Patents

Literature

38results about How to "Increase sewing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

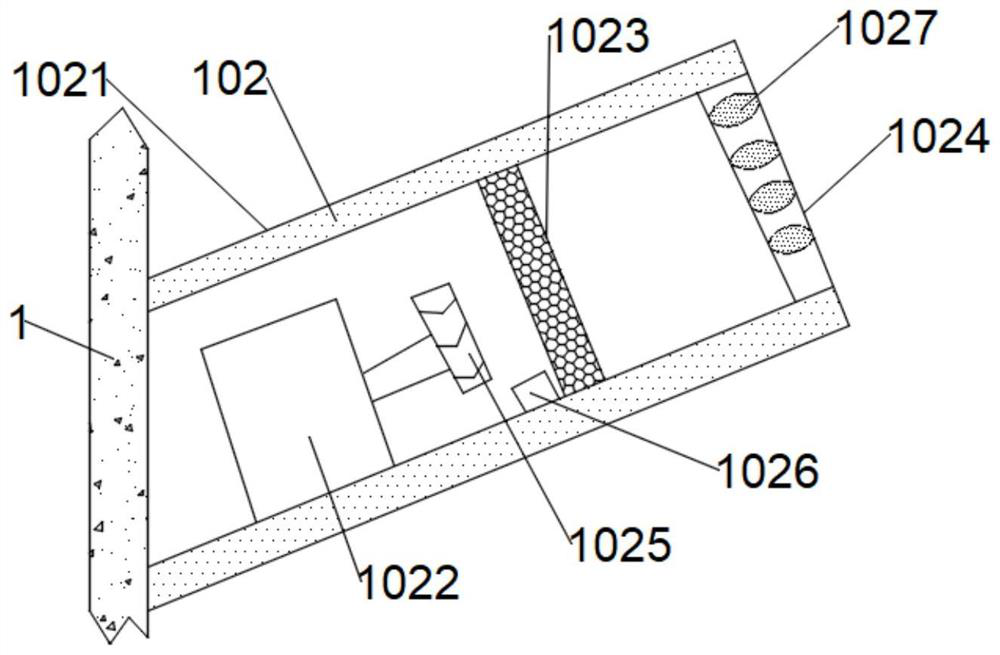

Finished product coloring equipment for automatic production of leather product

ActiveCN108396081AImprove drying efficiencyIncrease the areaSkins/hides/leather/fur manufacturing apparatusLeather/skins/hides/pelt chemical treatment apparatusPulp and paper industryAir drying

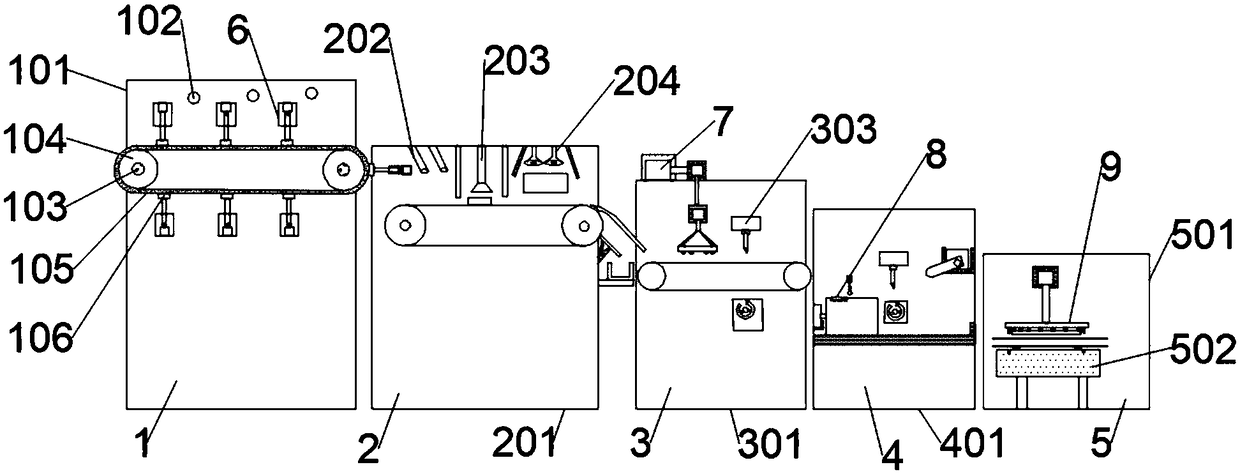

The invention discloses finished product coloring equipment for automatic production of a leather product. The finished product coloring equipment comprises an efficient leather blow-dry device. The efficient leather blow-dry device comprises a mounting frame; a coloring device is arranged at the right end of the mounting frame and comprises a mounting shell; a cold wind blow-flattening device, anink jet device and a drying device are sequentially mounted at the top end inside the mounting shell from left to right; a leather conveying belt is mounted inside the mounting shell through two rollers; a leather clamp mounted on the inner wall of the mounting shell is arranged at the bottom end of the ink jet device; and the leather conveying belt is located at the lower right end of a straightplate conveying chain, and a leather-fabric sewing device is arranged at the lower right end of the leather conveying belt. Leather is subjected to blow-flattening by the cold wind blow-flattening device before being machined by the coloring device, and then the leather is colored by the ink jet device, so that the coloring quality is good; and the leather is heated and dried by infrared drying lamps after being colored, thus the air-drying time is saved, and the production efficiency of the leather product is improved.

Owner:周磊

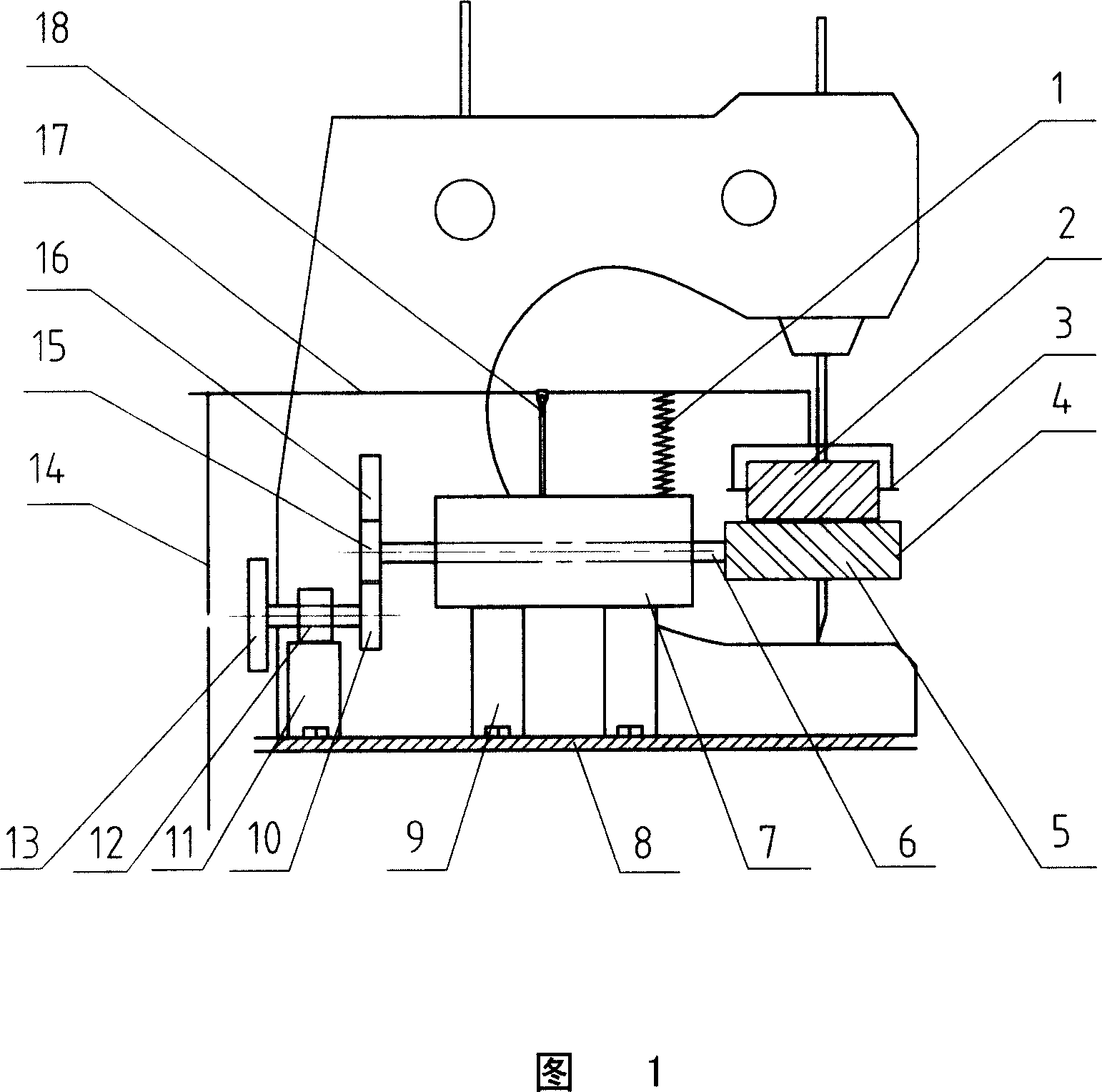

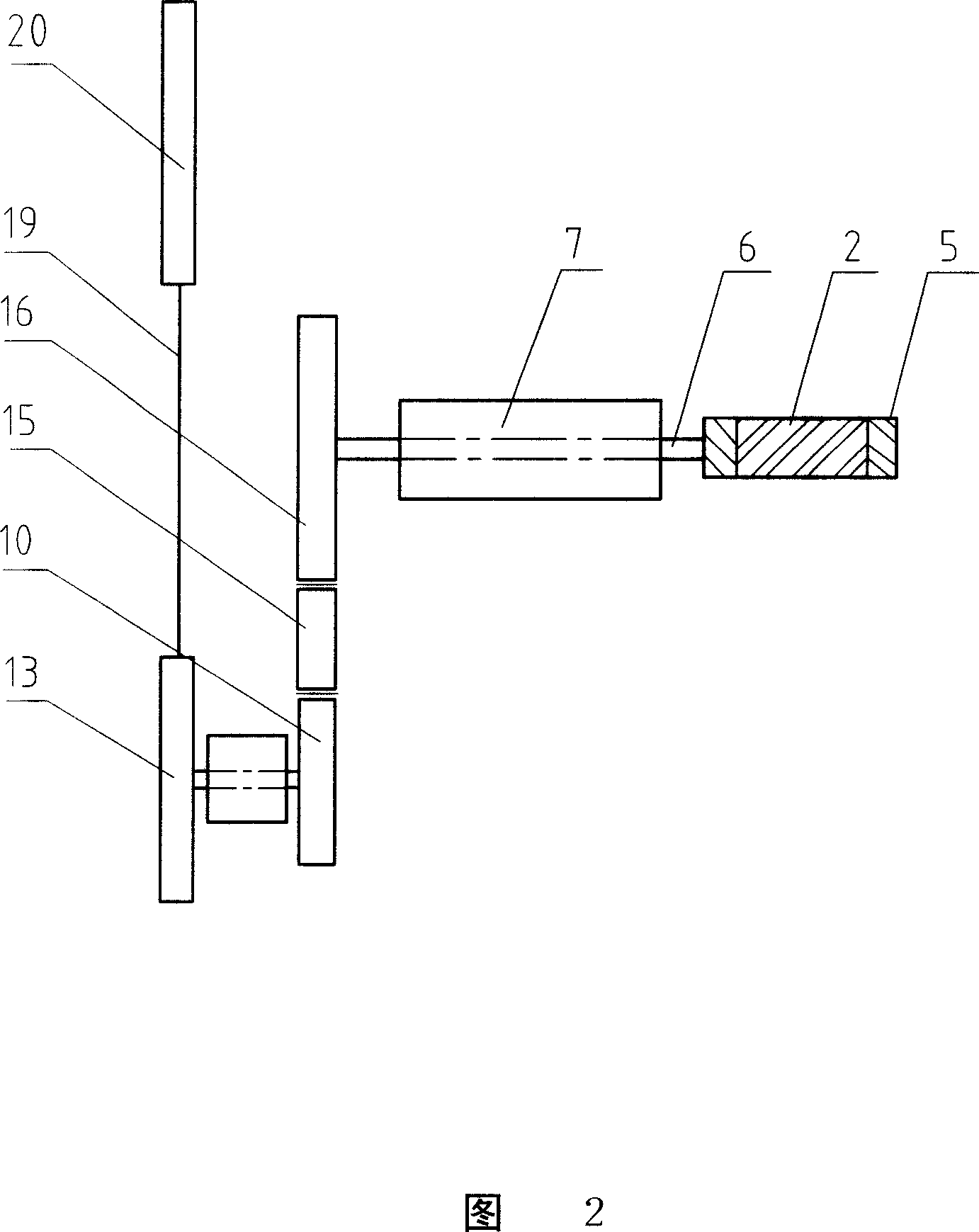

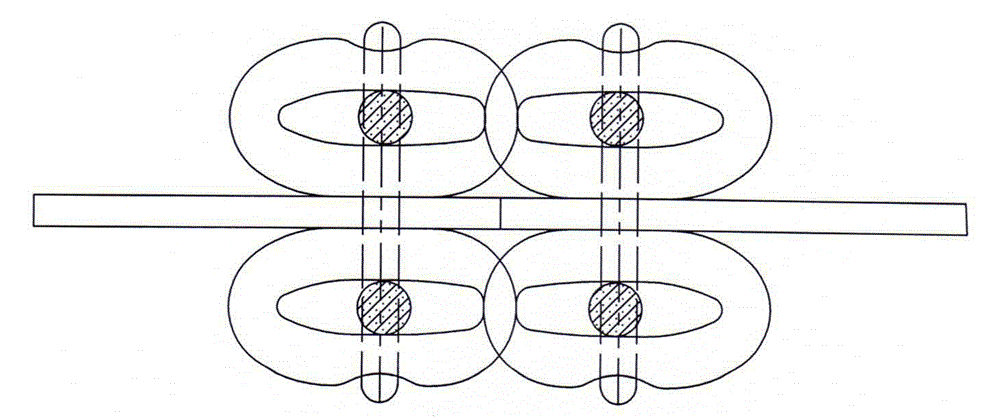

Fabric synchronizing tractor of industrial sewing machine

InactiveCN101074519ATroubleshoot synchronous traction issuesCorrect and maintain sewing directionWork-feeding meansJoystickClutch control

This invention discloses one synchronous traction device of industrial sewing machines fabric, it includes stent installed on the table and driving wheel of machine heads, the point is that install one follower wheel with transmission gears at the back of driving wheel, the follower wheel is connected with driving wheel by belt; one shaft is installed at one side of the gear of driven wheel, at one side of the shaft install a differential gear and an active roller at the other side, the steering Gear is installed between the gear of driven wheel and differential gear, the two gear in between match; one support bar is installed on the double-bearing, its top connect with one connecting rod, at one side the connecting rod connect without fix with clutch control rod, at the other side it connect with friction roll by pin, in order to make the friction roll work closely with active roll one tension spring is installed between the double-bearing and connecting rod. This invention has the traits of new structure, reasonable design, good synchronous effect, it not only improves the quality of sewing fabric, but also lowered the cost of production and widely to be installed to use in the industrial sewing machines of flake sewing fabric.

Owner:刘青

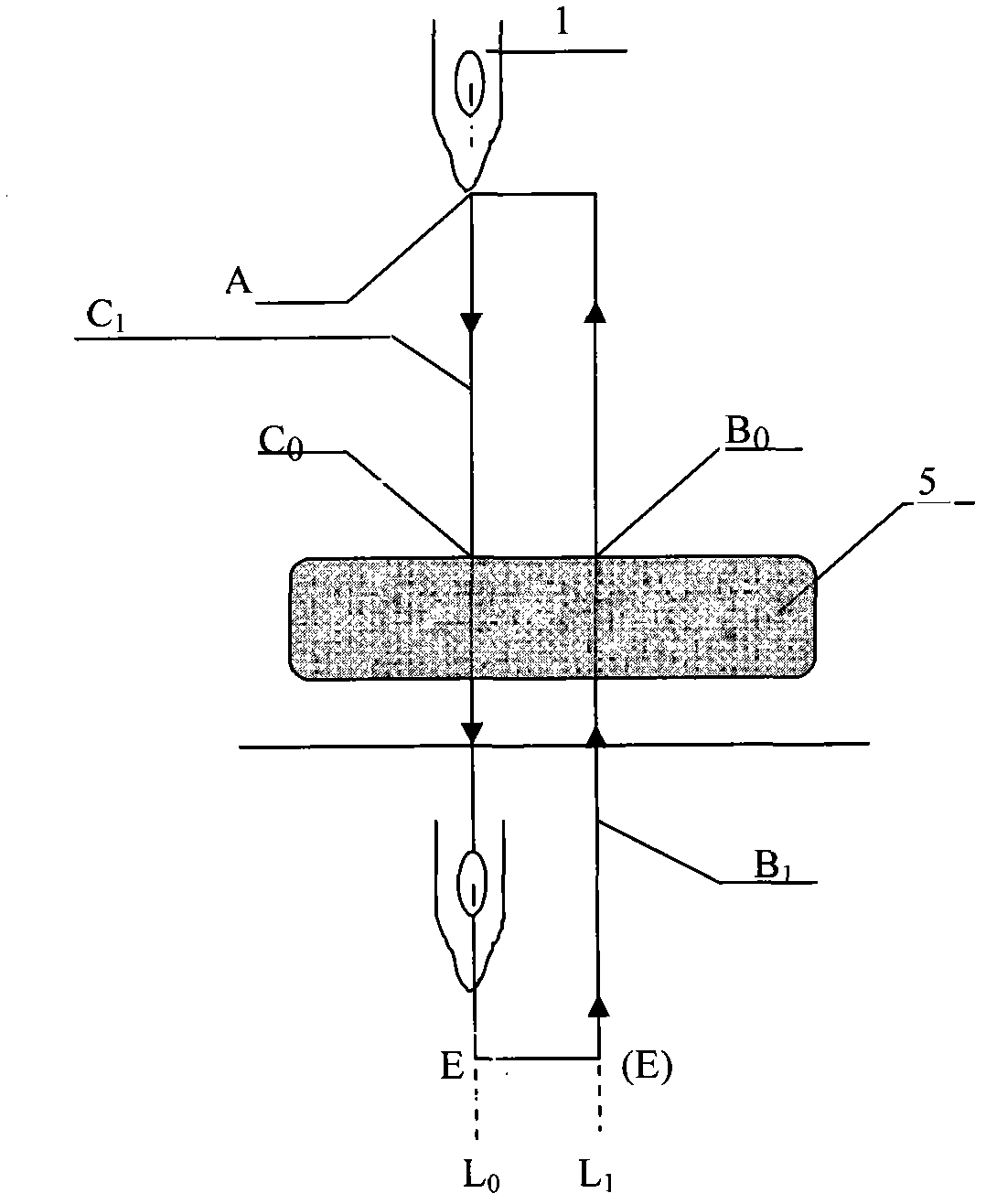

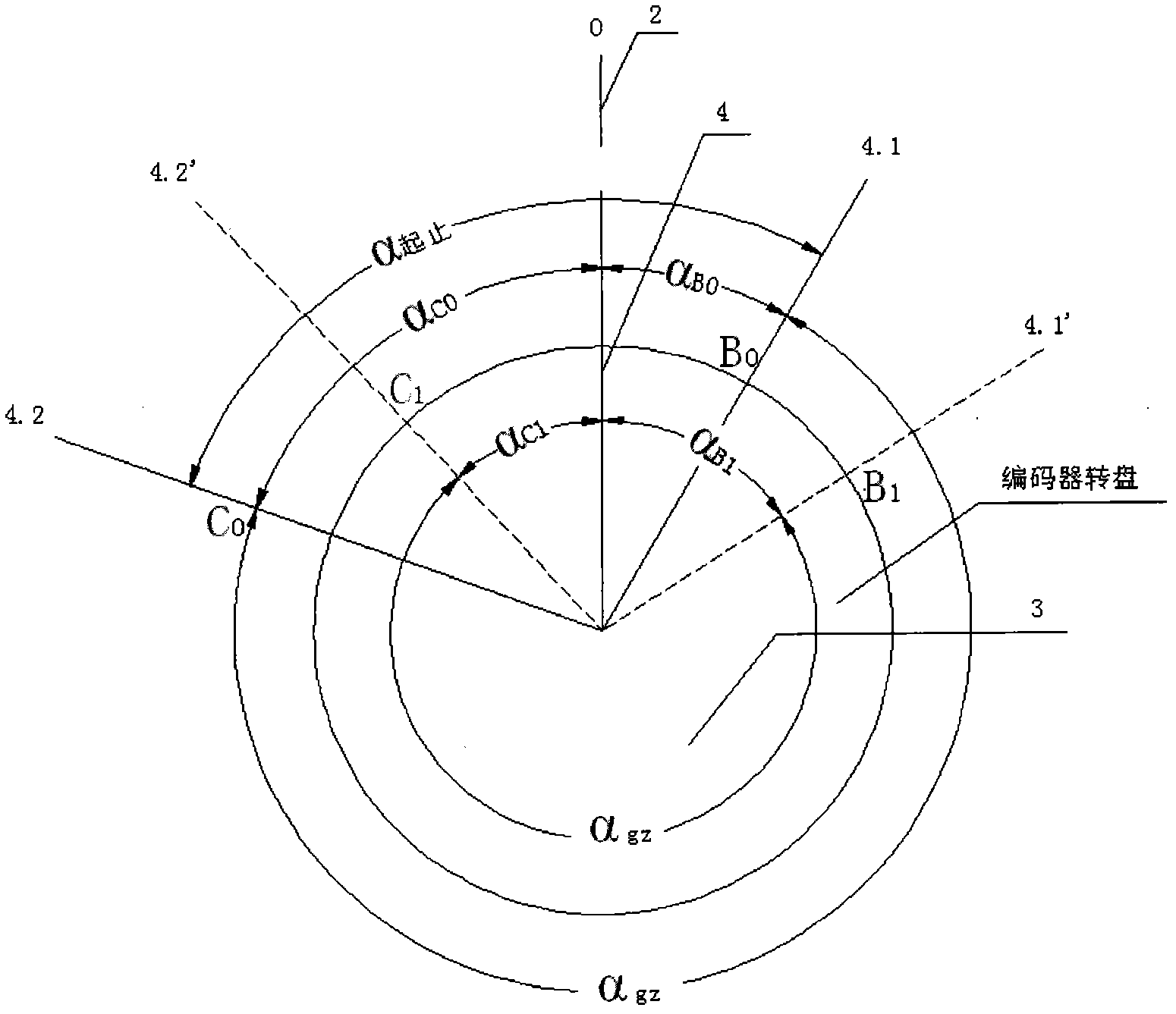

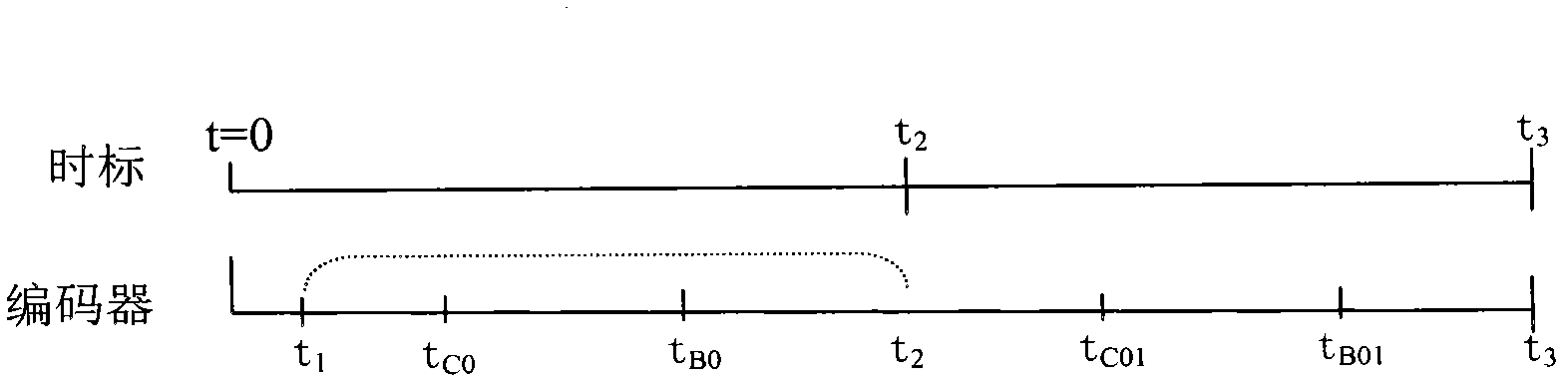

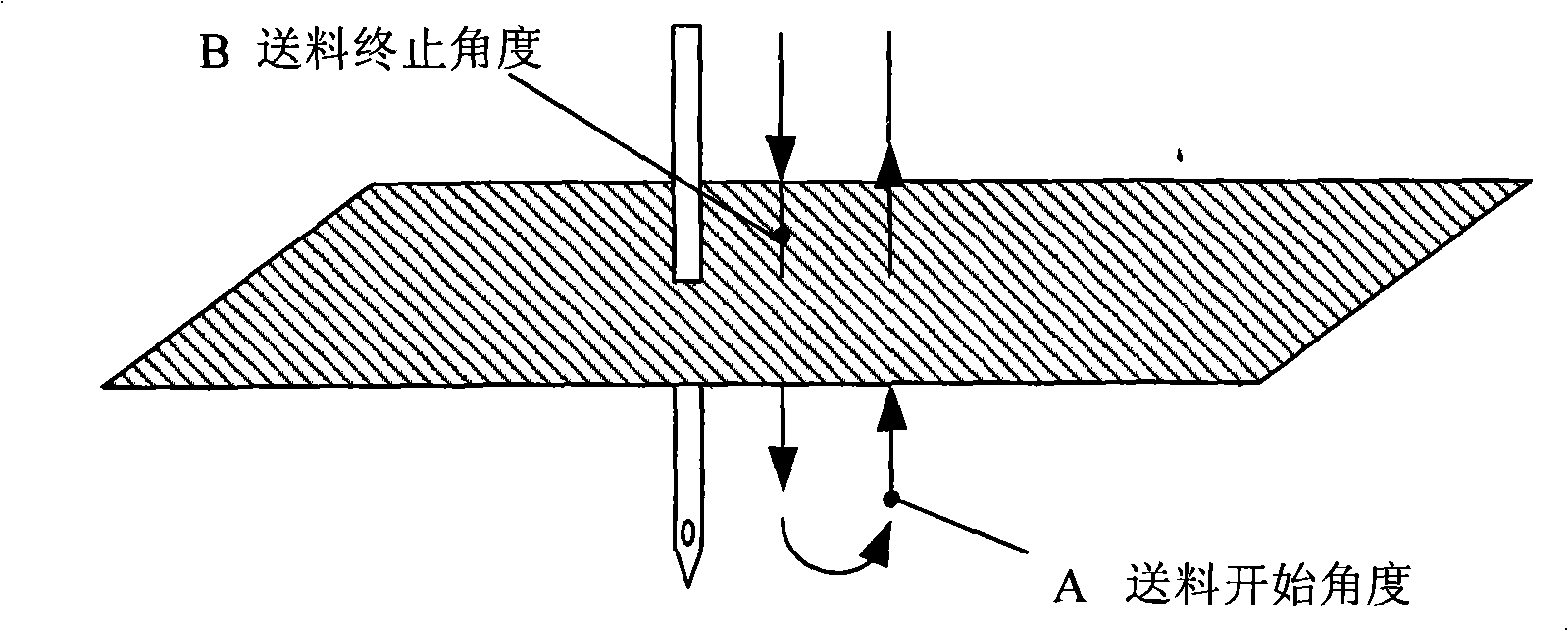

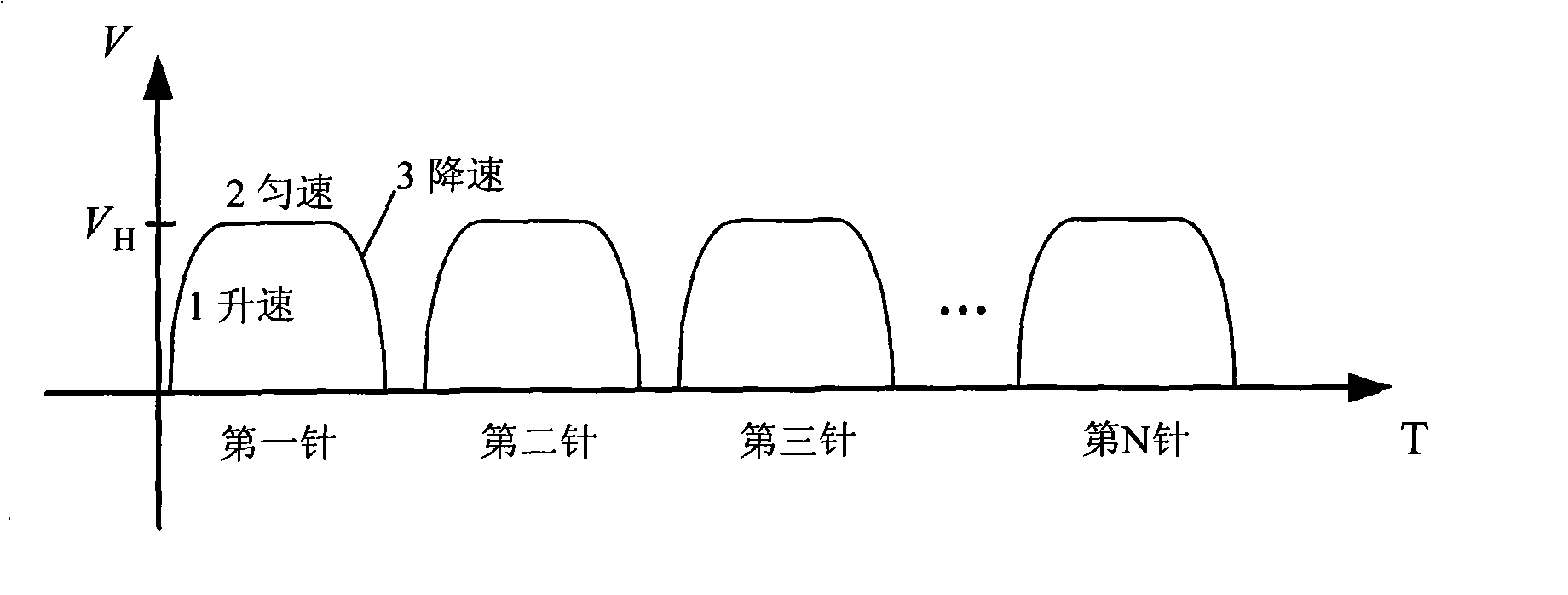

Method for controlling high-speed running of direct drive industrial sewing machine

ActiveCN102321955AImprove sewing speed and sewing effectSolve pattern reductionWork-feeding meansSewing-machine control devicesEngineeringTextile

The invention provides a method for controlling high-speed running of a direct drive industrial sewing machine. The method comprises the step of determining the relation between the needle bar up-and-down moving and sewing process and up-and-down moving of a main shaft as well as the angle of an encoder under the condition of not conveying cloth, and particularly the method realizes the purpose of improving the sewing speed and sewing effect through dynamically adjusting the cloth conveying time of the X shaft and Y shaft of the sewing machine. By using the method, the problems that in the existing control method, the patterns are reduced when a thick fabric is sewn and the sewing efficiency is low can be solved, and the sewing efficiency is further improved on the premise of guaranteeing the sewing quality.

Owner:陕西新瑞阳科技有限公司

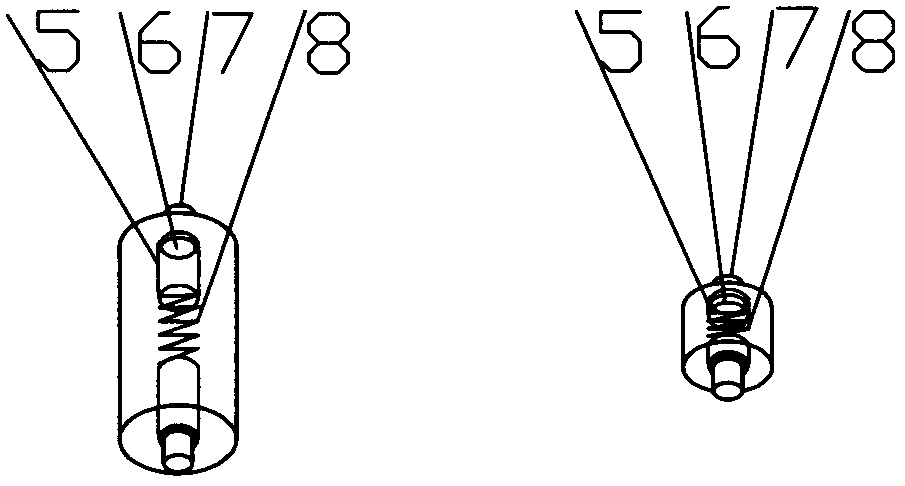

Pressure foot of sewing machine

The invention provides a pressure foot of a sewing machine. The pressure foot comprises a pressure foot body, pin rollers and rubber line belts, wherein three grooves are formed in the bottom of the pressure foot body, at least three pairs of small holes are correspondingly formed in the two sides of each groove, all the small holes are located in a same horizontal line, the pin rollers matched with the grooves are arranged in the small holes, the surfaces of the pin rollers are higher than the edges of the two sides of each groove, the pin rollers among the grooves are covered and connected through the end-to-end rubber line belts, and the rubber line belts drive the pin rollers to roll freely. The pressure foot of the sewing machine has the advantages that the rolling pressure foot is adopted to replace a sliding pressure foot, friction resistance is reduced, the cloth feeding process is well completed, the sewing quality and technology are improved, the sewing speed is increased, and meanwhile, the pressure foot is convenient to produce and use, safe, reliable, high in working efficiency, remarkable in benefit, and suitable for application and popularization.

Owner:黄昌辉

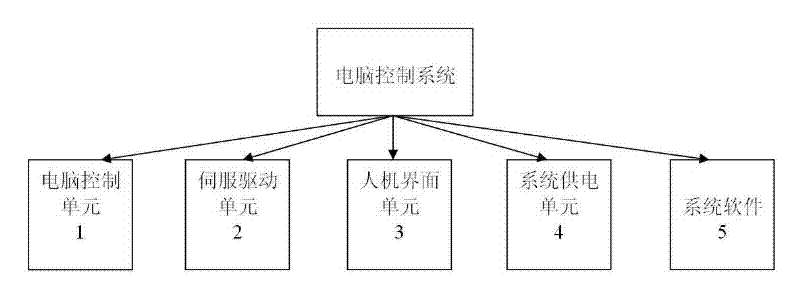

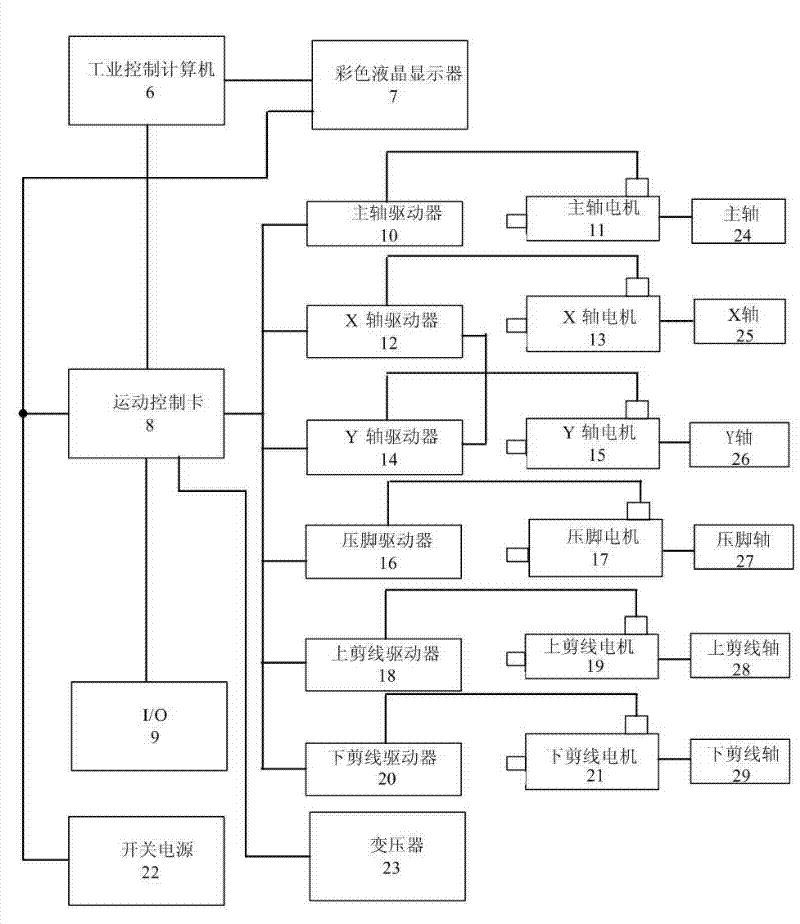

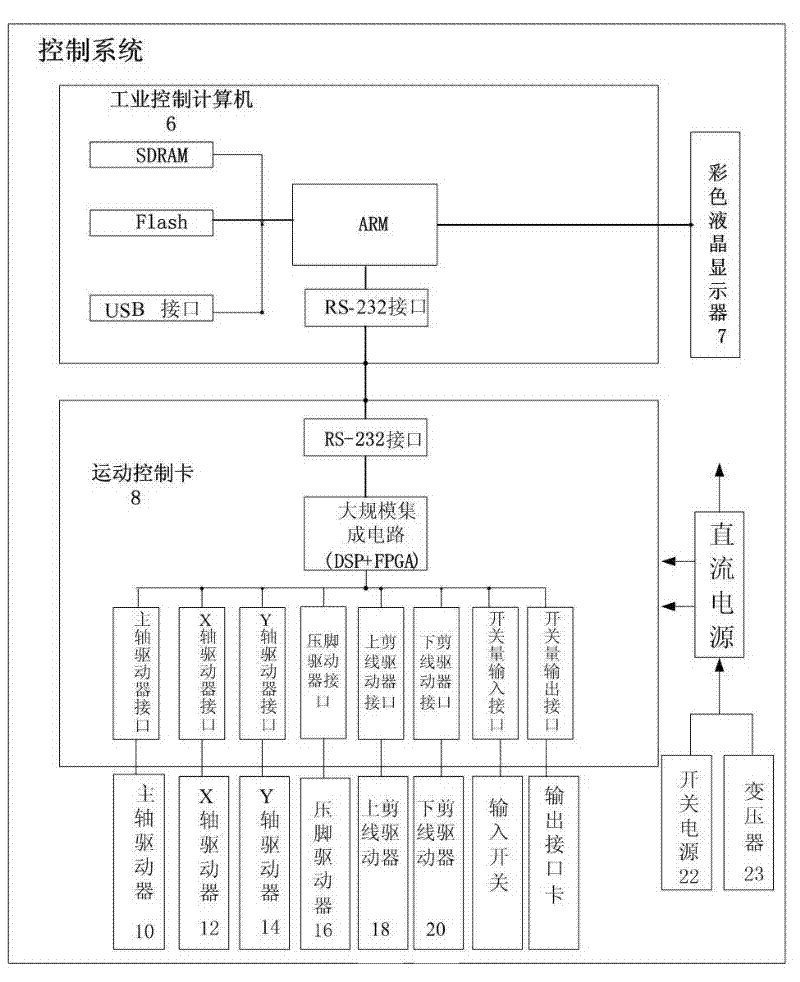

Computer control system for flat-buttonhole buttonholing machine

InactiveCN102560906AIncrease sewing speedGuaranteed uptimeProgramme-controlled sewing machinesHuman–machine interfaceTransformer

The invention provides a computer control system for a flat-buttonhole buttonholing machine, comprising a computer control unit consisting of an industrial control computer, a motion control card and an I / O (input / output), a server driving unit consisting of an alternating current motor and a stepping motor, a human-computer interface unit consisting of a color LCD with a touch function, a system power supply unit consisting of a switching power supply and a transformer, and system software planning a human-computer interface to realize human-computer interaction. The computer control system adopts a modularized and unitized structure, each unit is internally and relatively independent and self-contained, so that the computer control system is high in integration degree, and corresponding part forming systems can be flexibly configured according to the different host computers of the flat-buttonhole buttonholing machine. Various buttonhole graphics are automatically sewn by a system software procedure with high speed, the computer control system is stable in running, small in noise, attractive and even in stitch, and convenient to operate, various graphic data files are quickly and simply generated, the labor intensity is greatly reduced, and the production efficiency is improved.

Owner:MIANYANG WEIBO ELECTRONICS

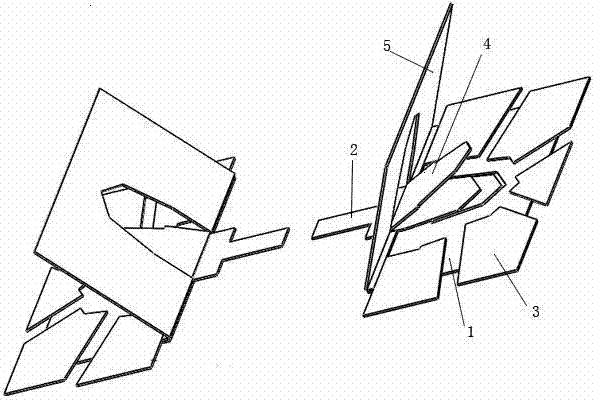

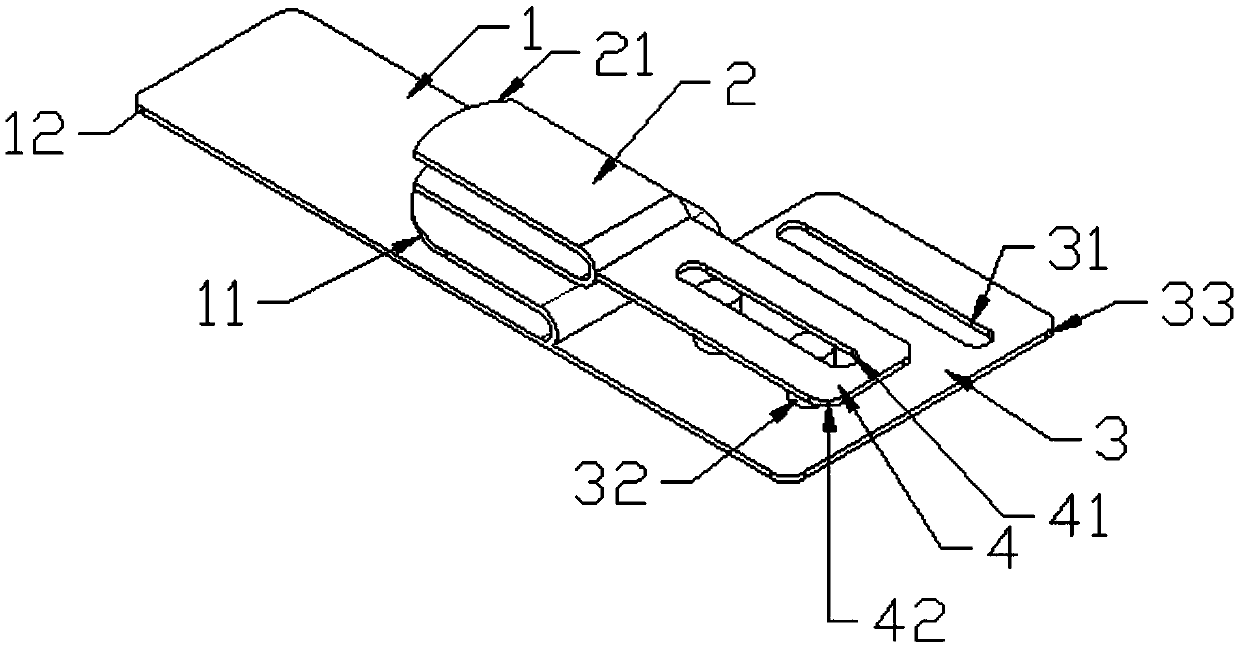

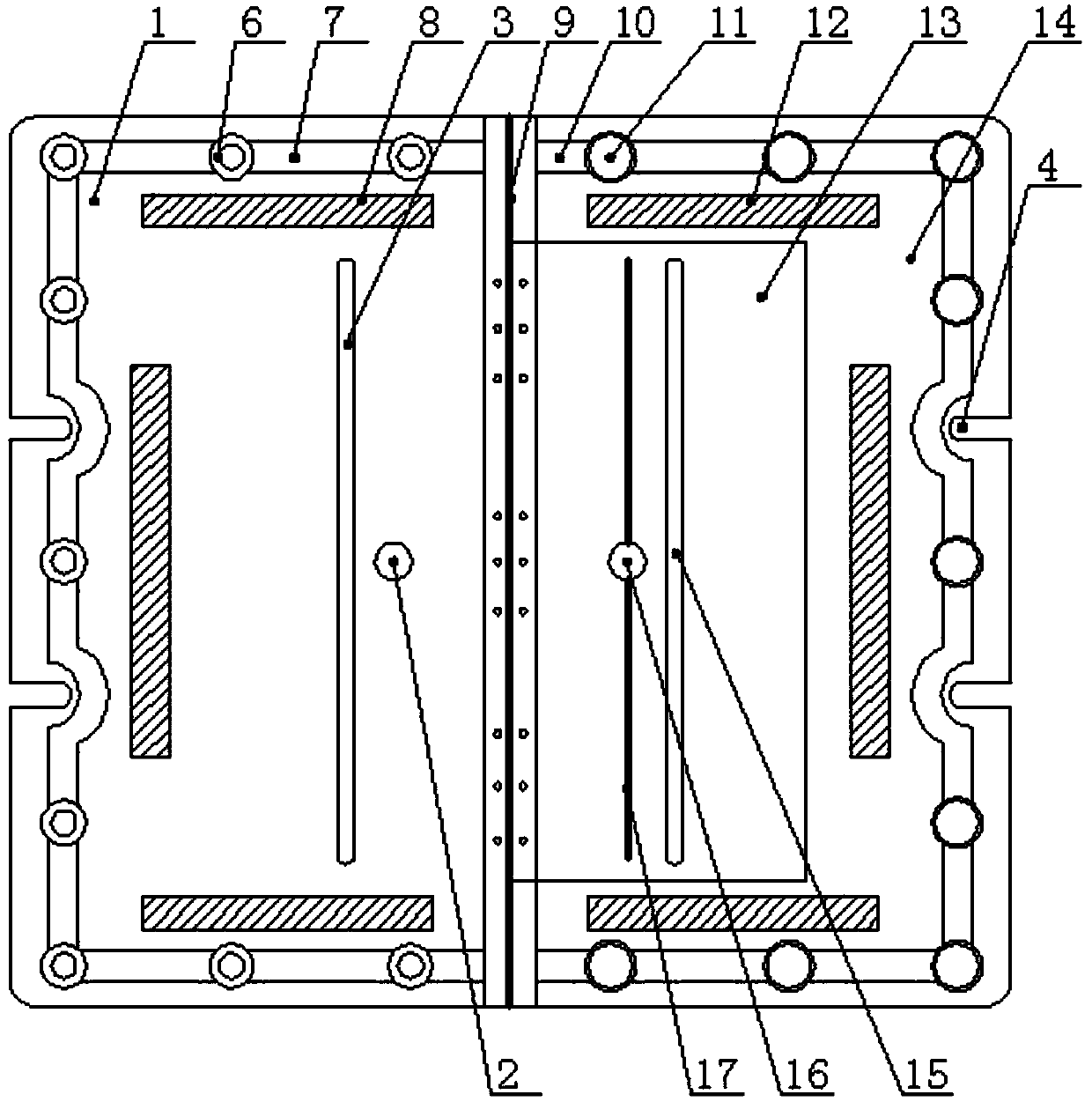

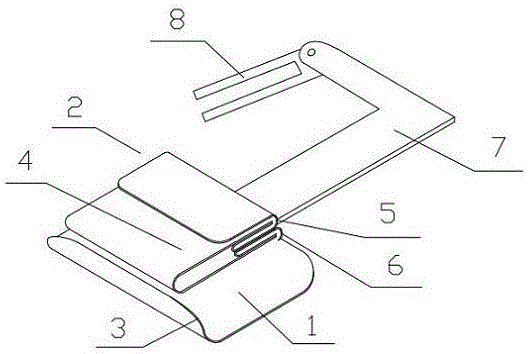

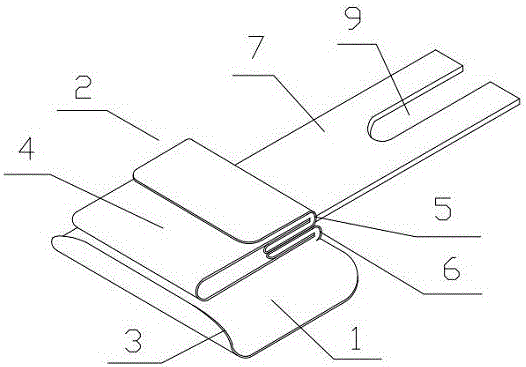

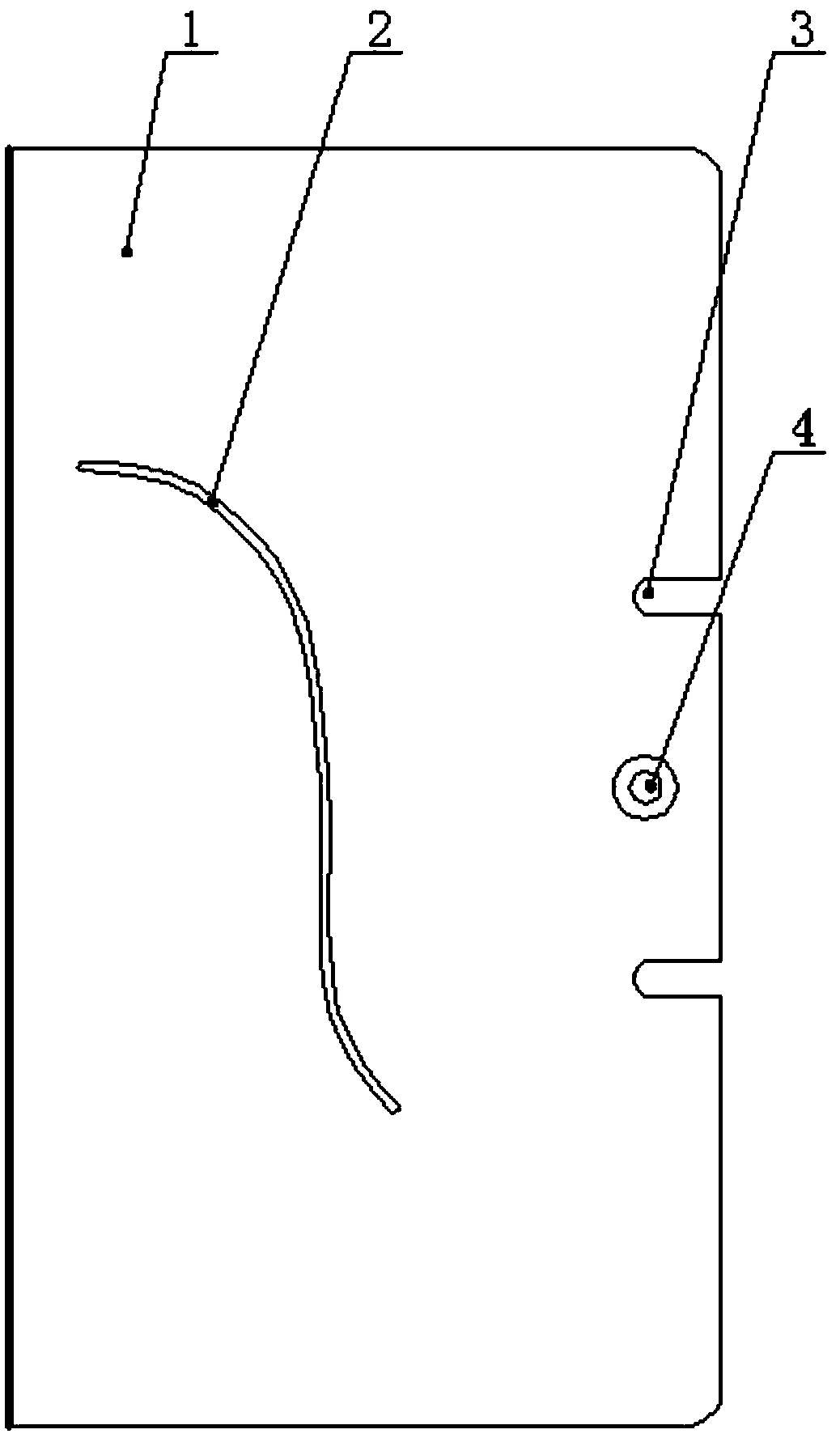

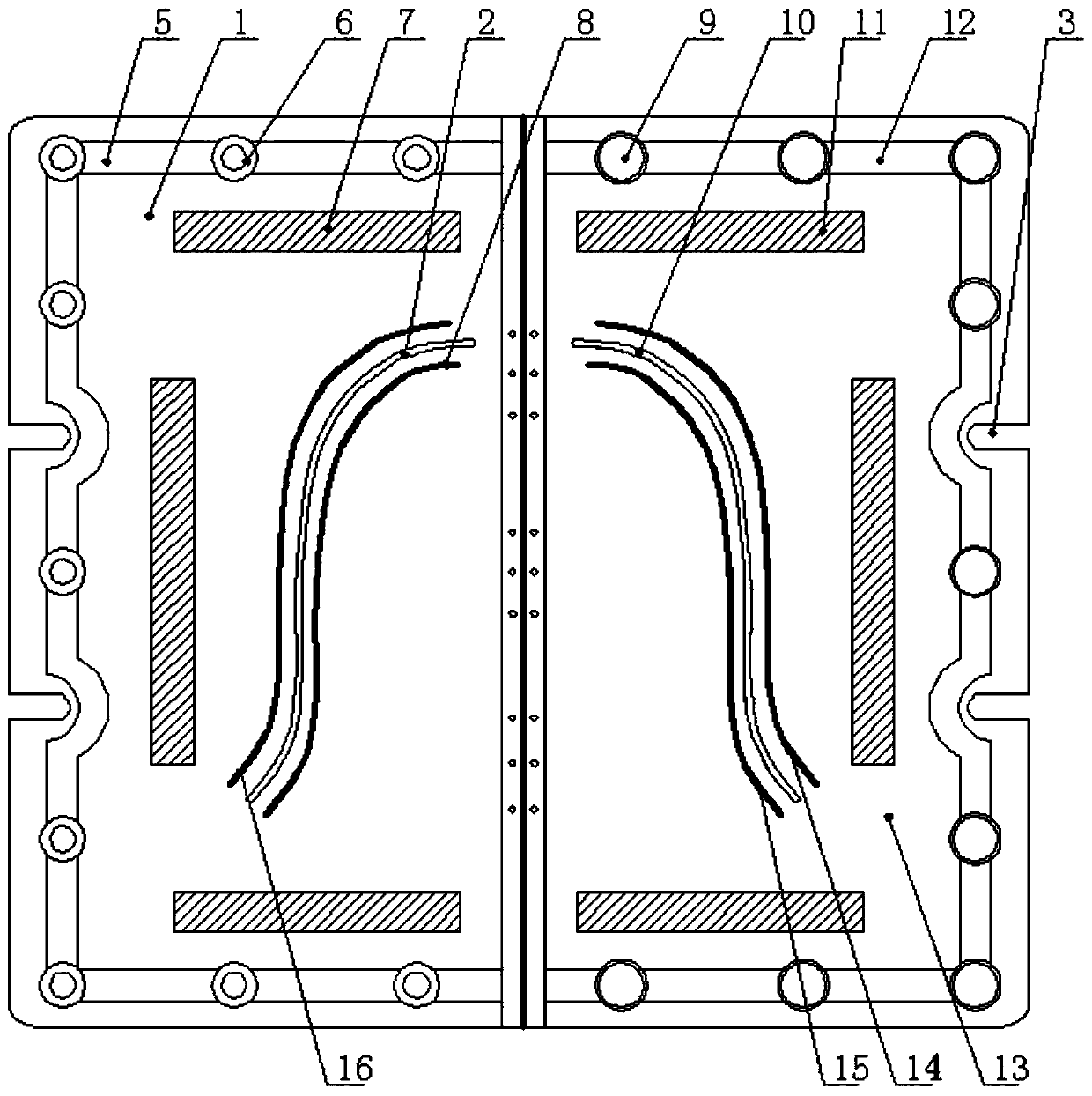

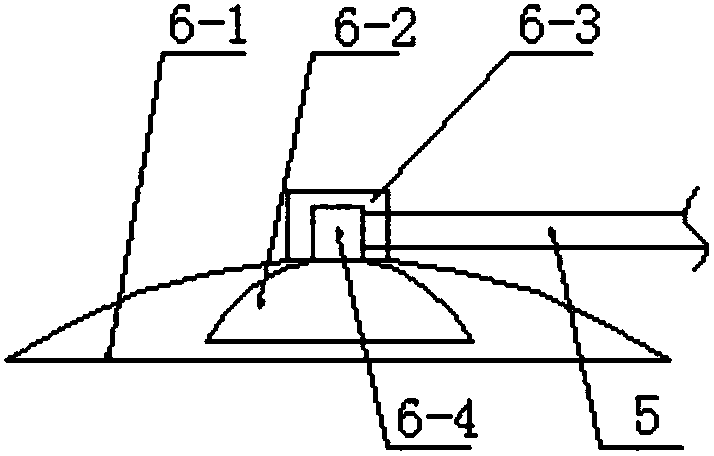

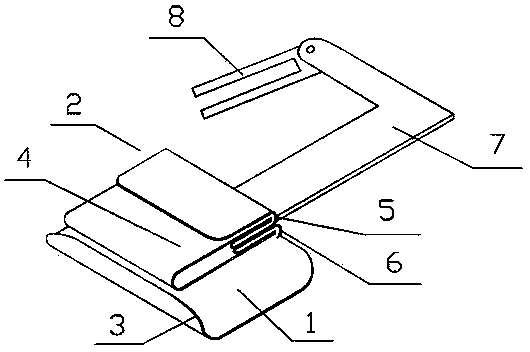

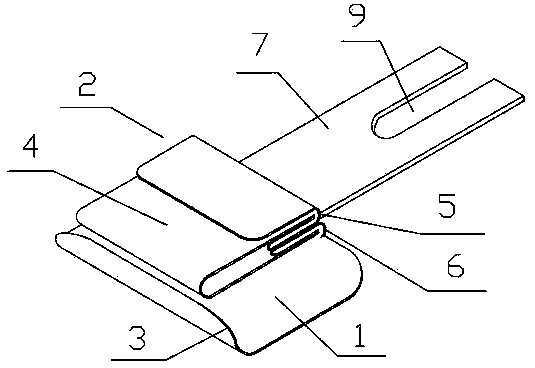

Template for sewing non-ironing sleeve tab

InactiveCN104705879ASimple structureEnsure sewing qualityWork-feeding meansClothes making applicancesEngineeringWedge shape

A template for sewing a non-ironing sleeve tab comprises two edge folding template bodies capable of being oppositely opened or closed. Each edge folding template body comprises an orbital groove plate on the first layer, a movable pressing plate on the second layer and an edge pressing plate on the third layer, wherein sewn curves of the orbital groove plate are consistent and are each in a sleeve tab shape, the movable pressing plate is matched with the outer edge of an orbital groove, movable edge folding plates are arranged on the periphery of the curve edge of the movable pressing plate, the corresponding side faces of the movable pressing plate and the movable edge folding plates are in matched wedge shapes, the edge pressing plate is consistent with the edge of the orbital groove, a supporting plate consistent with the outer edge of the orbital groove is arranged outside the edge pressing plate, the sum of the thicknesses of the orbital groove plate, the movable edge folding plates and the supporting plate is the same as the sum of the thicknesses of the orbital groove plate and the edge pressing plate, the single sides of the orbital groove plate, the edge pressing plate and the supporting plate are attached and connected through adhesive tape, and abrasive paper is attached to the orbital groove plate, the edge pressing plate and the supporting plate. The template is simple in structure and easy to learn and use, the sewing quality is ensured, the sewing difficulty is lowered, and the sewing speed is increased.

Owner:ZHENGZHOU YERAD GARMENTS

Jacket processing equipment

InactiveCN105506869AGuaranteed accuracyGuaranteed to be tidy and beautifulWork-feeding meansEngineeringSewing machine

The invention provides jacket processing equipment comprising a first guide assembly, a second guide assembly, a first guide bottom plate and a second guide bottom plate, wherein the first guide assembly and the second guide assembly are M-shaped, the first guide assembly is fixed on the first guide bottom plate, an opening of the first guide assembly is far away from the first guide bottom plate, the first guide bottom plate is fixed on a sewing machine, the second guide assembly is fixed on the second guide bottom plate, an opening of the second guide assembly is far away from the second guide bottom plate, and the first guide bottom and the second guide bottom plate are separated. The jacket processing equipment is simple in structure and short in processing period, can quickly sew sleeves at different levels and can greatly improve the working efficiency and increase the percent of pass of jackets.

Owner:天津市宝坻区志远制衣有限公司

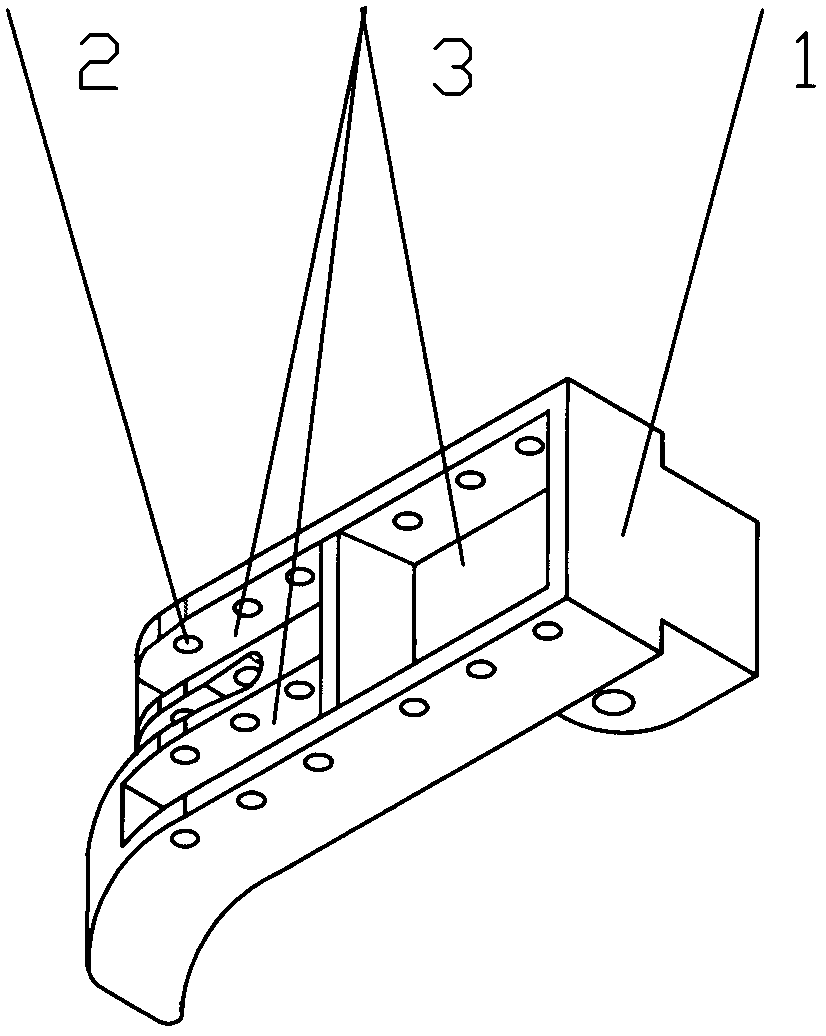

Device for automatic separation and resetting of needle rods of double-needle machine

The invention provides a device for automatic separation and resetting of needle rods of a double-needle machine. The device comprises a sliding shaft, one end of the sliding shaft is connected with a separating assembly, the other end of the sliding shaft is connected with a resetting assembly, the separating assembly comprises a swing rod and a driving rod which can conduct straight reciprocating motion, one end of the swing rod is connected with the sliding shaft, the other end of the swing rod is connected with the driving rod, the middle portion of the swing rod can be rotatably connected with an installation frame, the driving rod is connected with a driving mechanism, and the driving mechanism is connected with an automatic control system. According to the device for automatic separation and resetting of the needle rods of the double-needle machine, the driving mechanism is controlled by the automatic control system to act, so that the sliding shaft is driven to act, and the needle rods are separated; stitch numbers of single needle rod walking are controlled by the automatic control system, so that the stitch numbers of single needle rod walking before and after rotation of a sewing material during corner sewing are consistent, and the sewing precision and the sewing stability are improved; and the operation of the corner sewing is simplified, so that the speed of the corner sewing is accelerated, and the production efficiency is effectively improved.

Owner:JACK SEWING MASCH CO LTD

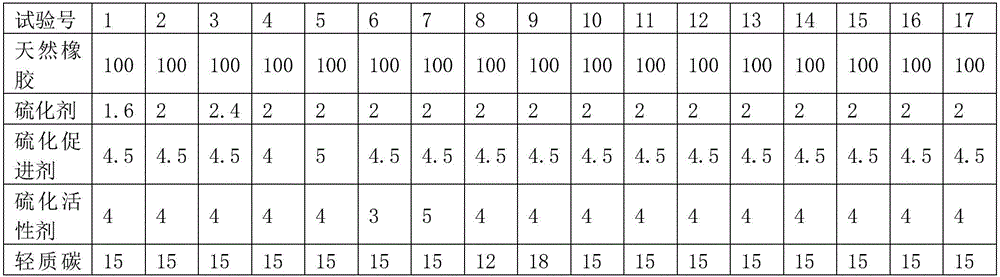

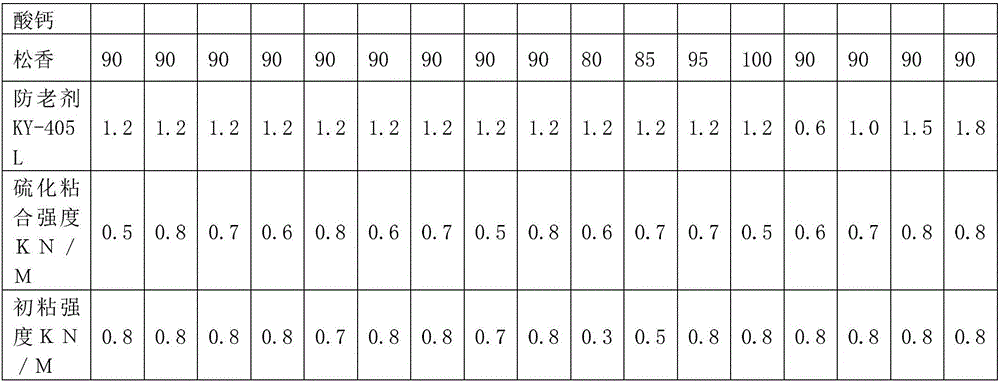

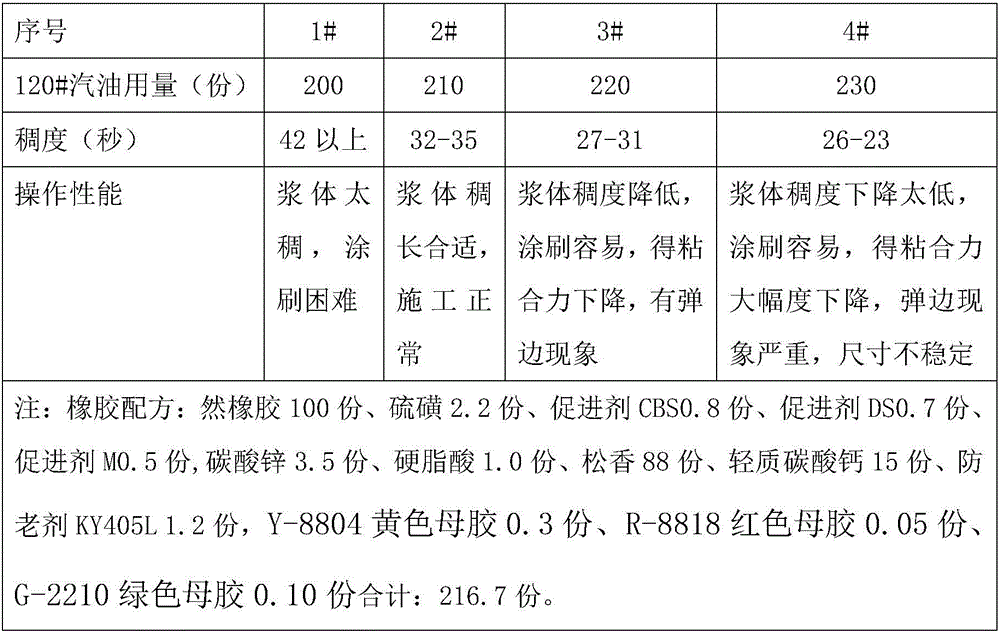

Green rubber slurry for rubber shoe wrapping sponge adhesion, preparation method and applications thereof

InactiveCN106244048AIncrease sewing speedIncrease productivityNatural rubber adhesivesNon-macromolecular adhesive additivesCross-linkPolymer science

The invention discloses a green rubber slurry for rubber shoe wrapping sponge adhesion, a preparation method and applications thereof, wherein the preparation raw materials comprise a natural rubber, sulfur, an accelerator, zinc carbonate, stearic acid, rosin, a Y-8804 yellow rubber master batch, a R-8818 red rubber master batch, a G-2210 green rubber master batch, and 120 # gasoline. According to the present invention, the cross-linking stress of the product is increased, it is ensured that the adhesion stress is greater than the compression resilience of the polyurethane foam and the bending rebound force of the composite shoe throat cloth, the cross-linking shaping speed of the rubber slurry is increased, and it is ensured that the composite shoe throat cloth is tightly fixed on the shoe upper lining cloth; with the application of the wrapping sponge to adhere the shoe throat cloth and the counter, the problem that the inaccurate shoe throat cloth positioning and the non-unified pressing loosening of the wrapping sponge cause the non-unified appearance quality of the rubber shoe rear shoe throat during the sewing process of the shoe throat cloth and the counter is solved, and the shoe upper shoe throat wrapping sponge sewing speed and the production efficiency can be substantially improved; and after the adhesion rubber slurry is used, the rubber shoe throat wrapping sponge repair rate is reduced to 0 from the original 5%, and the production efficiency is increased by 15%.

Owner:JIHUA 3537 SHOE MAKING

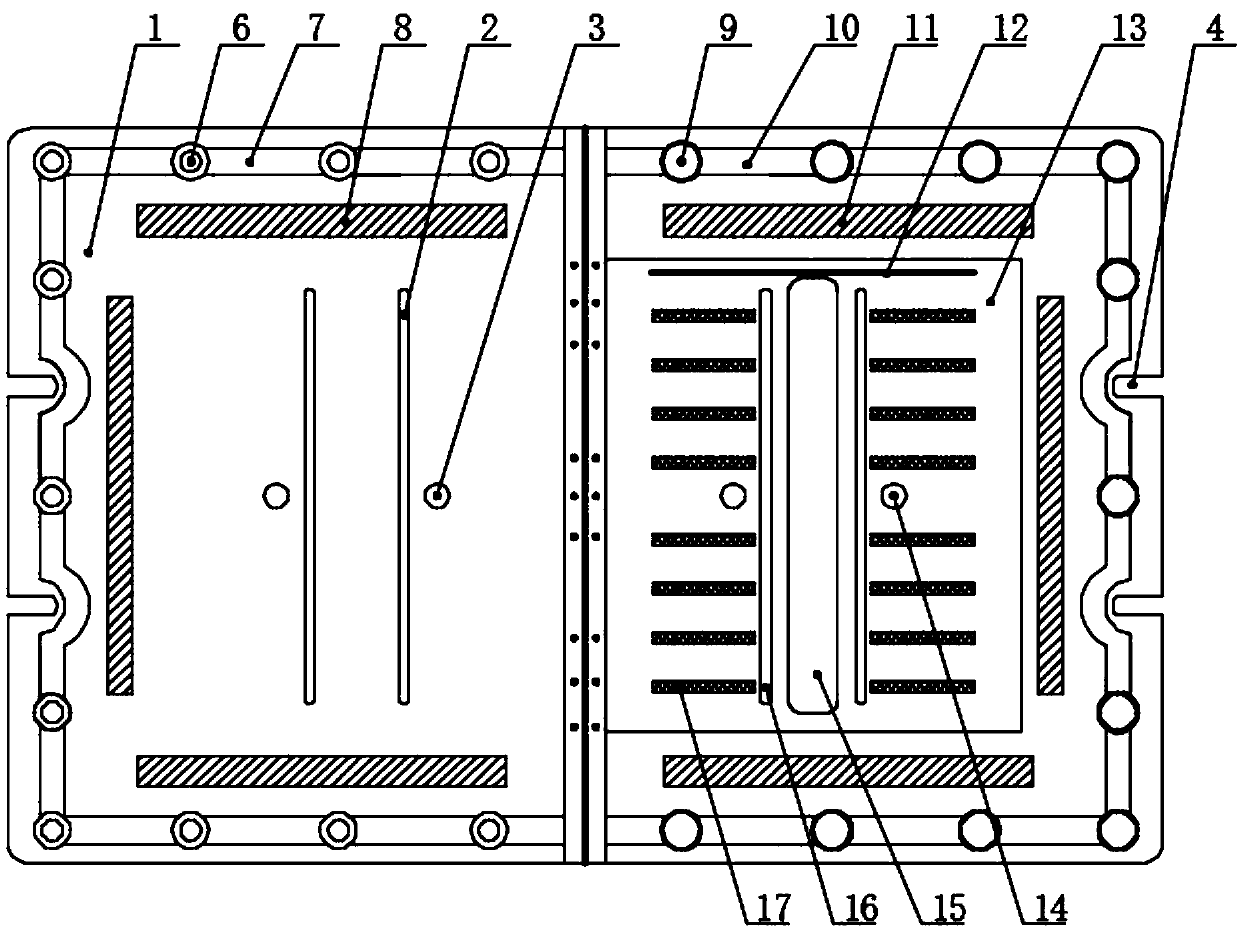

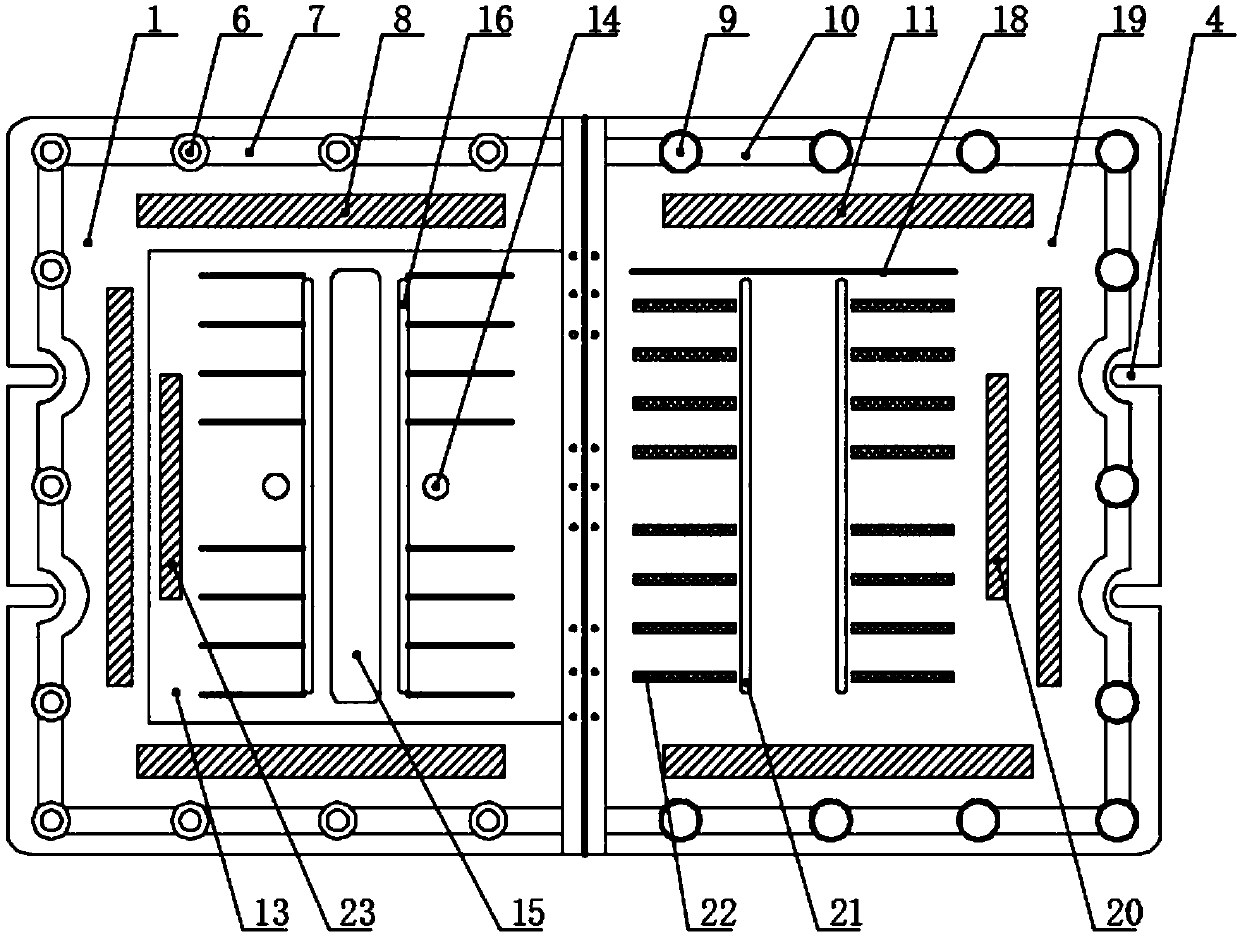

Pocket dual-flanging template special for automatic template sewing machine

InactiveCN109853143ASolve the cumbersome processing methodWay to overcomeWork-feeding meansFlangingEngineering

Owner:TIANJIN SANDA CLOTHING

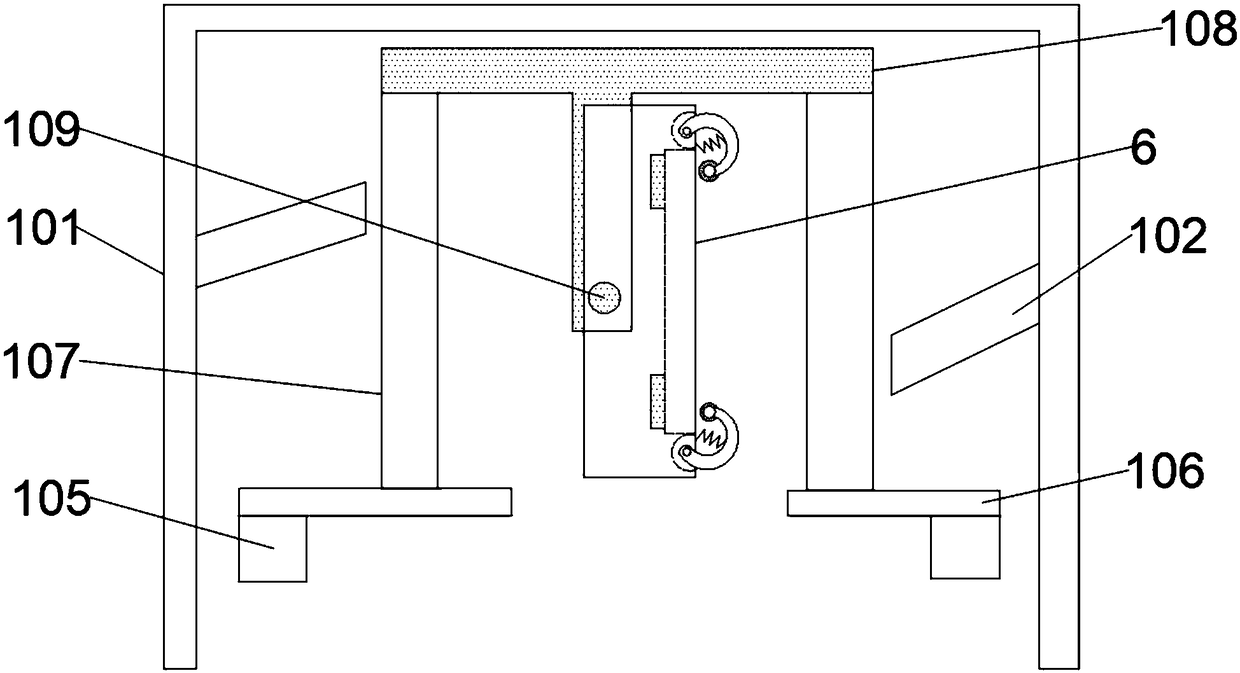

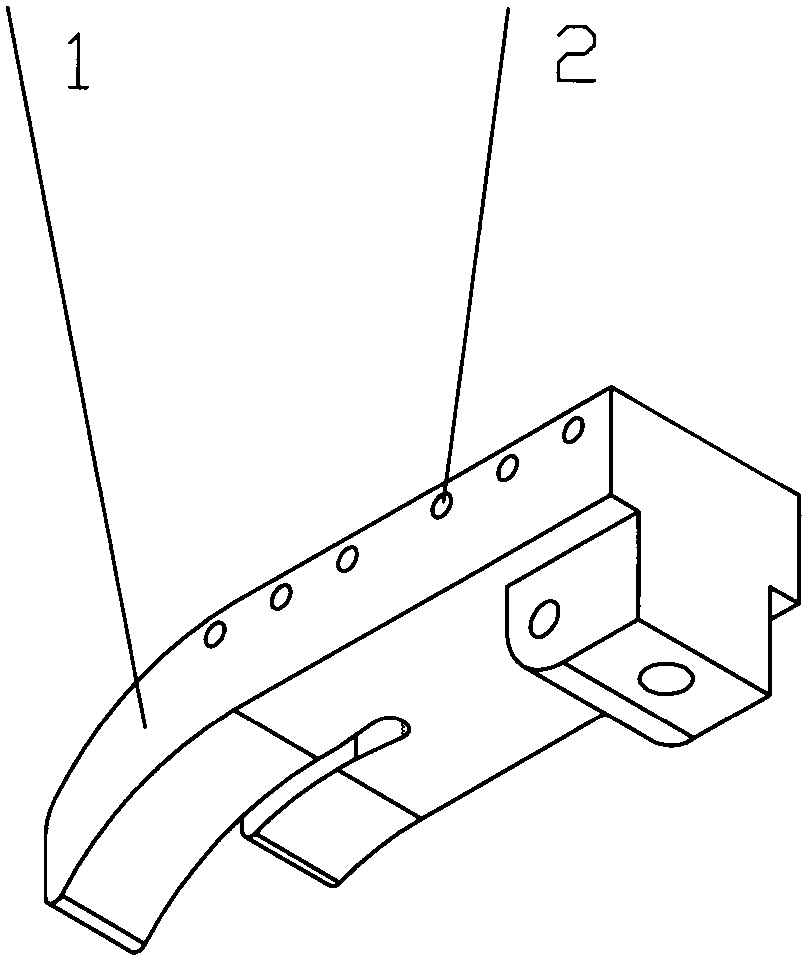

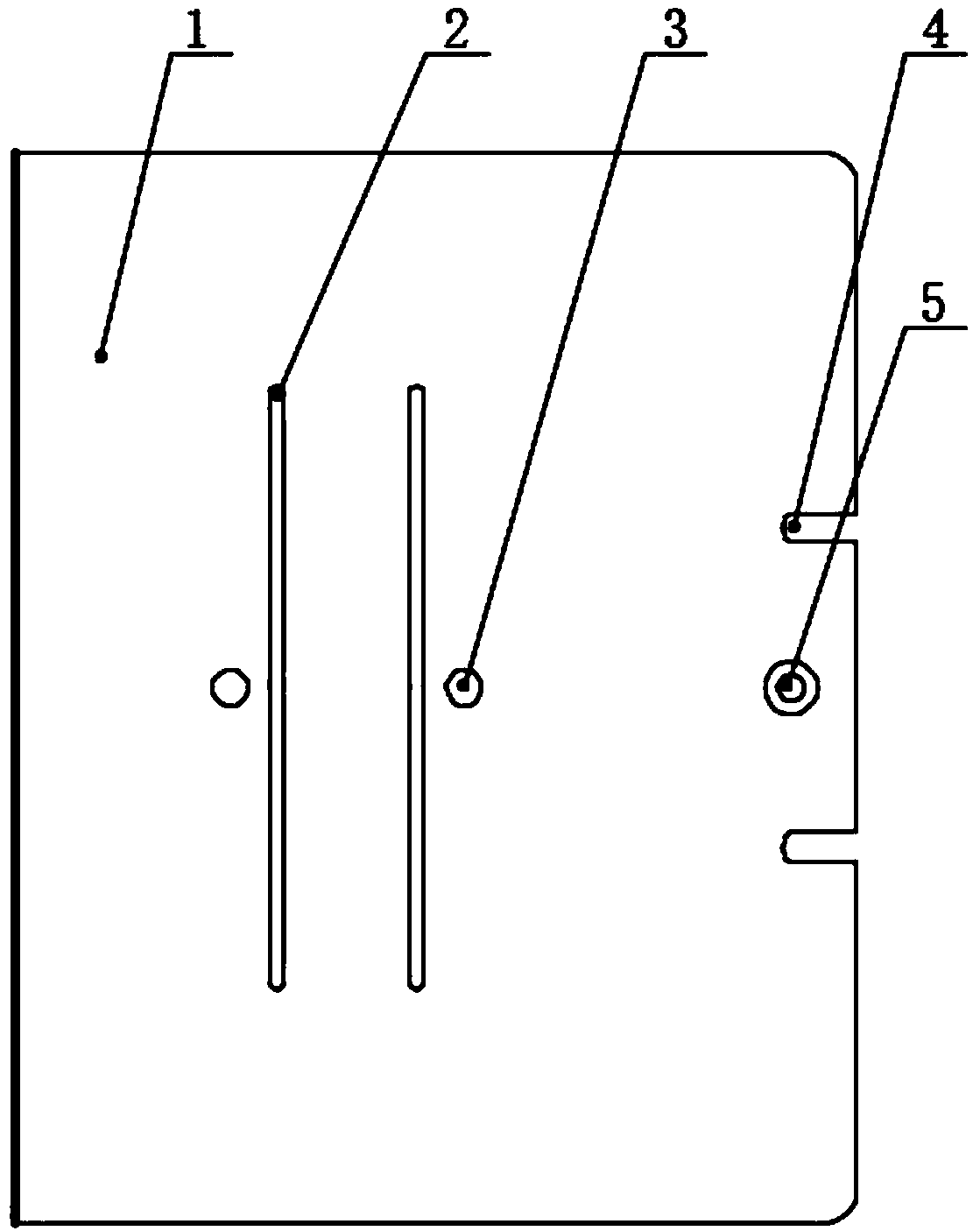

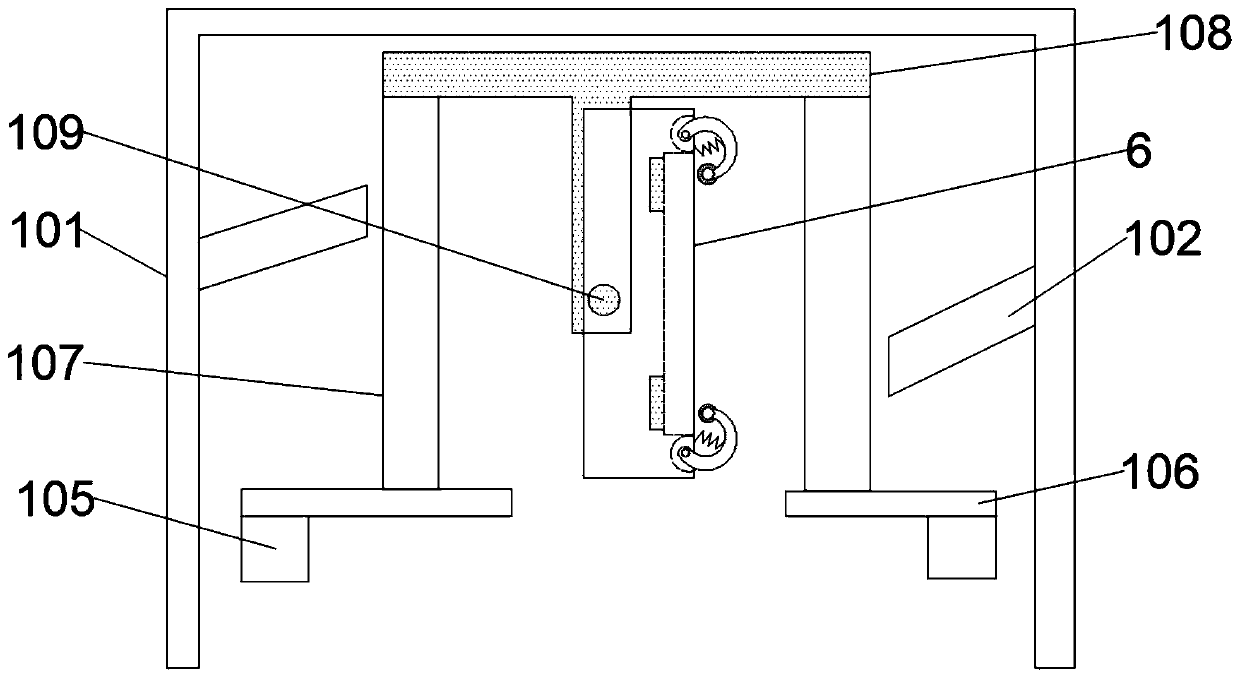

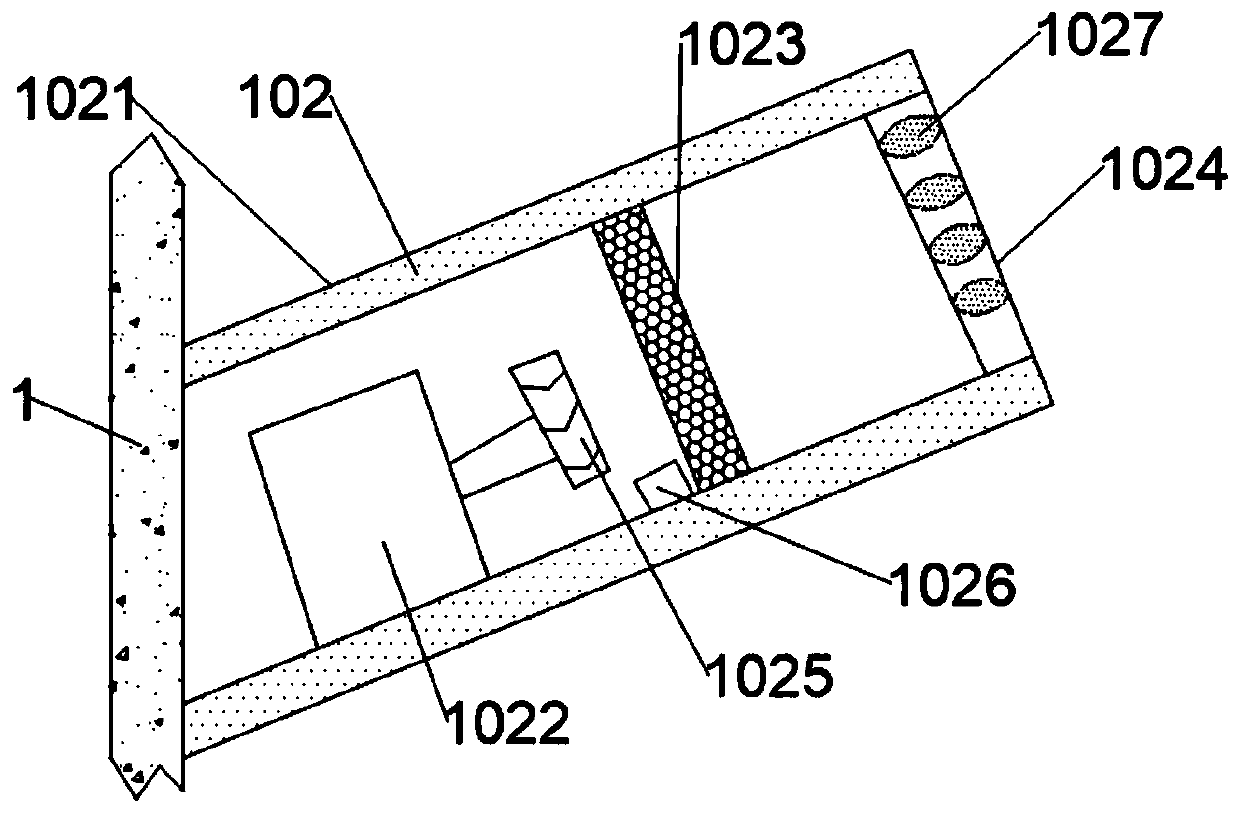

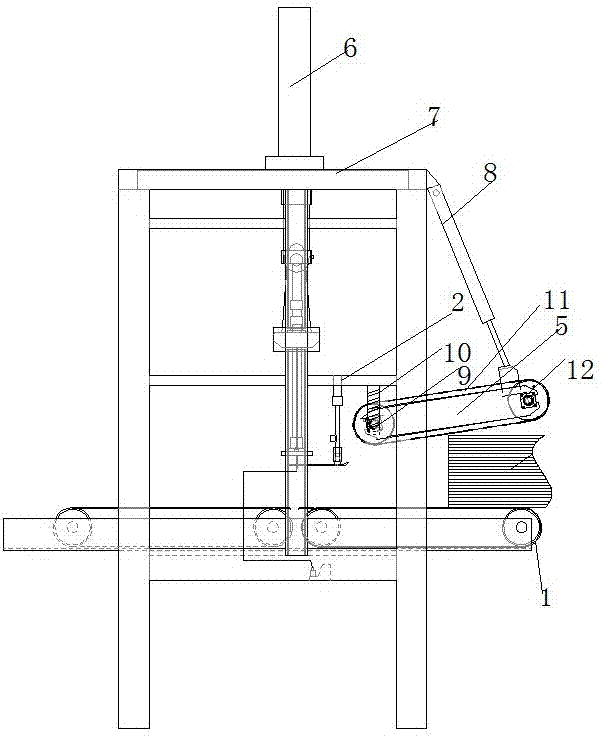

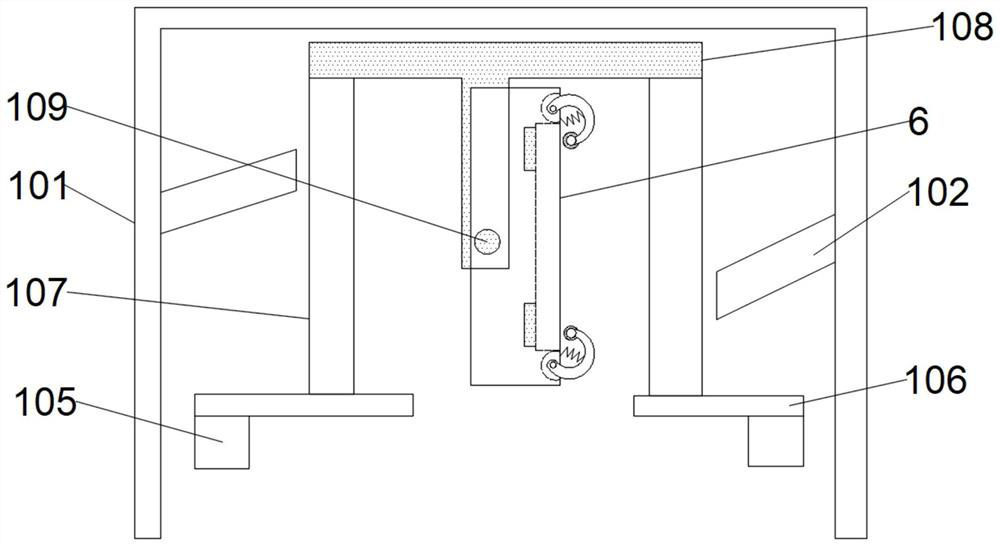

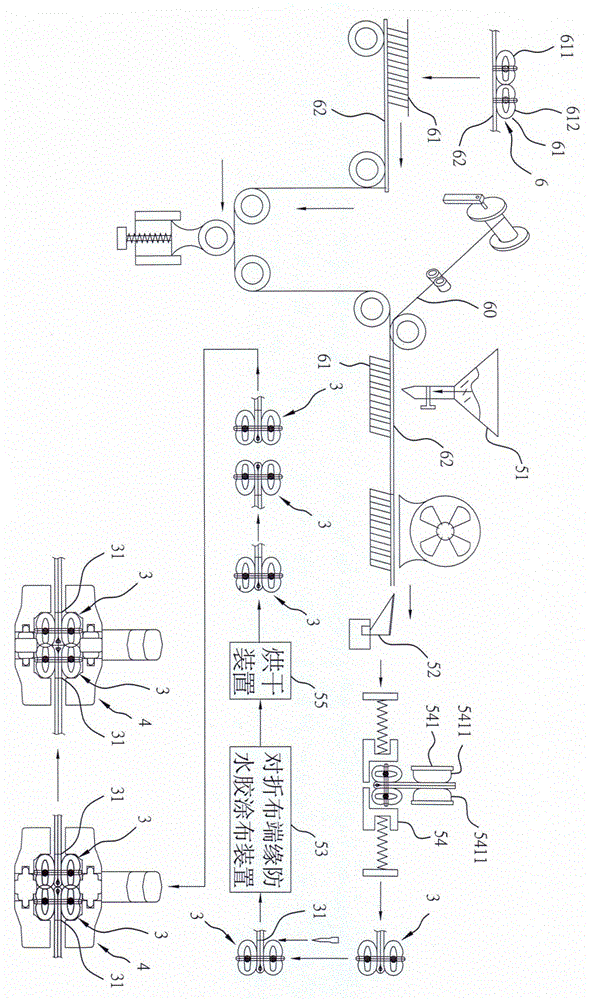

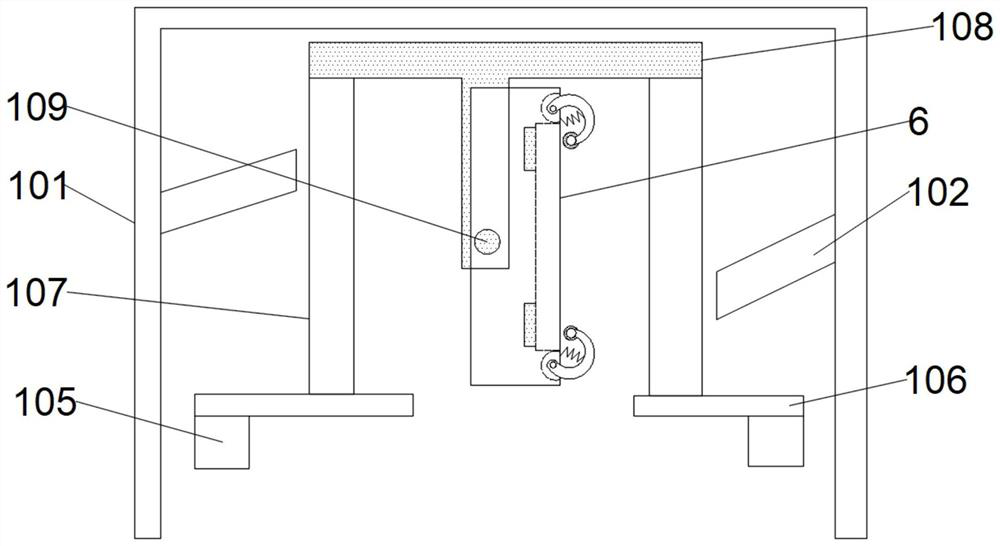

A cloth clamping device for an automatic production line of leather products

ActiveCN108517379BImprove drying efficiencyIncrease the areaDrying gas arrangementsSkins/hides/leather/fur manufacturing apparatusElectric machineryMotor shaft

The invention discloses a fabric clamping device of a leather product automatic production line. The fabric clamping device comprises a fabric clamping and displacement device, wherein the fabric clamping and displacement device comprises a first oil cylinder which is fixedly mounted at the top end of an arch-shaped mounting plate through an oil cylinder seat; the right side of the first oil cylinder is connected with a sliding seat through a horizontal retractable rod; a second oil cylinder is mounted in the sliding seat; the bottom end of the second oil cylinder is connected with a motor seat through a vertical hoisting rod; the motor seat is internally provided with a speed reducing motor; the bottom end of the speed reducing motor is connected with four fixed strips through a motor shaft; bottom end faces of the four fixed strips are located on the same horizontal plane and bottom ends of the four fixed strips are commonly connected with a frame-shaped clamping seat plate; the frame-shaped clamping seat plate is provided with a plurality of electromagnetic clamps; an iron block or an iron strip is attracted by utilizing an electromagnet so as to tightly clamp leather; when theelectromagnet is powered off, the iron block loosens the leather or a fabric due to an elastic force of a spring.

Owner:福州盛世凌云环保科技有限公司

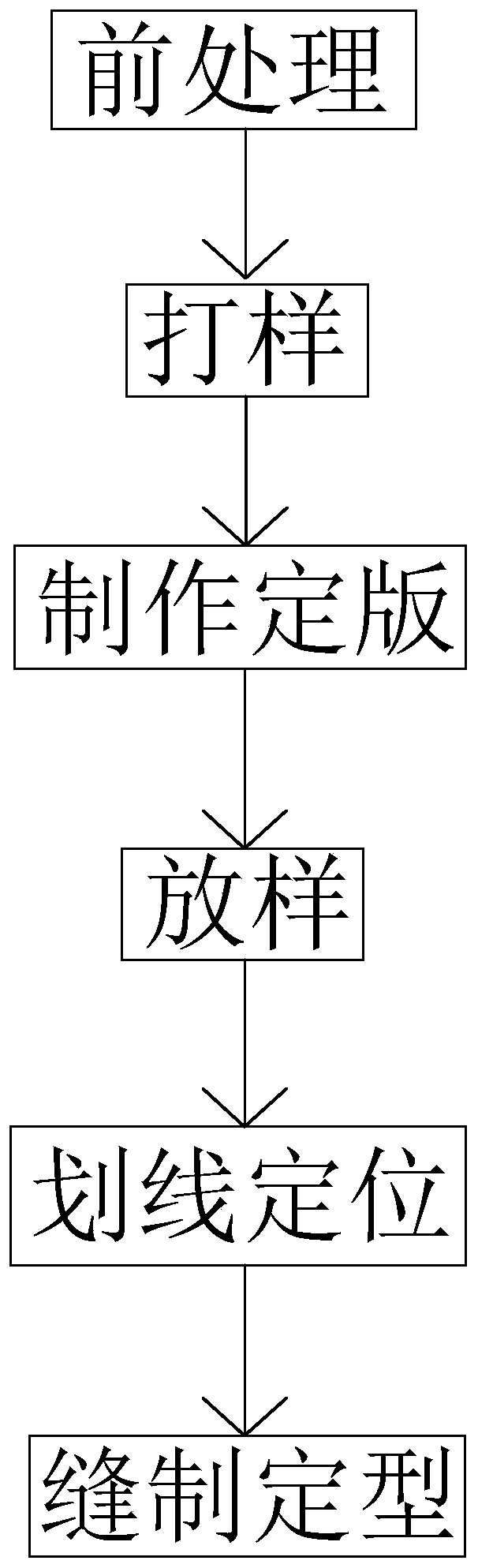

A typesetting method for positioning, dashing, and typesetting

ActiveCN108618245BReduce dosageReduce manufacturing costWork-feeding meansClothes making applicancesMechanical engineeringIndustrial engineering

The invention discloses a positioning-scribing typesetting method. The positioning-scribing typesetting method comprises six steps including pretreatment, paper sample making, fixed sample manufacturing, lofting, positioning by scribing, and sewing for sizing. According to the method, the original fur part is cut to manufacture a fur part, the use amount of fur can be effectively saved, and thus the production cost is fundamentally reduced; invisible scribing powder replaces the traditional scribing powder, so that the later working procedure of eliminating marks is reduced, and thus the workefficiency is improved; a fixed sample is manufactured for uniform scribing, the traditional method of scribing on each piece of shell fabric is replaced, thus the scribed parallel lines are straight,the distance control is reasonable, the quality and efficiency of positioning by scribing are improved, meanwhile, after the fur part is sewn at the later stage, the product with fur has the sense ofdepth and the sense of natural grace, and also has the good aesthetic sense.

Owner:桐乡市志强皮毛染色厂

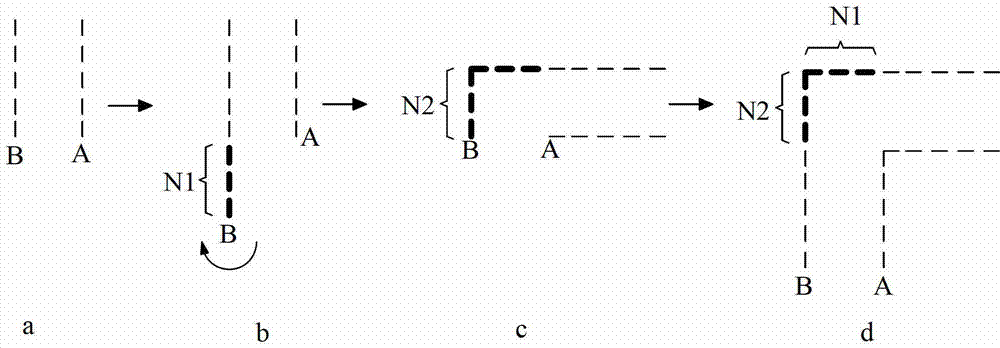

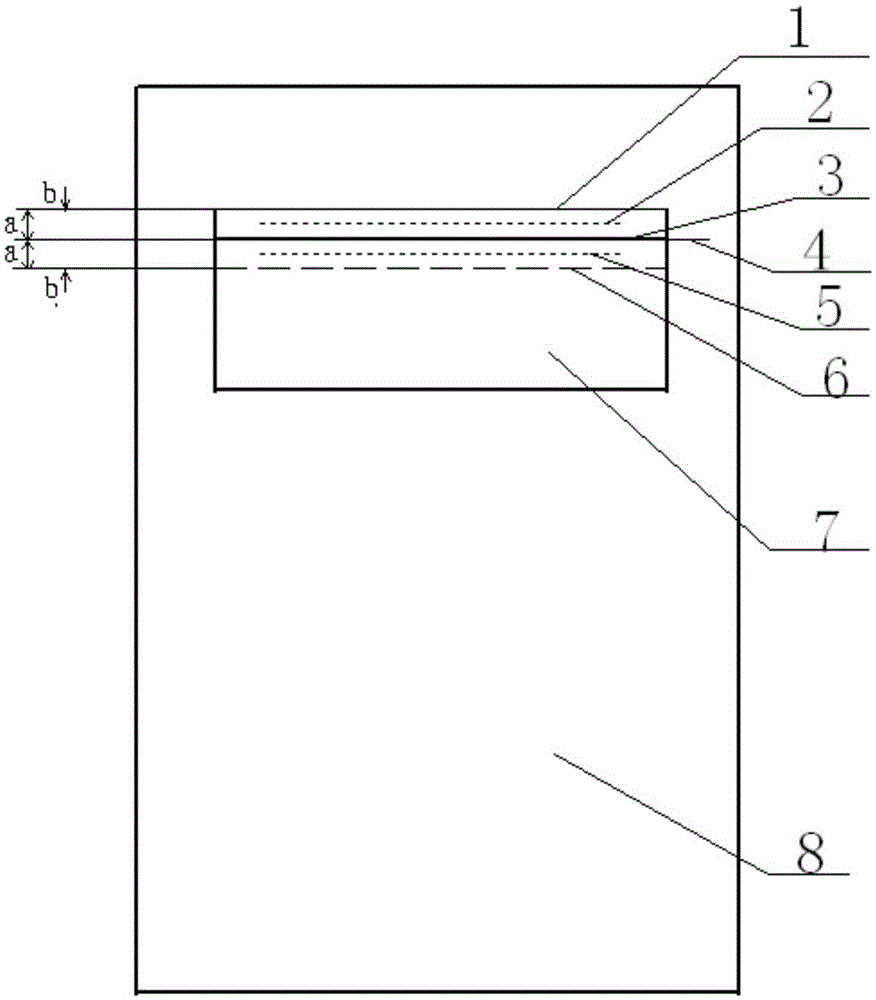

A Sewing Method of Double Welt Pocket

ActiveCN104585947BReduce processing difficultyFast and efficient sewingGarmentsClothes making applicancesFlangingEngineering

The invention provides a sewing method of a double-embedded-wire pocket. A pocket center line is drawn in the front side pocket position part of a clothes piece and is used as a positioning line; the rough edge on the top of wire-embedded cloth is downwards flanged for a first distance, the flanged part is subjected to buckling ironing for forming a first flanging line, then, the edge is downwards flanged for a second distance being the twice length of the first distance, and the part which is flanged again is subjected to buckling ironing for forming a second edge flanging line; in the second step, the rough edge, downwards flanged for the first distance, of the wire-embedded cloth is aligned with the center line of the pocket, a press foot with the same width as the first distance is adopted for sewing a first embedded wire in the middle position of the flanged edge with the same width as the first distance, and during the sewing, the lower edge of the press foot is aligned with the positioning line; the press foot is adopted for sewing a second embedded wire in the middle position between the rough edge of the wire-embedded cloth and the second edge flanging line, during the sewing, the press foot is just pressed on a fabric with the same width as the first distance between the rough edge and the second edge flanging line, and the two sides of the press foot are respectively aligned with the rough edge and the second edge flanging line.

Owner:JIANGXI INST OF FASHION TECH

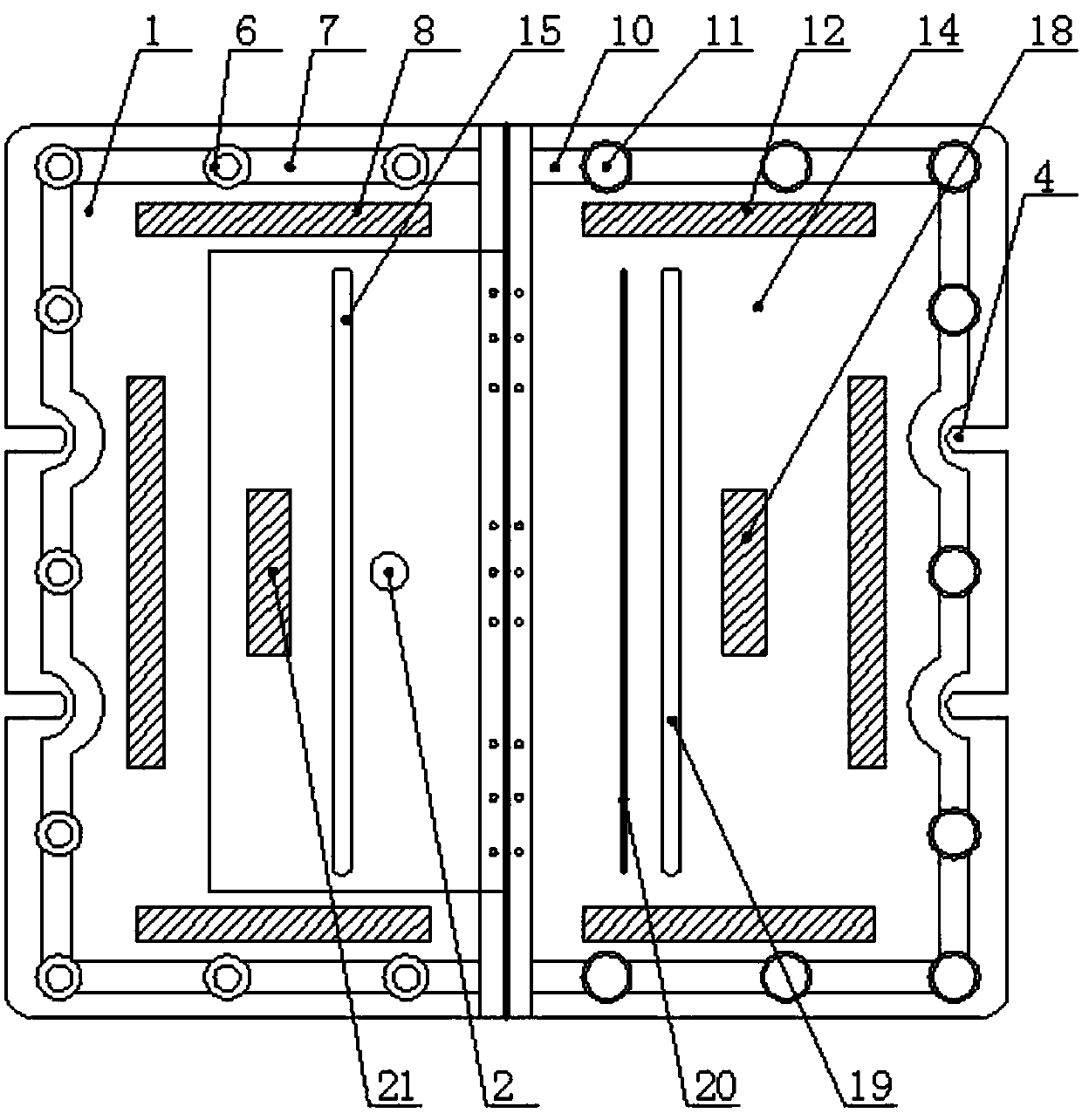

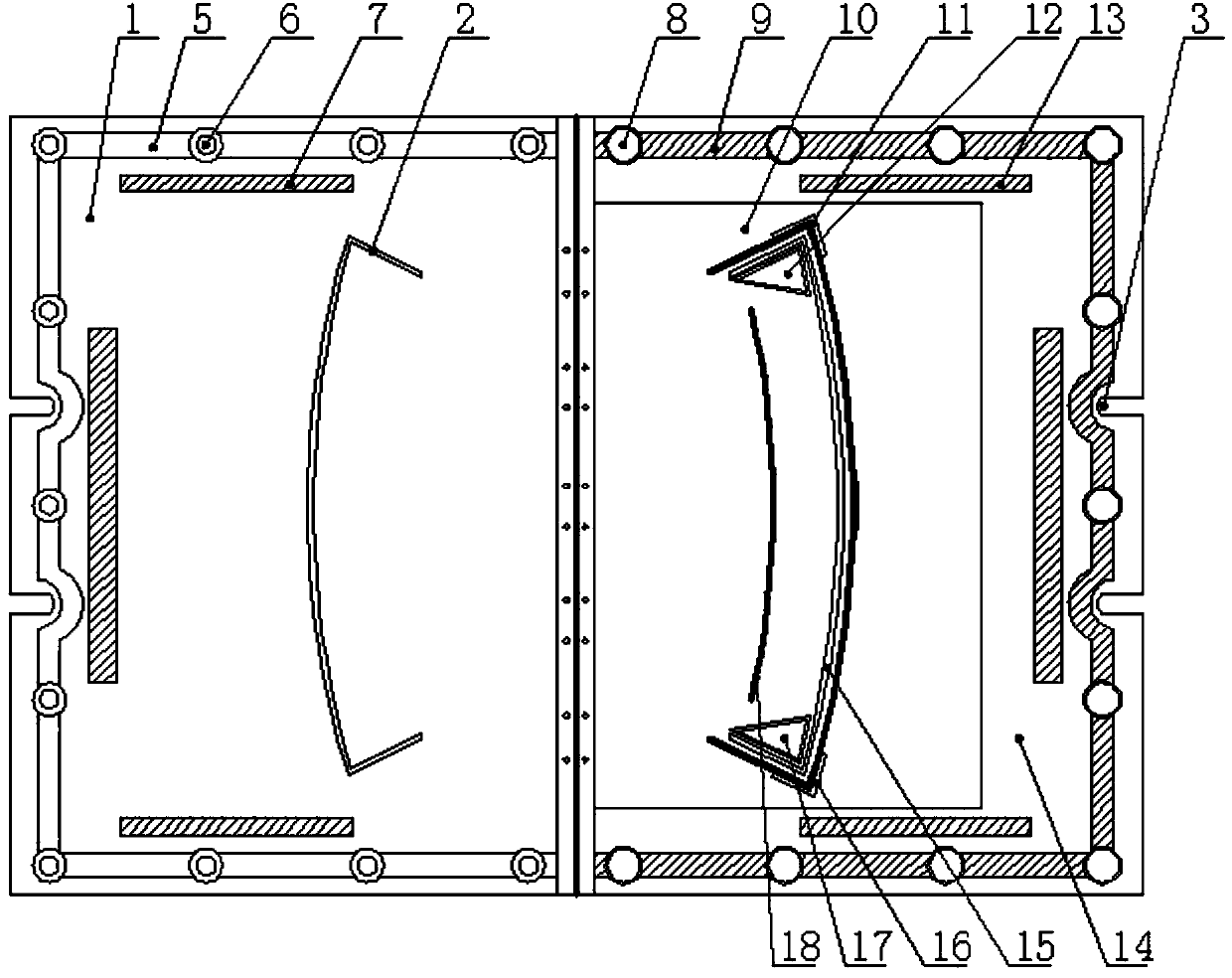

Pocket single-flanging template special for automatic template sewing machine

InactiveCN109853144ASolve the cumbersome processing methodWay to overcomeWork-feeding meansFlangingEngineering

The invention provides a pocket single-flanging template special for an automatic template sewing machine. The pocket single-flanging template comprises a bottom plate, a backing plate and a cover plate, the cover plate and the bottom plate are coaxially hinged to one side of the backing plate, backing plate sewing through grooves, bottom plate sewing through grooves and cover plate sewing throughgrooves are formed in the backing plate, the bottom plate and the cover plate respectively and can be mutually overlapped, a backing plate round through groove is formed in the middle of the backingplate, a cover plate round through groove is formed in the middle of the cover plate, and the backing plate round through groove and the cover plate round through groove are matched with buttons. A plurality of adsorption devices are uniformly arranged on the periphery of the cover plate, the adsorption devices are communicated through air pipes, a plurality of adsorption grooves are uniformly formed in the periphery of the bottom plate, and the adsorption grooves are communicated through air pipe containing grooves. Through the hinged cooperation of the backing plate, the bottom plate and thecover plate, a worker only needs to place the template into the automatic template sewing machine, and then all operation can be completed. The problems that a pocket single-flanging processing method is complicated and the requirement for the operation level of the worker is high are solved radically.

Owner:TIANJIN SANDA CLOTHING

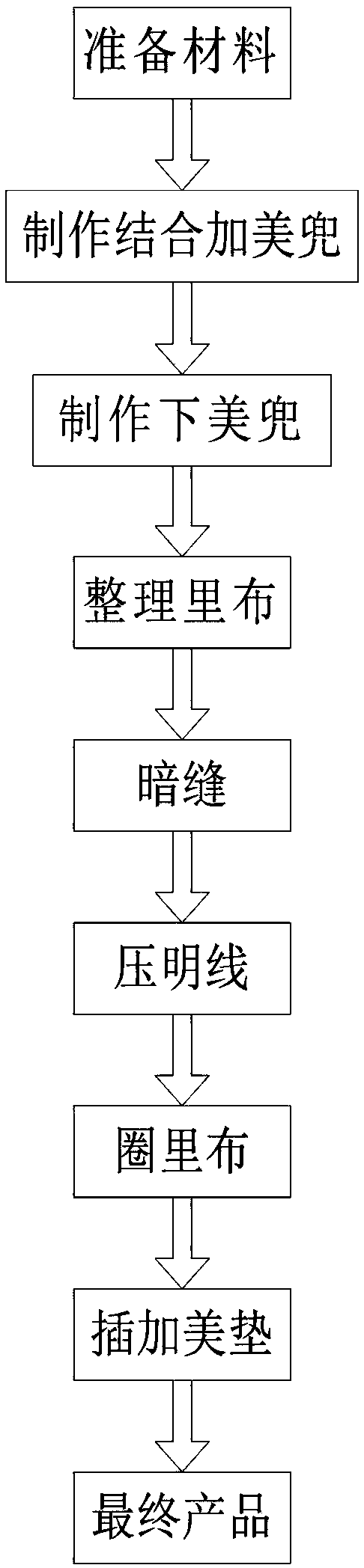

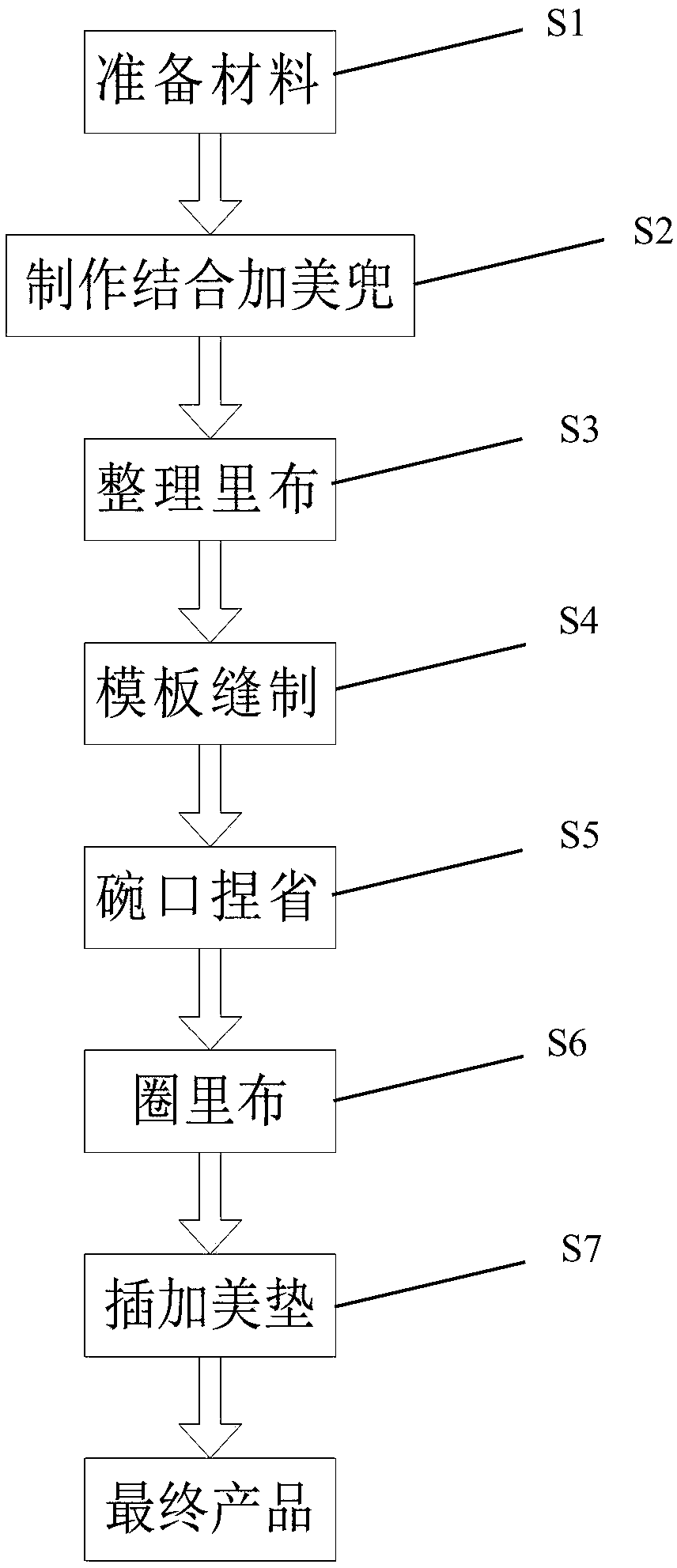

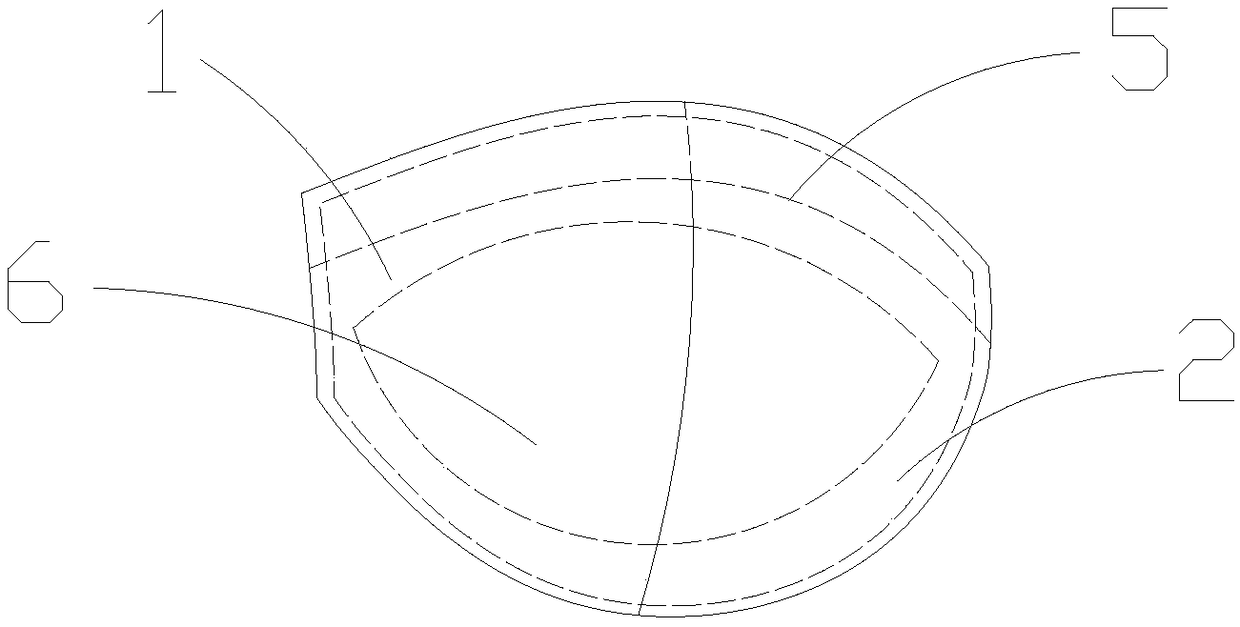

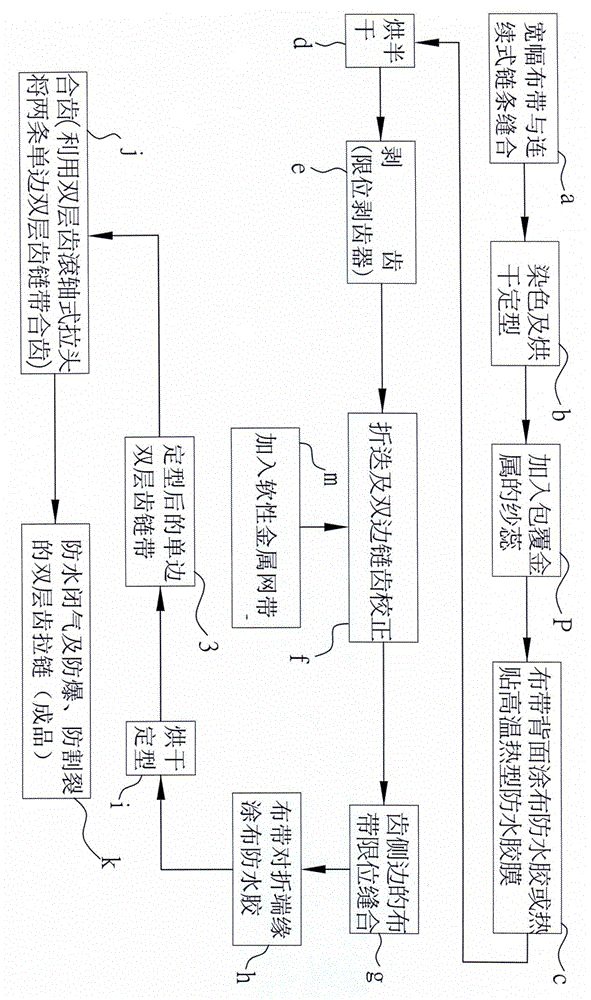

A method of making a mold cup

The invention discloses a manufacturing method for a mould cup. The method comprises the following steps: a) preparing materials: preparing a lining cloth and a cup body, wherein the lining cloth comprises a left pocket, a right pocket and a lower blocking lining cloth; b) preparing a combined pocket: preparing the left pocket and the right pocket into the combined pocket; c) settling the lining cloth: putting the lower blocking lining cloth and the combined pocket into a sewing template and settling; d) sewing the template: performing template sewing; e) pinching a bowl rim: forming a mould cup sphere matched with the cup body; f) circling the lining cloth: putting the lining cloth into the cup body and sewing the periphery. According to the manufacturing method for the mould cup, provided by the invention, the cutting of upper and lower blocking lining clothes is cancelled, the cost is lowered, the template sewing is adopted, the operation is simple and the sewing speed is high, so that the production efficiency is increased, the product still has a function of inserting the pocket, the product is free from quality problems, such as, inclined tuft, the yield is increased and higher social benefit and economic benefit are achieved.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

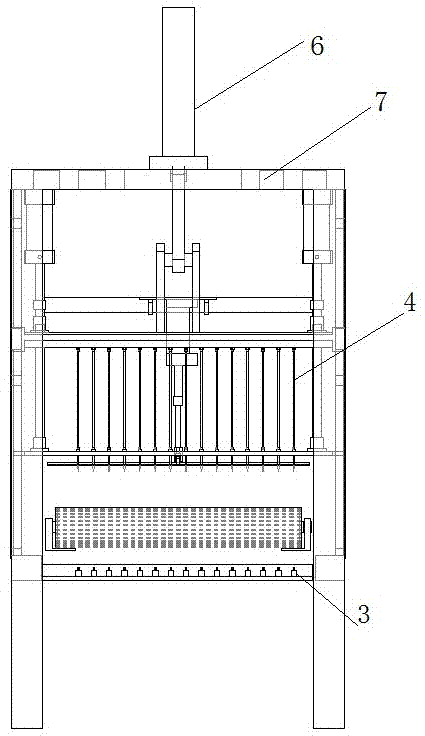

Sewing equipment for sewing fiber module

The invention discloses sewing equipment for sewing a fiber module. A hydraulic oil cylinder is located on the top of a machine rack, the hydraulic oil cylinder is connected with an auxiliary sewing foot pressing plate, the auxiliary sewing foot pressing plate is connected with sewing needles, grooves are formed in the head portions of the sewing needles, conveying chain plate conveyor tables arearranged below the sewing needles, ceramic slip-aiding sewing wiring coils are arranged above the conveying chain plate conveyor tables, and the auxiliary sewing foot pressing plate is connected witha screw lifting device. By means of the sewing equipment for sewing the fiber module, the production cost of raw materials is greatly saved, the labor cost and the construction complexity are reducedthrough the full-automatic sewing equipment, and the sewing speed is improved through the hydraulic oil cylinder.

Owner:SUZHOU HONEN NEW MATERIALS TECH

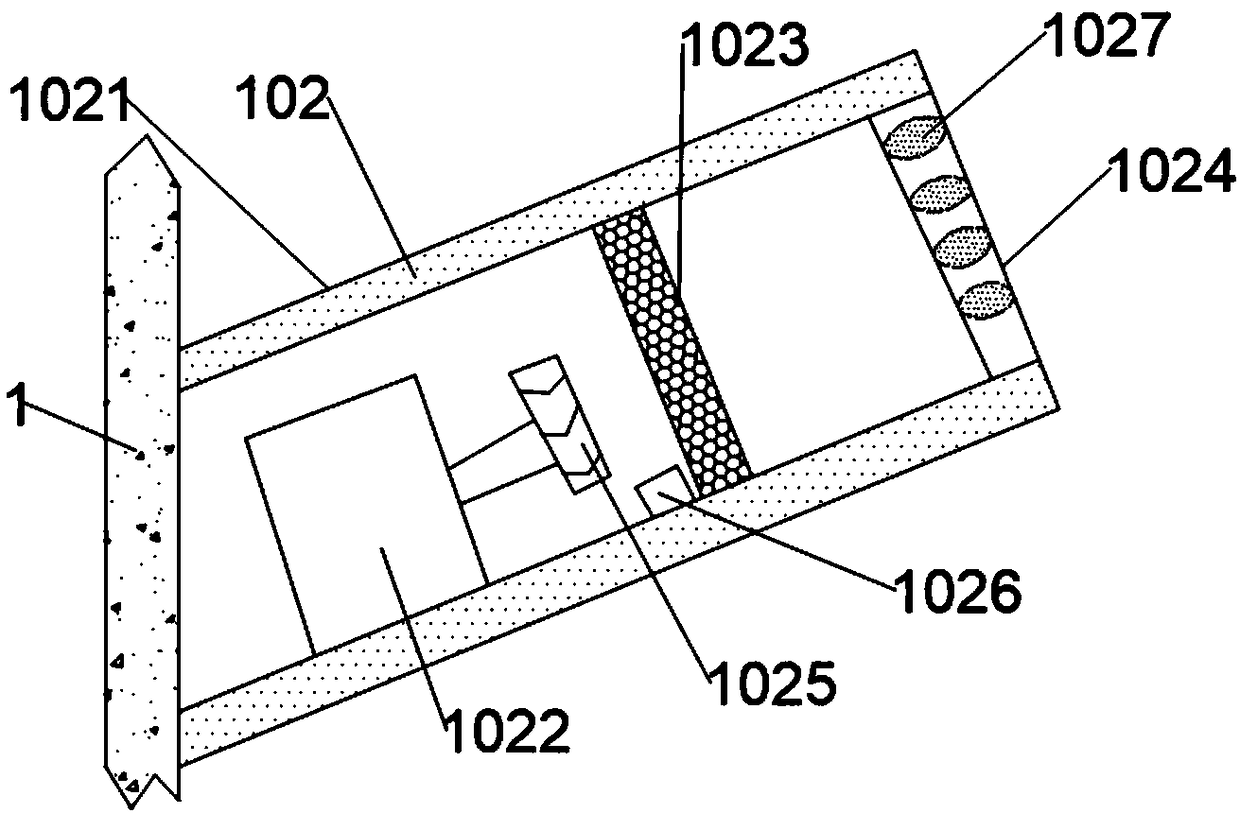

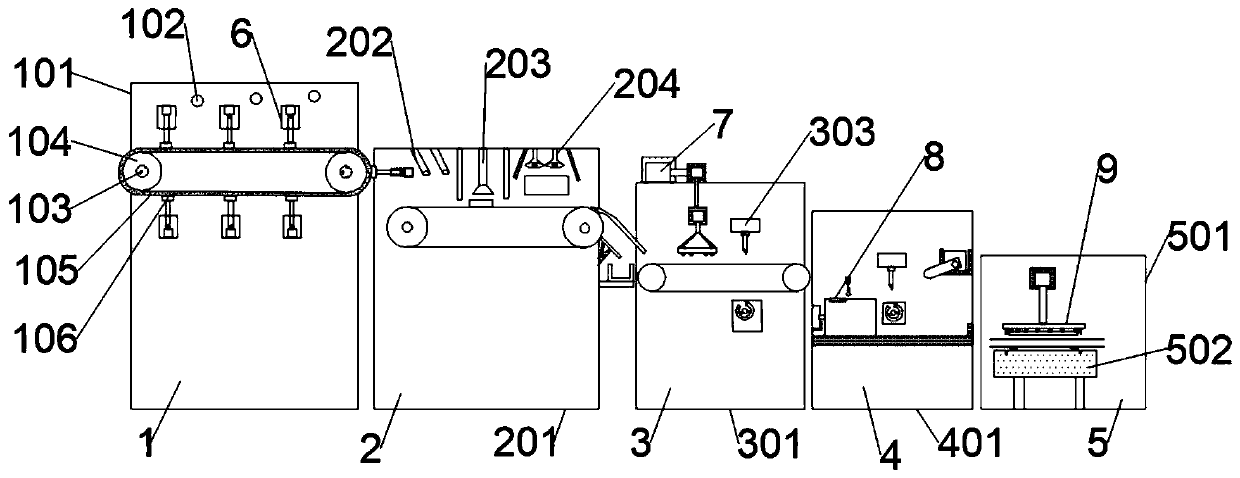

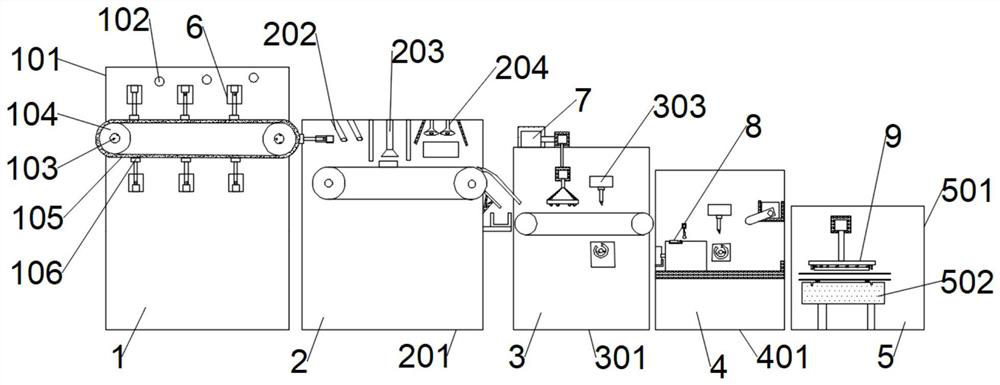

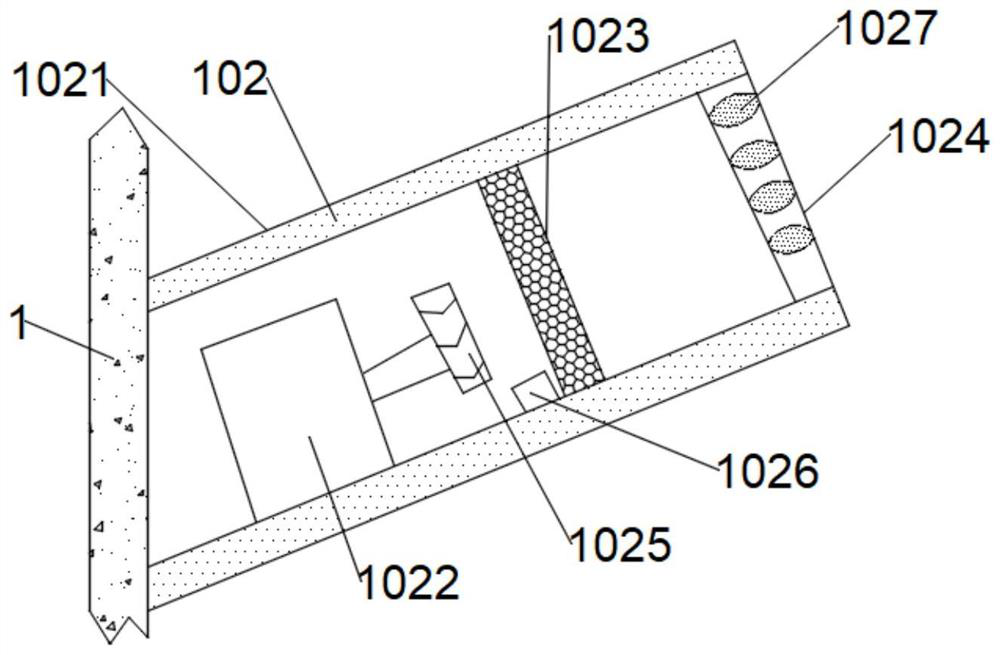

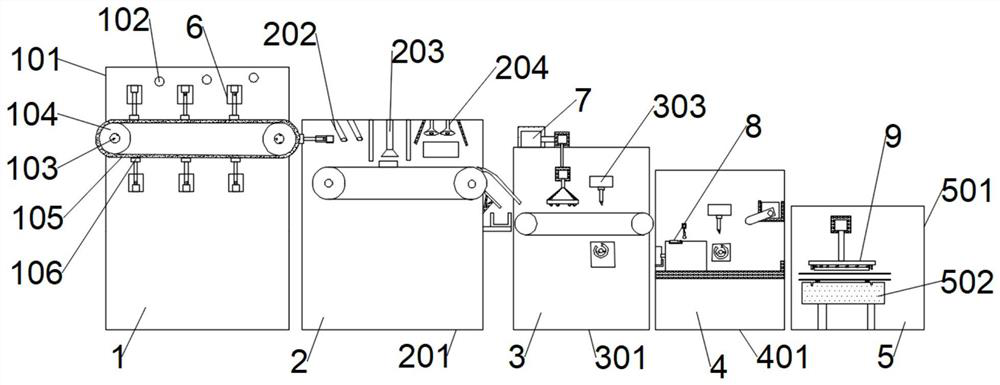

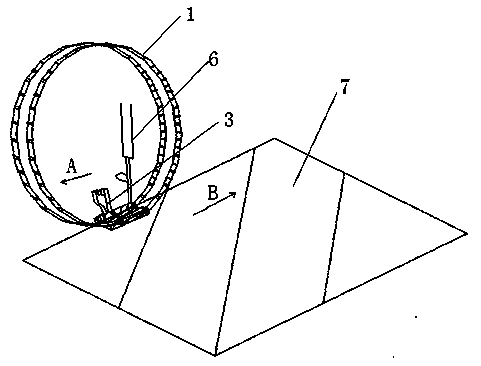

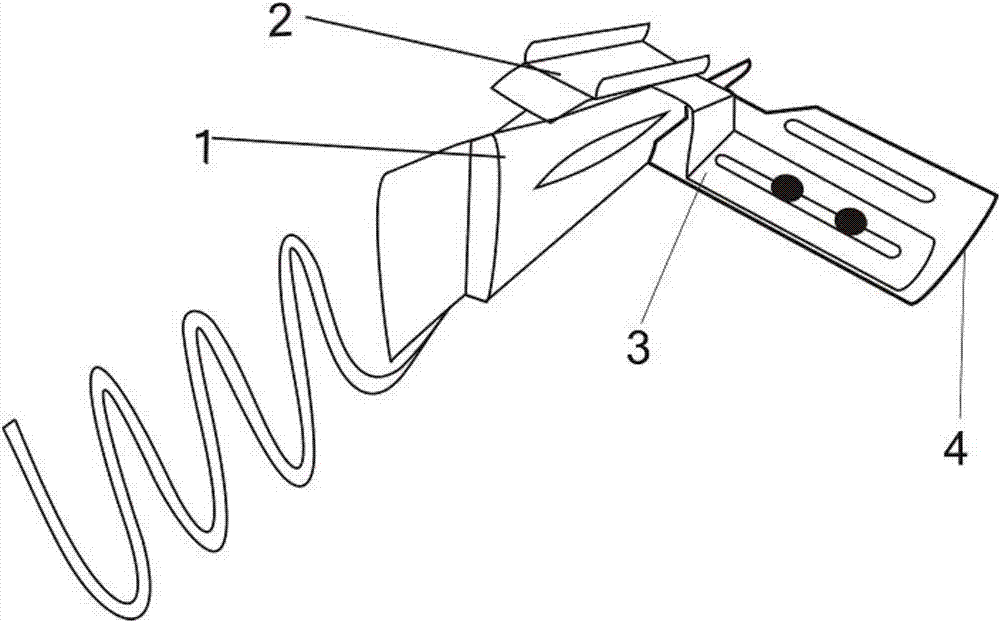

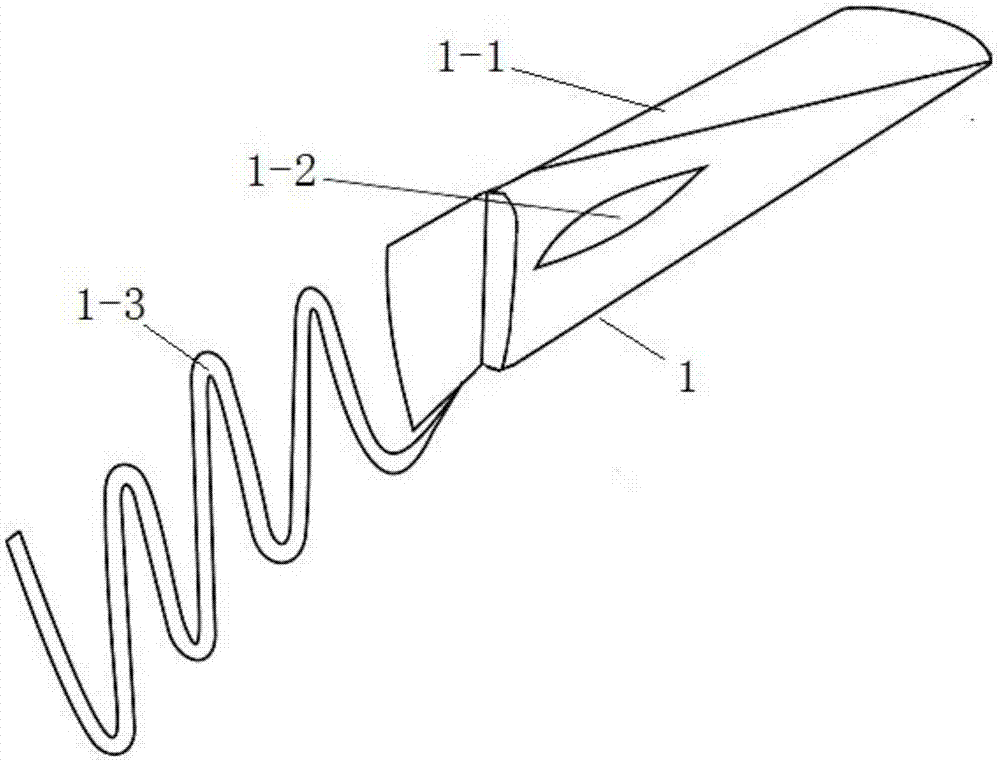

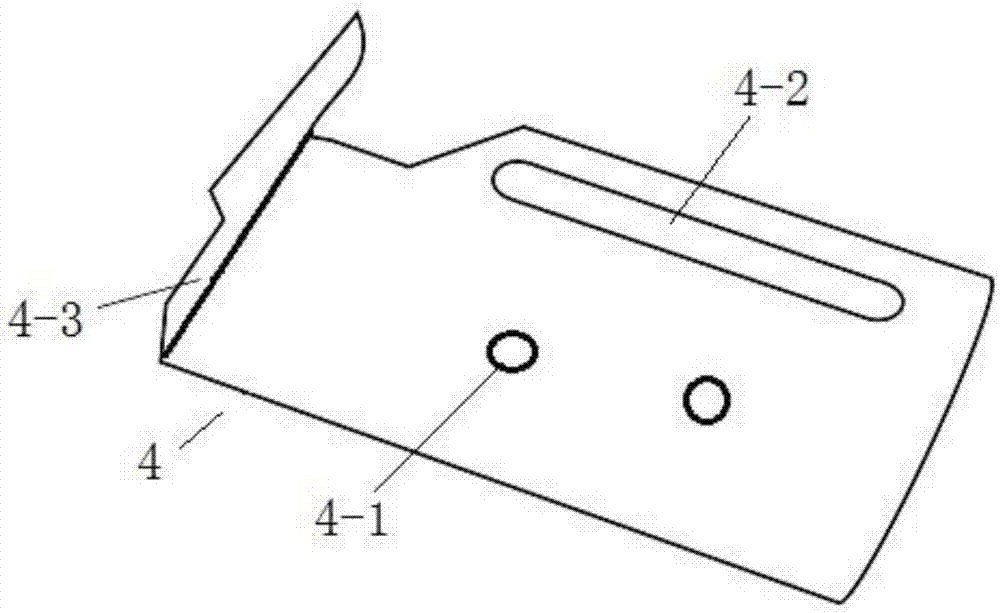

Leather cloth sewing equipment for production and processing of leather products

ActiveCN108516152BImprove drying efficiencyIncrease the areaWrappers shrinkageWork-feeding meansConveyor beltManufacturing line

Owner:ZHEJIANG MAX SEWING MACHINE

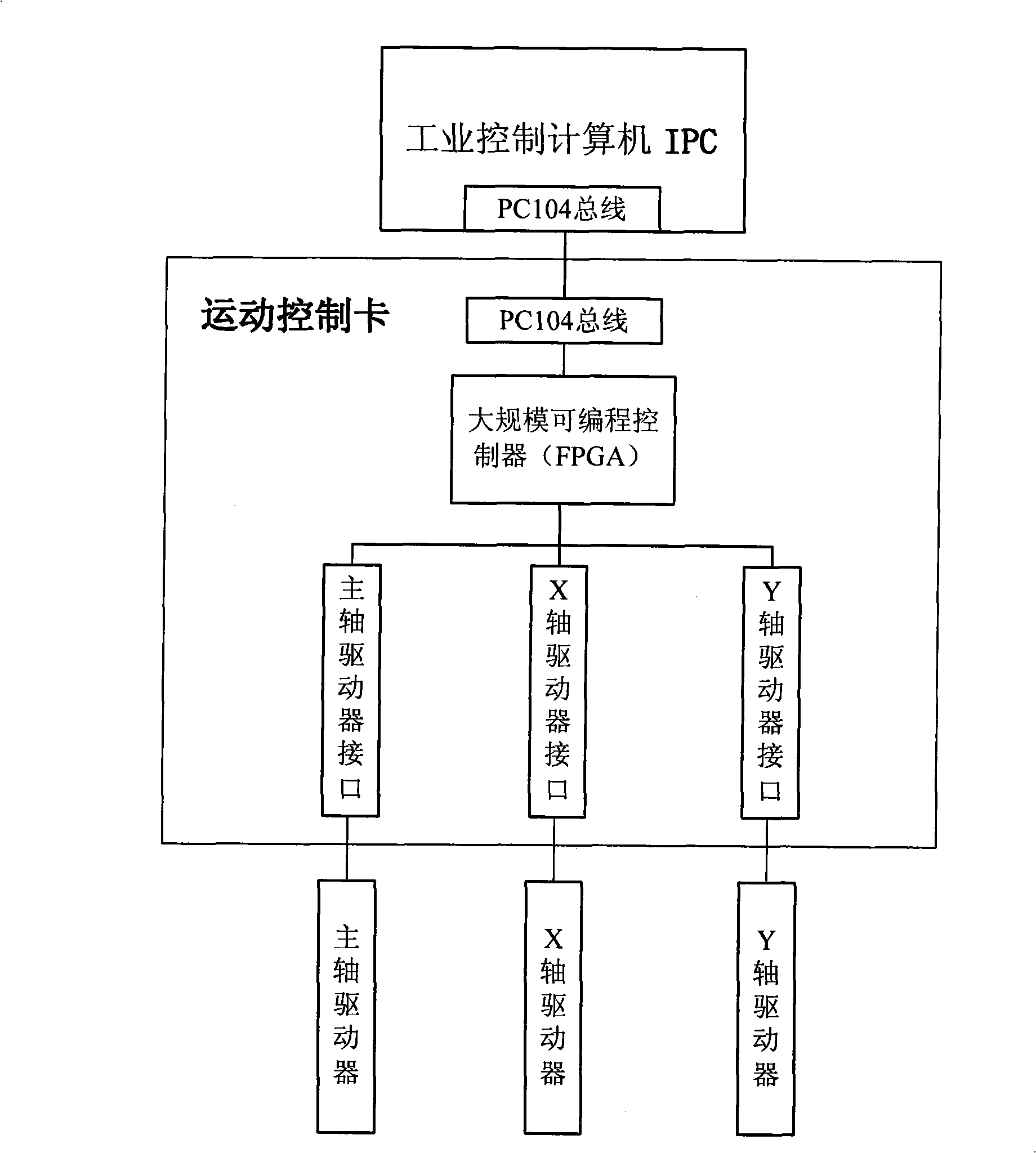

Method for controlling the motion of computerized pattern sewing machines

InactiveCN101519831BIncrease sewing speedGuaranteed uptimeProgramme-controlled sewing machinesNumerical controlLow noiseControl system

The invention provides a method for controlling the motion of computerized pattern sewing machines. The method is that a controlling system controls the feeding movement of an X-axis and a Y-axis by dThe invention provides a method for controlling the motion of computerized pattern sewing machines. The method is that a controlling system controls the feeding movement of an X-axis and a Y-axis by detecting the angle of a spindle servo motor when the spindle servo motor is running uniformly. An industrial controlling computer and a Field Programmable Gate Array (FPGA) process and control the movetecting the angle of a spindle servo motor when the spindle servo motor is running uniformly. An industrial controlling computer and a Field Programmable Gate Array (FPGA) process and control the movement respectively, i.e., the data operated by CPU is stored in sequence in an array provided by the FPGA and the FPGA fetches and controls the data in the array in sequence. The computer and the FPGAement respectively, i.e., the data operated by CPU is stored in sequence in an array provided by the FPGA and the FPGA fetches and controls the data in the array in sequence. The computer and the FPGArun at the same time thus greatly saving controlling time and raising the sewing speed. The computerized pattern sewing machines adopting the method has the advantages of high speed, smooth operation run at the same time thus greatly saving controlling time and raising the sewing speed. The computerized pattern sewing machines adopting the method has the advantages of high speed, smooth operation, low noise and beautiful and even stitch. The method is applicable to the motion control of the current computerized pattern sewing machines or other similar industrial sewing machines., low noise and beautiful and even stitch. The method is applicable to the motion control of the current computerized pattern sewing machines or other similar industrial sewing machines.

Owner:MIANYANG WEIBO ELECTRONICS

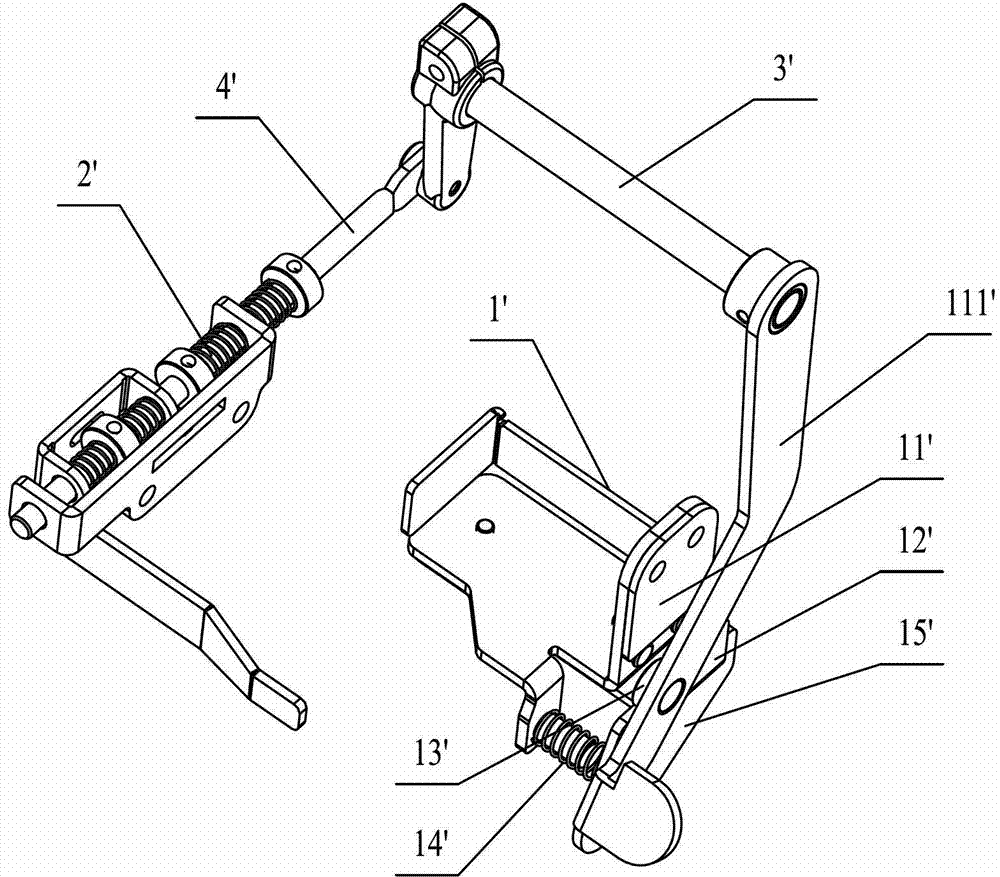

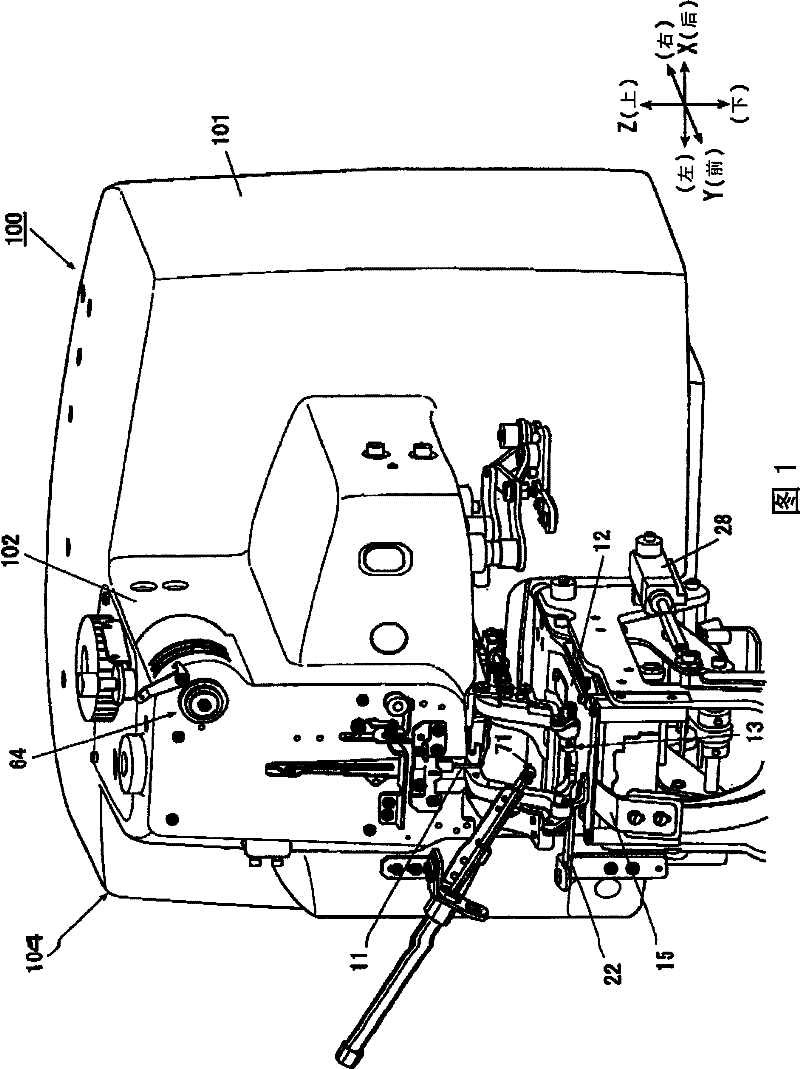

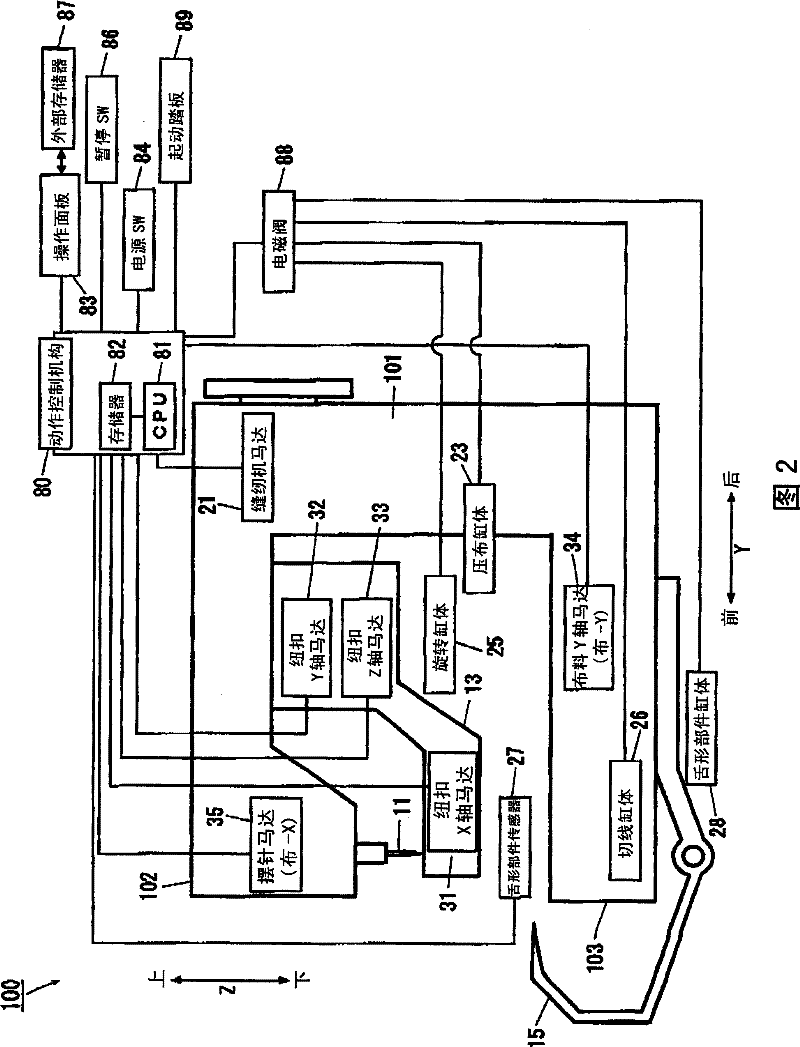

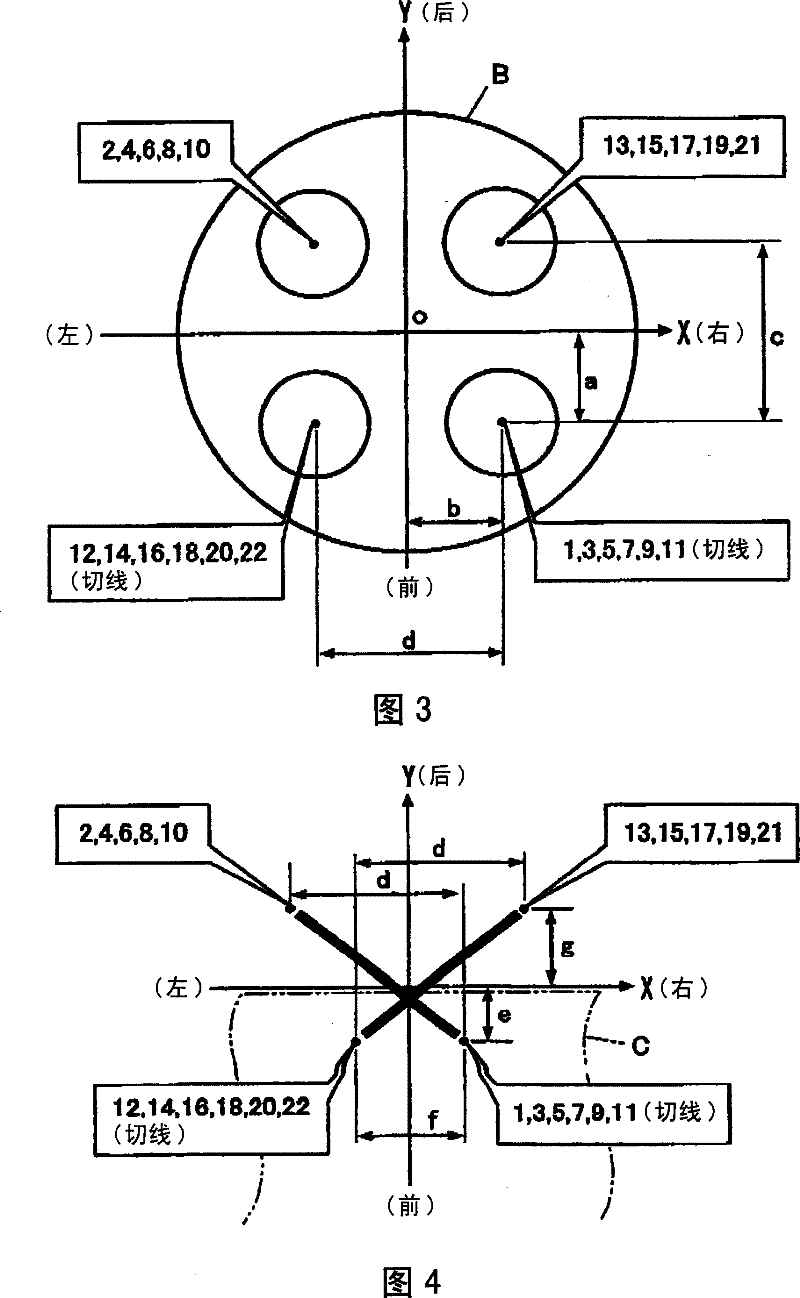

Button-sewing machine

ActiveCN1818185BIncrease sewing speedReduce the stretchProgramme-controlled sewing machinesEngineeringSewing needle

This button sewing machine is equipped with a vertically moving mechanism which drives the sewing needle (11) in the vertical direction while performing a needle swinging, a button holding mechanism (13), a fabric holding member (15) which is extended to the rear side, and folds back and holds the article (C) to be sewn, and a fabric moving mechanism (34) which moves and positions the article to be sewn. The button sewing machine is also equipped with button moving mechanisms (31, 32) which move and position a button (B), a looper (41) which forms a loop by catching a sewing thread, and a thread gathering member (42) which makes the sewing thread between the article to be sewn and the looper avoid the sewing needle which is lowered. A needle swinging limiting means (81) which performs a control for moving the button in the opposite direction from the needle swinging by the button moving mechanism so that the needle swinging may not be performed exceeding a limit amount for the needle swinging. The button sewing machine suppress a thread gathering defect.

Owner:JUKI CORP

Waterproof, anti-explosion and cutting-resistant high-strength double-layer toothed zipper and method for manufacturing same

The invention discloses a waterproof, anti-explosion and cutting-resistant high-strength double-layer toothed zipper and a method for manufacturing the same. The waterproof, anti-explosion and cutting-resistant high-strength double-layer toothed zipper comprises a left double-layer toothed chain belt, a right double-layer toothed chain belt and a zipper puller, the left double-layer toothed chain belt and the right double-layer toothed chain belt are meshed with each other in the left-right direction, an upper zipper chain, a lower zipper chain and a woven belt are sewn to form each double-layer toothed chain belt, and the zipper puller is used for opening and closing the left double-layer toothed chain belt and the right double-layer toothed chain belt. The waterproof, anti-explosion and cutting-resistant high-strength double-layer toothed zipper is characterized in that each woven belt is folded by one step, the zipper chains are respectively sewn at edges of outer surfaces of the upper and lower folded woven belts, and the two folded woven belts are sewn and connected with each other by harnesses. The waterproof, anti-explosion and cutting-resistant high-strength double-layer toothed zipper and the method have the advantages that the zipper is high in zipper chain and woven belt sewing speed, zipper chain and cloth belt connection strength, waterproof, anti-explosion and cutting-resistant performance and transverse strength, and the zipper can be opened and closed easily by the aid of the puller; each single-layer zipper chain is sewn with the corresponding woven belt when the zipper chains are required to be sewn with the woven belts, so that the sewing speed is greatly increased, and needles cannot be broken; and each single-layer zipper chain is sewn with the corresponding single-layer woven belt, and each double-layer zipper chain is sewn with the corresponding woven belt by the corresponding double-fold harness, so that the connection strength is doubled as compared with the traditional zipper.

Owner:芊茂(浙江)拉链有限公司

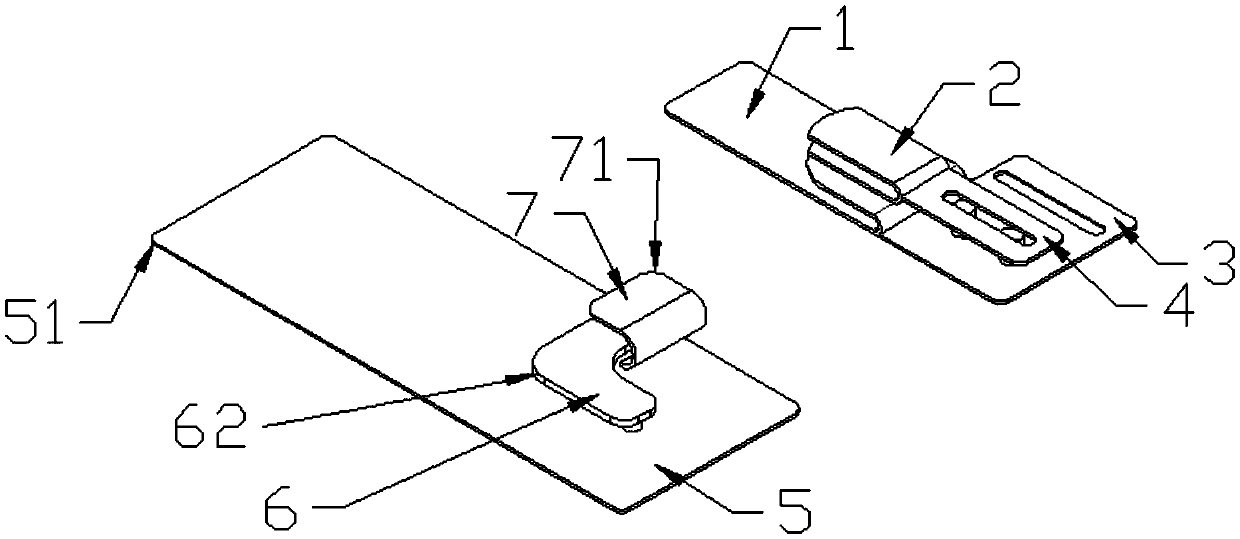

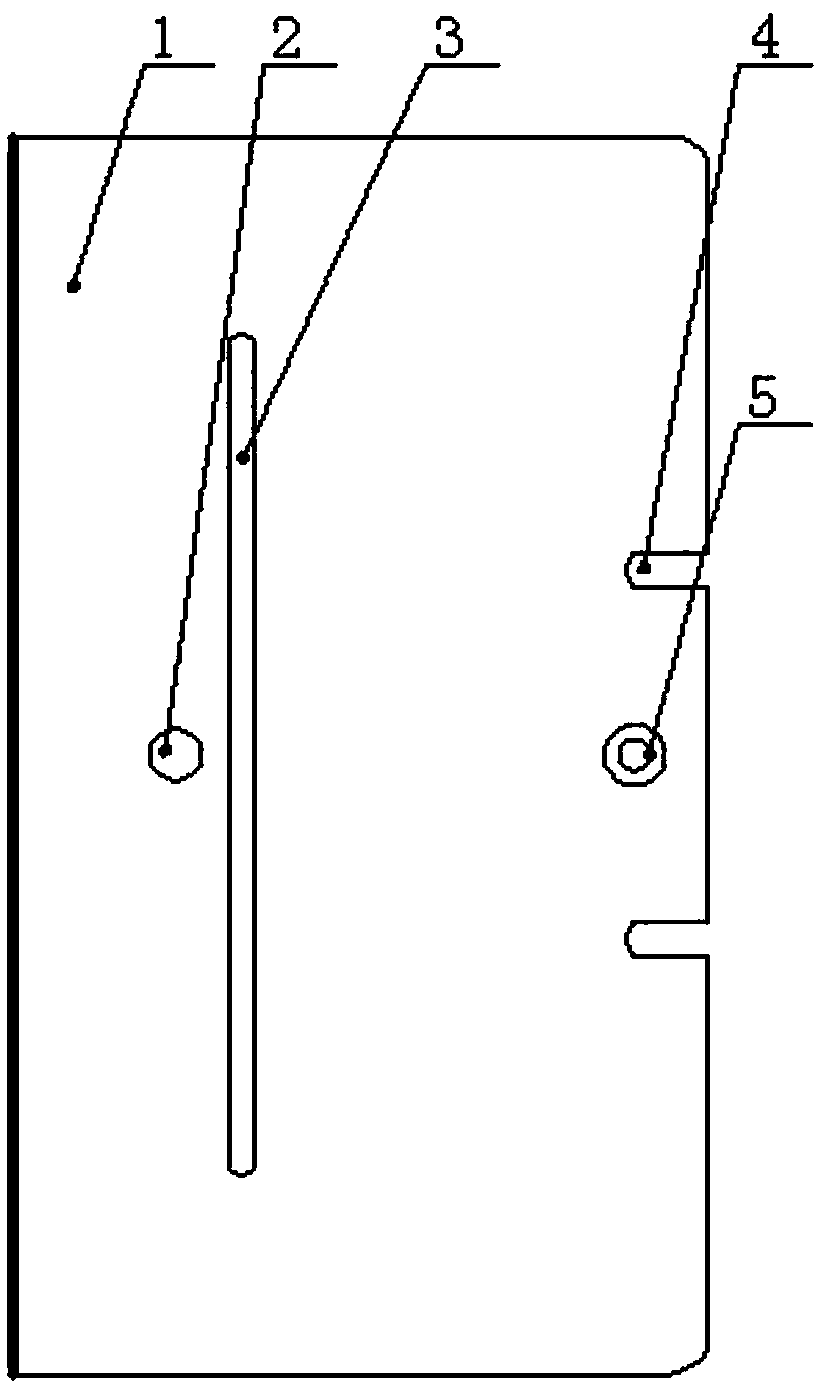

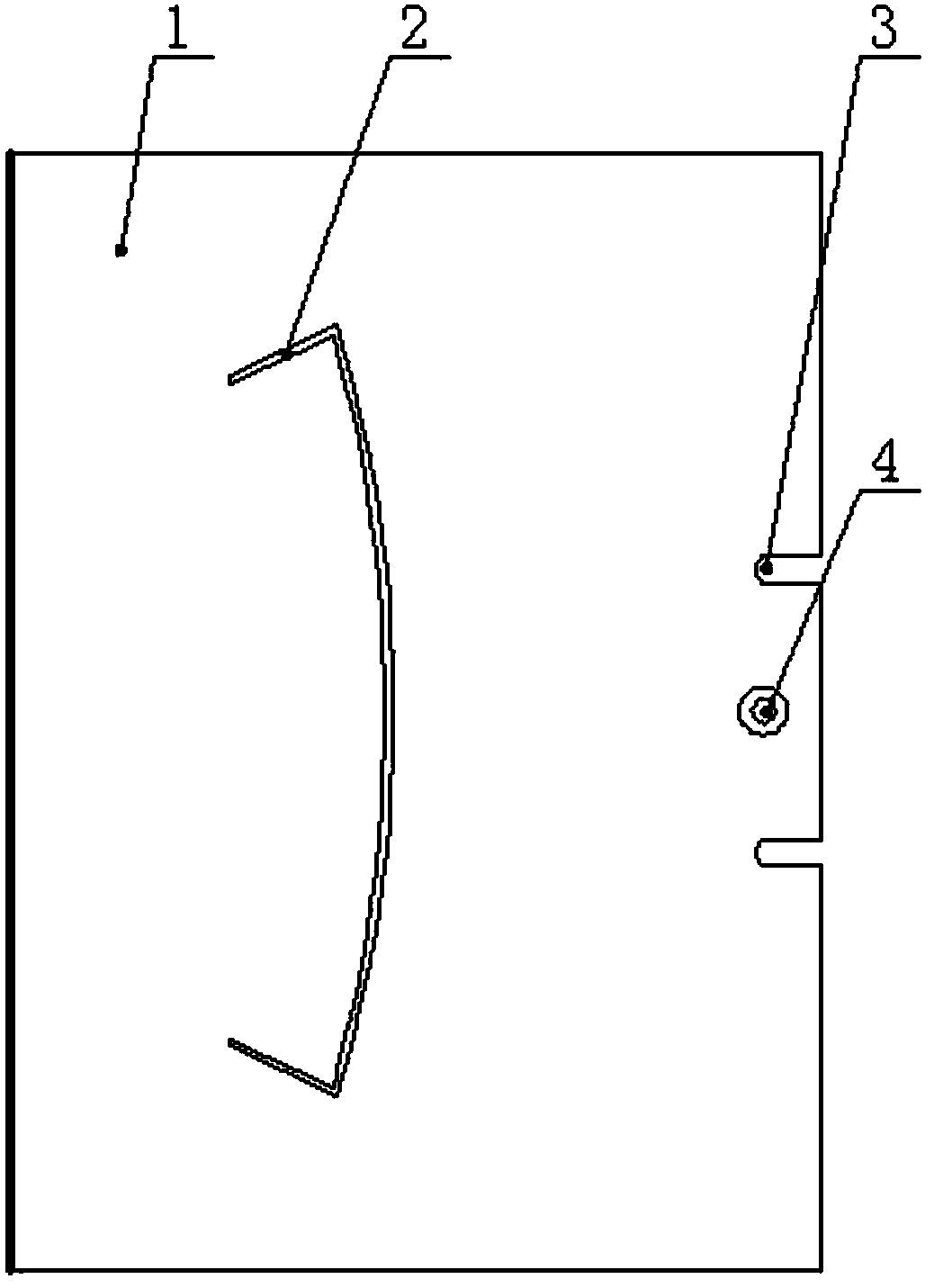

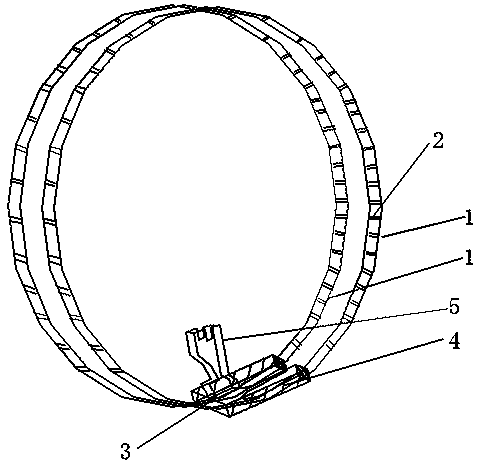

A mold for sewing back belts

The invention discloses a mold for sewing a back waist band, and relates to the technical field of sewing machines. The mold comprises a first guiding piece and a second guiding piece, the first guiding piece comprises a base plate, a semi-U-type hook with a rightward opening is arranged on the left side of the base plate, the second guiding piece comprises a support, the upper face of the support is provided with an upper U-type hook with a leftward opening, the lower face of the support is provided with a lower U-type hook with a leftward opening, and a lower half U-type hook body of the lower U-type hook is fixed on the base plate. The mold is simple in structure and low in manufacturing cost, the steps of ironing, seam reversing, seam allowance and the like are omitted, an open thread is directly sewed, the sewing quality can be guaranteed, the sewing speed is greatly quickened, and the work efficiency is greatly improved.

Owner:JIHUA 3534 CLOTHING

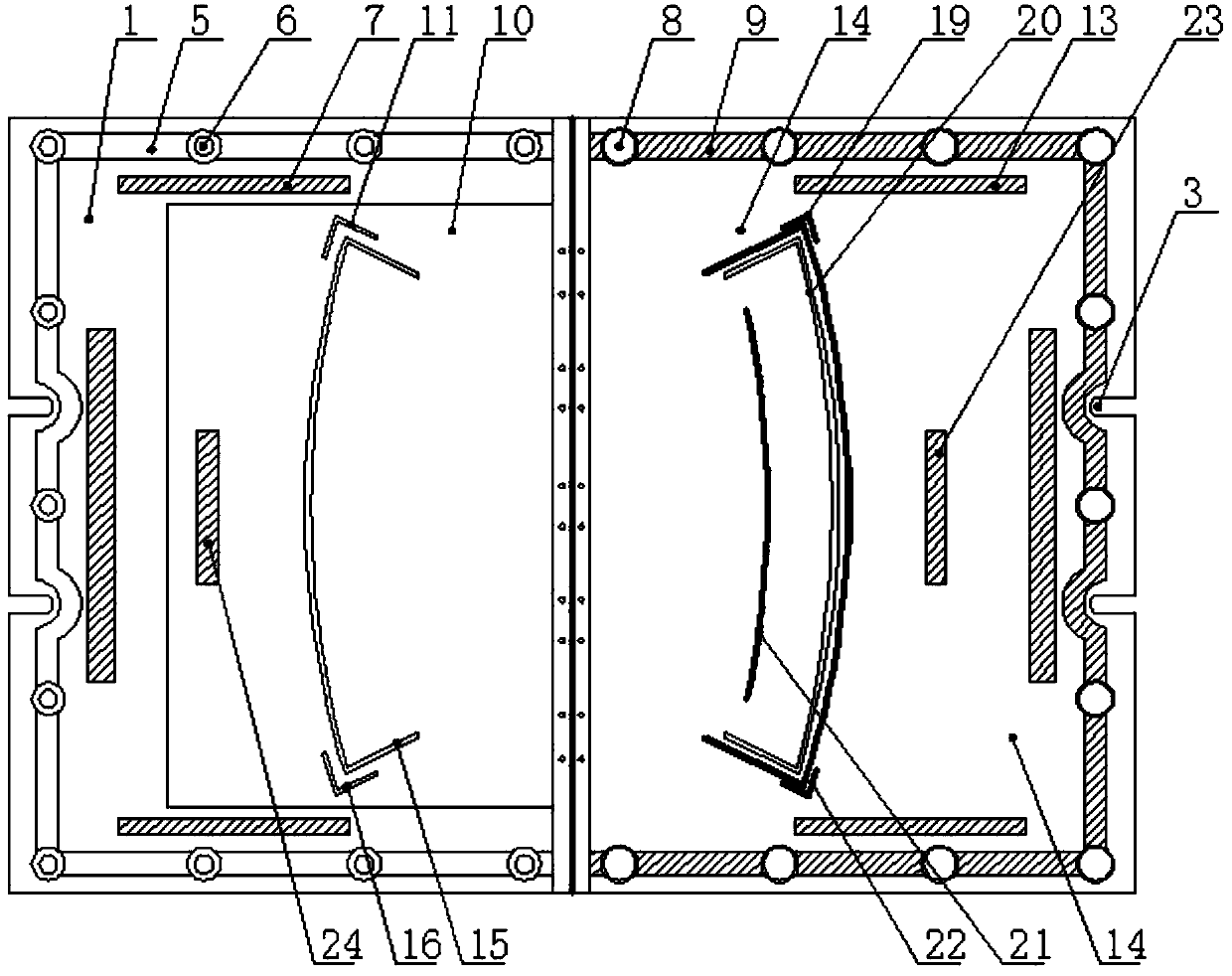

Collar template special for automatic template sewing machine

InactiveCN109853149ASolving technical problems with high operational requirementsAvoid wastingWork-feeding meansEngineeringSewing machine

The invention discloses a collar template special for an automatic template sewing machine. The collar template comprises a bottom plate, a backing plate and a cover plate, wherein one side of the bottom plate is in coaxial hinged connection with the backing plate and the cover plate, the bottom plate, the backing plate and the cover plate are provided with a backing plate sewing through groove, abottom plate sewing through groove and a cover plate sewing through groove respectively, the backing plate sewing through groove, the bottom plate sewing through groove and the cover plate sewing through groove are matched with the shape of a collar and can be mutually overlapped, and upper and lower cushion blocks are arranged at the bending positions at the upper end and the lower end of the backing plate sewing through groove on the side, on the backing plate, of the contact surface of the cover plate and the backing plate. A plurality of adsorption devices are uniformly distributed on theperiphery of the cover plate, the adsorption devices are communicated through air pipes, a plurality of adsorption grooves are uniformly formed in the periphery of the bottom plate, and the adsorption grooves are communicated through air pipe containing grooves. The technical problems that in the collar making process, the processing method is complicated, inconvenience is brought to positioningand the requirement for the operation level of a worker is high are solved, through the cooperation of the bottom plate, the backing plate and the cover plate, integrated formation is achieved, and the technical problems that the processing method is complicated in the collar making process, and the requirement for the operation level of a worker is high are solved radically.

Owner:TIANJIN SANDA CLOTHING

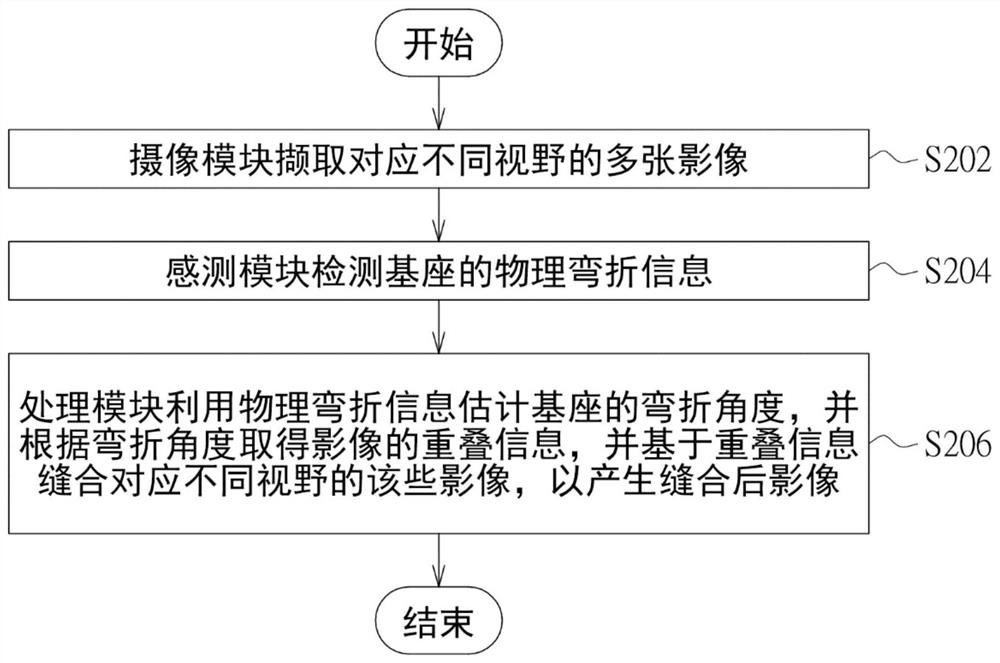

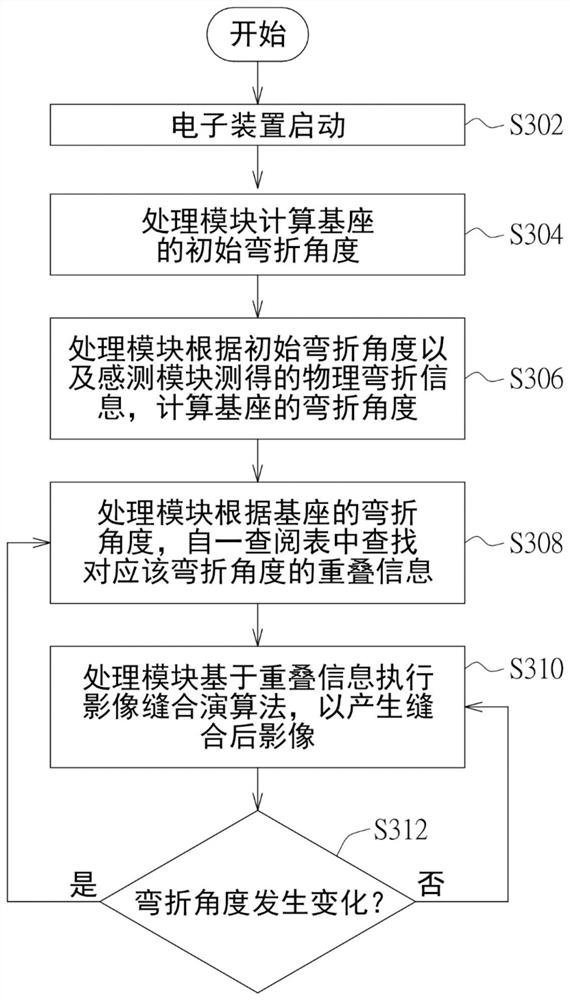

Image stitching method and electronic device using same

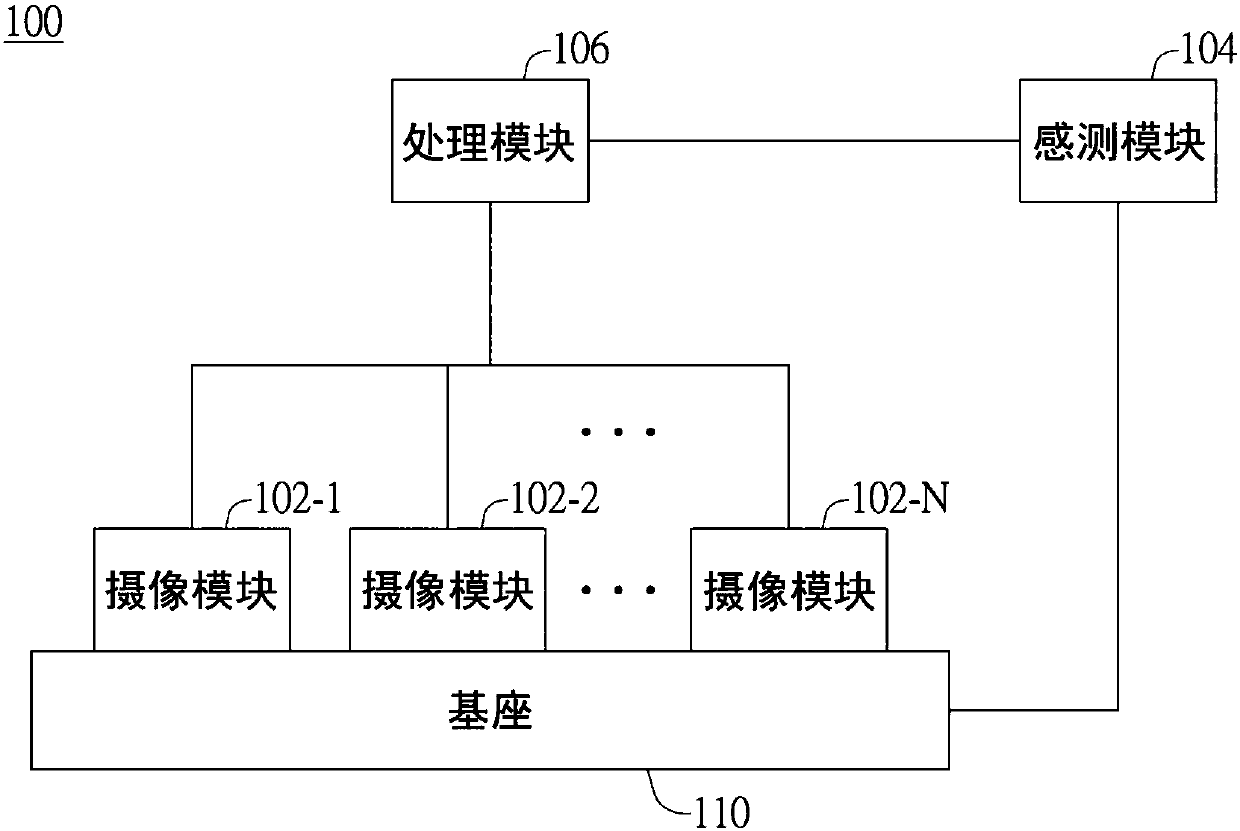

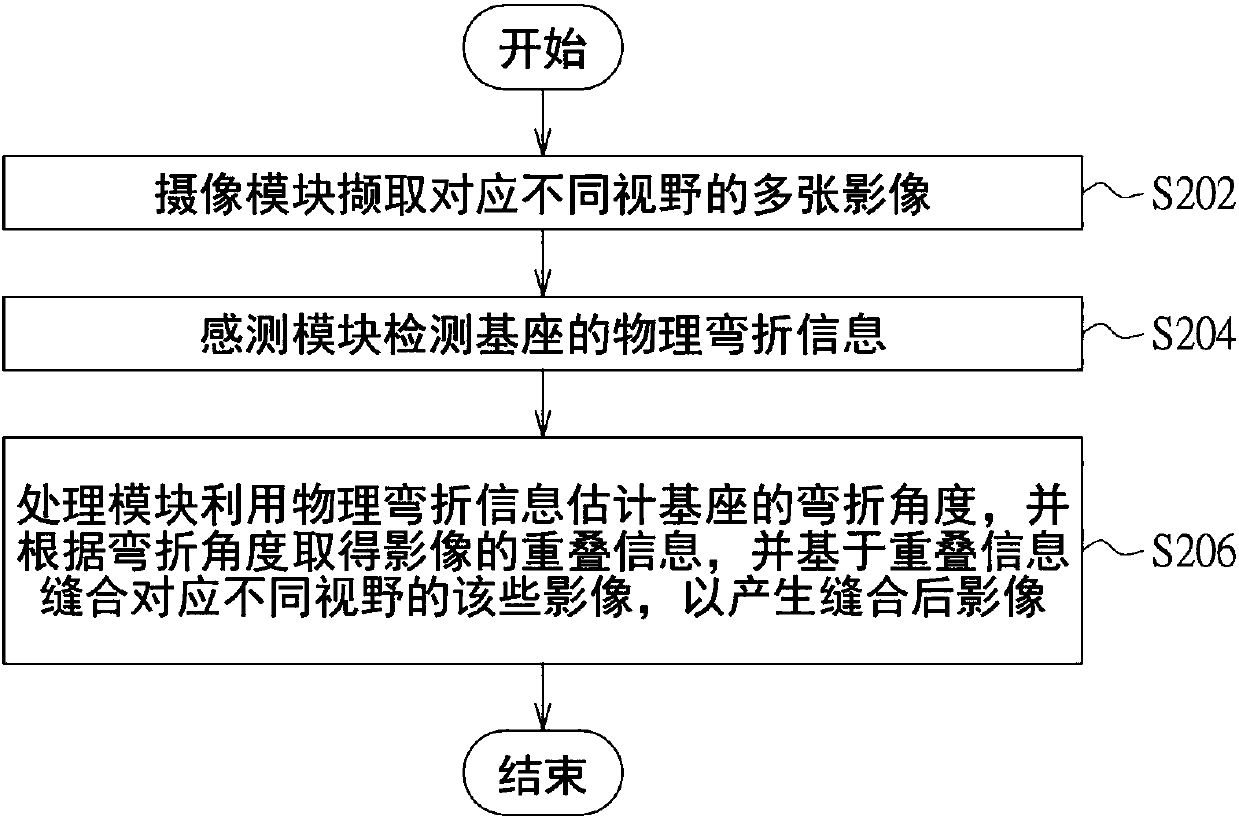

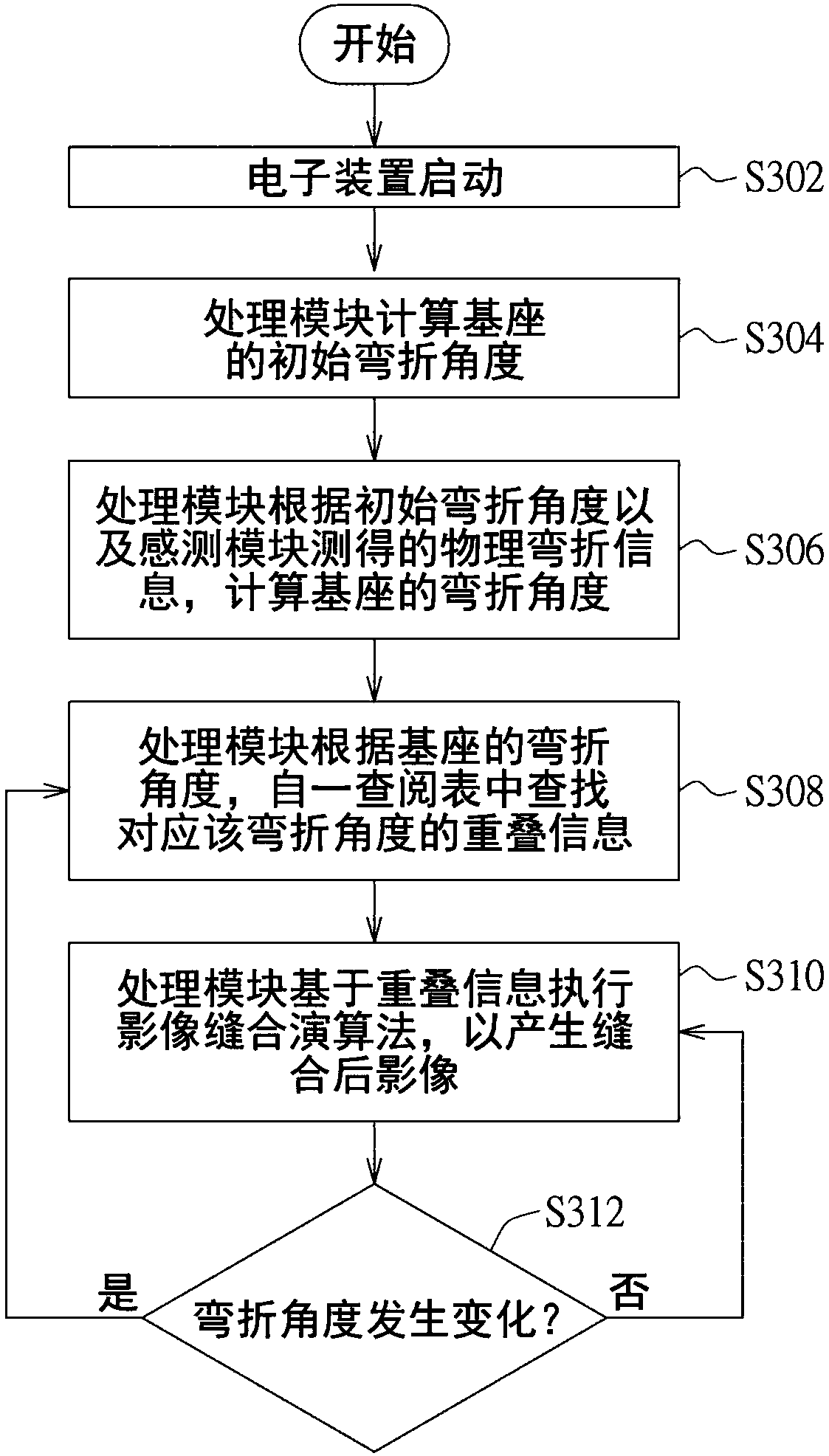

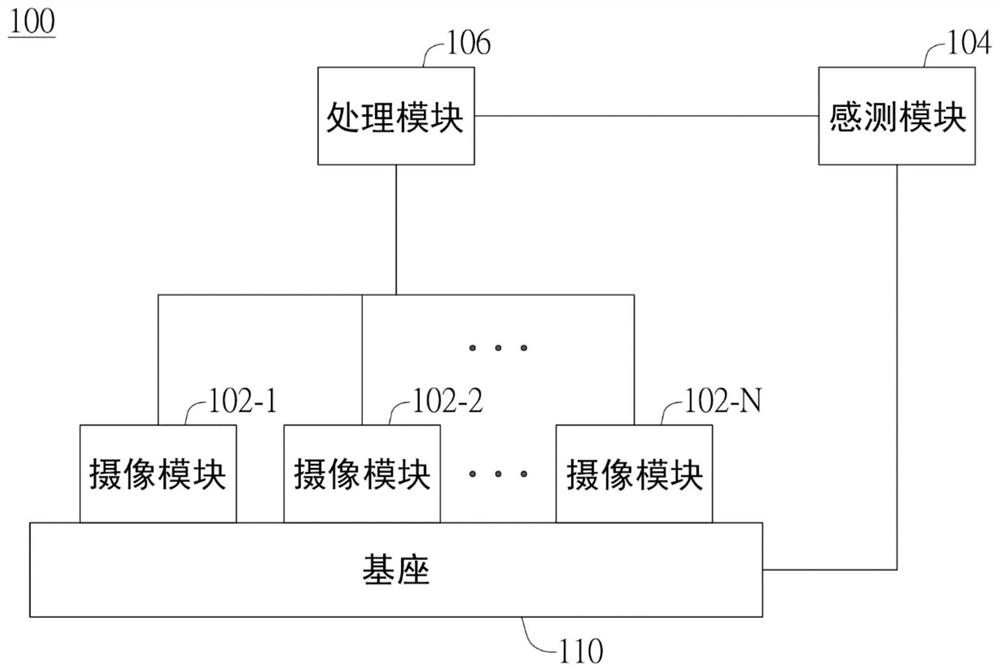

ActiveCN110324525AIncrease sewing speedShorten the timeTelevision system detailsColor television detailsComputer moduleCamera module

The invention discloses an image stitching method and an electronic device using the same. The electronic device comprises a bendable base, a plurality of camera modules, a sensing module and a processing module. The camera modules are arranged on the base and can capture a plurality of images corresponding to different visual fields. The sensing module is coupled to the base and used for detecting physical bending information of the base. The processing module is coupled to the camera module and the sensing module, and is used for estimating the bending angle of the base by using the physicalbending information, obtaining overlapping information among a plurality of images according to the bending angle, and stitching the images based on the overlapping information to generate a stitchedimage.

Owner:ACER INC

Image stitching method and electronic device using same

ActiveCN110324525BIncrease sewing speedShorten the timeTelevision system detailsColor television detailsInformation processingComputer graphics (images)

An image stitching method and an electronic device applied thereto. The electronic device includes a bendable base, a plurality of camera modules, a sensing module and a processing module. The camera modules are installed on the base, and can capture multiple images corresponding to different fields of view. The sensing module is coupled to the base, and is used for detecting physical bending information of the base. The processing module is coupled to the camera module and the sensing module, and is used for estimating the bending angle of the base using physical bending information, and obtaining overlapping information between multiple images according to the bending angle, and stitching the images based on the overlapping information, to generate stitched images.

Owner:ACER INC

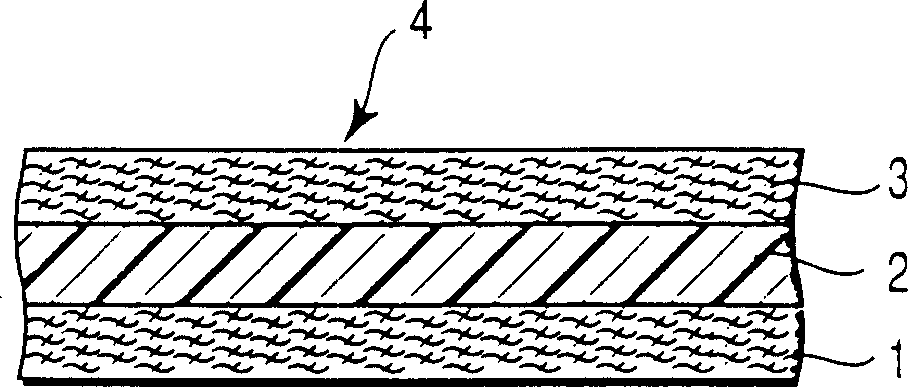

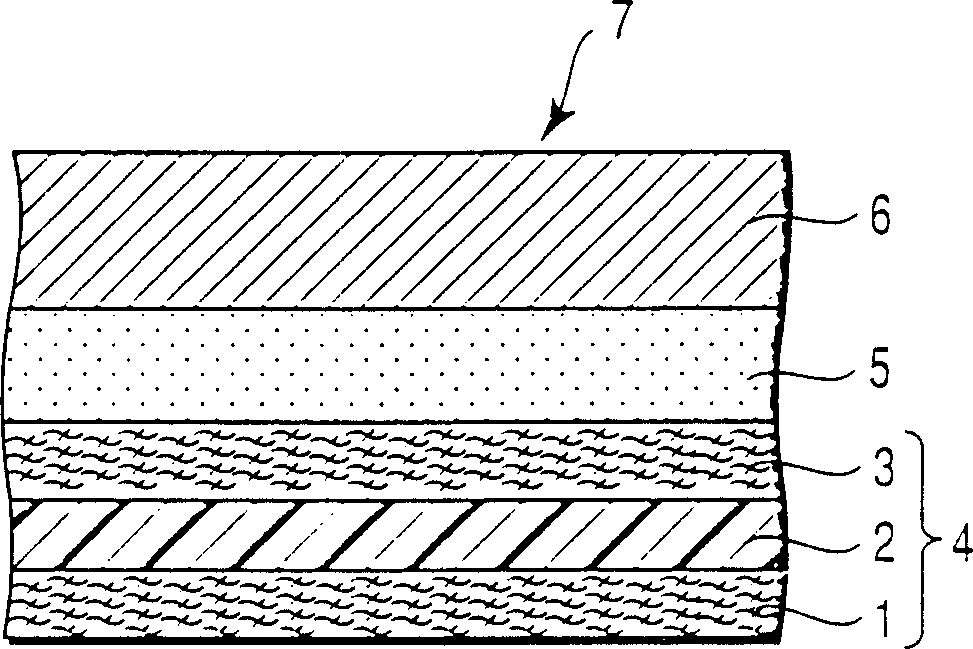

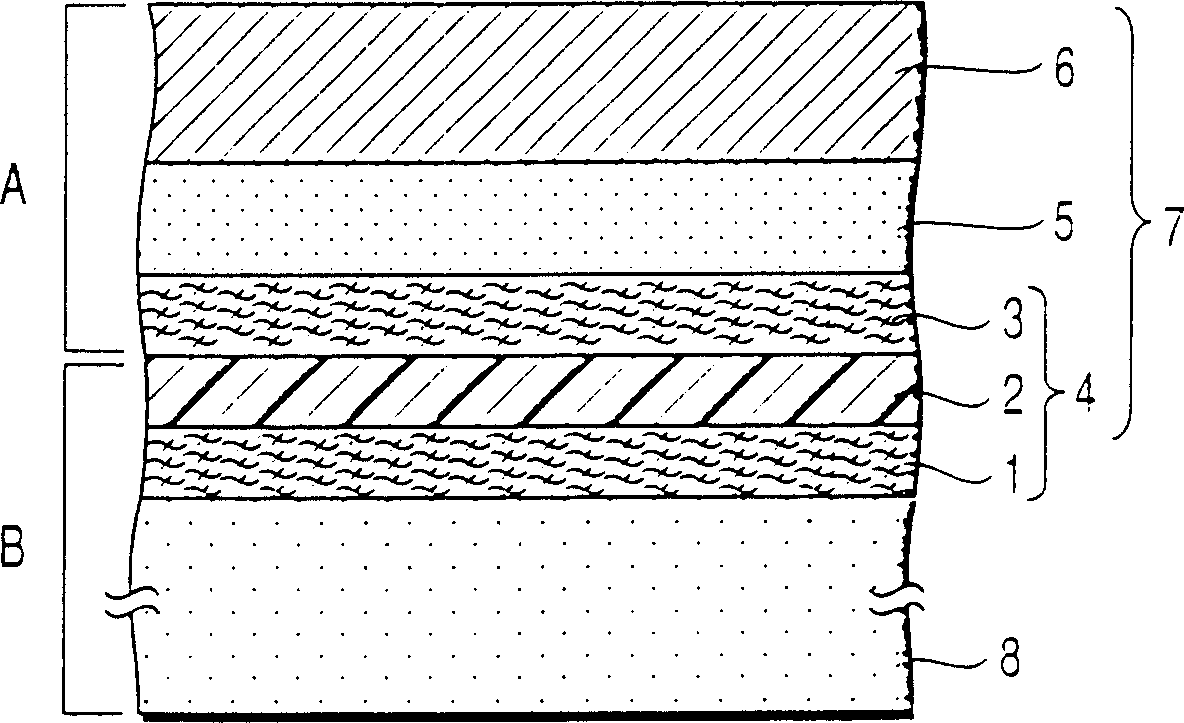

Covering material and moulded foams binded with covering material

InactiveCN1283454CLow costIncrease sewing speedUpholstery manufactureStuffed mattressesCuticleCombined use

A skin material (7) used in combination with polyurethane foam (8), the skin material (7) comprising a foam material protective layer (4) distributed on the side of the polyurethane foam (8) and Plastic foam (5) and skin (6) laminated sequentially on the protective layer (4), the foam raw material protective layer (4) has at least one layer of non-woven fabric and laminated fabric distributed on the side of the polyurethane foam (8) A plastic film on one surface of a nonwoven fabric.

Owner:TOKYO QUALITY ONE CORP

A film packaging equipment for automatic production of leather products

ActiveCN108584015BImprove drying efficiencyIncrease the areaLeather sewingWrapping material feeding apparatusHermetic packagingMaterials science

The invention discloses film packing equipment for leather product automatic production. The film packing equipment comprises a film packing mechanism; the film packing mechanism comprises a mountingbox; two film coil feeding wheels are mounted at the front end and the back end of the mounting box; a bearing table is mounted in the center of the mounting box; shrinkage films are wound on the filmcoil feeding wheels; a frame groove and an electric heating pressure bearing bar are arranged at the top end of the bearing table; a pressing and cutting mechanism is arranged rightly above the bearing table for pressing, hot sealing and cutting films, so that a pressing mechanism and a hot sealing device are saved, the structure is simple, and the cost is low; leather bags are automatically andtightly packed; pressing, hot sealing and die cutting of film packages are performed in succession, so that the packing efficiency of leather products is greatly improved; and the leather products arenot easy to be polluted by dust or damped after packing, so that the leather products are more convenient to store, subsequently process and finish.

Owner:温州金沙江实业有限公司

Special western style pants under front hooking template for automatic template sewing machine

InactiveCN109853150ASolve the cumbersome processing methodWay to overcomeWork-feeding meansEngineeringHooking

A special western style pants under front hooking template for an automatic template sewing machine is composed of a bottom plate and a cover plate, wherein the cover plate is hinged to one side of the bottom plate, and the bottom plate and the cover plate are provided with a bottom plate sewing through groove and a cover plate sewing through groove which can coincide with each other and are matched with the western style pants under front processing allowance; a plurality of adsorption devices are uniformly distributed on the periphery of the cover plate, and the adsorption devices are communicated through air pipes; a plurality of adsorption grooves are uniformly formed in the periphery of the bottom plate, and the adsorption grooves are communicated through air pipe containing grooves.The technical problems that in the western style pants under front hooking process, the processing mode is complex, positioning is inconvenient, the processing allowance is not uniform, and the operation level requirement of workers is high are solved; the base plate, the bottom plate and the cover plate are hinged and matched with one another, so that the workers only need to place the template in the automatic template sewing machine to complete all operations, and the technical problems that the processing mode during lower hem hooking and facing is complex and the operation level requirement of the workers is high are fundamentally solved.

Owner:TIANJIN SANDA CLOTHING

Wide strip edge pressing tool

InactiveCN103510289AEasy squeezePrevent disengagementWork-feeding meansStructural engineeringMechanical engineering

Owner:中江县四海制衣有限责任公司

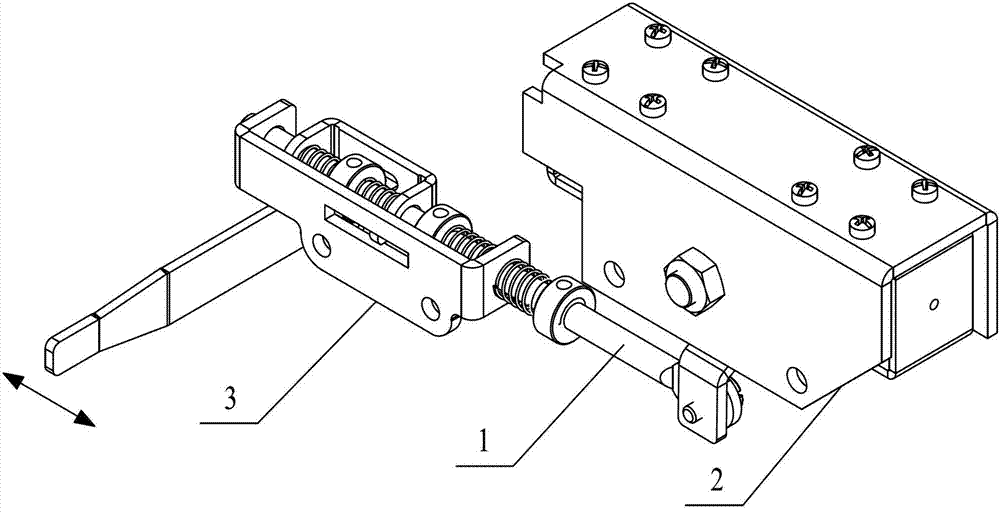

Sewing aided tool for top fly zipper trimming panel strips

The invention discloses a sewing aided tool for top fly zipper trimming panel strips. The sewing aided tool comprises an installation substrate, a zipper track support is arranged on the installation substrate, a zipper track is arranged on the zipper track support, and a panel strip double-folded device is arranged below the zipper tack; the panel strip double-folded device further comprises a transition deformation shell, the tail end of the transition deformation shell is in a vertical strip-like opening shape, the front end of the transition deformation shell is in a lateral strip-like opening shape, and the middle part of the transition deformation shell is gradually transitively deformed to the lateral strip-like opening shape from the vertical strip-like opening shape. By means of the sewing aided tool, the problems that in the existing sewing process of the top fly zipper trimming panel strips, the sewing speed is low and the quality is not easy to ensure are solved.

Owner:江苏华瑞时尚集团有限公司 +2

Mold for sewing back waist band

The invention discloses a mold for sewing a back waist band, and relates to the technical field of sewing machines. The mold comprises a first guiding piece and a second guiding piece, the first guiding piece comprises a base plate, a semi-U-type hook with a rightward opening is arranged on the left side of the base plate, the second guiding piece comprises a support, the upper face of the support is provided with an upper U-type hook with a leftward opening, the lower face of the support is provided with a lower U-type hook with a leftward opening, and a lower half U-type hook body of the lower U-type hook is fixed on the base plate. The mold is simple in structure and low in manufacturing cost, the steps of ironing, seam reversing, seam allowance and the like are omitted, an open thread is directly sewed, the sewing quality can be guaranteed, the sewing speed is greatly quickened, and the work efficiency is greatly improved.

Owner:JIHUA 3534 CLOTHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com