Clothing sewing equipment

A technology of equipment and clothing, applied in the field of clothing manufacturing, can solve problems such as poor sewing quality, unstable thread speed, and low work efficiency, and achieve the effects of stable thread routing, uniform tension, and improved sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

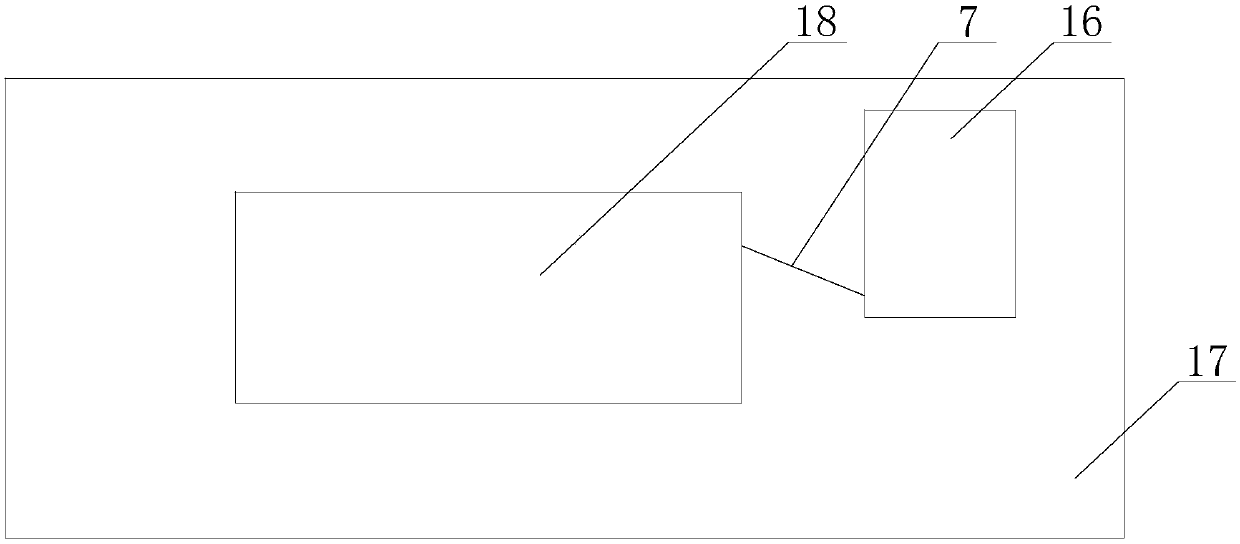

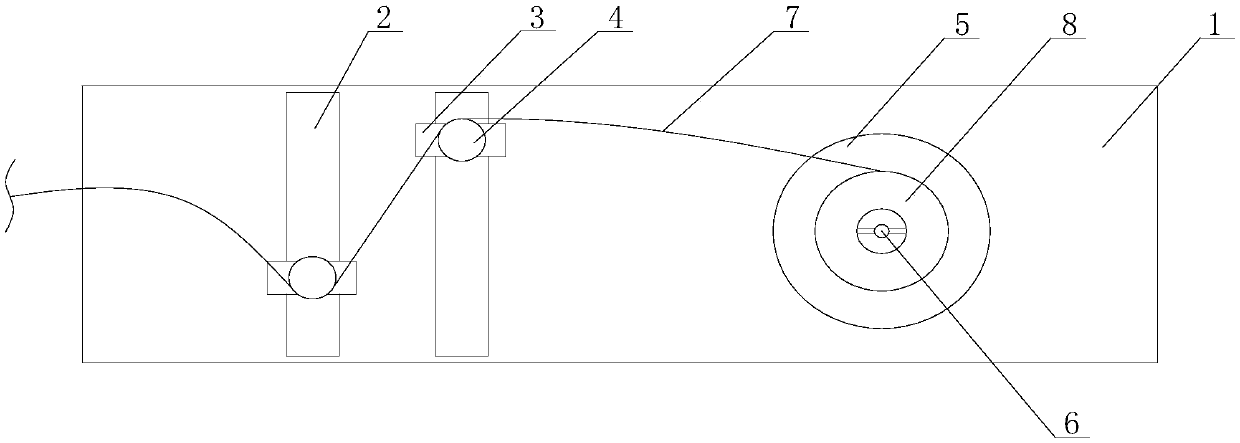

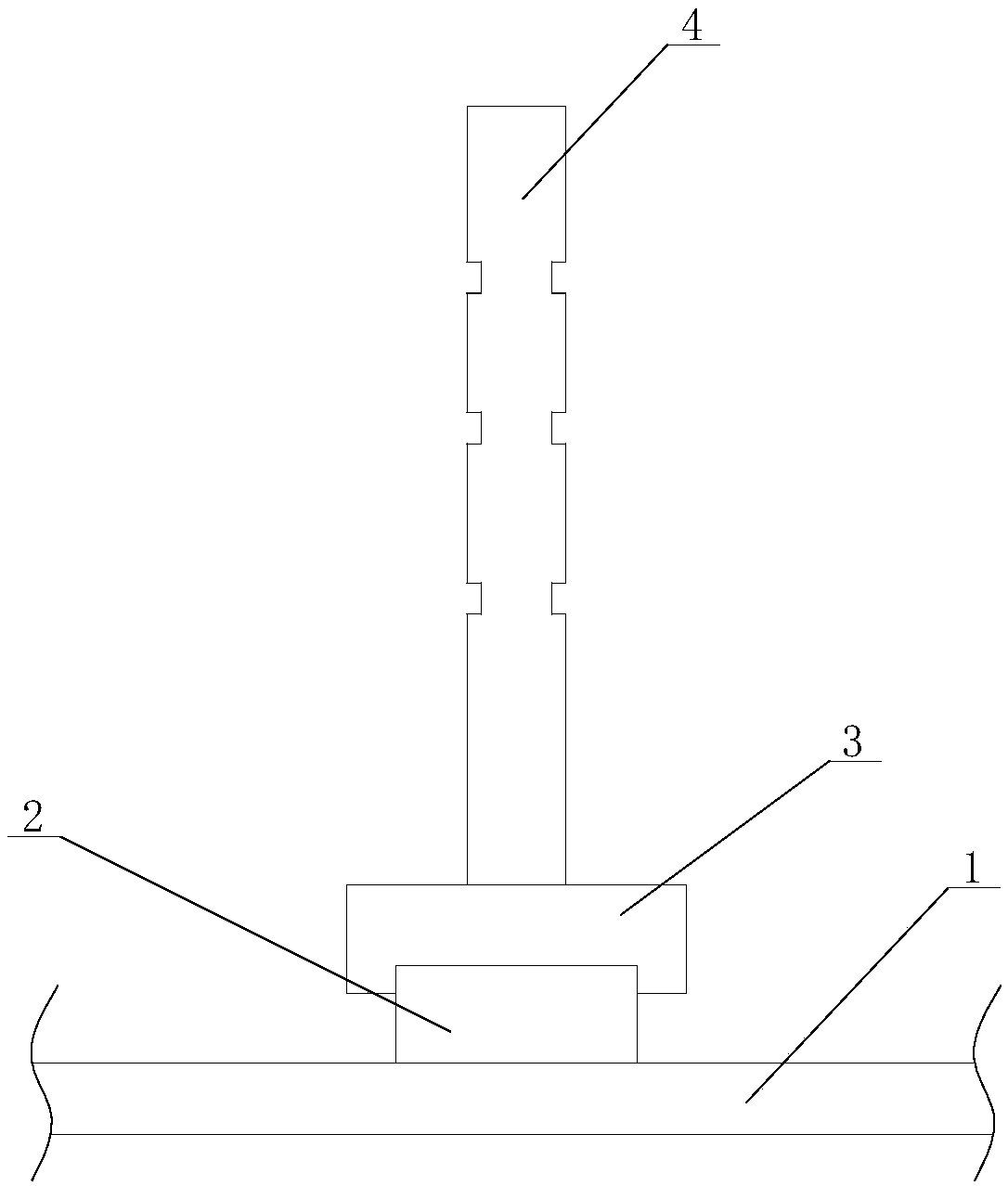

[0032] like Figure 1 to Figure 5 The shown garment sewing equipment includes a workbench 17, on which a sewing machine main body 18 and a threading table 16 are arranged, the threading table 16 includes a base 1, and a coil plate is arranged on the base 1, and the coil plate includes a The disc 5 and the fixed column 6 are provided with a tension adjustment mechanism on the base 1. The tension adjustment mechanism includes two parallel rails 2. A slider 3 matching the rail 2 is installed on the rail 2, and a cylinder is fixed on the slider 3. 4; the cylinder 4 is provided with an annular groove; the annular groove is provided with a rubber layer; the distance between the two rails 2 is 6-12 cm; the fixed column 6 is provided with a number of mounting holes 9 , the mounting hole 9 is provided with an internal thread, and also includes an elastic telescopic mechanism, one end of the elastic telescopic mechanism is provided with an external thread, and the external thread matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com