A method of making a mold cup

A production method and mold cup technology, applied in clothing, applications, bras, etc., can solve the problems of high resignation rate of operators, long equipment downtime, and low production hours of employees, so as to reduce employee fatigue and save labor costs. , the effect of reducing the amount of lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

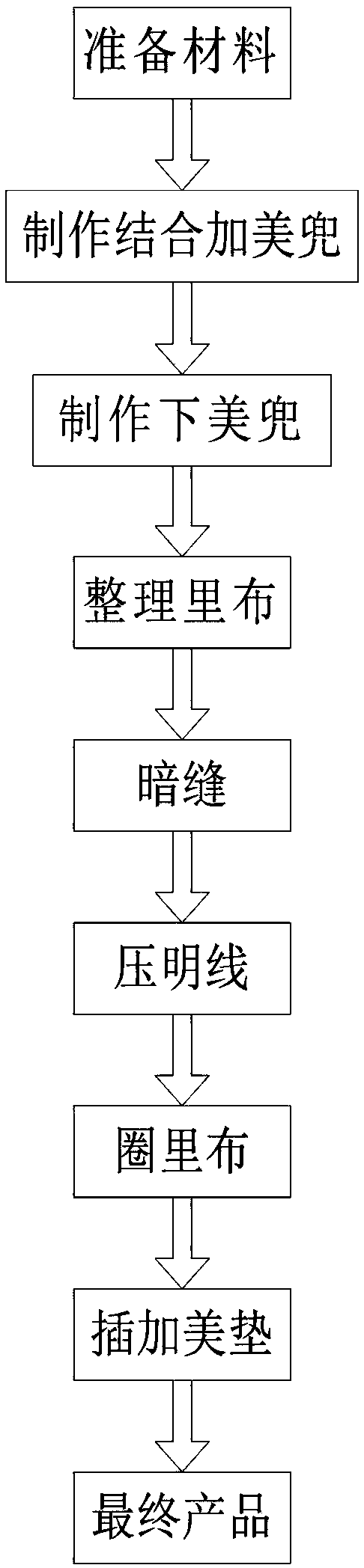

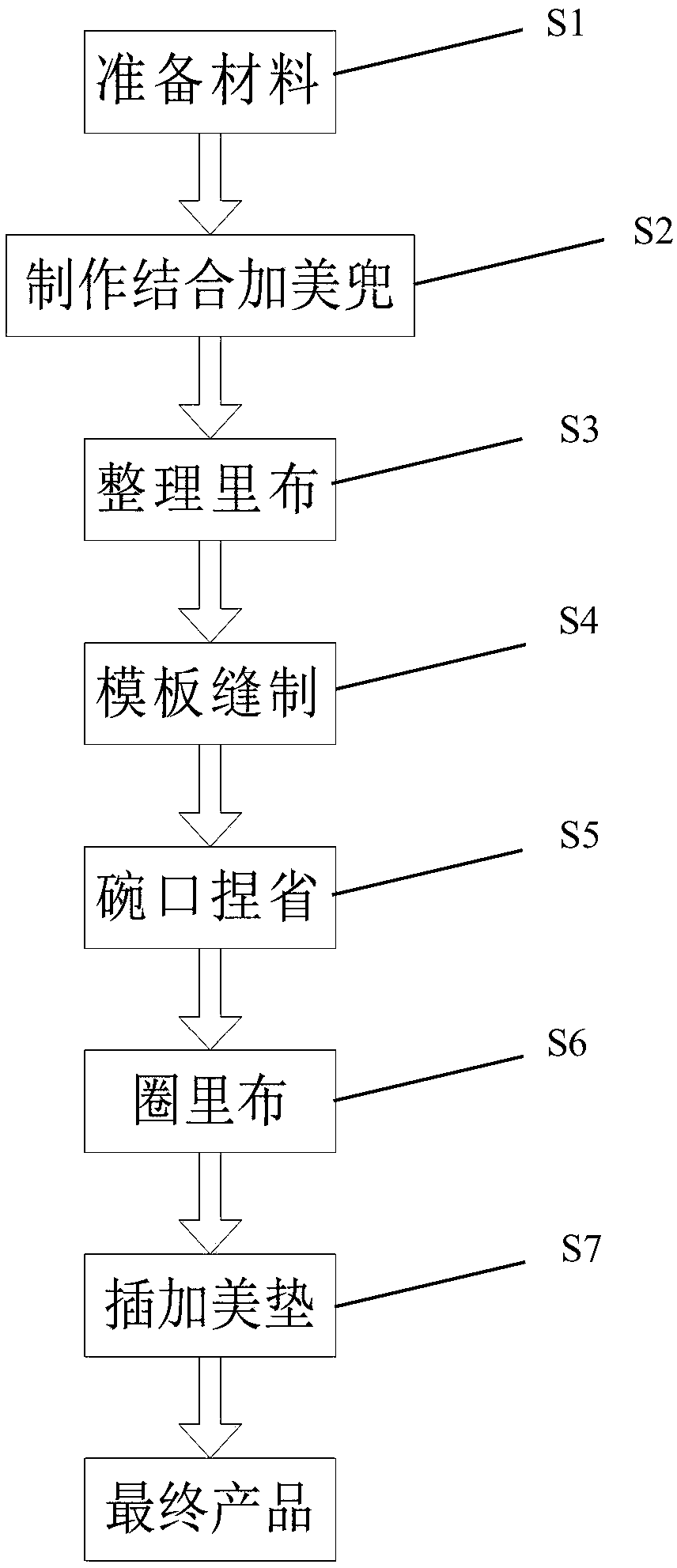

[0031] Such as Figure 2-4 Shown, the manufacture method of a kind of mold cup of the present embodiment comprises the following steps:

[0032] Step S1: Prepare materials

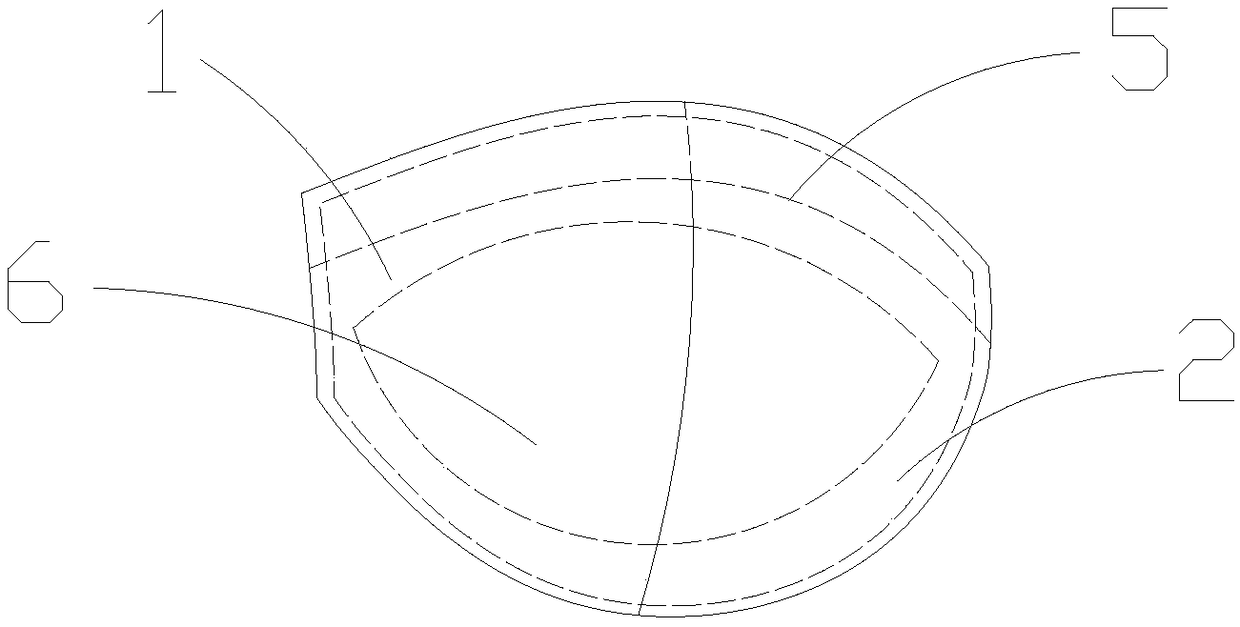

[0033] Prepare the lining cloth and the cup body 4 of the preset size, the lining includes the left Kami pocket 1, the right Kami pocket 2 and the lower caribou 3. The cup body 4 matches the contour of the lower caribou 3 .

[0034] Step S2: Make a combined game bag

[0035] The left Kami pocket 1 and the right Kami pocket 2 are made into a combined Kami pocket. The production method is: fold the right end of the left Kami pocket 1 and the left end of the right Kami pocket 2 inward along a straight line and sew them down along the upper end of the folding line 4 -5cm, made with a combination of Kami pockets. Combined with a cami pocket to match the silhouette of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com