Template machine

A template machine and frame technology, which is applied in the direction of cloth pressing mechanism, sewing machine components, textiles and papermaking, etc. It can solve the problems that are difficult to achieve systematization, achieve beautiful stitches, smooth thread routing, and reduce difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

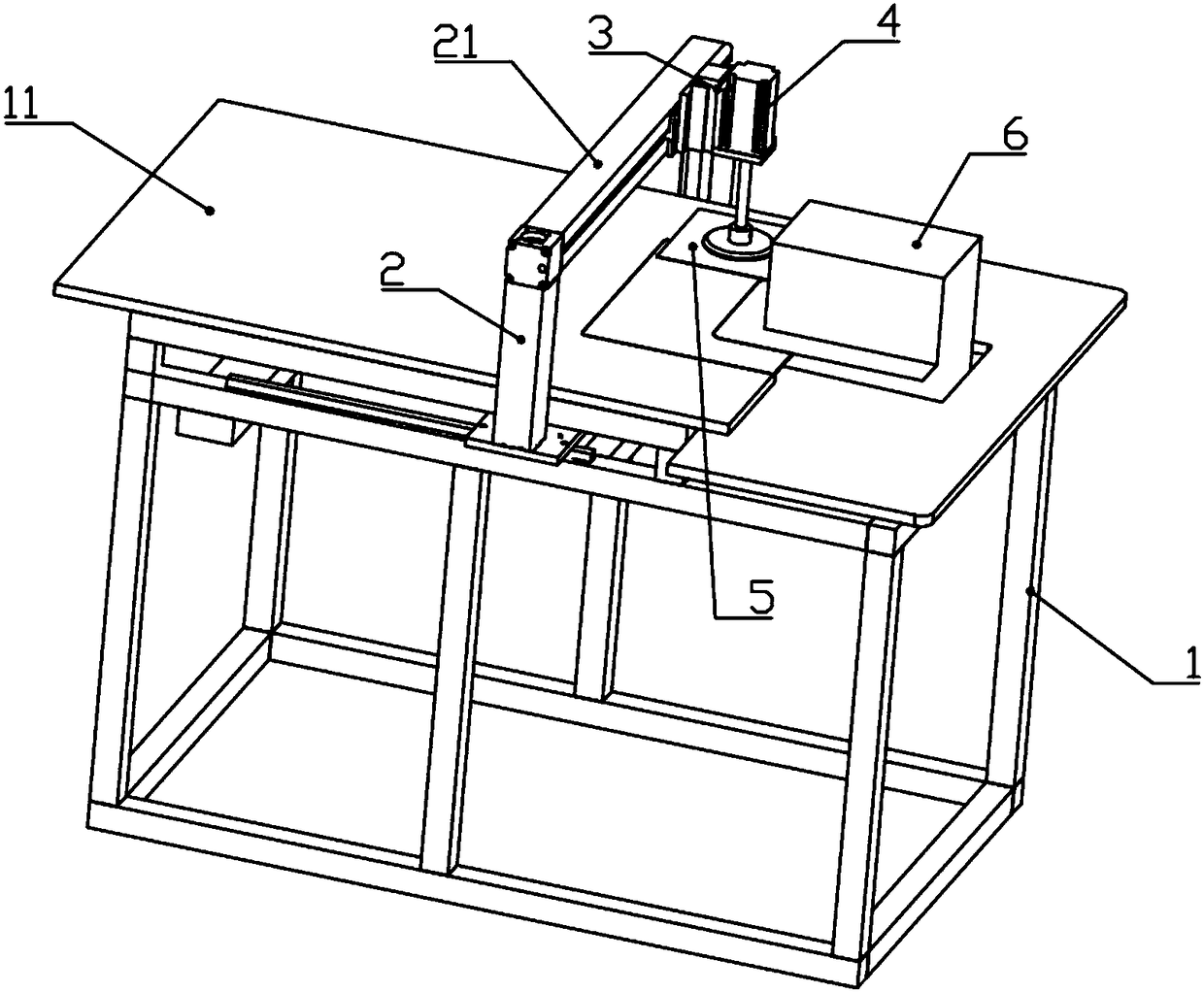

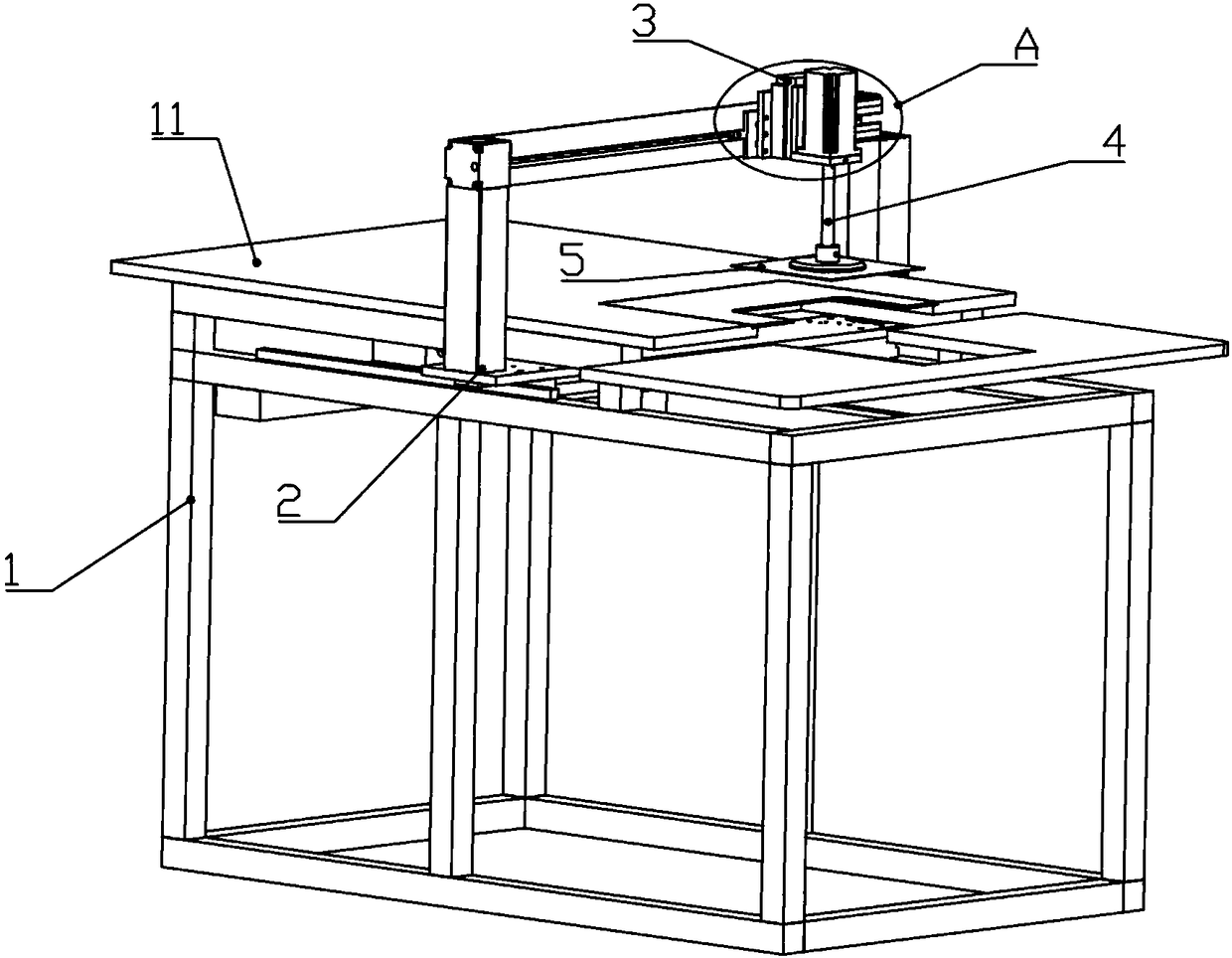

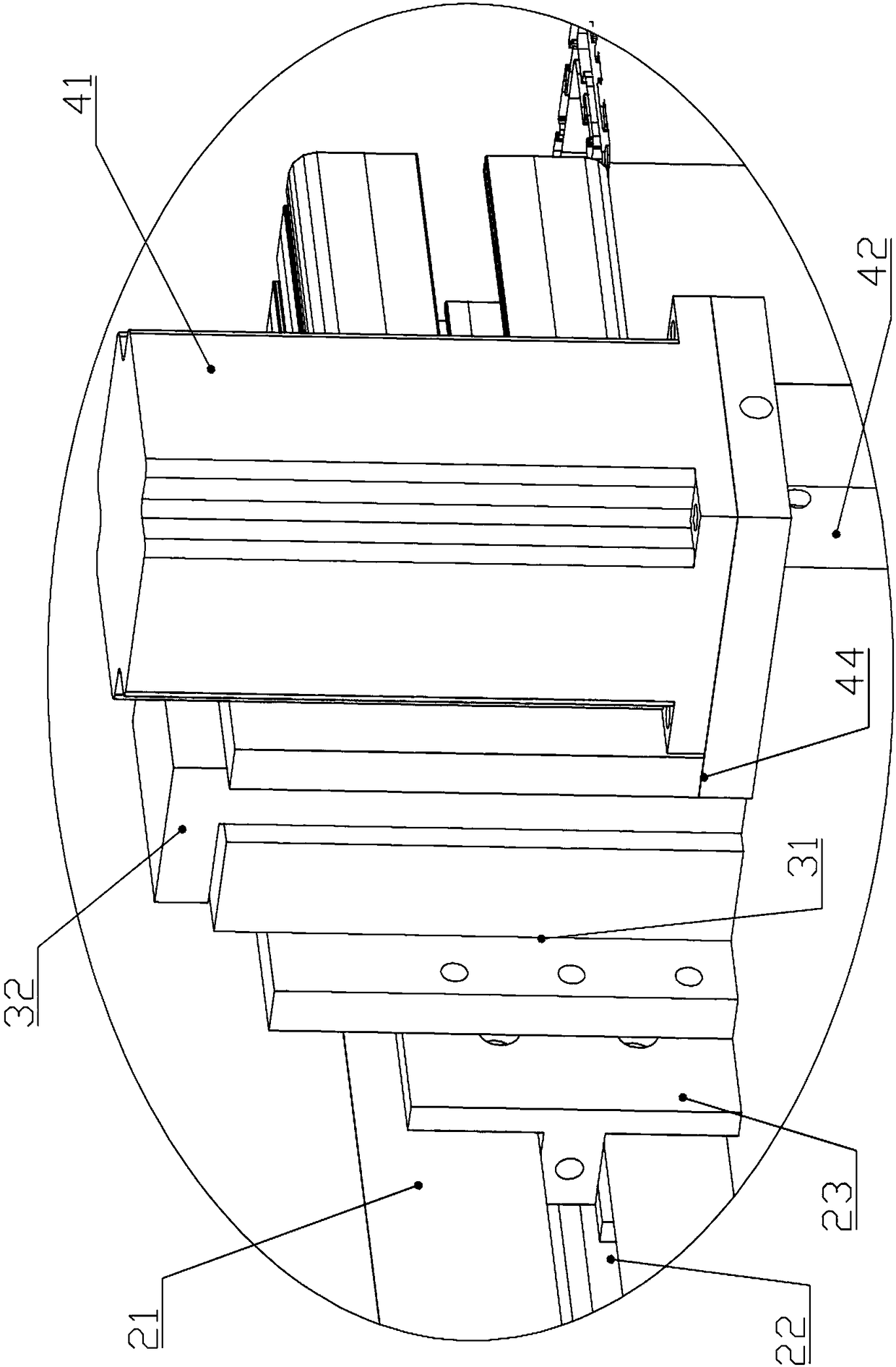

[0033] Embodiment one: if Figure 1-8 As shown, a template machine includes a frame 1, a sewing machine 6 and a sewing table 11 are arranged on the frame 1, and a sewing feeding system is arranged on one side of the sewing machine 6; the sewing feeding system includes a movable The plane feeding mechanism 2 arranged on the seam table 11, the plane feeding mechanism 2 is provided with a pressing device 5 vertically downward through the lifting device 3 and the steering device 4, and the pressing device 5 is provided with a pressing device. The device is used to clamp the cloth so that the cloth can move on the sewing table 11 with the plane feeding mechanism 2 and rotate on the sewing table 11 with the steering device 4 and cooperate with the sewing machine 6 to carry out sewing operations.

[0034] The patent of the present invention specifically provides a highly versatile feeding system for sewing equipment. Through such a feeding system, the current problems of complicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com