Sewing aided tool for top fly zipper trimming panel strips

An auxiliary tooling and zipper technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of slow sewing speed and difficult quality assurance, and achieve the advantages of improving sewing speed, simple operation and ensuring sewing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

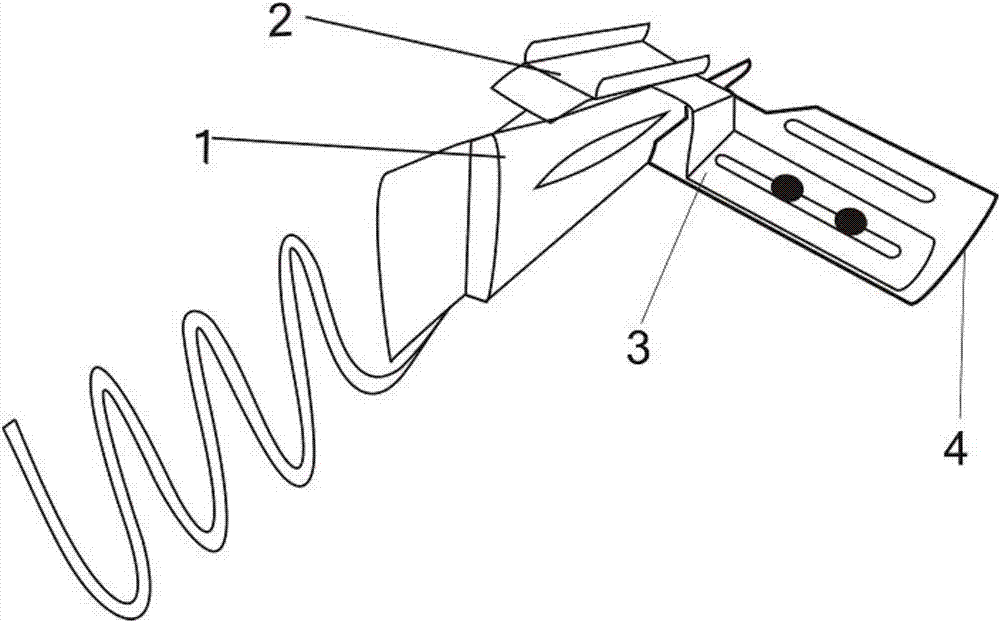

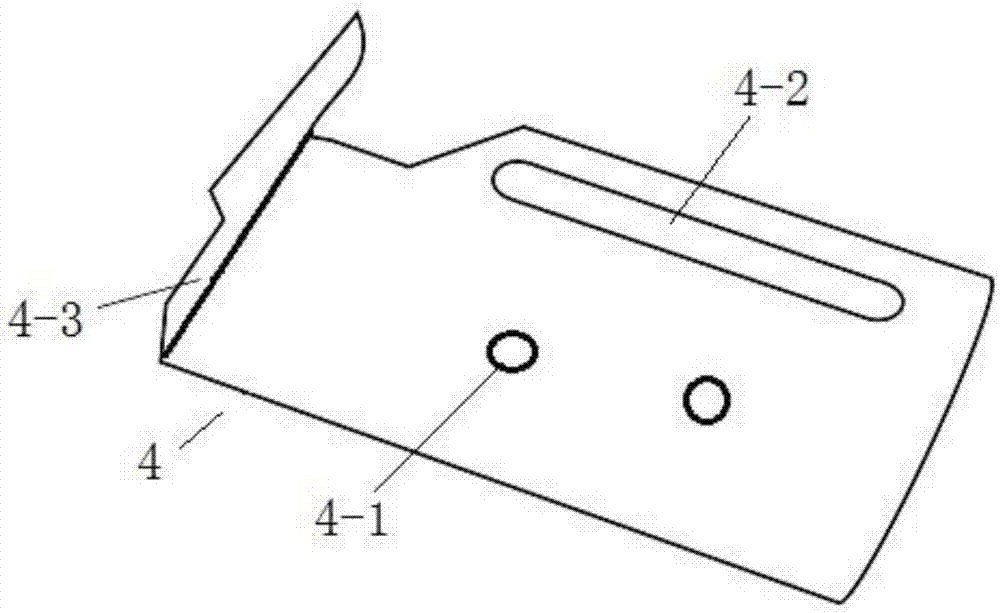

[0023] Such as figure 1 As shown, a sewing auxiliary tooling of a door zipper decorative molding of the present invention includes a mounting base 4, a zipper track bracket 3 is arranged on the installation base 4, a zipper track 2 is arranged on the zipper track bracket 3, and The bottom of the zipper track 2 is provided with a strip folder 1 .

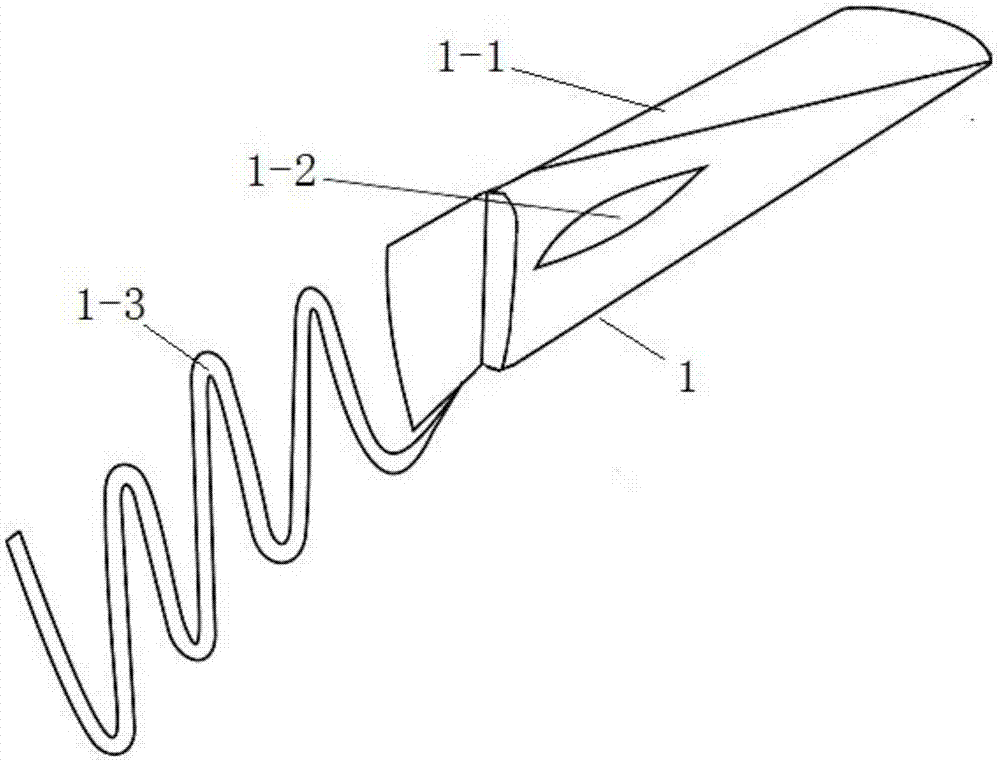

[0024] Such as figure 2 As shown, the strip doubler 1 includes a transitional deformation housing 1-1, the tail end of the transitional deformation housing 1-1 is in the shape of a vertical strip opening, and the front end of the transition deformation housing 1-1 is in the shape of a transverse strip opening , the middle part of the transition deformation shell 1-1 is gradually deformed from a vertical strip-shaped opening to a horizontal strip-shaped opening. Be provided with notch 1-2 on the side of transitional deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com