Six-guide-wheel multi-line cutting machine

A multi-wire cutting machine and guide wheel technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of increasing the diameter of the cutting wire 5, difficult to ensure product quality, and reducing the machining accuracy of workpieces. The effect of smooth wiring, reducing wiring resistance and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

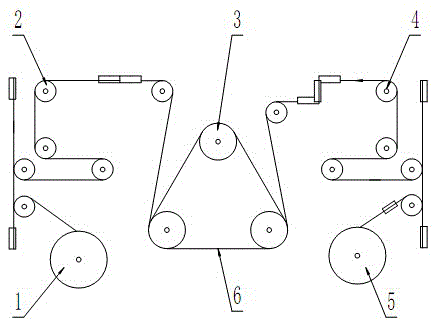

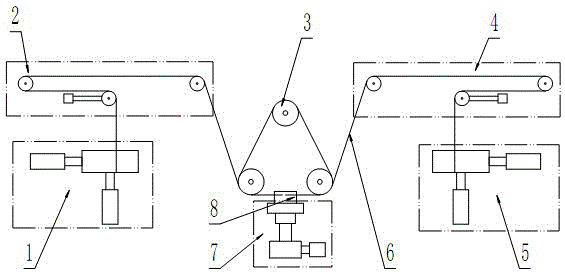

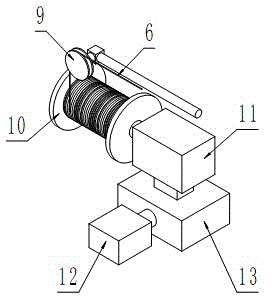

[0016] see figure 2 , the present invention is provided with pay-off roller assembly 1, pay-off guide wheel assembly 2, sheave assembly 3, take-up guide wheel assembly 4, take-up roller assembly 5, cutting line 6 and workbench 7; Said cutting line 6 One end is wound on the pay-off roller assembly 1, which is guided by the pay-off guide wheel assembly 2 and wound on the sheave assembly 3 to form a steel wire mesh, then guided by the take-up guide wheel assembly 4 and wound on the take-up roller assembly 5 Above; the cutting line 6 realizes reciprocating motion under the joint drive of the pay-off roller assembly 1 and the take-up roller assembly 5, the workpiece 8 to be cut is placed on the workbench 7, and the feed of the workpiece 8 is realized by lifting the workbench 7 , which is special in that: the pay-off guide wheel assembly 2 and the take-up guide wheel assembly 4 are symmetrically arranged on the left and right sides of the sheave assembly 3, and are co-located betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com