Non-sliding wire drawing device

A non-sliding, wire-drawing machine technology, applied in the field of wire-drawing machines, can solve problems such as loss, difficulty, and impact on yield, and achieve the effects of reducing vibration and noise, increasing service life, and reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

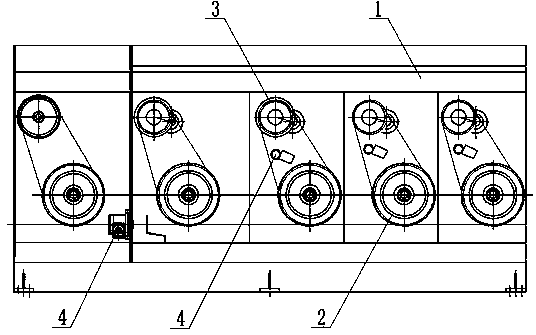

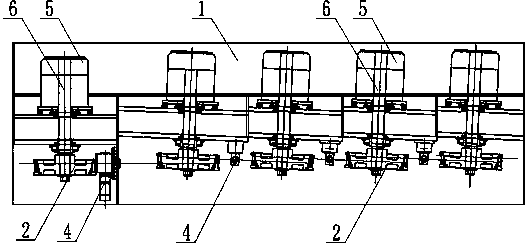

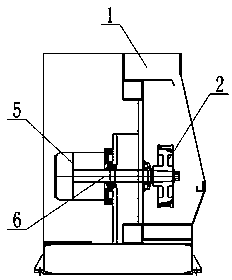

[0029] Non-sliding wire drawing machine of the present invention, its structure is shown as figure 1 with figure 2 As shown (the number of wire-drawing drums 2 and motors 5 in the figure is only for illustration, and does not indicate the specific number), the wire-drawing machine includes a fuselage 1, and a group of wire-drawing drums 2 is arranged on the fuselage 1, and each wire-drawing drum The upper part of 2 is provided with tension adjustment wheel 3, and the wire drawing mold base 4 is arranged on the corresponding position of wire drawing drum 2 and tension adjustment wheel 3, and described wire drawing drum 2 is driven by the motor 5 that is set, and described motor 5 is Servo motor, the rotating shaft 6 of the motor 5 is directly connected with the cable drum 2 coaxially, that is, the motor 5 and the cable drum 2 share the same rotating shaft 6, and the axis of the cable drum 2 is directly sleeved on the rotating shaft 6, canceling The traditional reduction mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com