Patents

Literature

44results about How to "Beautiful stitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

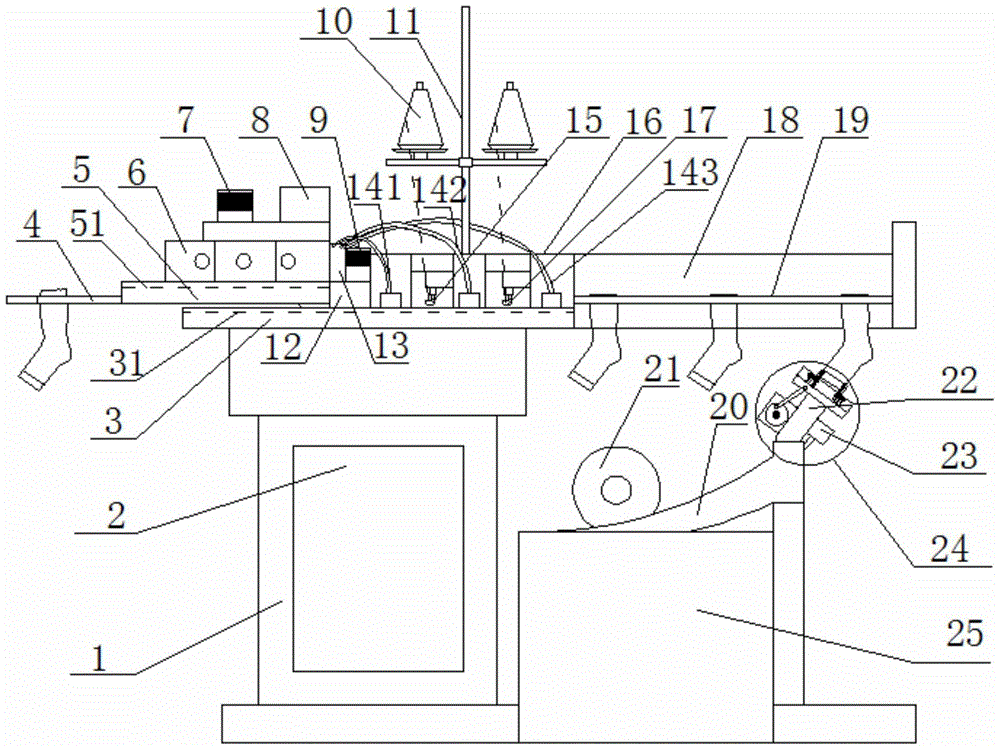

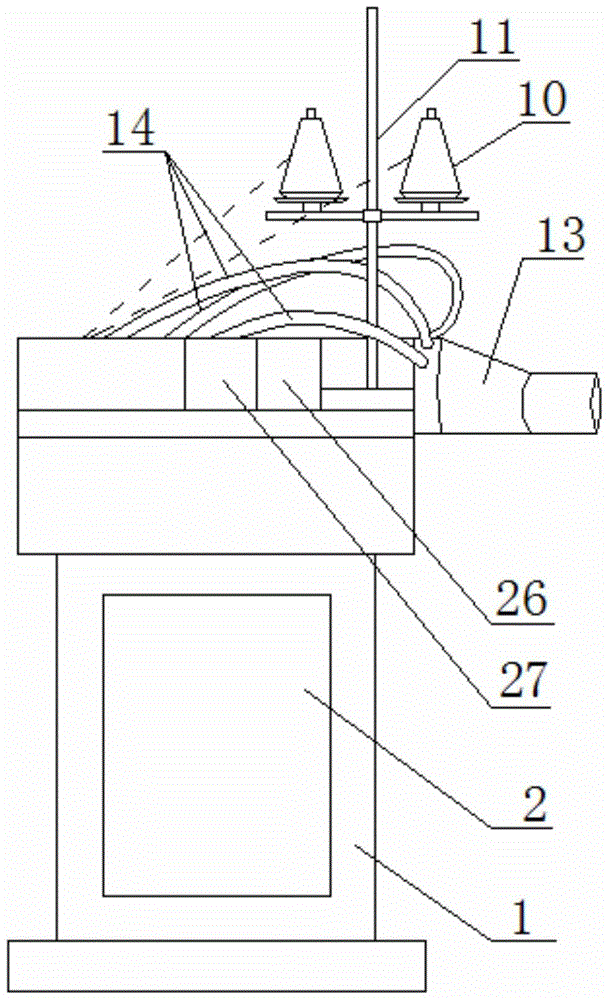

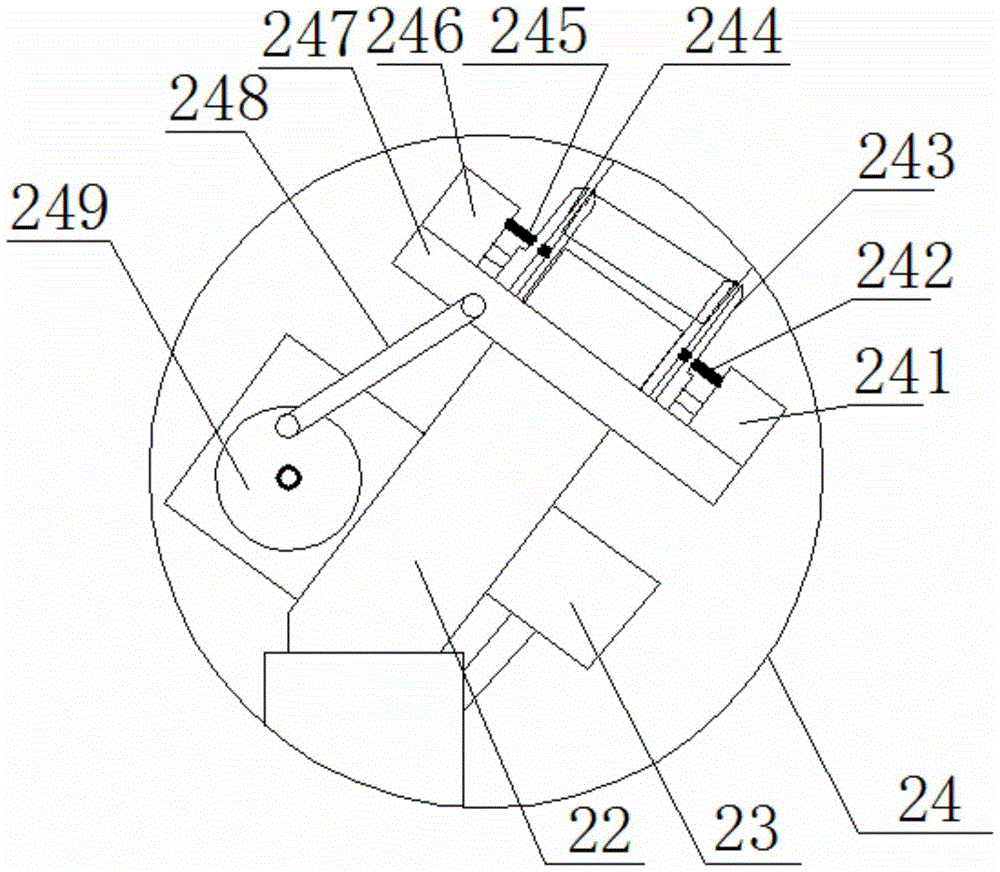

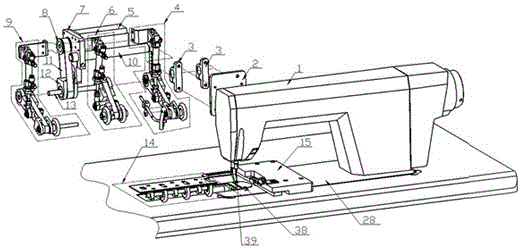

Sock production device

ActiveCN104233634ARealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

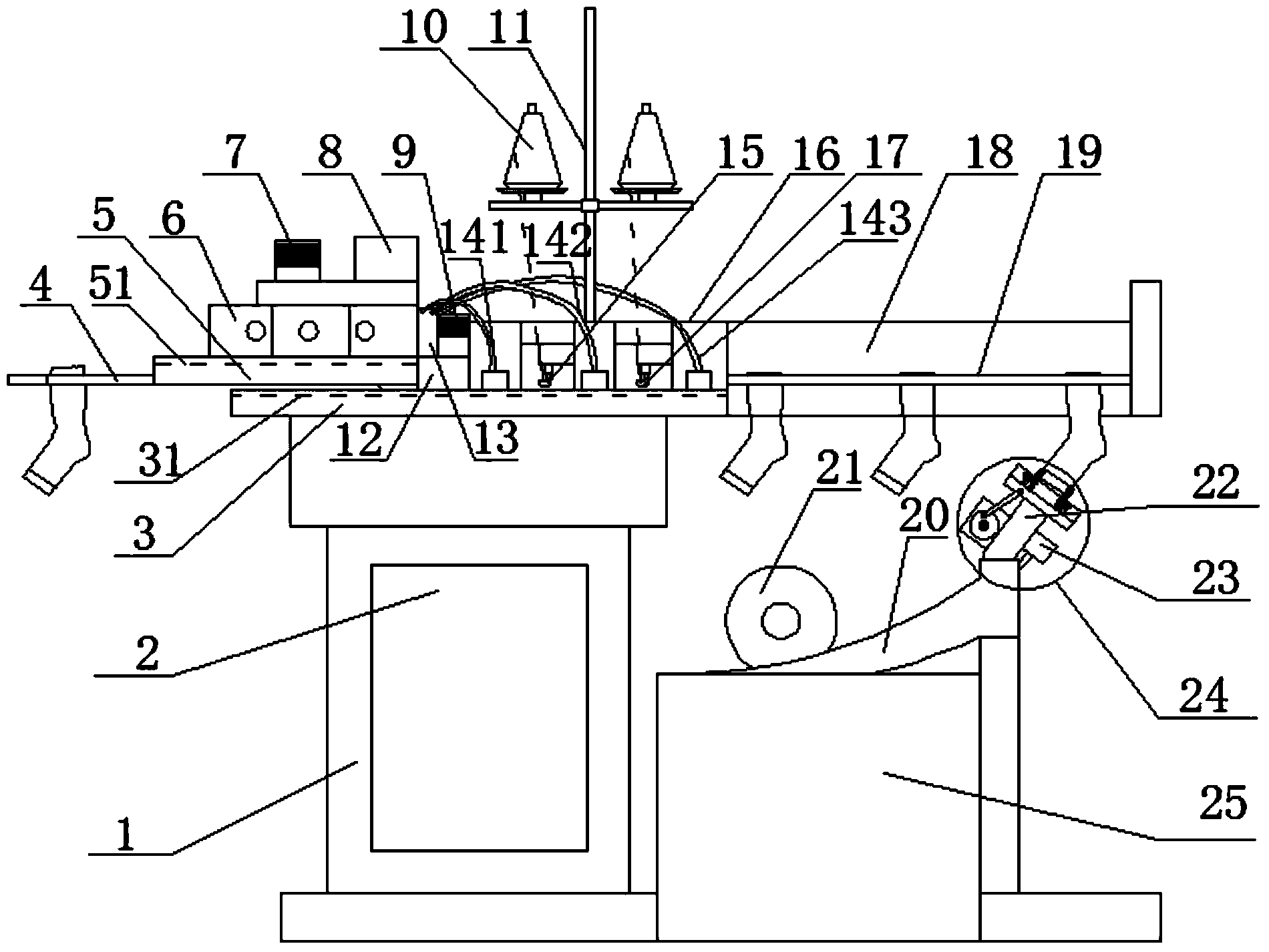

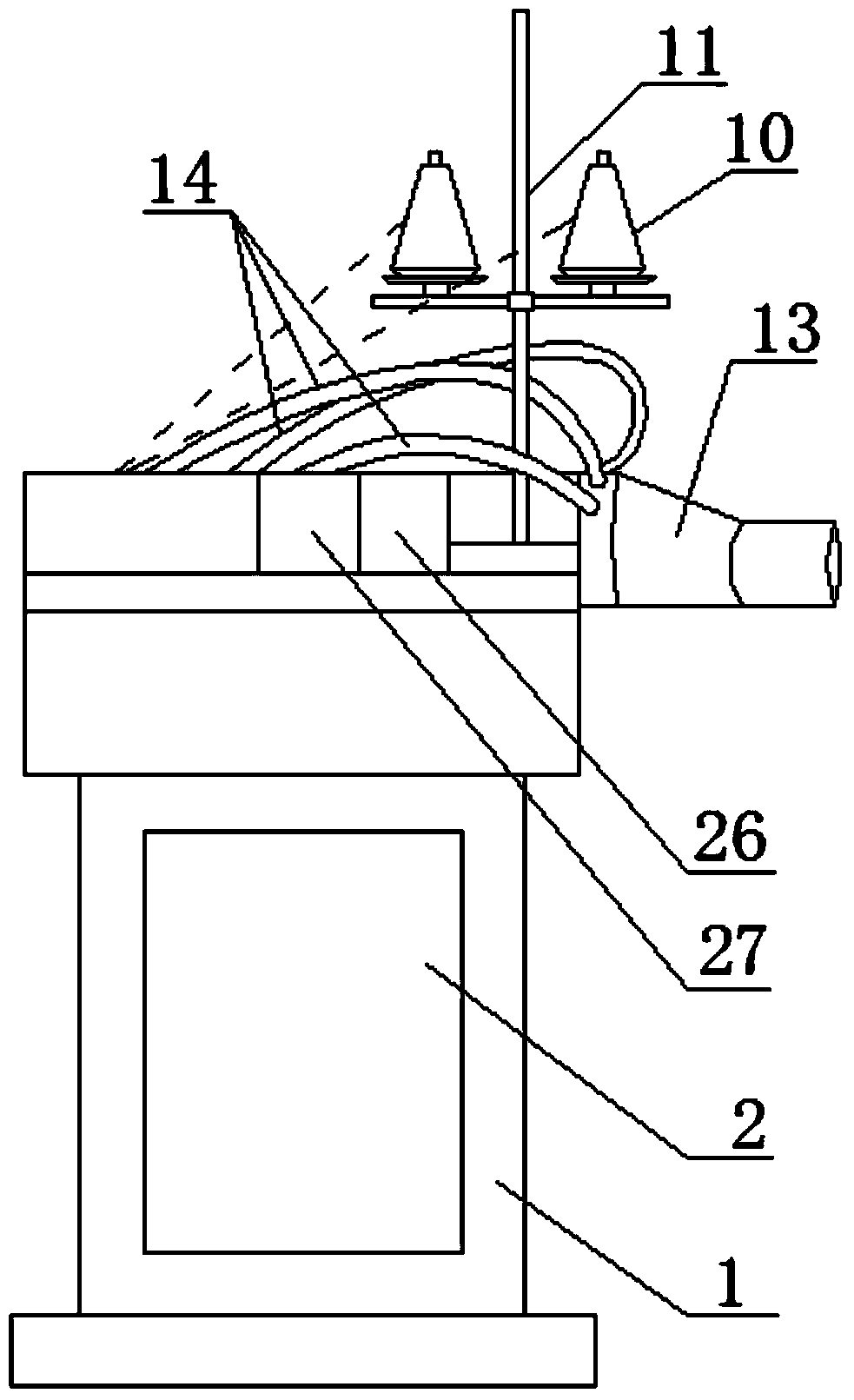

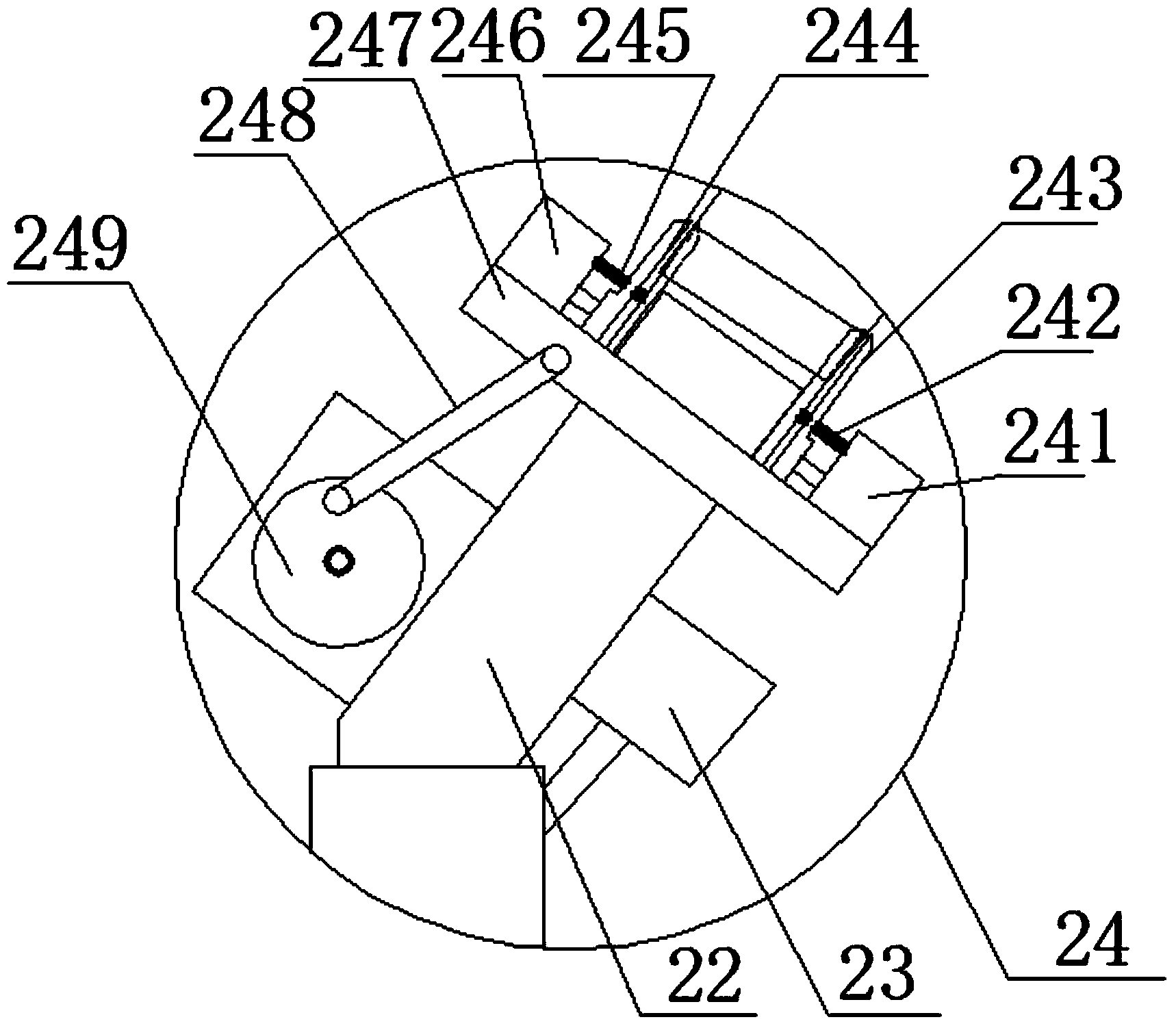

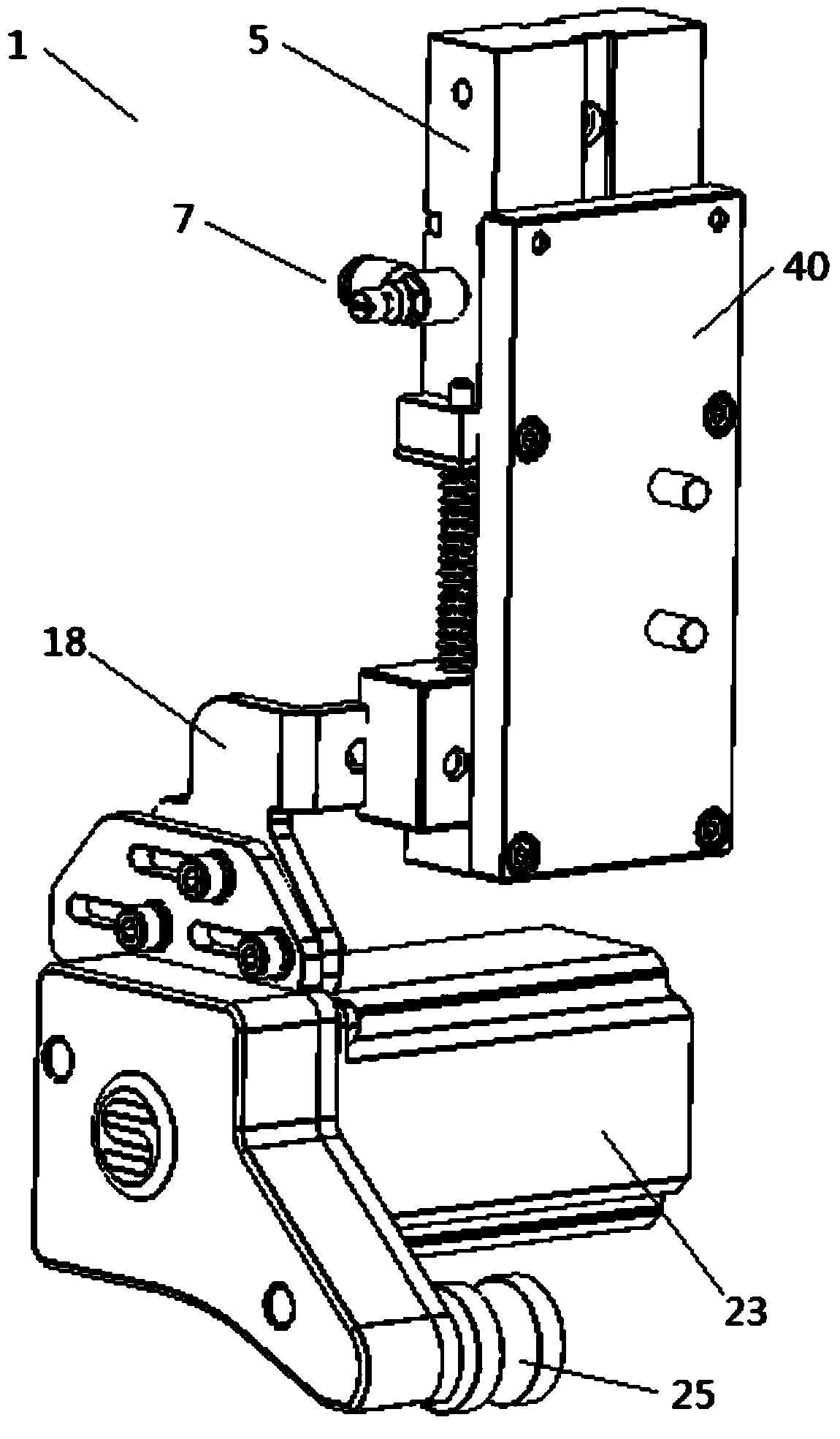

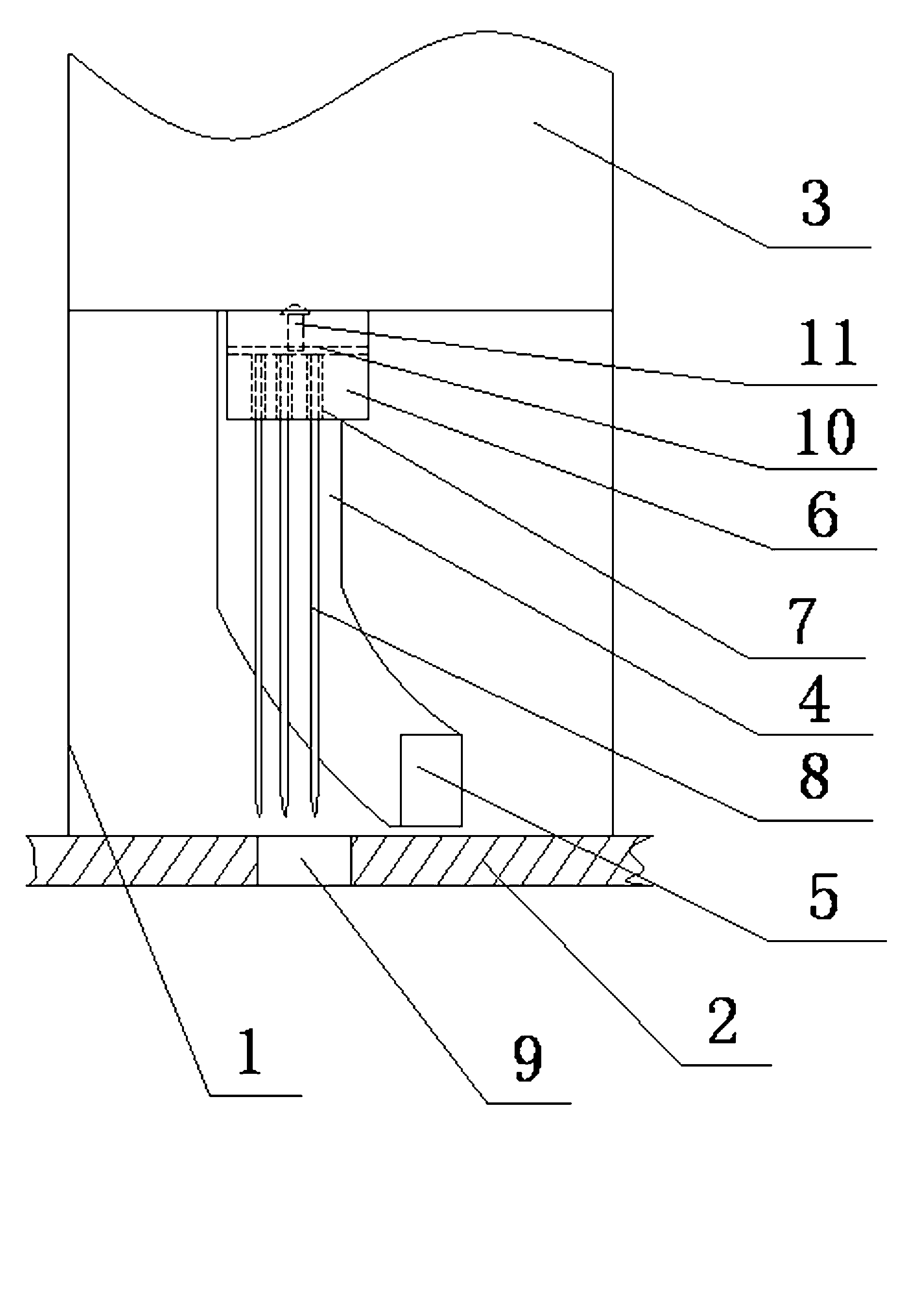

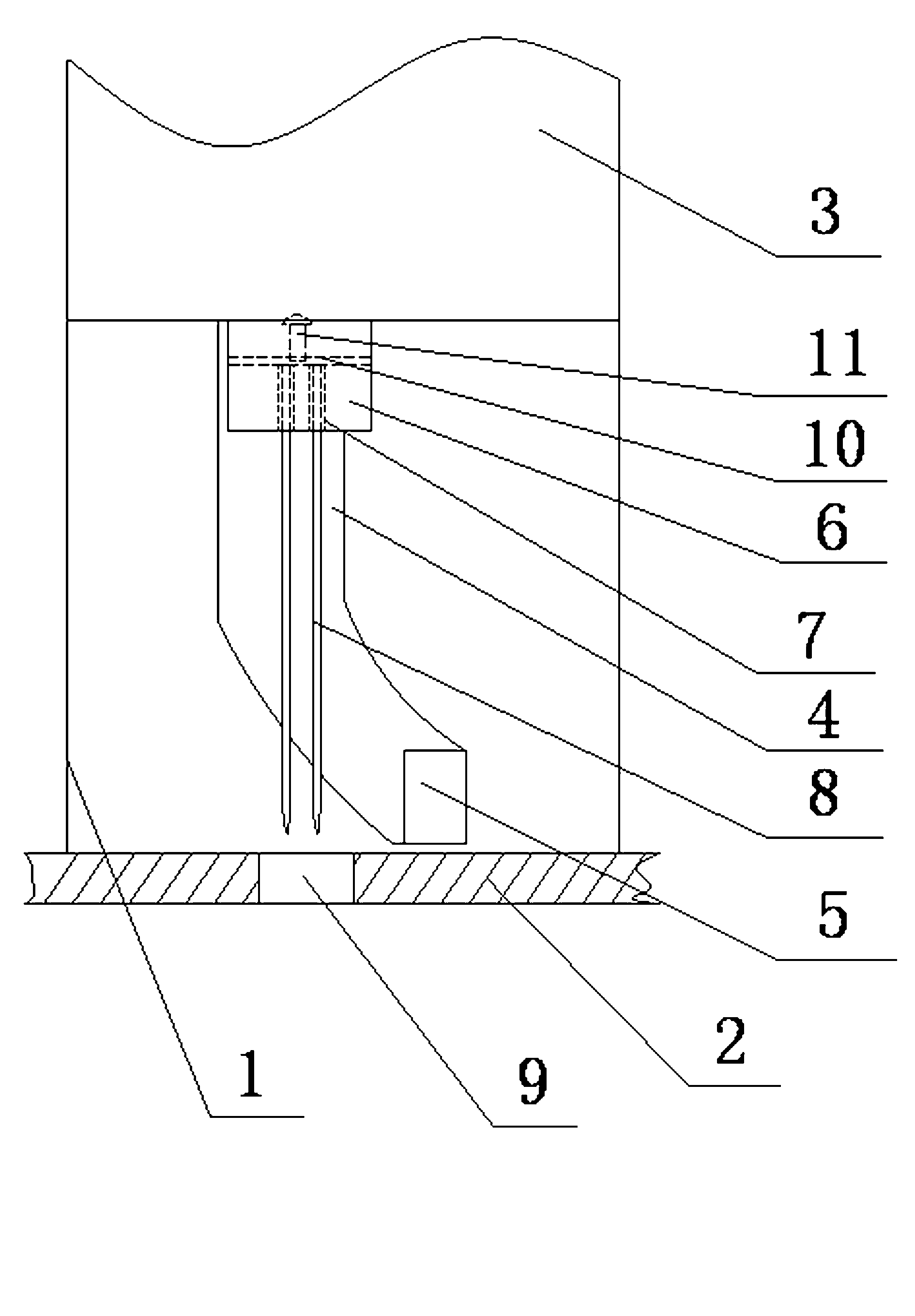

The invention discloses a sock production device. The sock production device comprises a rack, a feeding device, a waste material recovery device, a sewing box, a discharging device and a sock turning device, wherein the feeding device comprises a guide rail, a guiding frame, a guiding box, a feeding box and a first electric motor component; the waste material recovery device comprises a negative air pressure pumping device and a pipeline, the negative air pressure pumping device is arranged on the rack, and one end of the pipeline is connected to the negative air pressure pumping device; the sewing box is fixedly arranged on the rack and is sequentially and fixedly provided with a first sewing head and a second sewing head from left to right; the right end of the rack is fixedly provided with the discharging device, the discharging device is provided with a discharging guide rail, the lower part of the discharging guide rail is provided with a sock guiding pipe, and the sock guiding pipe is provided with the sock turning device. According to the sock production device disclosed by the invention, socks can be automatically turned after the socks are sewed when a seam of a sock point is completely sewed, meanwhile, the situation that waster materials which are generated by the first sewing head, the second sewing head and a sock point cutting mechanism can be collected is realized, the automation degree is high, the working efficiency is increased, and the labor cost is reduced.

Owner:浙江圣邦化纤针织有限公司

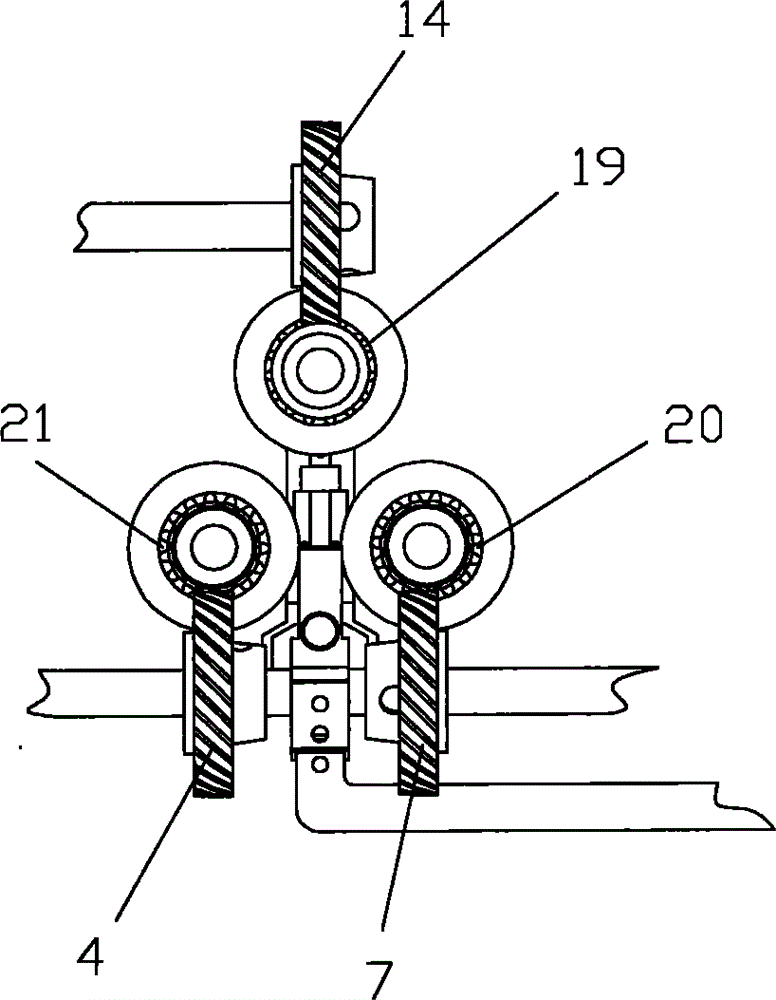

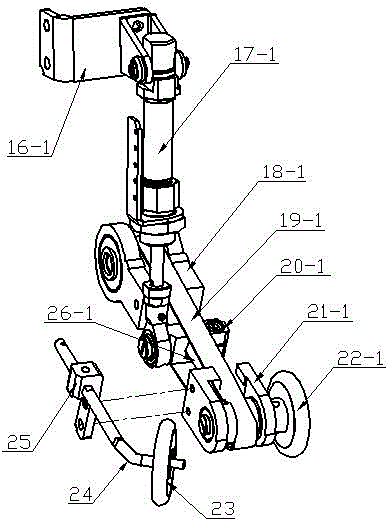

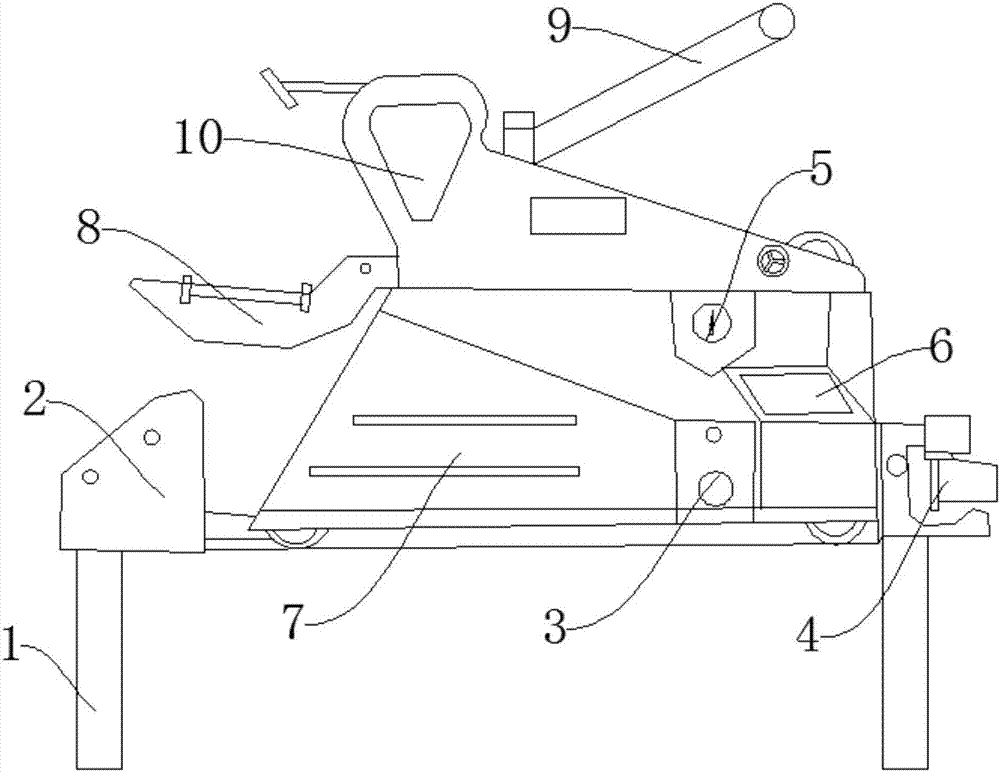

Full-automatic cloth dragging machine

InactiveCN103938373ASimple structureReduce manufacturing costSewing-machine control devicesControl unitProcess requirements

A full-automatic cloth dragging machine comprises a main body, a monitoring unit and a control unit. The main body comprises a cloth dragging wheel, a driving mechanism, a pressing foot lifting mechanism and a position regulating mechanism. The control unit controls and regulates operation of the driving mechanism according to main machine sewing speed monitored through the monitoring unit so as to control and regulation rotation of the cloth dragging wheel. The full-automatic cloth dragging machine can meet the modern sewing process requirements, is high in work efficiency, can guarantee quality of sewn products, and is simple in overall structure, good in stability, attractive in stitch and wide in application.

Owner:乐清智博缝纫机有限公司

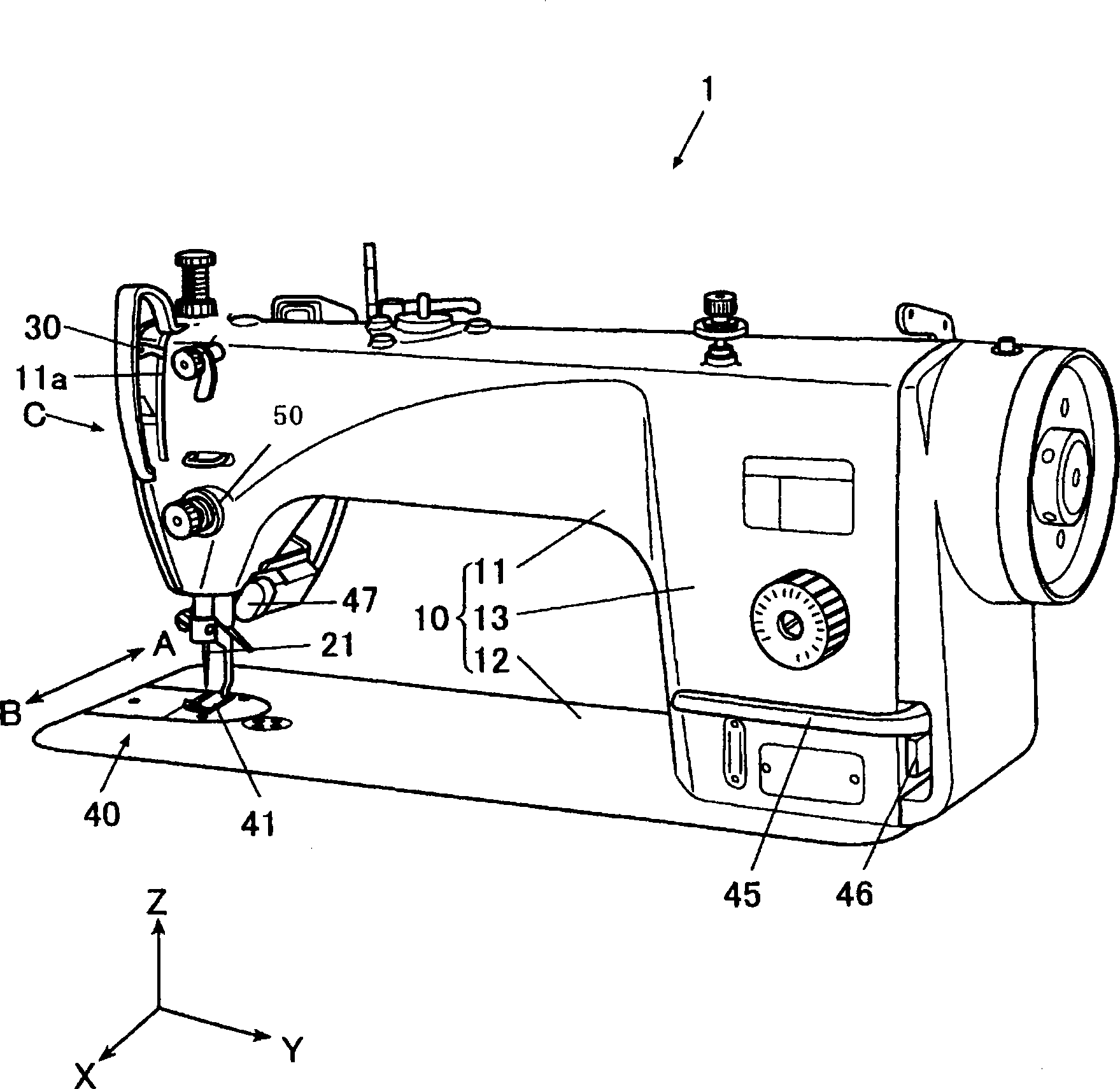

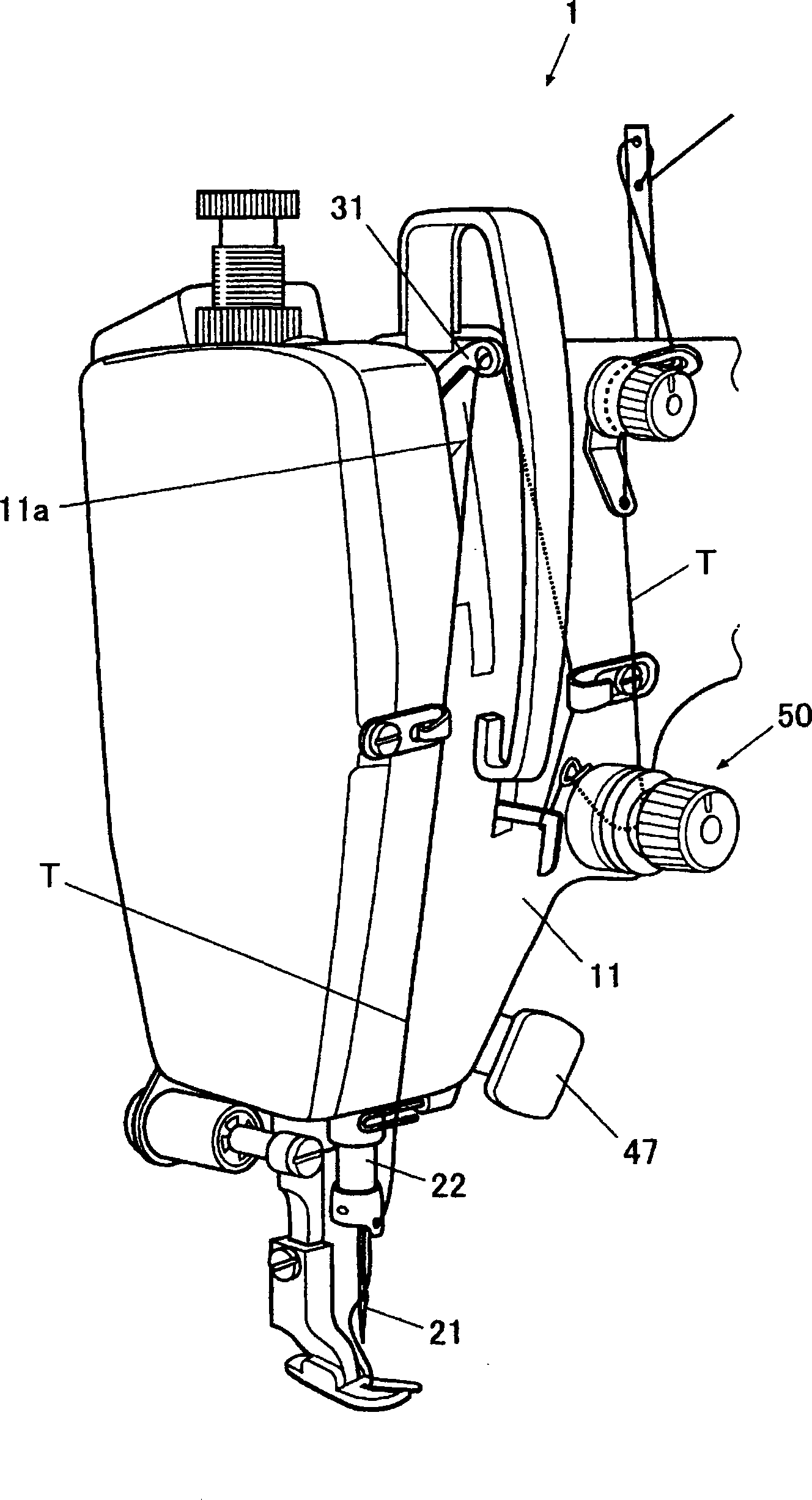

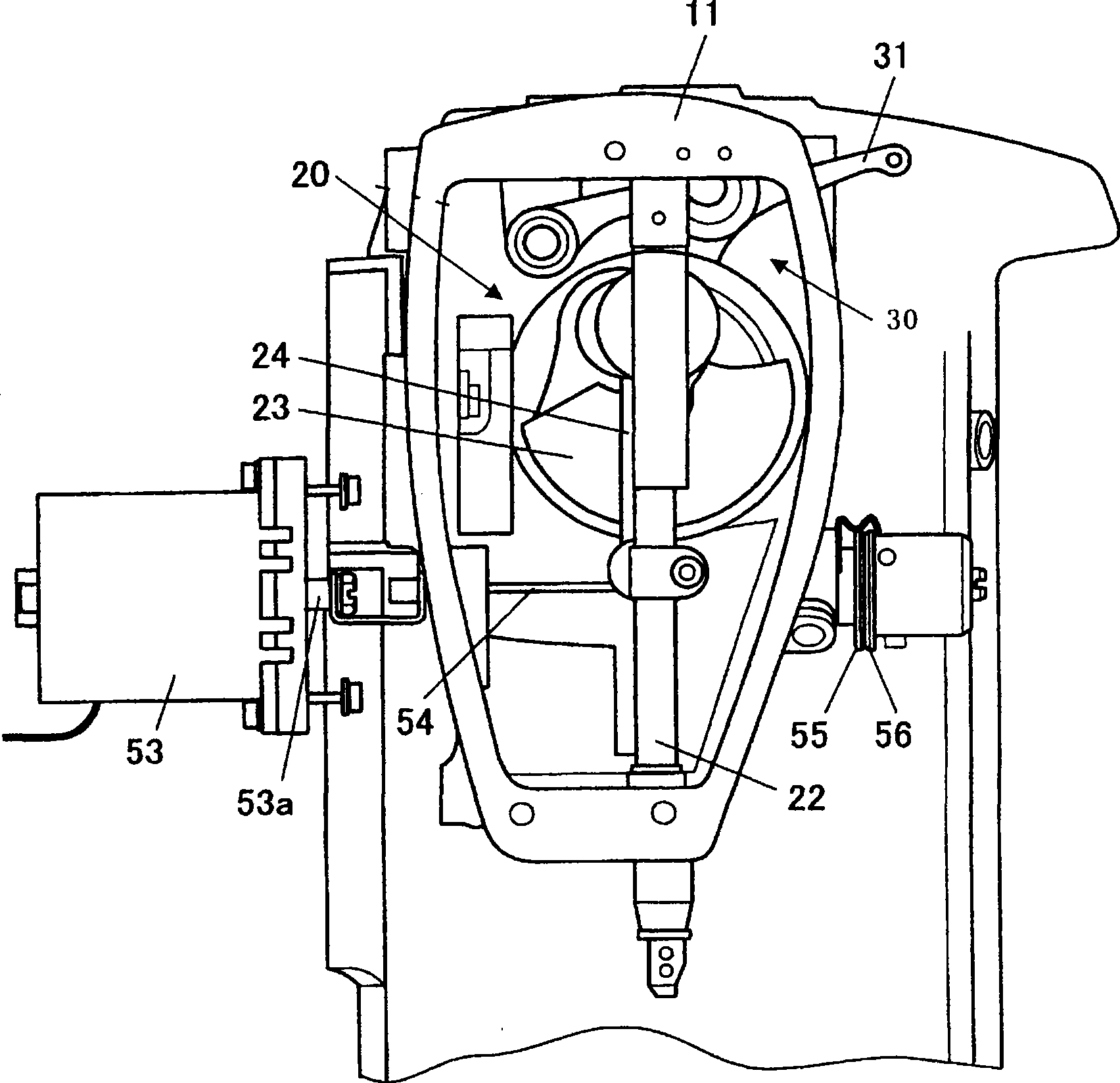

Sewing machine

InactiveCN101377038APrevent knotted stitchesBeautiful stitchesTensioning devicesElectrical and Electronics engineeringSewing machine

The invention provides a sewing machine which applies a proper thread tensile force no mater what the cloth feeding direction is. A feeding switching detection sensor (46) is set to detecting whether the cloth feeding direction switches from forward to backward by the operation of the returning operation bar (45). The controlling unit (100) works according to the detection signal from the feeding switching detection sensor (46) and a touch auxiliary switch (47), while the feeding direction is detected to switched from forward to backward, the controlling unit (100) reduces the thread tensile force automatically by a thread adjusting solenoid (53); Thus, knotted stitch is prevented from being created in backward feeding switching. Consequently, pretty stitches can be achieved.

Owner:JUKI CORP

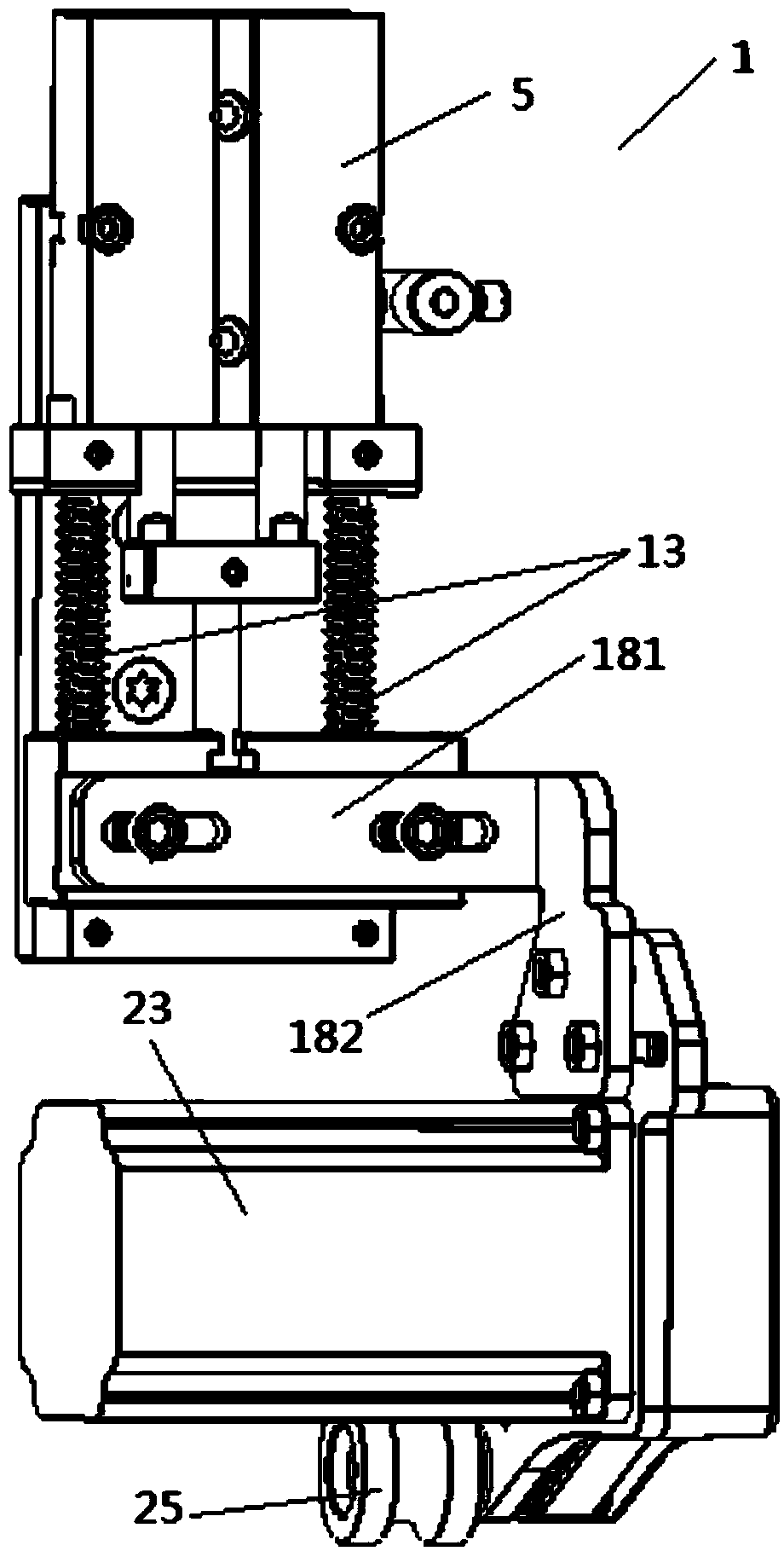

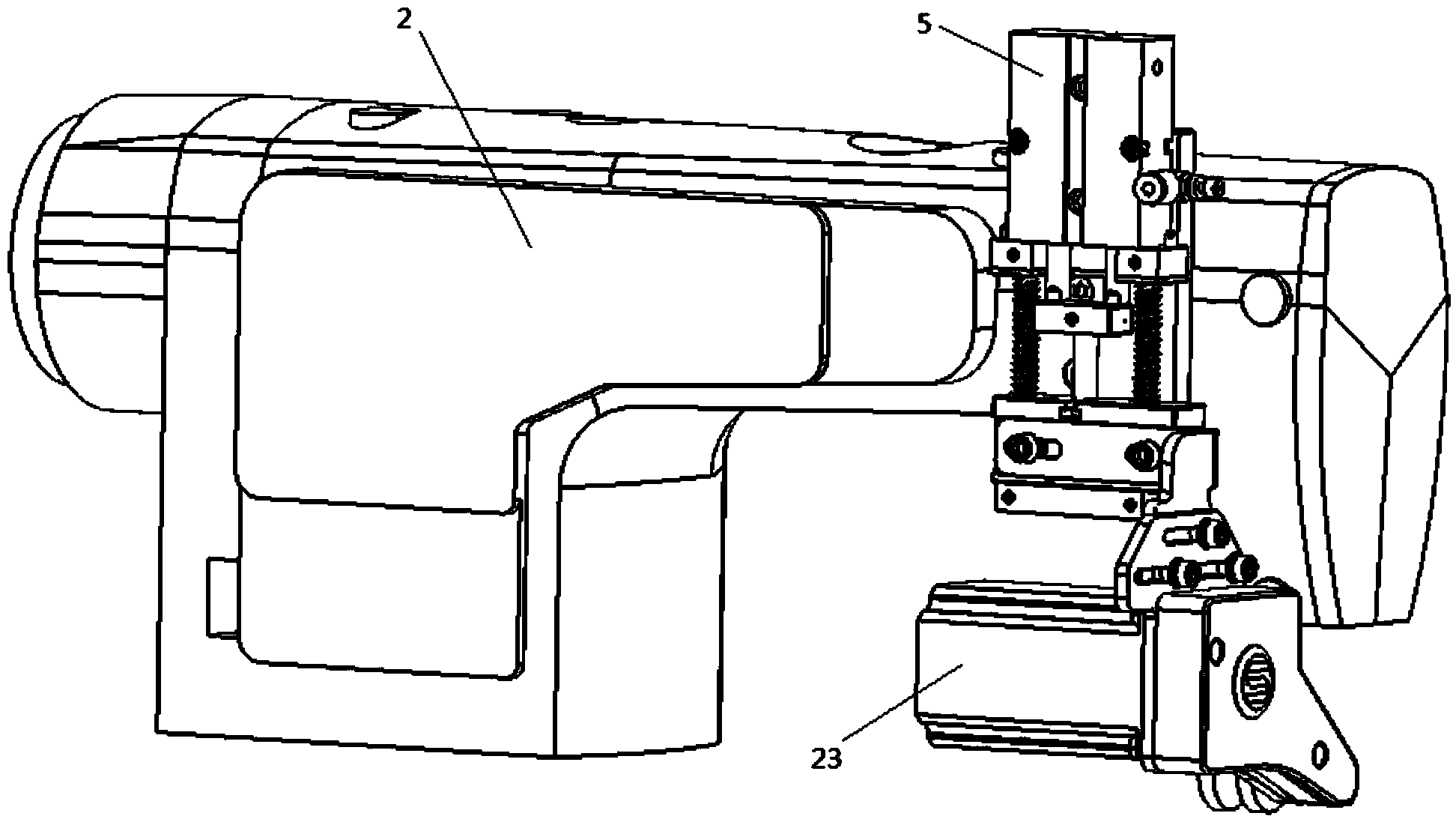

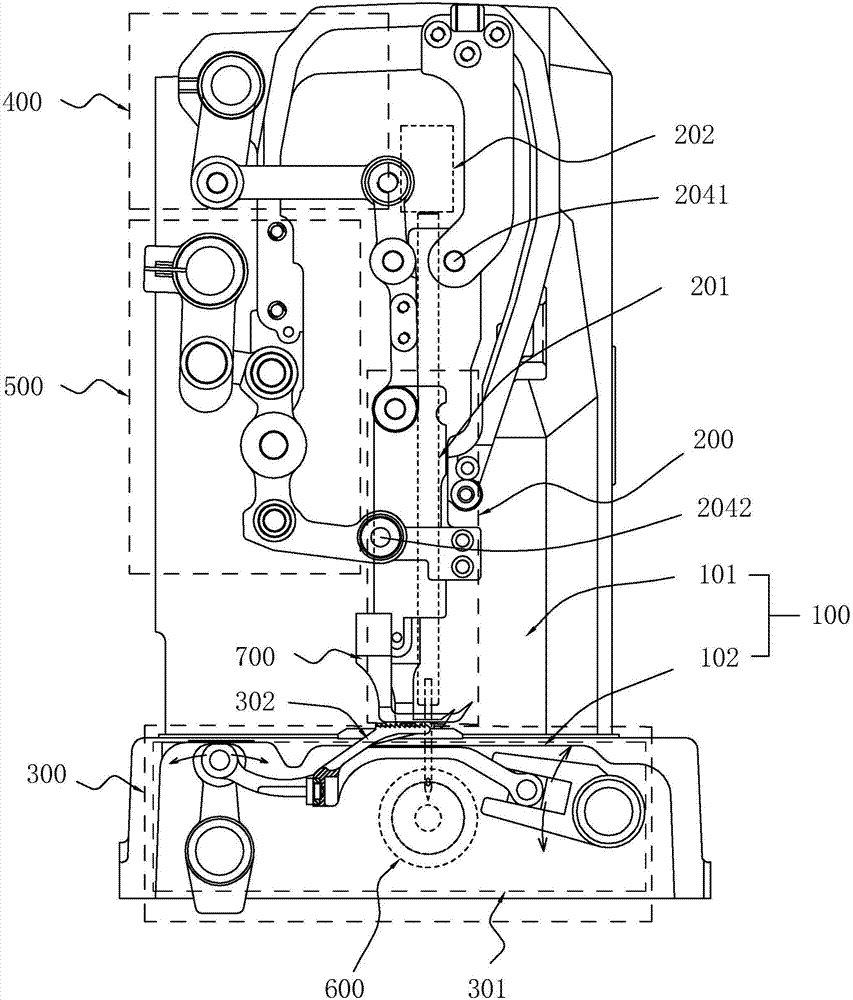

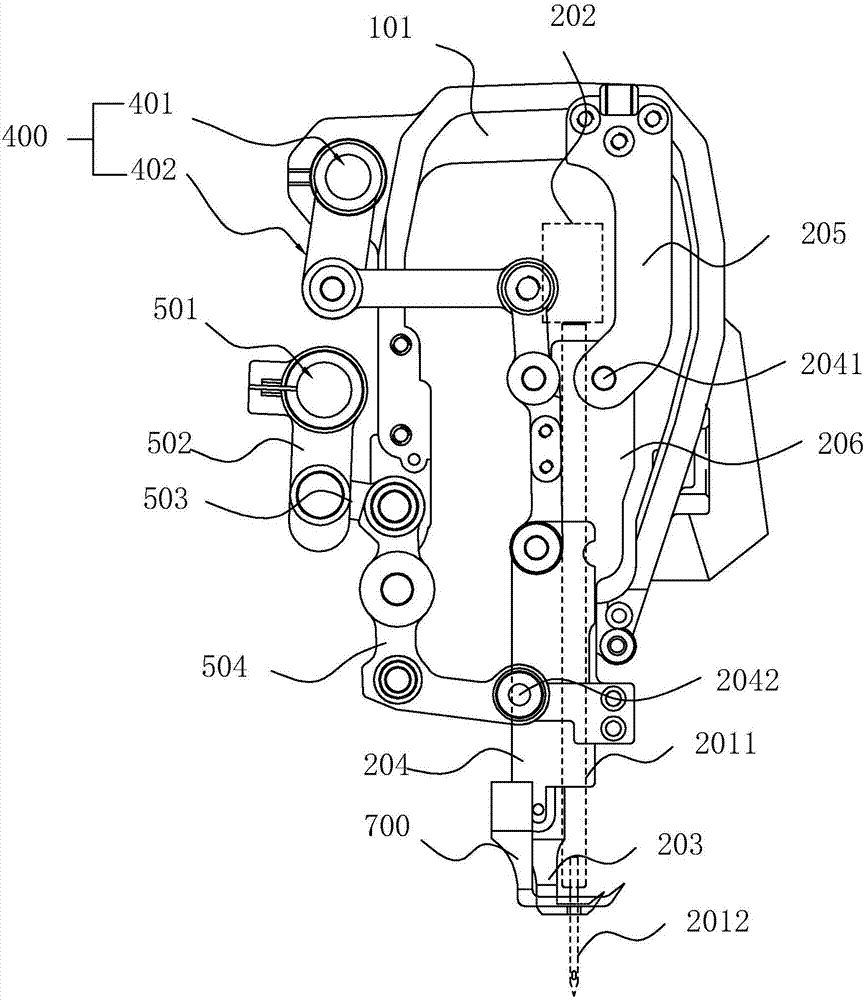

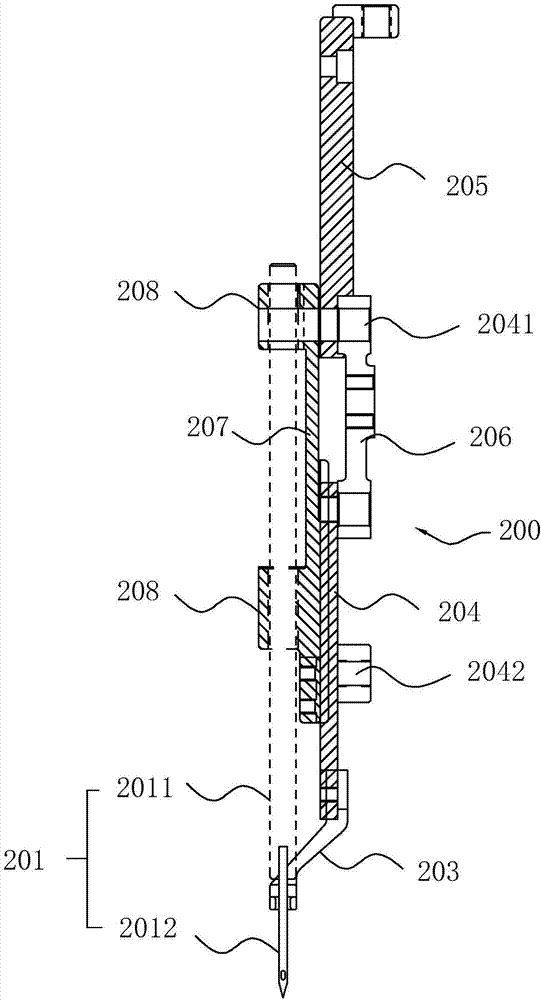

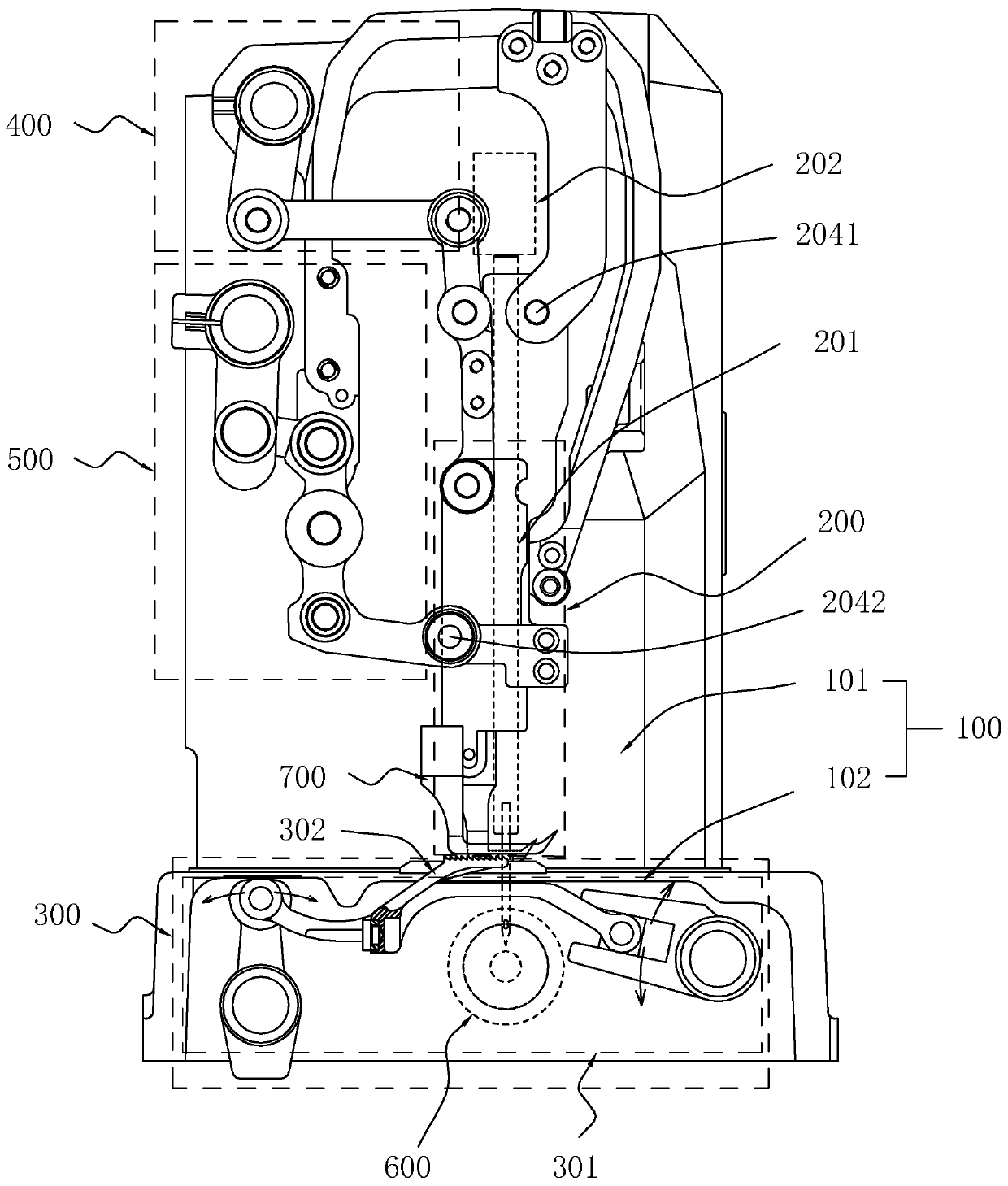

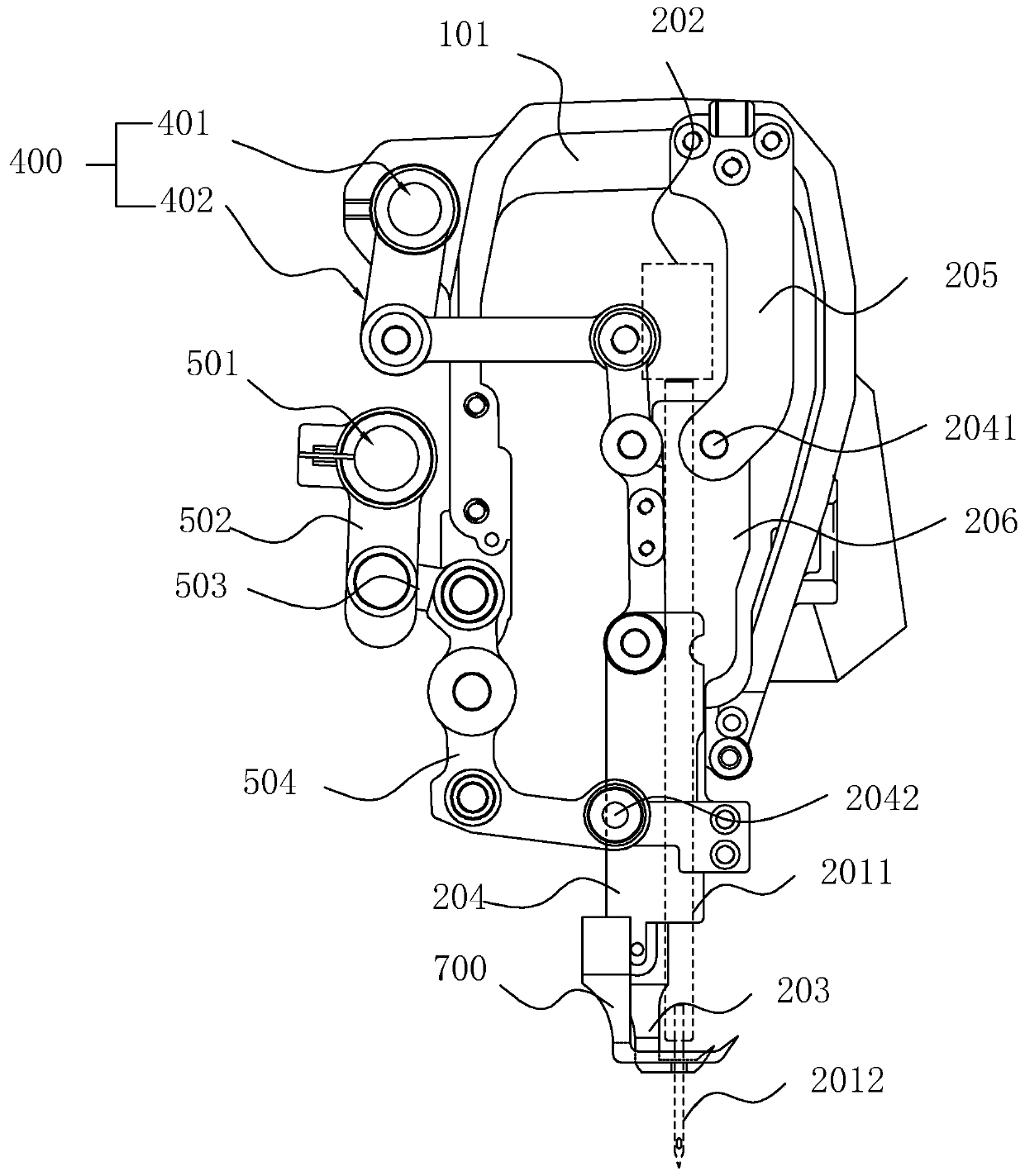

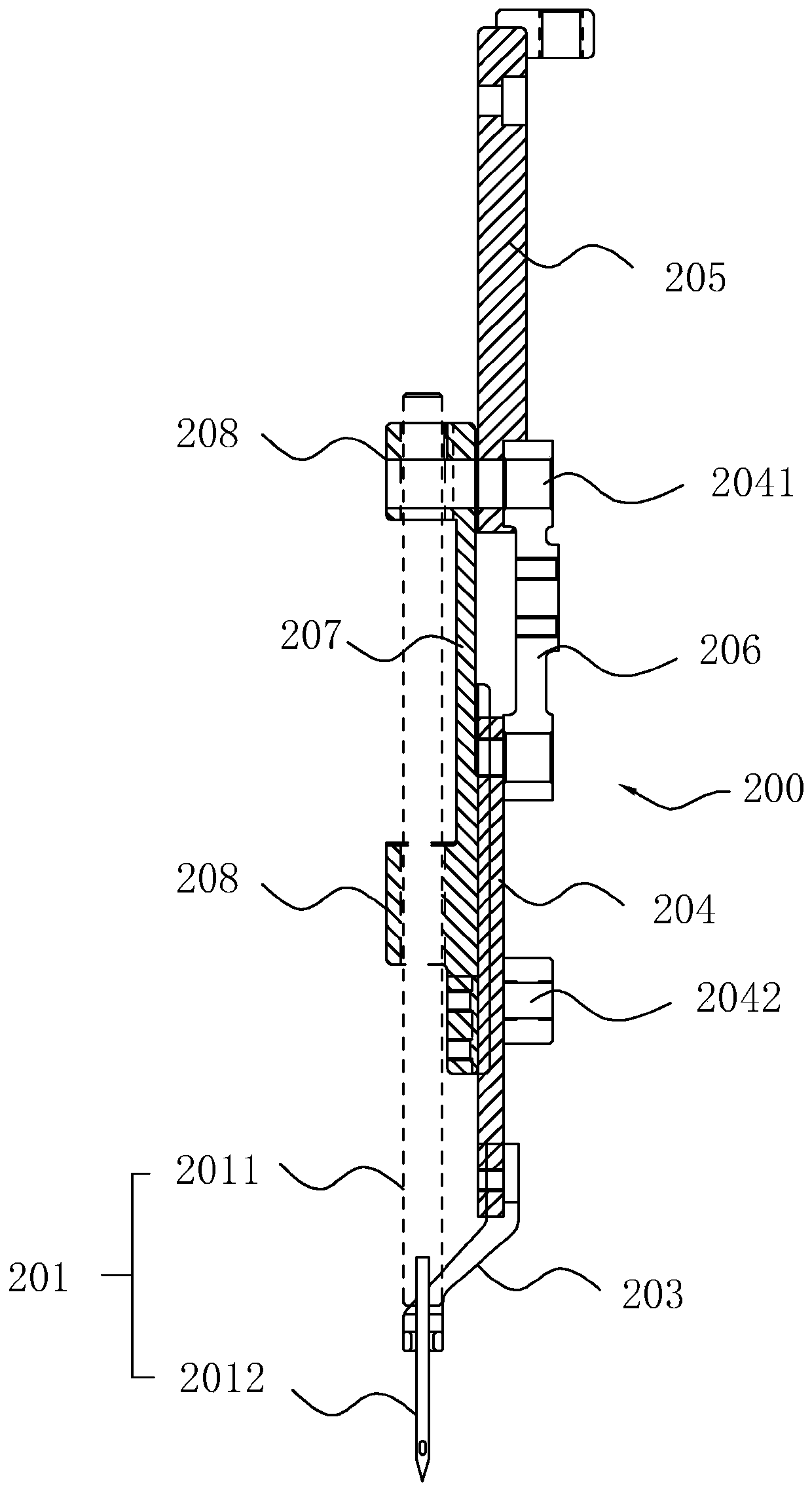

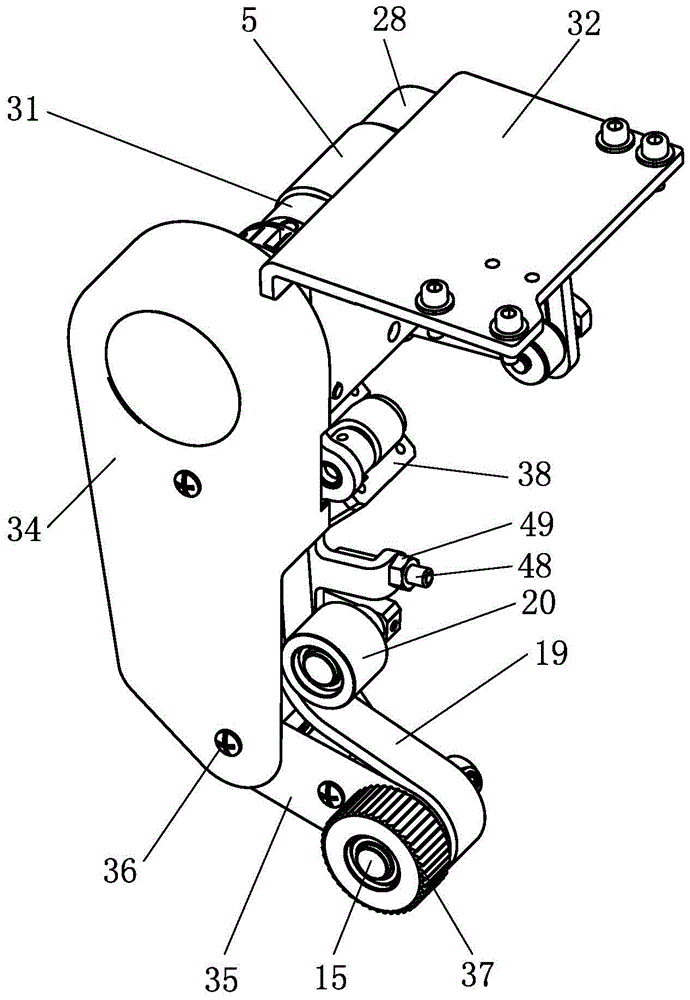

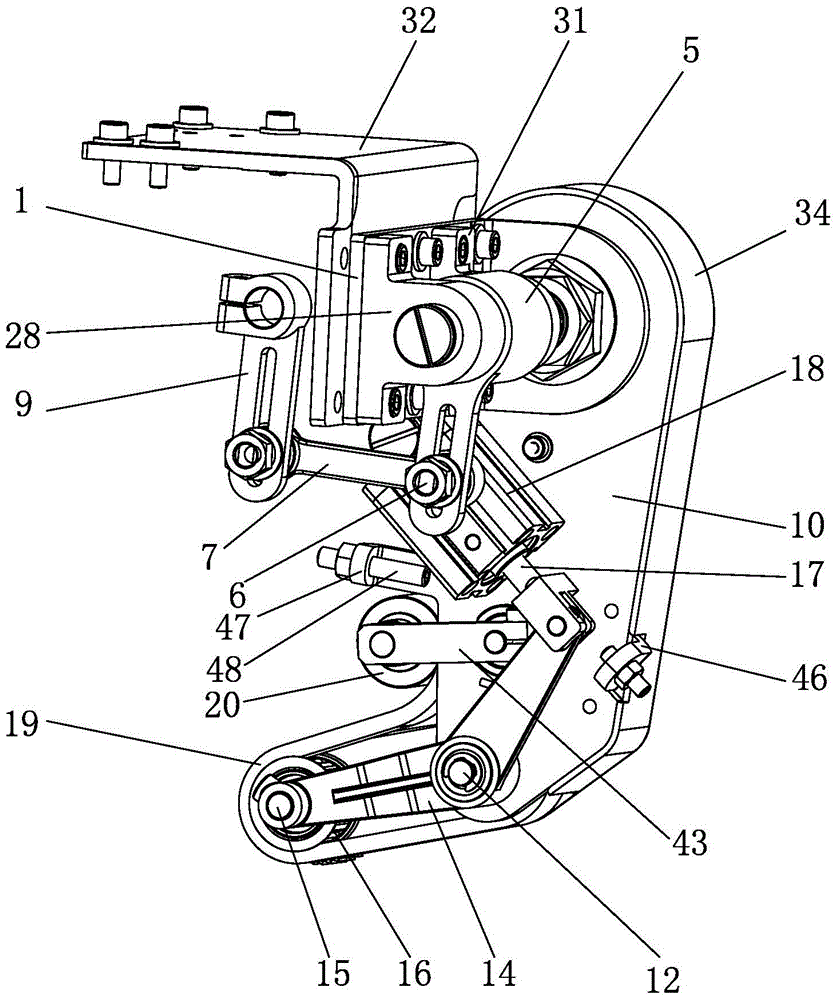

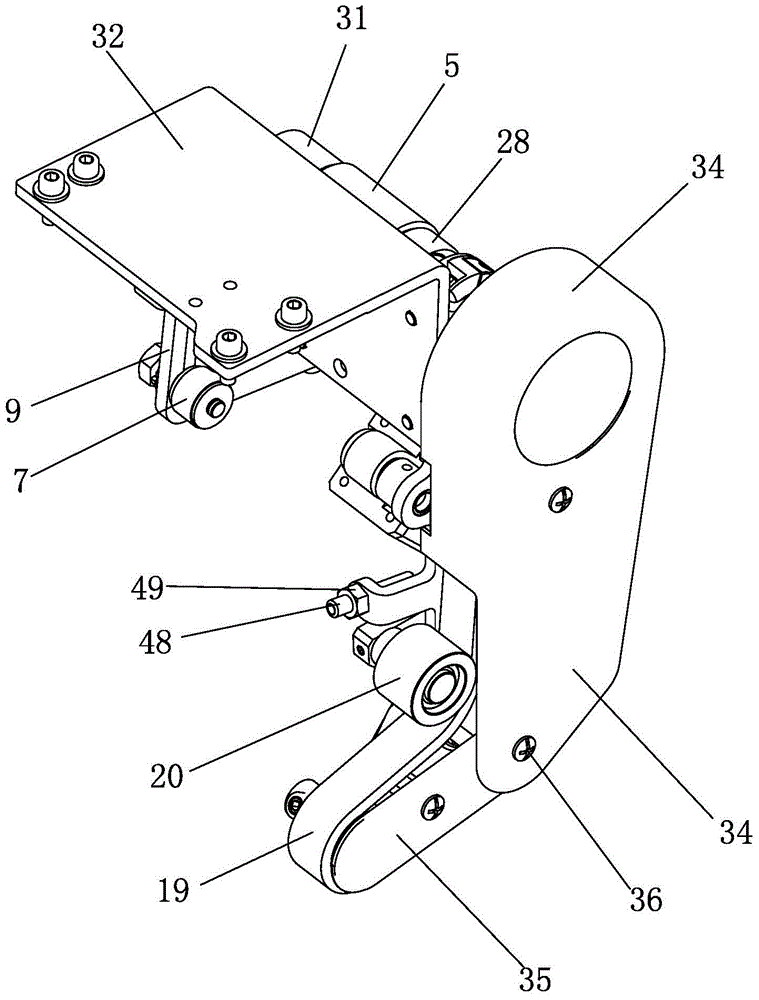

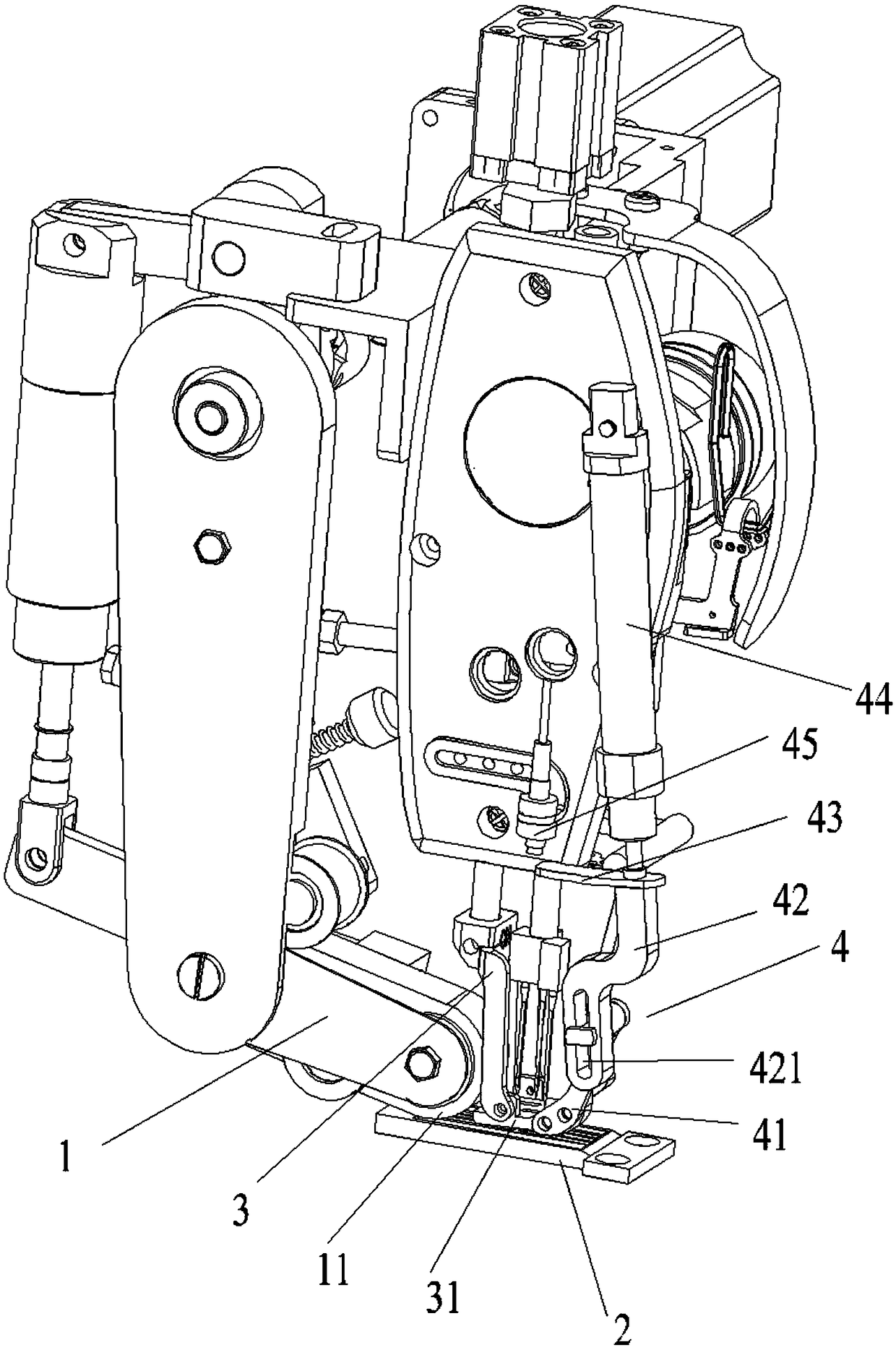

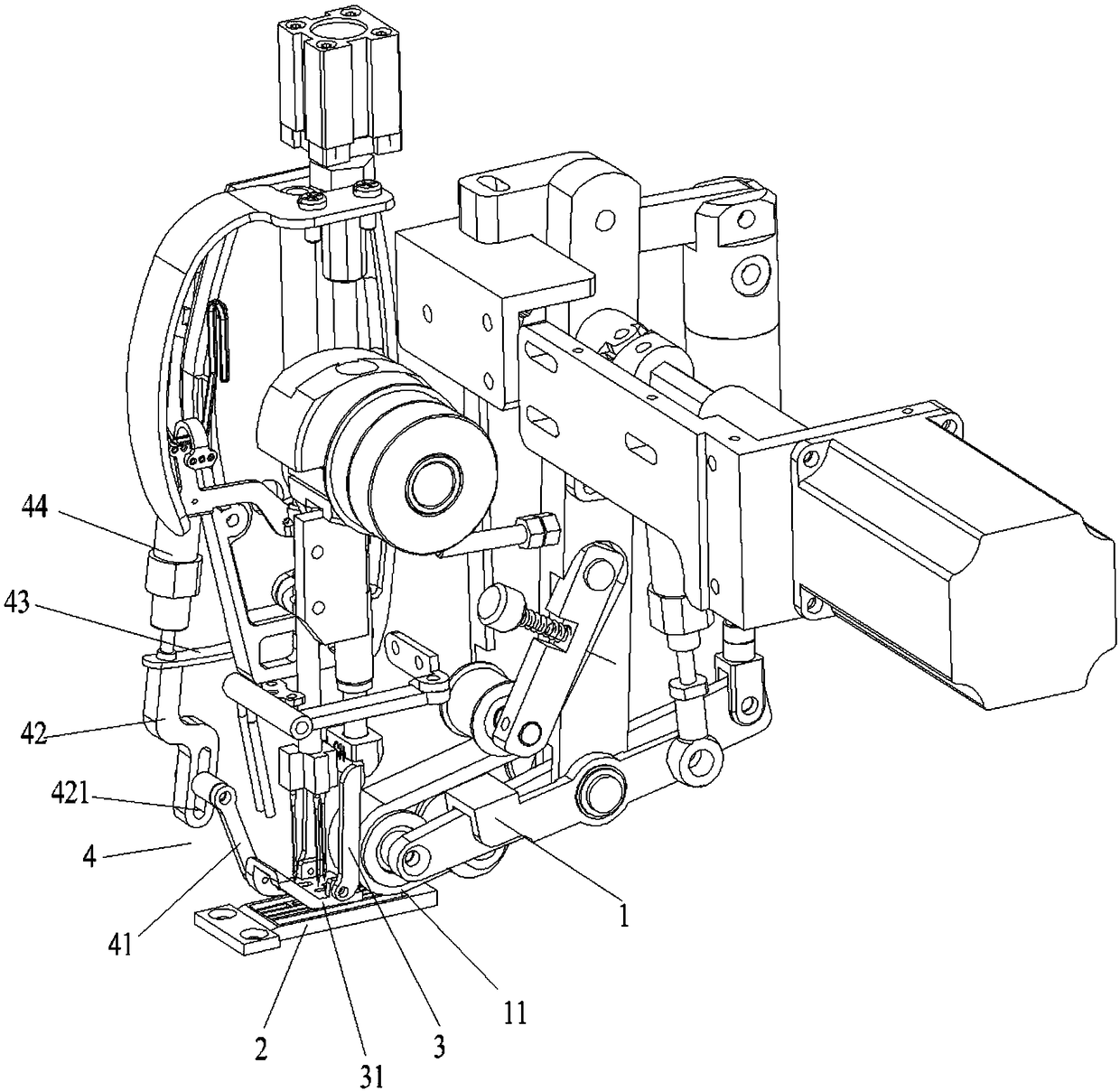

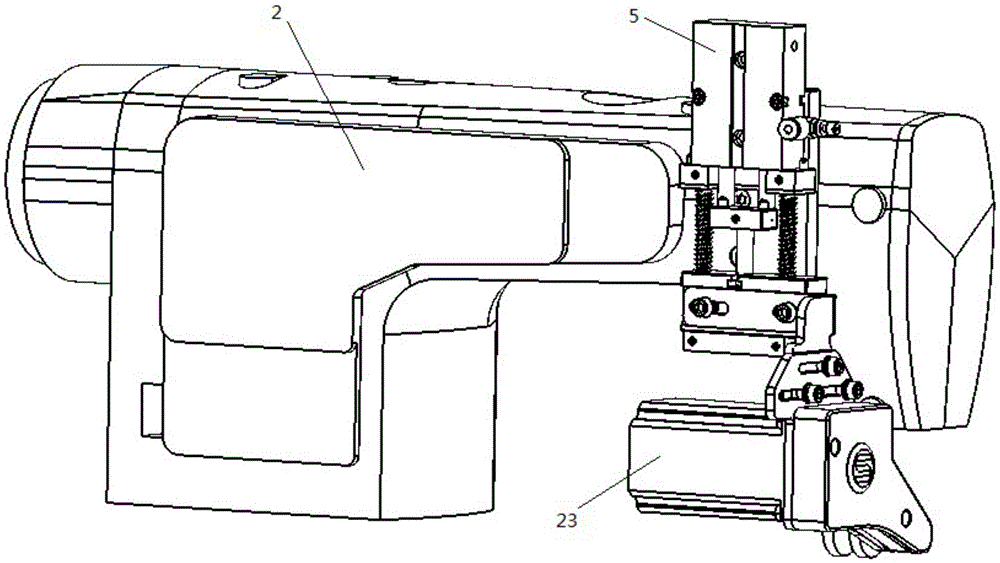

Sewing and embroidering process of high-speed intelligent thread-hooking trimming leather sewing and embroidering machine

The invention relates to a sewing and embroidering process of a high-speed intelligent thread-hooking trimming leather sewing and embroidering machine. The technical problems that upper thread is so tight as to be snapped when thick thread used for a thick embroidery material is trimmed, cloth pressing force of a press foot is not enough, press foot drive and needle rod drive cannot be controlled respectively independently, the thick thread cannot be trimmed, thread hooking displacement cannot be controlled and the like in the prior art can be solved sequentially through a thread-loosening thread-passing device, a thread-hooking line take-up device, a press foot independent-driving mechanism and a trimming restorer. The sewing and embroidering process has the advantages that tension of the upper thread is moderate when the thick thread is trimmed, the lowest position of the working height of the press foot can be adjusted intelligently, the press foot drive and the needle rod drive are controlled respectively independently to improve sewing and embroidering speed and efficiency of the machine, yield is improved, thick thread trimming operation is simple, thread loosening is avoided in trimming, a pair of scissors is long in service life, and thread hooking is controlled easily, and the like.

Owner:FUJIAN YONGXIN NUMERICAL CONTROL TECH

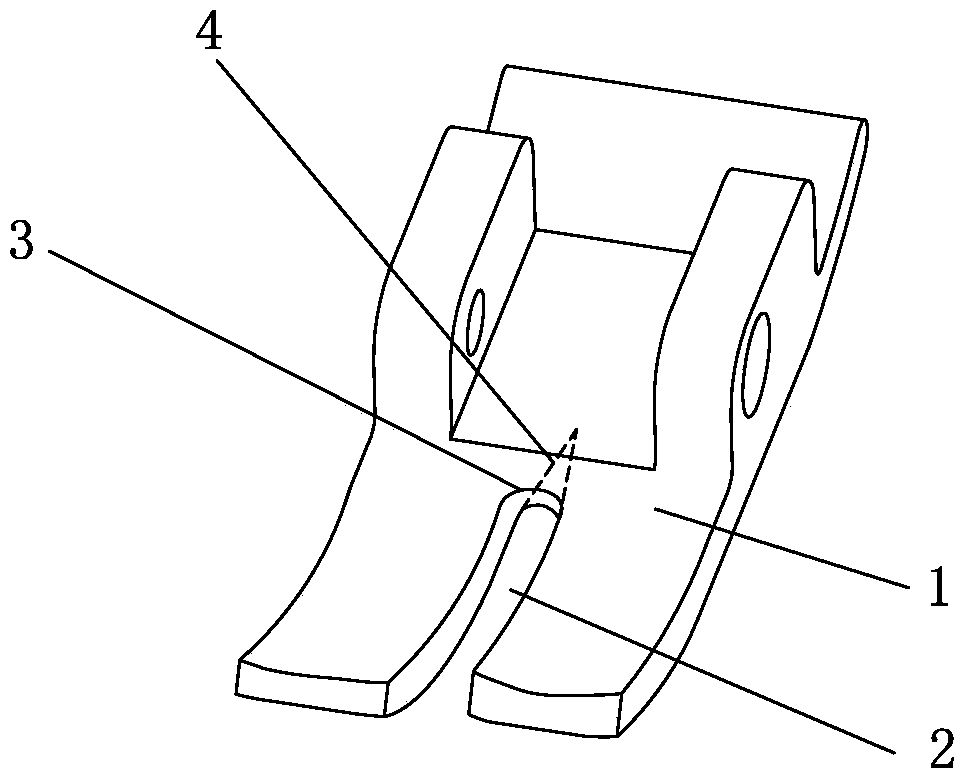

Shoe upper computer sewing machine

ActiveCN104233636AExtended service lifeStable processingLeather sewingPressersComputer engineeringSewing machine

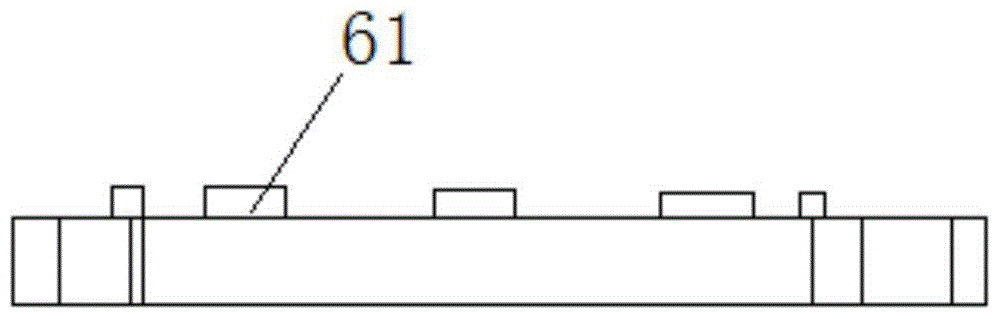

The invention discloses a shoe upper computer sewing machine. The shoe upper computer sewing machine comprises steel wire spring clamps, stitches, starting points, ending points, stitch templates and stitch through grooves, wherein the stitch templates are arranged below shoe side fabrics; the stitch through grooves are formed in the stitch templates; the stitches are arranged in the stitch through grooves; the starting points and the ending points are arranged on the heads and the tails of the stitches; the shoe upper fabrics are fixed on a sewing machine motion platform through a plurality of steel wire spring clamps. The shoe upper computer sewing machine has the advantages of simple structure and good sewing effect, and a sewn shoe upper pattern is high in consistence; moreover, a plurality of machines can be operated simultaneously, so that the production efficiency is increased greatly.

Owner:盐城市鑫亚机械有限公司

Sewing machine

InactiveCN102995299ABeautiful stitchesSewing fastSewing-machine casingsNeedle barsEngineeringNeedle placement

The invention relates to a sewing machine, which comprises a rack. The sewing machine is characterized in that the bottom of the rack is provided with a table top, wherein the top of the rack is provided with a power head; the bottom of the power head is fixedly provided with an edge pressing column; the bottom end of the edge pressing column is connected with an edge pressing mechanism; the bottom of the power head is also fixedly provided with a machine needle fixing mechanism; the machine needle fixing mechanism is provided with a plurality of machine needle placement holes; the inside of each machine needle placement hole is provided with a machine needle; the tail parts of the machine needles are movably fixedly arranged on the machine needle fixing mechanism; the head parts of the machine needles approach to the table top; the table top is provided with a groove by corresponding to the position of the machine needle placement holes; the machine needle fixing mechanism is movably provided with a regulation plate; and the regulation plate is fixedly arranged on the machine needle fixing mechanism by a regulation screw and is contacted with the tail part of the machine needle. The sewing machine disclosed by the invention has the advantages of tidy and attractive stitch, high sewing speed, convenience in use, simple structure and high working efficiency, is flat and firm and is safe and reliable.

Owner:陆海涛

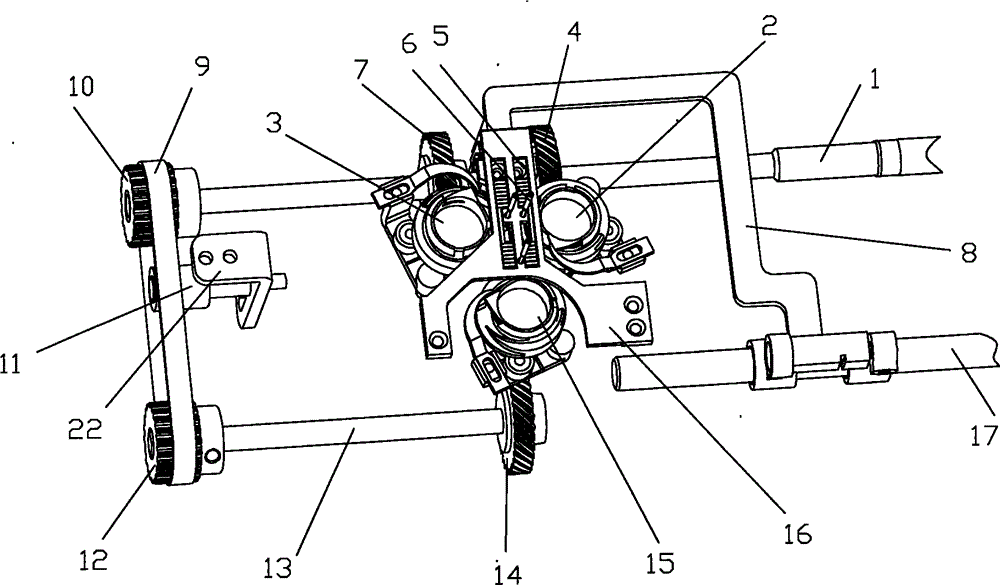

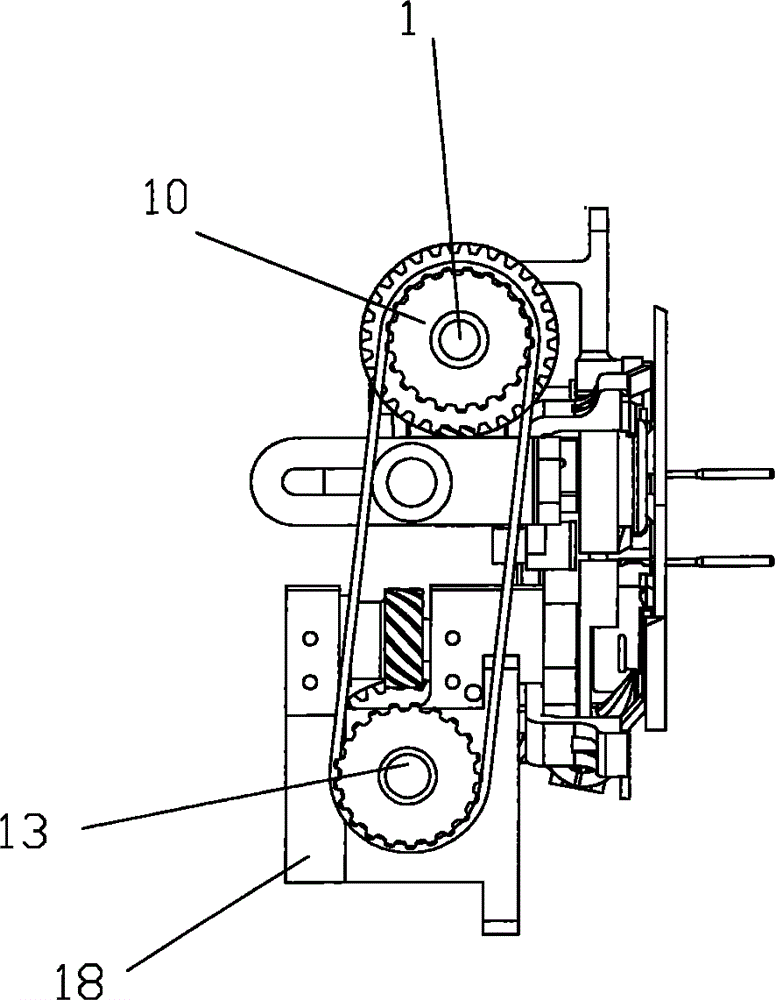

Transmission mechanism of three-needle lock stitch sewing machine

The invention belongs to sewing machine technology, and provides a sewing machine that can complete three parallel lock stitch in one step instead of two in prior art. A left-handed shuttle and right-handed shuttle are driven to rotate by the engagement of two large helical gears and a small helical gear installed on a lower shaft; a synchronous pulley installed on the lower shaft and a synchronous pulley installed on an intermediate shuttle shaft are connected through a synchronous belt; the rotation of the lower shaft is transmitted to a middle large helical gear; a middle is driven to rotate by the engagement of the large and the small helical gears; when three needles move downward, three shuttles hook at the same time to form three-needle lock stitch, wherein, the third needle and the two needles form an isosceles triangle, and the third shuttle and the two shuttles form an isosceles triangle. The advantages of the three-needle lock stitch sewing machine are that the sewing efficiency is high; three parallel equidistant stitches can be made by one step; and the stitch seam is beautiful.

Owner:TAIZHOU UNIV +1

Novel small-head sewing machine

ActiveCN107227560AOvercome the disadvantage that the eye of the needle is easily pulled out of the long groove by the sewing needleOvercome the disadvantage of being easily pulled out of the long groove by the sewing needleWork-feeding meansNeedle severing devicesEngineeringSupport point

The invention discloses a novel small-head sewing machine, which is characterized by comprising a machine shell; an installing wall and a worktable; a main pressing pin for pressing fabrics to be sewed, a delivering mechanism, a push mechanism, and a lifting mechanism are arranged on the installing wall; the delivering mechanism comprise a sewing needle, a needle driving part, a swaying pressing pin, and a swaying pressing rod; a supporting point and a driving point are arranged on the swaying pressing rod; a pusher and a shearing mechanism are installed in the worktable; the pusher comprises a material pushing driving part and a cloth delivering tooth in opposite to the swaying pressing foot; the pusher is applied to the driving point, thus the swaying pressing rod and the sewing needle are crossly and repeatedly swayed around the supporting point; the lifting mechanism applies force to the swaying pressing rod, and the shearing mechanism is used for shearing the sewing line crossed through the sewing needle. Through three-synchronous delivering mechanisms, the novel small-head sewing machine overcomes the shortcoming that the needle eye is easy to be pulled out of a long slot by the sewing needle during the working process of a traditional two-synchronous delivering sewing machine; the sewed line trace is beautiful, the sewing quality is greatly promoted; the overall structure is compact, and the movement stability is high.

Owner:TAIZHOU SANBEN SEWING EQUIP CO LTD

Automatic reverse stitching device control system and method for sewing machine

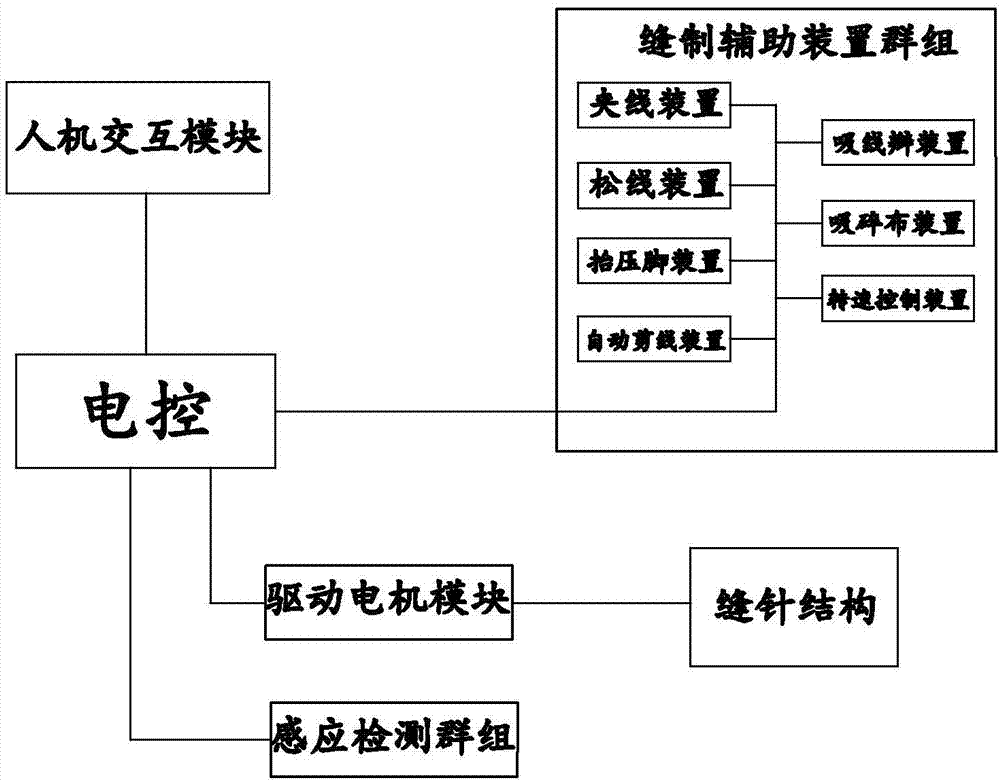

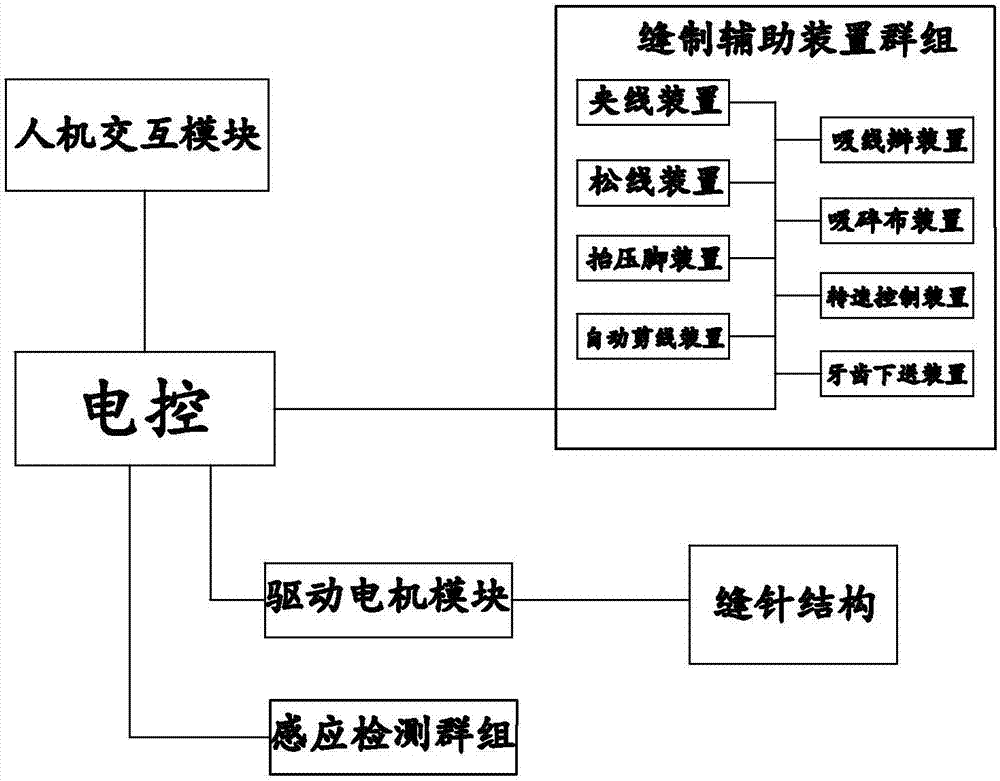

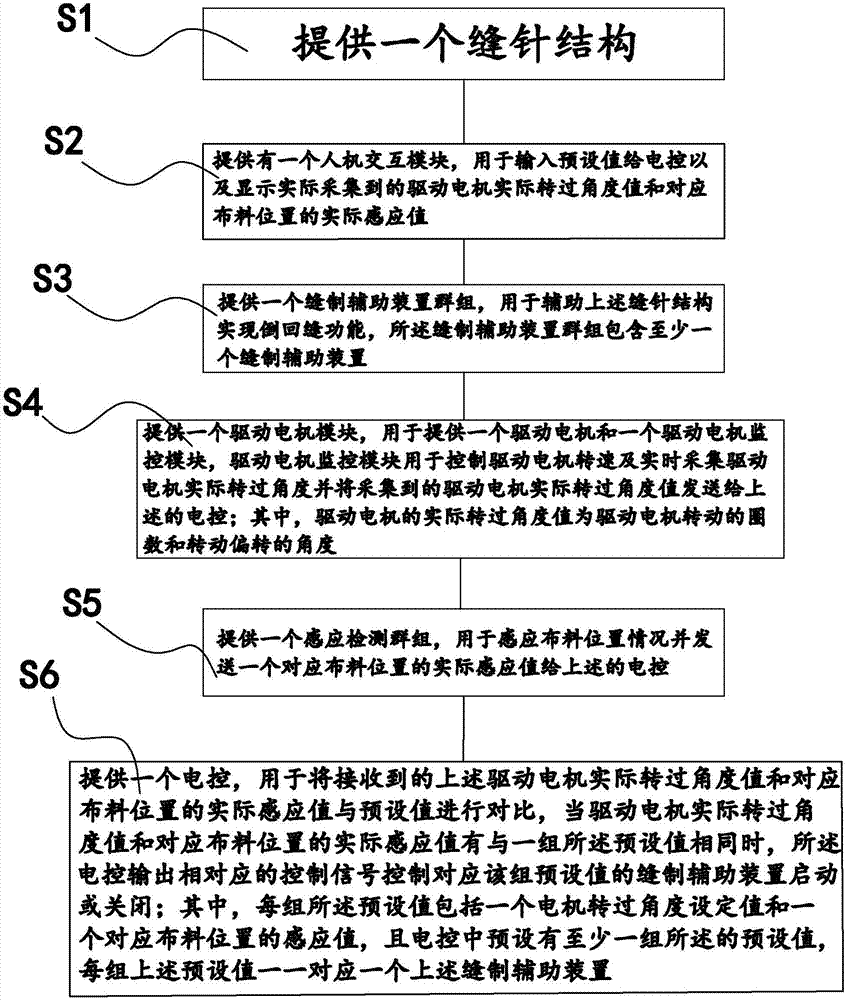

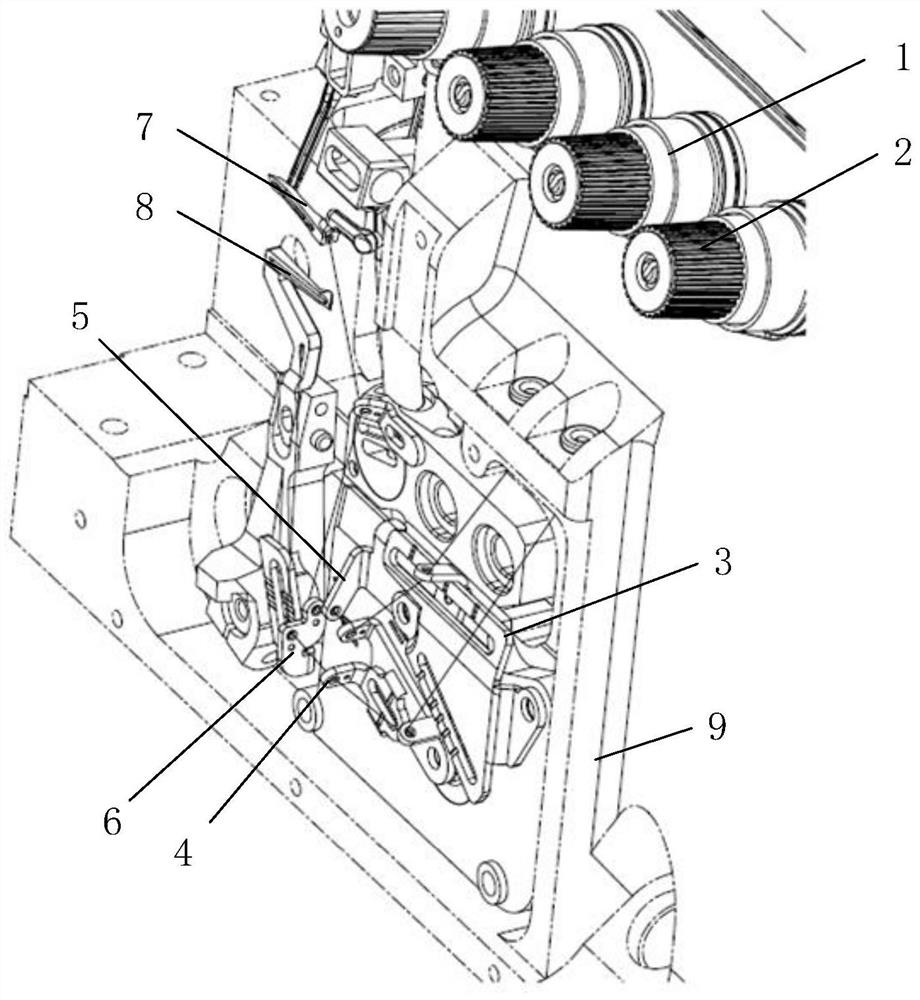

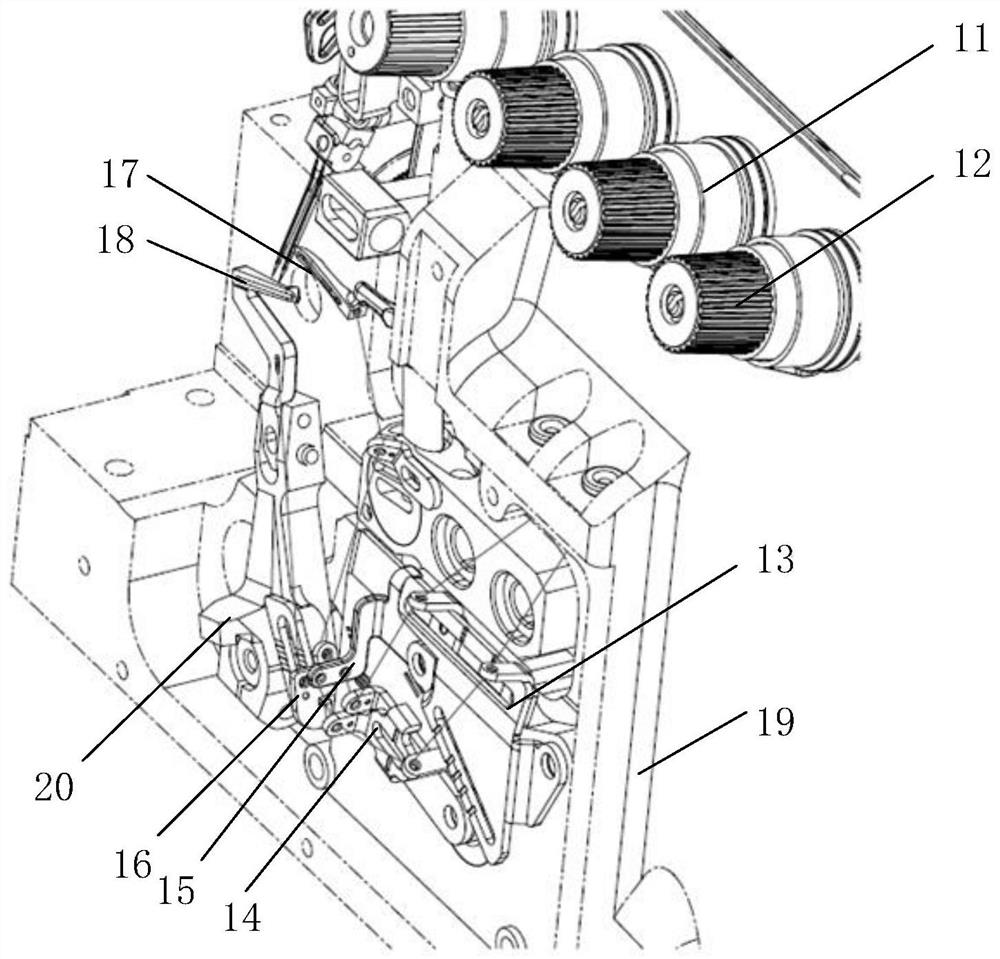

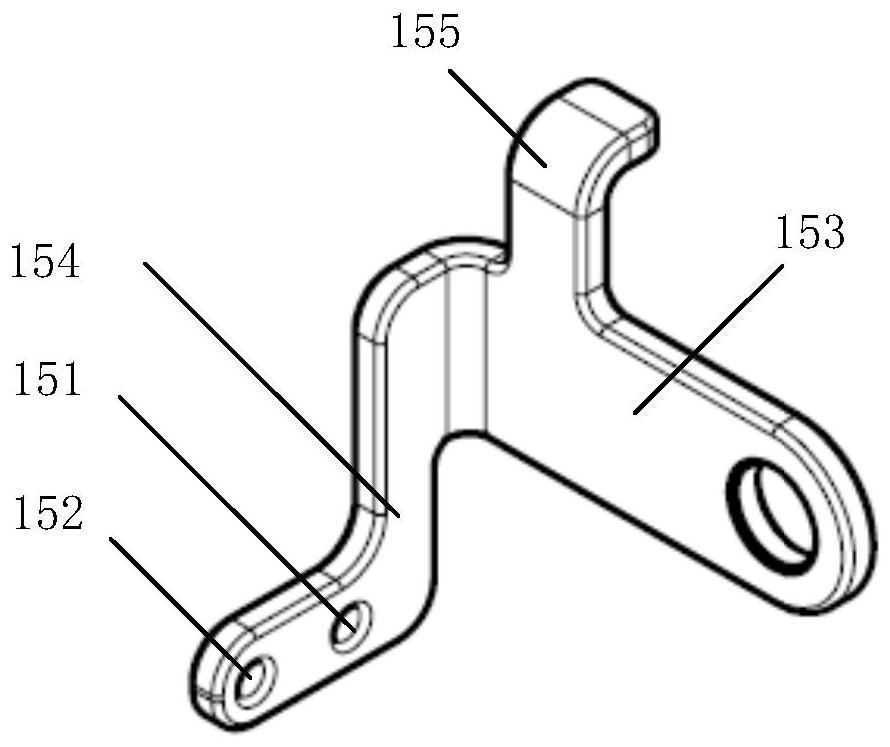

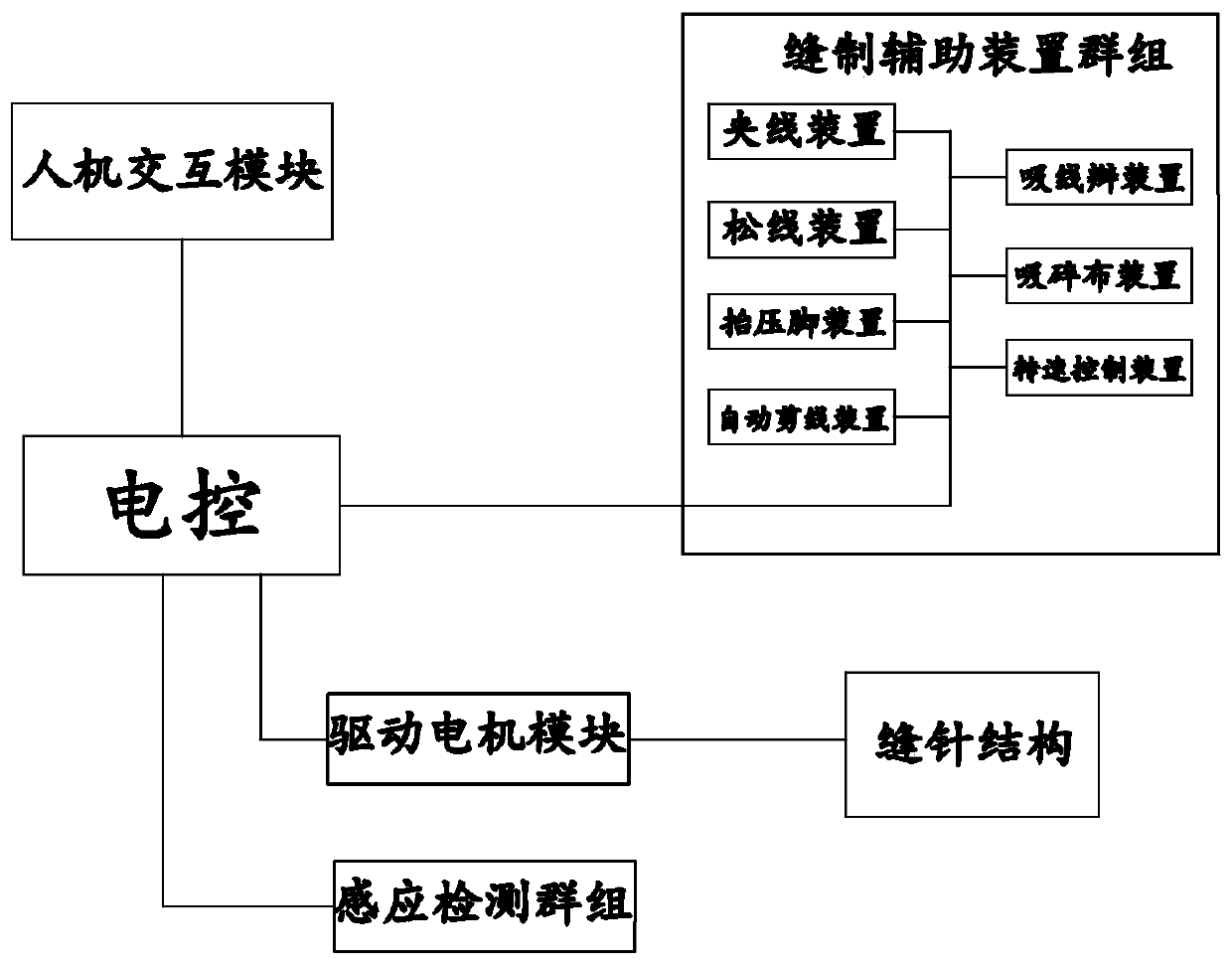

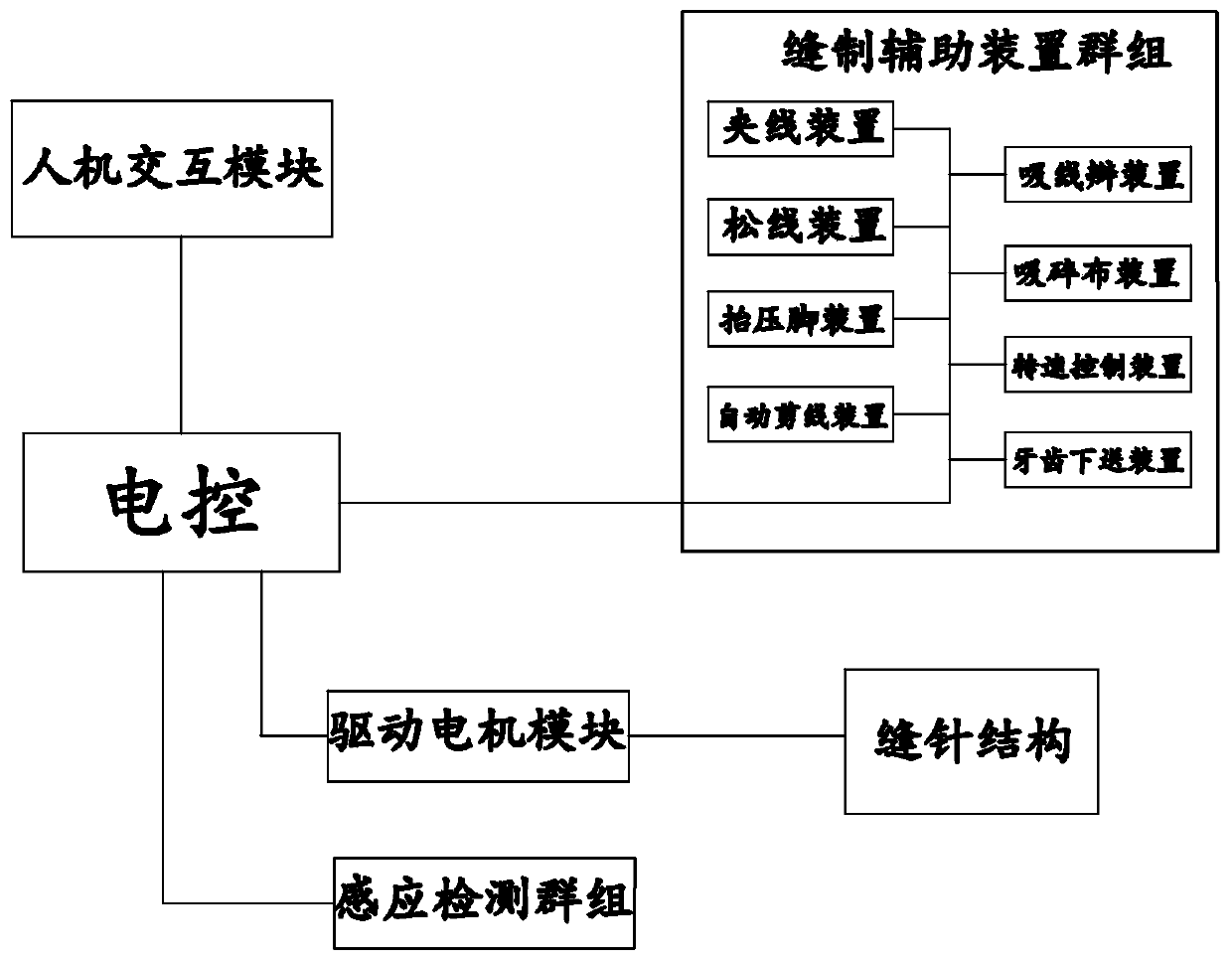

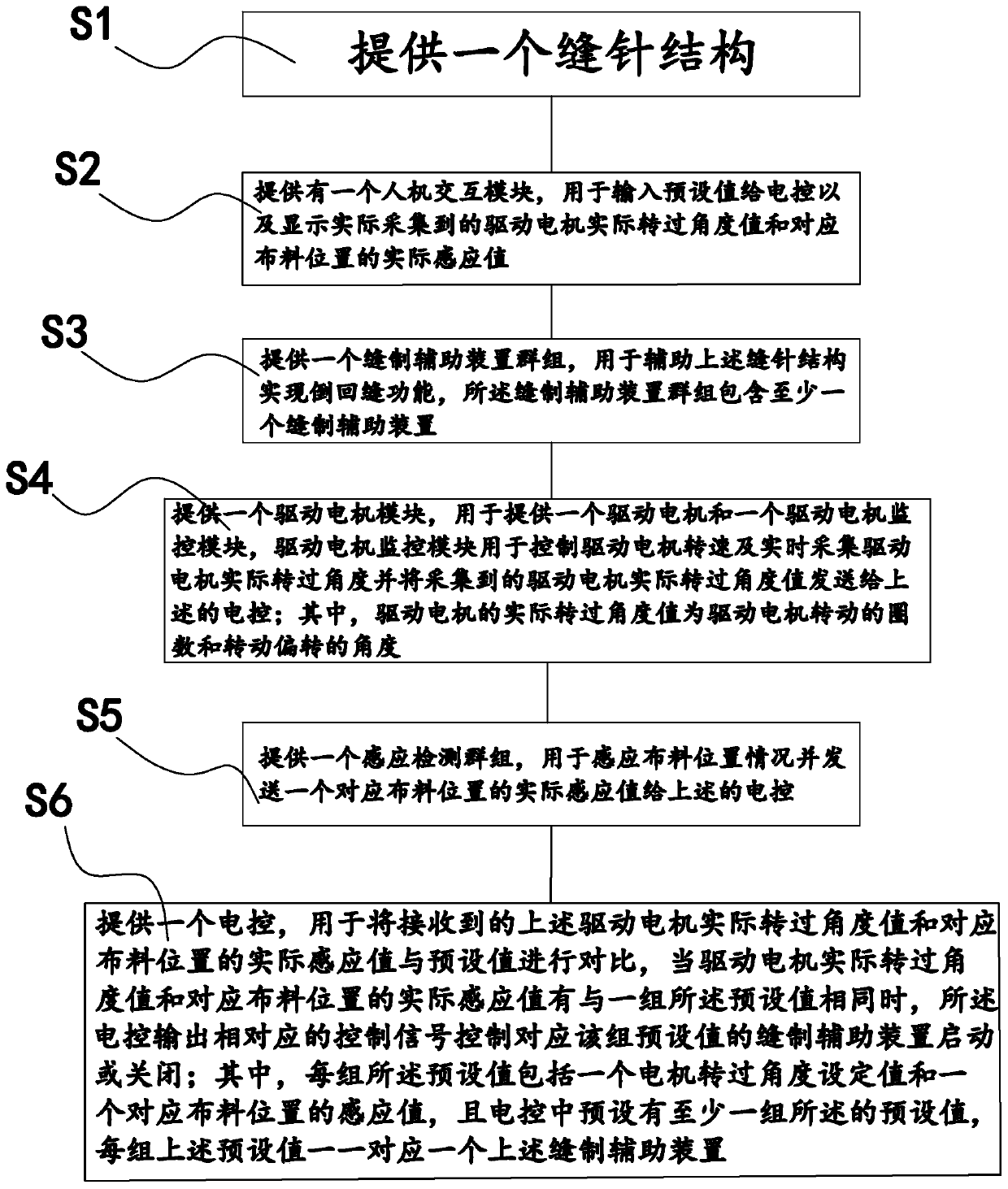

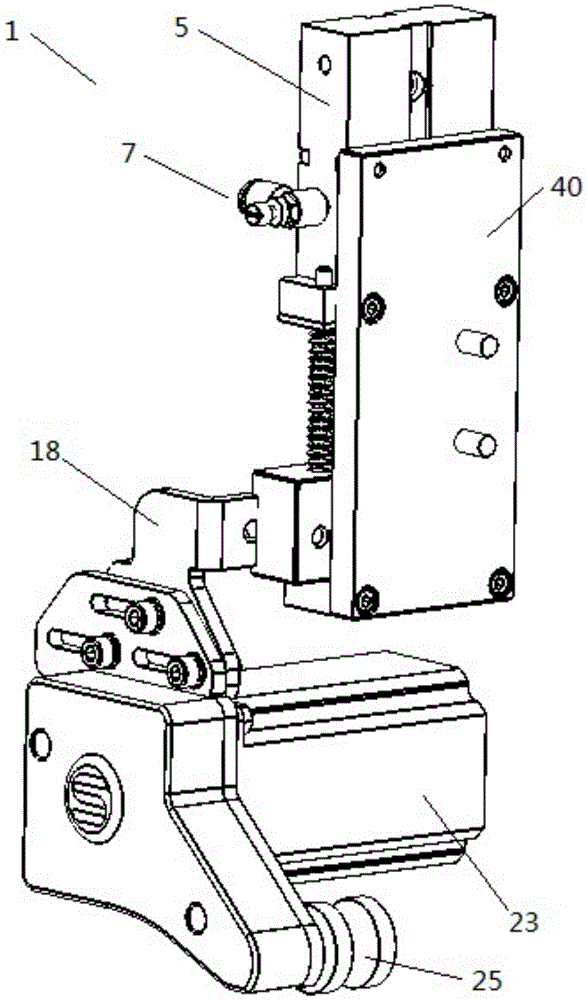

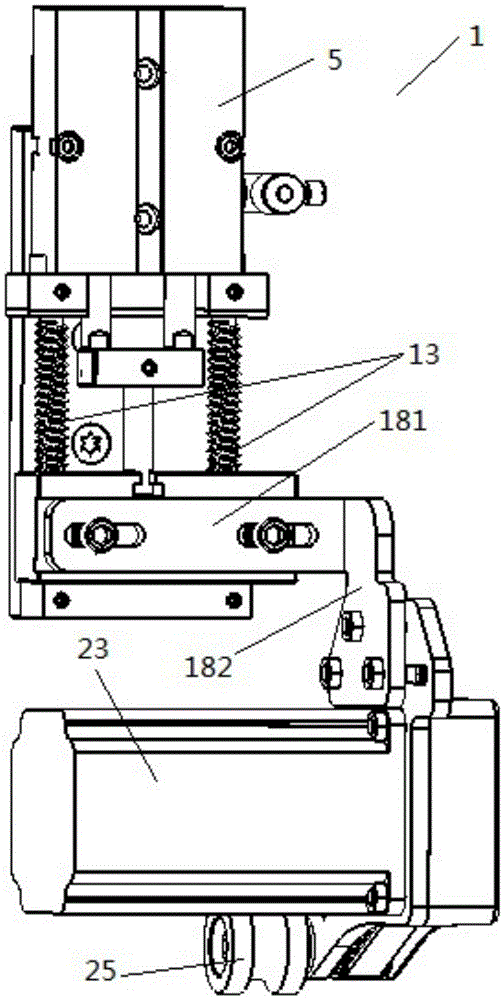

ActiveCN107090669ASimplify complexityReliable operation logicProgramme-controlled sewing machinesTurn angleControl system

The invention provides an automatic reverse stitching device control system and method for a sewing machine, belongs to the technical field of sewing machines and solves the problems of low success rate of existing thread end overlocking and poor attractiveness. The automatic reverse stitching device control system for the sewing machine comprises a stitching structure, a driving motor module, an electric control unit, an inductive detection group and a sewing assisting device group, wherein at least one group of preset values are set on the electric control unit in advance, and when the actual turning angle value of a driving motor and an actual induction value of the corresponding cloth position are identical to a group of preset values, the electric control unit outputs corresponding control signals to control starting or stopping of one sewing assisting device corresponding to the group of preset values. The automatic reverse stitching device control system for the sewing machine has the advantages that the judgement result is more accurate, the success rate of thread end overlocking is higher and overlocked stitches are more attractive.

Owner:JACK SEWING MASCH CO LTD

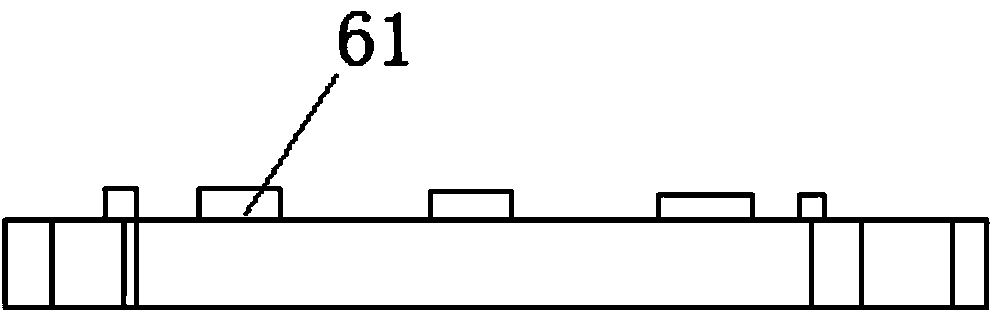

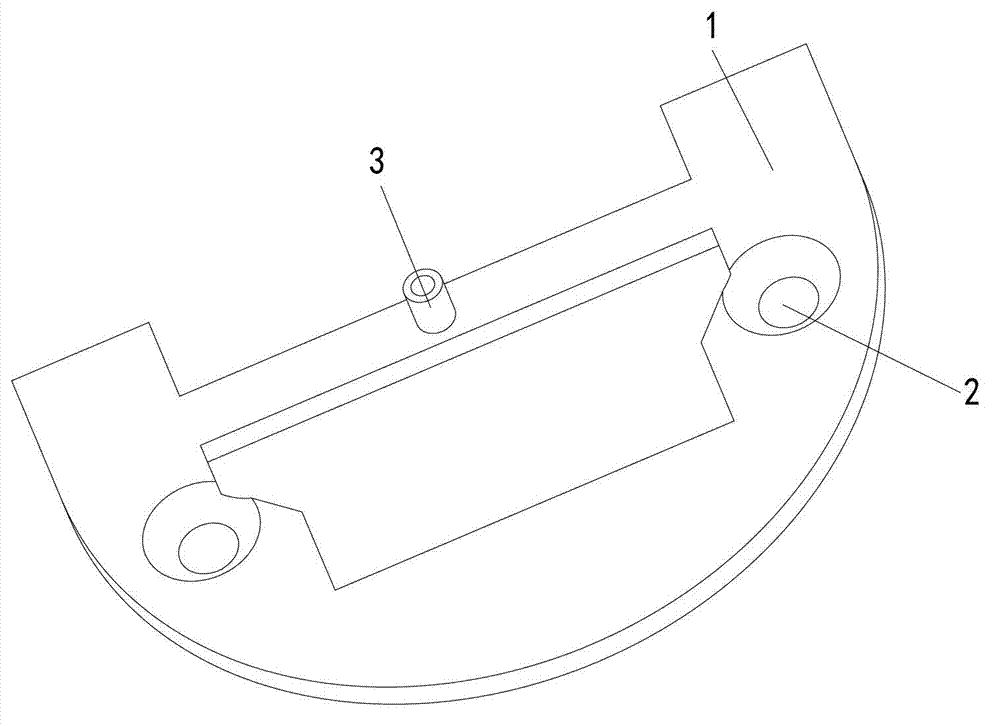

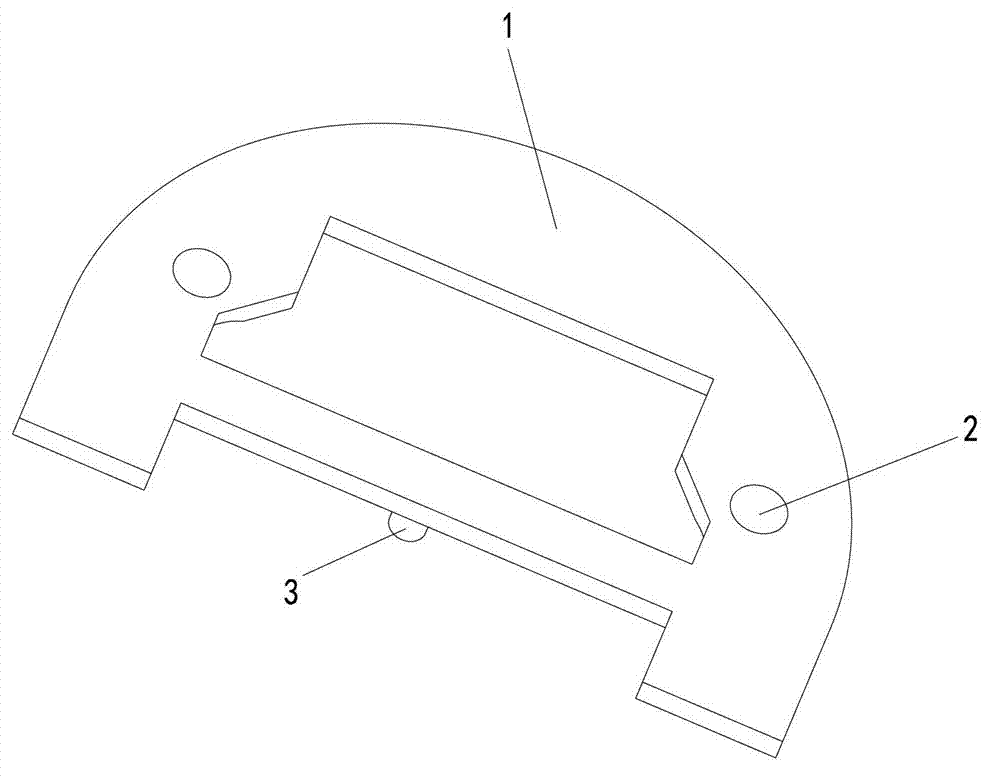

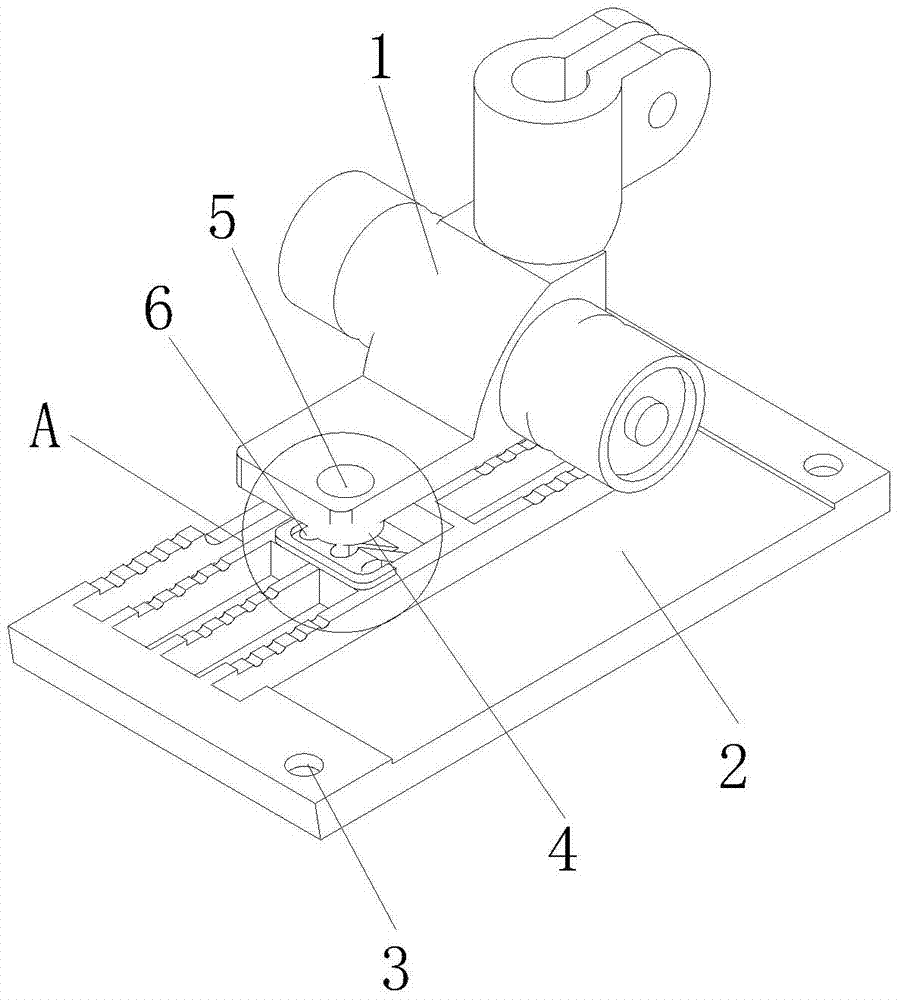

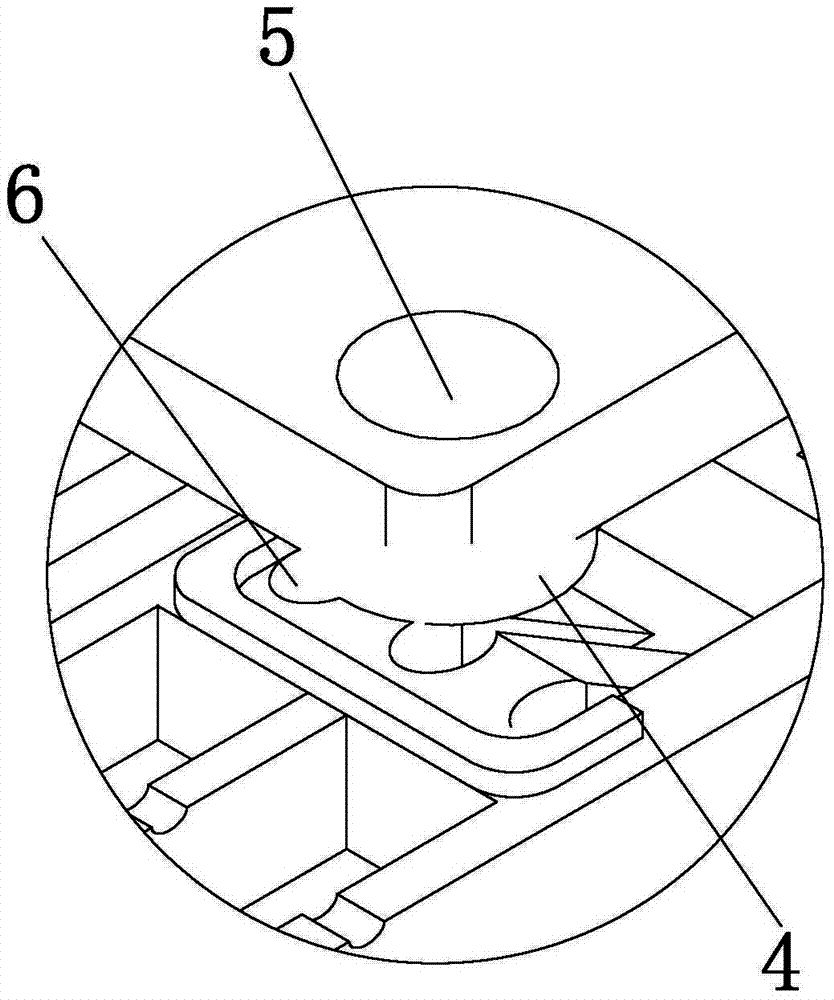

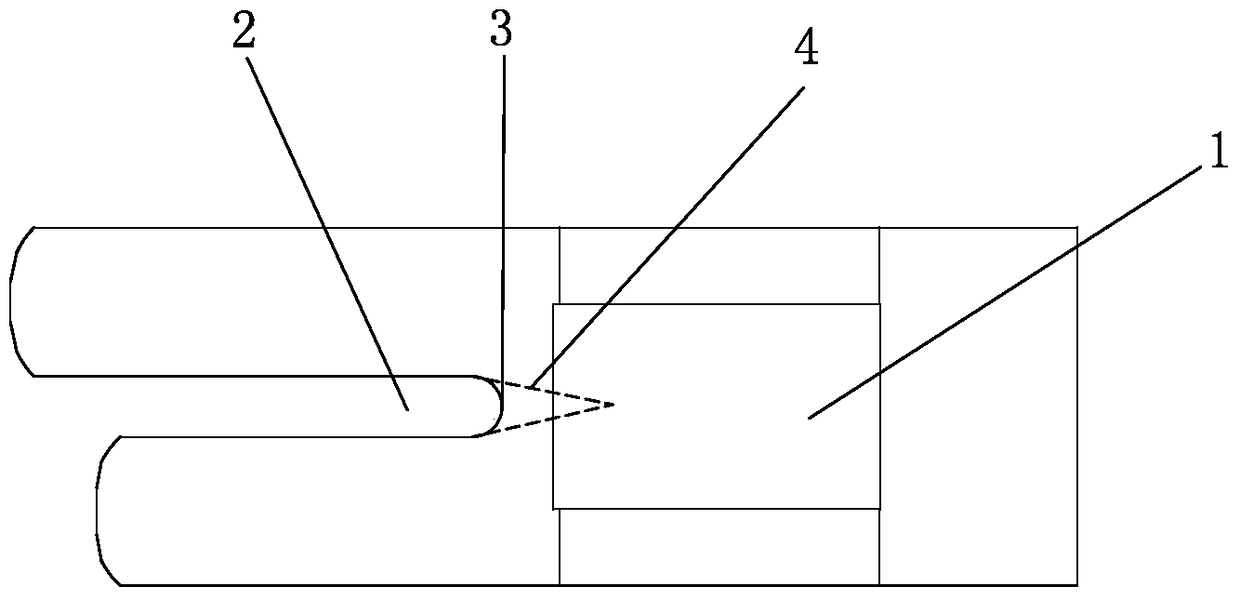

Guide faller

InactiveCN103397485AReduce labor intensityPlay a guiding roleSewing-machine casingsEngineeringUltimate tensile strength

The invention discloses a guide faller. Two holes are formed in a faller body. A guidepost is arranged on the faller body. The guidepost is additionally arranged on the faller, so that when a sewing machine sews through a template, the guidepost is fastened in a through groove of the template, thereby functioning in guiding; the sewing machine is ensured to sew accurately in the direction of the template, so that labor intensity of workers is reduced, production efficiency is improved, and processed products are attractive in stitch; the faller is applicable to large-scale batch application.

Owner:SUZHOU JUKANG SEWING ROBOT

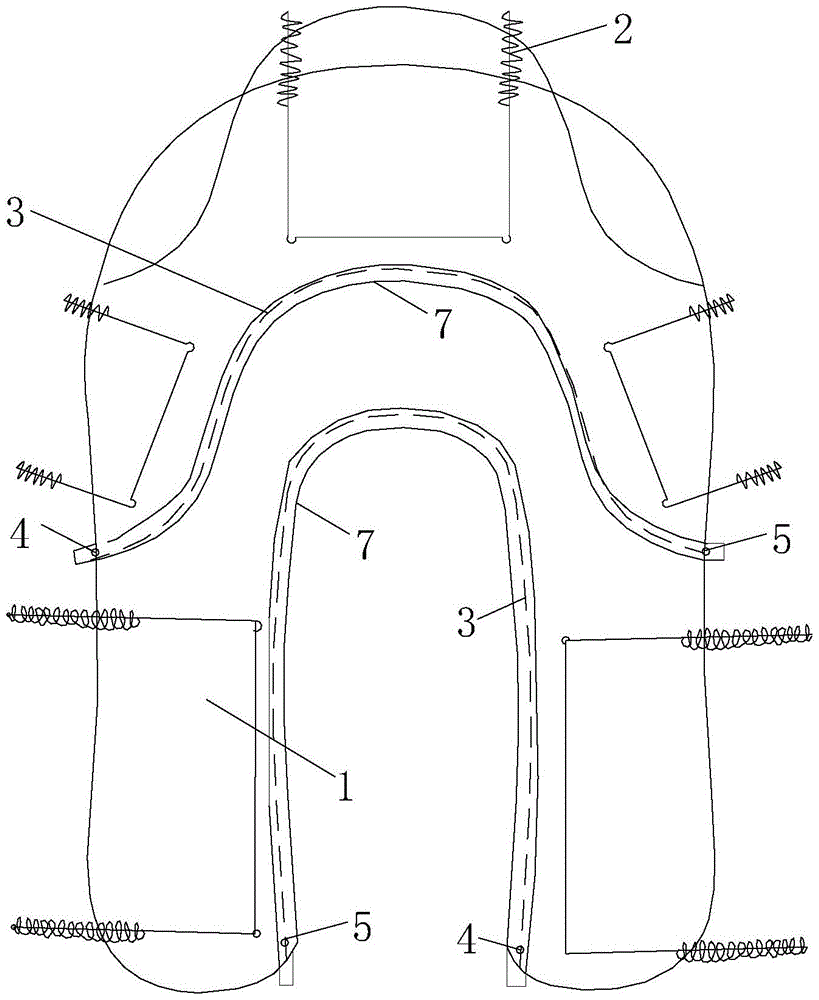

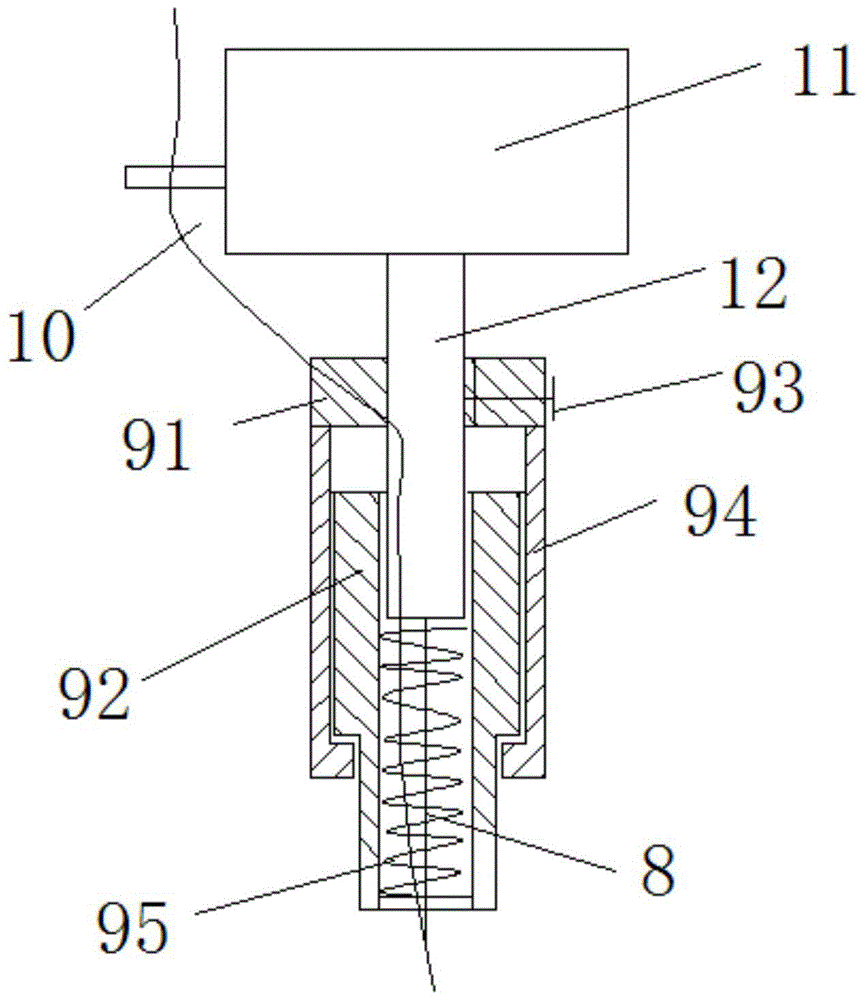

A sock production device

ActiveCN104233634BRealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

The invention discloses a sock production device, which comprises a frame, a feeding device, a waste recycling device, a seam head box, a discharging device, and a sock turning device; the feeding device includes a guide rail, a guide frame, a guiding box, a feeding box, a first A motor assembly; the waste recycling device includes a negative air suction device and a pipeline, the negative air suction device is installed on the frame, and one end of the pipeline is connected to the negative air suction device; the seam head box is fixedly installed on the machine On the frame, the first seam head and the second seam head are fixed in order from left to right in the seam head box; a discharge device is fixed at the right end of the frame, and a discharge guide rail is installed on the discharge device. The sock tube is provided with a sock turning device. The present invention can automatically turn over the sock after sewing the toe of the sock, and at the same time collect the waste produced by the toe and toe cutting mechanism, which has a high degree of automation, improves work efficiency and reduces labor costs .

Owner:浙江圣邦化纤针织有限公司

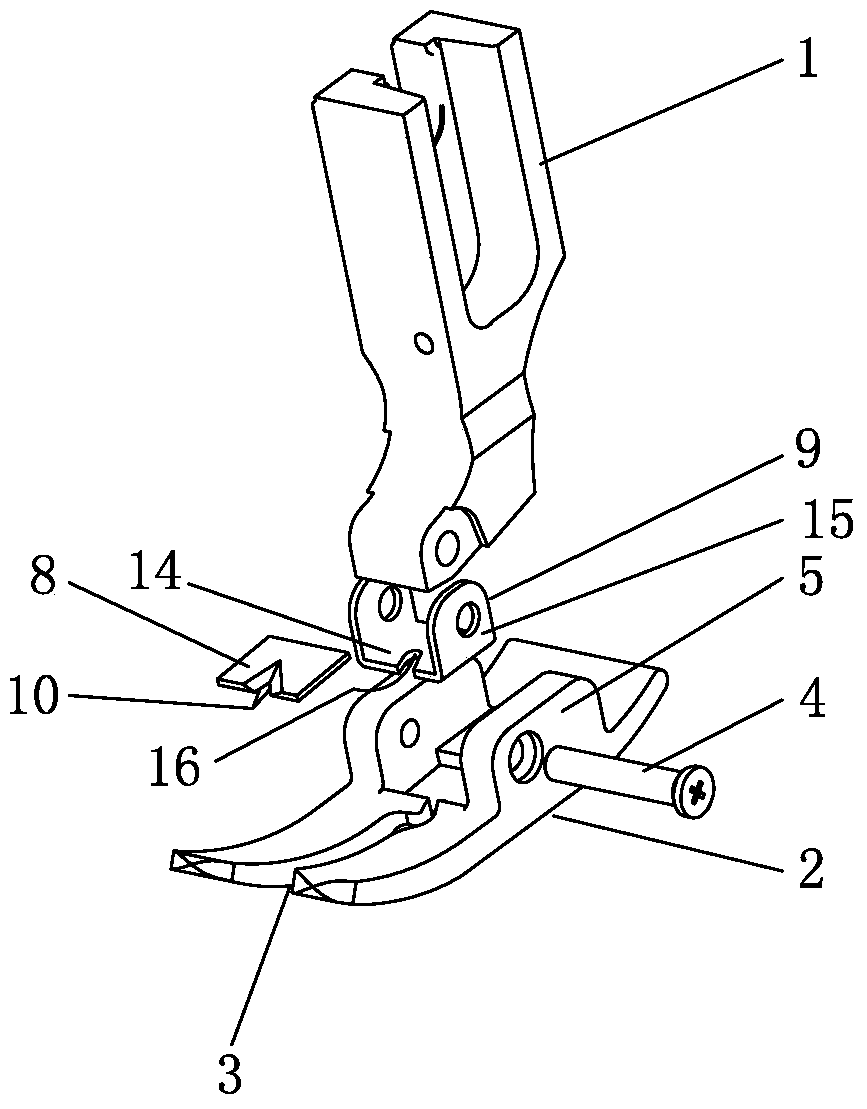

Presser foot for template sewing of zigzag sewing machine

The invention discloses a presser foot for template sewing of a zigzag sewing machine. The presser foot comprises a presser foot body. A strip-shaped needle hole is formed in the presser foot body and extends in the width direction of the strip-shaped needle hole, a boss is arranged below the strip-shaped needle hole and protrudes downwards so as to be clamped into a template groove, and the strip-shaped needle hole is throughout the boss downwards. The boss is arranged on the presser foot of the zigzag sewing machine, and therefore a needle of the zigzag sewing machine can work accurately along the template groove when performing zigzag sewing; the presser foot can be used in cooperation with different fallers, and therefore all types of fabric can be sewn; especially for thin and soft fabric, the presser foot is used in cooperation with an anti-wrinkling faller, so that processed stitches are attractive, mellow and free of winkles; the presser foot has prominent substantial characteristics and significant progressiveness.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Crocheting device of sewing machine

The invention discloses a crocheting device of a sewing machine. The crocheting device comprises a crochet rod body, a shuttle hook mechanism and a spinning reel, wherein the crochet rod body comprises an alloy vertical crochet body; a crochet tip structure is arranged at the lower end of the alloy vertical crochet body; a crochet opening with an elliptical structure is arranged at the connecting part of the alloy vertical crochet body and the crochet tip structure; threads for the sewing machine are pulled out through the spinning reel, and penetrate through the crotchet opening. The crocheting device of the sewing machine keeps continuity of crocheting work and is high in crocheting efficiency, easy and convenient to use and control, and sewed lines are tidy and attractive.

Owner:常熟市古里镇淼泉利达机械厂

Wrapping executing structure of high-density over lock machine of cup seaming machine

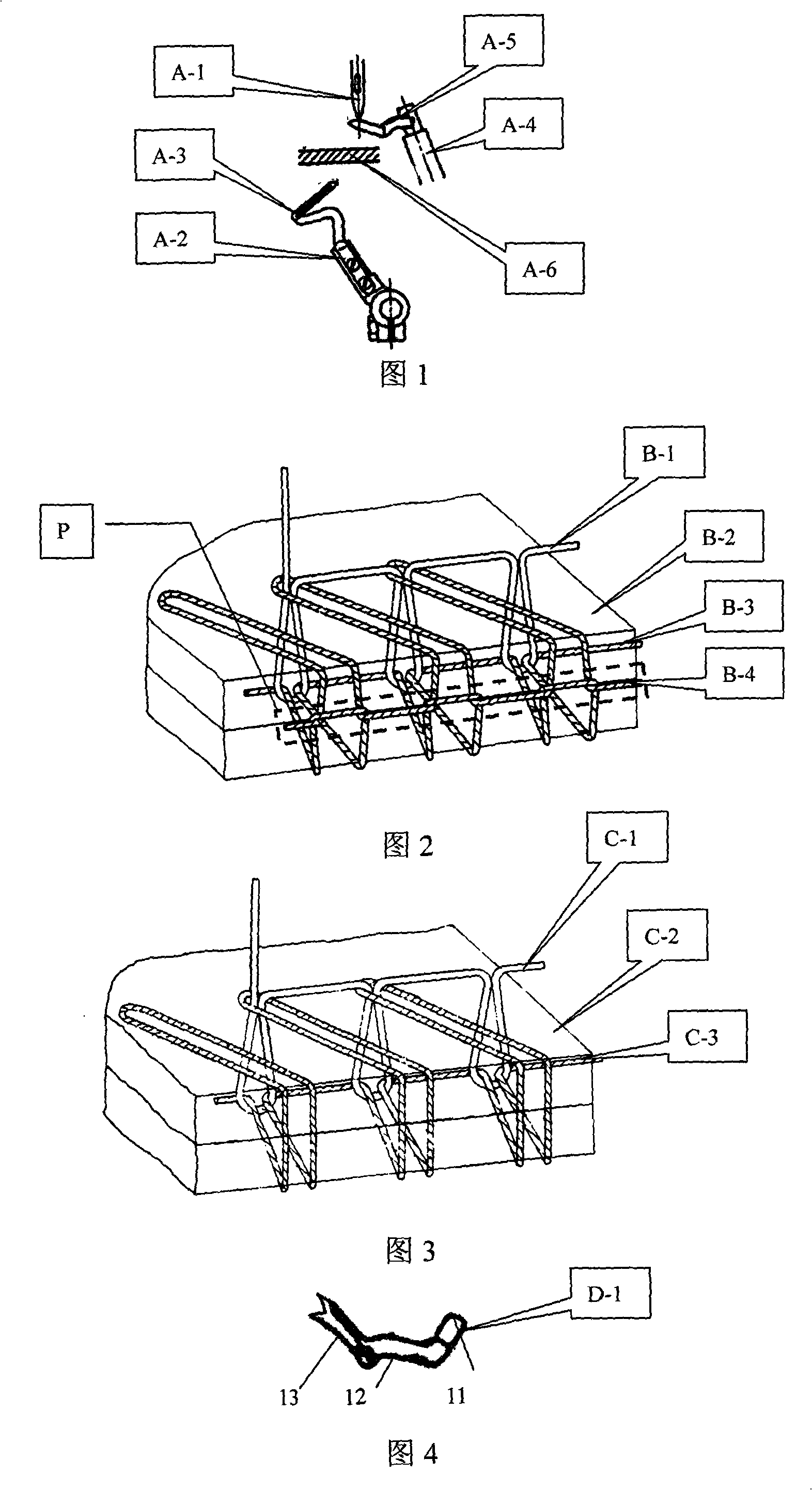

InactiveCN101338494ABeautiful stitchesReduce thread consumptionThread-laying mechanismsNeedle barsHigh densityEngineering

The present invention relates to a tipping structure of a high-density edge processing machine of an overedger. The tipping structure comprises a needle (A-1), a lower bending needle (A-3) arranged on a lower bending needle rocker (A-2), an upper bending needle guide rod (A-4), a needle plate (A-6), and a forked needle (D-1) for thread poking without using stitching; the forked needle (D-1) is arranged on the upper bending needle guide rod (A-4). The beneficial effects of the present invention are that: denser, narrower and more pleasant stitching is realized based on the changes of a few spare parts, and the thread consumption is reduced.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

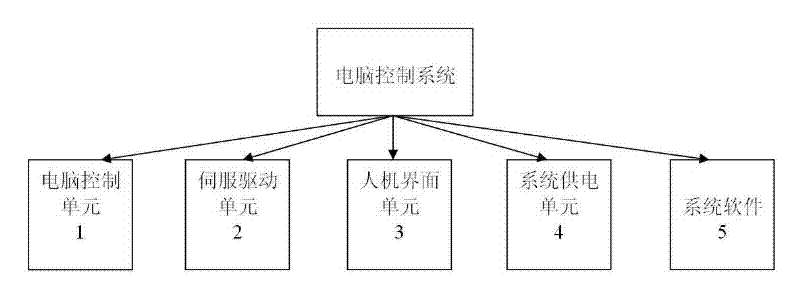

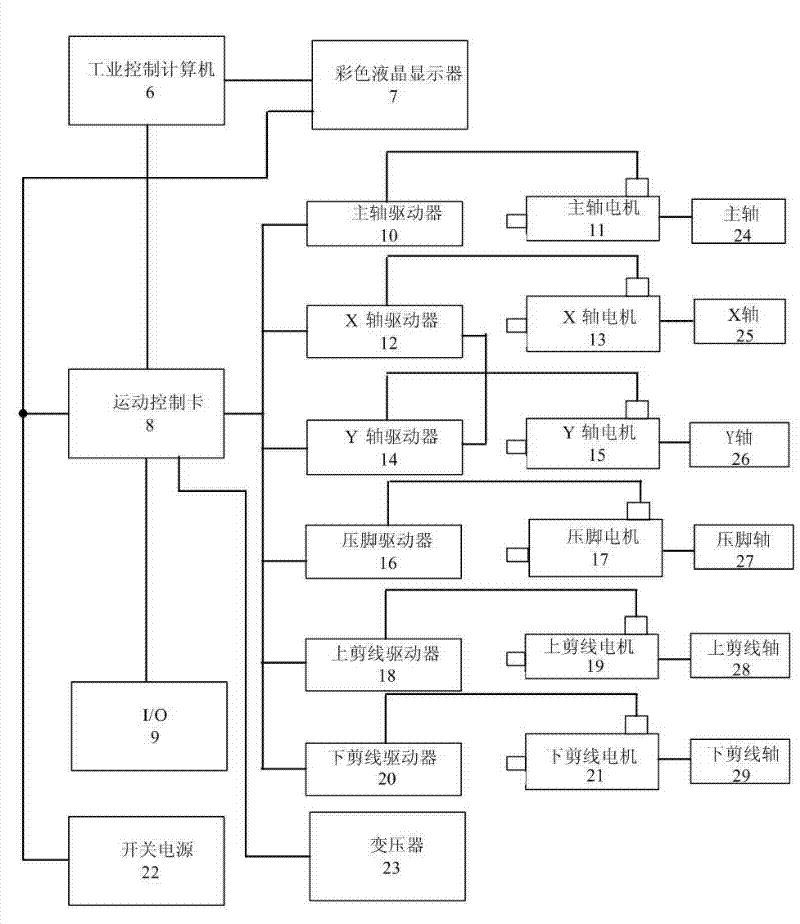

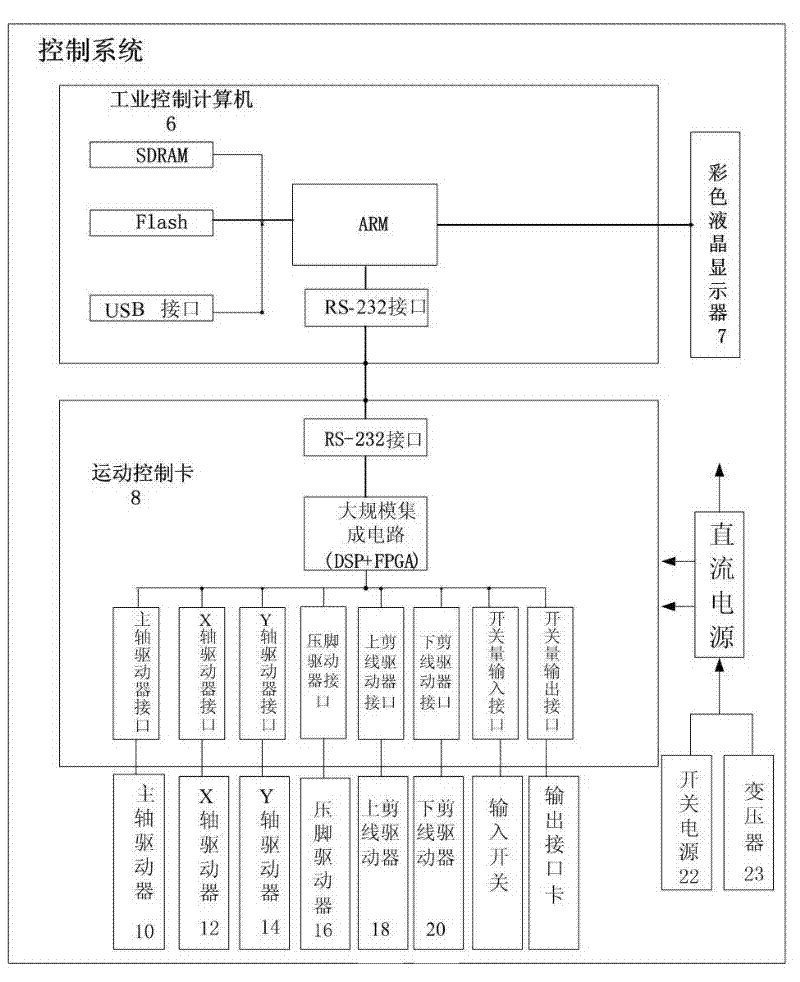

Computer control system for flat-buttonhole buttonholing machine

InactiveCN102560906AIncrease sewing speedGuaranteed uptimeProgramme-controlled sewing machinesHuman–machine interfaceTransformer

The invention provides a computer control system for a flat-buttonhole buttonholing machine, comprising a computer control unit consisting of an industrial control computer, a motion control card and an I / O (input / output), a server driving unit consisting of an alternating current motor and a stepping motor, a human-computer interface unit consisting of a color LCD with a touch function, a system power supply unit consisting of a switching power supply and a transformer, and system software planning a human-computer interface to realize human-computer interaction. The computer control system adopts a modularized and unitized structure, each unit is internally and relatively independent and self-contained, so that the computer control system is high in integration degree, and corresponding part forming systems can be flexibly configured according to the different host computers of the flat-buttonhole buttonholing machine. Various buttonhole graphics are automatically sewn by a system software procedure with high speed, the computer control system is stable in running, small in noise, attractive and even in stitch, and convenient to operate, various graphic data files are quickly and simply generated, the labor intensity is greatly reduced, and the production efficiency is improved.

Owner:MIANYANG WEIBO ELECTRONICS

Sewing mechanism

InactiveCN103498298ABeautiful stitchesIncrease productivityWork-feeding meansSewing needleBiomedical engineering

The invention discloses a sewing mechanism. The sewing mechanism comprises a presser foot and a needle plate, wherein the presser foot is located above the needle plate which is provided with a plurality of installation holes; a positioning block is fixedly arranged below the presser foot; the positioning block is provided with a plurality of positioning holes; the needle plate is provided with a plurality of sewing needle holes; the positioning block is cylindrical; the sewing needle holes are three in number. According to the sewing mechanism, as the positioning block is additionally arranged below the presser foot of the sewing mechanism, the positioning block is provided with the positioning holes, and the needle plates is provided with the sewing needle holes corresponding to the positioning holes, when a sewing machine starts to work, sewing is conducted only through the positioning holes in the positioning block. Therefore, during operation, manual alignment is not needed, stitches of sewn fabric are beautiful, production efficiency is high, and market requirements are met.

Owner:SUZHOU JUKANG SEWING ROBOT

A new type of small head sewing machine

ActiveCN107227560BOvercome the disadvantage that the eye of the needle is easily pulled out of the long groove by the sewing needleOvercome the disadvantage of being easily pulled out of the long groove by the sewing needleWork-feeding meansNeedle severing devicesEngineeringSupport point

Owner:TAIZHOU SANBEN SEWING EQUIP CO LTD

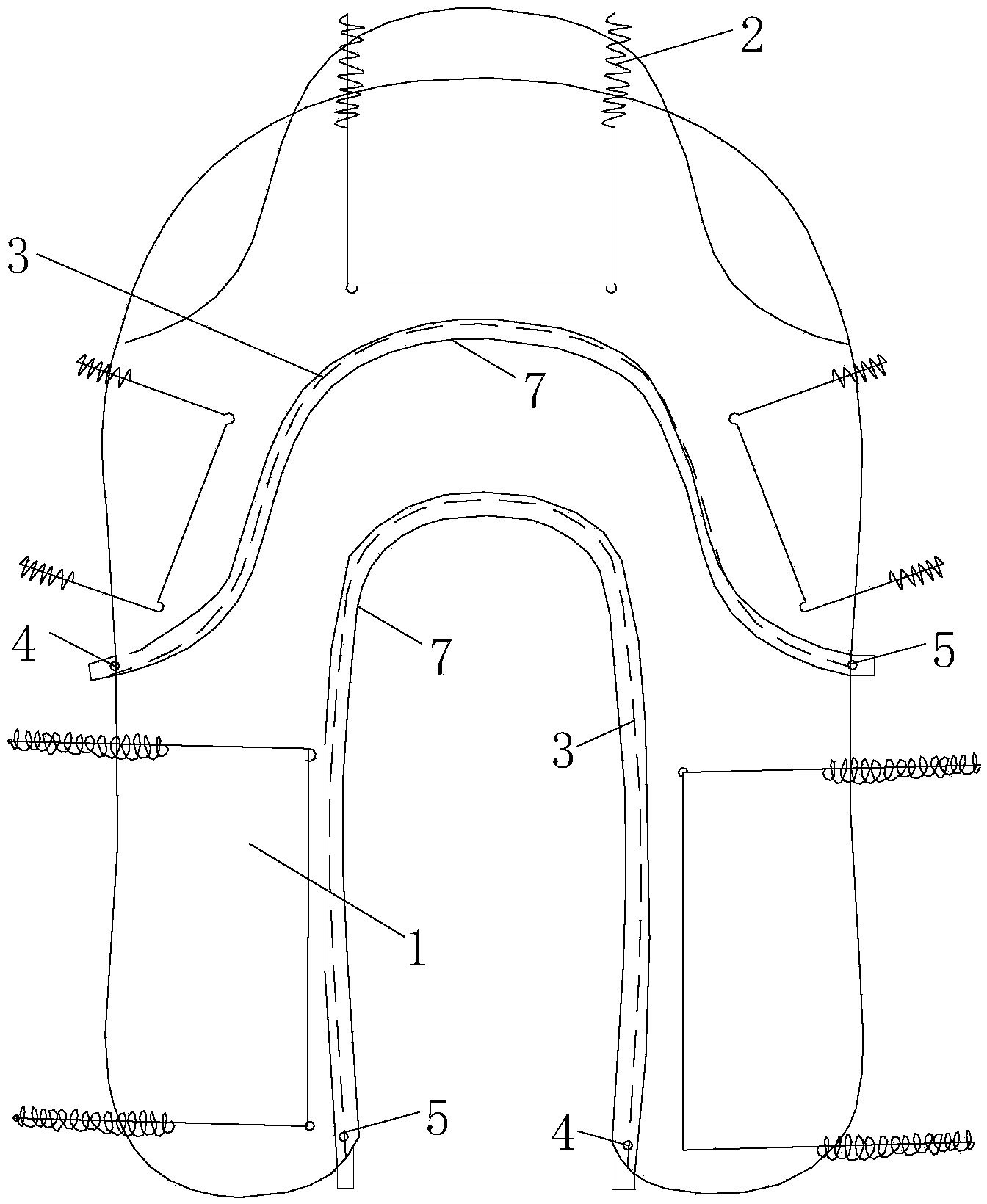

Chain type sewing machine special for knitted hat

InactiveCN104928860AReduce wearReduce noiseLubrication/cooling devicesSewing-machine control devicesChain typeCam

The invention relates to a chain type sewing machine special for a knitted hat. The chain type sewing machine special for the knitted hat comprises a belt wheel, a spindle, an eccentric cam assembly, a turbine, an oil pump, a spindle synchronous belt wheel, a synchronous belt, a take-up-lever crank, a take-up-lever assembly and a crochet hook. The spindle synchronous belt wheel is fixed to the spindle through a key. The spindle comprises an upper spindle body and a lower spindle body. The spindle synchronous belt wheel comprises an upper spindle synchronous belt wheel body and a lower spindle synchronous belt wheel body. The eccentric cam assembly comprises a feeding eccentric cam assembly and a tooth lifting eccentric cam assembly. Single thread chain type stitches are formed through needle bar take-up and crotchet needle thread hooking, and the stitches are tidy, firm, attractive, rich in elasticity, and capable of expanding or shrinking along with knitted products.

Owner:张文勇

Automatic envelope sewing machine

ActiveCN106757814ACorner Sewing UniformBeautiful stitchesLeather sewingWork-feeding meansElectric machineryEngineering

The present invention relates to the technical field of sewing machines, and specifically relates to an automatic envelope sewing machine. An upper roller feeding structure is used for assisting a pull-over device to realize automatic sewing. According to the technical scheme of the invention, the automatic envelope sewing machine comprises a handpiece and a bottom plate, wherein a mounting plate is arranged on one side of the handpiece, two wire clamping seats are connected to the mounting plate, the wire clamping seats are connected with a motor mounting seat through steel pipes, a motor is connected to the motor mounting seat, a main synchronous belt pulley is connected to the motor, the main synchronous belt pulley is connected with a lower synchronous belt pulley component through a synchronous belt, the lower synchronous belt pulley component is arranged on a main connecting shaft, a first feeding component, a second feeding component and a third feeding component are connected to the main connecting shaft, the first feeding component and the third feeding component are located on a right side of a motor mounting plate, the second feeding component is located on a left side of the motor mounting plate, an auxiliary feeding component is arranged on the left side of a needle plate of the bottom plate, and a pull-over detection component is arranged on the right side of the needle plate of the bottom plate.

Owner:XIAN TYPICAL IND

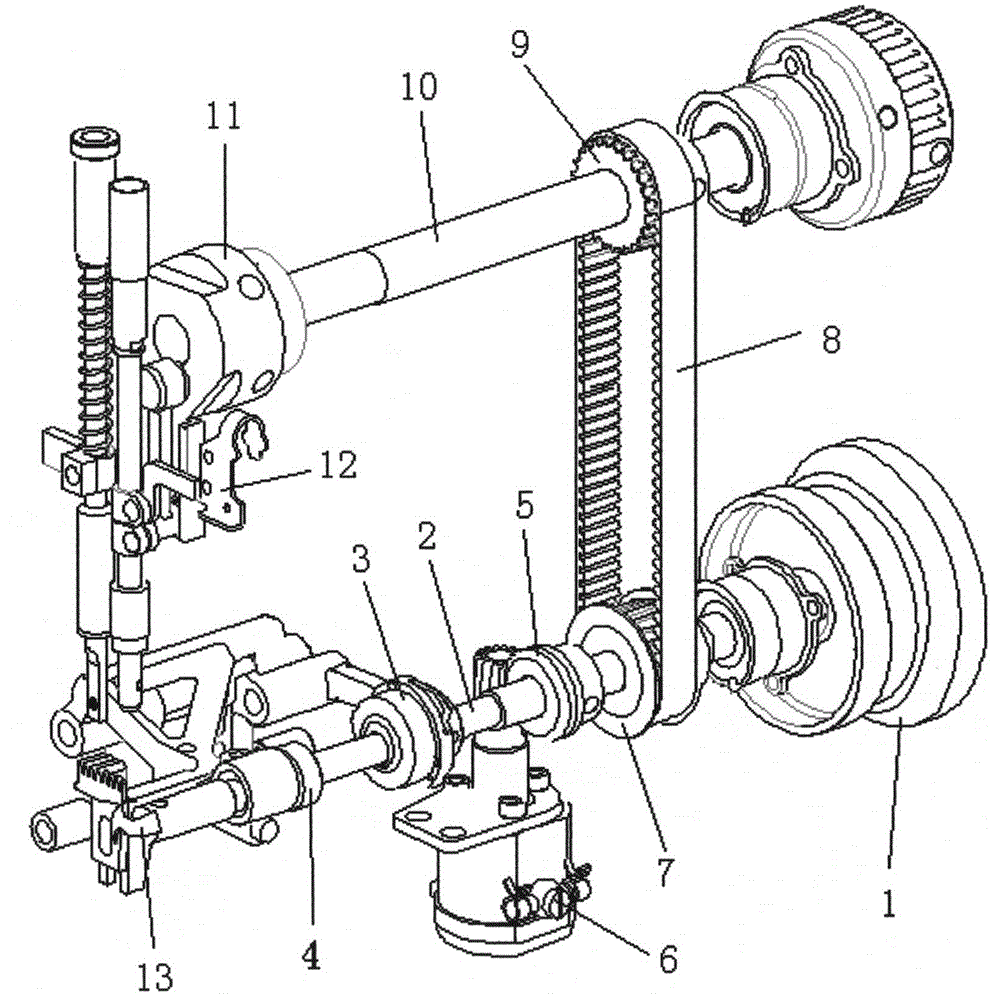

Auxiliary feeding device for sewing machine

The invention belongs to the technical field of sewing machines, and specifically relates to an auxiliary feeding device for a sewing machine. The device comprises an one-way clutch driving assembly and a dragging wheel assembly; the one-way clutch driving assembly comprises an one-way clutch driving planetary gear shaft which is connected through a coupling and rotates in one direction, and a large synchronizing wheel hinge pin; a driving swinging rod sleeves the one-way clutch driving planetary gear shaft; the other end of the driving swinging rod is connected with one end of a connecting rod through the hinge pin; an adjusting connecting rod which is connected with the swinging shaft is arranged on the other end of the connecting rod; the dragging wheel assembly comprises a large synchronizing wheel, a first small synchronizing wheel and a second small synchronizing wheel; synchronizing belts are arranged at the outsides of the large synchronizing wheel, the first small synchronizing wheel and the second small synchronizing wheel; compressing wheels for tensioning the synchronizing belts are arranged on the synchronizing belts. The device is high in reliability, durability and stability; materials can be synchronously and stably fed, and the material grabbing force and driving force are high during passing through a joint, thus the sewing is smooth, and the stitches are uniform and nice.

Owner:ZHEJIANG ZHONGSEN SEWING MACHINE

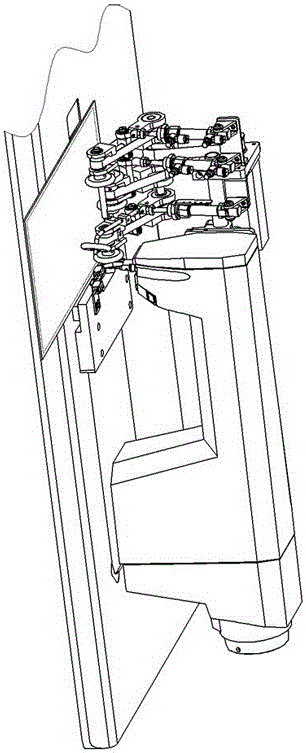

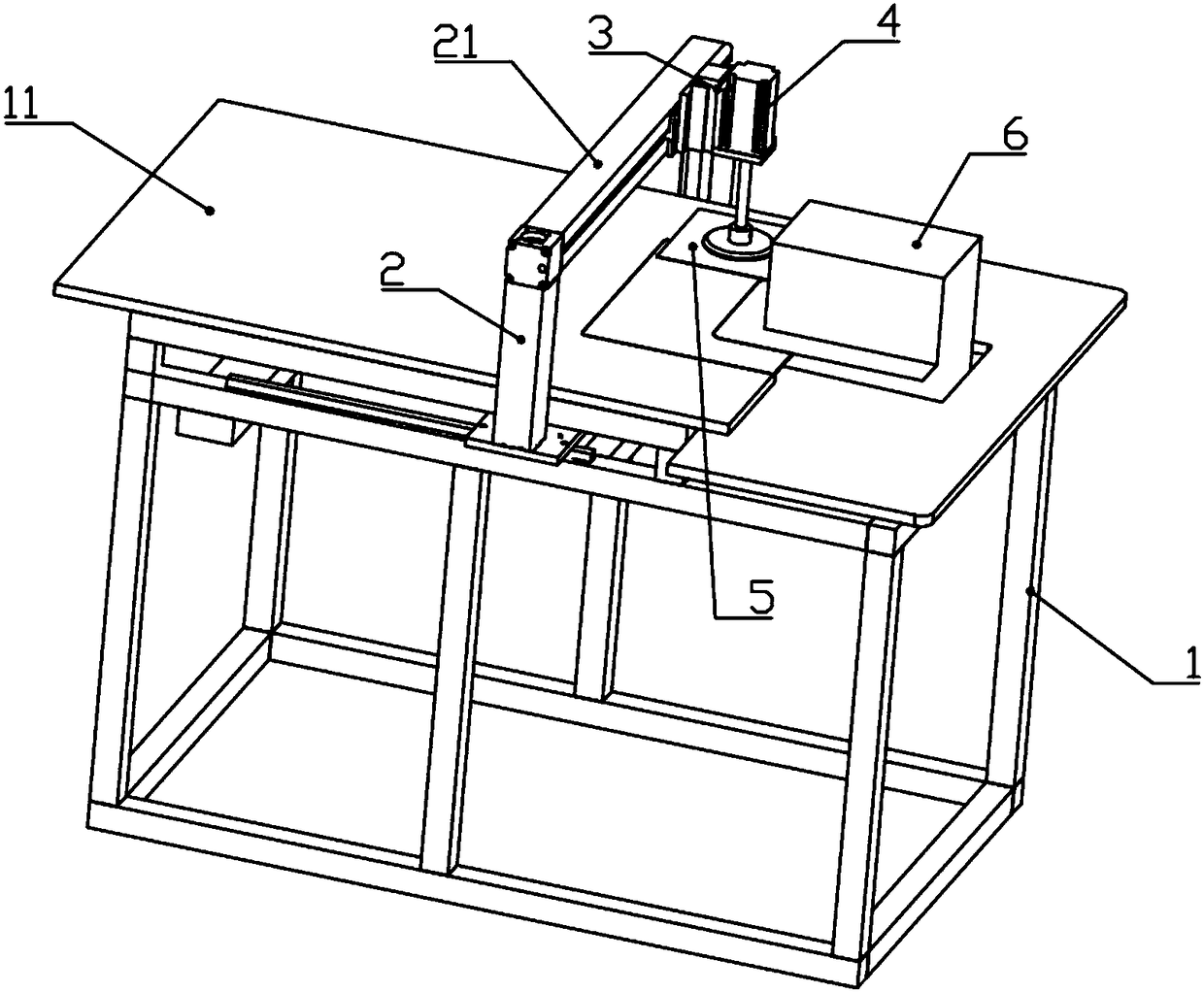

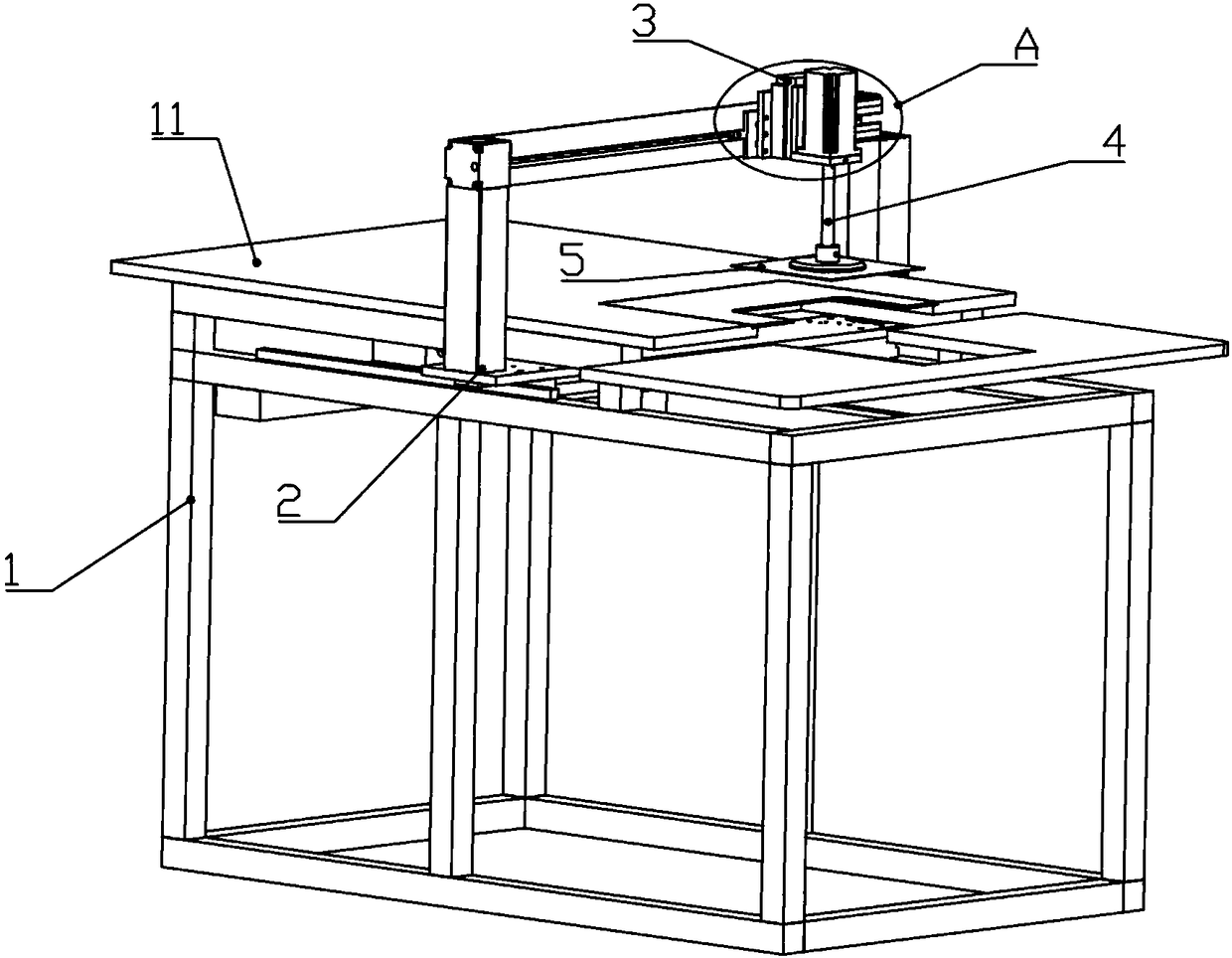

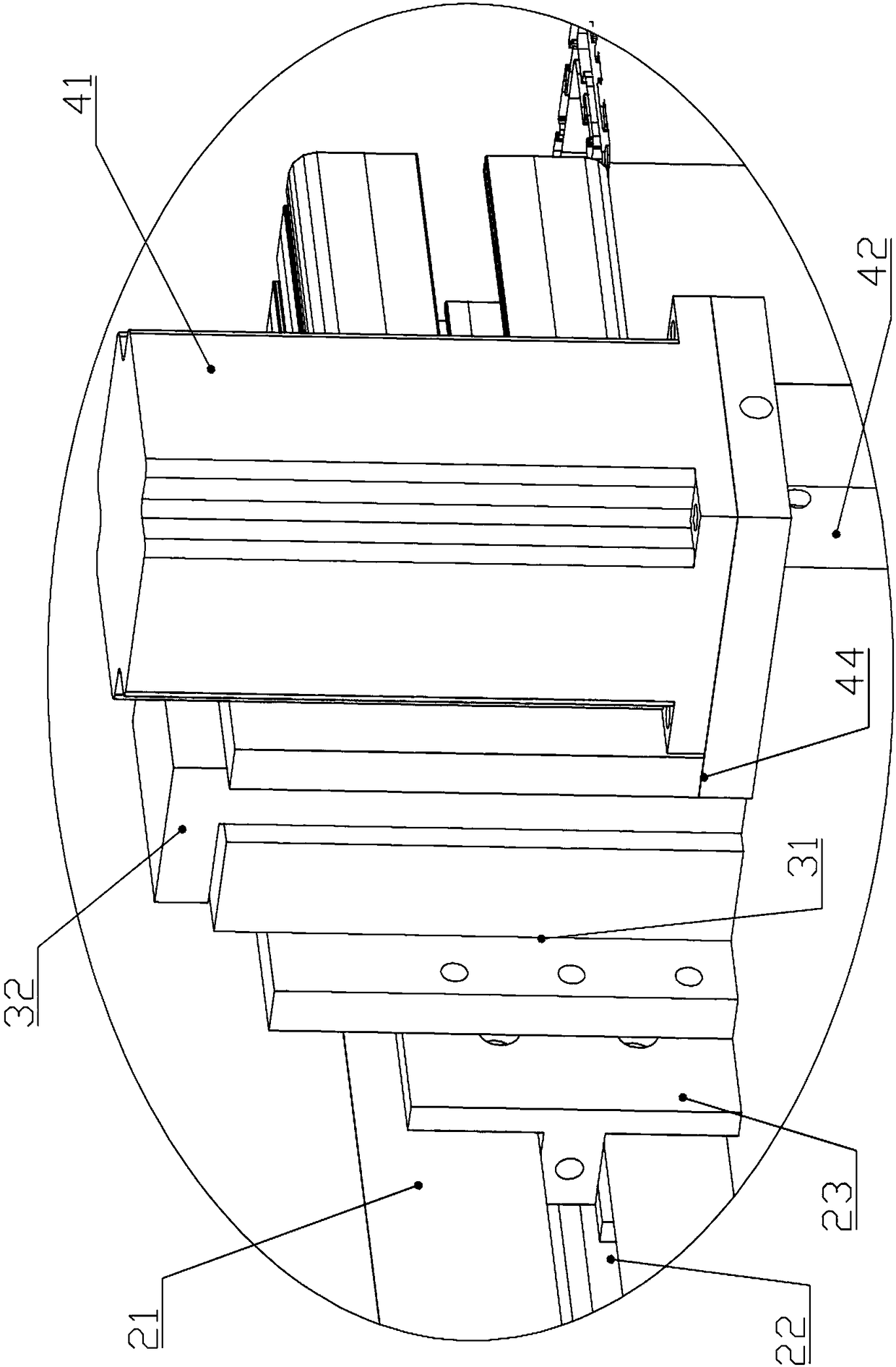

Template machine

The invention discloses a template machine, and belongs to the technical field of sewing equipment. The template machine comprises a rack, wherein a sewing machine and a sewing table surface are arranged on the rack; a sewing feeding system is arranged on one side of the sewing machine; the sewing feeding system comprises a planar feeding mechanism movably arranged on the sewing table surface; a material pressing device is arranged on the planar feeding mechanism through a lifting device and a steering device in a vertical downward manner; and a material presser is arranged in the material pressing device and is used for clamping fabrics so that the fabrics can be moved on the sewing table surface along with the planar feeding mechanism, rotated on the sewing table surface along with the steering device and matched with the sewing machine for sewing. According to the template machine disclosed by the invention, ways of feeding and thread routing in the prior art are changed, through combination of an added way of rotating through a clamping device and movement of a feeding device on the horizontal plane, control of thread routing is realized, so that a thread routing process is smoother, and thread traces are more attractive.

Owner:阮波

Auxiliary pulling mechanism of a sewing machine

The invention relates to the technical field of sewing machines, in particular to an auxiliary pulling mechanism of a sewing machine, which includes a processor and an auxiliary presser foot assembly;the auxiliary presser foot assembly includes an auxiliary presser bar hinged to a lift presser foot of the presser foot assembly, a driving device connected to the auxiliary presser bar and a sensorused for detecting the thickness of cloth; the processor is connected to the sensor and the driving device; the sensor sends the measured cloth thickness information to the processor, whereby the processor controls the driving device to control the pressure exerted by the auxiliary presser bar on the lift presser foot. When the sensor detects that the lift presser foot begins to rise, the sensor sends the measured cloth thickness information to the processor and the processor controls the driving device accordingly to increase the pressure exerted by the auxiliary presser bar on the lift presser foot, so that the cloth is not deformed due to insufficient vertical downward pressure, a folded part of the cloth can smoothly pass between the a press wheel and a needle cushion, and smooth sewing and uniform stitching and beautiful stitches are guaranteed.

Owner:东莞创辉缝纫机有限公司

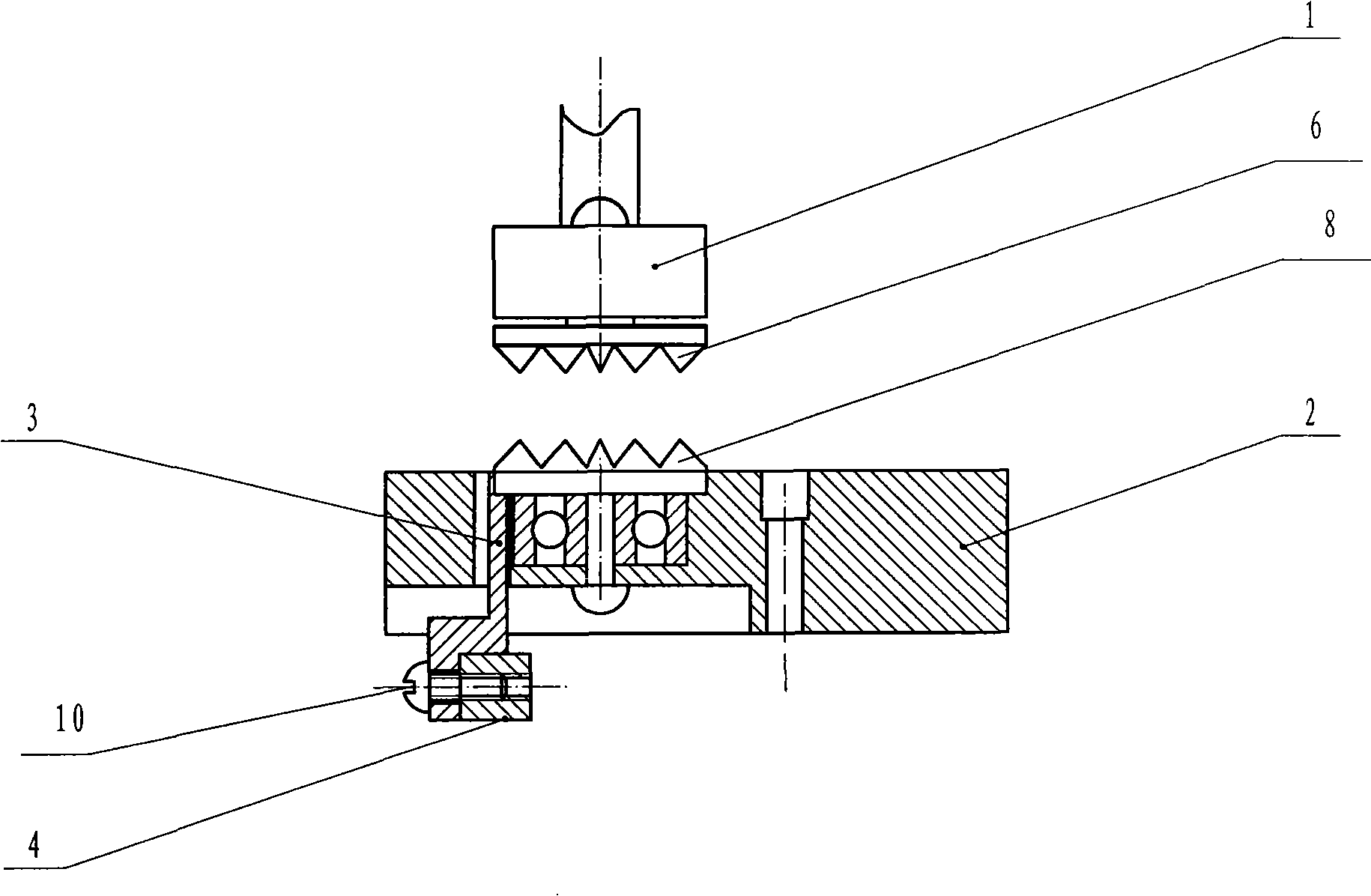

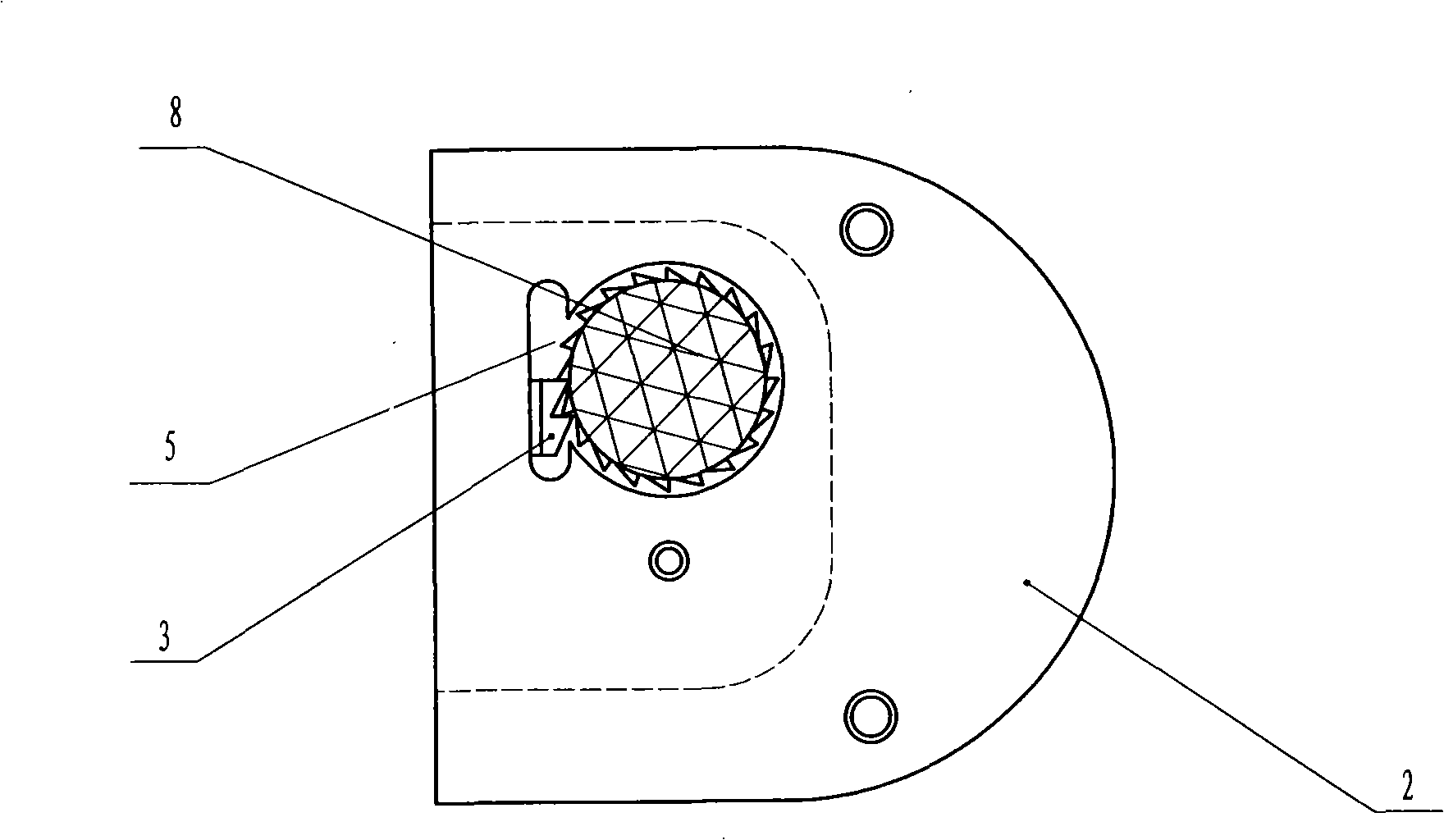

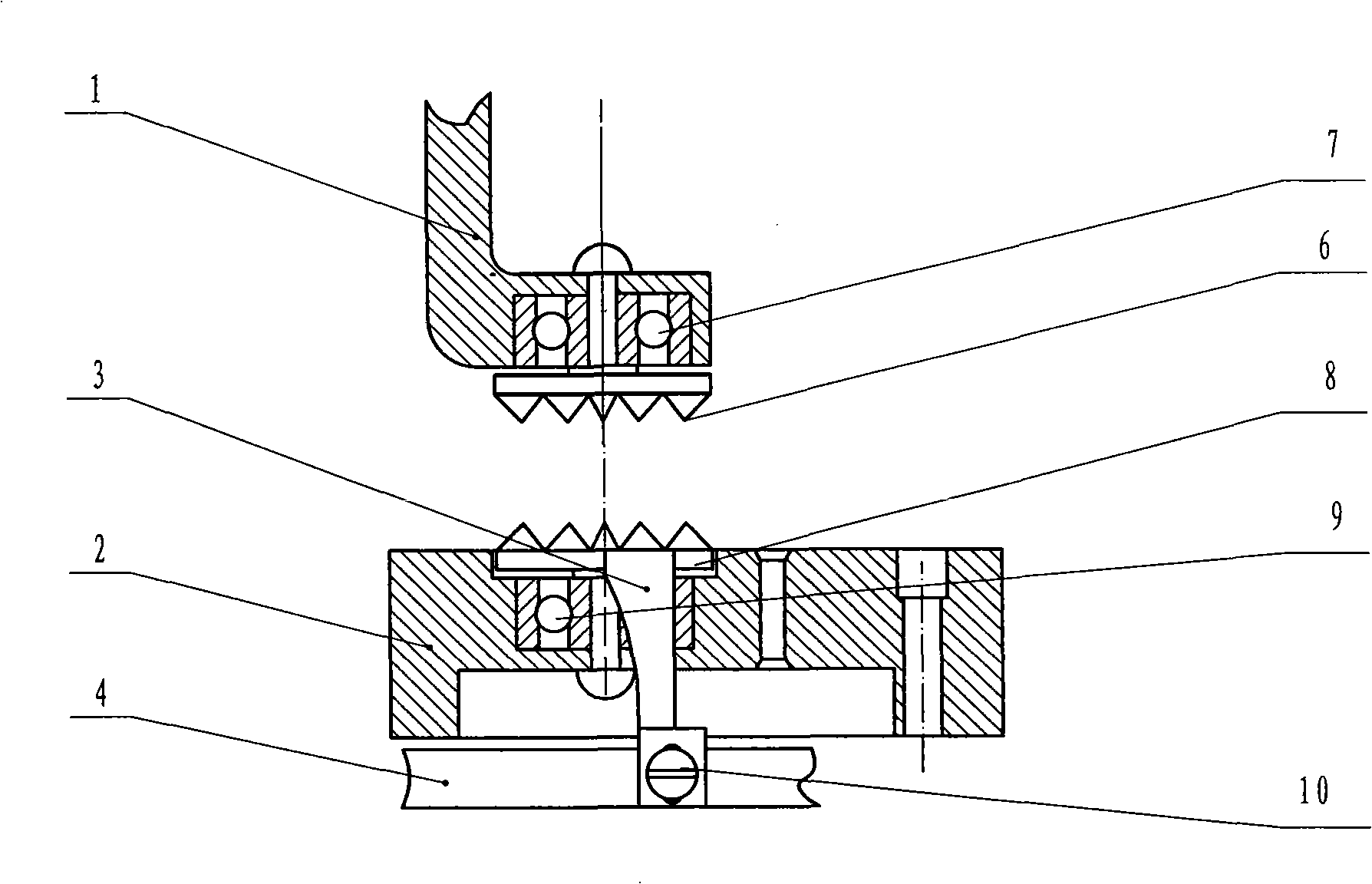

Circular rotating apparatus of flat seamer

InactiveCN101407981AEasy to operateSewing flatWork-feeding meansLoop takersEngineeringUltimate tensile strength

The invention relates to a flat bed sewing machine rounding device which is suitable for being used together with various single needle flat bed sewing machines. The invention aims at solving the technical problems of the existing technique that the labor intensity is large, the working efficiency is low and the production cost is high. The invention adopts the following technical proposal in order to solve the technical problems: the flat bed sewing machine rounding device comprises a presser foot body, a needle plate body and a machine tooth bracket, wherein, the device also comprises a tooth surface turntable, a tooth surface ratchet wheel turntable, a vertical type wheel-pulling machine tooth, and two bearings; the tooth surface turntable is installed on the presser foot body by the first bearing, the tooth surface ratchet wheel turntable is installed on the needle plate body by the second bearing, the lower part of the vertical type wheel-pulling machine tooth is connected with the machine tooth bracket by screw, and the machine tooth arranged at the upper part of the vertical type wheel-pulling machine tooth is contacted with the ratchet wheel of the tooth surface ratchet wheel turntable so as to push the tooth surface ratchet wheel turntable to rotate. The flat bed sewing machine rounding device has the advantages of simple operation, flat sewing, beautiful and uniform stitch, and good roundness, greatly improving work efficiency, being time-saving and labor-saving and meeting the requirement of large-scale production, and the like.

Owner:JIHUA 3534 CLOTHING

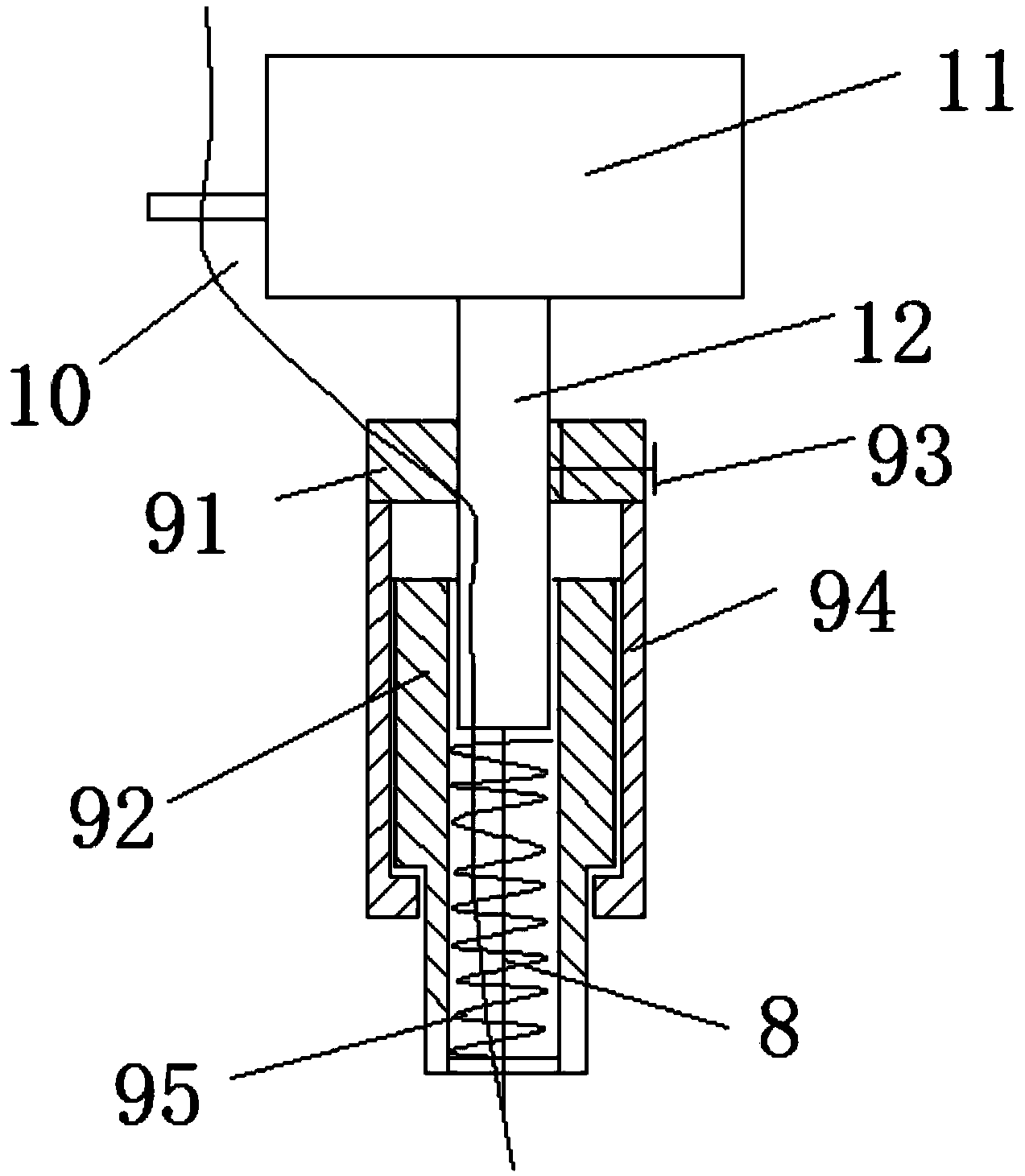

Sewing machine thread passing structure and sewing machine

PendingCN113235236AStable line storageStable thread consumptionThread-break detectorsTake-up devicesEngineeringSewing machine

The invention provides a sewing machine thread passing structure and a sewing machine. The sewing machine thread passing structure comprises a first thread clamping device, a second thread clamping device, a first threading plate, a thread picking plate, a thread passing plate, an upper curved needle and a lower curved needle; the thread picking plate is rotatably connected with a machine body of the sewing machine; the thread passing plate is provided with a first thread passing part and a second thread passing part; a first needle thread sequentially penetrates through the first threading plate, the thread picking plate, the first thread passing part and the upper curved needle through the first thread clamping device; and a second needle thread sequentially penetrates through the first threading plate, the thread picking plate, the second thread passing part and the lower curved needle through the second thread clamping device. The first thread passing part and the second thread passing part are arranged on the thread passing plate to pass threads respectively, so that the thread storage amount and the thread use amount of the upper curved needle and the lower curved needle can be stabilized, various sewing processes such as thin, medium and thick material overlocking and the like can be met, smooth thread outgoing and flat and attractive stitches can be ensured, and meanwhile, the product quality can be improved.

Owner:上海富山精密机械科技有限公司

A control system and method for an automatic reverse sewing device of a sewing machine

ActiveCN107090669BSimplify complexityReliable operation logicProgramme-controlled sewing machinesControl signalControl system

The invention provides an automatic reverse stitching device control system and method for a sewing machine, belongs to the technical field of sewing machines and solves the problems of low success rate of existing thread end overlocking and poor attractiveness. The automatic reverse stitching device control system for the sewing machine comprises a stitching structure, a driving motor module, an electric control unit, an inductive detection group and a sewing assisting device group, wherein at least one group of preset values are set on the electric control unit in advance, and when the actual turning angle value of a driving motor and an actual induction value of the corresponding cloth position are identical to a group of preset values, the electric control unit outputs corresponding control signals to control starting or stopping of one sewing assisting device corresponding to the group of preset values. The automatic reverse stitching device control system for the sewing machine has the advantages that the judgement result is more accurate, the success rate of thread end overlocking is higher and overlocked stitches are more attractive.

Owner:JACK SEWING MASCH CO LTD

Automatic mop machine

InactiveCN103938373BSimple structureReduce manufacturing costSewing-machine control devicesEngineeringProcess requirements

Owner:乐清智博缝纫机有限公司

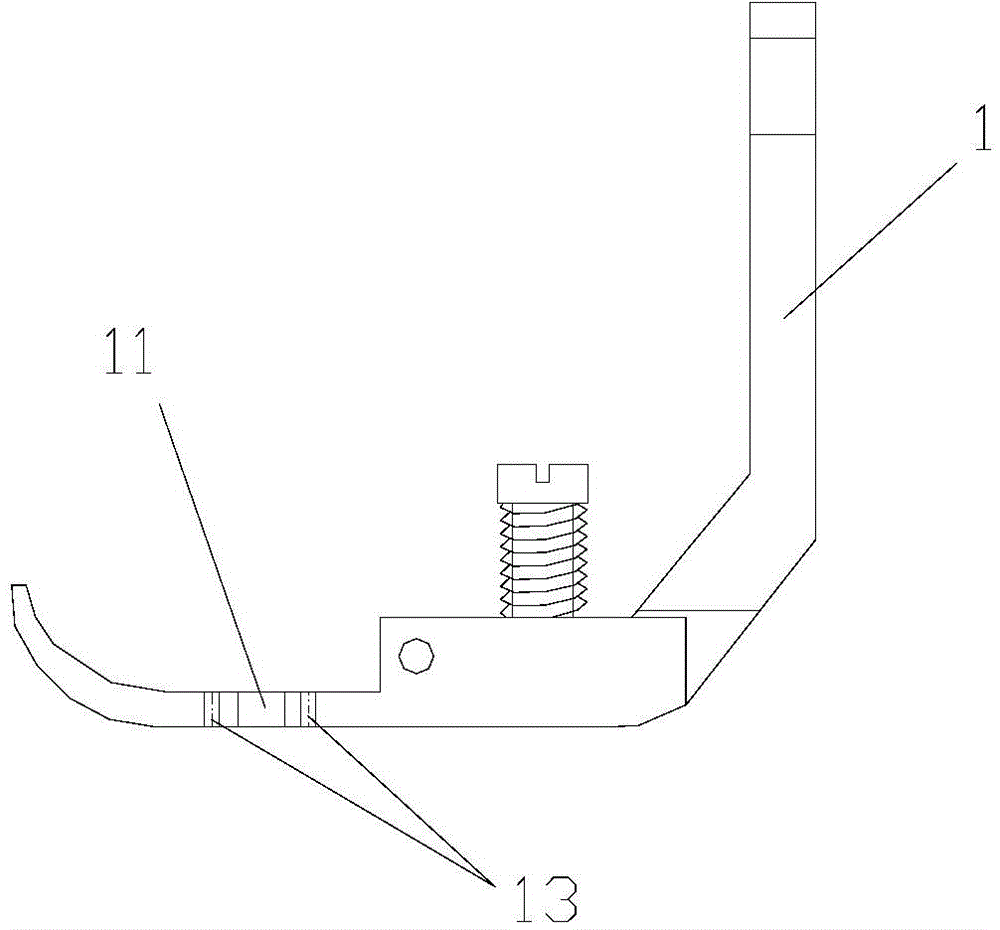

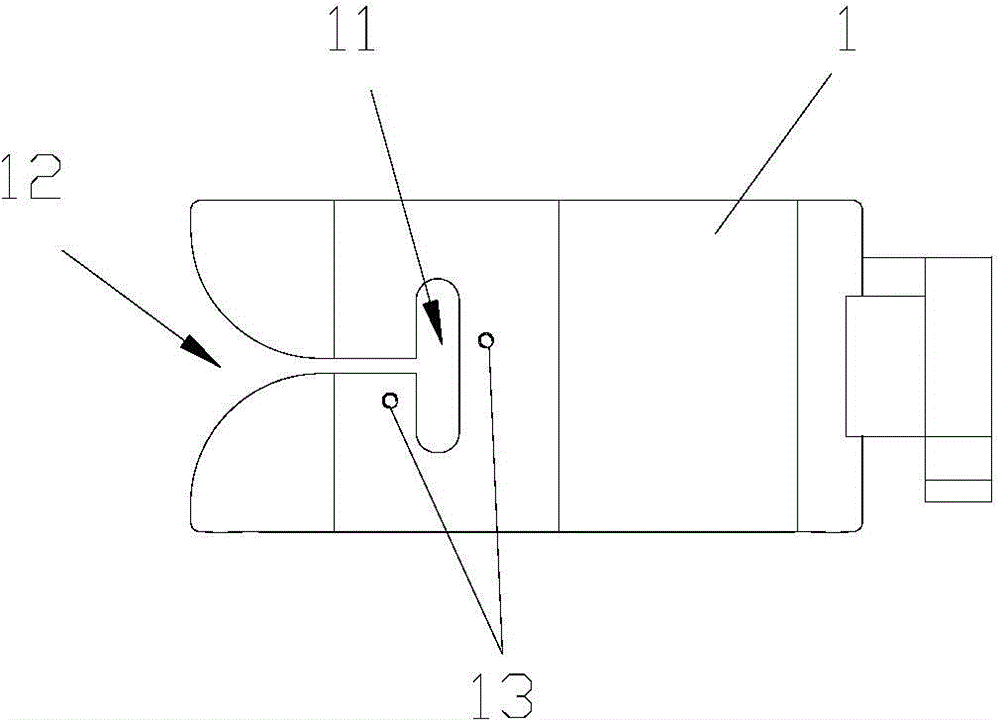

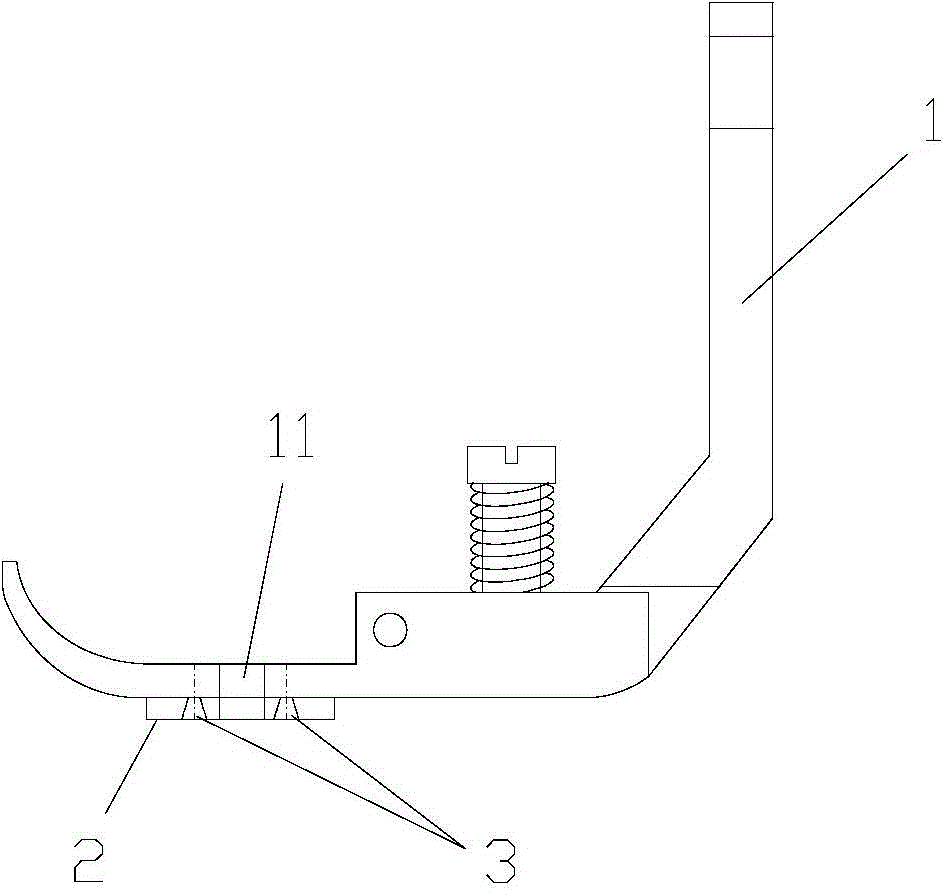

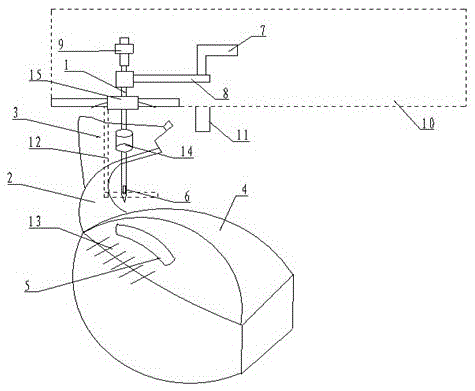

A kind of sewing machine to go to the bird's nest and quickly change the knife with a knife presser foot

ActiveCN105420938BQuick tool changeEasy to assemble and disassembleNeedle severing devicesPressersEngineeringSewing machine

Owner:JACK SEWING MASCH CO LTD

Sewing and embroidering process of high-speed intelligent thread-hooking trimming leather sewing and embroidering machine

The invention relates to a sewing and embroidering process of a high-speed intelligent thread-hooking trimming leather sewing and embroidering machine. The technical problems that upper thread is so tight as to be snapped when thick thread used for a thick embroidery material is trimmed, cloth pressing force of a press foot is not enough, press foot drive and needle rod drive cannot be controlled respectively independently, the thick thread cannot be trimmed, thread hooking displacement cannot be controlled and the like in the prior art can be solved sequentially through a thread-loosening thread-passing device, a thread-hooking line take-up device, a press foot independent-driving mechanism and a trimming restorer. The sewing and embroidering process has the advantages that tension of the upper thread is moderate when the thick thread is trimmed, the lowest position of the working height of the press foot can be adjusted intelligently, the press foot drive and the needle rod drive are controlled respectively independently to improve sewing and embroidering speed and efficiency of the machine, yield is improved, thick thread trimming operation is simple, thread loosening is avoided in trimming, a pair of scissors is long in service life, and thread hooking is controlled easily, and the like.

Owner:FUJIAN YONGXIN NUMERICAL CONTROL TECH

Upper Computer Stitching Machine

ActiveCN104233636BExtended service lifeStable processingLeather sewingPressersComputer engineeringSewing machine

The invention discloses a computerized sewing machine for shoe uppers, which comprises steel wire spring clips, stitches, a starting point, an end point, a stitch template, and a stitch channel. , There are stitches in the stitch channel, the beginning and the end of the stitches are the starting point and the end point respectively, and the upper fabric is fixed on the sewing machine movement platform through a plurality of steel wire spring clips. The invention has the advantages of simple structure, good sewing effect, good pattern consistency of the sewn vamp, and can operate multiple sets, greatly improving the production efficiency.

Owner:盐城市鑫亚机械有限公司

Automatic cloth spreader used for production of garment material

InactiveCN107572301AMeet the requirements of modern technologyImprove work efficiencyUnfolding thin materialsDisplay deviceEngineering

The invention discloses an automatic cloth spreader used for production of garment material. The automatic cloth spreader comprises a support rack, a cloth loosening device, a starting button, a controller and a pressure gauge. The cloth loosening device is arranged on the support rack. One side of the cloth loosening device is provided with the starting button, one side of which is equipped withthe controller. The pressure gauge is disposed above the controller. One side of the pressure gauge is provided with a display, one side of which is equipped with a heat dissipating housing. An elevator is arranged above the heat dissipating housing. One side of the elevator is provided with a support rod, one side of which is equipped with a cloth spreading device. The automatic cloth spreader used for production of garment material has the following beneficial effects: modern technological demands are met; working efficiency is high; product quality is ensured; additionally, the overall structure is simple and stable; stitches are attractive; and the automatic cloth spreader has a broad application.

Owner:SHENGZHOU BINGE CLOTHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com