / residual lifetime metrics in the calculation of the desirability of nodes and links between nodes as parts of an overall route. A route selection metric for each route may be determined from routing cost metrics for the nodes on the route and the number of hops on the route. A node may then select a best route according to the determined route selection metrics for the routes.

Owner:ORACLE INT CORP

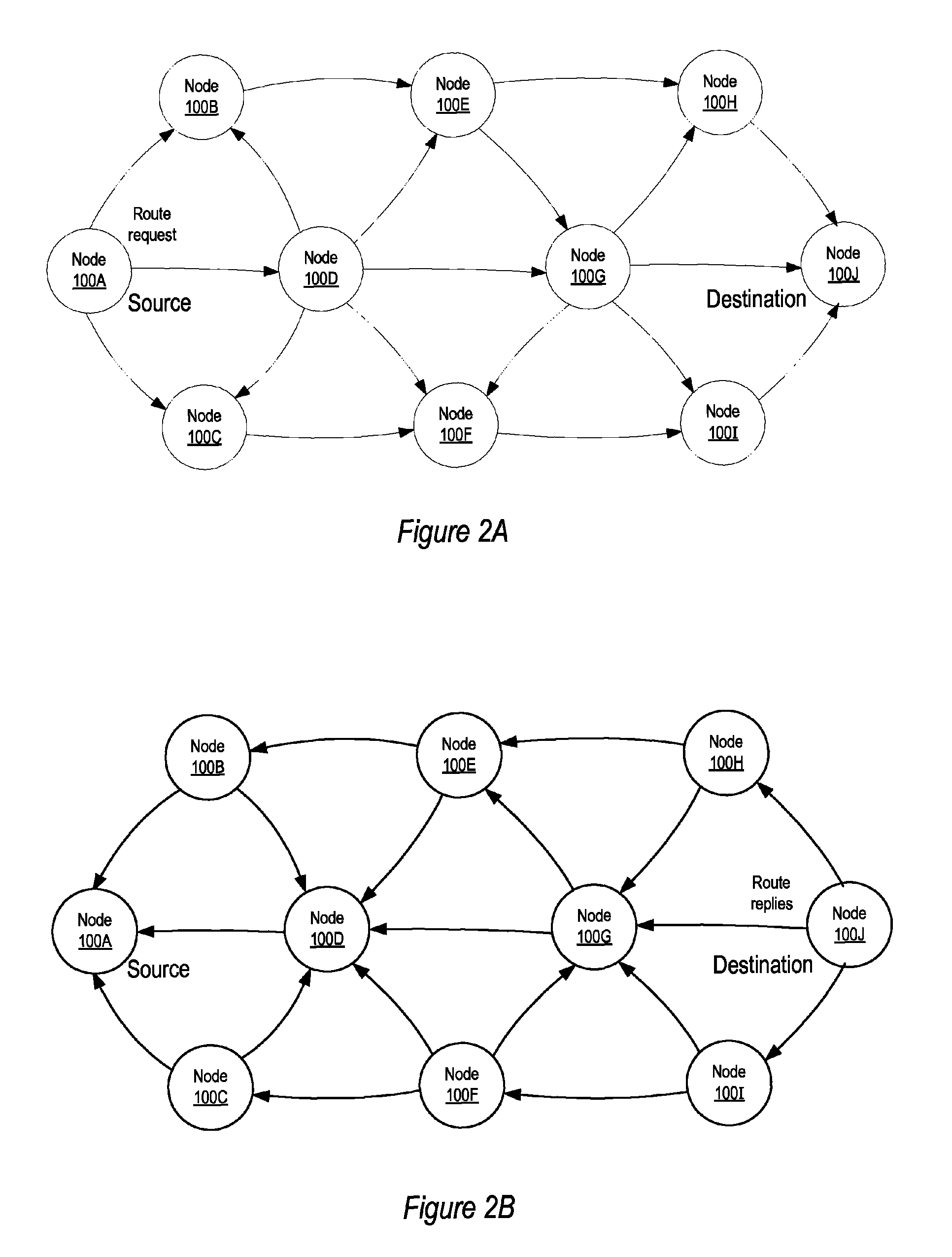

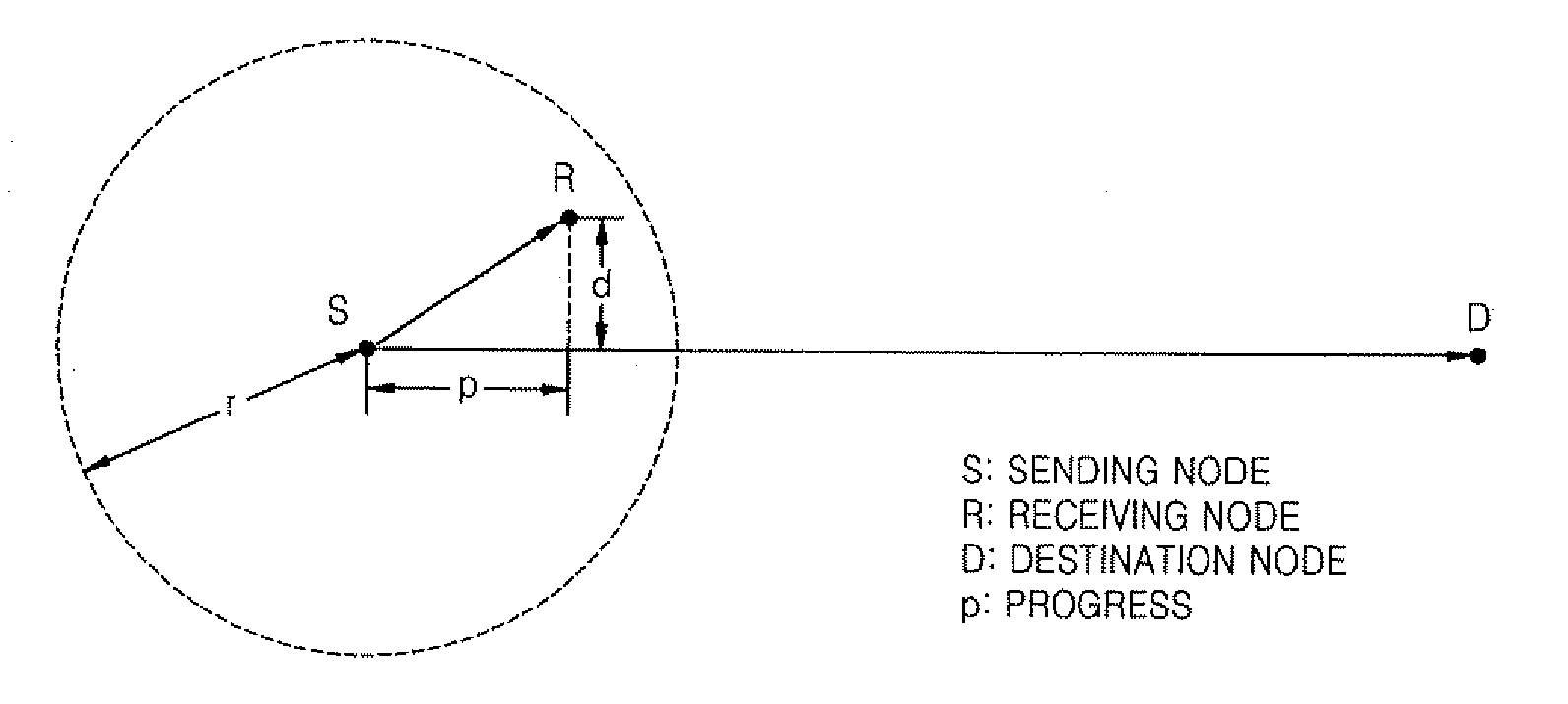

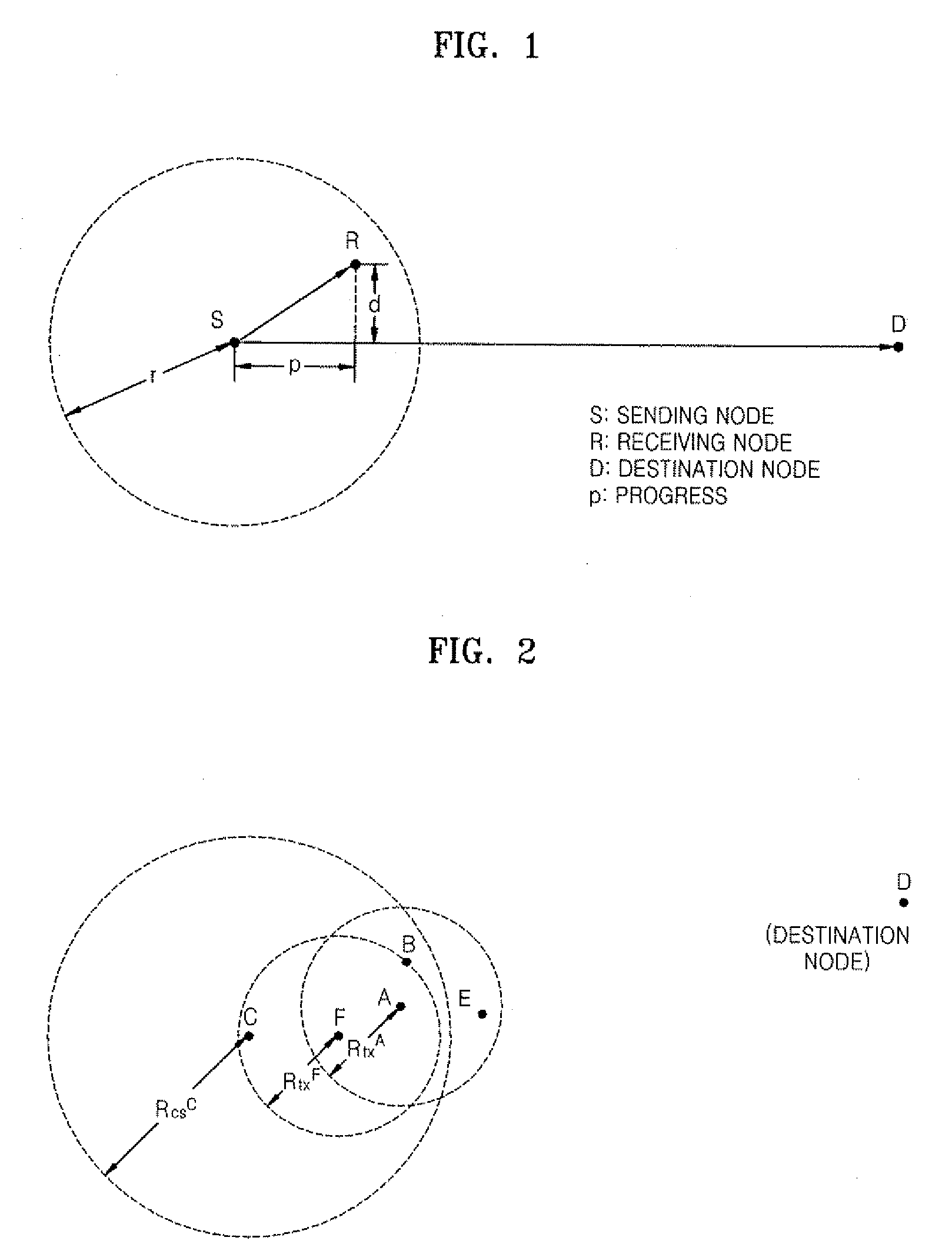

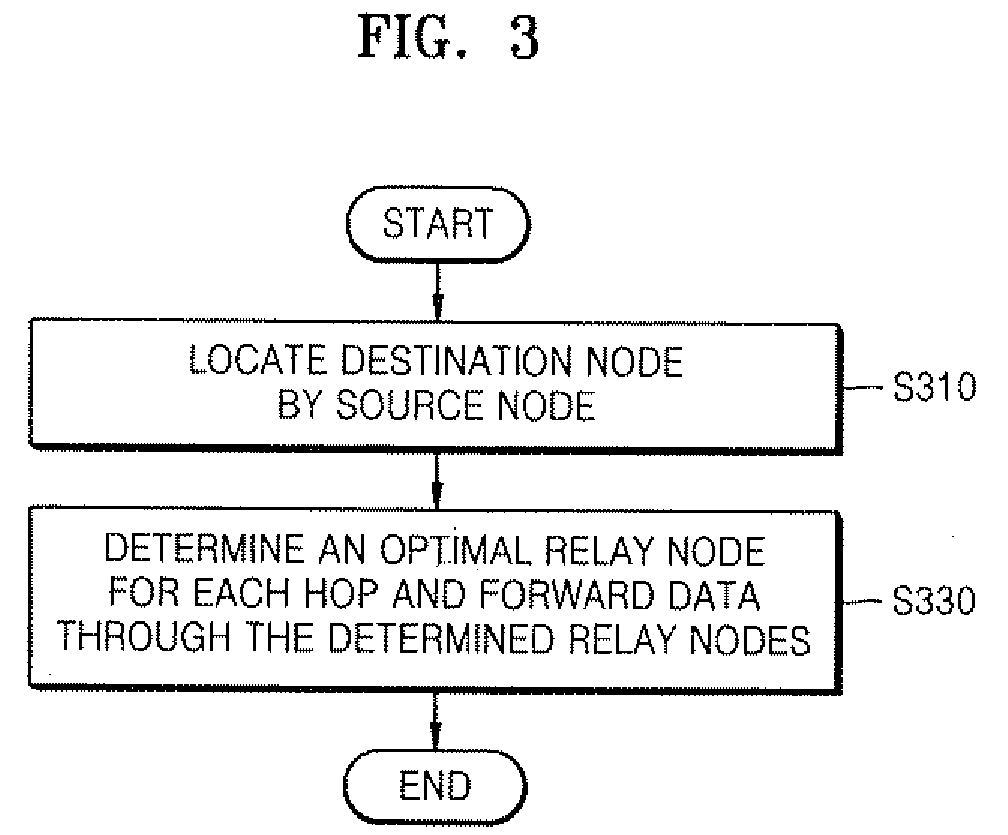

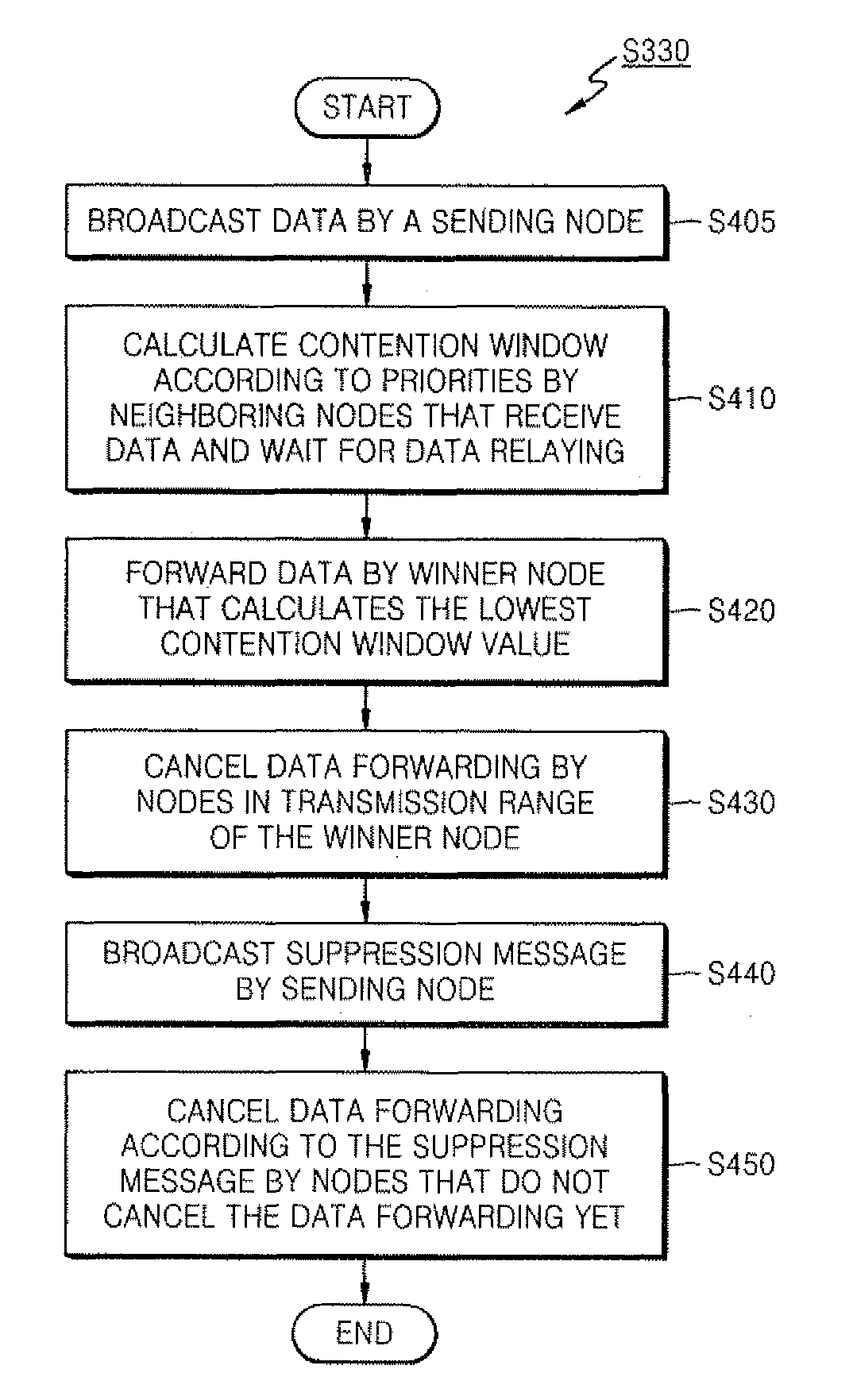

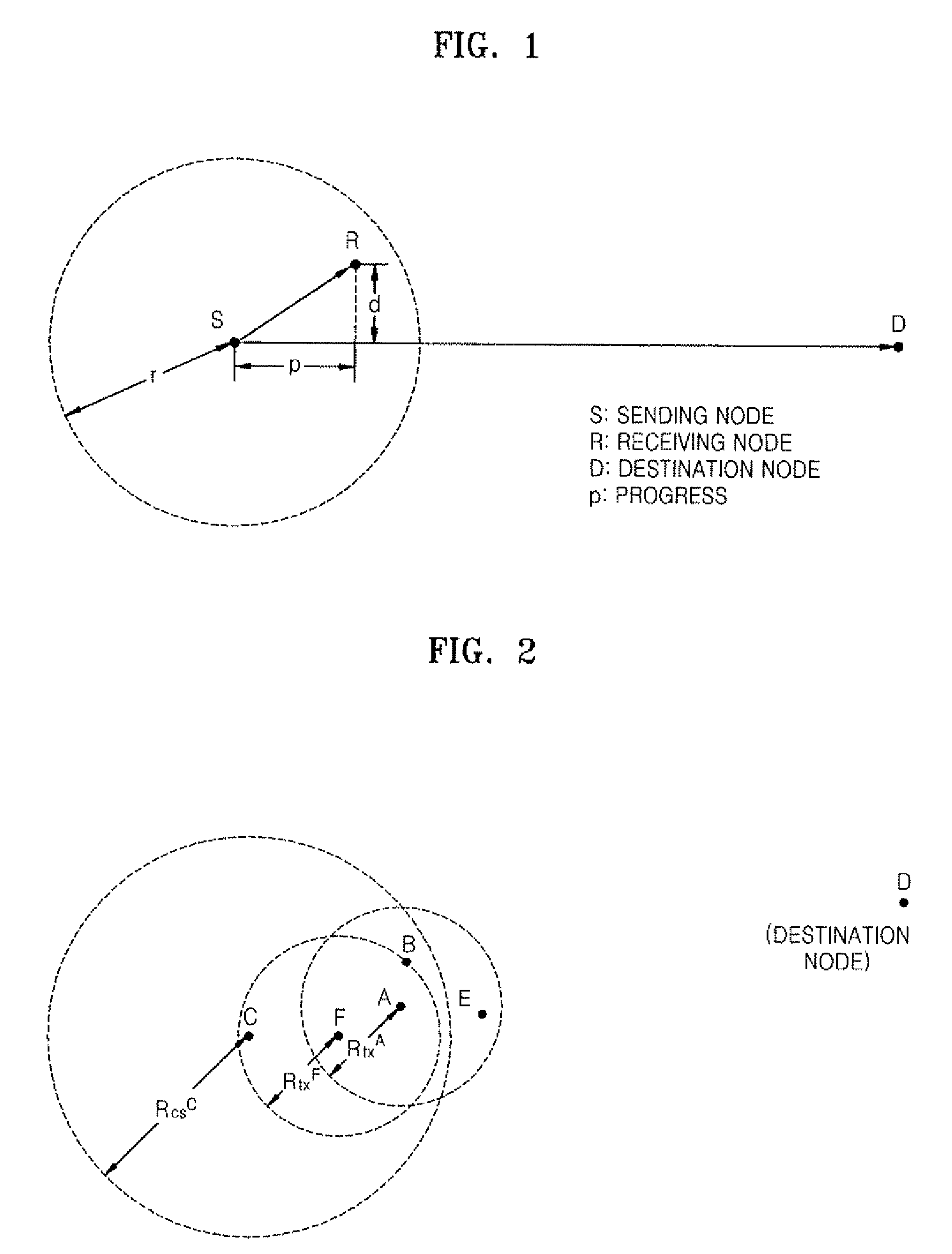

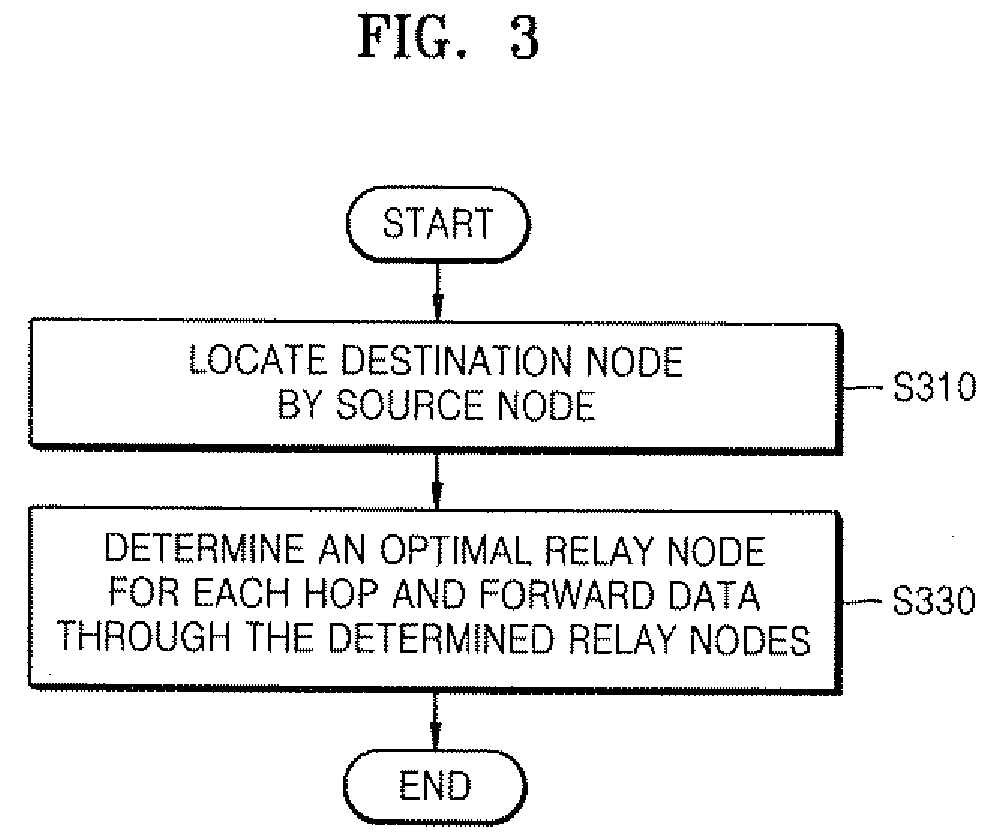

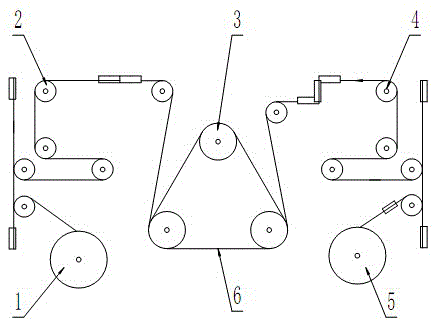

Cross-layer routing method in wireless sensor network

InactiveUS20090147725A1Improve network performanceSmooth routingError preventionTransmission systemsLine sensorWireless mesh network

Provided is a cross-layer routing method in a wireless sensor network including: locating a destination node which is a final destination of data by a source node which generates the data; and determining an optimal relay node among one or more neighboring nodes using their position information for each hop and forwarding the data from the source node to the destination node through the determined relay nodes. Therefore, an effective and stable routing which reduces overheads of additional control messages used for stable data forwarding and reduces collisions in a shared channel by using wireless link layer characteristics can be implemented.

Owner:ELECTRONICS & TELECOMM RES INST

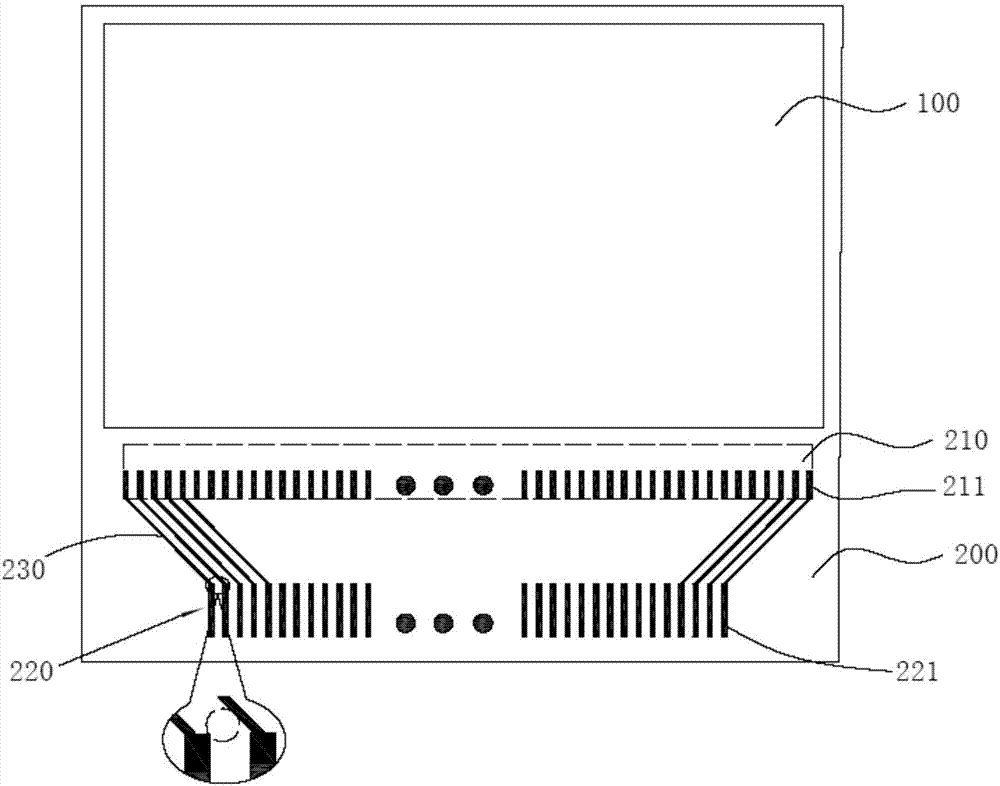

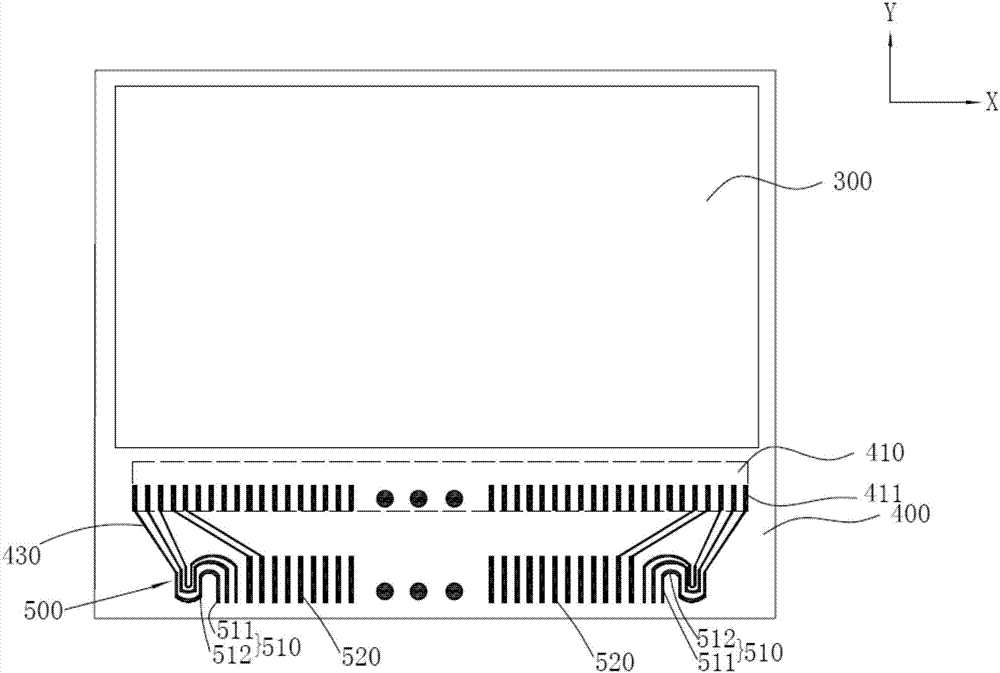

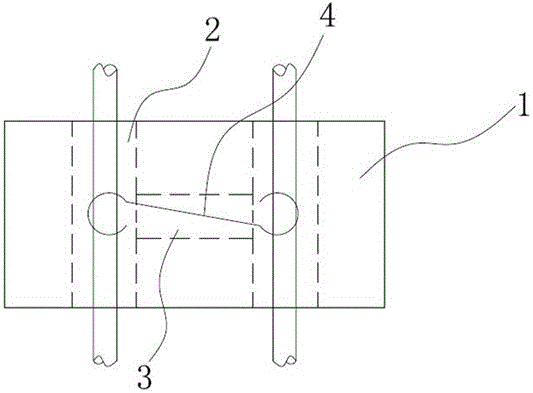

Narrow frame display panel and display

ActiveCN106873222AReduce spacingSimple designPrinted circuit aspectsPrinted circuit manufactureFlexible circuitsDisplay device

The embodiment of the invention discloses a narrow frame display panel. The narrow frame display panel includes an integrated circuit input pad which is positioned on a lower side of the display panel and includes a plurality of input terminals; a flexible printed circuit bonding pad which is position on a lower edge of the display panel and is positioned under the integrated circuit input pad, wherein the flexible printed circuit bonding pad includes a plurality of binding terminals, binding terminals at one end, of the flexible printed circuit bonding pad are first binding terminals, and each first binding terminal includes at least one three-side surrounded structure extending outward in the horizontal direction; and a wire which is electrically connected to the integrated circuit input pad and the flexible printed circuit bonding pad. The embodiment of the invention also discloses a display. The narrow frame display panel and the display are conductive to a narrow frame design.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Cross-layer routing method in wireless sensor network

InactiveUS8102794B2Improve network performanceSmooth routingError preventionTransmission systemsWireless mesh networkWireless sensor networking

Provided is a cross-layer routing method in a wireless sensor network including: locating a destination node which is a final destination of data by a source node which generates the data; and determining an optimal relay node among one or more neighboring nodes using their position information for each hop and forwarding the data from the source node to the destination node through the determined relay nodes. Therefore, an effective and stable routing which reduces overheads of additional control messages used for stable data forwarding and reduces collisions in a shared channel by using wireless link layer characteristics can be implemented.

Owner:ELECTRONICS & TELECOMM RES INST

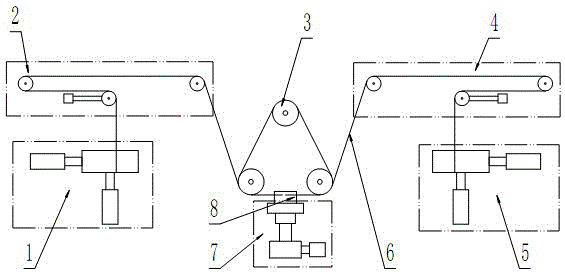

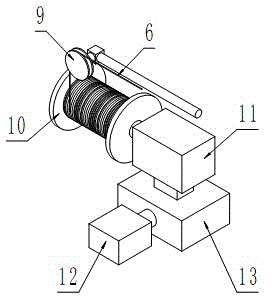

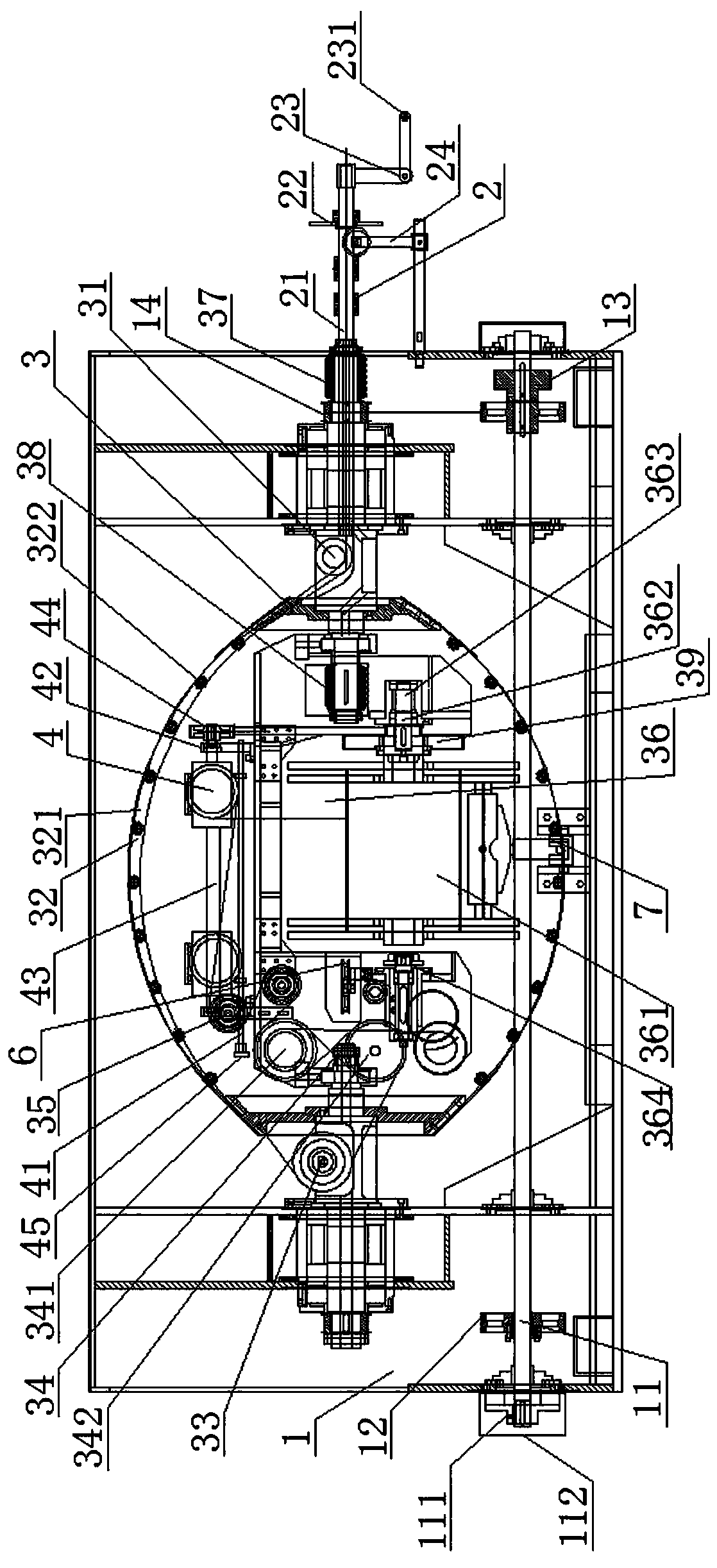

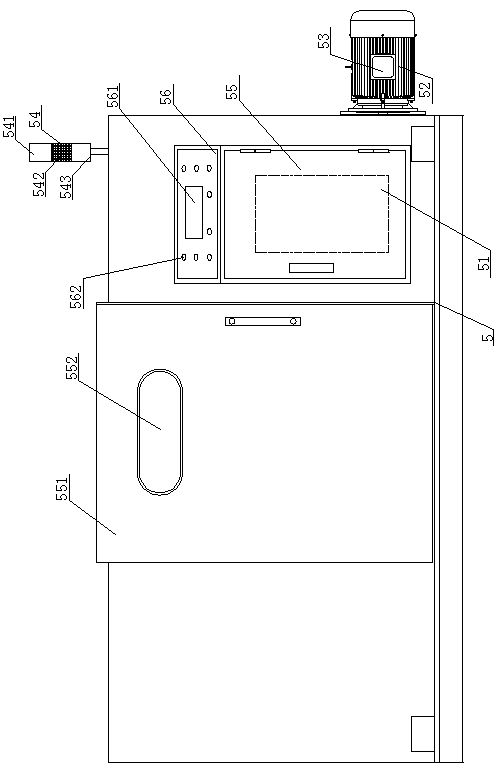

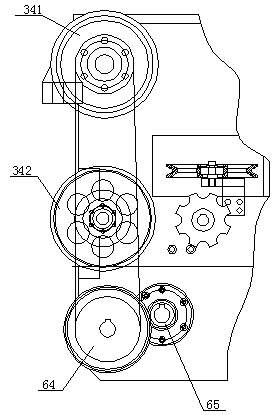

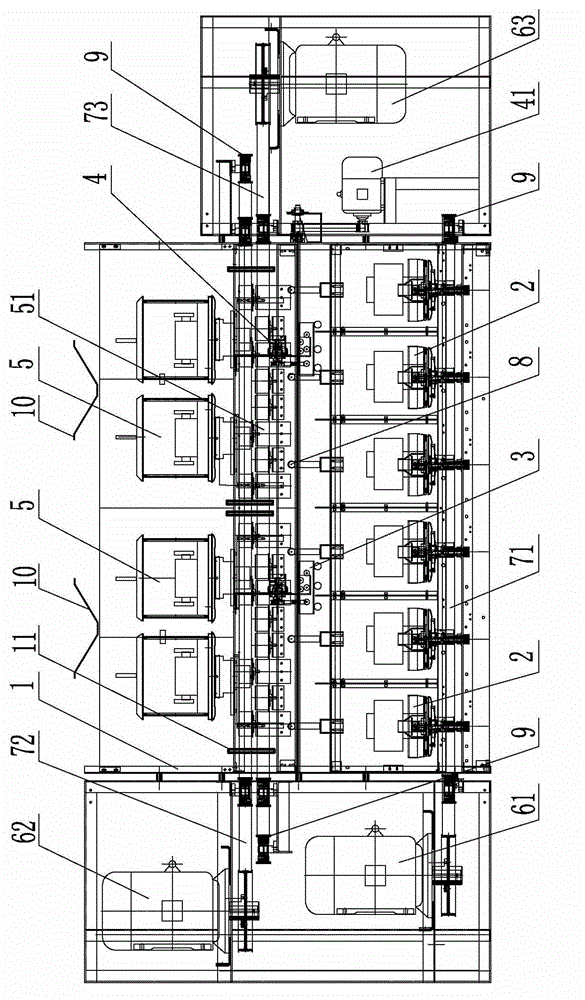

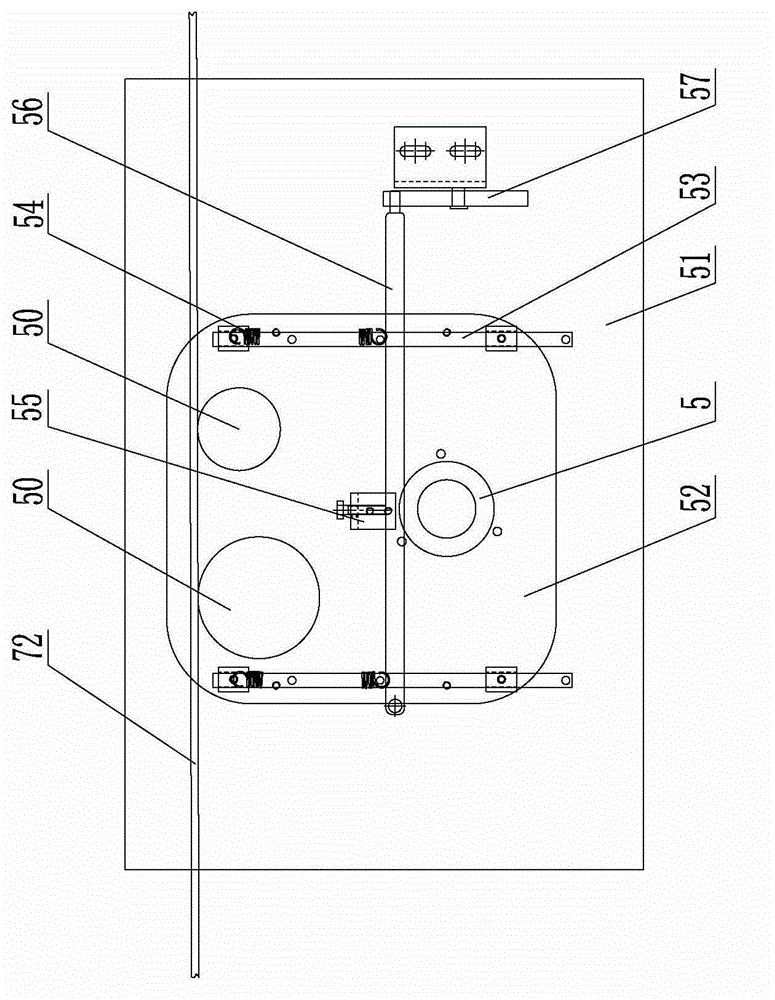

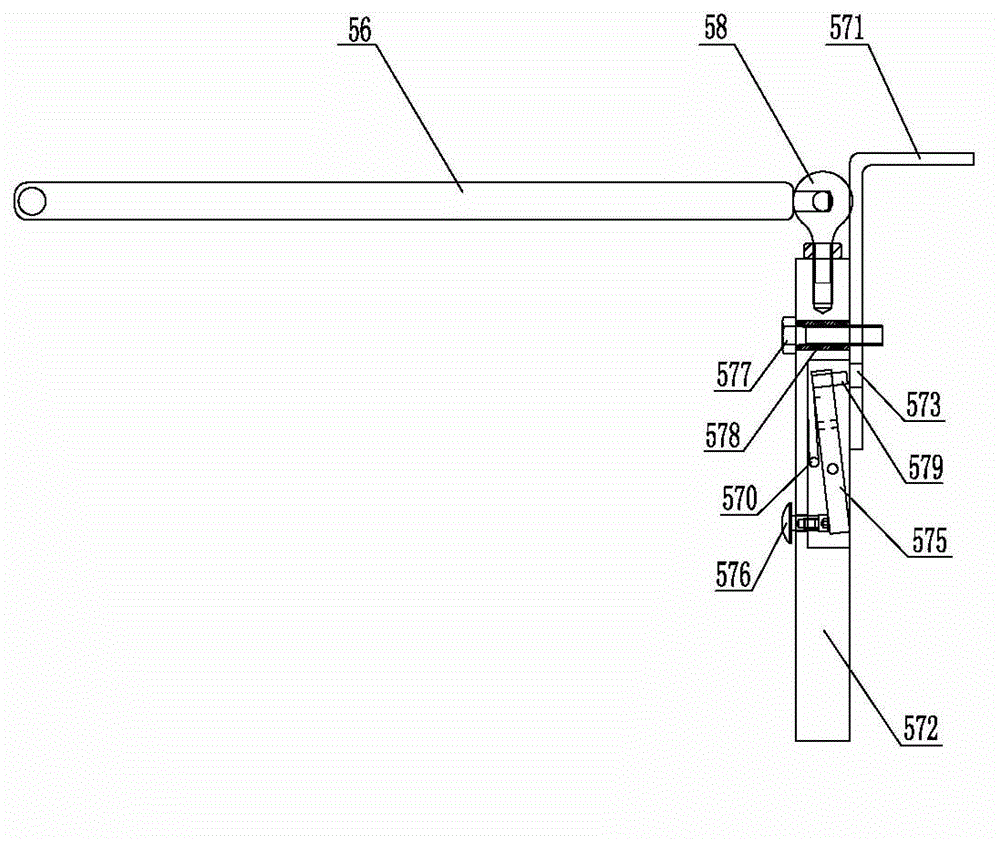

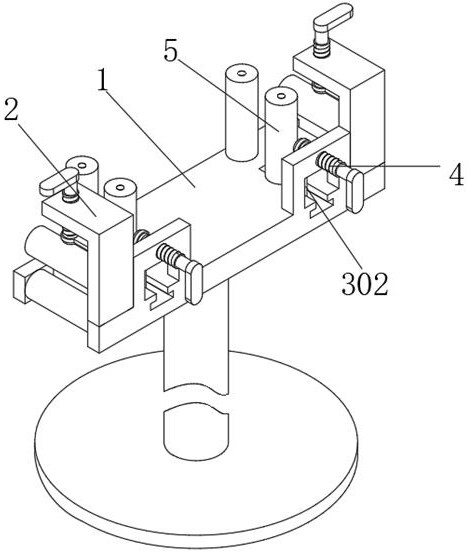

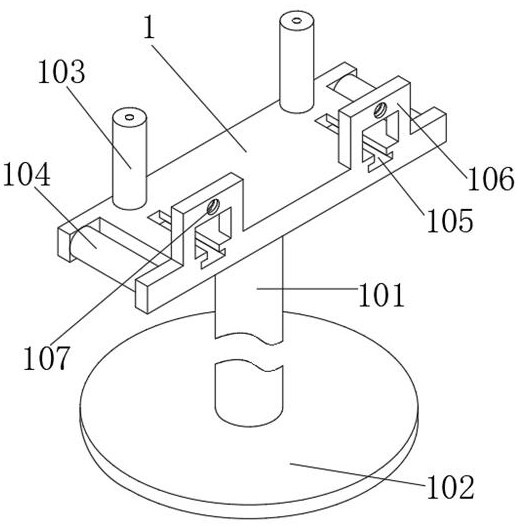

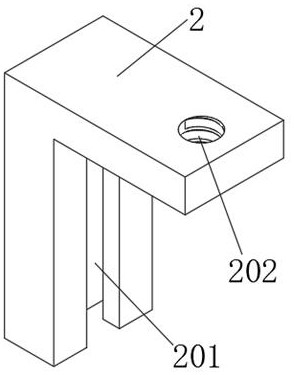

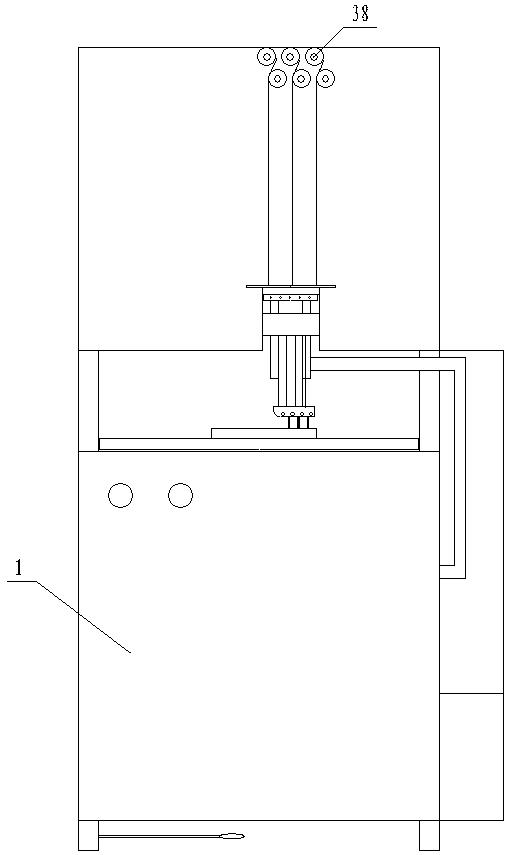

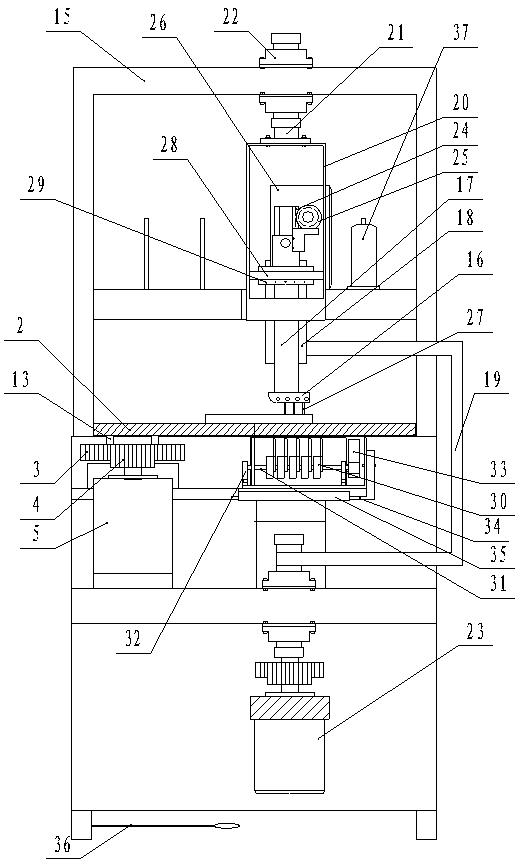

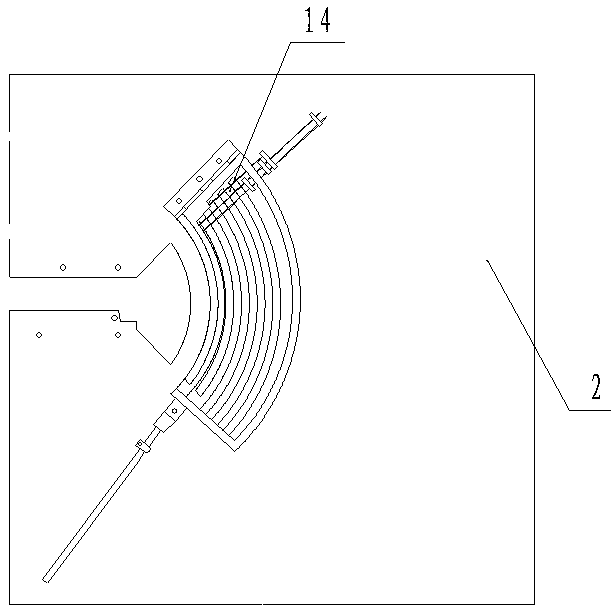

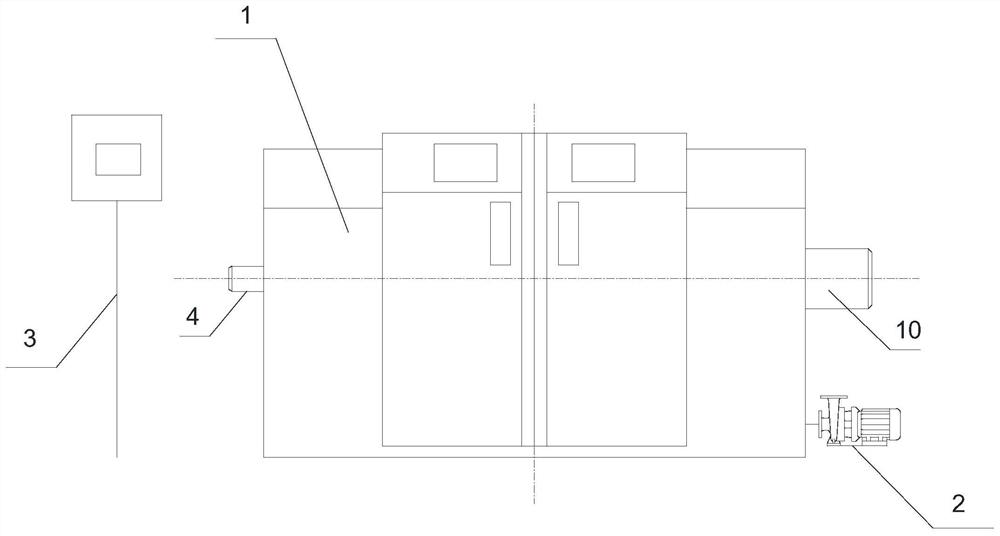

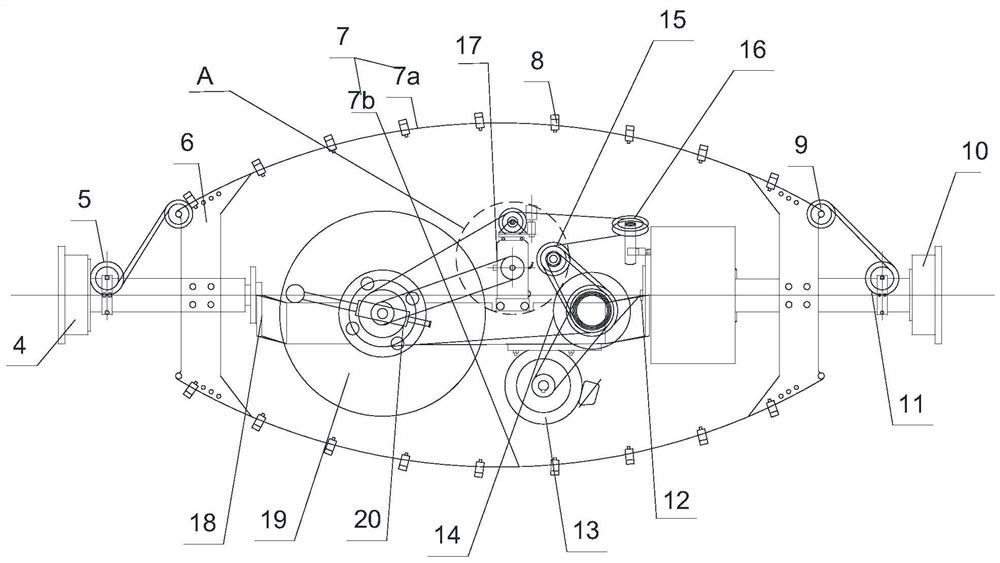

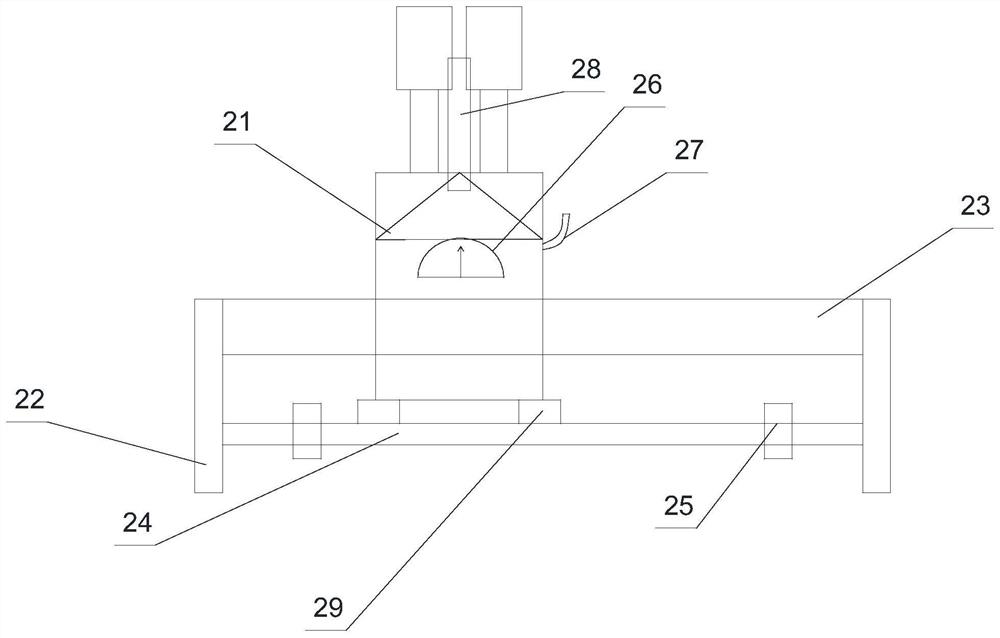

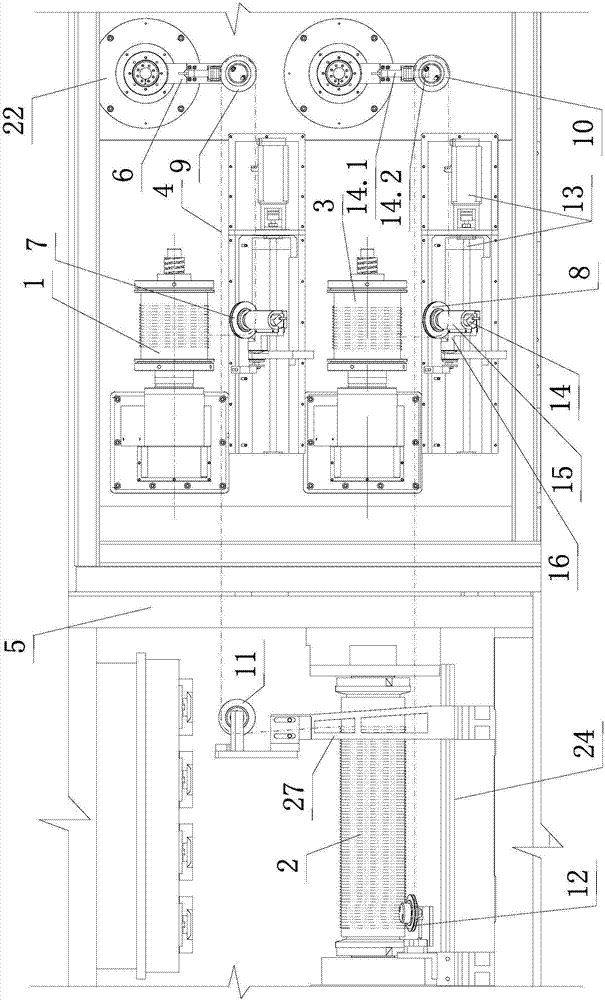

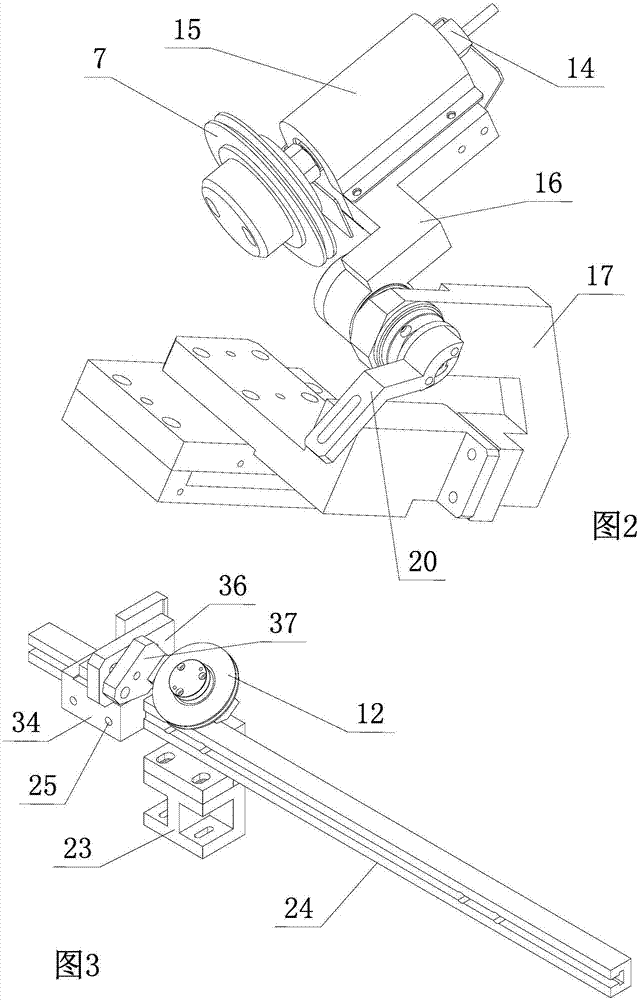

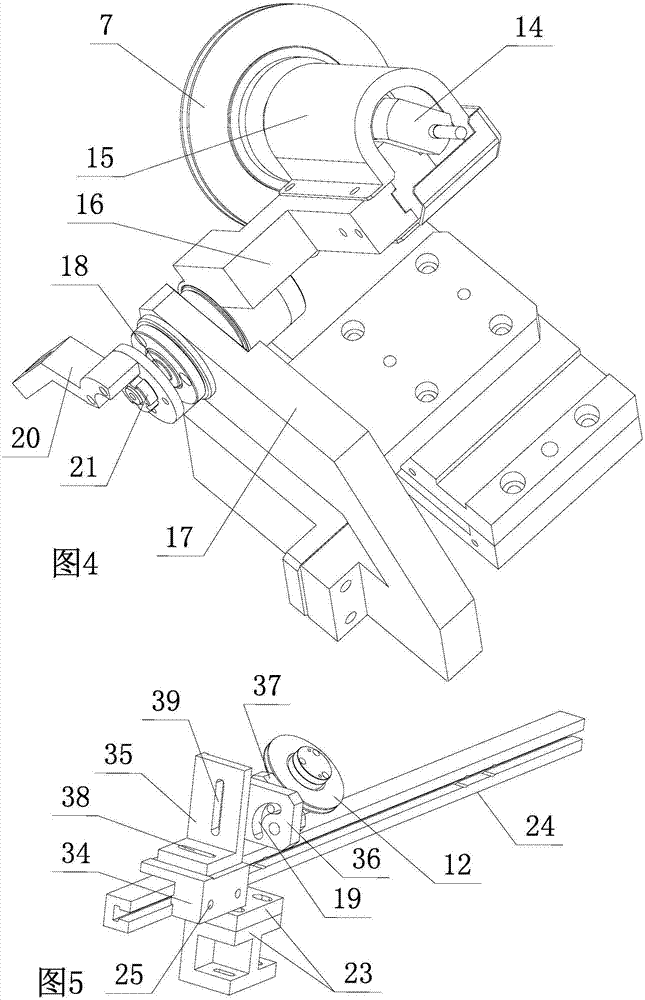

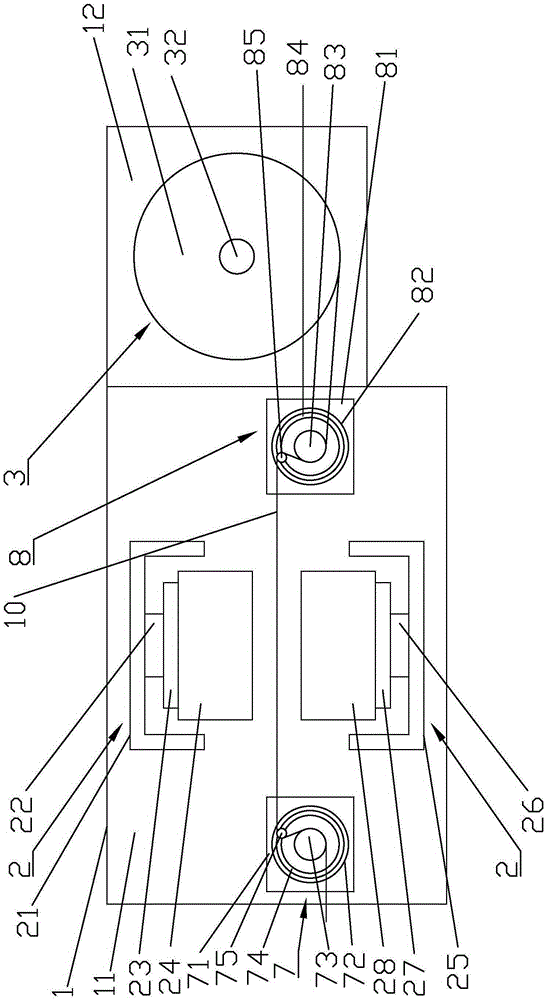

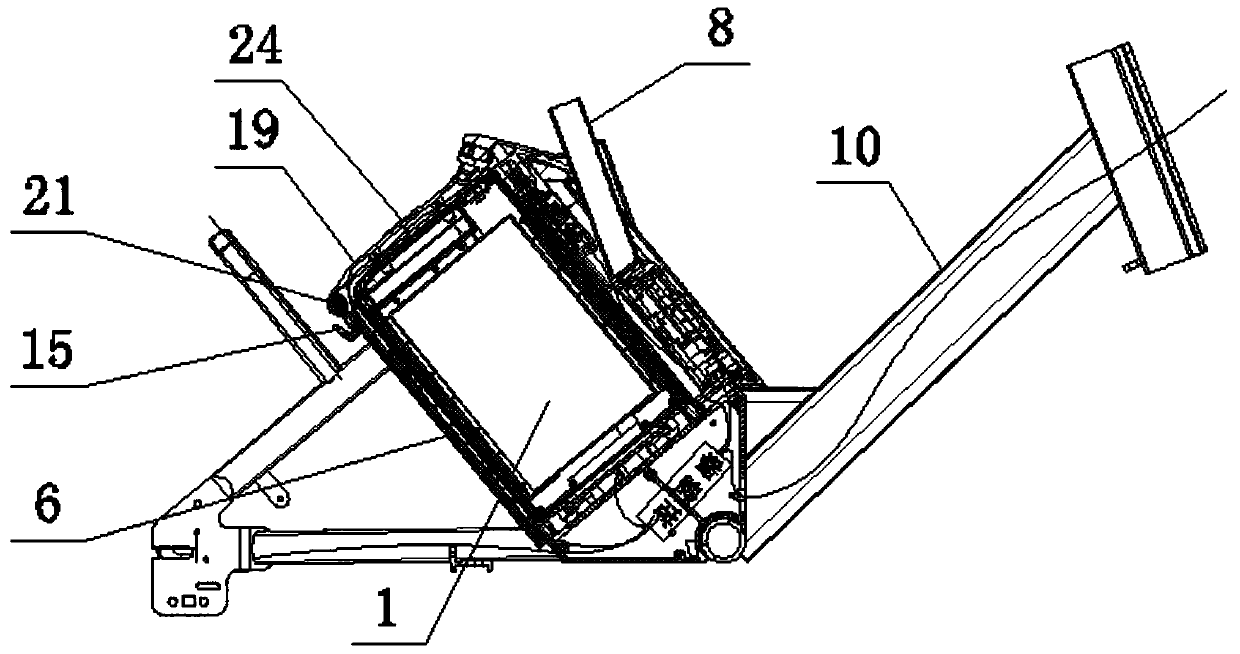

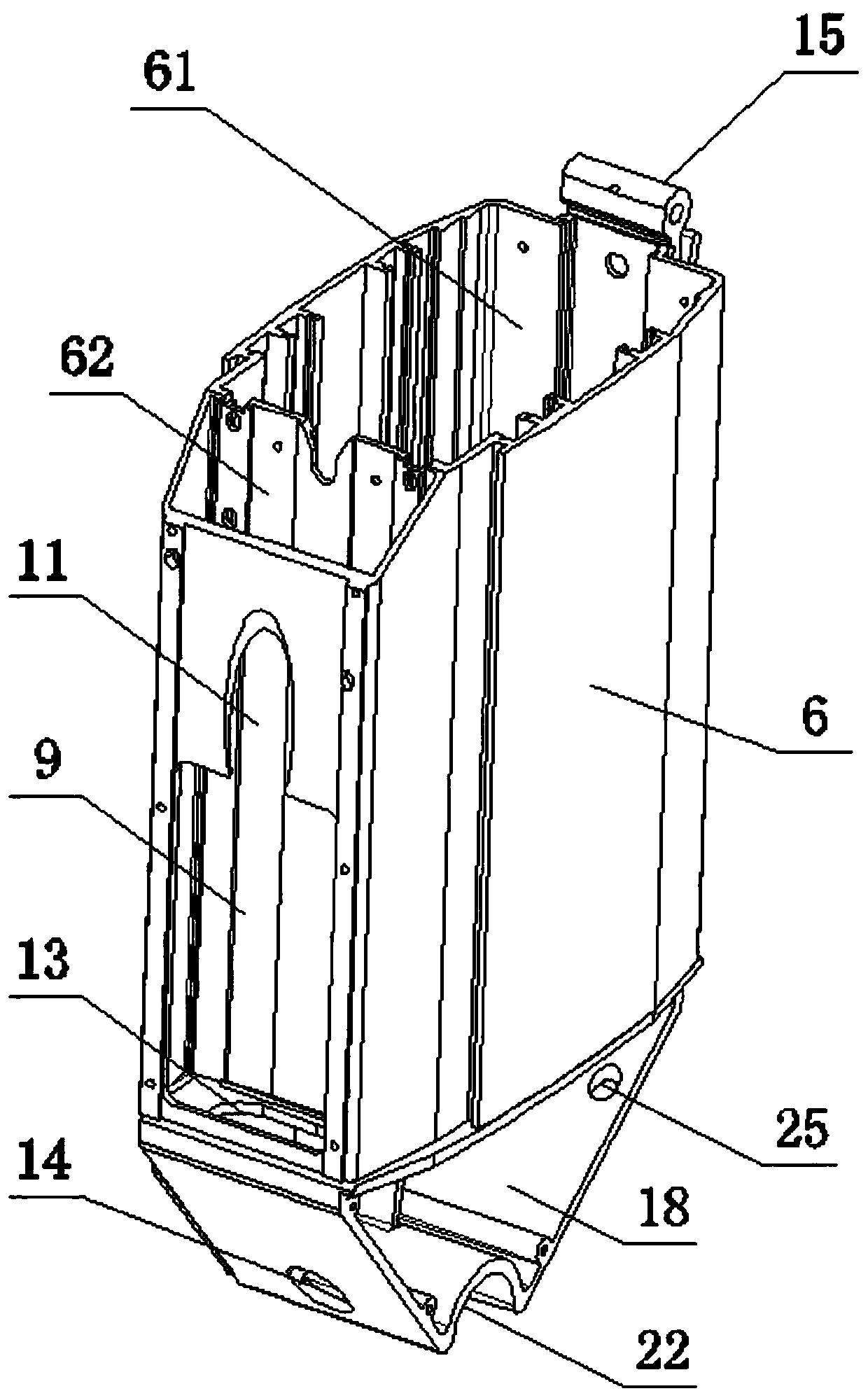

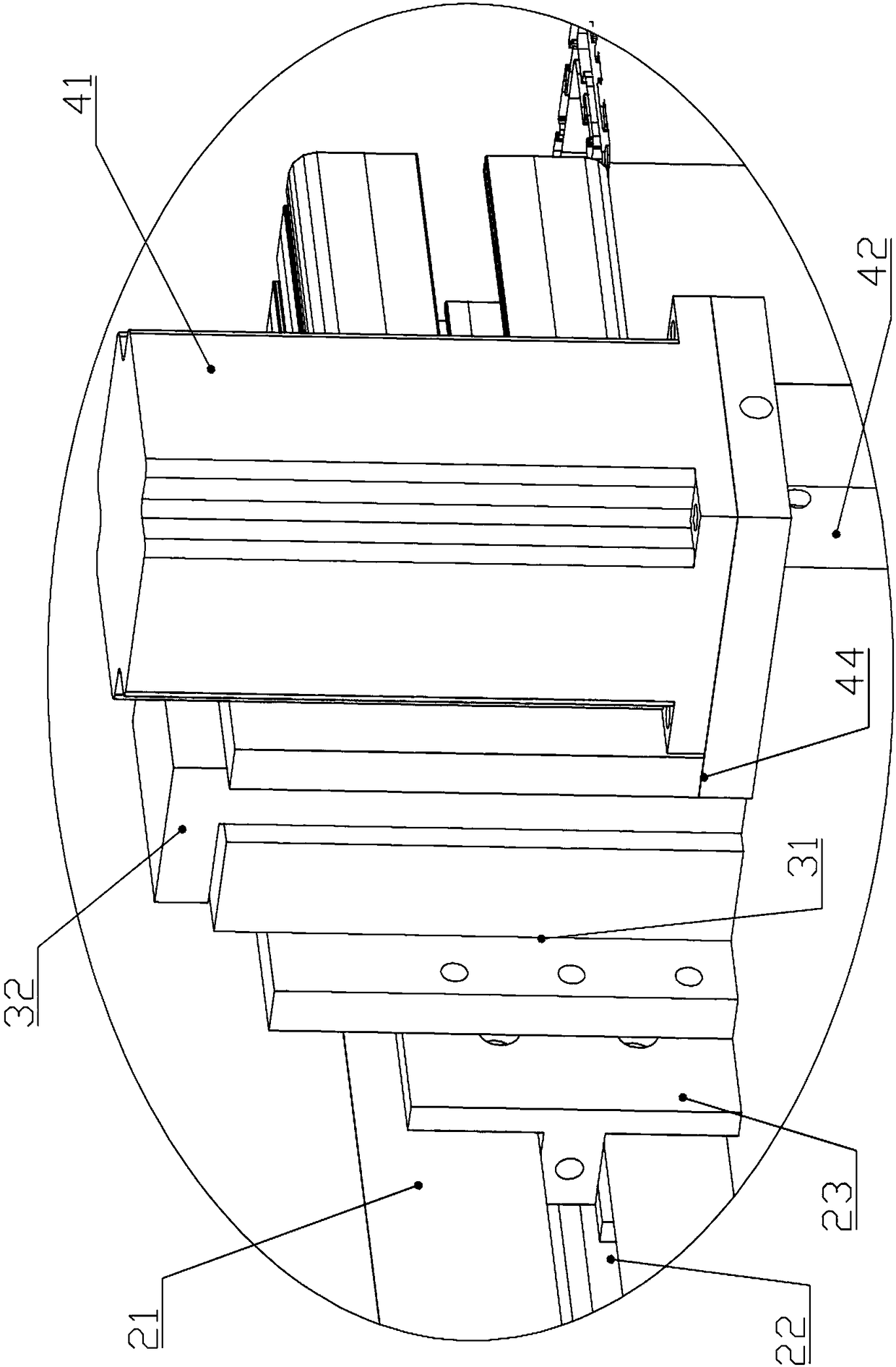

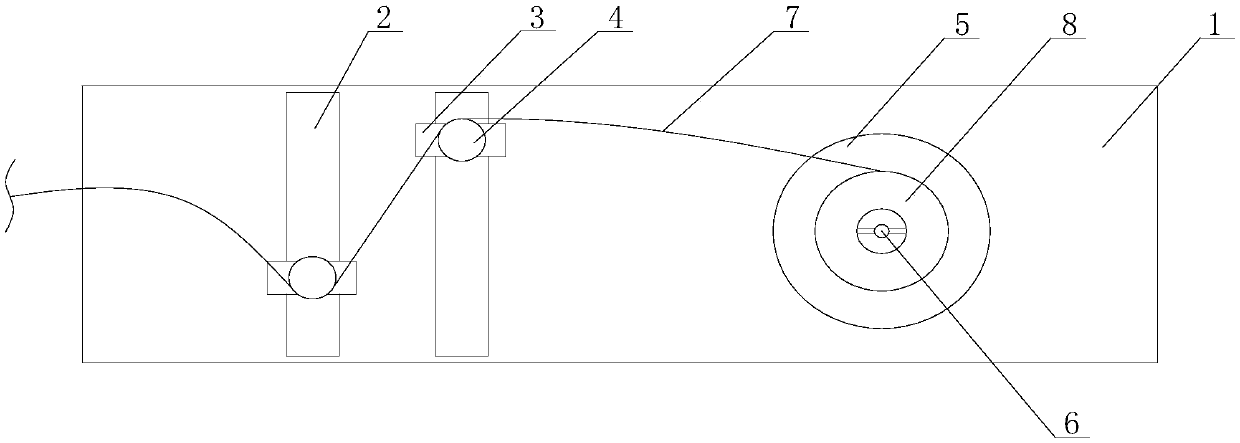

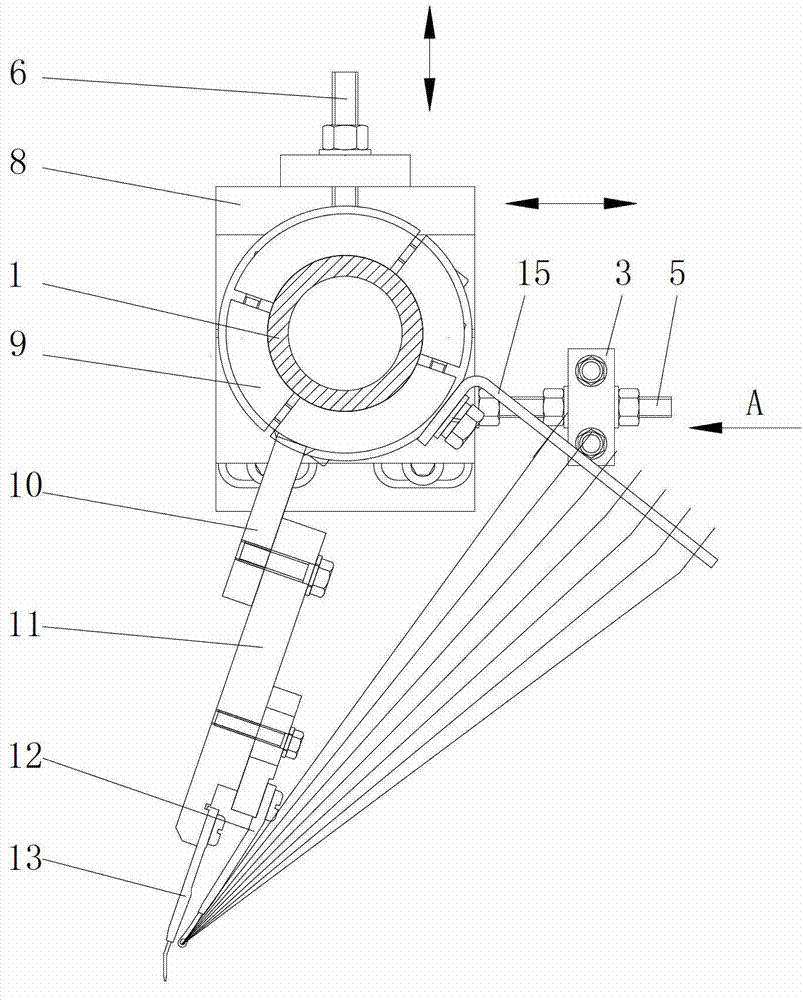

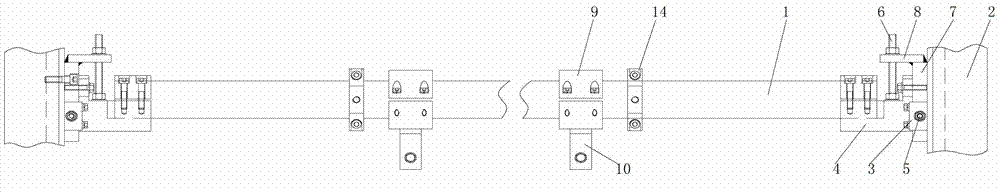

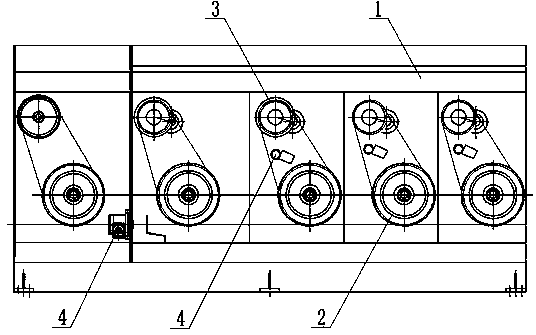

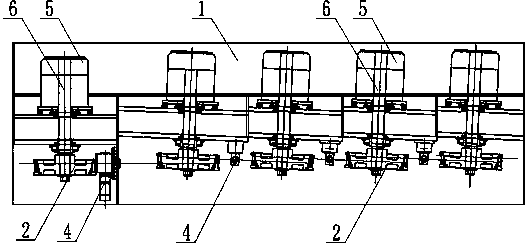

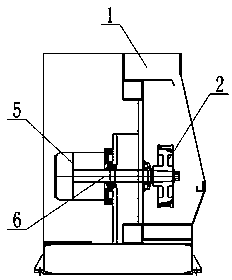

Six-guide-wheel multi-line cutting machine

InactiveCN103950120AReduce wire resistanceSmooth routingFine working devicesReciprocating motionEngineering

The invention provides a six-guide-wheel multi-line cutting machine, which is used for solving the problem that a cutting line of an existing multi-line cutting machine is unsmooth to route. The machine is provided with a pay-off roller component, a pay-off guide wheel component, a grooved wheel component, a take-up guide wheel component, a take-up roller component, a cutting line and a worktable, wherein one end of the cutting line is intertwined on the pay-off roller component; the cutting line is guided and intertwined on the grooved wheel component through the pay-off guide wheel component to form a steel wire net, and then is guided and intertwined on the take-up roller component through the take-up guide wheel component; the cutting line is jointly driven by the pay-off roller component and the take-up roller component to realize reciprocating motion; the multi-line cutting machine realizes the feeding of a workpiece through the lifting of the worktable, and is characterized in that total six guide wheels are arranged in each of the pay-off guide wheel component and the take-up guide wheel component. By applying the six-guide-wheel multi-line cutting machine, not only can the cutting speed be improved, but also the product quality is guaranteed; meanwhile, the service life of the cutting line is also prolonged, and the production cost is lowered.

Owner:唐山晶玉科技股份有限公司

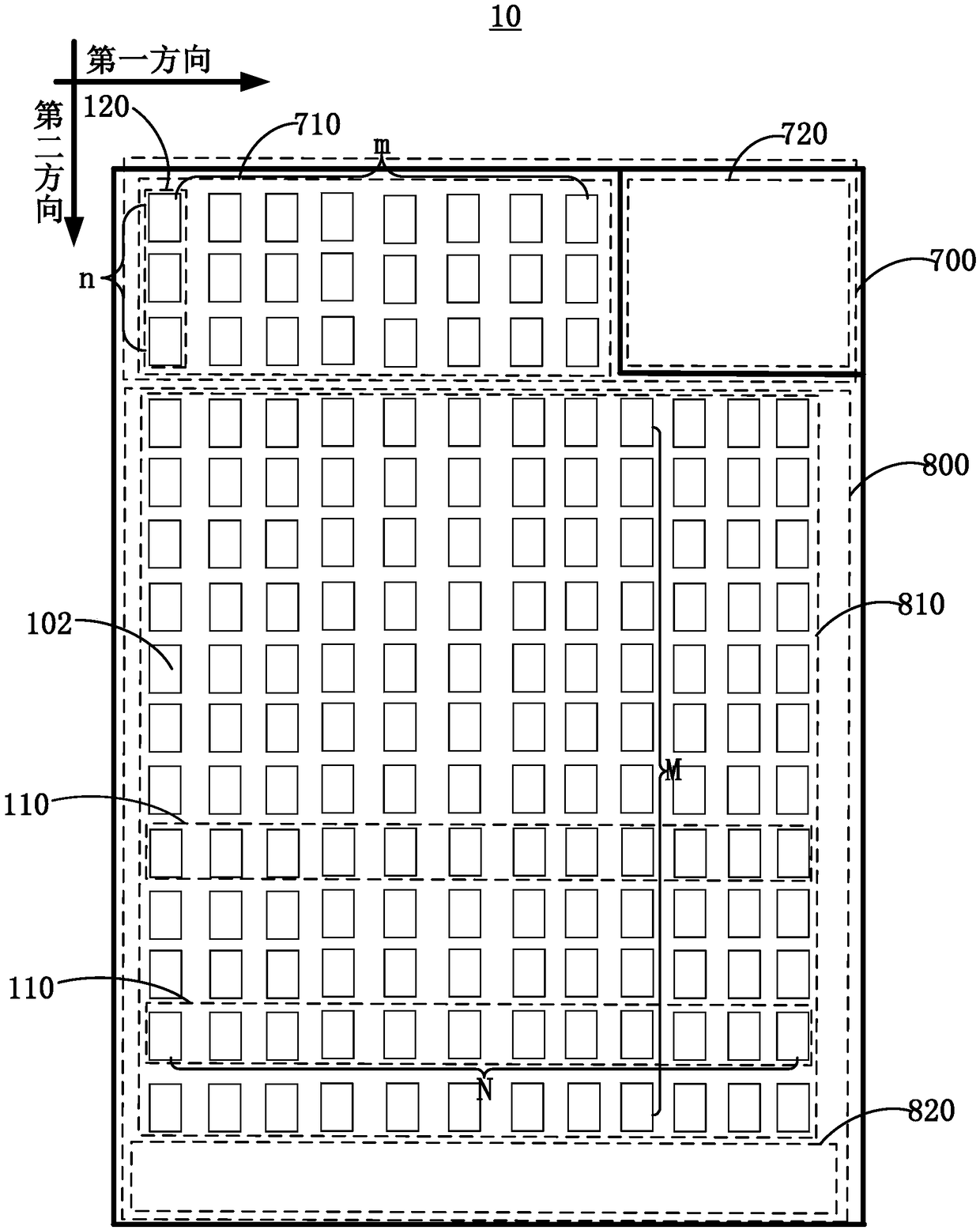

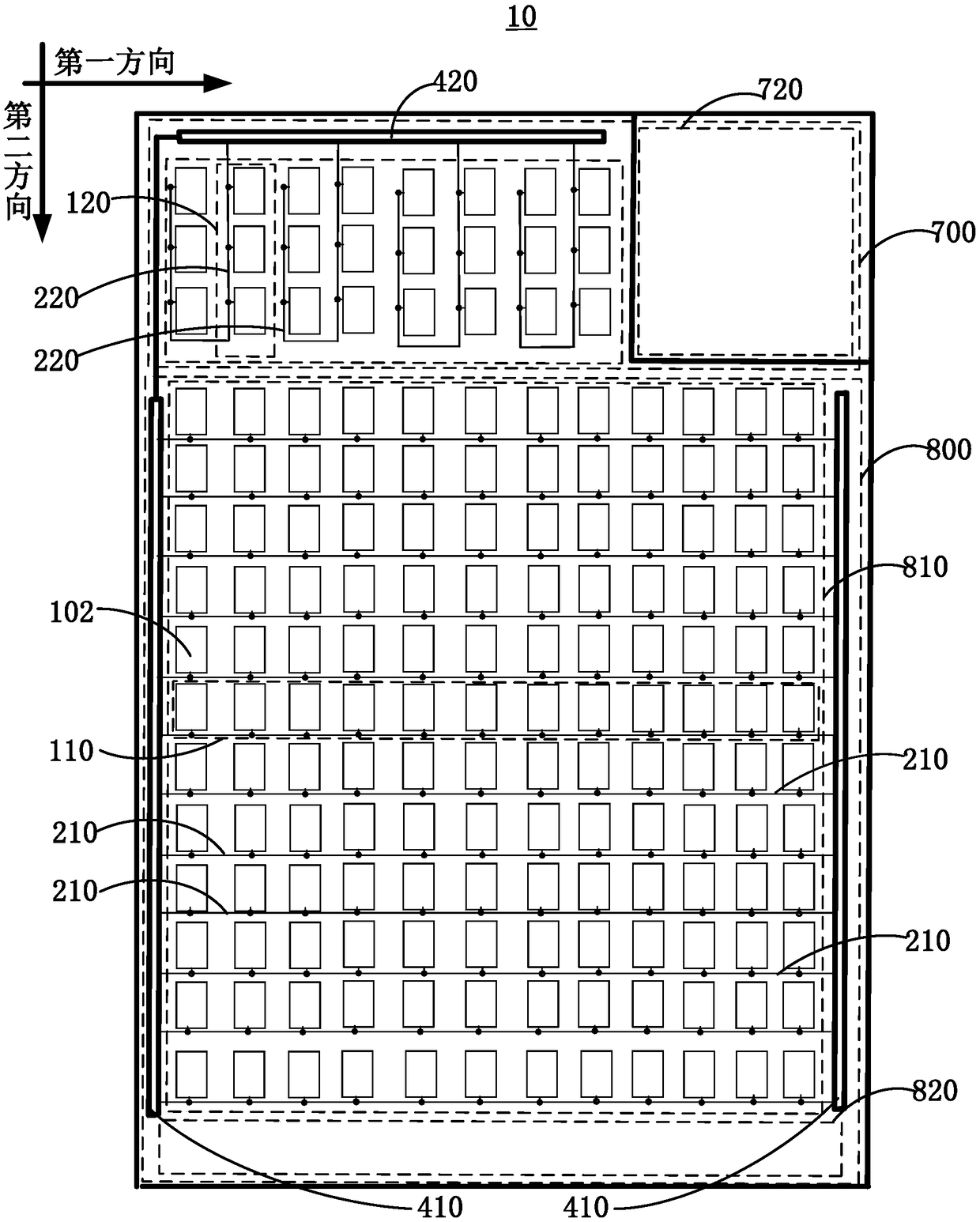

Display panel and display device

ActiveCN108646484ASmooth routingIncrease the screen ratioSolid-state devicesNon-linear opticsElectricityScan line

The invention relates to a display panel which comprises multiple first pixel unit lines, multiple first pixel unit columns, multiple first scan lines and multiple second scan lines. The display panelcomprises a special-shaped area and a non-special-shaped area. Each first scan line is electrically connected with N pixel units in one first pixel unit line. Each second scan line is electrically connected with multiple pixel units in the first pixel unit columns adjacent or spaced at intervals of two columns. By adopting the arrangement way of the first scan lines and the second scan lines, line layout, nearby the special-shaped area, of the display panel is uniform, and the phenomenon of piling of metal lines in the special-shaped area is avoided. In addition, when the pixel units electrically connected with the second scan lines and the pixel units electrically connected with the first scan lines are equal in quantity, no compensation unit is needed in the special-shaped area, so thatthe screen-to-body ratio of the display panel is higher.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

High-speed wire twisting machine with excellent performance

PendingCN109686506AEasy loading and unloadingQuality improvementCable/conductor manufactureCopper wireEngineering

The invention provides a high-speed wire stranding machine with excellent performance. The high-speed wire stranding machine with excellent performance comprises a case, a wire inlet mechanism, a wiretake-up mechanism and a wire arranging device, wherein the wire inlet mechanism comprises a wire inlet main shaft, a wire inlet die holder, a broken wire supporting rod and a meter counting wheel. Acontrol device is arranged outside the case, the wire take-up mechanism sequentially comprises a wire drawing wheel, a winch, a wire passing wheel, a traction wheel, a guide wheel and a wire take-up cradle stand, a drawing part is arranged below the traction wheel and comprises a speed reduction box, a main shaft synchronous wheel, a motor synchronous wheel, driven hanging teeth, active hanging teeth and a connecting shaft, and a lifting device is arranged below a take-up reel and comprises a lifting platform, a connecting rod mechanism and a pushing mechanism. The high-speed wire stranding machine with excellent performance can reduce noise, facilitate wire take-up, is stable in transmission, makes wire threading and winding smoother, ensures set constant tension, makes copper wires or core wires not damaged in the wire stranding process, and ensures that high-quality wires can be machined in the wire industry.

Owner:浙江金莱尔机电设备有限公司

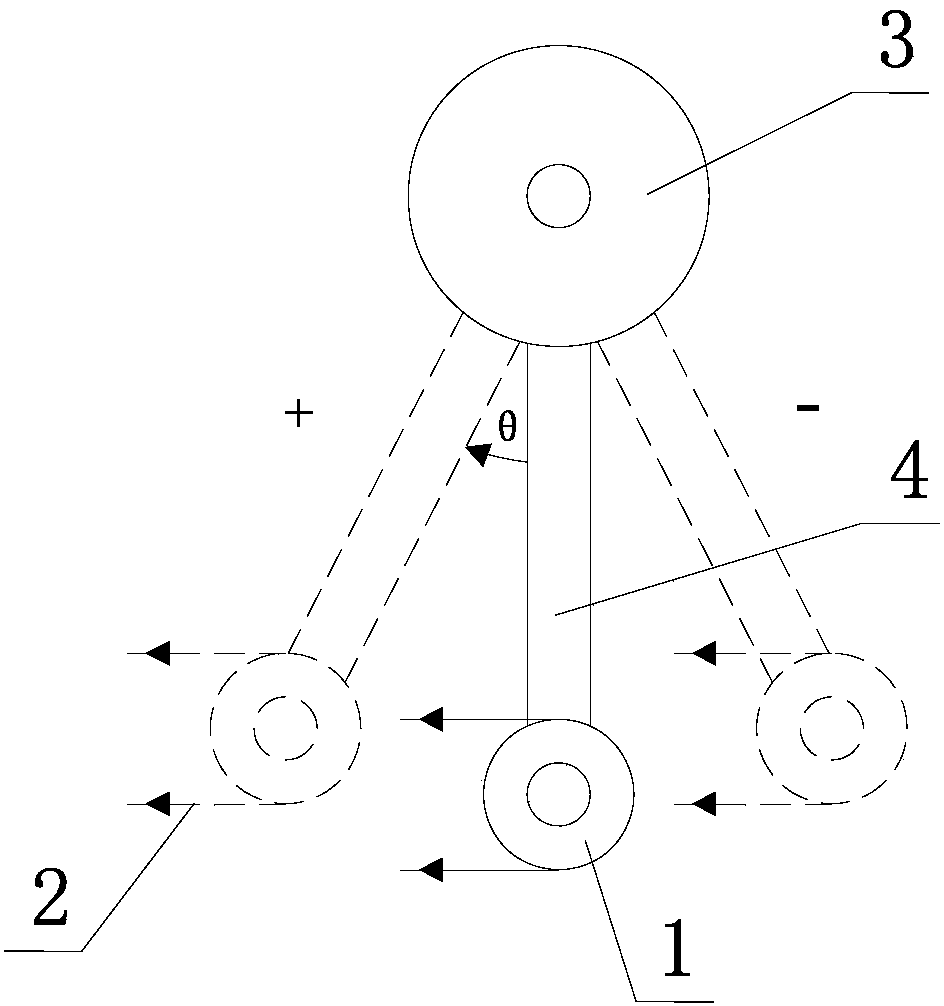

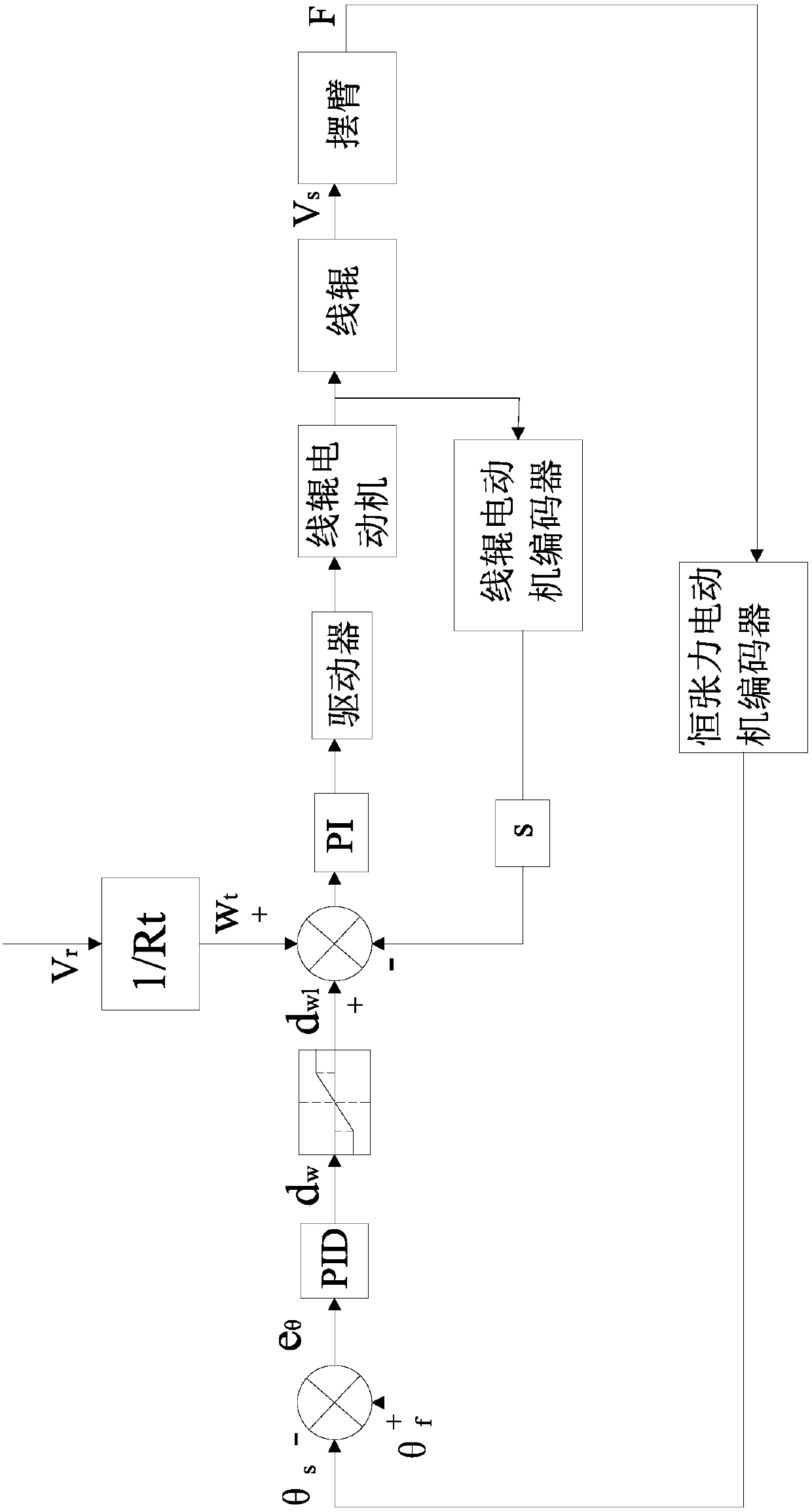

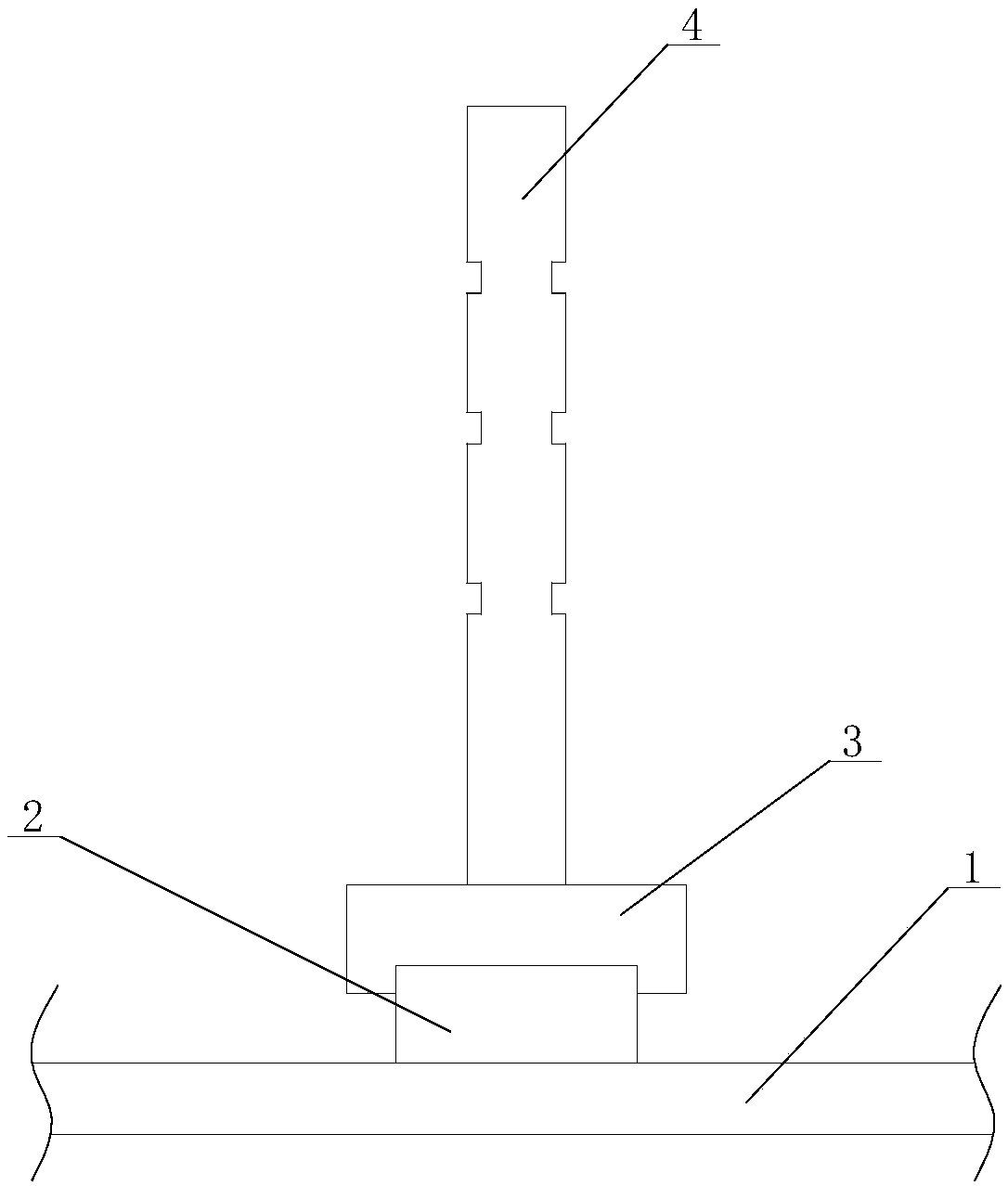

Constant-tension control method for diamond line cutting machine

InactiveCN108044822AAvoid errorsHigh adjustment accuracyWorking accessoriesFine working devicesPid control algorithmTension control

The invention discloses a constant-tension control method for a diamond line cutting machine. According to the constant-tension control method, the swing angle error e<theta> serves as the control basis, and the control target is to enable the swing angle error e<theta> to be 0; the feed-forward datum angular speed omegat is obtained through feed-forward control; the angular speed initial fine adjustment amount domega is obtained by utilizing the PID control algorithm through feedback control; the angular speed soft-limiting processing fine adjustment amount domegaL is obtained through soft-limiting processing; and finally, the feed-forward datum angular speed omegat calculated in feed-forward control is superposed with the angular speed soft-limiting processing fine adjustment amount domegaL, and thus the target angular speed omegay of a line roller is obtained. According to the control method, it can be ensured that line routing of the diamond line is steady and line routing tensionis constant, and tension fluctuation is avoided.

Owner:宁波钜德精工机械有限公司

Multifunctional double-twisting machine

The invention relates to a multifunctional double-twisting machine, which comprises a rack, a plurality of first twist spindles, a yarn bunching device, an overfeeding mechanism and a plurality of second twist spindles, wherein the first twist spindles, the yarn bunching device, the overfeeding mechanism and the second twist spindles are arranged on the rack in sequence from bottom to top; at least two first twist spindles are arranged into a group, and are matched with one second twist spindle; the first twist spindles are driven by a first motor and a first tangential belt; the overfeeding mechanism is driven by an overfeeding motor; each second twist spindle comprises two spindle belt plates; each of the two spindle belt plates are respectively abutted on a second tangential belt and a third tangential belt; and the second tangential belt and the third tangential belt are respectively connected with a second motor and a third motor. With the adoption of the multifunctional double-twisting machine, the processing steps such as first twisting, doubling, re-twisting and cladding can be realized, so that the investment of equipment is greatly reduced, the production efficiency is improved, the equipment occupies less land, and the labor and the electricity are saved.

Owner:ZHEJIANG KAICHENG TEXTILE MACHINERY

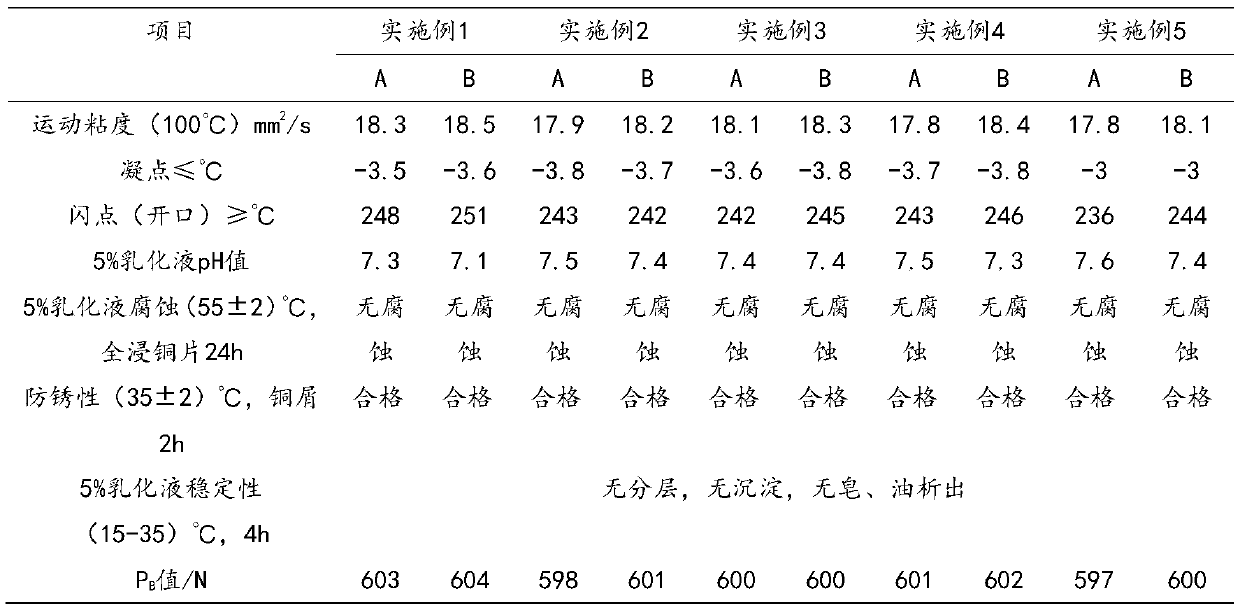

Cleaning friction-reducing high-efficiency drawing oil

InactiveCN103992855AGood drawing effectImprove the lubrication effectLubricant compositionMicrocrystalline waxPOLYOXYETHYLENE ETHER

The invention relates to a drawing oil, specifically to a cleaning friction-reducing high-efficiency drawing oil. The drawing oil is prepared from the following raw materials by weight: 10 to 12 parts of microcrystalline wax, 40 to 50 parts of lanolin oil, 80 to 100 parts of epoxidized soybean oil, 3 to 5 parts of 2-octyl-dodecanol, 1 to 2 parts of triethanolamine borate, 1 to 2 parts of dodecyl trimethyl ammonium chloride, 6 to 8 parts of octadecanoyl polyoxyethylene ether, 1 to 2 parts of propylene glycol monophenyl ether, 8 to 10 parts of rosin-polythylene oxide ester, 1 to 2 parts of sulfurated cottonseed oil and 2 to 3 parts of an auxiliary agent. According to the invention, lanolin oil and epoxidized soybean oil are used as base oil, so the drawing oil is more environment-friendly and safer; the drawing oil has strong adhesion on the surface of metal, effectively reduces a friction coefficient between a die and a wire rod, enables wiring to be more smooth and a good wire drawing effect to be obtained and has good cleaning performance and dispersibility and longer service life.

Owner:贵州水钢金属科技有限公司

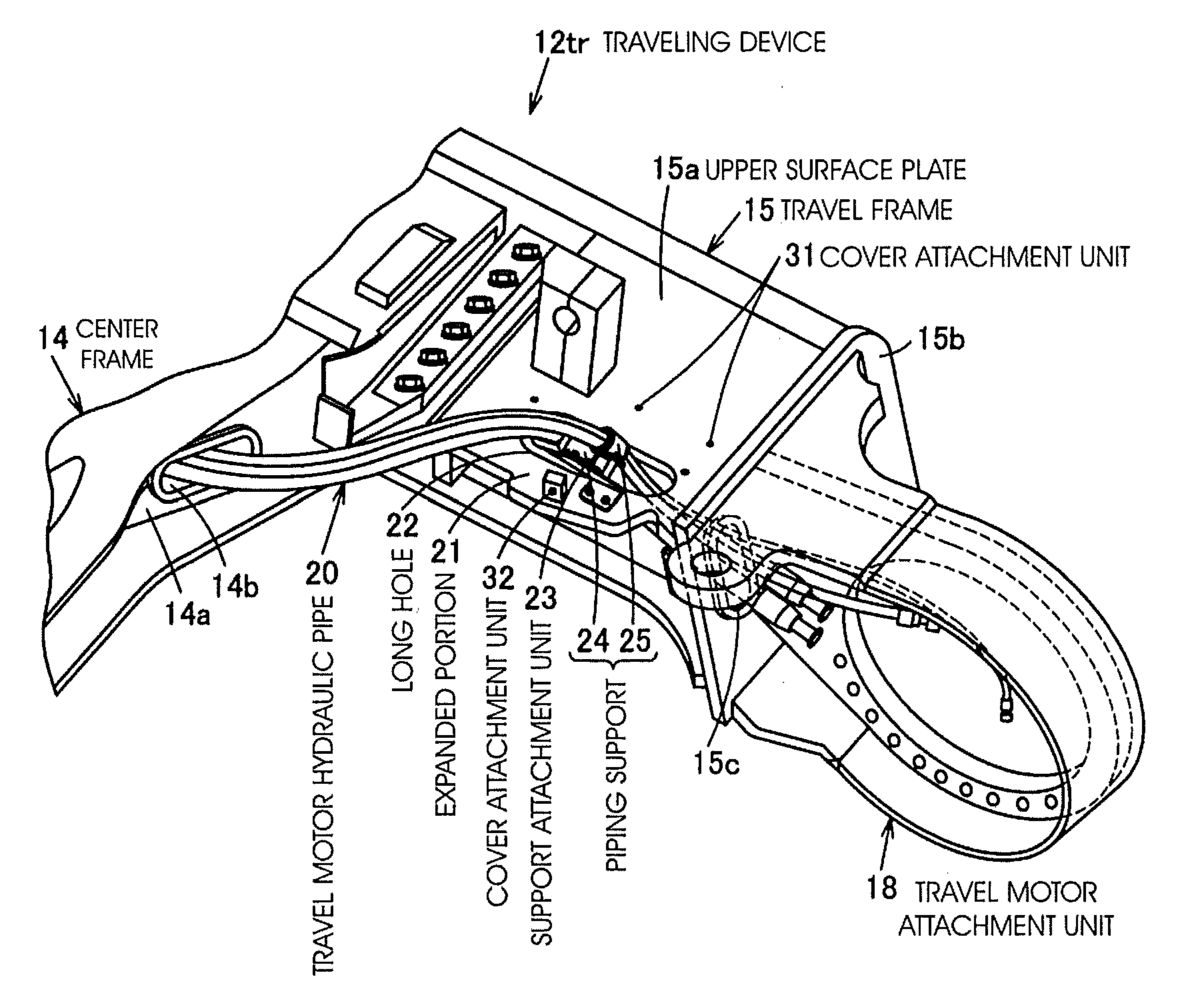

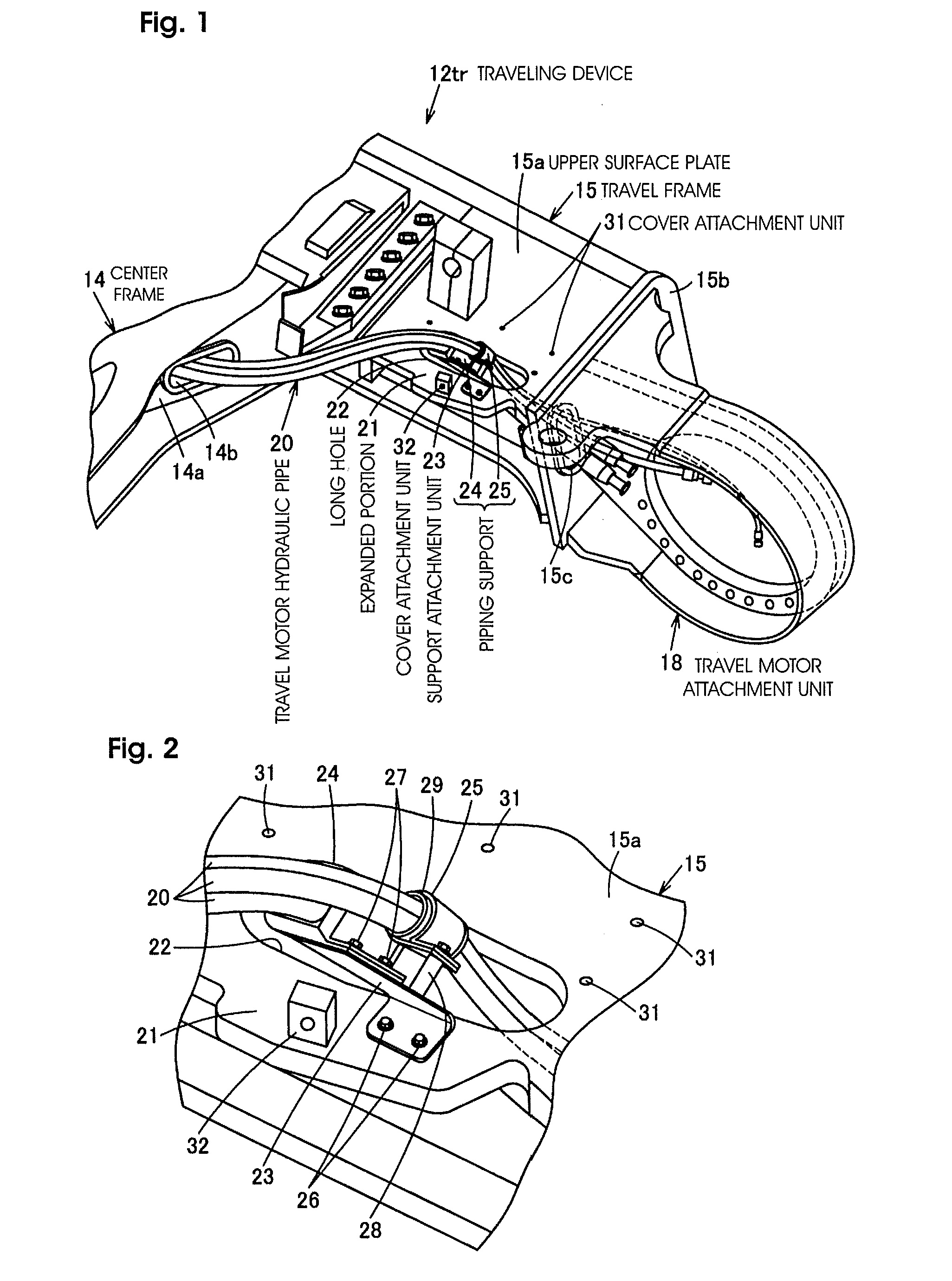

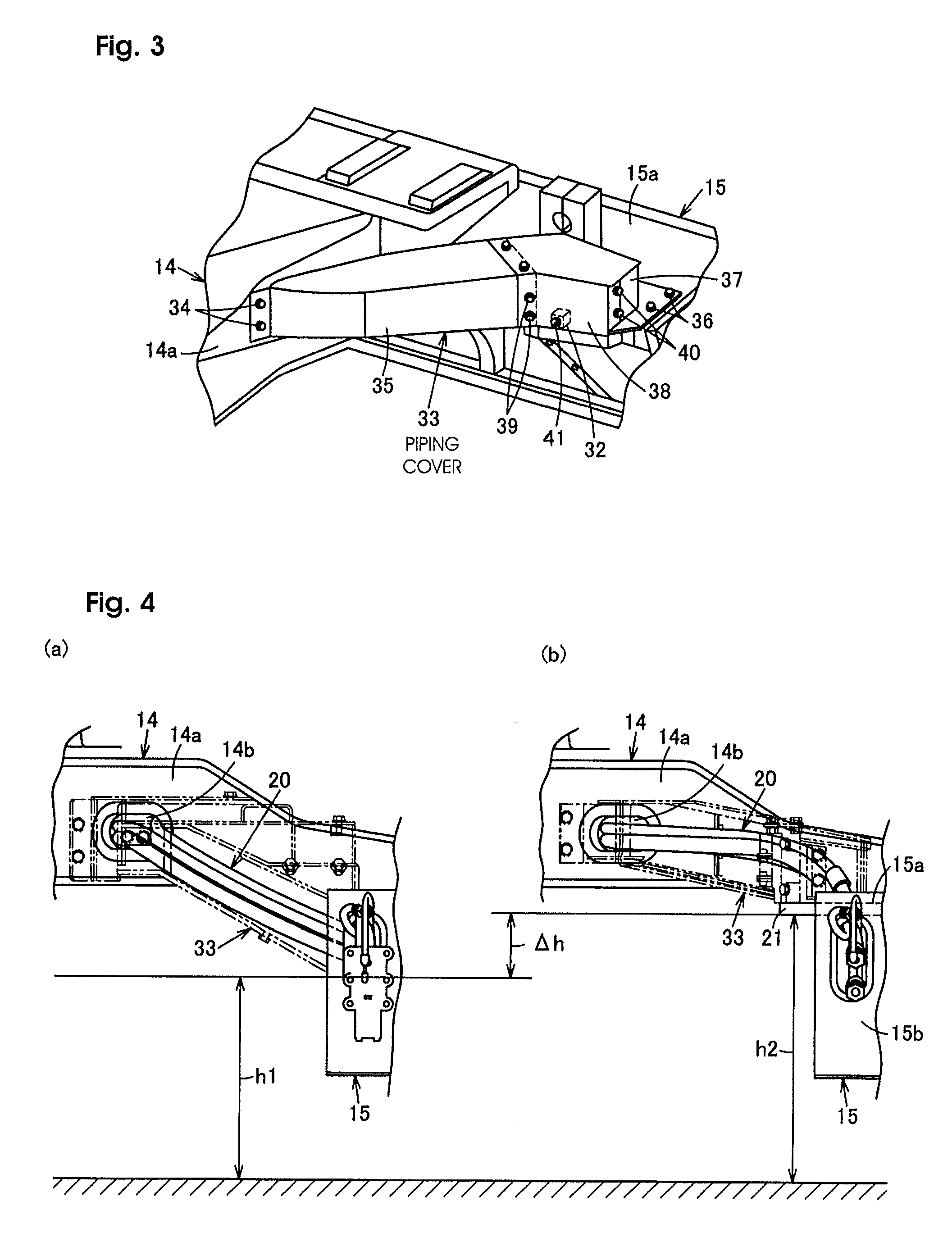

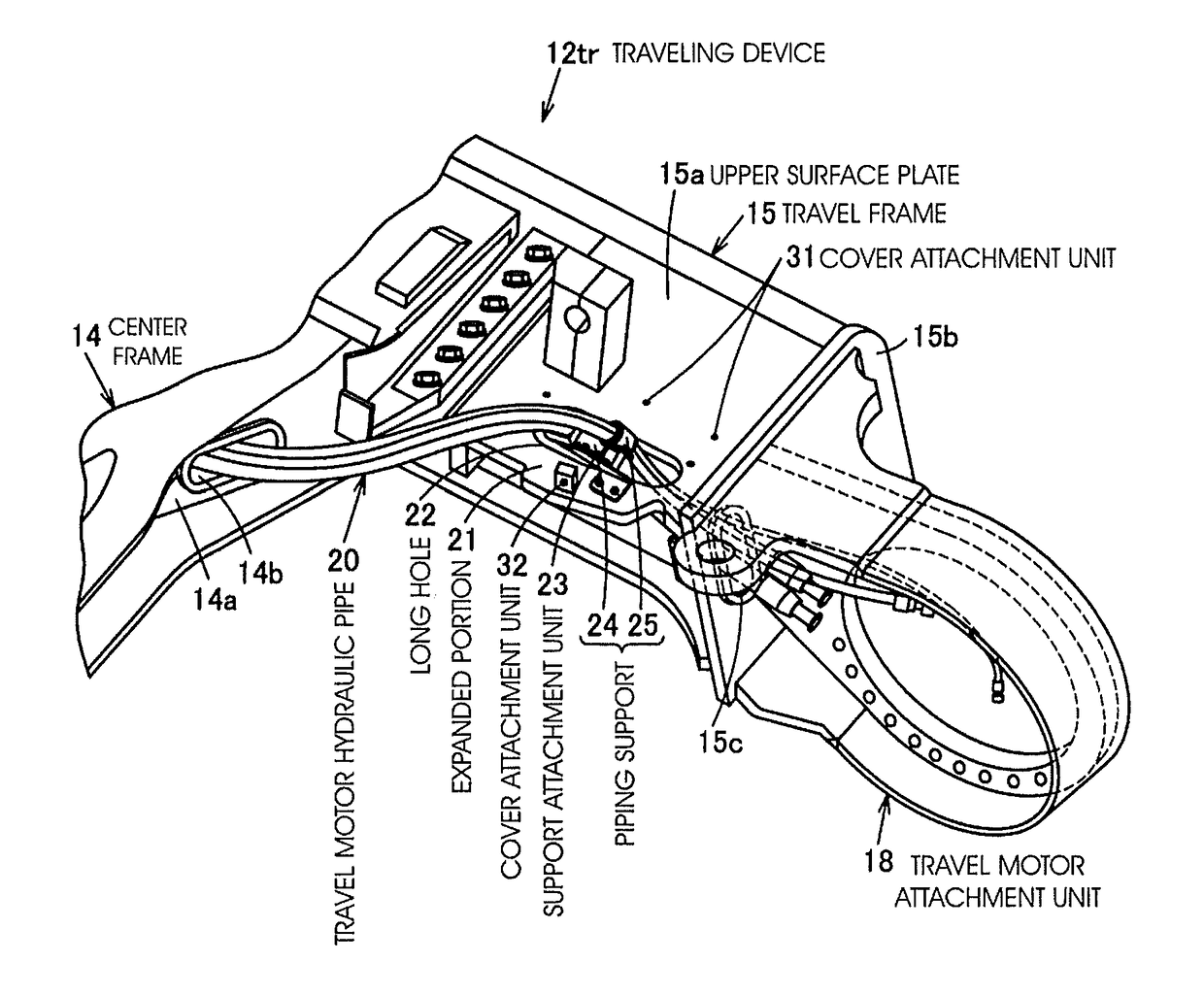

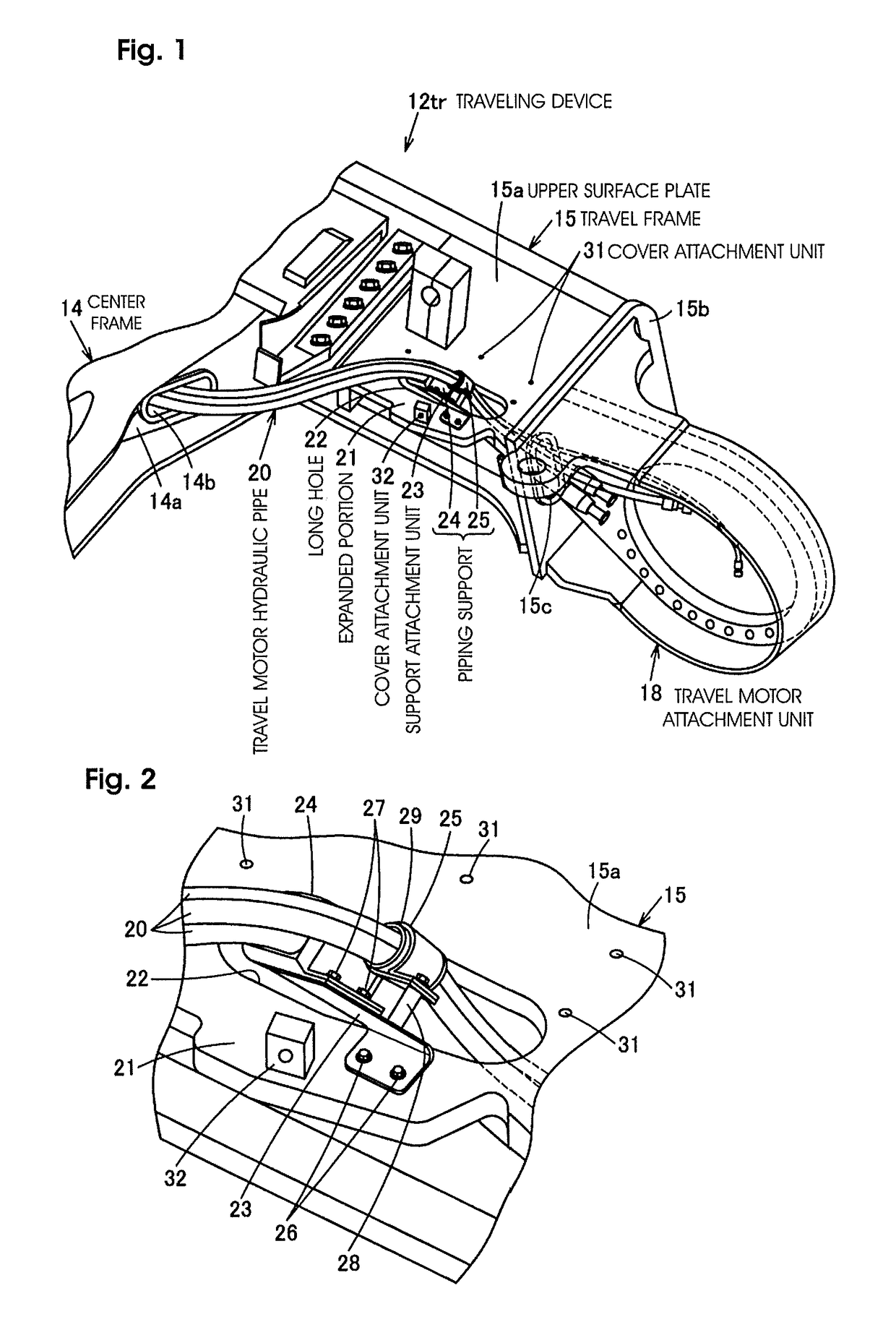

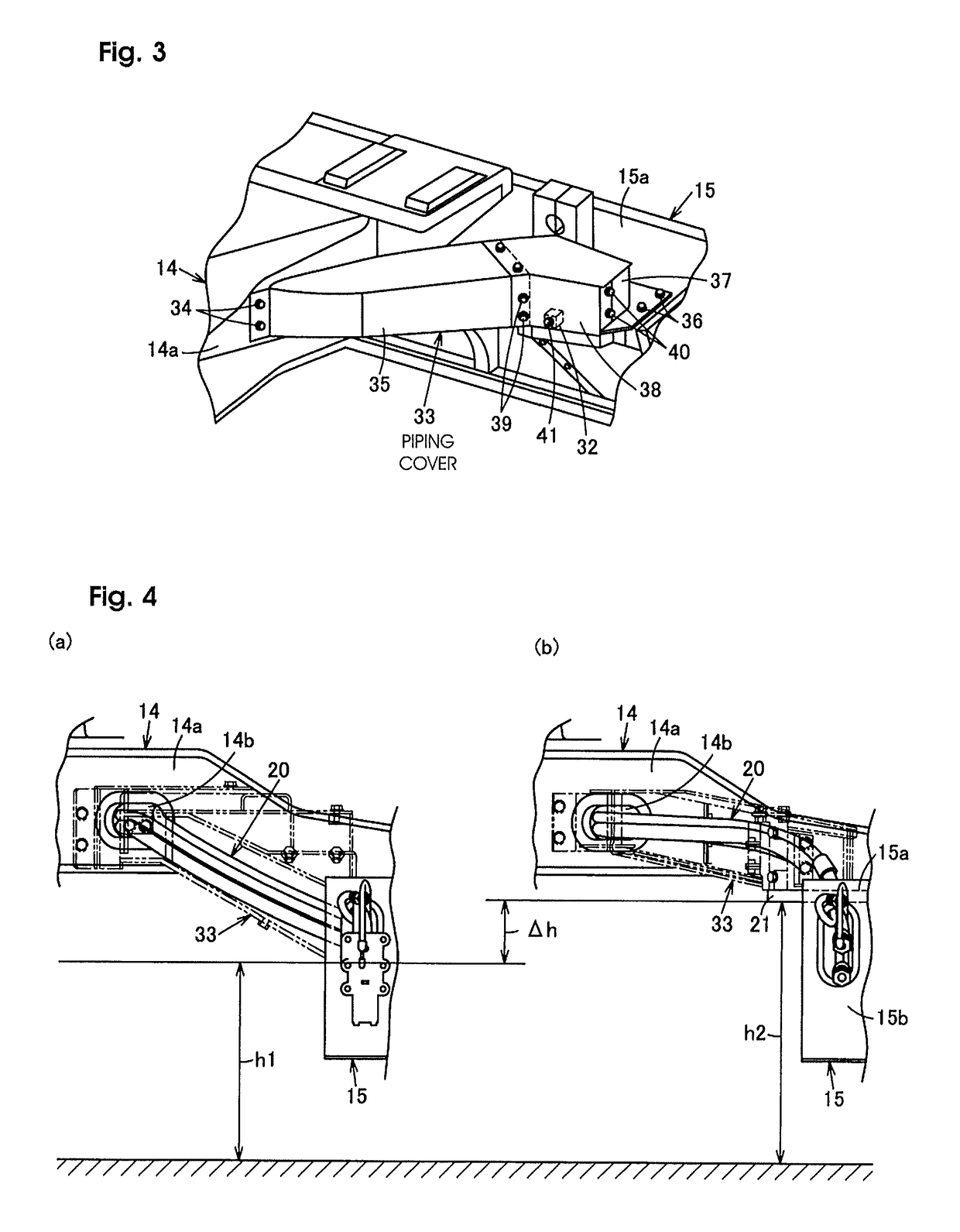

Traveling Device and Working Machine

InactiveUS20160281325A1Avoid damageAvoid collisionMechanical machines/dredgersMotor depositionEngineeringPiping

A travelling frame of a travelling device positioned between a center frame and a travelling motor attachment portion includes an upper plate extended toward the center side of the vehicle to form an extended portion. A long hole into which travelling motor hydraulic piping is inserted is formed in the upper plate along the extended portion. The travelling motor hydraulic piping extends from a lead-out hole opened in an end plate of the center frame, through the long hole of the upper plate and a tong hole opened in an end plate, and inserted into the travelling motor attachment portion.

Owner:CATEPILLAR SARL

Yarn guiding nozzle, yarn feeding method and yarn feeding method for adding spandex

The invention discloses a yarn guiding nozzle, a yarn feeding method and a yarn feeding method for adding spandex. The yarn guiding nozzle comprises a fixed plate and a yarn guiding plate, wherein the fixed plate has a first fixed hole and a second fixed hole which are through; one side edge of the yarn guiding plate is connected with the fixed plate, the yarn guiding plate has a first surface and a second surface which are opposite to each other, a plurality of yarn guiding holes for yarn to pass through are formed in the yarn guiding plate, a yarn guiding slot for yarn to pass through is formed in the first surface, the yarn guiding slot extends to the opposite side edge from one side edge of the yarn guiding plate, adjacent to the fixed plate, and one end of the yarn guiding slot is far away from the fixed plate gradually. The yarn guiding nozzle can ensure normal spandex adding of a lower single edge in weaving.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Wire and cable routing device

The invention discloses a wire and cable routing device, and relates to the field of wire and cable processing. The wire and cable routing device comprises a routing main frame, second adjusting frames, T-shaped sliding tables, threaded rods and adjusting rollers, wherein the T-shaped sliding tables sleeves with the adjusting rollers, the threaded rods are rotatably connected with connecting rods, two first fixed rollers are arranged on the upper surface of the routing main frame, the two T-shaped sliding tables are slidably connected to the front surface of the routing main frame, and the two first fixed rollers are arranged on the upper surface of the routing main frame; the routing main frame is in threaded connection with the two threaded rods, second fixed rollers are arranged on the two sides of the routing main frame, two second adjusting frames are fixedly connected to the upper surface of the routing main frame, the two second adjusting frames are symmetrically distributed about the vertical center line of the routing main frame, the second adjusting frames are in sliding connection with the T-shaped sliding tables, and the T-shaped sliding tables are in sliding connection with the routing main frame; the second adjusting frames are in threaded connection with the threaded rods. The wire and cable routing device is provided.

Owner:西安谷德电子科技有限公司

Broom automatic knitting machine

InactiveCN107558012AReasonable structureEven sewing routingThread-break detectorsMechanical engineeringIndustrial engineering

The invention discloses a broom automatic knitting machine and relates to the technical field of spinning equipment. The broom automatic knitting machine comprises a machine box, a sewing plate is arranged on the machine box, multiple arc-shaped sewing ports in parallel arrangement are formed in the middle of the sewing plate, an arc-shaped press ring is hinged at one end, along the length direction, of each arc-shaped sewing port, and a spacing strip is axially arranged at one end of the outer side of the arc-shaped sewing port on the outermost side; a sliding rod with a sewing head is suspended at the top of the sewing plate and connected in a sewing sliding sleeve in an up-down sliding manner, the sewing sliding sleeve is fixedly connected with a rotating arm capable of rotating horizontally, and crochet hooks capable of sliding leftwards and rightwards and swinging up and down are arranged below the arc-shaped sewing ports; the sewing plate, the sewing head, the rotating arm and the crochet hooks are driven by respective driving devices which are controlled by a controller. Compared with the prior art, the broom automatic knitting machine has the advantages that when the broomautomatic knitting machine is used for sewing brooms, each broom can be sewn within 1min, the broom automatic knitting machine is uniform in sewing thread distribution, tight and forceful in thread tightening, better in effect than manual sewing and faster than manual sewing by more than ten times, and yield is increased greatly.

Owner:岑溪市拓丰科技发展有限公司

Double-pitch twisting machine

PendingCN112079187AGuaranteed processing efficiencyImprove processing efficiencyFilament handlingClassical mechanicsElectric machinery

The invention relates to the field of machining, in particular to a double-pitch twisting machine which comprises a double-pitch twisting machine shell, a driving device and a control console. The double-pitch twisting machine is characterized in that a base is arranged at the bottom of the double-pitch twisting machine shell, and a lifting table is arranged at the top of the base; the driving device is installed on one side of the outer portion of the double-pitch twisting machine shell, the driving device is a motor, and the double-pitch twisting machine is sequentially provided with a firstmain shaft, a first main shaft guide wheel, a stranding bow, a second main shaft, a second main shaft guide wheel and a cradle frame according to a product machining sequence; the cradle frame internally comprises a traction device, a wire arrangement device and a take-up reel, and the traction device comprises a wire traction motor, a driving leading taking wheel, a driven leading taking wheel and a reversing wire passing guide wheel; the take-up reel is arranged on the cradle frame, and the wire arranging device is arranged between the cradle frame and the traction device; and observation openings are further formed in the two sides, close to the main shafts, of the double-pitch twisting machine shell.

Owner:JIANFENG SLING

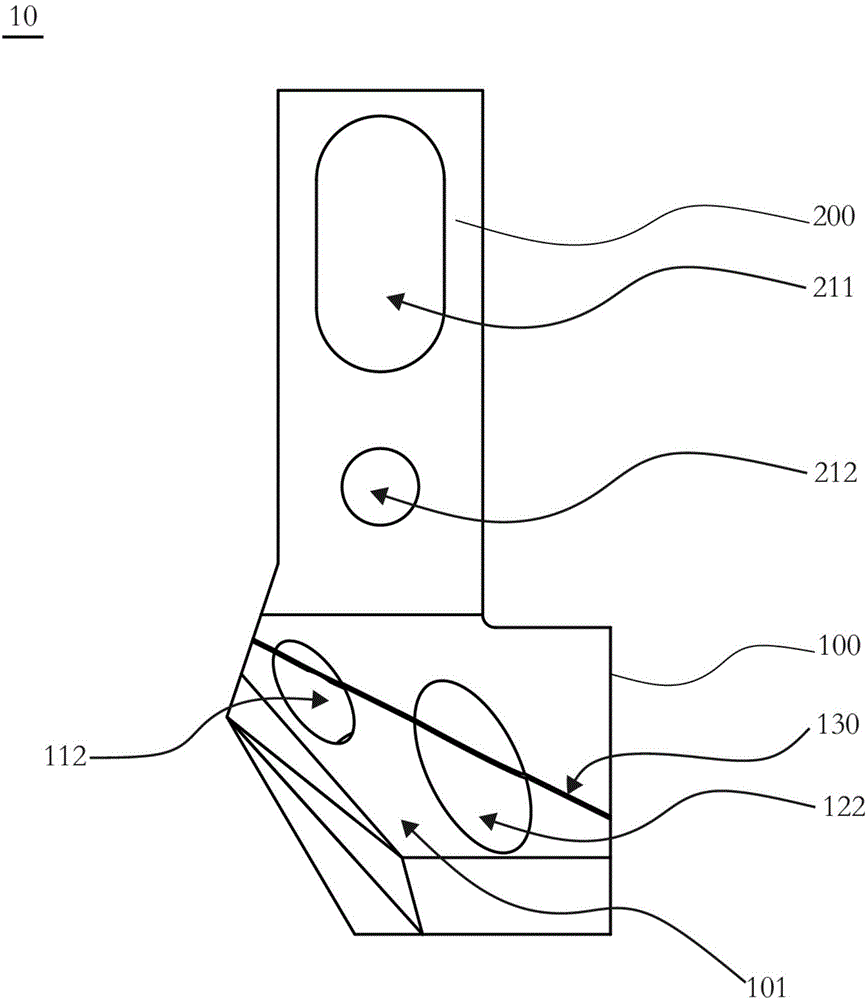

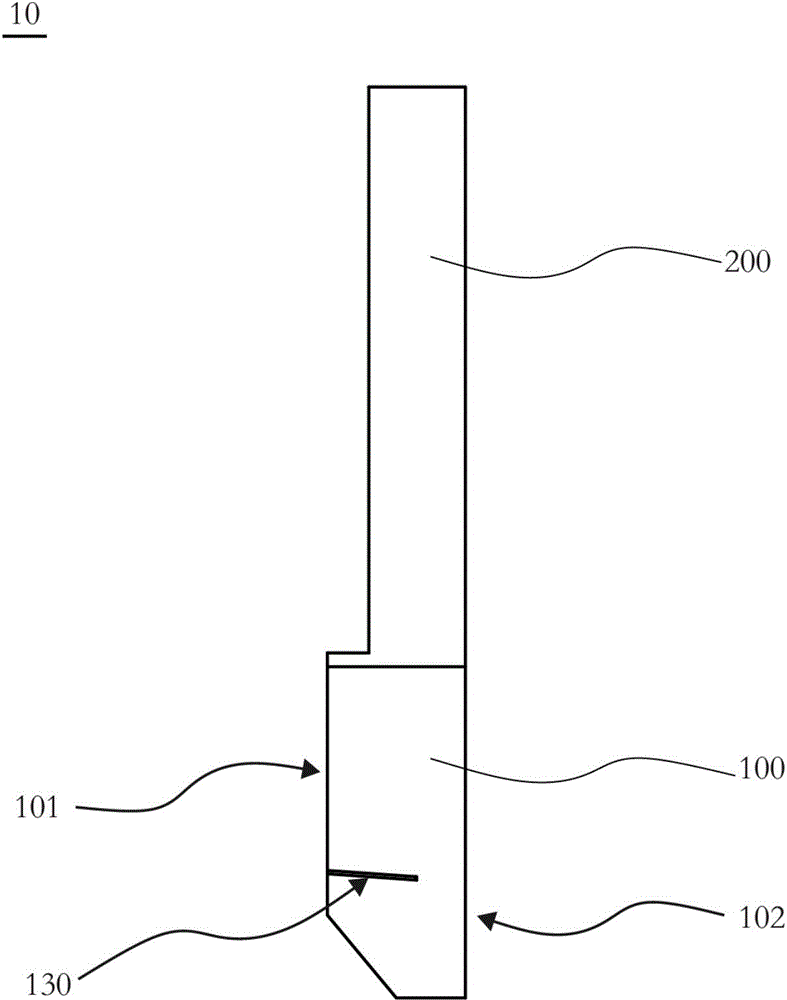

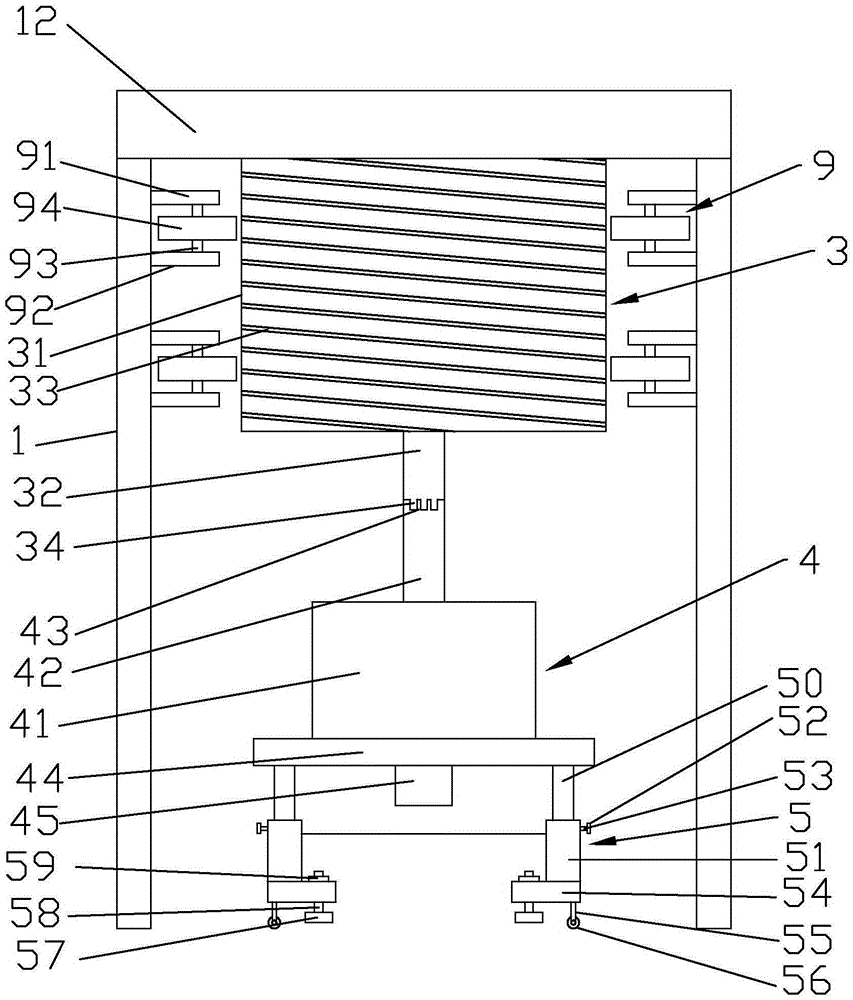

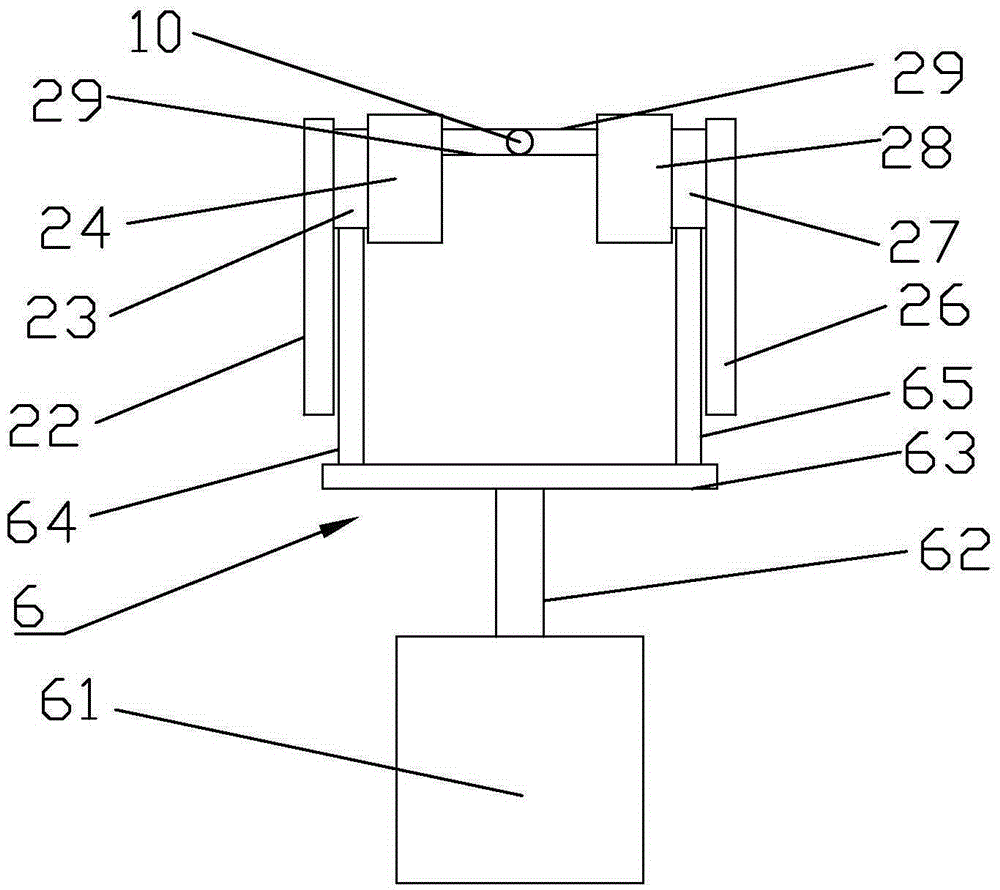

Wire winding mechanism of diamond wire cutting machine and constant tension control method based on wire winding mechanism

PendingCN108000737AStable tensionShorten the winding distanceWorking accessoriesFine working devicesDrive shaftWire cutting

The invention discloses a wire winding mechanism of a diamond wire cutting machine and a constant tension control method based on the wire winding mechanism. The wire winding mechanism comprises a wire unwinding roller, a driving shaft, a driven shaft, a wire winding roller, an upper moving module, a lower moving module, an upper swing arm, a lower swing arm, a first fixed guide wheel and a secondfixed guide wheel. A moving guide wheel is installed on each moving module, and a swing guide wheel is installed on each swing arm. A diamond wire is led out of the wire unwinding roller, passes through the first moving guide wheel, the first swing guide wheel and the first fixed guide wheel, then is wound around the driving shaft and the driven shaft to form a wire net, passes through the secondfixed guide wheel, the second swing guide wheel and the second moving guide wheel, and finally is led to the wire winding roller. The control method is characterized in that the feed-forward standardangular velocity wt calculated through feed-forward control and the angular velocity soft amplitude limiting treatment fine adjustment quantity dwl are superposed, so that the target angular velocitywy of each wire roller is acquired. The wire winding mechanism and the control method have the advantages that the number of the guide wheels can be reduced, the rigidity of the diamond wire can be improved, and the wire routing tension can be constant.

Owner:宁波钜德精工机械有限公司

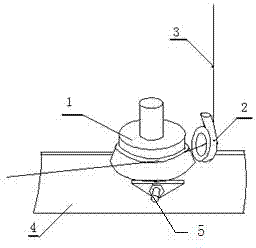

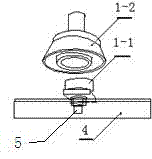

Cake wax of bobbin winder

The invention relates to cake wax of a bobbin winder, comprising cake wax and an installation frame. The cake wax is fixedly installed on the installation frame. A guide ring is fixedly installed on the installation frame. Yarn is drawn from the cake wax and enters the guide ring. The cake wax further comprises a cake wax body which is provided with a rolling bearing. The rolling bearing is fixedly installed on the installation frame through a fixed shaft. The invention effectively solves the problem that the yarn breaks when the yarn enters the bobbin winder.

Owner:JIANGSU ZHENGHENG DYEING FINISHING

Wire rewinding machine applied to aluminum wire production

The invention discloses a wire rewinding machine applied to aluminum wire production. The wire rewinding machine comprises a machine frame and a wire rewinding trolley, wherein a detection platform and a wire winding platform are arranged on the machine frame; the wire rewinding trolley is arranged below the wire winding platform; a detecting device is arranged on the detection platform; the detecting device comprises a detecting frame; the detecting frame is provided with a photoelectric transmitter and a photoelectric receiver; the photoelectric transmitter is used for transmitting infrared light; an aluminum wire is arranged between the photoelectric transmitter and the photoelectric receiver; a wire winding device is arranged on the wire winding platform and comprises a wire winding reel and a wire winding shaft; the wire winding reel is provided with a wire winding groove and is connected with the wire winding shaft; the wire winding shaft is vertically arranged; the wire rewinding trolley comprises a wire rewinding platform and a wire rewinding reel; the wire rewinding reel is arranged on the wire rewinding platform; a wire rewinding shaft is arranged inside the wire rewinding reel; the upper end of the wire rewinding shaft is connected with the wire winding shaft; the lower end of the wire rewinding shaft is connected with a wire rewinding motor. The machine is simple in structure, scientific, convenient, highly targeted, high in automation degree and capable of commendably achieving wire rewinding and detection in aluminum wire production.

Owner:嵊州市银河铝业有限公司

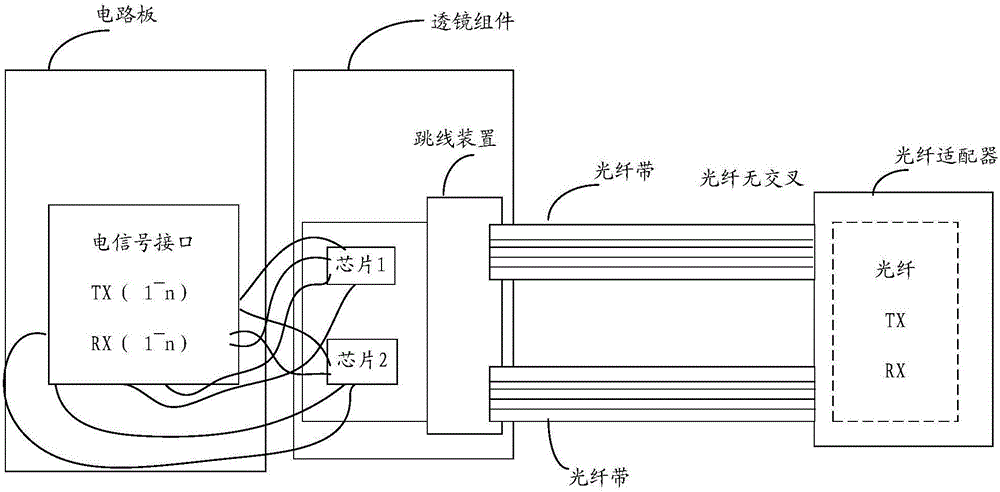

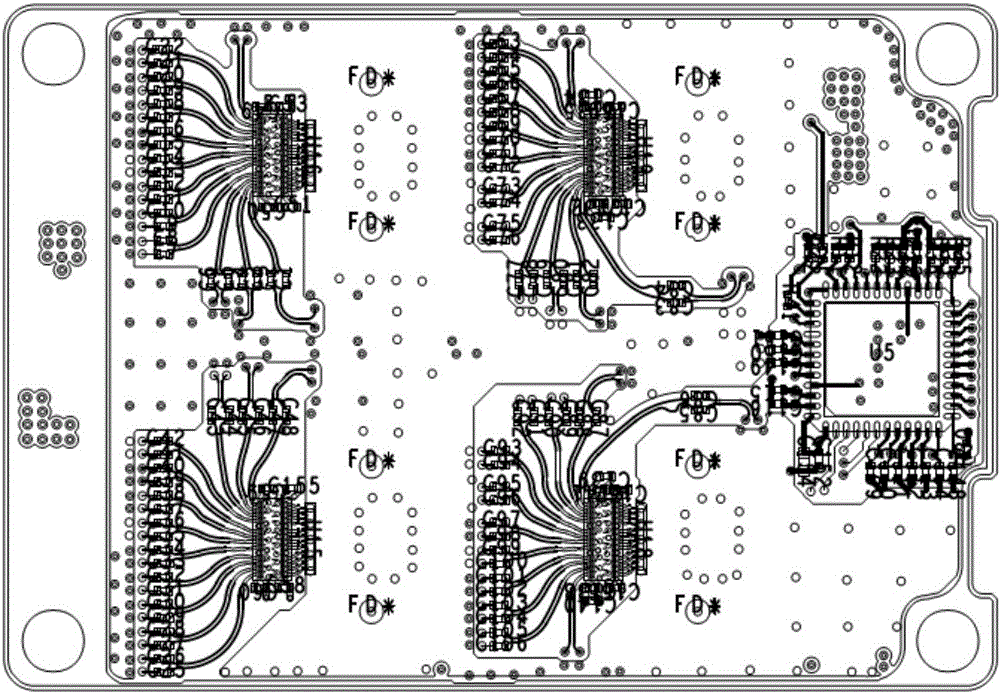

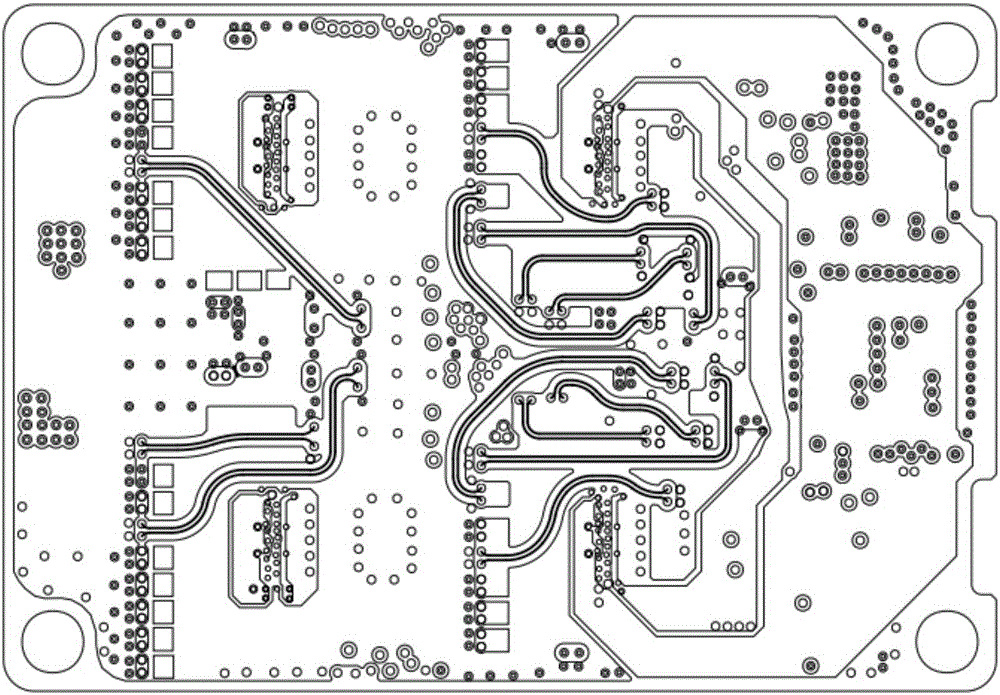

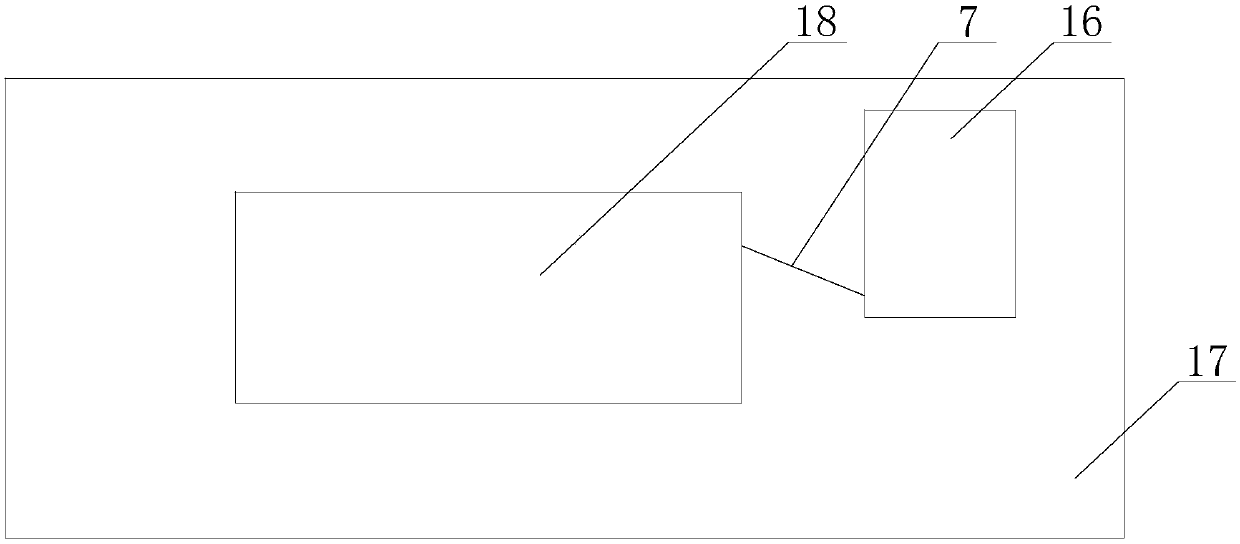

Optical module

ActiveCN105929494APerformance is not affectedSmooth routingCoupling light guidesElectricityOptical Module

The invention discloses an optical module and solves the problem of PCB wiring difficulty in the prior art. The optical module comprises a circuit board, a lens assembly and a fiber adapter corresponding to the lens assembly, wherein the driving chip of the lens assembly communicates with electric signal interfaces on a specific position area on the circuit board to reduce intersects of communicating channels between the electric signal interfaces on the specific position area and the driving chip. The electric signal interfaces on the specific position area are determined according to the types of the optical assemblies driven by the driving chip, and types and arrangement of each electric signal interface on the circuit board. A jumper wire device of the lens assembly communicates with the fiber adapter through an optical fiber ribbon. The sequence of the optical fiber ribbon accessing to the channels on the jumper wire device side is different from the sequence of the optical fiber ribbon accessing to the channels on the fiber adapter side. The optical module accesses the electric signal interfaces on the specific position area to the driving chip, which reduces or eliminates intersects of PCB wirings.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

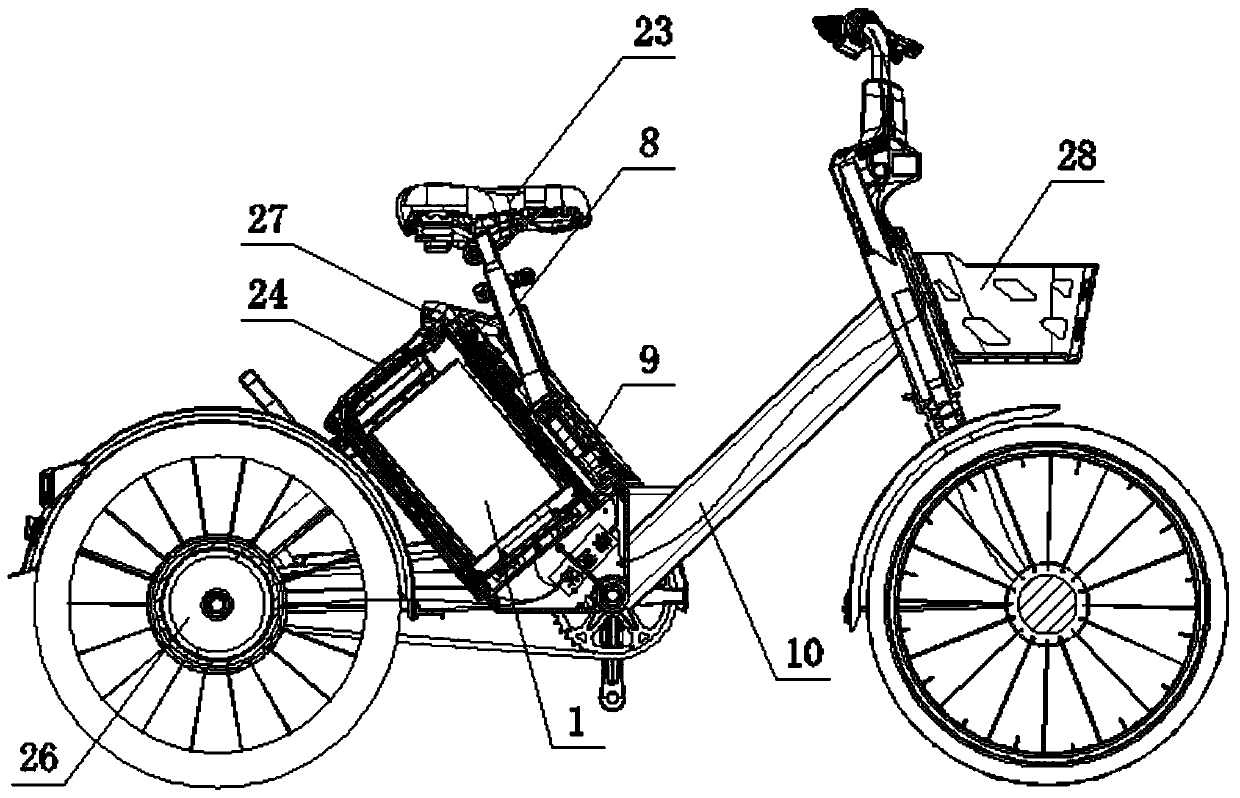

A wiring structure of a moped, a vehicle frame and the moped

PendingCN109703676AAvoid intertwiningEvenly distributedMotorcyclesRider propulsionElectricityVehicle frame

The invention discloses a wiring structure of a moped, a vehicle frame and the moped. The problems that wiring assembly and maintenance are inconvenient due to disordered wiring of all electric control parts, a battery capacity is low and signal receiving effect of a main control antenna box is poor are solved; the technical key points are as follows: the bottom of a battery bin fixed on the vehicle frame is in adding connection with a controller box, and wire harnesses of the electric control parts are arranged towards each electric control part end in an umbrella-shaped manner by taking thecontroller as the center, so that the wire harness of each electric control part is very smooth in assembly, and is convenient to install and maintain subsequently; the battery bin is embedded in a middle pipe of the vehicle frame through a middle pipe hole formed in the front surface of the battery bin; a battery bin upper cover is arranged at a bin opening of the battery bin; an electric controllock is arranged between the battery bin upper cover and the battery bin; the battery bin comprises a first cavity and a second cavity, the first cavity accommodates a battery, the middle pipe hole is formed in the second cavity, and the second cavity is provided with an antenna box cavity, so that the main control antenna box is placed in front of the middle pipe, no metal shielding object exists, the signal receiving capability of the main control antenna box is higher, and the wiring mode is smoother.

Owner:SHANGHAI JUNZHENG NETWORK TECH CO LTD

Template machine

The invention discloses a template machine, and belongs to the technical field of sewing equipment. The template machine comprises a rack, wherein a sewing machine and a sewing table surface are arranged on the rack; a sewing feeding system is arranged on one side of the sewing machine; the sewing feeding system comprises a planar feeding mechanism movably arranged on the sewing table surface; a material pressing device is arranged on the planar feeding mechanism through a lifting device and a steering device in a vertical downward manner; and a material presser is arranged in the material pressing device and is used for clamping fabrics so that the fabrics can be moved on the sewing table surface along with the planar feeding mechanism, rotated on the sewing table surface along with the steering device and matched with the sewing machine for sewing. According to the template machine disclosed by the invention, ways of feeding and thread routing in the prior art are changed, through combination of an added way of rotating through a clamping device and movement of a feeding device on the horizontal plane, control of thread routing is realized, so that a thread routing process is smoother, and thread traces are more attractive.

Owner:阮波

Wire passing brick

InactiveCN107435408AIndestructible strengthReasonable structural designBuilding componentsBrickEngineering

The invention discloses a wiring brick, which comprises a brick body, wherein wiring holes are arranged symmetrically in the brick body, hook installation holes are arranged between the wiring holes, and cable fixing hooks are arranged in the hook installation holes The structure design of the present invention is reasonable, and the effect of wiring in the wall can be realized through the wiring hole, and the cable is fixed by the cable fixing hook, which is convenient for wiring, stable for wiring, does not damage the strength of the whole wall, stable in structure, and easy to operate .

Owner:JIANGYIN DONGSHENG BUILDING MACHINERY

Traveling device and working machine

InactiveUS9732497B2Reduce riskEasy to operateMechanical machines/dredgersMotor depositionEngineeringPiping

A travelling frame of a travelling device positioned between a center frame and a travelling motor attachment portion includes an upper plate extended toward the center side of the vehicle to form an extended portion. A long hole into which travelling motor hydraulic piping is inserted is formed in the upper plate along the extended portion. The travelling motor hydraulic piping extends from a lead-out hole opened in an end plate of the center frame, through the long hole of the upper plate and a long hole opened in an end plate, and inserted into the travelling motor attachment portion.

Owner:CATEPILLAR SARL

Clothing sewing equipment

The invention discloses a garment sewing device, which comprises a workbench, on which a sewing machine main body and a wire-paying table are arranged, and the wire-paying table includes a base, and a coil disk is arranged on the base, and the coil disk It includes a placement plate and a fixed column. The base is provided with a tension adjustment mechanism. The tension adjustment mechanism includes two parallel rails. A slider matching the rail is installed on the rail, and a cylinder is fixed on the slider. . The tension of the sewing thread is more uniform, the main thread of the sewing machine is more stable, the sewing quality is improved, and the sewing thread can quickly enter from the loose state to the tight state, which improves the production efficiency.

Owner:四川三好服饰有限公司

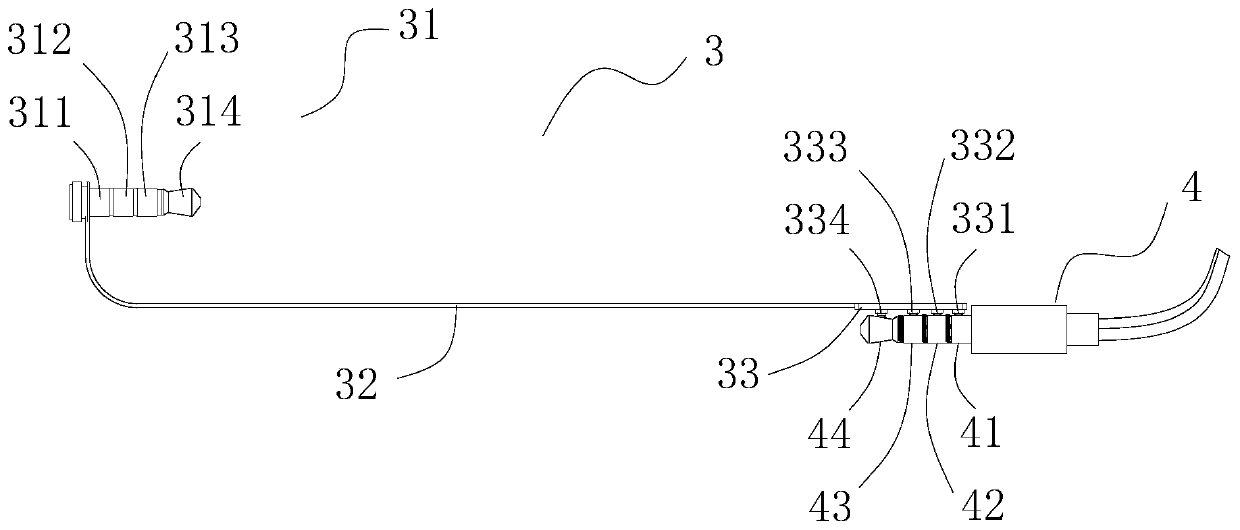

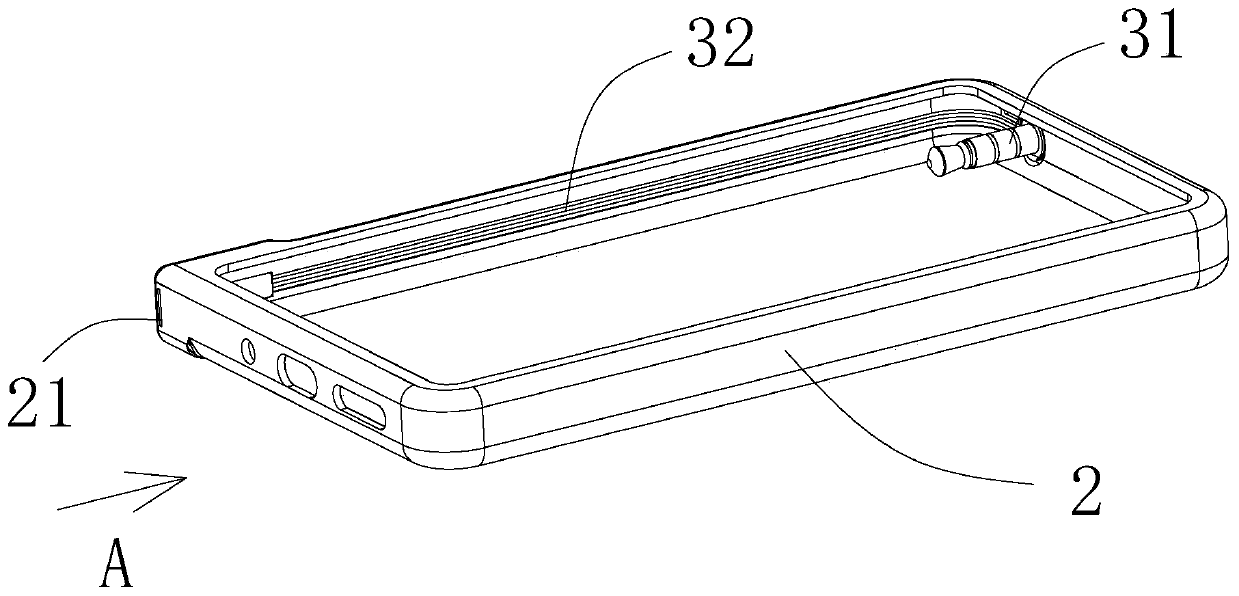

A multifunctional mobile phone case

The invention discloses a multifunctional mobile phone case, which relates to the field of mobile phone accessories. It includes a mobile phone case, a first plug, a wire and a circuit board. The first plug is fixed on the mobile phone case and inserted into the first earphone hole of the mobile phone. The conductive ring of the first plug is electrically connected to the corresponding contacts of the circuit board through wires. After the plug is inserted into the second earphone hole on the mobile phone cover, the conductive ring of the plug contacts the corresponding contact on the circuit board, which is equivalent to the plug being directly inserted into the first earphone hole of the mobile phone; the second earphone hole is a flat and elastic blind Hole, when the plug is inserted into the second earphone hole, the second earphone hole is stretched to clamp the plug tightly; a normally open switch is connected between the first ring and the second ring of the first plug to reduce the frequency of using the keys of the mobile phone . The second earphone hole is designed at the optimal position of ergonomics, which makes up for the design deficiency of the user's mobile phone. The invention has the advantages of smooth earphone routing, wires that are not easy to break, easy to carry, and the keys of the mobile phone are not easily damaged.

Owner:盐城泓文广告传媒有限公司

Zero-degree yarn feeding device

The invention relates to a zero-degree yarn feeding device. Both ends of a shaft are supported on a bracket; a plurality of groups of supporting devices are arranged on a shaft body; each group of the supporting devices consist of a yarn blocking needle base bonding piece and a clamping ring; the yarn blocking needle base bonding piece and the clamping ring are arranged on the shaft body of the shaft at an interval; a yarn blocking device is fixedly arranged on the yarn blocking needle base bonding piece; the yarn blocking device comprises a yarn blocking needle bed, a yarn guide needle bed and a yarn blocking needle; one end of the yarn blocking needle bed is fixedly connected with the yarn blocking needle base bonding piece, and the other end of the yarn blocking needle bed is connected with the yarn blocking needle; the yarn guide needle bed is fixedly arranged on the yarn blocking needle bed; a plurality of pairs of yarn collection boards are mounted on the clamping ring; and the yarn collection boards are fixedly arranged on the clamping ring in a state of being inclined to the yarn blocking device. According to the zero-degree yarn feeding device provided by the invention, multiple pairs of the yarn collection boards and the yarn blocking needle base bonding piece are arranged, so that various different yarns can be delivered simultaneously. Meanwhile, the zero-degree yarn feeding device has the advantage of compact structure.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

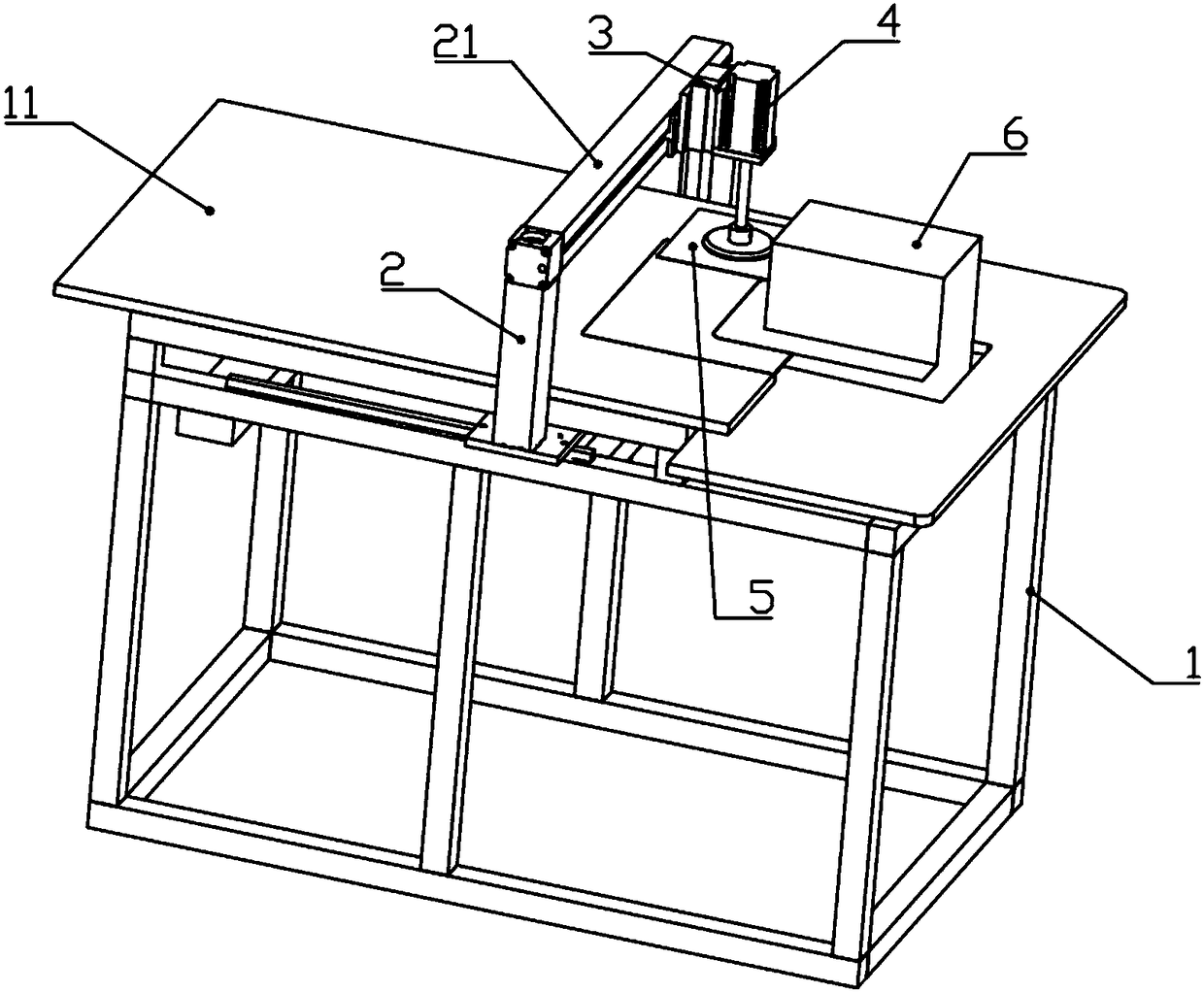

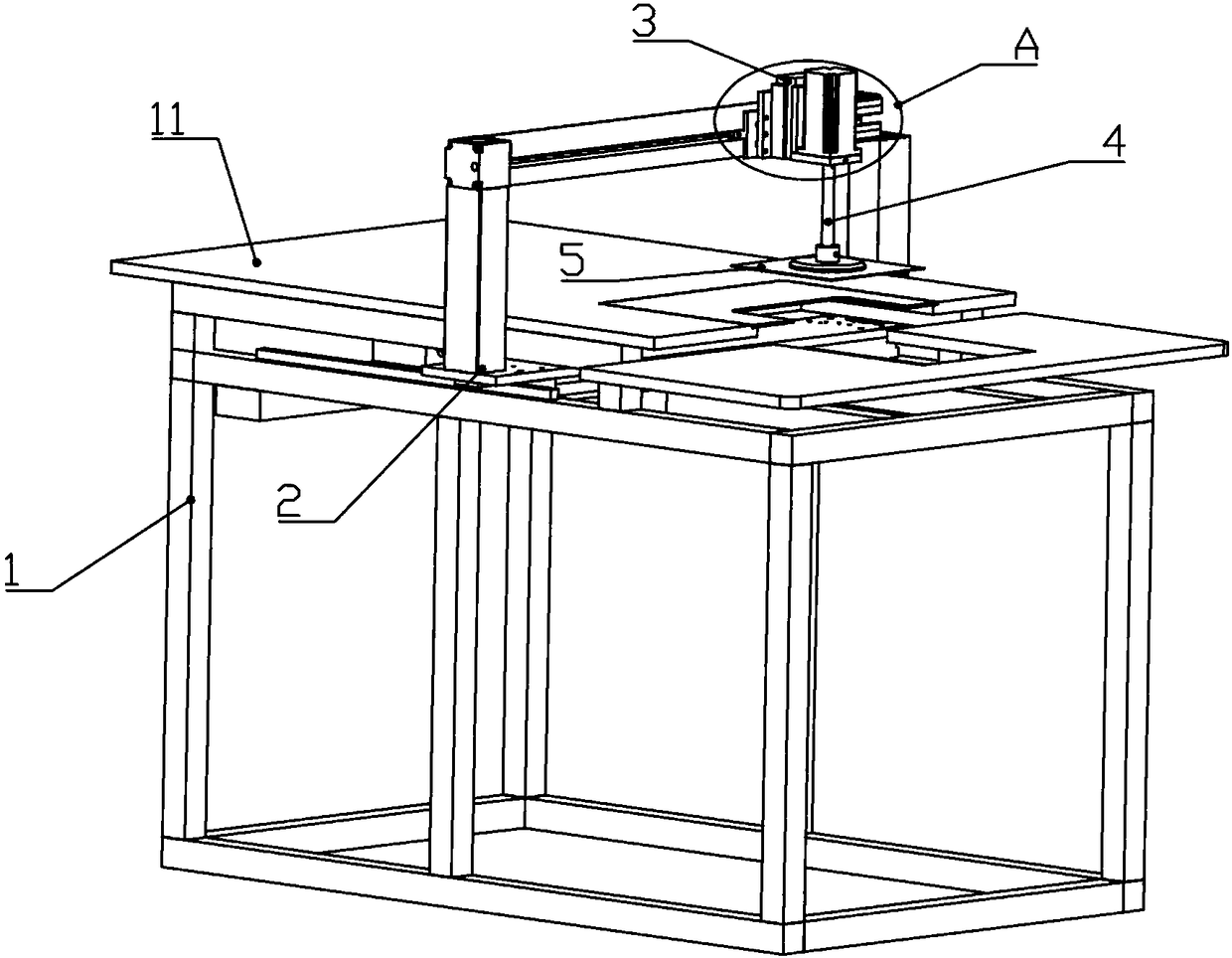

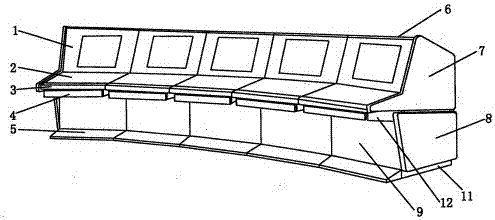

Assembled control console

InactiveCN107493664ALow costAvoid blind spotsSide-by-side/stacked arrangementsCasings with display/control unitsEngineeringBack door

The invention relates to an assembled control console, and belongs to the technical field of mechanical design. The assembled control console comprises a plurality of single control consoles and an upper side wall and a lower side wall; and each single control console also comprises a monitoring panel fixed with a mounting plate and an angle support, an operation panel, a front decoration lever, a keyboard drawer fixed with a sliding channel, an upper end cover, a front door provided with a lock, a back door provided with a lock, a table base fixed with a pedal, a front tray, a sliding channel bracket connected with the sliding channel, a connecting plate, a front framework and a back framework. Compared with a common control console, the assembled control console is small in occupied area, simple and convenient to operate, has more stations, and capable of operating multiple stations under monitoring of one person, and saving the occupation area and personnel cost and other consumption; and compared with a conventional control console trace structure, the first and second trace channels are connected with trace grooves of the control console trace structure, so that dead angles occur in the first and second trace channels and the trace grooves can be avoided, quite convenient and smooth tracing can be realized, and the assembling efficiency of the product is greatly improved.

Owner:SUZHOU GUANGNENG ELECTRONICS TECH CO LTD

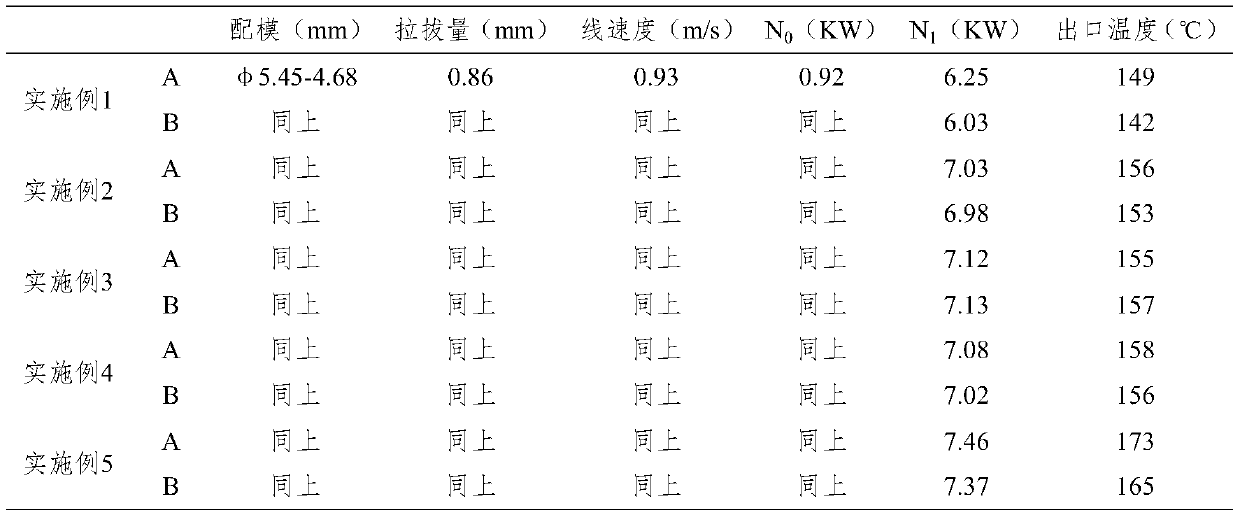

Improved drawing oil and preparation method thereof

ActiveCN111423924AImprove the lubrication effectReduce dosageLubricant compositionMicrocrystalline waxPhenyl Ethers

The invention relates to the technical field of lubricants, particularly to improved drawing oil and a preparation method thereof. According to the invention, epoxidized soybean oil and lanolin oil are used as base oil, and on the basis that the excellent lubricating property of the base oil is environment-friendlier and safer compared with mineral oil, the relative content of each raw material component in the drawing oil is adjusted, so the use amount of the base oil is reduced, the amount of microcrystalline wax is properly increased, 2-octyldodecanol and propylene glycol phenyl ether are properly reduced, and octadecanol polyoxyethylene ether, rosin polyoxyethylene ester and auxiliaries are properly increased; and therefore, the performance of the drawing oil is effectively improved, the lubricating effect of the drawing oil is improved, a friction coefficient between a die and a wire is reduced, and energy consumption is reduced.

Owner:贵州水钢金属科技有限公司 +1

Non-sliding wire drawing device

The invention discloses a non-sliding wire drawing device, and belongs to the field of wire drawing device equipment and technology. The non-sliding wire drawing device comprises a machine body; the machine body is provided with a set of wire drawing drum wheels; a fitting position of each wire drawing drum wheel is provided with a wire drawing die holder; and a rotating shaft of each wire drawing drum wheel and a rotating shaft of a servo motor of each wire drawing drum wheel are connected in a coaxial manner. The wire drawing drum wheels are driven by the servo motors in the non-sliding wire drawing device, and wire drawing drum wheels are driven by belt pulleys or reducer casing to rotate in conventional wire drawing devices, so that the non-sliding wire drawing device is capable of reducing vibration and noise caused by mechanical deceleration effectively, improving the quality of material surface in the whole wire drawing process, avoiding the generating of large amount of metal dust, reducing the generating of material surface microcracks caused by vibration in the process of drawing hard alloy wires effectively, increasing production quality of products. In addition, advantages of the servo motors are that, speed is stable, speed regulation precision is high, synchronization performance is excellent, torque is large, and efficiency is high.

Owner:德阳杰创线缆机械有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com