Patents

Literature

54results about How to "Guaranteed sewing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

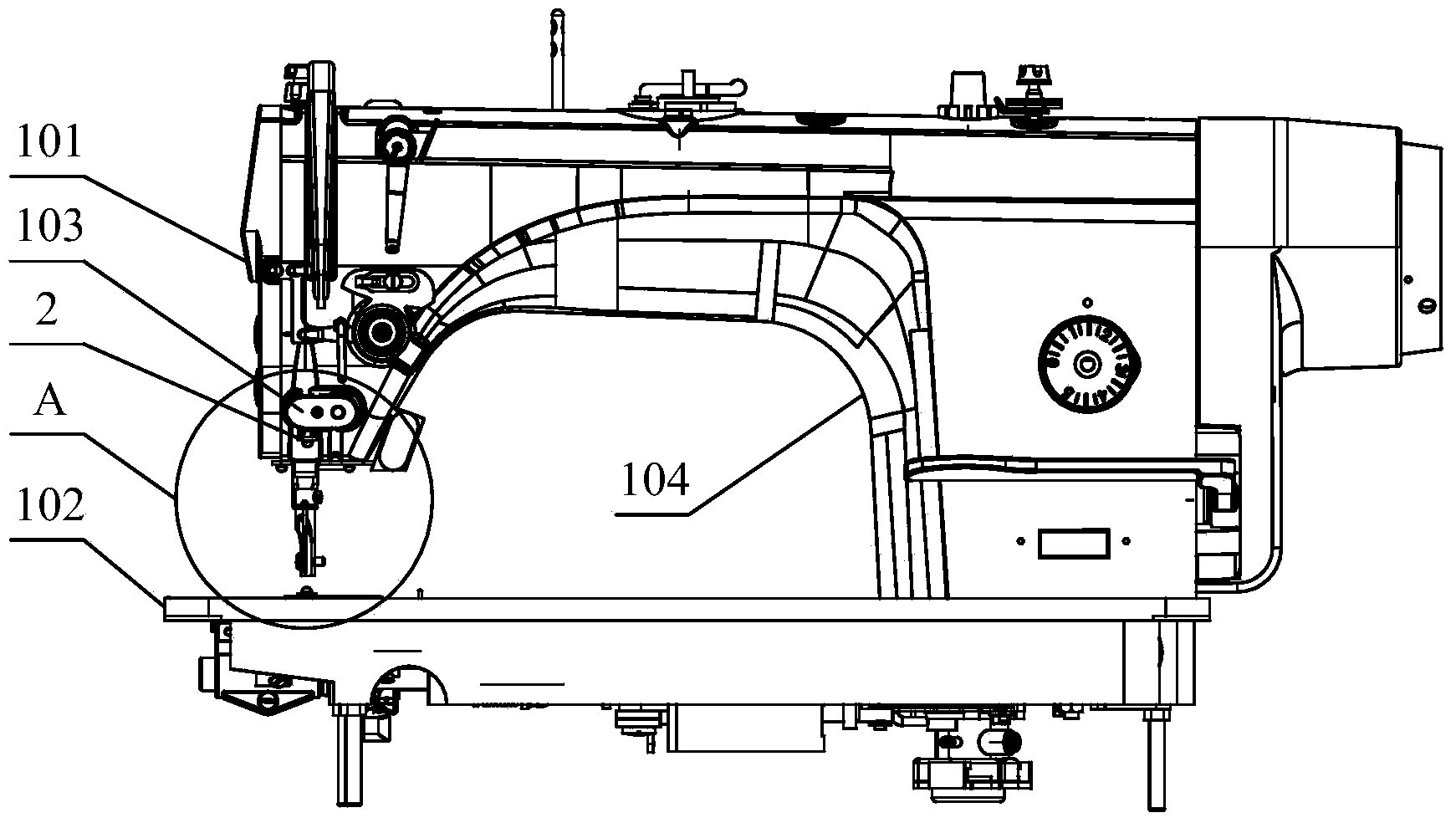

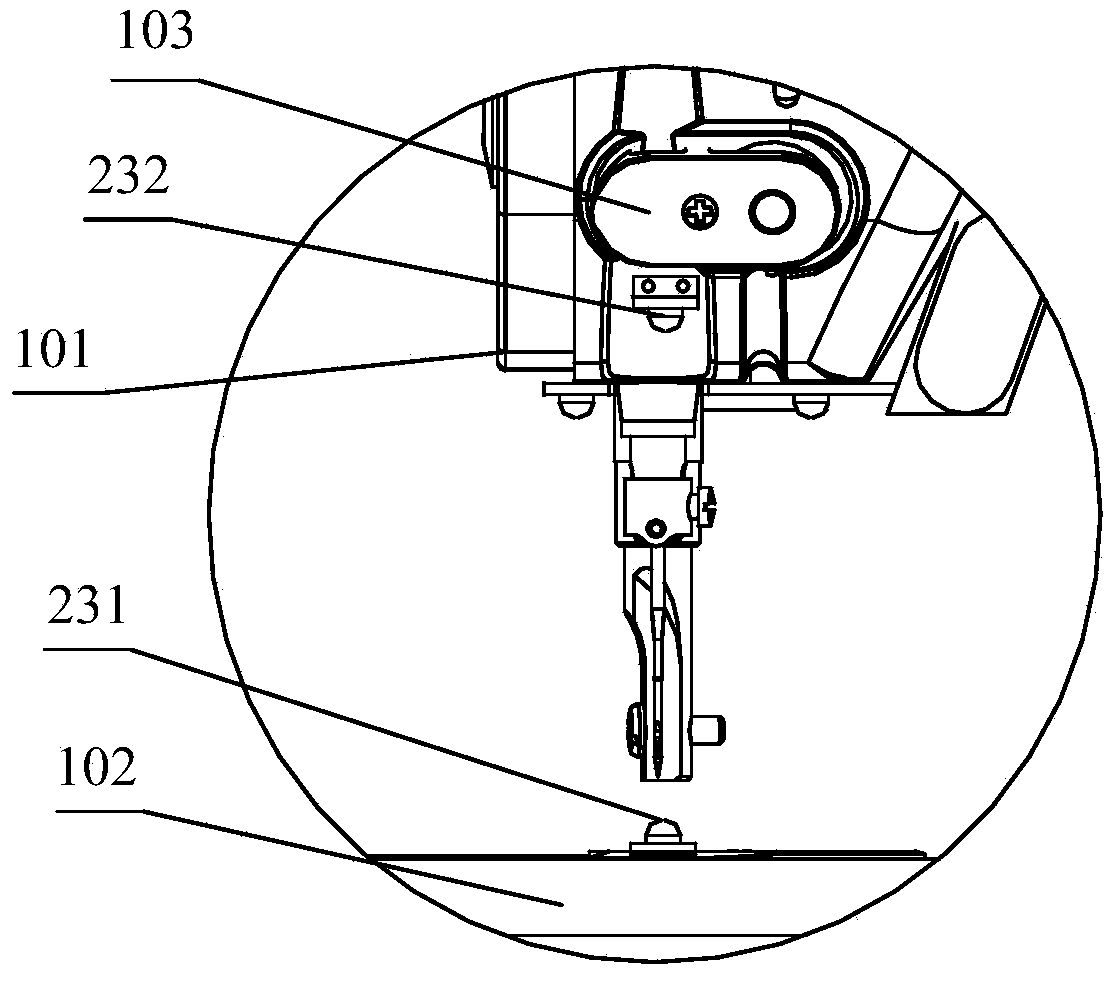

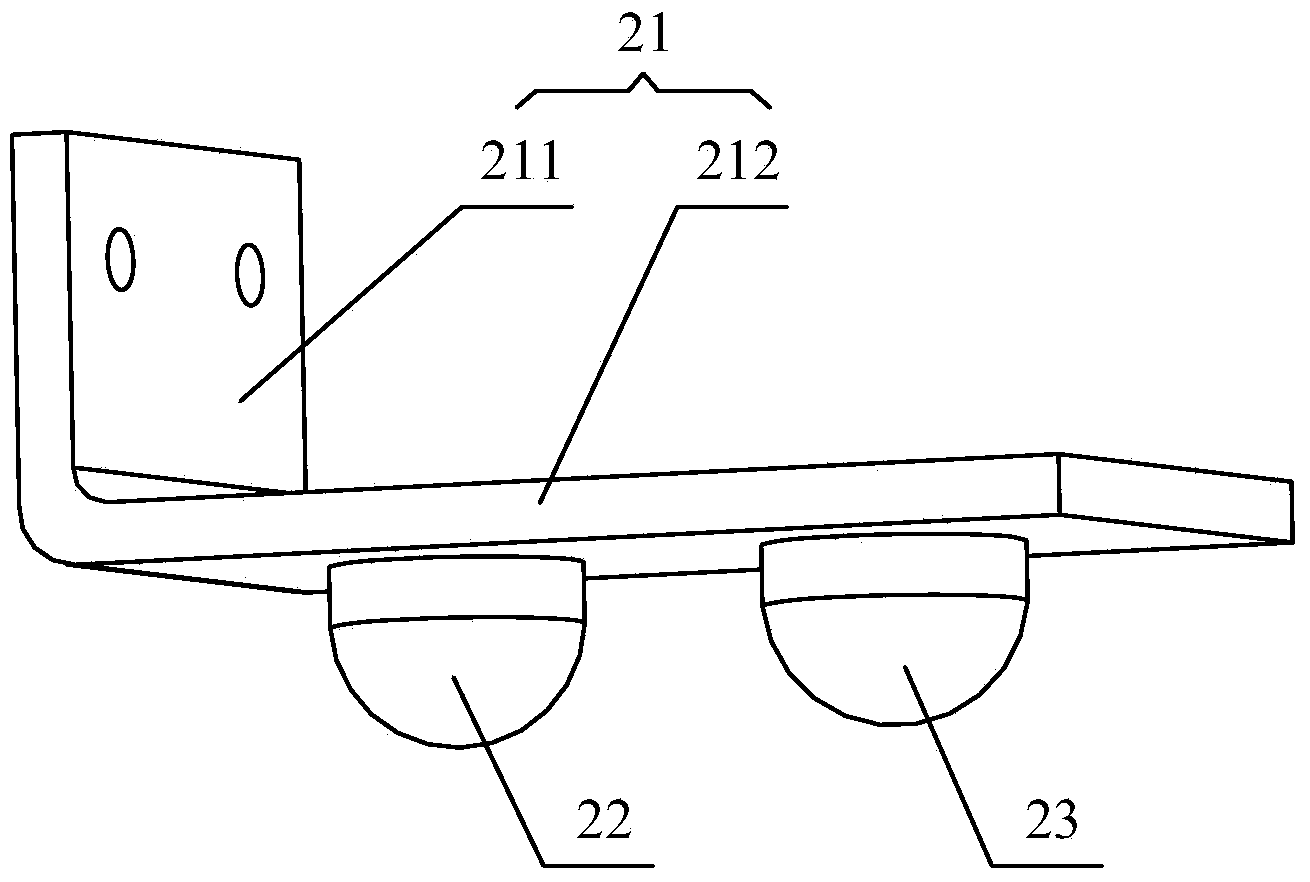

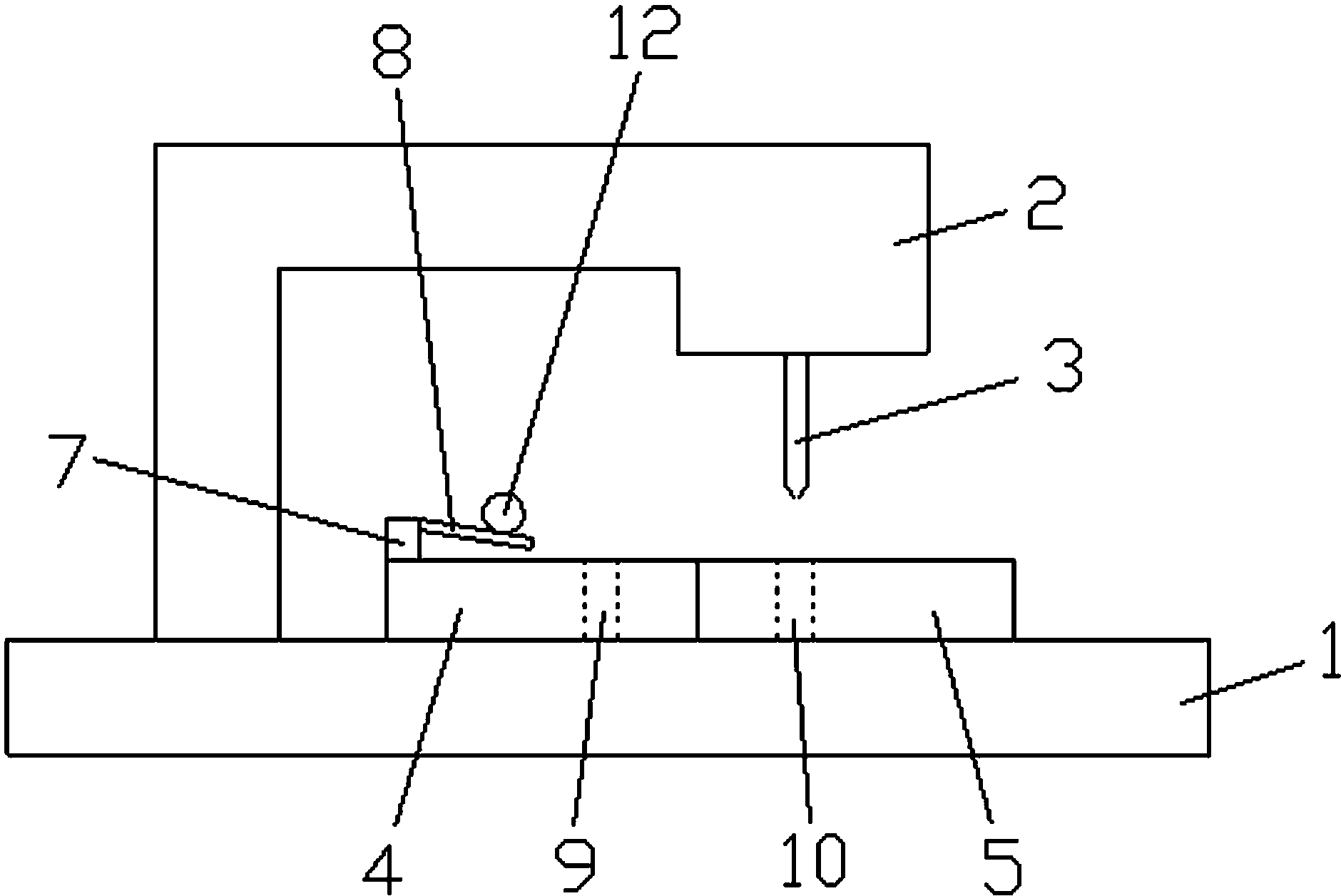

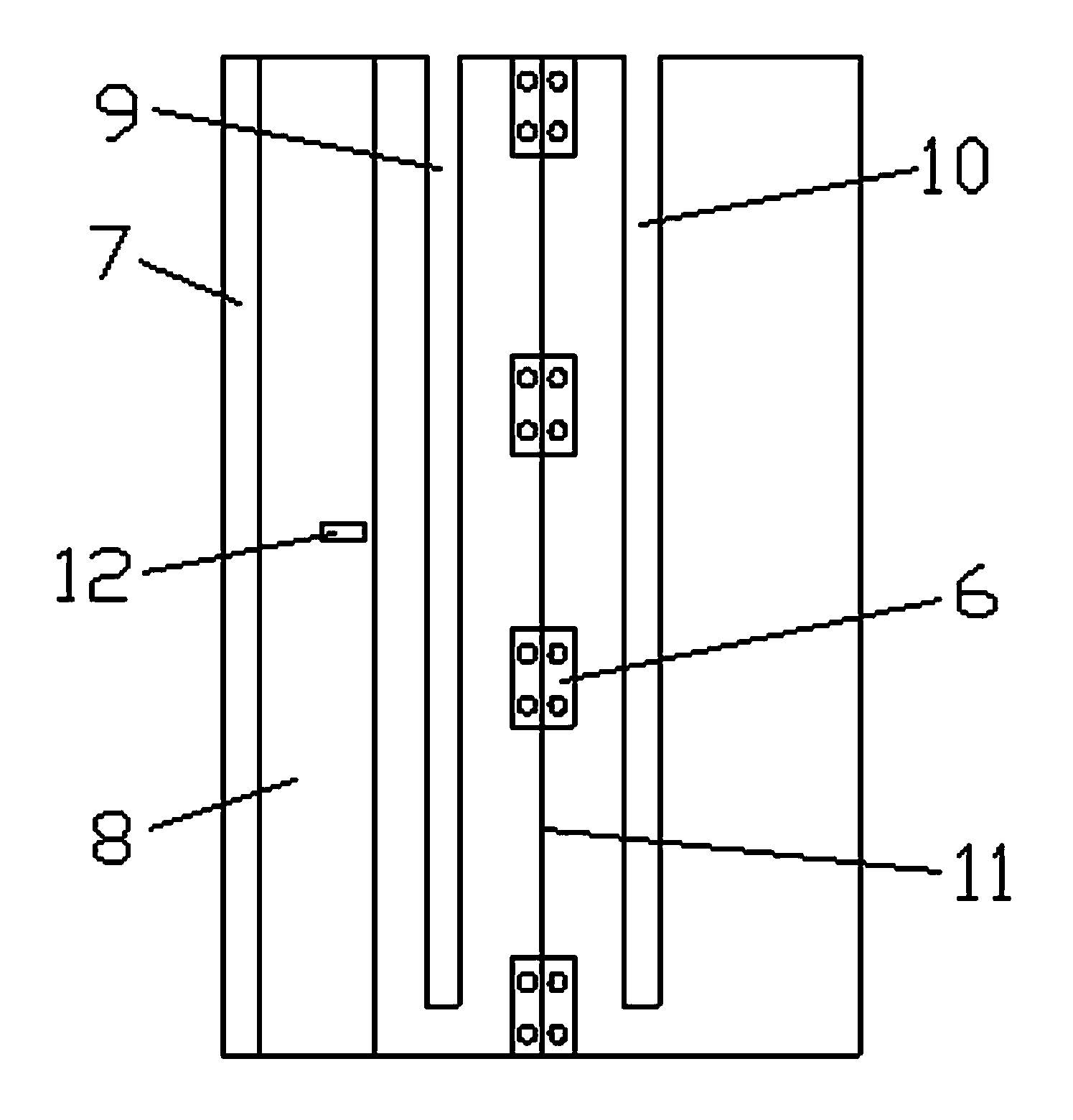

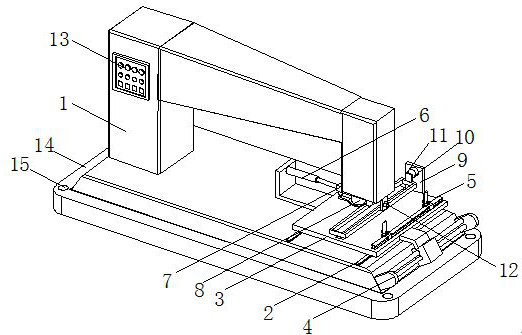

Sewing material detecting device and automatic presser foot height adjusting system for sewing machine

ActiveCN103866496ARealize fully automatic controlAccurately adjust the lifting heightPressersAutomatic controlEngineering

The invention provides a sewing material detecting device for a sewing machine. The sewing machine comprises a machine head and a table plate. The sewing material detecting device for the sewing machine is characterized in that the sewing material detecting device comprises a mounting plate, a circuit board and a sewing material thickness detector, the mounting plate is fixed to the machine head, the circuit board and the sewing material thickness detector are fixed on the mounting plate, the circuit board comprises a micro-control unit, the sewing material thickness detector exactly faces the table plate, and the sewing material thickness detector is connected with the micro-control unit through the circuit board. The sewing material detecting device for the sewing machine is mounted on the machine head of the sewing machine, the thickness of sewing materials to be sewn on the table plate of the sewing machine can be accurately detected through the sewing material thickness detector and the micro-control unit, the lifting height of presser feet is adjusted accurately according to the detected thickness of the sewing materials, a strong basis is provided for the adjustment of the lifting height of the presser feet, and accurate full automatic control over the sewing machine can be ensured.

Owner:JACK SEWING MASCH CO LTD

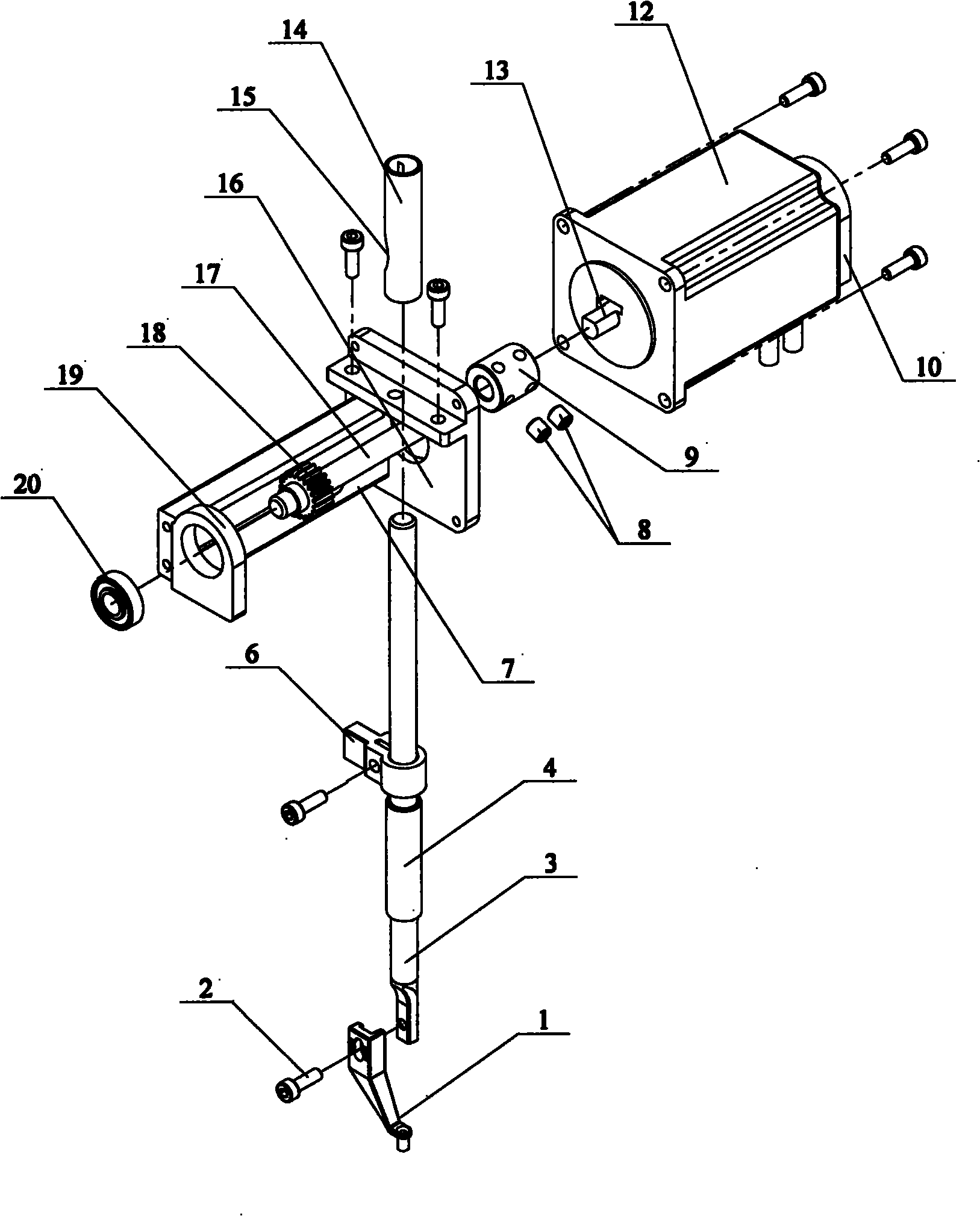

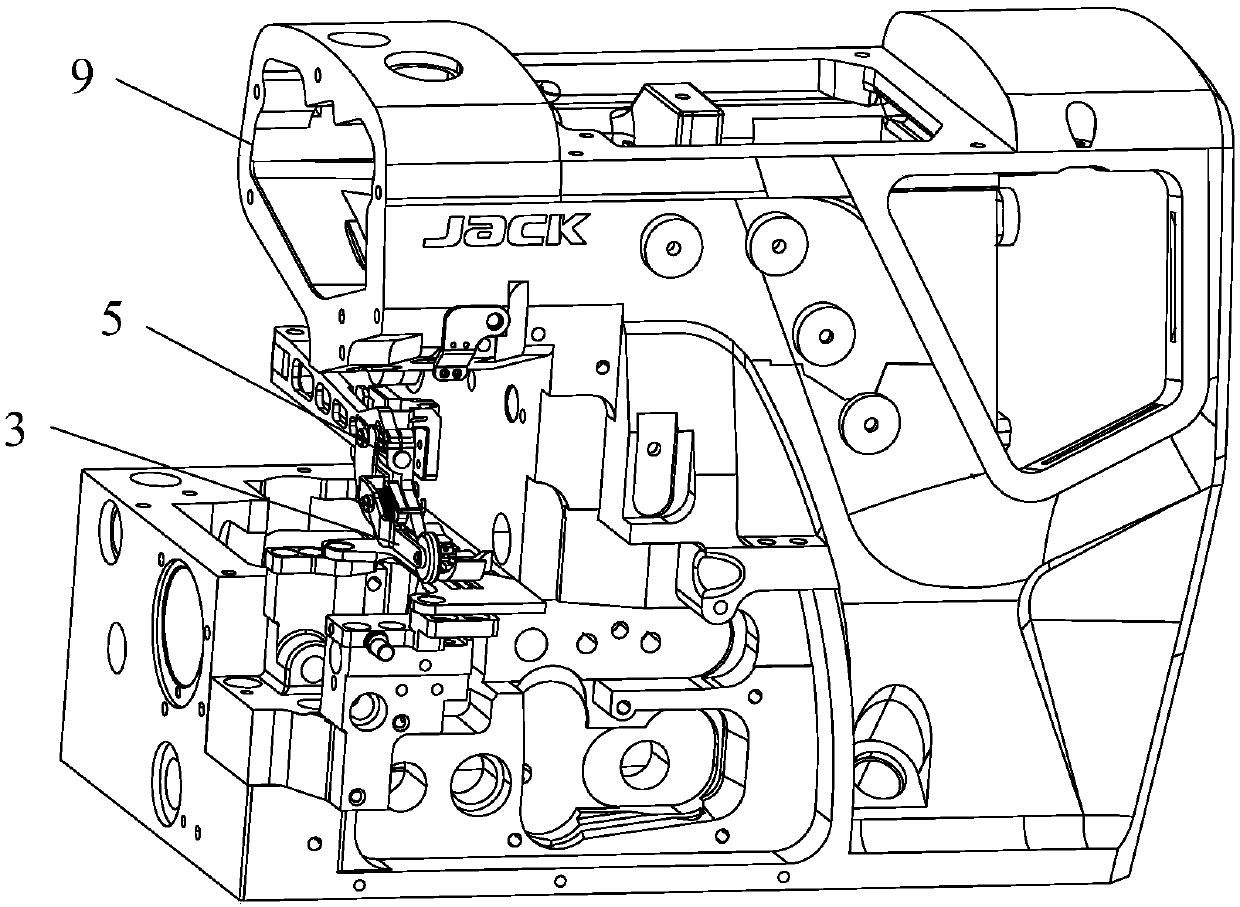

Middle presser foot mechanism of sewing machine

The invention discloses a middle presser foot mechanism of a sewing machine. The mechanism comprises a presser foot rod and a driving device driving the presser foot rod to move up and down, wherein the presser foot rod is arranged in a shell of the sewing machine. The driving device comprises a servo motor and a control unit, wherein the servo motor is fixed in the shell of the sewing machine; the output shaft of the servo motor is connected with a gear shaft through a connecting head; and the control unit gives out a servo motor start or stop control signal according to a selected instruction of an operator to control the servo motor to start or stop. A rack is arranged on the upper part of the presser foot rod; a middle presser foot is fixed to the lower end of the presser foot rod; and the rack is meshed with a gear on the gear shaft. In the middle presser foot mechanism, the middle presser foot is driven through an independent servo motor and has nothing to do with the motion of a main shaft of a machine needle; and whether the middle presser foot is matched with the needle of the sewing machine or not is manually selected according to different sewing fabrics and processes, so the abrasion of the middle presser foot mechanism is reduced and the sewing speed is increased at the same time.

Owner:四川精上缝纫机有限公司

Sewing material thickness detection device and sewing machine

InactiveCN110042582AIncrease or decrease speedDecrease or increase speedSewing-machine control devicesElectric machineryComputer module

Owner:JACK SEWING MASCH CO LTD

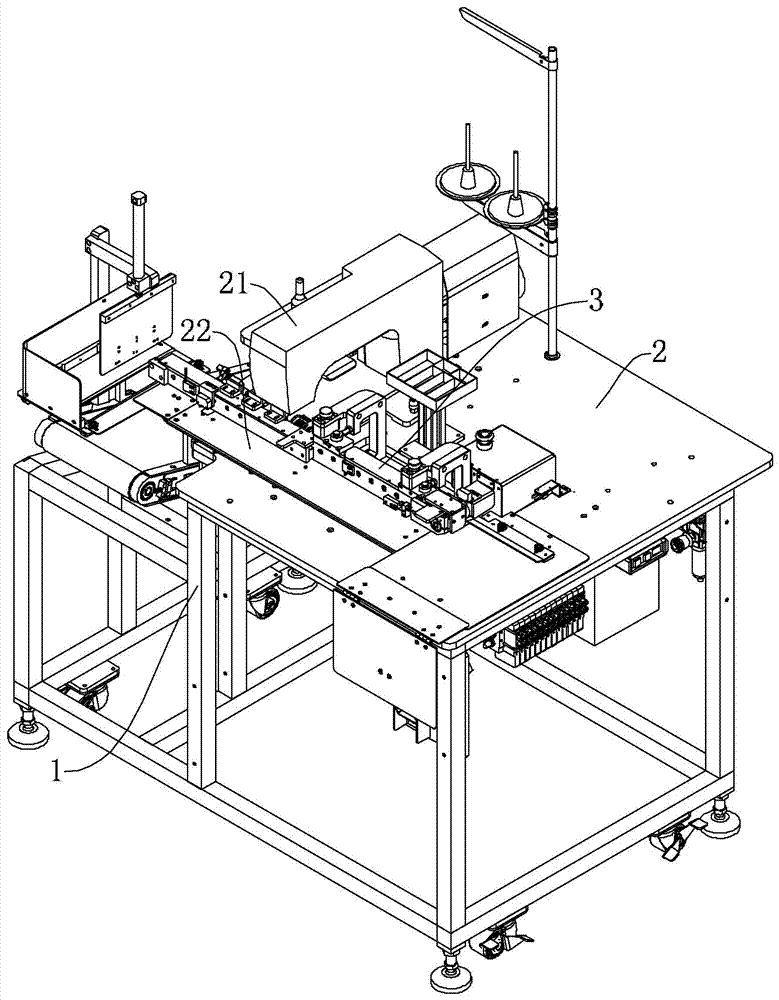

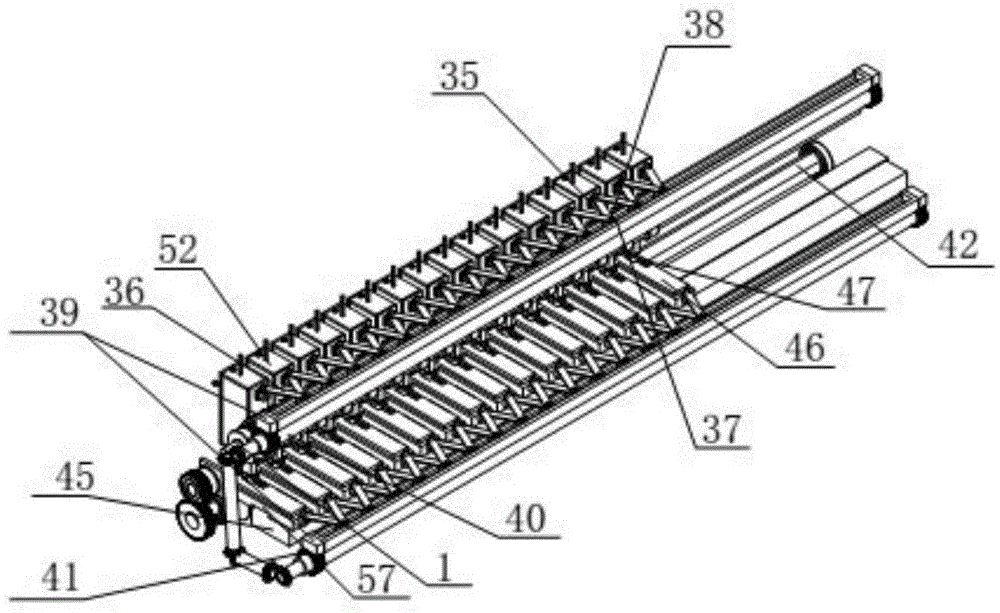

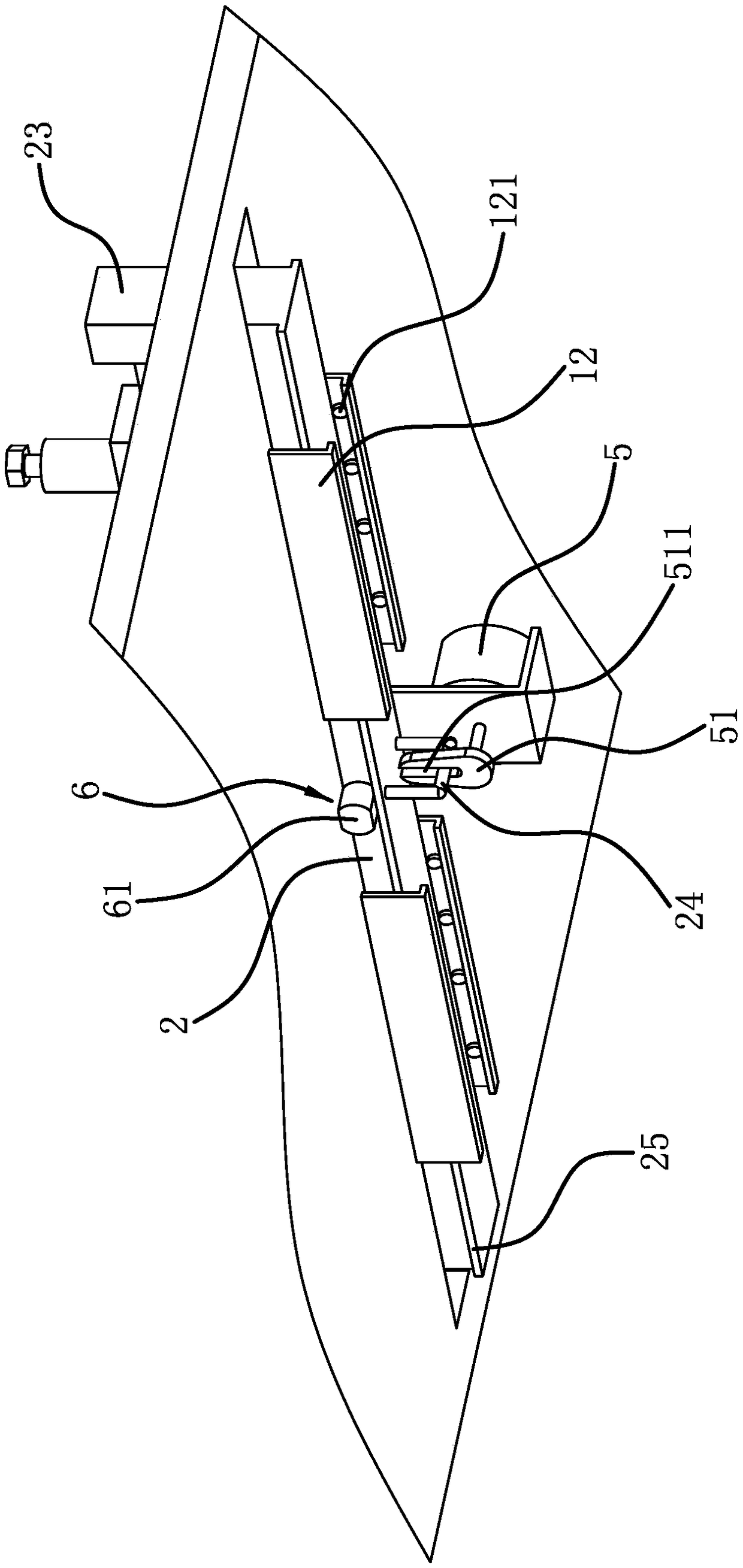

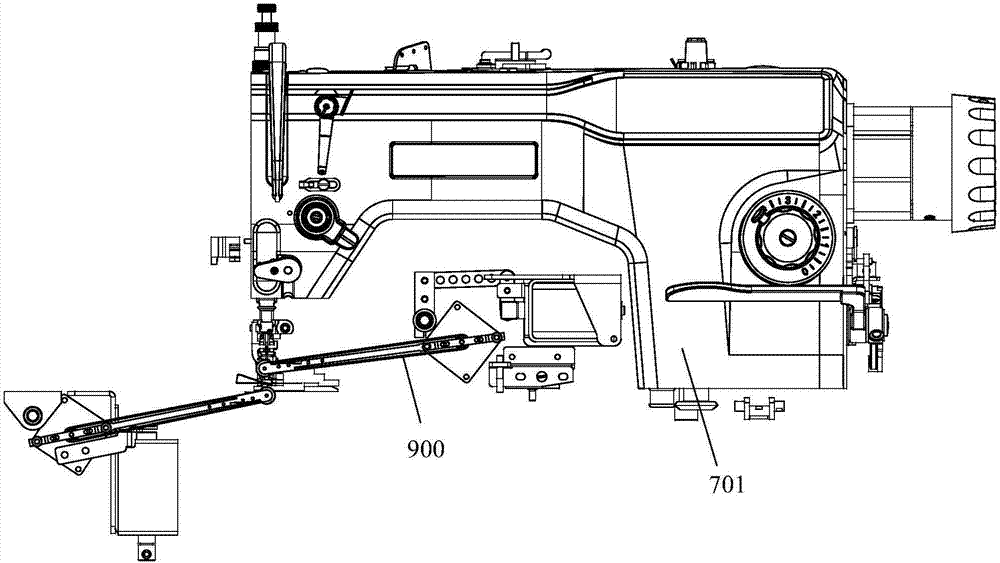

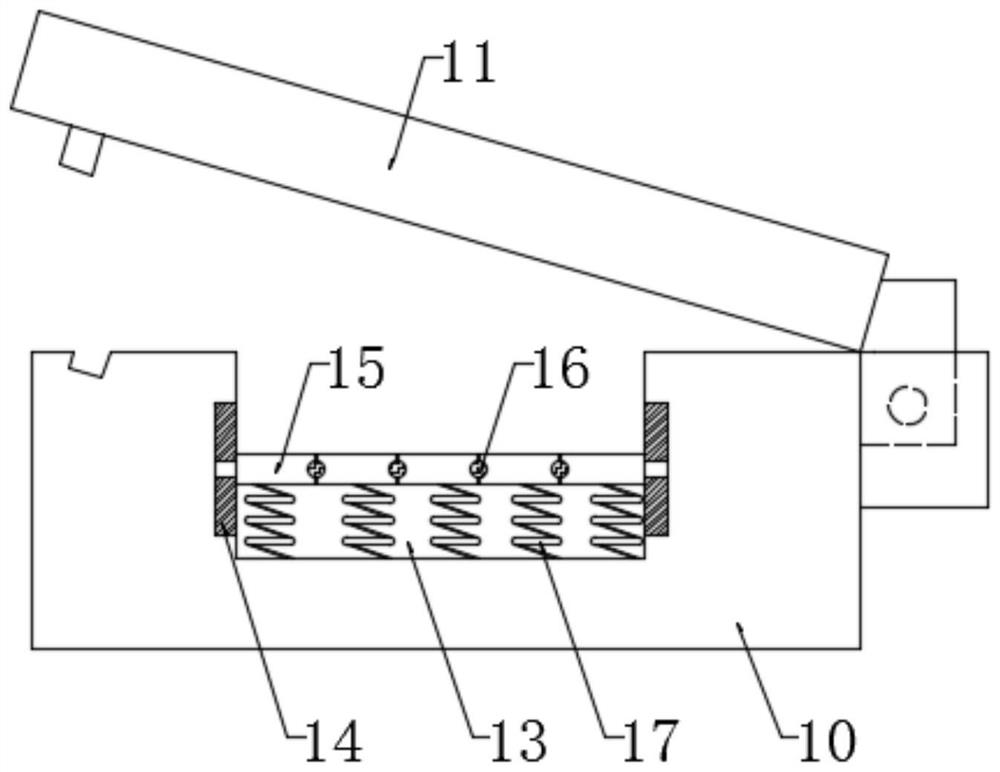

Hemming sewing machine with automatic conveying function

ActiveCN106868722AAutomatically adjust working postureEasy to transportWork-feeding meansWork-collecting devicesEngineeringSewing machine

The invention discloses a hemming sewing machine with an automatic conveying function. The hemming sewing machine comprises a rack, a worktable and a sewing machine head, wherein the workable and the sewing machine head are arranged on the rack. A conveying bottom plate is arranged on the worktable, and a synchronous belt conveying mechanism for linearly moving sewing materials along the conveying bottom plate is arranged above the conveying bottom plate. Two installing supports are fixed to the worktable, each installing support is provided with a universal bearing, each universal bearing is provided with a movable connecting shaft, and the lower ends of the movable connecting shafts are connected with the top of the synchronous belt conveying mechanism. Balance pressing blocks are fixed to the installing supports, and the bottoms of the balance pressing blocks are provided with springs for applying elastic pressure to the top of the synchronous belt conveying mechanism. By adopting the hanging structure of the universal bearings and applying the elastic pressure through the springs, the working posture of the synchronous belt conveying mechanism can be automatically adjusted, installing and adjusting are convenient, conveying of sewing materials of different thicknesses is convenient, and the sewing material hemming and sewing quality is guaranteed.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

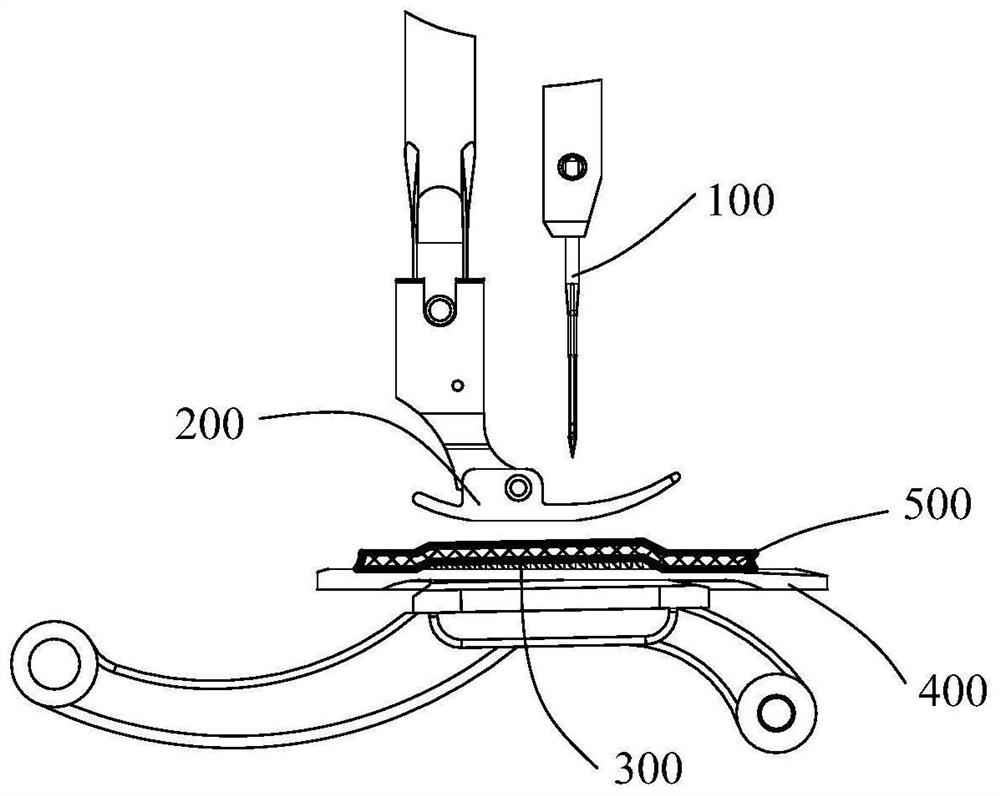

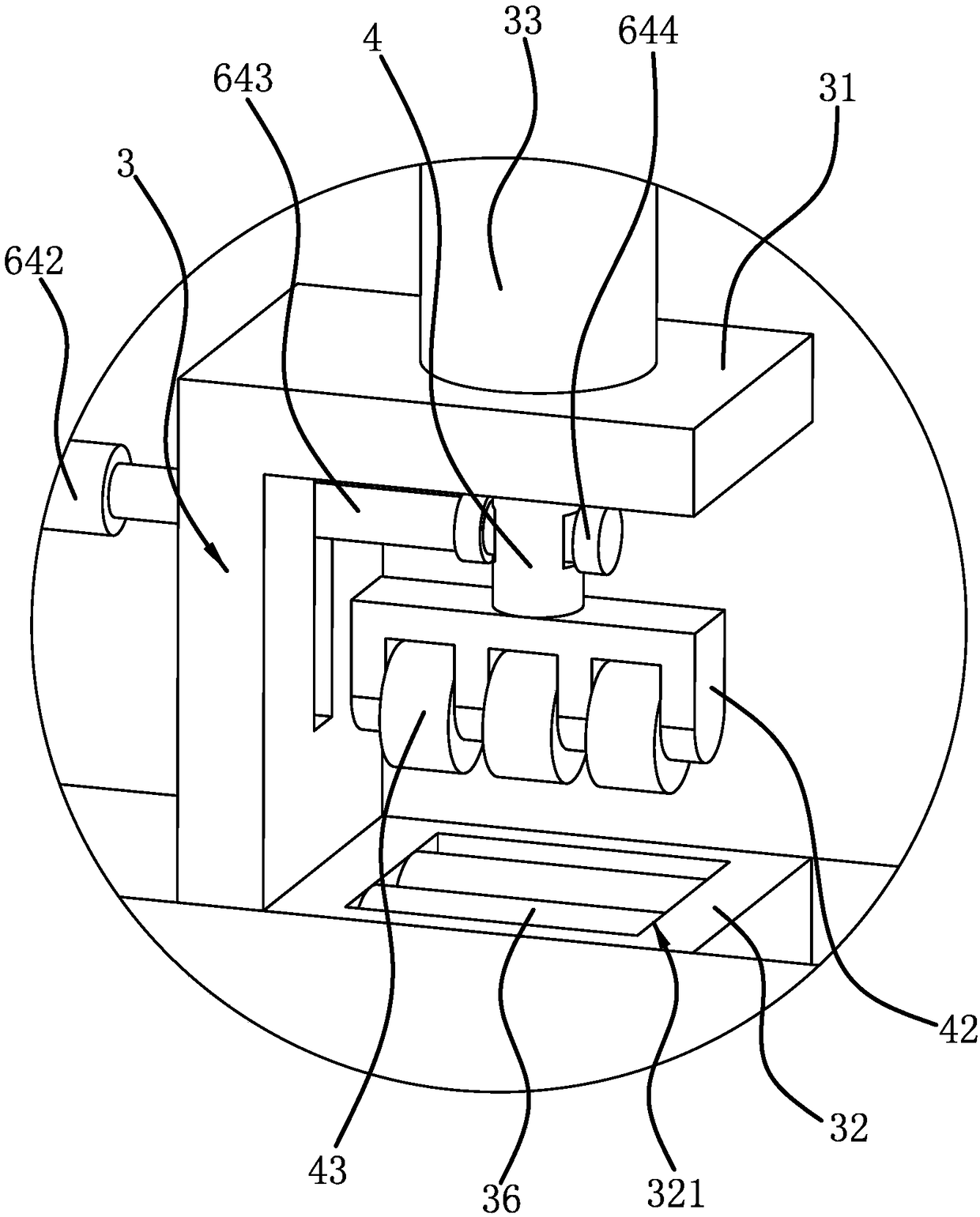

Fabric hemming and stitching device

The invention relates to a fabric hemming and stitching device which comprises a bedplate, a machine head located on the bedplate and a frame needle mounted on the machine head, wherein a first support plate and a second support plate hinged with the first support plate are arranged on the bedplate; a spring piece is arranged at the free end of the first support plate through a baffle; a first through groove is formed in the first support plate; a second through groove is formed in the second support plate; and the first through groove and the second through groove are symmetrically arranged relative to a hinged line formed by the first support plate and the second support plate. The fabric hemming and stitching device is simple in structure and convenient to use; the spring piece is pulled away through a pull ring, one end of the fabric is clamped between the spring piece and the first support plate, then the first support plate is folded up to the second support plate through a hinge, and hemming is achieved; and meanwhile, the frame needle penetrates through the first through groove and the second through groove to stitch the hemmed fabric, the stitching quality is guaranteed, and the working efficiency is high.

Owner:SUZHOU XINBOTAI TEXTILE RES

Over-step speed reducer of sewing machine and control method

ActiveCN110761006AThere is no slowdown lagAvoid disconnectionWork-feeding meansSewing-machine control devicesElectric machineryElectric control

The invention provides an over-step speed reducer of a sewing machine. The over-step speed reducer of the sewing machine comprises an electric control module of the sewing machine, a main motor for driving the sewing machine to operate, a presser foot seat and a presser foot plate, and further comprises a pressure spring and a pressure sensor fixed on the presser foot plate, wherein one end of the presser foot plate is a feeding end, the presser foot plate is hinged to the lower end of the presser foot seat and is provided with a fixed swinging fulcrum, the upper end and the lower end of thepressure spring are separately butted to the presser foot seat and the pressure sensor, and the main motor and the pressure sensor are both connected with the electric control module; and the pressuresensor, the fixed swinging fulcrum of the presser foot plate and the feeding end of the presser foot plate are sequentially arranged from front to back along the feeding direction of forward feedingof the sewing machine. In the sewing process, the electric control module can judge whether it passes through steps or not during sewing in real time through the output signal of the pressure sensor,and when it passes through the steps during sewing, the electric control module immediately controls the sewing machine to reduce the speed for sewing, so that the speed of the sewing machine is reduced in time, speed reduction delay does not exist, thread breakage, needle breakage and the like can be effectively avoided, and finally the sewing quality is guaranteed.

Owner:JACK SEWING MASCH CO LTD

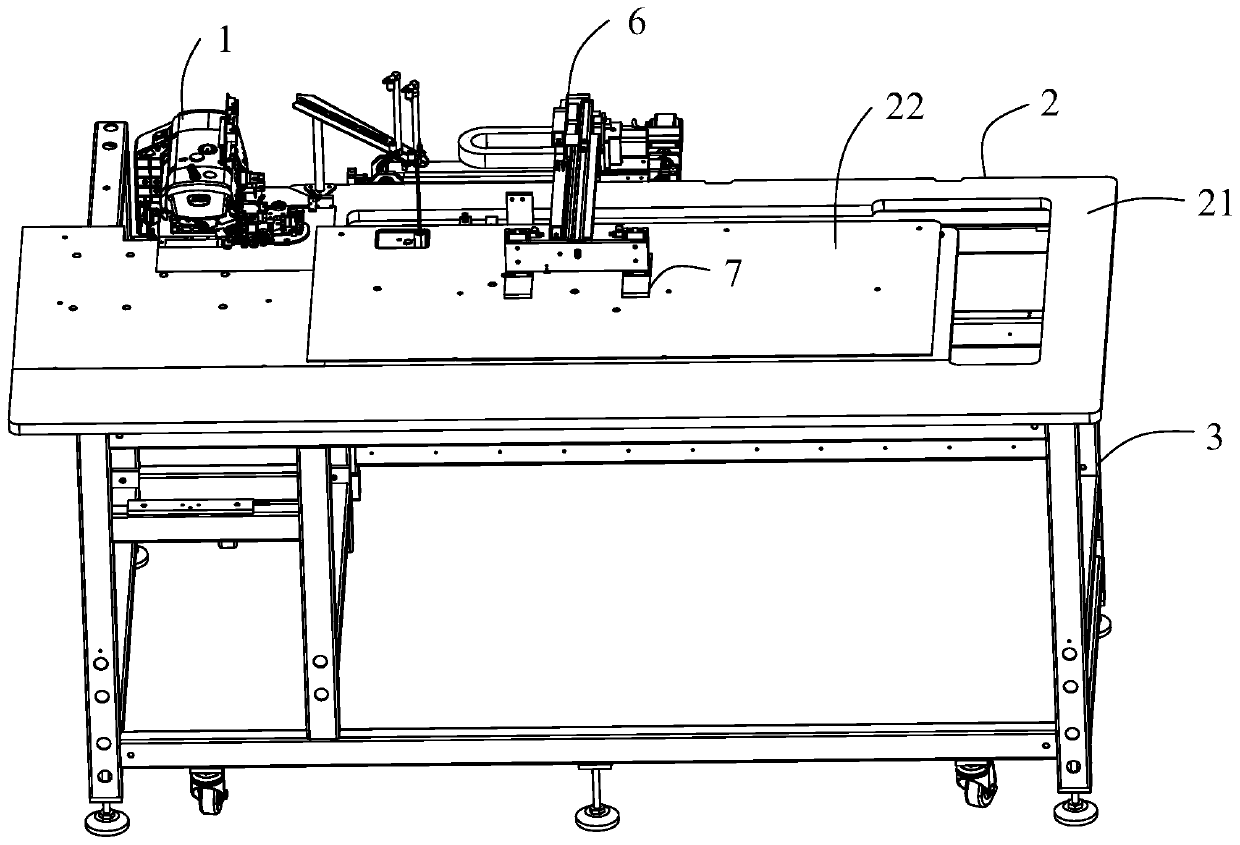

Waist portion pulling machine

ActiveCN108950903ASimple structureHigh degree of automationLubrication/cooling devicesWorkpiece carriersDrive wheelEngineering

The invention discloses a waist portion pulling machine. The waist portion pulling machine is characterized by comprising a workbench, a sewing assembly, an upper pulling wheel assembly and a lower pulling wheel assembly. The sewing assembly comprises a sewing machine head. The sewing machine head is fixedly arranged on a rack of the workbench. The upper pulling wheel assembly comprises an upper left pulling wheel assembly and an upper right pulling wheel assembly. The upper left pulling wheel assembly and the upper right pulling wheel assembly are successively and fixedly arranged on the leftportion of the back side of the sewing machine head from left to right and located behind a needle of the sewing machine head. The upper left pulling wheel assembly comprises an upper left pulling wheel, and the upper left pulling wheel is a drive wheel. The upper right pulling wheel assembly comprises an upper right pulling wheel, and the upper right pulling wheel is a drive wheel. The lower pulling wheel assembly comprises a lower front pulling wheel, and the lower front pulling wheel is a drive wheel. The lower front wheel is rotatably arranged on the lower left portion of the sewing machine head and located below the upper pulling wheel assembly. The upper left pulling wheel of the upper left pulling wheel assembly, the upper right pulling wheel of the upper right pulling wheel assembly and the lower front pulling wheel of the lower pulling wheel assembly clamp a cloth material and pull the cloth material out of the sewing machine head.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Precise positioning type sewing machine for processing high-end leather shoes

ActiveCN110318165AImprove work efficiencyPrevent movementWorkpiece holdersLeather sewingEngineeringSewing needle

The invention discloses a precise positioning type sewing machine for processing high-end leather shoes. The precise positioning type sewing machine comprises a sewing machine base and a groove, wherein the groove is formed in the upper surface of the sewing machine base. According to the precise positioning type sewing machine, by arranging a screw motor, a threaded rod and a guide rod which cooperate with one another to drive a moving plate to move in the horizontal direction, uppers are sewed in the horizontal direction; by arranging an electric push rod, a sliding block is pushed to move in the vertical direction to sew shoe sides in the vertical direction, wherein no manual fixing or shoe moving is needed in the whole process, and the working efficiency is high; by arranging a springat the lower end of a shoe groove, the spring squeezes a placement plate, so that the leather shoes are fixed under squeezing between the placement plate and an upper top plate, thereby preventing theshoes from moving in the sewing process, and a cross needle groove guides a sewing needle to ensure the sewing quality; by moving a shift lever, the distance dimension of the cross needle groove canbe adjusted, so that the sewing stitch length of each leather shoe is the same, and the defective rate of the shoes is reduced.

Owner:瑞安市佬赛鞋业有限公司

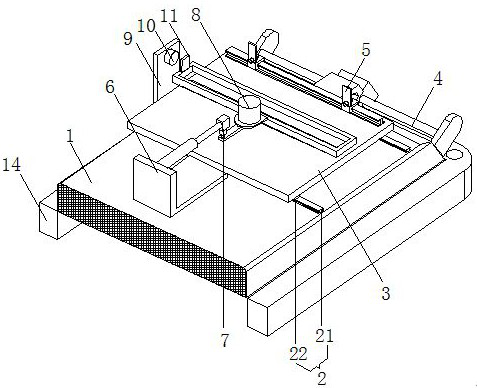

Elastic cord positioning and sewing device and sewing method for use in garment processing

ActiveCN110424101APrecise positioningGuaranteed sewing qualityWork-feeding meansSewing-machine control devicesEngineeringWorkload

The invention discloses an elastic cord positioning and sewing device and sewing method for use in garment processing. An electric sewing machine comprises a body and a base; a guide support mechanismis arranged on the right side of the upper end of the base of the electric sewing machine; a working plate is arranged at the upper end of the guide support mechanism; a sewing guide mechanism is arranged on the right side of the base of the electric sewing machine and is fixedly connected with the right side of the working plate; a sewing and positioning mechanism is arranged on the right side of the upper end of the working plate; a conveying mechanism is arranged on the left side of the working plate; a compression mechanism is arranged at the right end of the conveying mechanism and fitsa sewing needle structure of the body of the electric sewing machine; a suction fixing mechanism is arranged at the bottom of the compression mechanism; the edge of a sewing position of a garment andan elastic cord can be compressed, the garment and the elastic cord can be sewn along a sewing direction, the elastic cord can be gripped accurately and released quickly; elastic cord positioning is accurate, reasonable and efficient; sewing quality is guaranteed, workload is reduced for personnel, and positioning and sewing efficiency is improved.

Owner:珠海合和服装有限公司

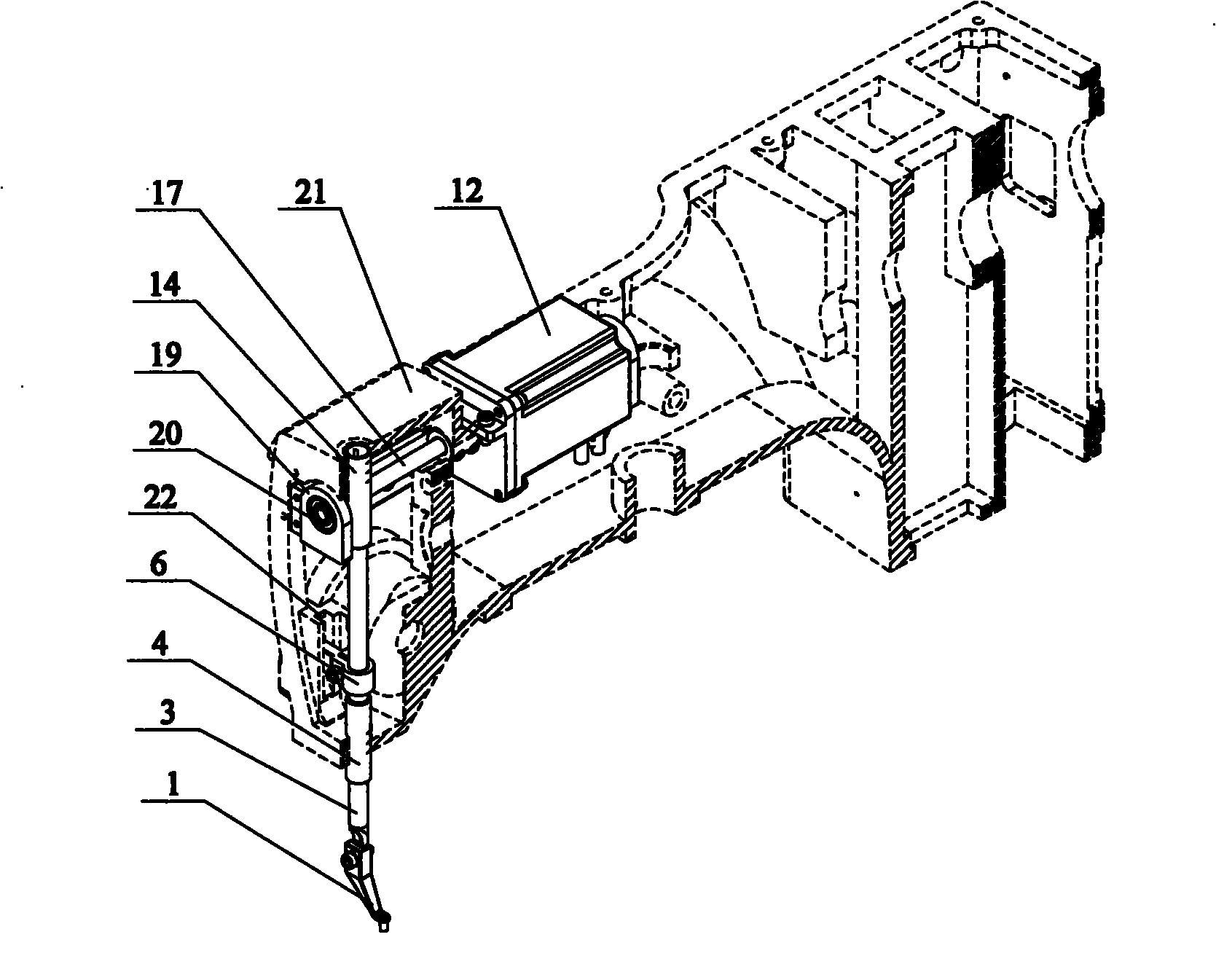

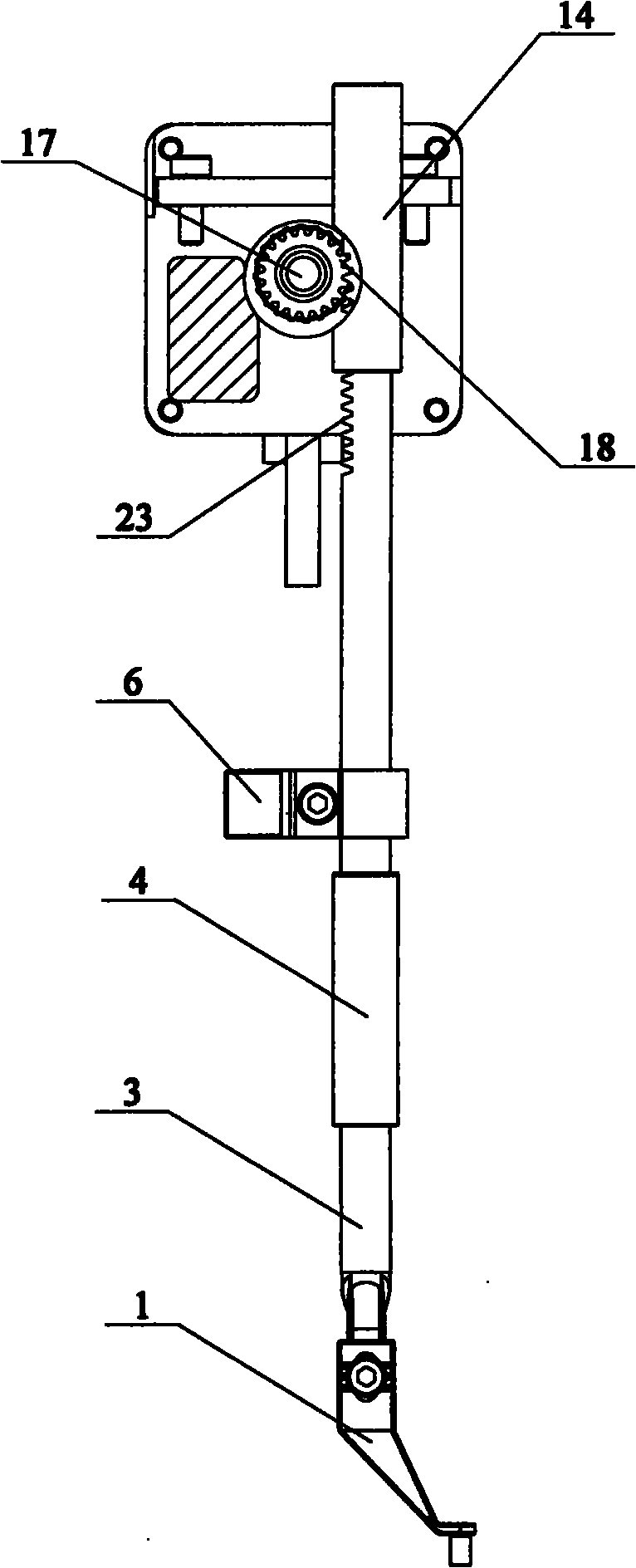

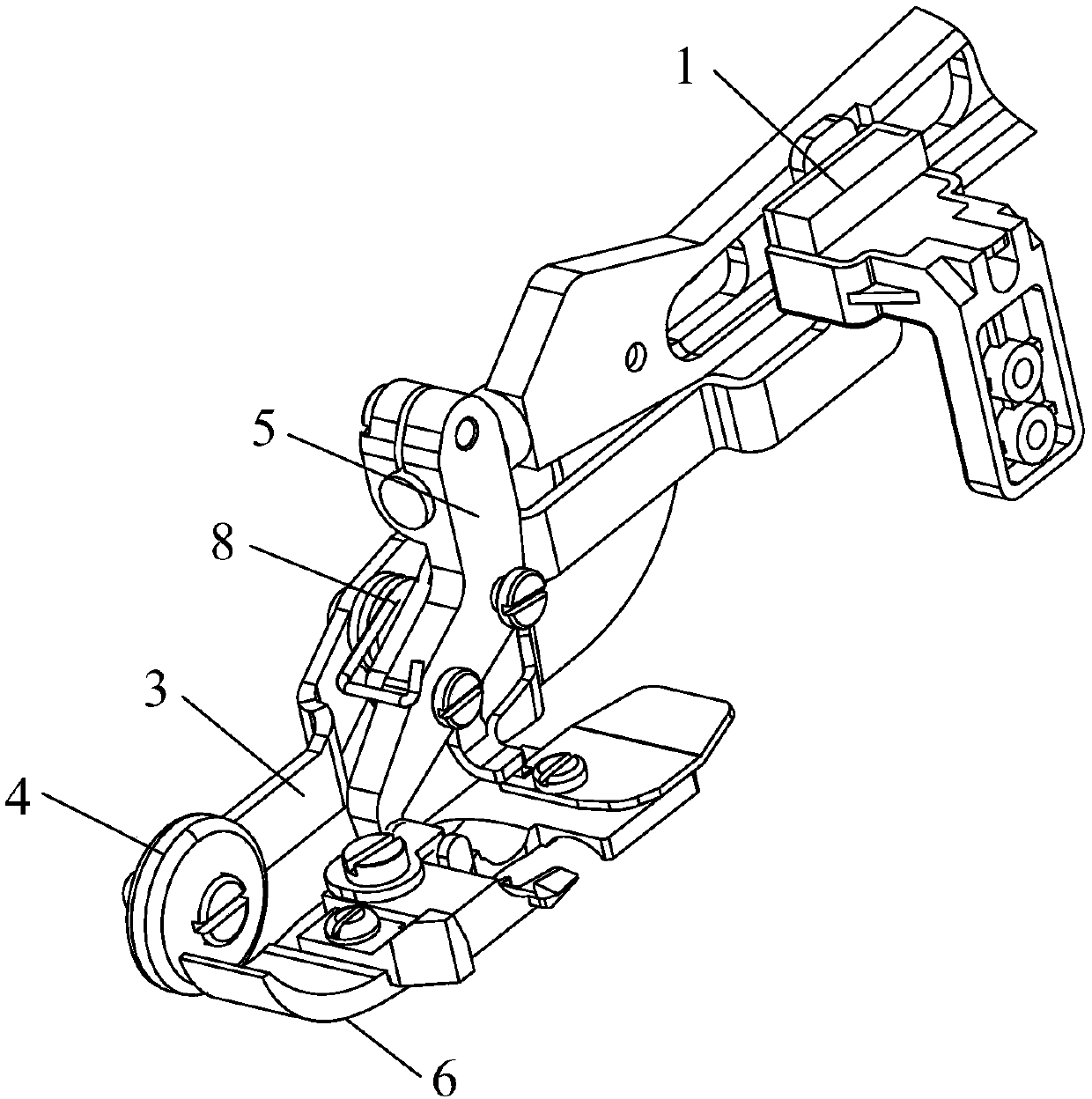

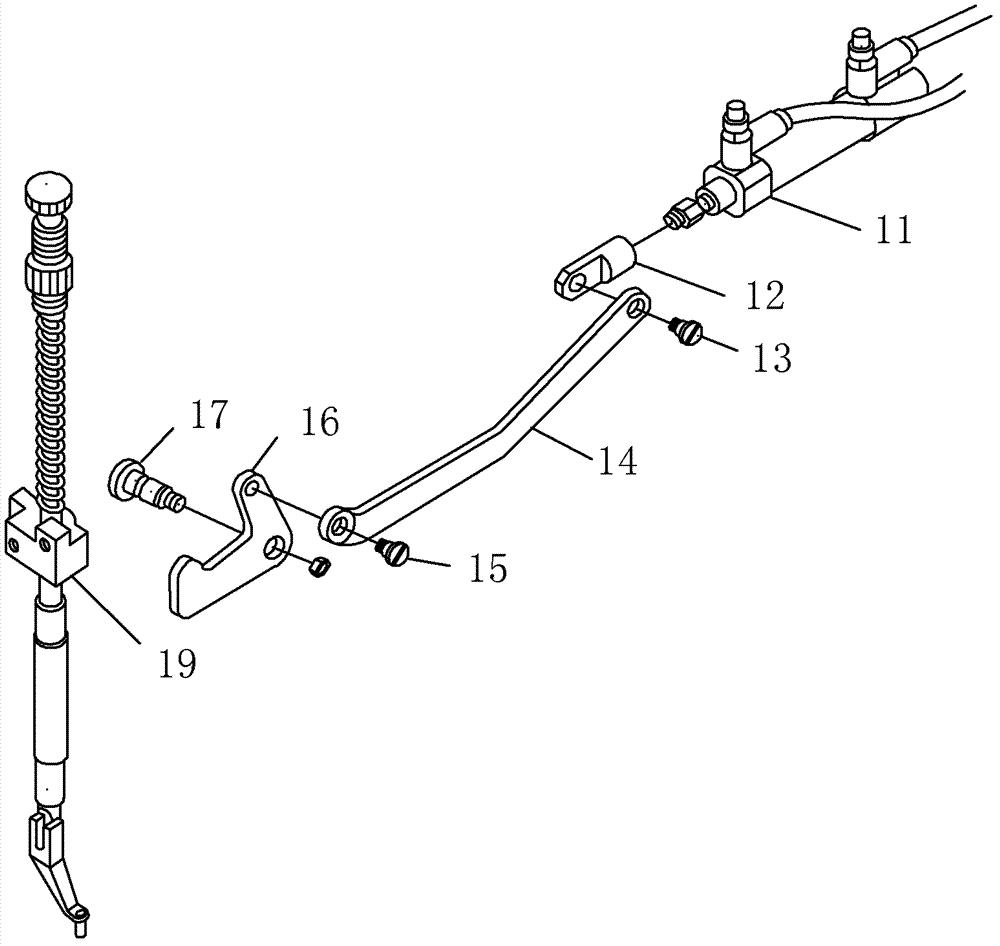

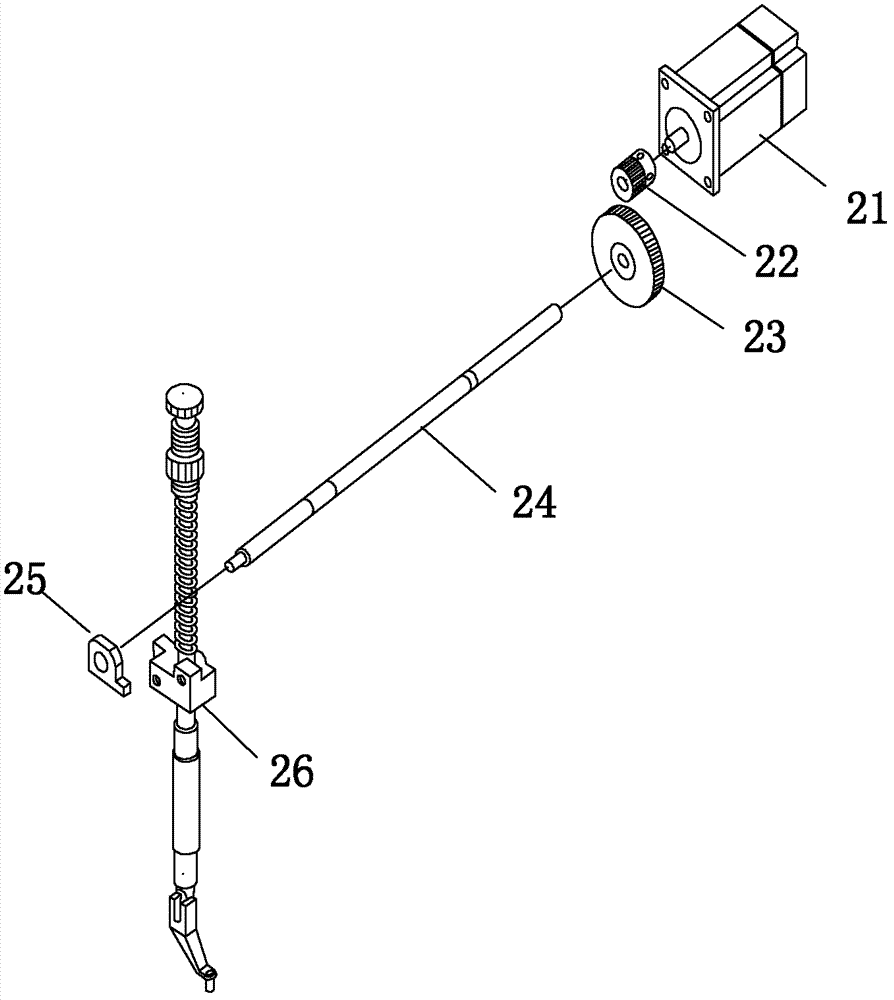

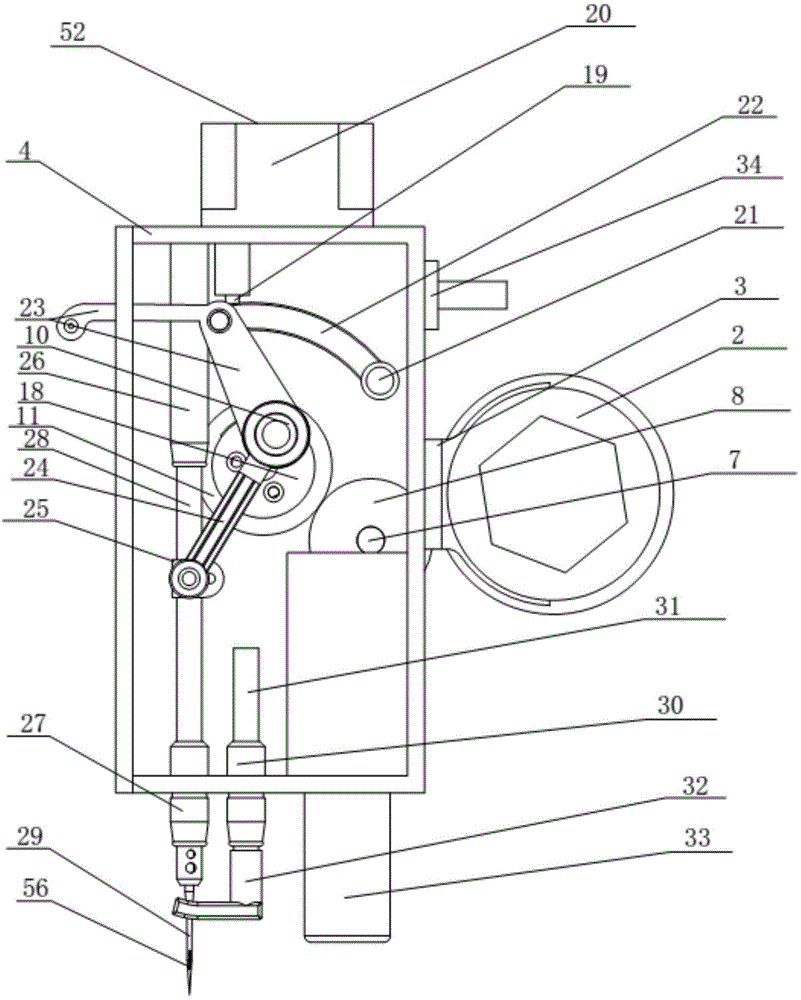

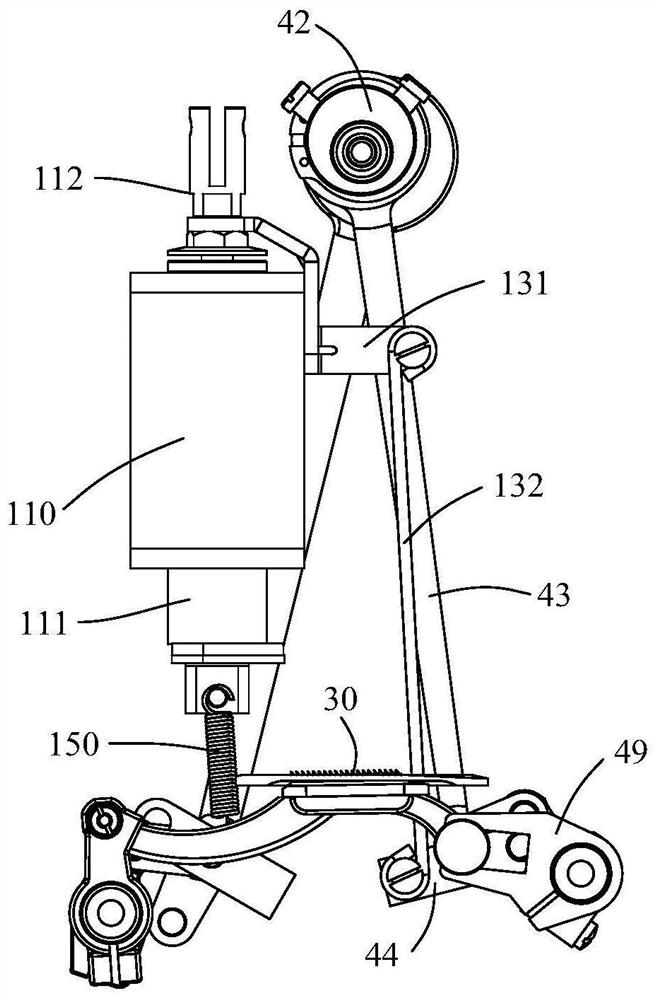

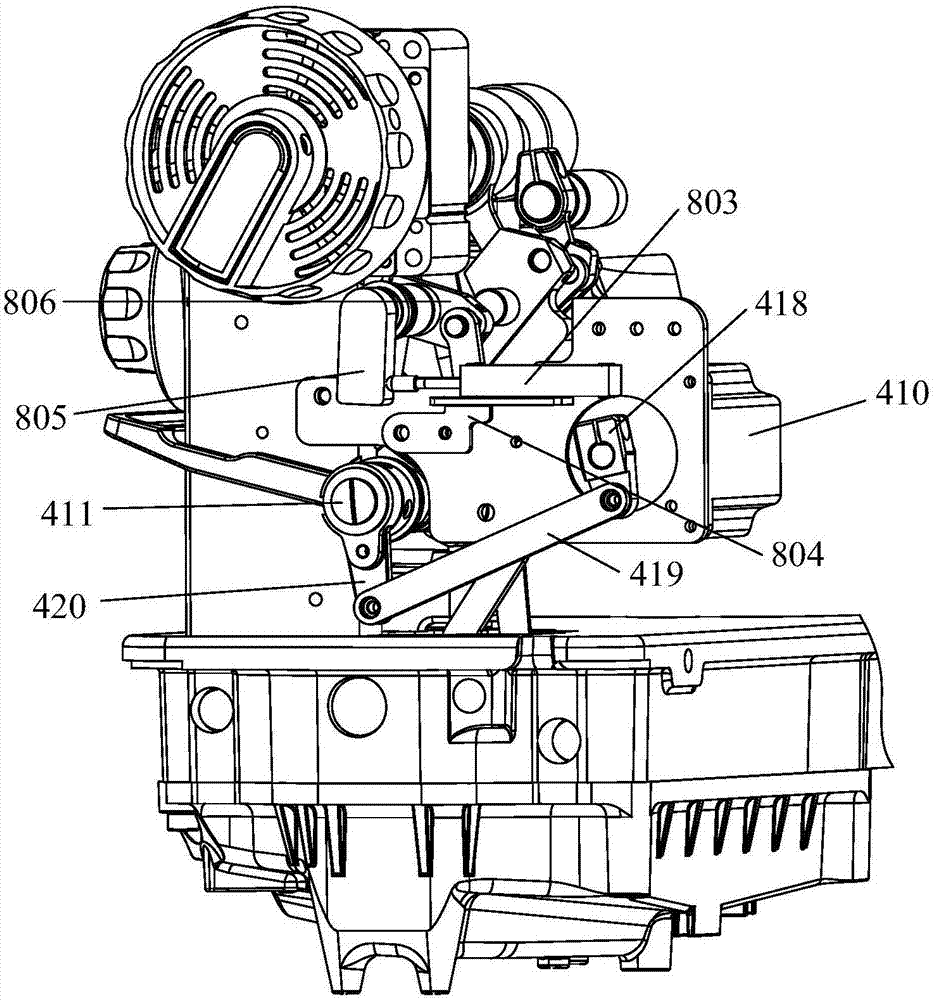

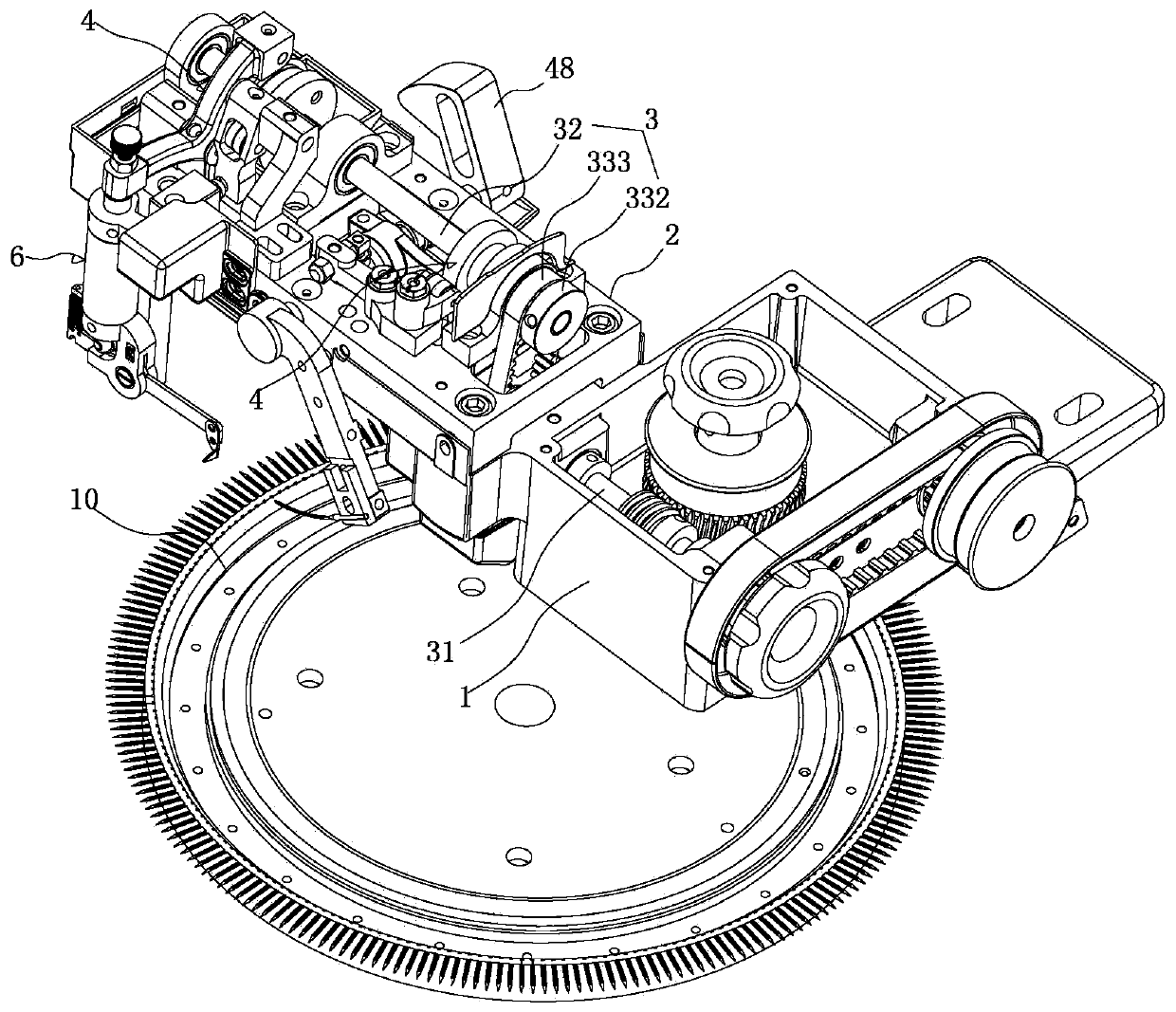

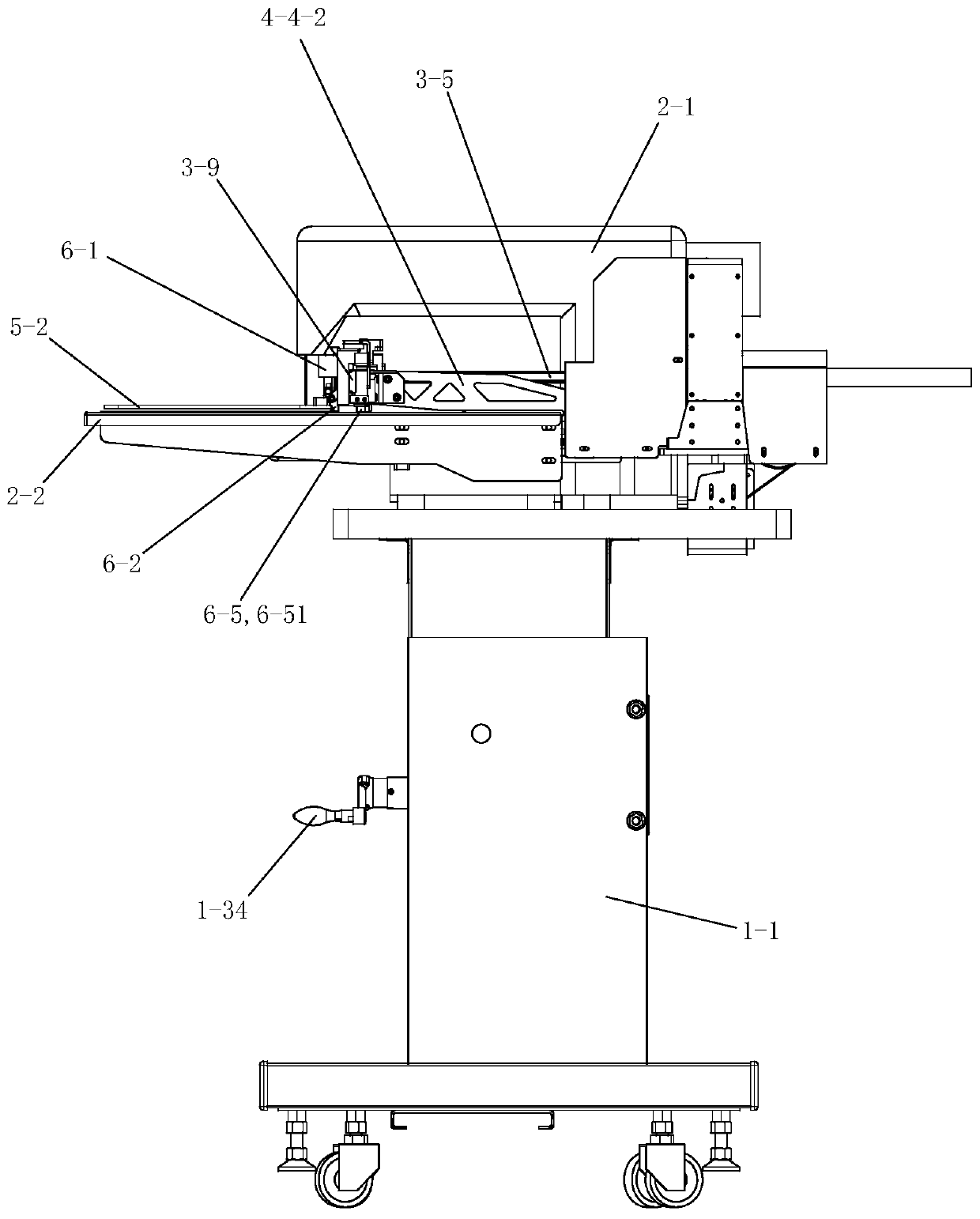

Intermediate presser foot lifting structure of pattern-sewing machine

InactiveCN102953241AControl altitude changeGuaranteed sewing qualitySewing-machine control devicesPressersEngineeringSewing machine

The invention discloses an intermediate presser foot lifting structure of a pattern-sewing machine. The intermediate presser foot lifting structure comprises a controllable motor, a driving gear, a driven gear, an intermediate presser foot lifting shaft and a lifting connecting rod, the controllable motor is connected with the driven gear which is in threaded connection with the driven gear, one end of the intermediate presser foot lifting shaft is connected with the driven gear, and the other end of the intermediate presser foot lifting shaft is connected with the lifting connecting rod. By the intermediate presser foot lifting structure of the pattern-sewing machine, height change of an intermediate presser foot can be controlled, and the height of the intermediate presser foot can be changed along with the thickness of materials when the materials different in thickness are sewed.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

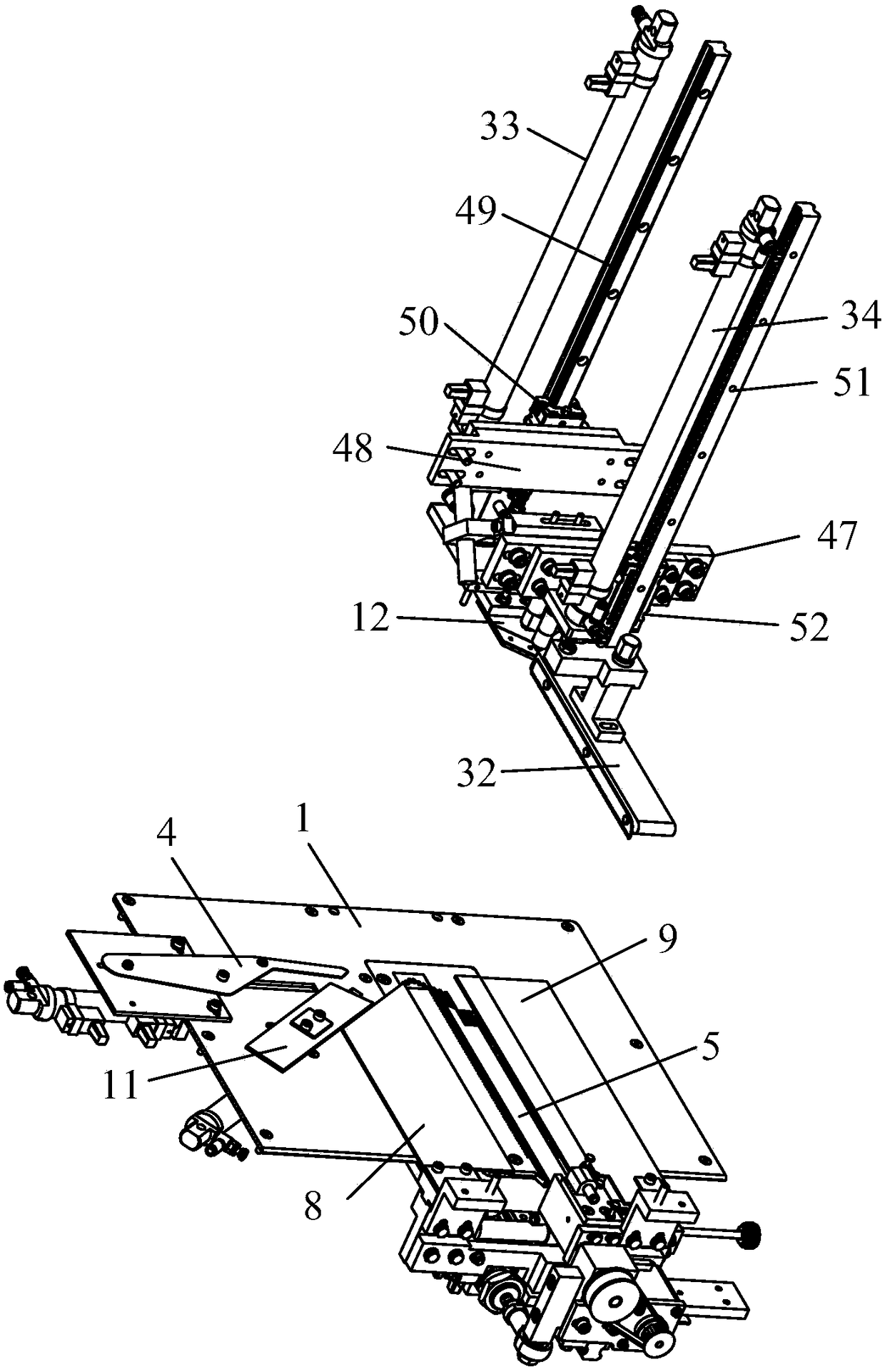

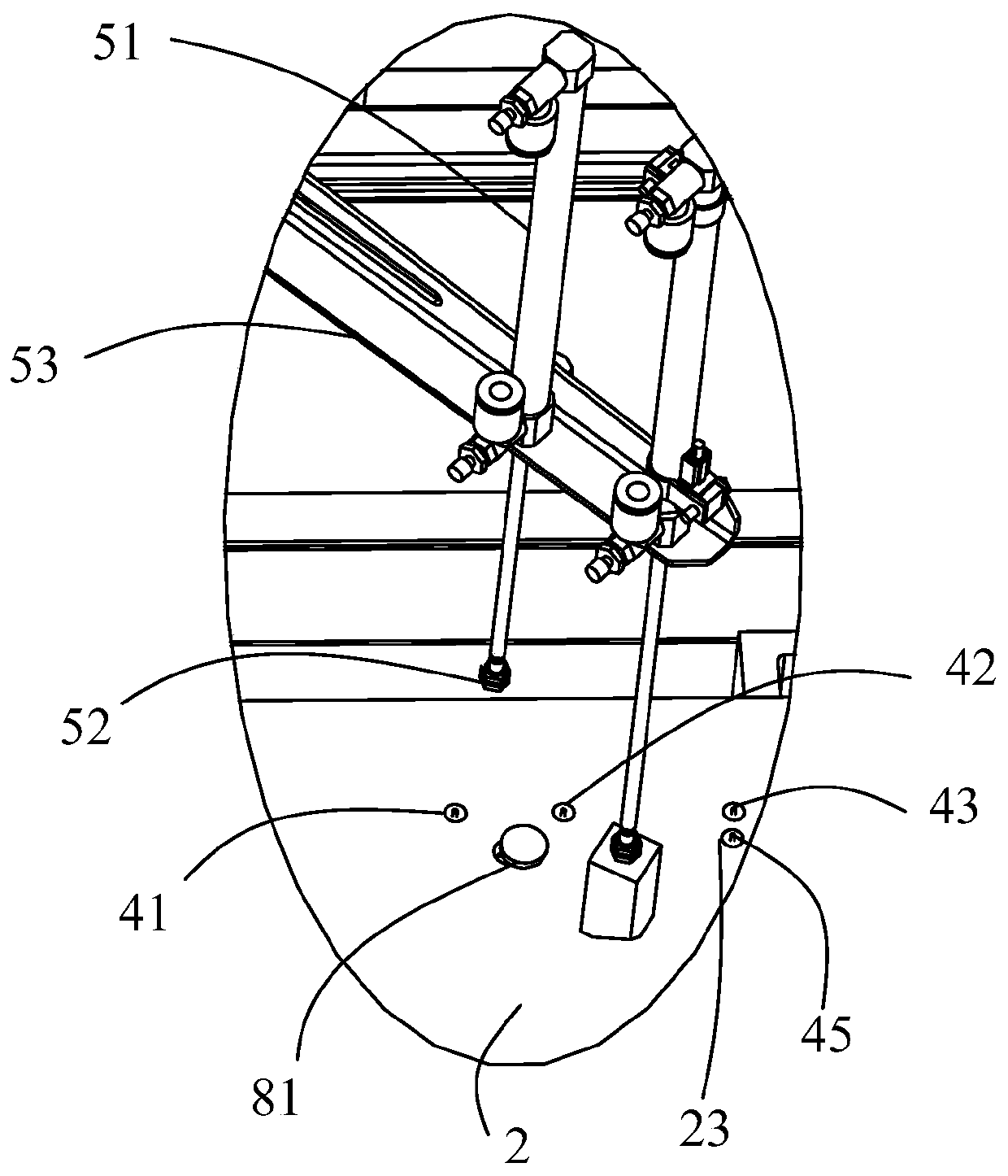

Automatic folding mechanism and method and sleeve placket sewing device

ActiveCN108505226AImprove folding efficiencyImprove fold qualityWork-feeding meansEngineeringMechanical engineering

The invention provides an automatic folding mechanism and method and a sleeve placket sewing device. The automatic folding mechanism comprises a fixing base plate, a discharging plate, a baffle assembly, a discharging cavity formed by the discharging plate and the baffle assembly, a turnover clamping assembly located in the discharging cavity and a fold material shifting piece. One end of the discharging cavity is provided with a sleeve placket end forming part, a plurality of first suction holes distributed in the peripheral direction of the discharging cavity at intervals are formed in the discharging plate, the clamping assembly comprises a movable clamping plate and a fixed clamping plate which are stacked, and a clamping cavity formed in the movable clamping plate and the fixed clamping plate, the movable clamping plate can move close to or away from the fixed clamping plate, the fold material shifting piece is located at the upper side of the baffle assembly and can move close toor away from the sleeve placket end forming part. The small cutting pieces and large cutting pieces are automatically folded into sleeve plackets, operators just need to place the small cutting pieces and the large cutting pieces, time and labor are saved during operation, and the cutting piece folding efficiency and quality are greatly improved.

Owner:JACK SEWING MASCH CO LTD

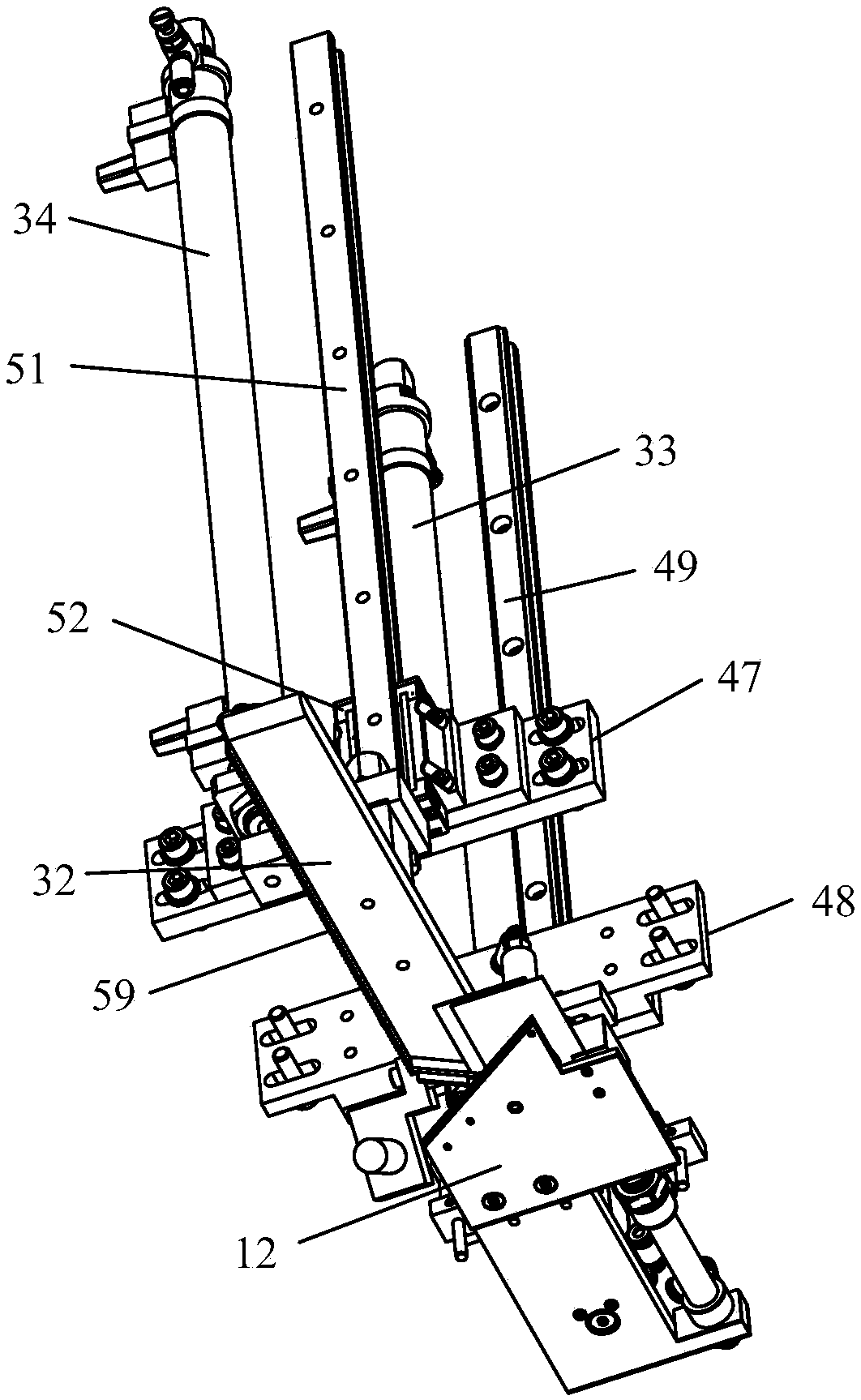

Bobbin thread remaining length calculation method and stopping control method for sewing machine

InactiveCN110359189ACancellation of specificityReduce processing difficultyBobbin-winding devicesBobbinControl theory

The invention provides a bobbin thread remaining length calculation method for a sewing machine. The method includes steps: acquiring bobbin thread winding length A in winding of a thread on a bobbin;enabling a controller of the sewing machine to acquire bobbin thread initial length L of the bobbin thread on the bobbin, wherein the bobbin thread initial length L refers to the bobbin thread winding length A or bobbin thread remaining length after finishing of last sewing; starting stitching; after sewing is finished, enabling the controller of the sewing machine to acquire a stitch number M and a bobbin thread utilization length B in each stitch pitch, and enabling the controller of the sewing machine to automatically calculate the bobbin thread remaining length Y, wherein Y=f(L, M, B), and f(L, M, B) is pre-stored in the controller of the sewing machine. By adoption of the method, the remaining length Y of the bobbin thread on the bobbin can be calculated effectively, and accordinglythe bobbin thread remaining length can be effectively monitored; especially, bobbin structural modification is avoided, the method can be implemented by adoption of a normal bobbin, exclusiveness of the bobbin is avoided, universality of the bobbin is realized, and processing difficulty of the bobbin is lowered.

Owner:JACK SEWING MASCH CO LTD

Multi-needle fine-adjustment computerized sewing machine

InactiveCN104674461ARelieve stressSave rental areaSewing-machine control devicesNeedle barsNeedle roller bearingDrive shaft

The invention provides a multi-needle fine-adjustment computerized sewing machine. A main drive shaft is connected with a main drive gear, a carrier shaft, a carrier gear, a gear pin, a needle bearing and a synchronous gear are arranged in a needle box, the synchronous gear, a left eccentric wheel and an eccentric wheel rack are respectively mounted on the gear pin, a synchronous moving pin is mounted in an air cylinder at the bottom of the needle box, retractable rods are respectively connected with movable blocks, roller pins and slide ways, the bottoms of both ends of the slide ways are provided with racks which are engaged with shuttle groove gears, the shuttle groove gears are mounted at both ends of shuttle groove drive shafts, a lower shifting fork is fixed at the bottom of a rotating shuttle slide way, the rotating shuttle slide way is mounted upon a rotating shuttle slide way-fixing rod, the rotating shuttle slide way-fixing rod is mounted under a frame, and an eccentric wheel gear-restoring spring is mounted on an internal eccentric wheel gear. The multi-needle fine-adjustment computerized sewing machine can set different programs according to requirements for different styles of quilting stitches producing cotton-padded clothes in order to meet requirements for different specifications of quilting stitches, and can carry out the process of making quilting stitches of cotton-padded clothes done by eight to ten sewers.

Owner:廖红艳

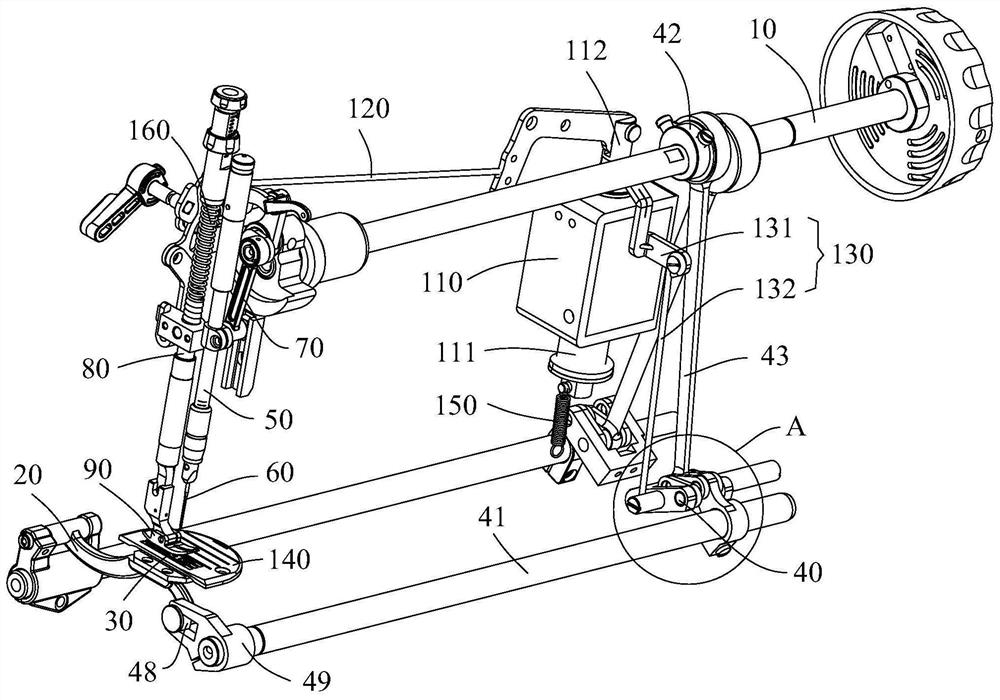

Sewing machine

The invention provides a sewing machine which comprises a main shaft, a feed dog fixed to a feed frame, a feed lifting transmission assembly connected between the main shaft and the feed frame, a pressing rod, a presser foot installed at the lower end of the pressing rod, a presser foot lifting driving source, a presser foot lifting transmission assembly connected between the presser foot lifting driving source and the pressing rod, and a feed lowering transmission assembly, wherein the output end of the presser foot lifting driving source is connected with a feed lifting transmission part in the feed lifting transmission assembly through the feed lowering transmission assembly. When the sewing machine stops taking and placing sewing materials, a machine needle is located above a needle plate, the presser foot lifting driving source acts, the presser foot lifting driving source enables the presser foot to be lifted upwards through the presser foot lifting transmission assembly, and the presser foot lifting driving source further enables the feed frame and the feed dog to move downwards to the position below the upper surface of the needle plate through the feed lowering transmission assembly. Therefore, the feed dog cannot influence the sewing materials placed on the needle plate, the sewing materials can enter and exit more conveniently, and the sewing materials can be prevented from being scratched, so that the sewing quality is guaranteed.

Owner:JACK SEWING MASCH CO LTD

Sewing machine

The invention provides a sewing machine, belongs to the technical field of sewing devices, and solves the problem that an existing sewing machine easily affects sewing quality when adjusting a fabric.The sewing machine comprises a needle plate, an adjusting plate is slidably connected with the lower portion of the needle plate, two material clamping seats are connected at two ends of the adjusting plate, two yielding notches are formed in the needle plate, the two material clamping seats penetrate upwards the two yielding notches, material clamping rods are slidably connected on the materialclamping seats, a plurality of material clamping wheels are rotatably connected at the lower ends of the material clamping rods, material clamping springs are arranged on the material clamping seats,the material clamping wheels fall by the material clamping springs, fabrics are closely clamped on the material clamping seats by the material clamping springs, an adjusting motor is arranged below the needle plate and can drive the adjusting plate to reciprocate when the fabrics are closely clamped by the material clamping wheels, and a releasing mechanism is arranged on the adjusting plate and can drive the material clamping wheels to rise and release the fabrics when the fabrics are adjusted in place. According to the sewing machine, a sewing path of a large fabric can be adjusted, and thesewing quality is improved.

Owner:衡阳诗妮芳服饰有限责任公司

Sewing machine

ActiveCN107956047AAvoid feed delaysEliminate misalignmentWork-feeding meansReciprocating motionEngineering

The invention provides a sewing machine, comprising a lower feeding mechanism. The lower feeding mechanism has a feed dog which does reciprocating motion front and back and up and down. An upper end of the feed dog has a lower feeding portion. The lower feeding portion is used to contact with a lower layer cloth, and drive the lower layer cloth to move forward. The sewing machine also comprises anupper feed mechanism. The upper feeding mechanism has cloth feeding presser feet which does reciprocating motion front and back and up and down. The lower end of the cloth feeding presser foot has anupper feeding portion. The upper feeding portion is used to contact with an upper layer cloth, and drive the upper layer cloth to move forward. In the sewing machine, the upper feeding mechanism feeds the upper layer cloth forward, and feeding delay of the upper layer cloth is effectively prevented, so that staggered layer phenomenon occurred between the two layers of cloths is eliminated, and sewing quality is guaranteed.

Owner:JACK SEWING MASCH CO LTD

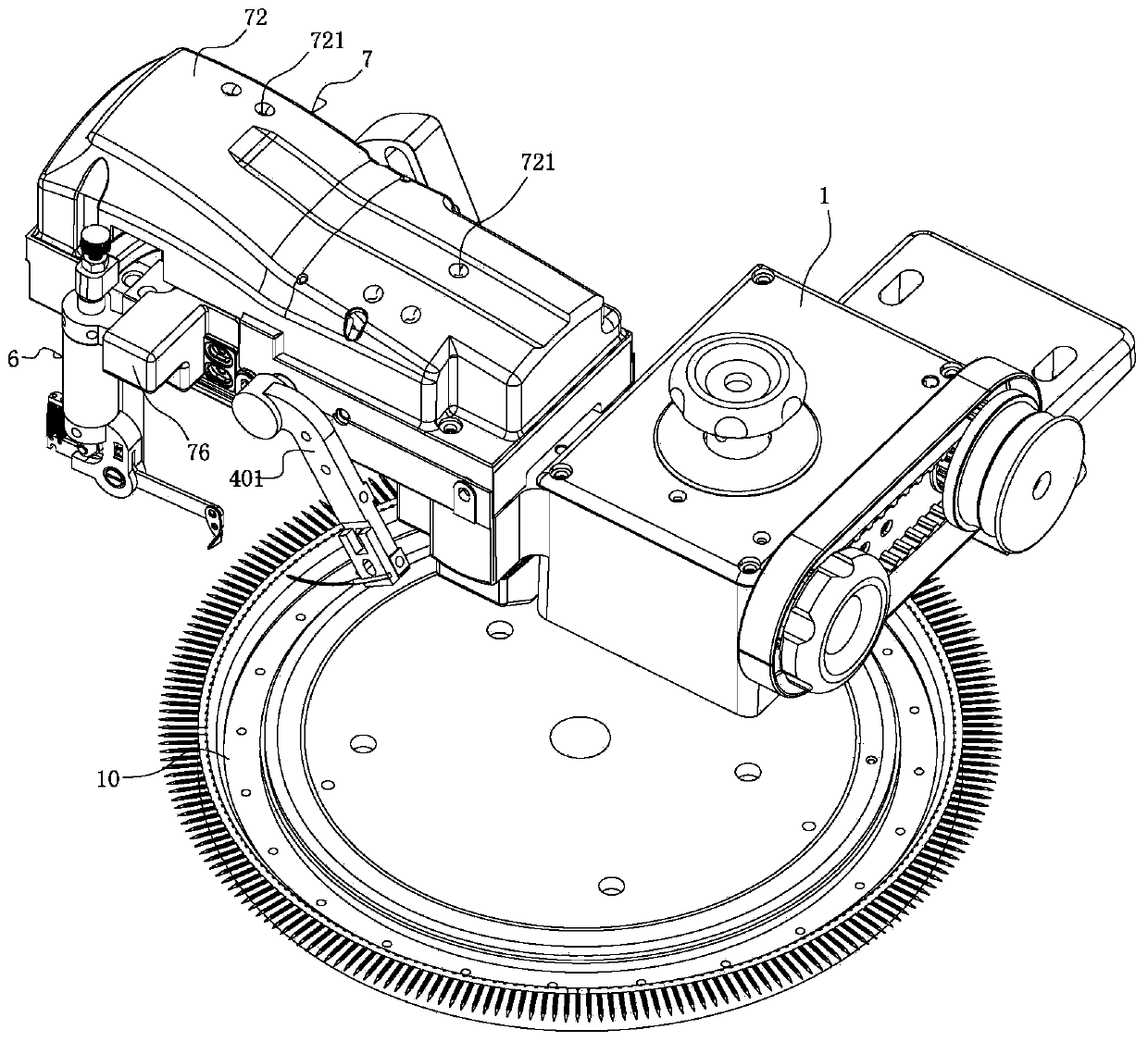

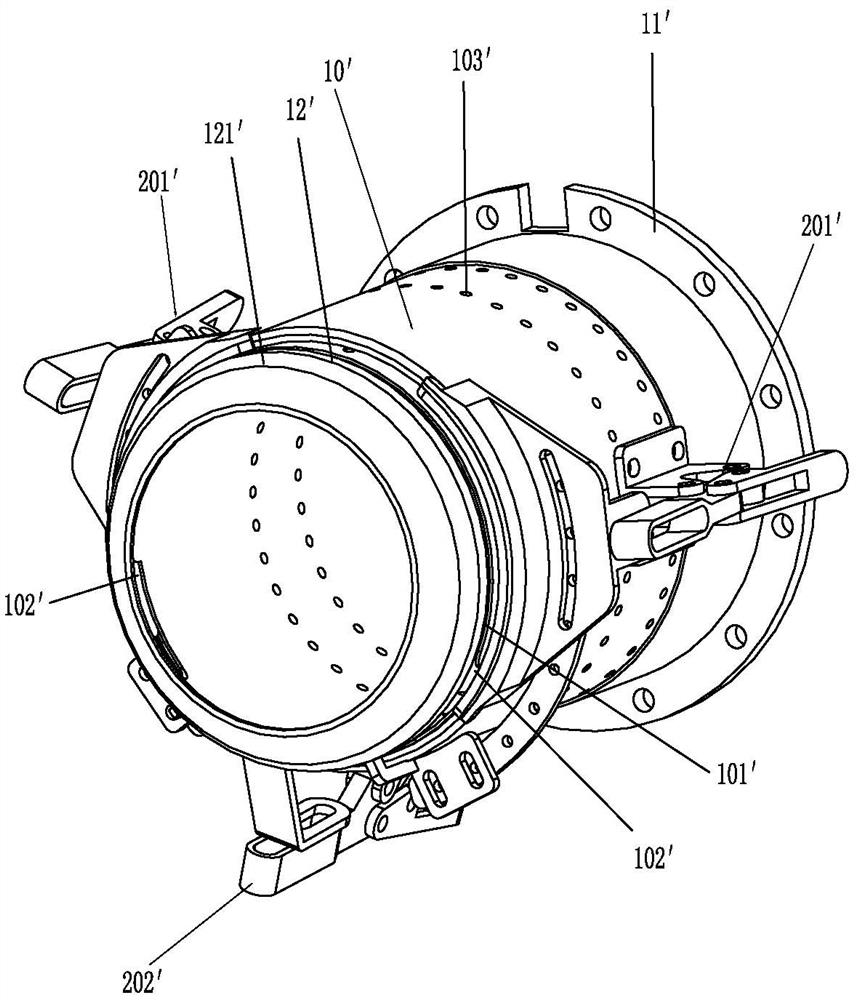

High-speed synchronous-belt dial linking machine

ActiveCN110644146AImprove installation strengthGuaranteed sewing qualityLubrication/cooling devicesSewing-machine control devicesControl engineeringMachine

The invention discloses a high-speed synchronous-belt dial linking machine, comprising a bed, a support mounted on the bed, a dial mounted at the lower end of the support, a synchronous belt drive structure mounted on the bed and the support, a needle swinging drive structure mounted on the support, a cantilever and a needle both mounted on the needle swinging drive structure, a thread take-up drive mechanism mounted on the support, a thread take-up device connected with the thread take-up drive mechanism, and an oil-storage lubricating structure mounted on the periphery of the support. The synchronous-belt drive structure comprises a main shaft mounted on the bed, an auxiliary shaft mounted on the support, and a synchronous belt assembly mounted between the main shaft and the auxiliary shaft; the synchronous belt assembly comprises a first synchronous wheel mounted at the end of the main shaft, a second synchronous wheel mounted at the end of the auxiliary shaft, and a synchronous belt mounted between the first synchronous wheel and the second synchronous wheel; the support is mounted at the edge of the upper end face of the bed, and a longitudinal space is formed between the support and the bed; a reinforced bearing pedestal for supporting the end of the main shaft is arranged on the lateral side of the bed.

Owner:东莞市缝神机械设备有限公司

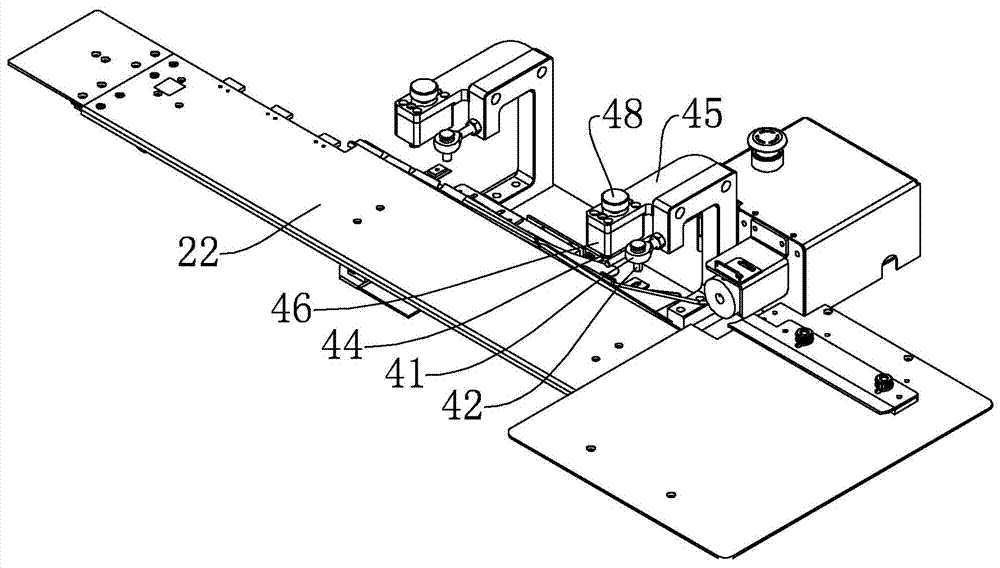

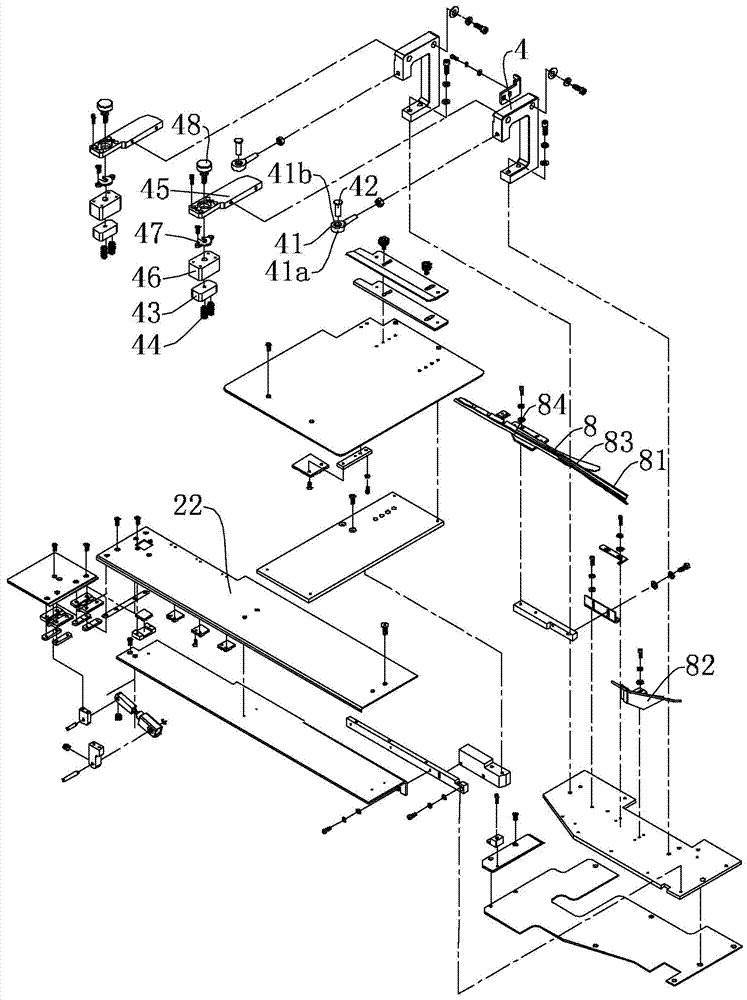

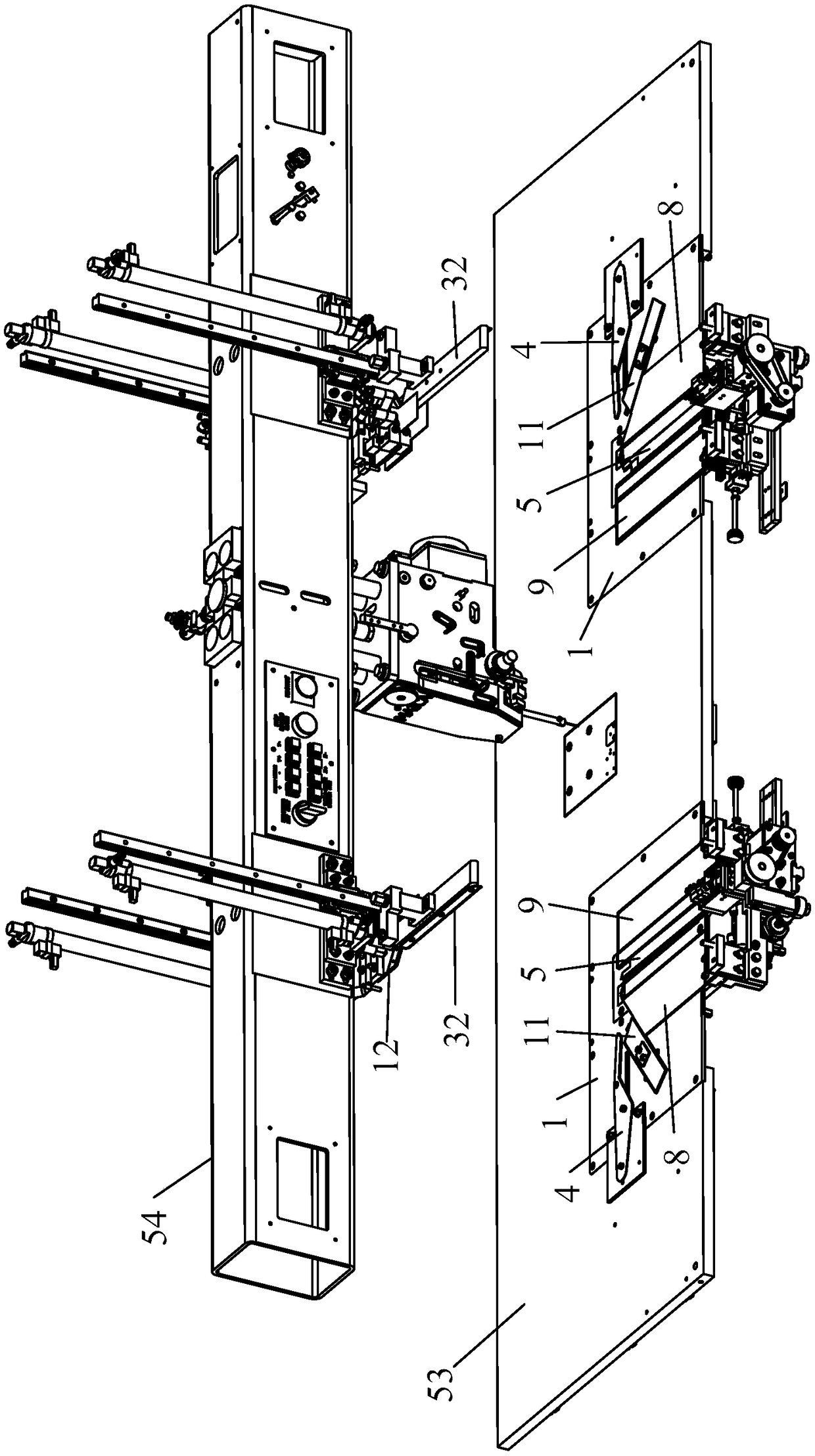

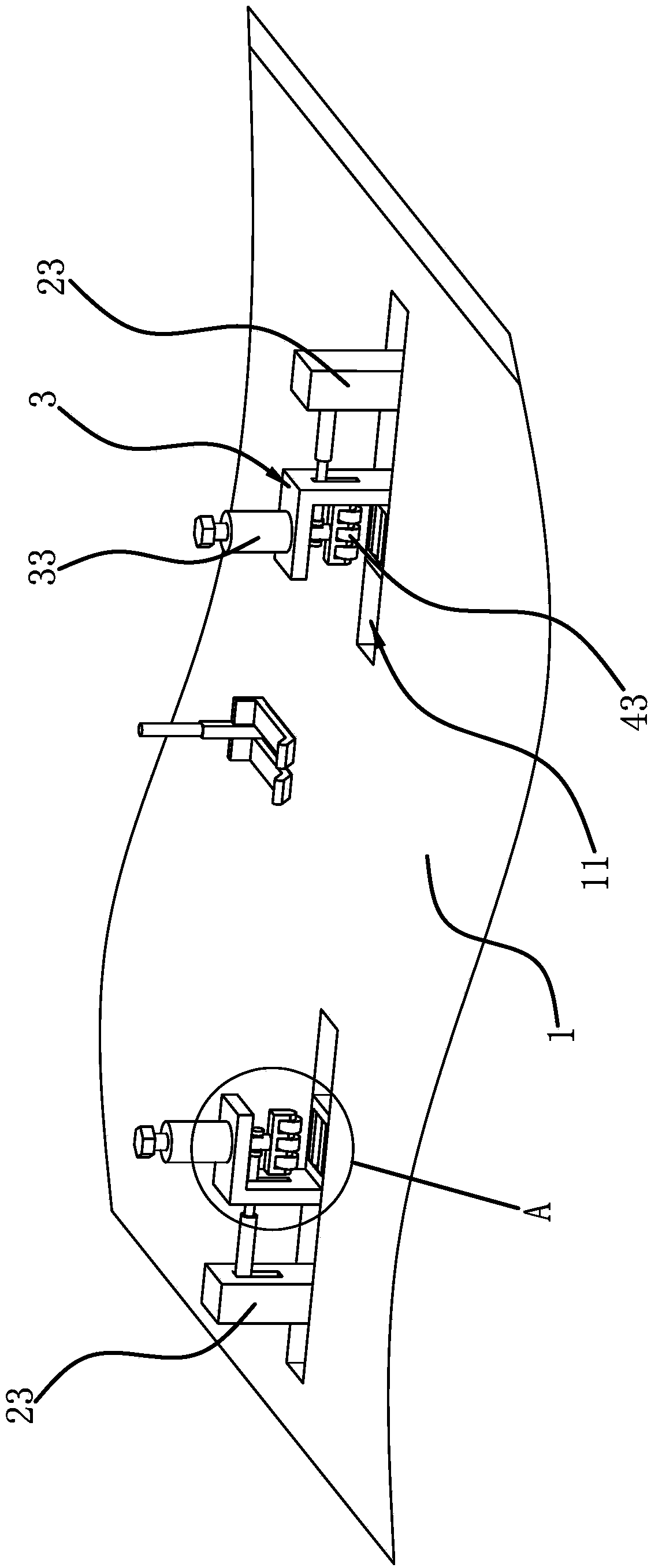

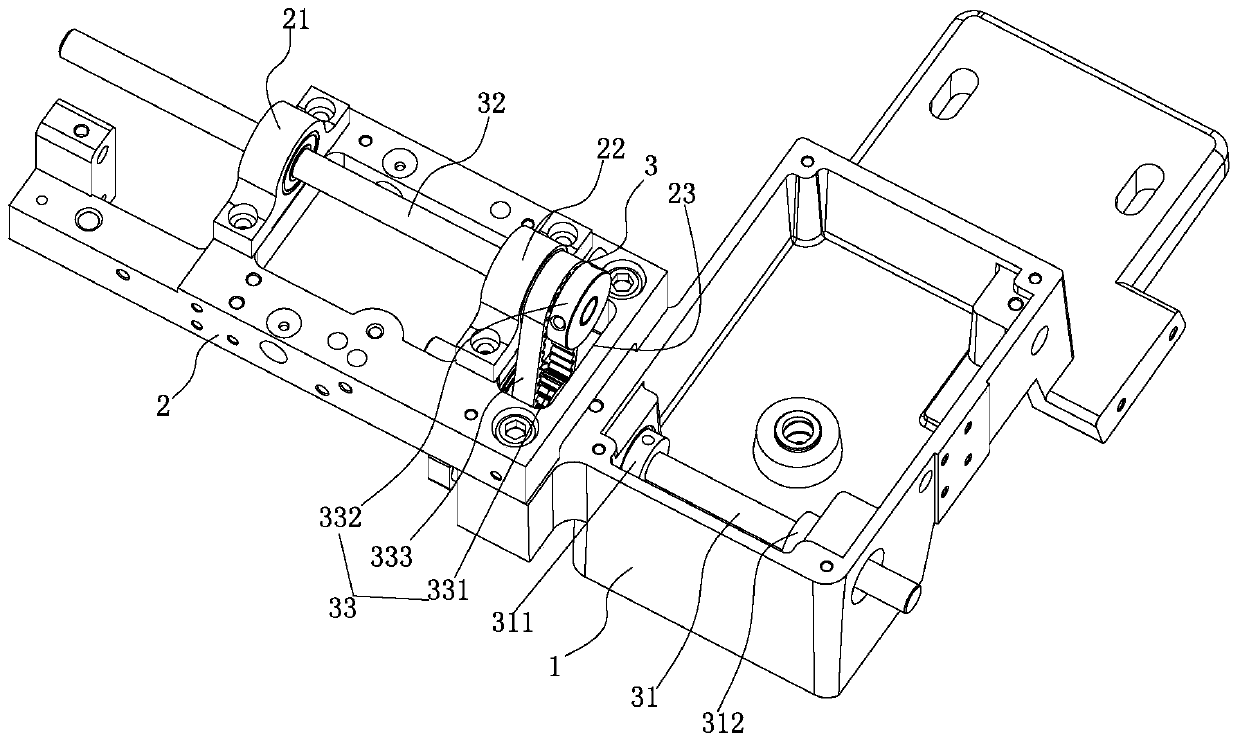

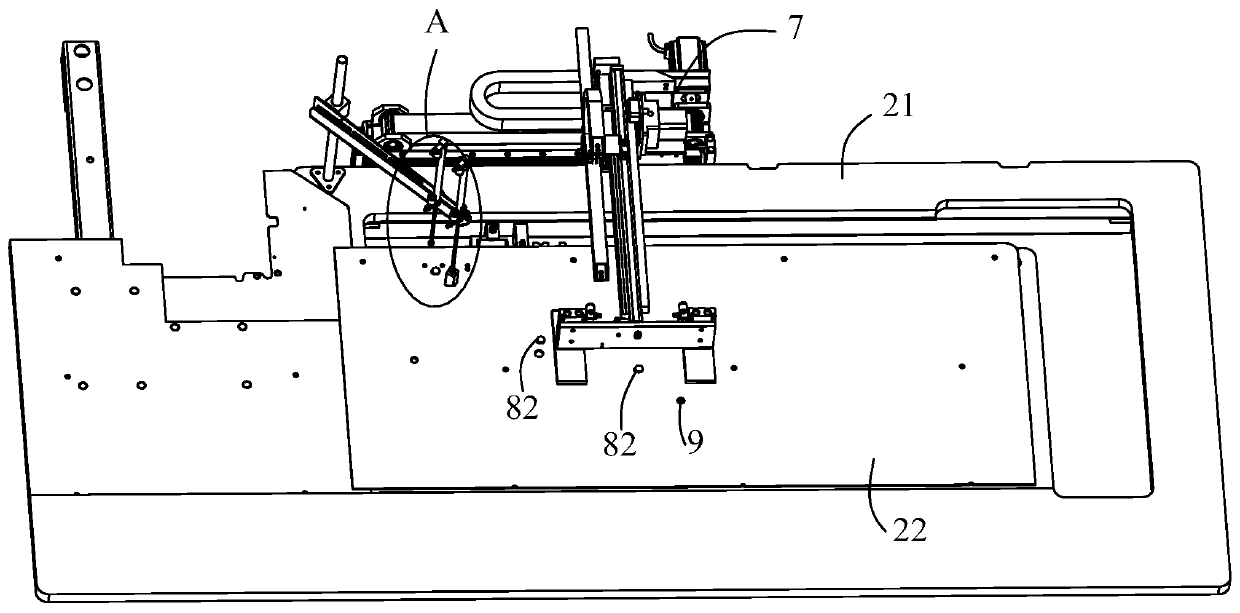

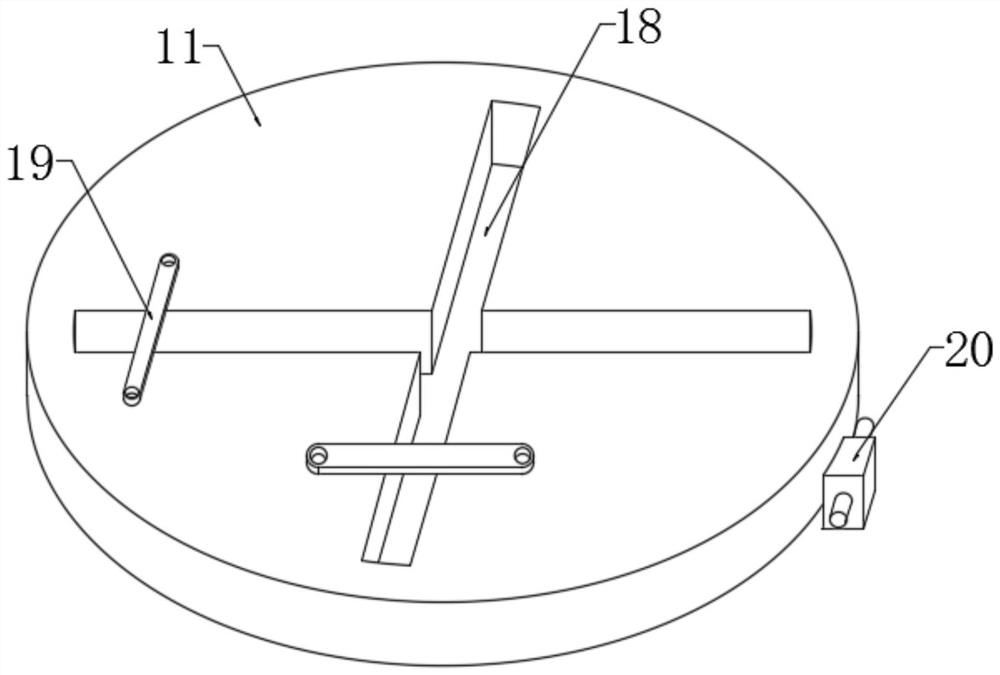

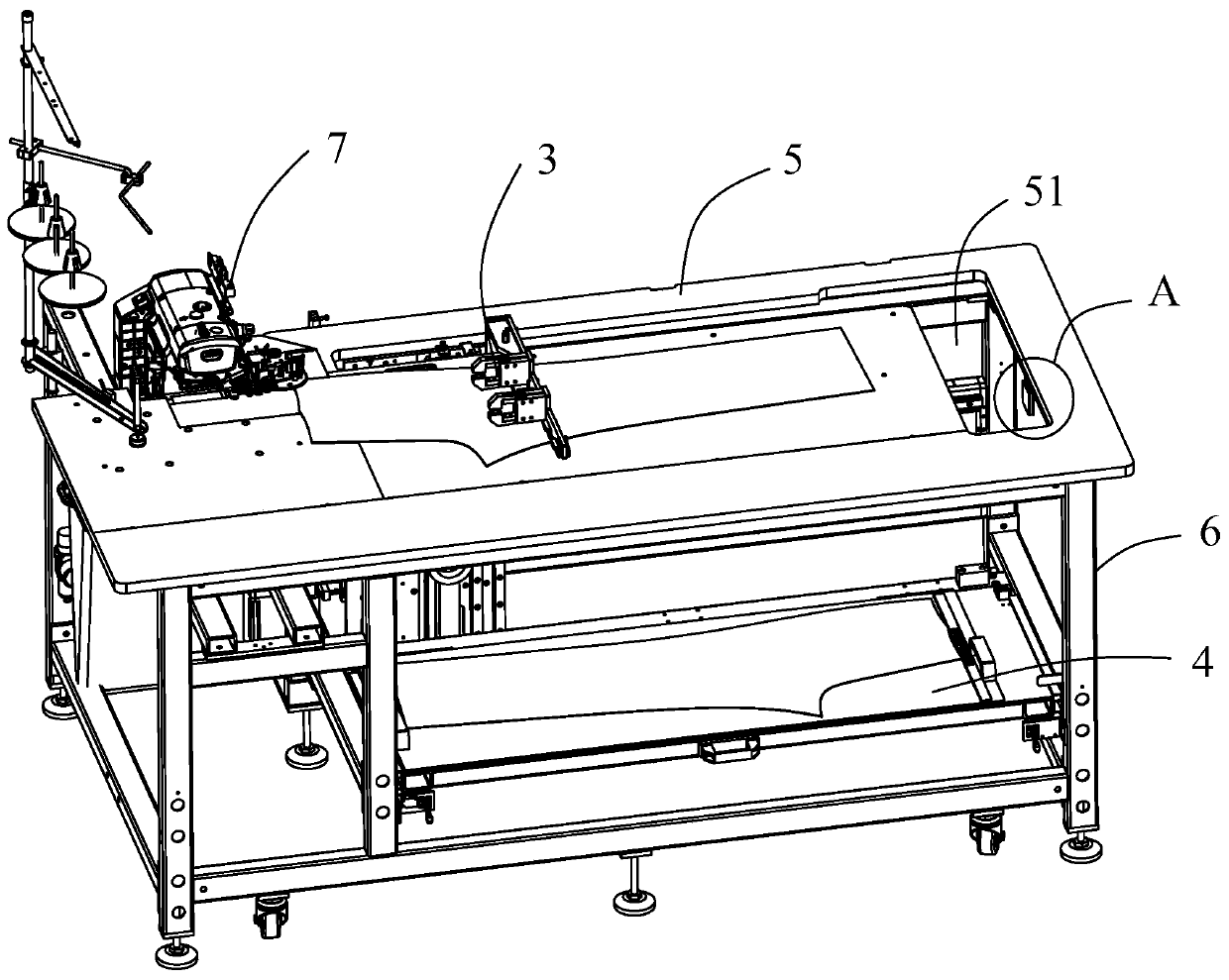

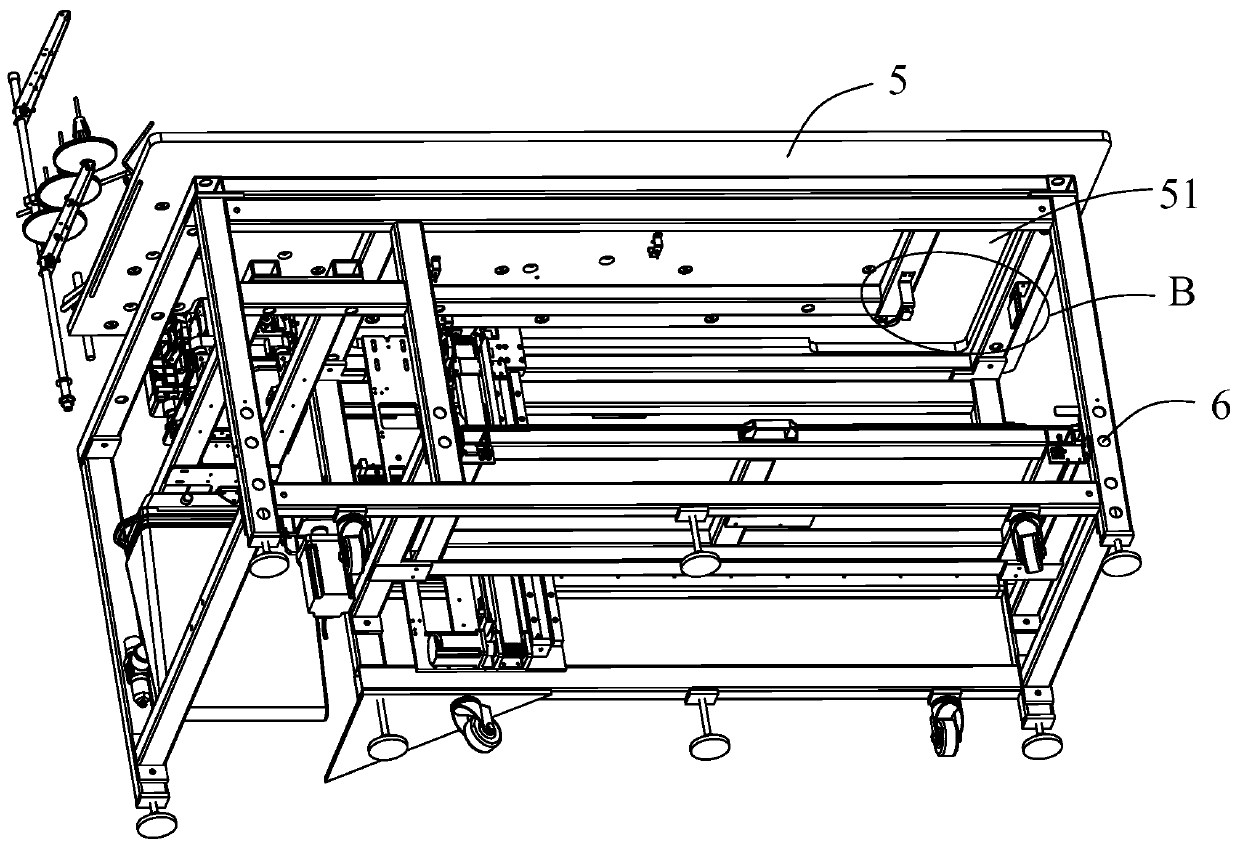

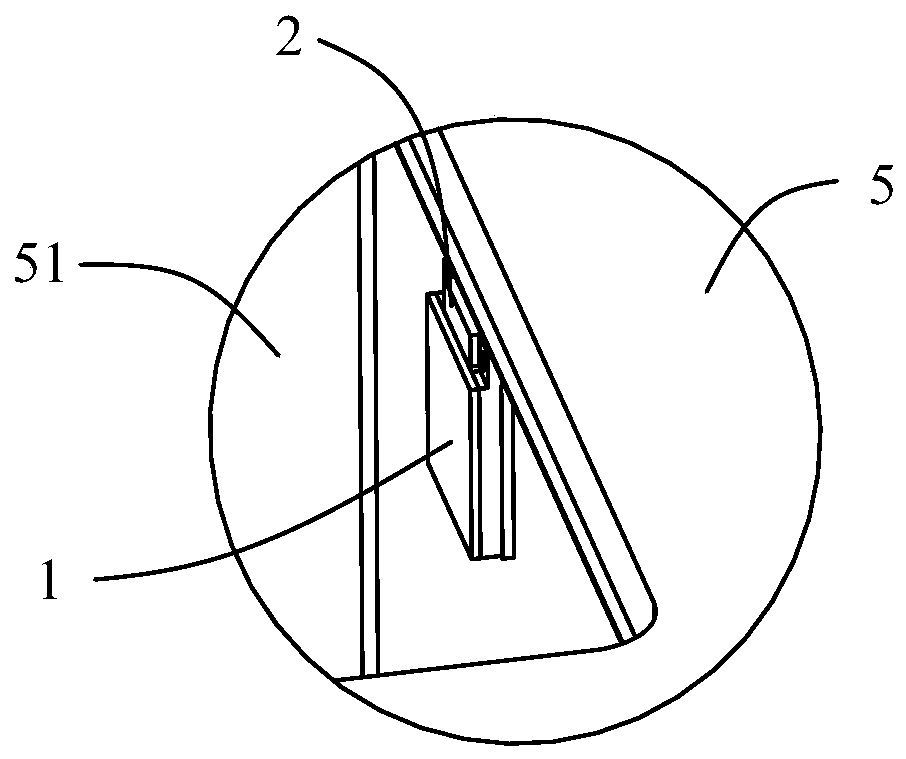

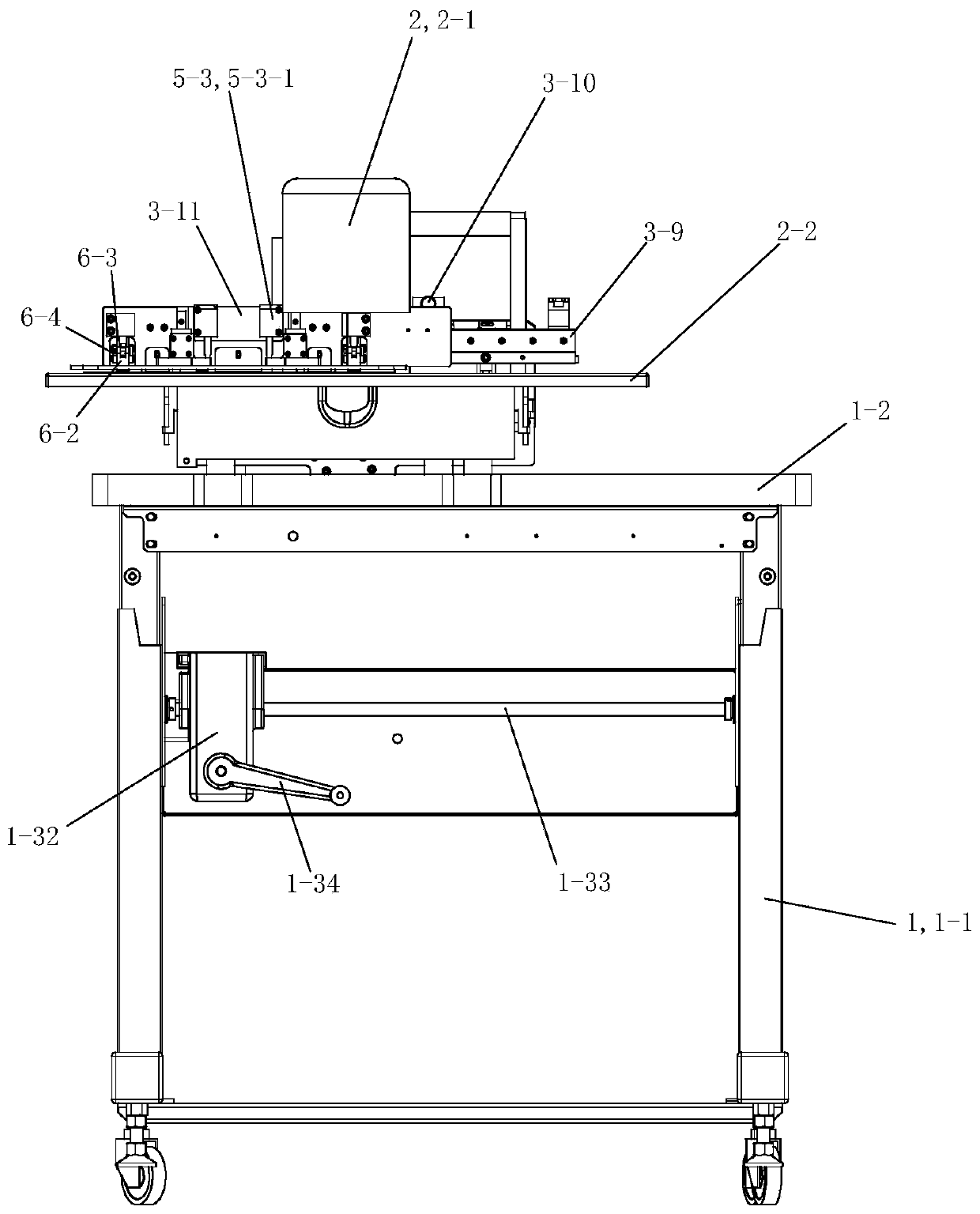

Sewing material alignment unit and method of automatic sewing device, and automatic sewing device

ActiveCN107400995BImprove alignment accuracyImprove accuracyProgramme-controlled sewing machinesWork-feeding meansEngineeringManipulator

The invention provides a sewing material aligning unit of an automatic sewing device. The sewing material aligning unit comprises a table plate for installing a sewing machine, material pressing driving sources, material pressing pieces driven by the material pressing driving sources to move up and down, a material transfer manipulator, and material transfer pieces driven by the material transfer manipulator to move and used for driving a sewing material to move. The material pressing pieces and the material transfer pieces are positioned at an upper side of the table plate. When the material transfer pieces drive one corner of the sewing material to move to a position under the material pressing pieces, the material pressing driving sources drive the material pressing pieces to move downwardly and press the corner of the sewing material, and then the material transfer pieces drive the sewing material to move and deflect around the material pressing pieces. Aligning precision and accuracy of edges of the sewing material can be effectively improved, and therefore sewing quality of the sewing material is ensured. The sewing material aligning unit is simple in structure and easy to control, and alignment of the sewing material is easy to implement.

Owner:JACK SEWING MASCH CO LTD

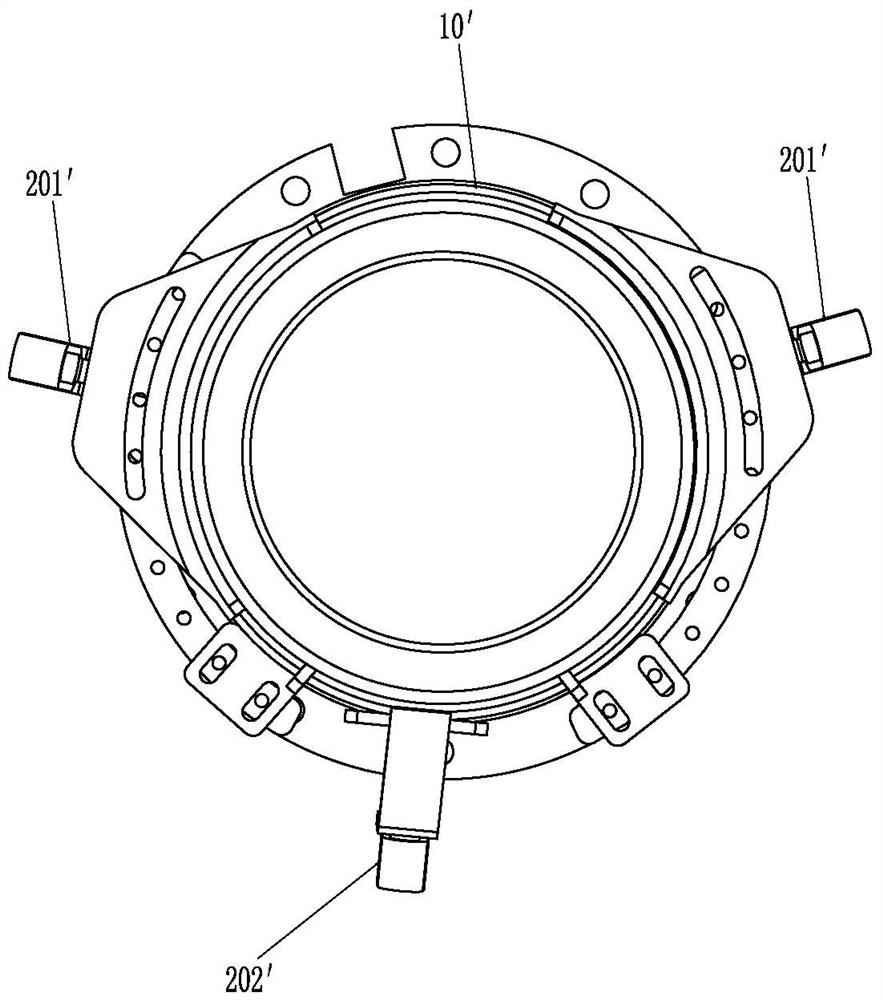

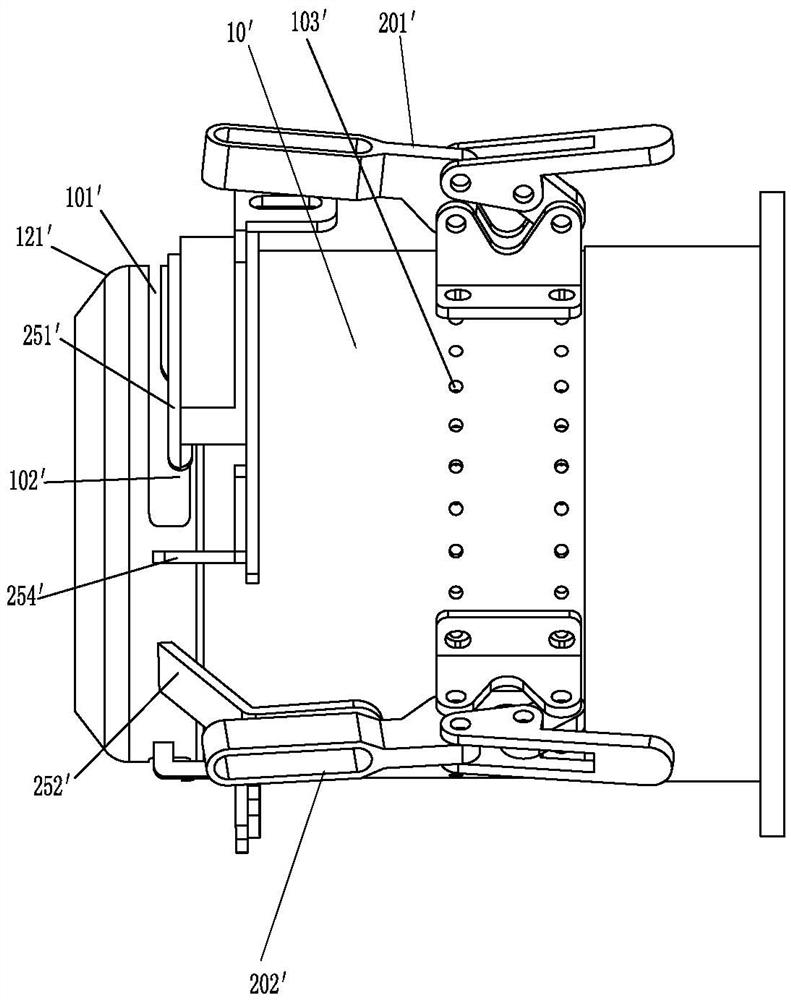

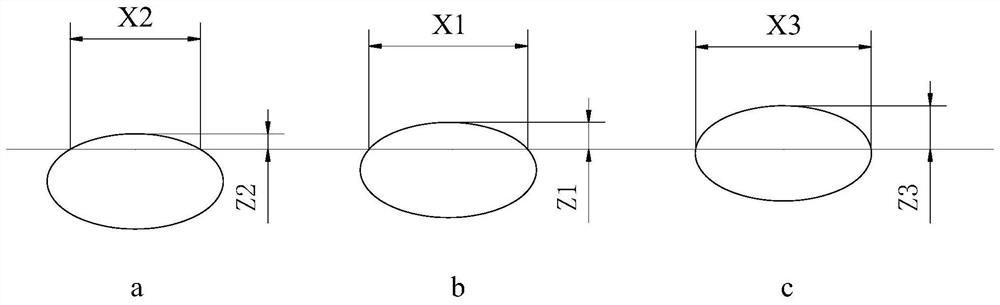

A sewing method for sleeve and shoulder joints

ActiveCN110373821BGuaranteed sewing qualityAvoid unclosedSewing apparatusCross connectionEngineering

Owner:GUANGDONG JIN YUE LAI AUTOMATION EQUIP CO LTD +1

A precise positioning sewing machine for high-end leather shoe processing

ActiveCN110318165BImprove work efficiencyPrevent movementWorkpiece holdersLeather sewingElectric machineryEngineering

The invention discloses a precise positioning type sewing machine for processing high-end leather shoes, comprising a sewing machine base and a groove, and the upper surface of the sewing machine base is provided with a groove; Cooperate with each other to drive the moving plate to move in the horizontal direction, so as to sew the upper in the horizontal direction. By setting the electric push rod, the slider is pushed to move in the vertical direction, so as to sew the side of the shoe in the vertical direction. The whole process does not require Manually fix and move the shoes, with high work efficiency; by setting the spring at the lower end of the shoe groove, the spring squeezes the placing plate, and the leather shoes are fixed under the pressing between the placing plate and the upper top plate, which avoids the shoes from moving during the sewing process. The cross needle groove plays a guiding role for the sewing needle to ensure the sewing quality; by moving the gear lever, the distance and size of the cross needle groove can be adjusted, so that the stitch length of each leather shoe is the same, and the defective rate of leather shoes can be reduced.

Owner:瑞安市佬赛鞋业有限公司

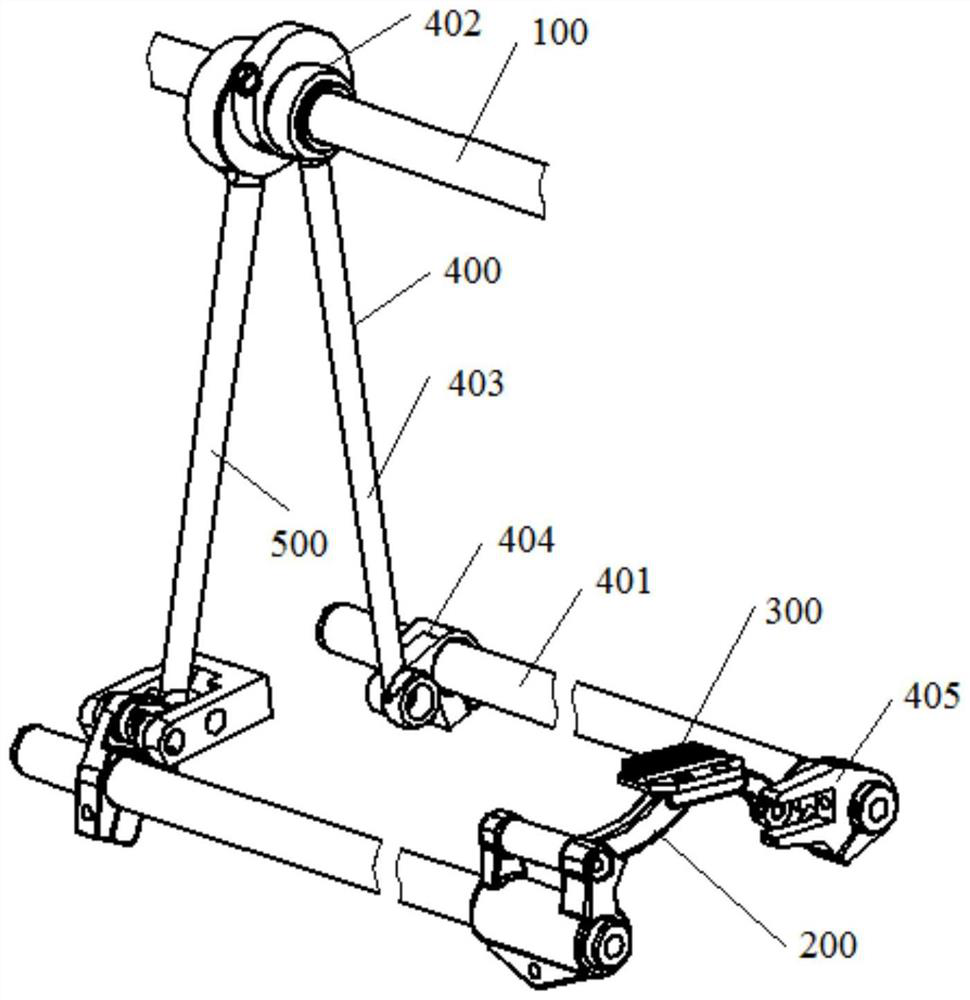

Feed lifting height adjusting method for sewing machine

ActiveCN112626733AImprove versatilityImprove adaptabilityWork-feeding meansEngineeringProcess engineering

The invention provides a feed lifting height adjusting method for a sewing machine. The sewing machine is provided with a main shaft, a feed lifting shaft parallel to the main shaft, a feed frame, a feed dog installed on the feed frame, a first feed lifting transmission assembly connected between the main shaft and the feed lifting shaft, and a second feed lifting transmission assembly connected between the feed lifting shaft and the feed frame. The feed lifting height adjusting method comprises the following steps: 1, a feed lifting height adjusting mechanism is arranged in the sewing machine, and the feed lifting height adjusting mechanism acts on the first feed lifting transmission assembly; 2, when feed lifting height needs to be adjusted, the feed lifting height adjusting mechanism acts to change the transmission efficiency of the first feed lifting transmission assembly, so that the swing amplitude of the feed lifting shaft driven by the main shaft through the first feed lifting transmission assembly is changed, and thus the feed lifting height of the feed dog is adjusted, the universality of the sewing machine is greatly improved, and therefore, the adaptability of the sewing machine to different sewing materials is greatly enhanced, and the competitiveness of products is improved.

Owner:JACK SEWING MASCH CO LTD

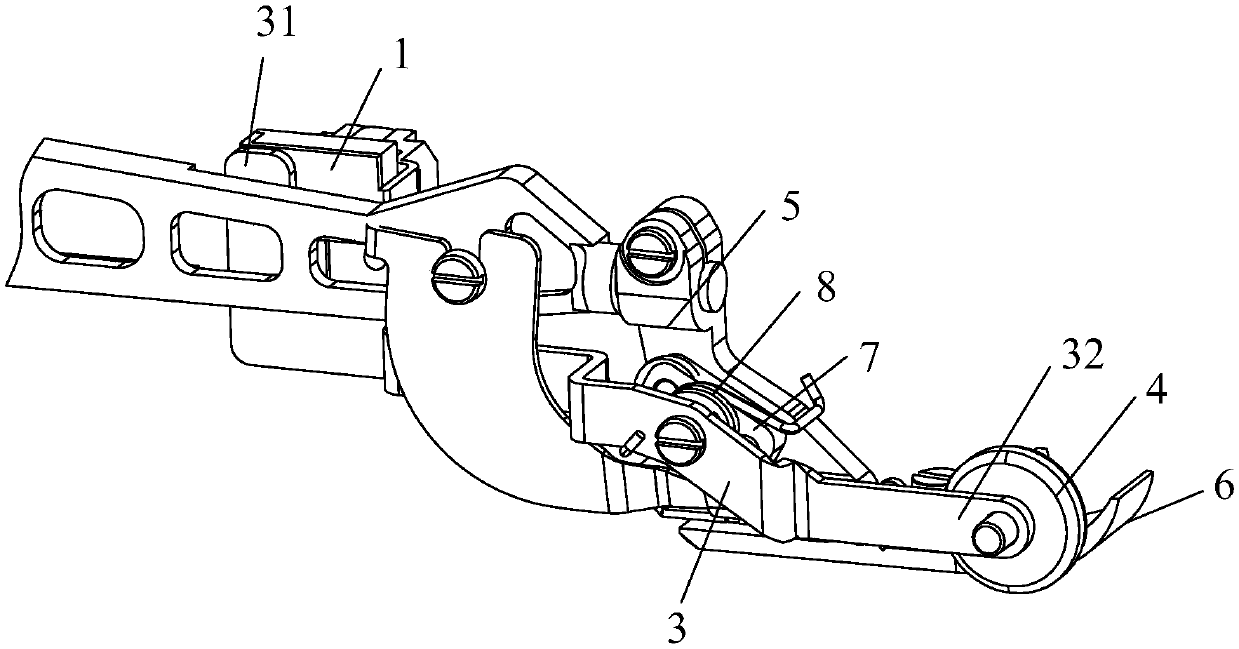

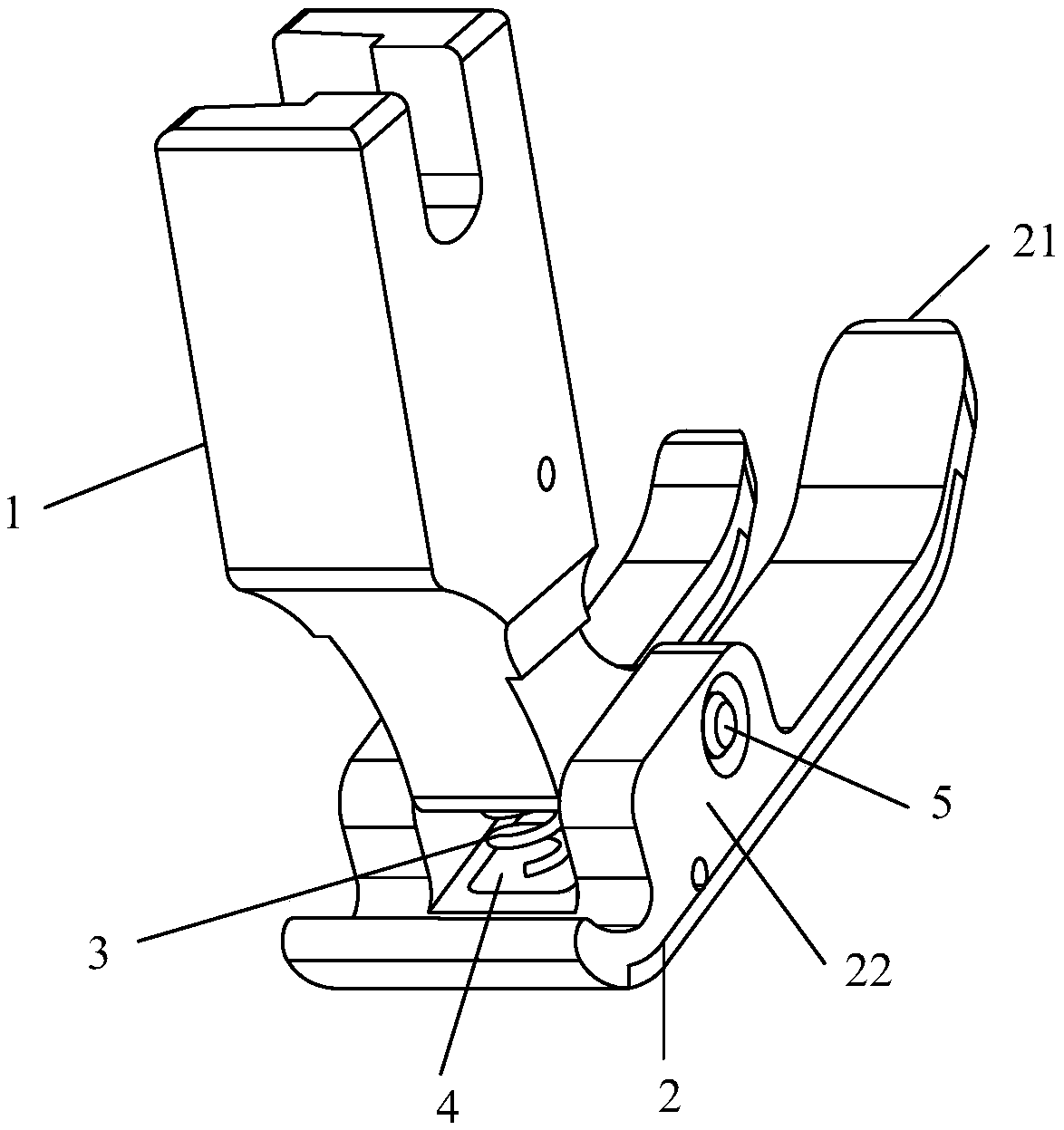

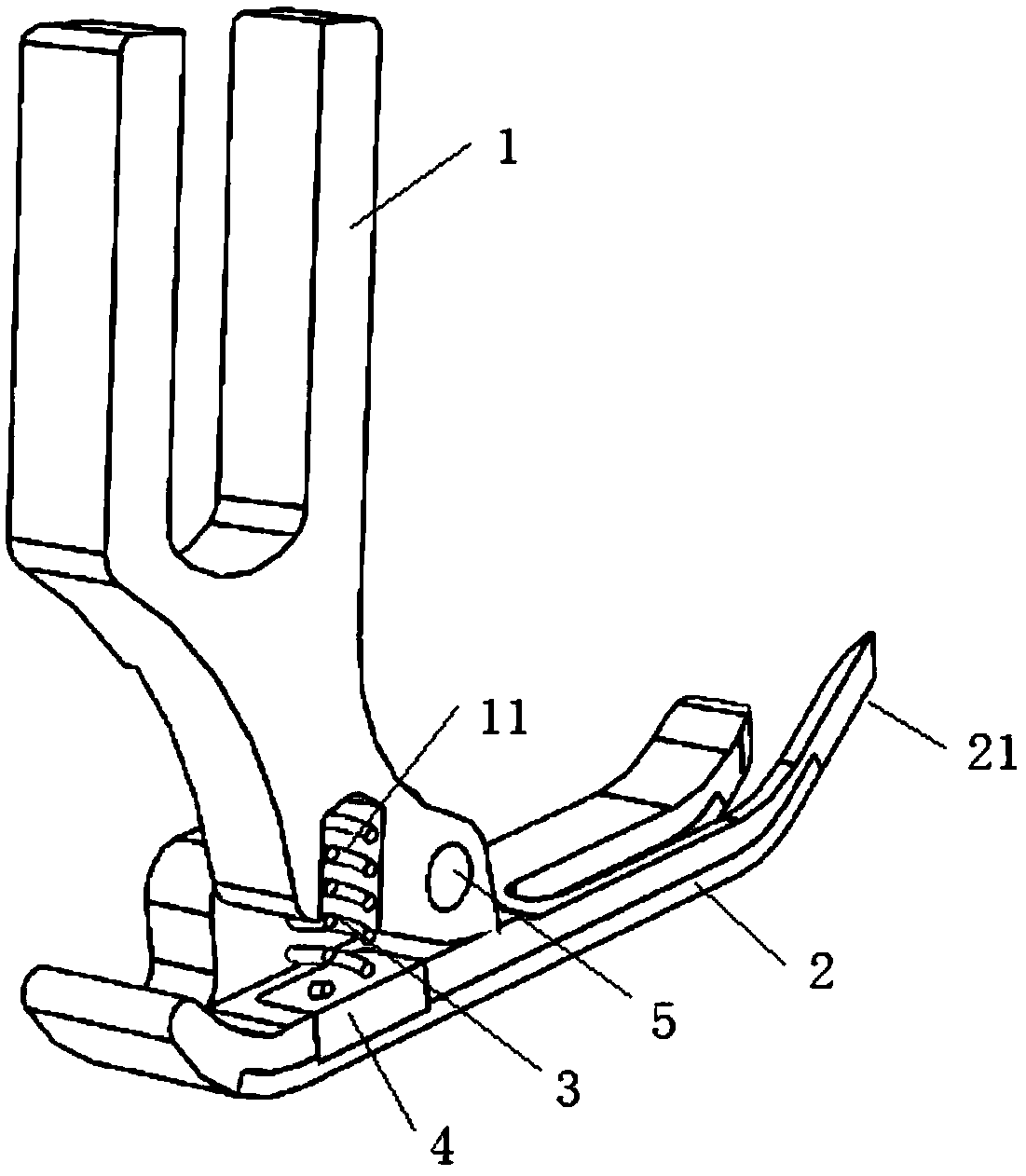

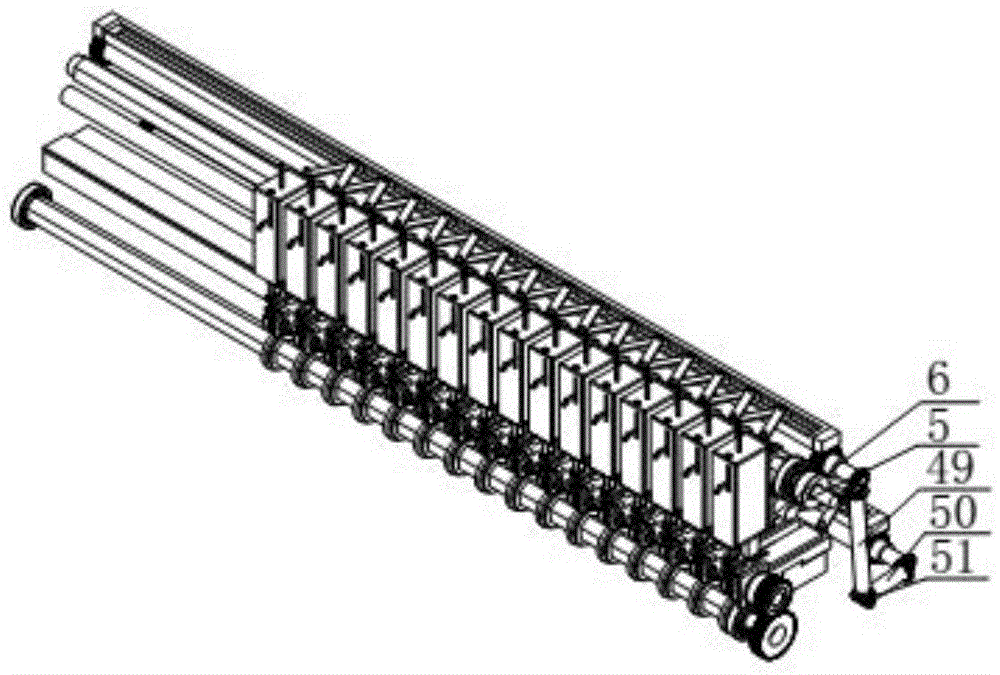

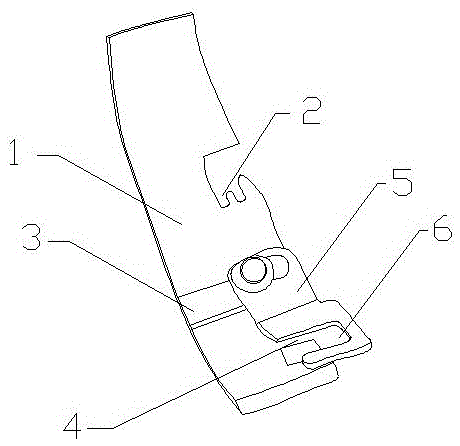

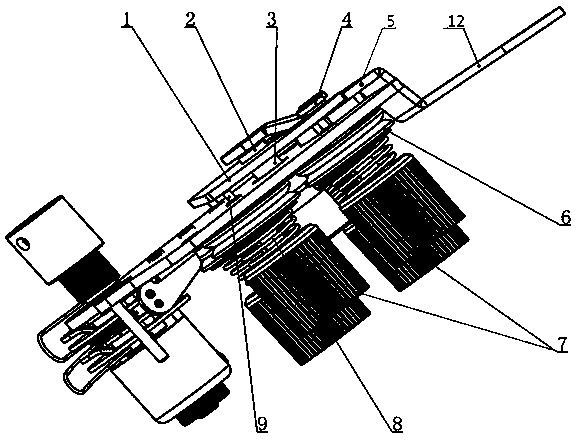

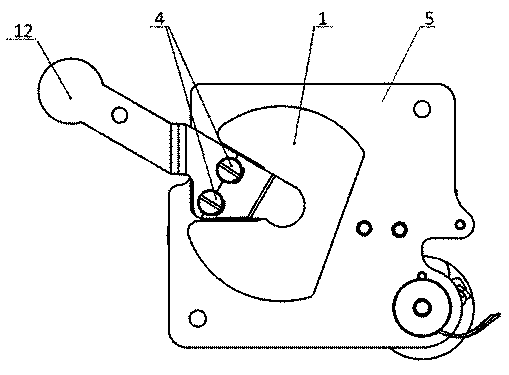

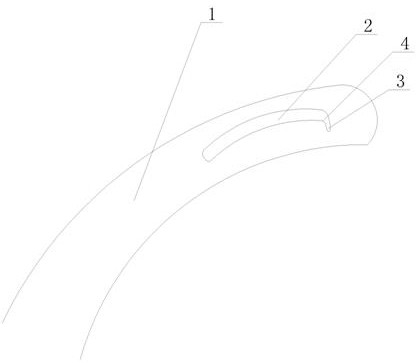

Bind-off-machine presser foot for feeding shoulder strap

InactiveCN106676767AEasy loadingGuaranteed sewing qualityPressersPhysical medicine and rehabilitation

The invention relates to a bind-off-machine presser foot for feeding a shoulder strap. The bind-off-machine presser foot comprises a bind-off-machine presser foot body (1) and is characterized in that a needle hole (2) is formed in the right of the middle portion of the presser foot body (1), a boss (3) is arranged on the front section of the presser foot body (1), a presser foot opening (4) is formed in the right of the presser foot body (1) in front of boss (3), a guide plate (5) is mounted onto the boss (3) through a screw, and a guide plate opening (6) is formed in the left of the guide plate (5) and located at a position in front of and above the presser foot opening (4). The bind-off-machine presser foot has the advantages that during shoulder strap feeding, the shoulder strap sequentially penetrates the guide plate opening and the presser foot opening and is sewn to fabric, the feeding direction of the shoulder strap is controlled automatically, and the presser foot is capable of facilitating shoulder strap feeding and guaranteeing sewing quality.

Owner:江阴市勤丰金属制品有限公司

A sewing material length detection device for automatic sewing equipment and automatic sewing equipment

ActiveCN107299460BGuaranteed sewing qualitySewing-machine elementsUsing optical meansEngineeringElectric control

The invention provides a sewing material length detection device of automatic sewing equipment. The sewing material length detection device is used for detecting length of a sewing material clamped by a sewing material clamping device, the sewing material clamping device can move between a cloth placement platform and a platen in the automatic sewing equipment and clamps one end of the sewing material in the length direction, the sewing material length detection device comprises a sewing material detection sensor used for detecting whether the sewing material passes or not, and the sewing material detection sensor is arranged on a moving track of the sewing material clamping device. Whether the sewing material passes or not is detected through the sewing material detection sensor to acquire time points when the sewing material passes the sewing material detection sensor along the length and two ends of the sewing material respectively, and the length of the sewing material can be calculated by combining with moving speed of the sewing material clamping device, so that powerful data support is provided to an electric control module in the automatic sewing equipment to automatically judge whether the sewing material is a defective material or not, and sewing efficiency and quality of the automatic sewing equipment are guaranteed finally.

Owner:JACK SEWING MASCH CO LTD

Elastic cord positioning sewing device and sewing method in garment processing

ActiveCN110424101BEasy to placePrecise positioningWork-feeding meansSewing-machine control devicesEngineeringSewing needle

Owner:珠海合和服装有限公司

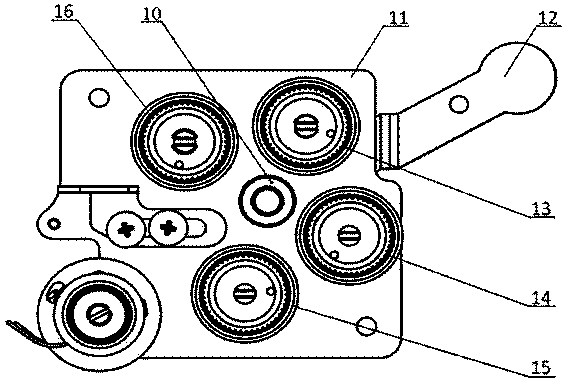

A double tension thread gripper

The invention relates to the technical field of sewing machine equipment, and specifically relates to a double tension wire clamping device. The double tension wire clamping device comprises wire clampers, a wire clamper fixing plate, a wire loosening plate A, a wire loosening plate B, a wire loosening plate shaft pin, a wire loosening plate shaft pin sleeve, first screws and a second screw. The wire clampers comprise four sets including a first coarse adjustment wire clamper, a second coarse adjustment wire clamper, a first fine adjustment wire clamper and a second fine adjustment wire clamper. The wire loosening plate A is fixed to the wire clamper fixing plate via the first screws. The wire loosening plate B is disposed between the wire loosening plate A and the wire clamper fixing plate and abutted against the wire loosening plate A. The wire loosening plate B is fixed to one end of the wire loosening plate shaft pin via the second screw, and the other end of the wire loosening plate shaft pin passes through the wire clamper fixing plate and is in interference clearance fit with the wire loosening plate shaft pin sleeve. Through a mode combined with coarse adjustment and fine adjustment, thread tension is extremely easy to adjust, appropriate tension of each thread is ensured, consistent tension of two threads is also ensured, and sewing quality is effectively ensured.

Owner:TYPICAL SEWING MACHINE WANPING MACHINERY

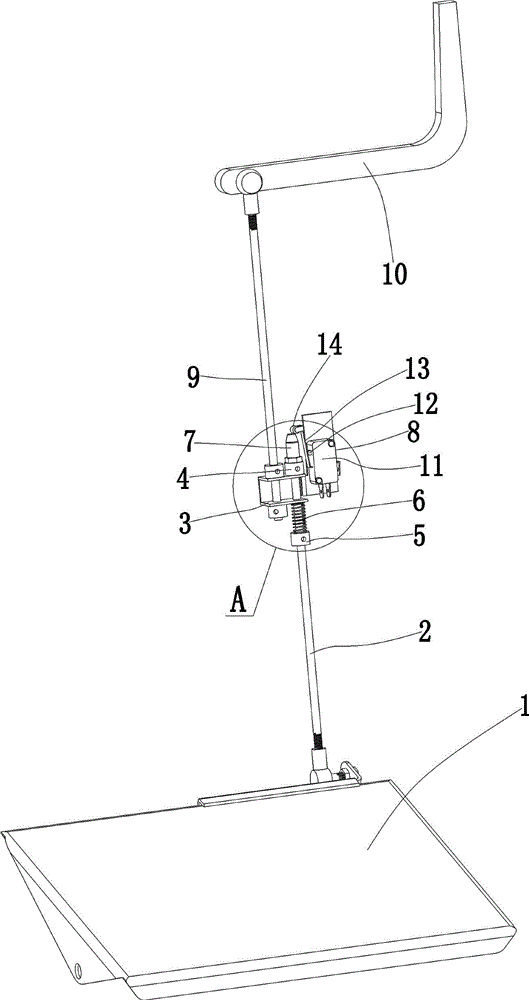

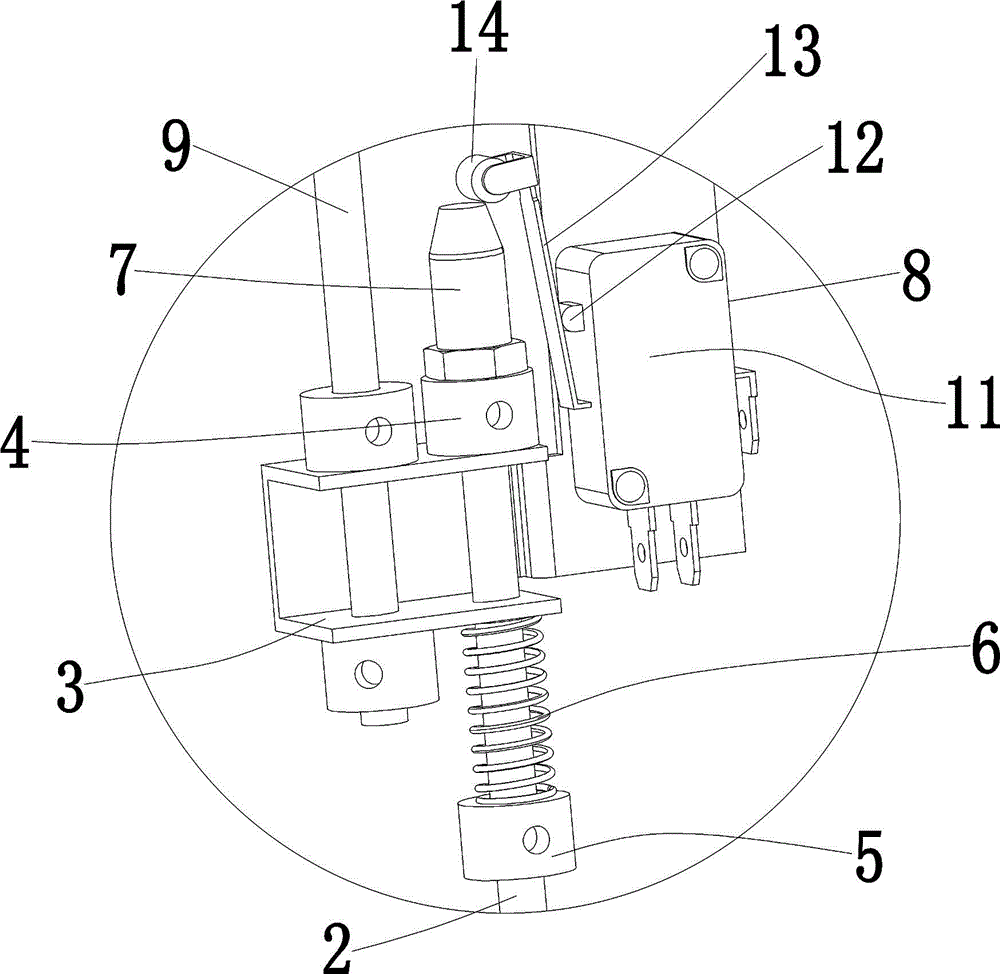

Control device for sewing machine

InactiveCN105155146AImprove efficiencyGuaranteed sewing qualityNeedle severing devicesSewing-machine control devicesCotton materialElectrical and Electronics engineering

The invention provides a control device for a sewing machine. The control device comprises a workbench, a sewing device arranged on the workbench, a thread trimming device arranged on the workbench and a foot rest, wherein the thread trimming device is connected with a controller; the foot rest is connected with a first connecting rod; the outside of the first connecting rod is sleeved by a connecting frame; a first fixed part is arranged above the connecting frame, and a second fixed part is arranged below the connecting frame; a spring is arranged between the connecting frame and the second fixed part; the upper end of the first fixed part is provided with a contact; the connecting frame is connected with a contact switch matched with the contact; the contact switch is connected with the controller; the connecting frame is fixedly connected with a second connecting rod; and the upper end of the second connecting rod is provided with a switch arm connected with the sewing device. By using the control device for the sewing machine, provided by the invention, a sewn fabric thread can be automatically trimmed within the first time after the sewing machine stops sewing by virtue of the foot rest, and manual thread trimming is not needed.

Owner:YUHUAN YI ELECTRONICS

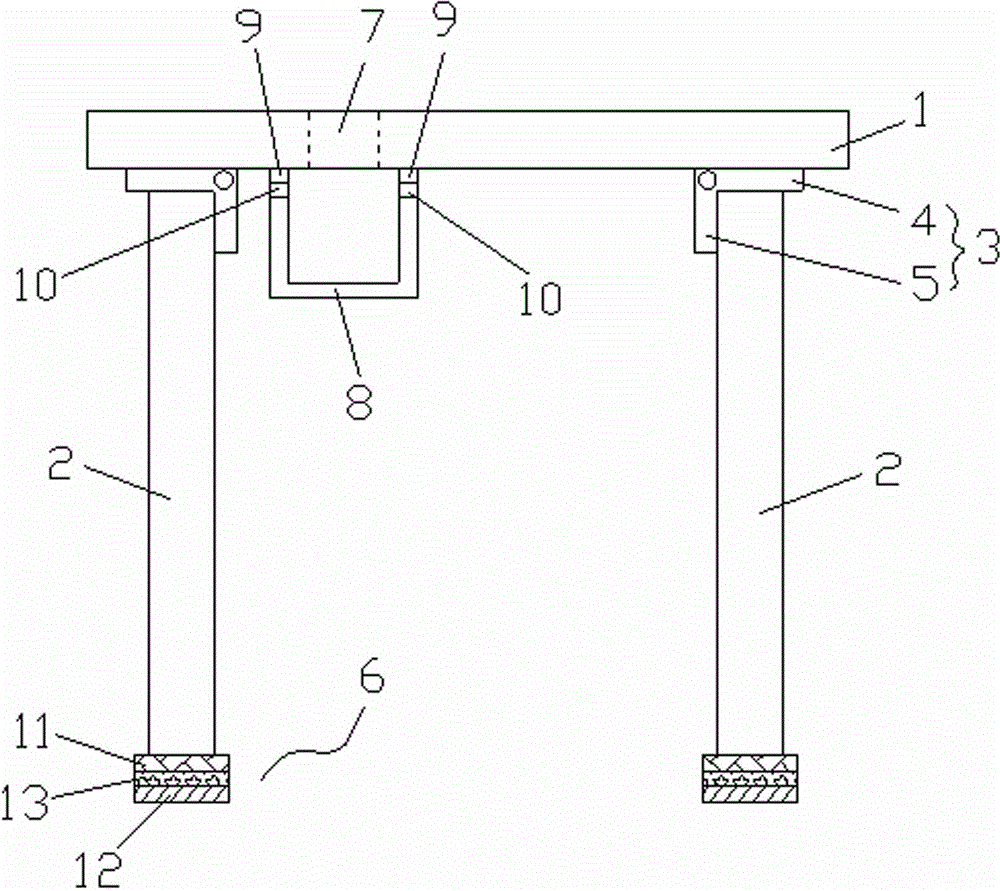

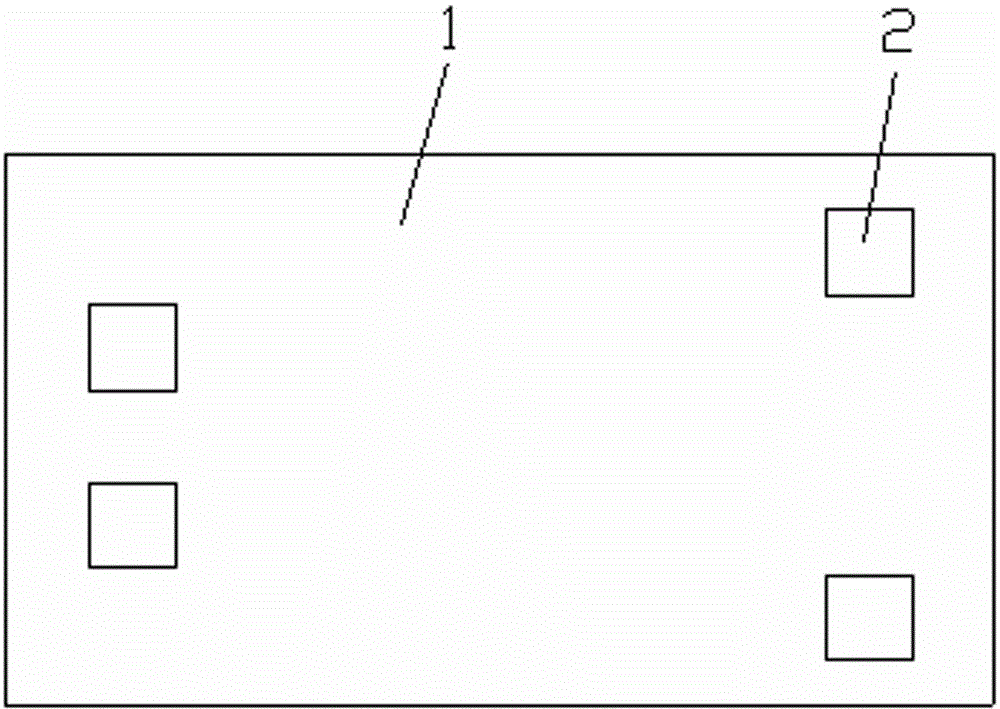

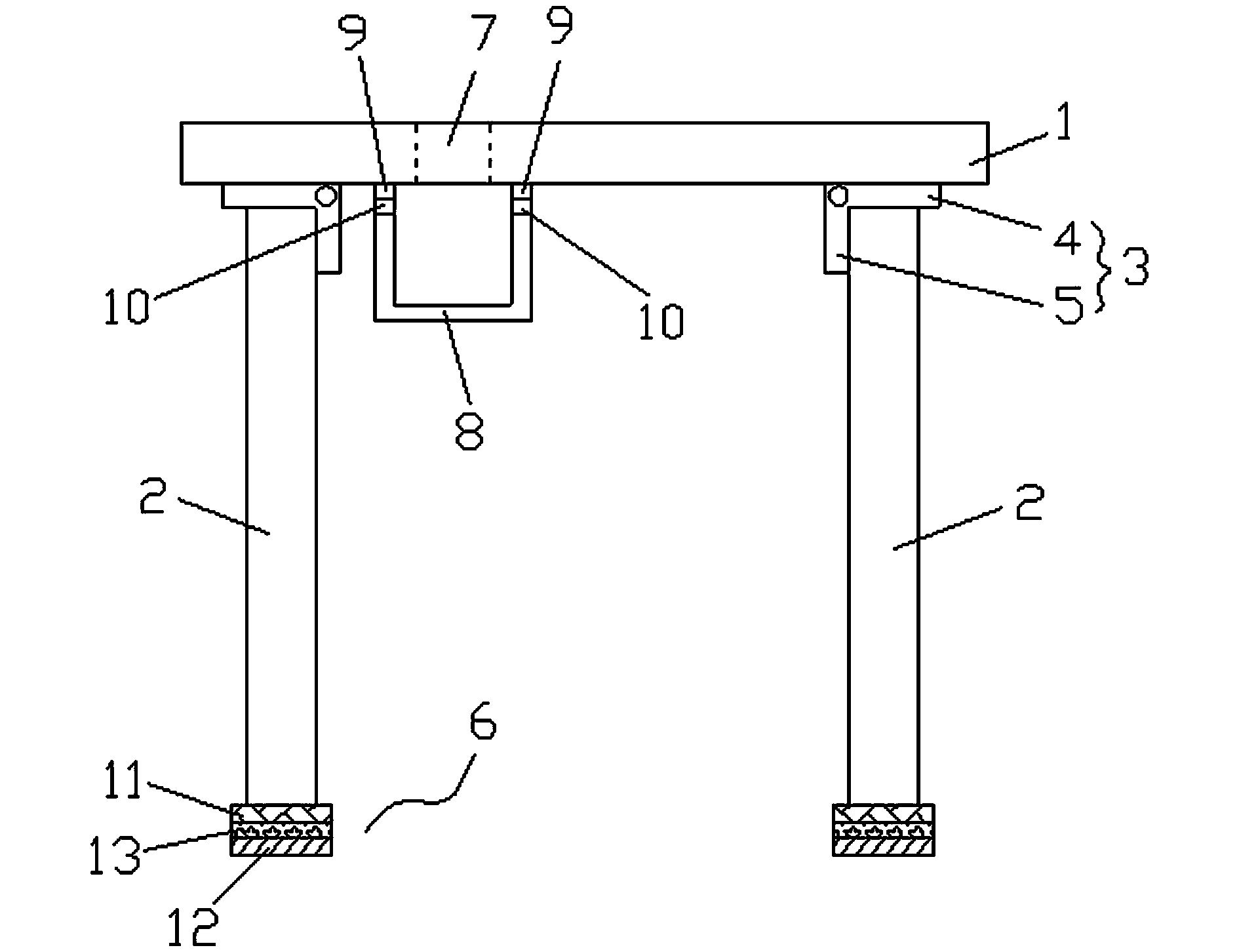

Sewing Rack

InactiveCN103541161BQuick collectionSimple structureSewing-machine elementsIsosceles trapezoidMechanical engineering

The invention relates to a frame for sewing. The frame comprises a support plate and four support legs. Connection lines of the four support legs form an isosceles trapezoid. A hinge seat is arranged at the lower end of the support plate and comprises a first hinge plate and a second hinge plate hinged to the first hinge plate. The support legs are fixed on the second hinge plate. Anti-vibration pads are arranged at the bottom ends of the support legs. The frame is simple in structure. The support legs can be folded and are not interfered by each other, the size is reduced, and transportation convenience is obtained. By means of a scrap storage groove, scraps can be collected quickly without mess. The anti-vibration pads are arranged at the bottom ends of the support legs, so that vibration is avoided, operators are protected from vibration effects, and sewing quality is guaranteed.

Owner:WUJIANG XILI MACHINERY FACTORY

Improved sewing machine take-up lever structure

PendingCN112501806AGuaranteed sewing effectGuaranteed sewing qualityTake-up devicesManufacturing engineeringSewing machine

The invention provides an improved sewing machine take-up lever structure. In the sewing process, when a take-up lever runs to different positions, the thread feeding amount of an upper thread and thepulling force of the upper thread are kept stable, therefore it is further guaranteed that stitches in the sewing process of clothes are stable, and the sewing effect and sewing quality of the clothes are better improved. The improved sewing machine take-up lever structure comprises a sewing machine take-up lever body, the sewing machine take-up lever body is provided with a threading hole whichis a long slotted hole, and the improved sewing machine take-up lever structure is characterized in that the long slotted hole is provided with a transverse notch.

Owner:无锡品益缝纫机有限公司

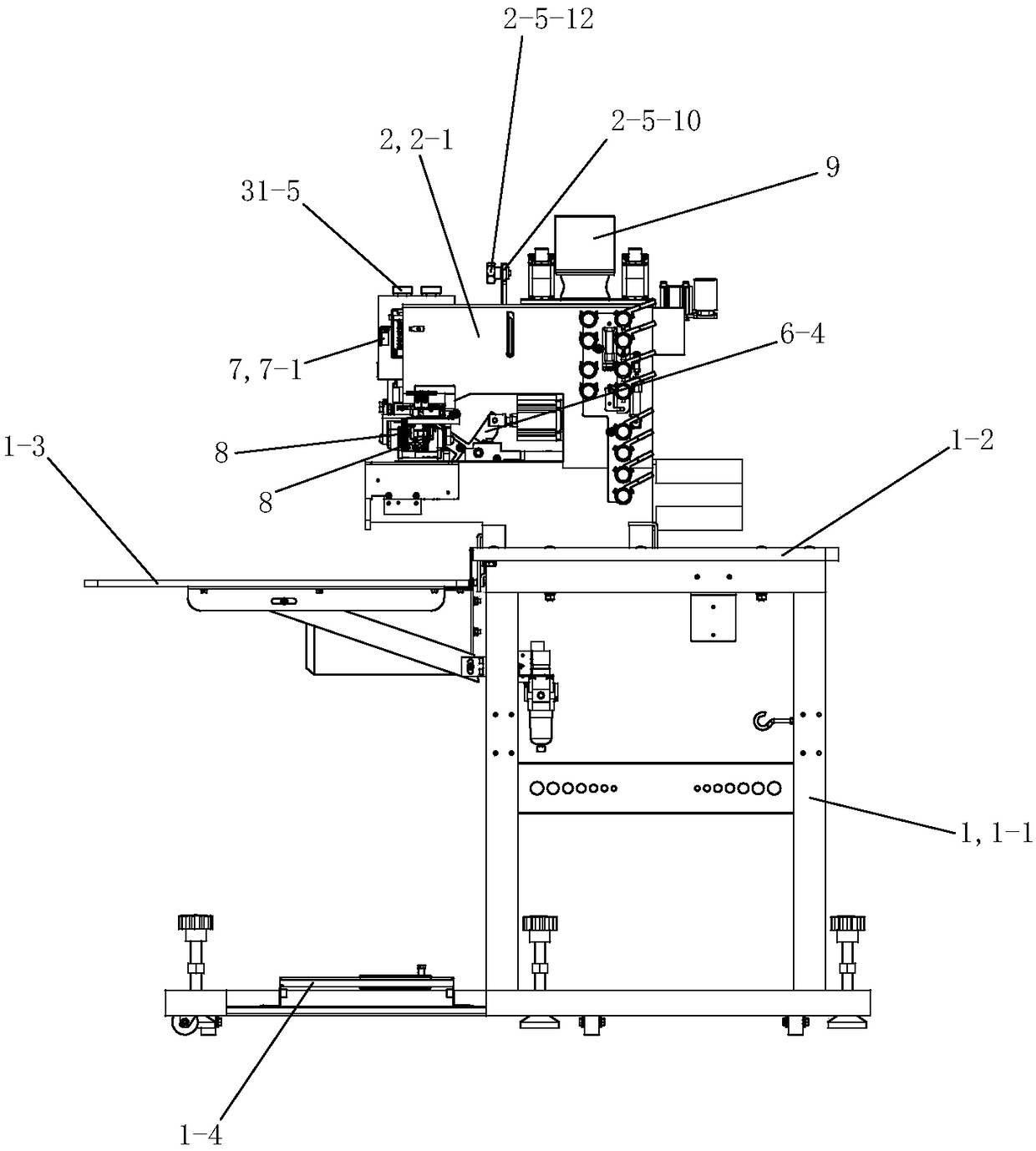

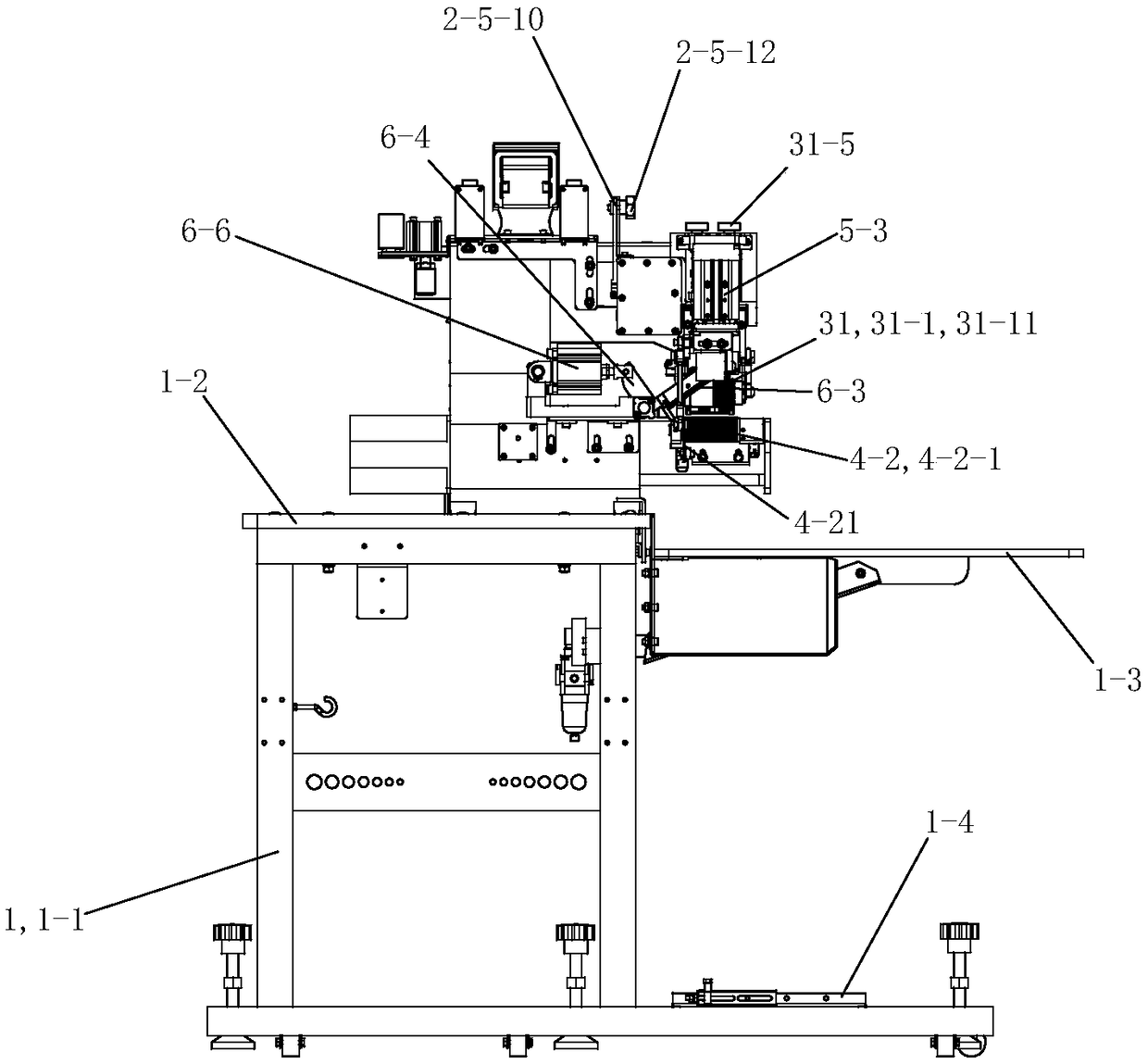

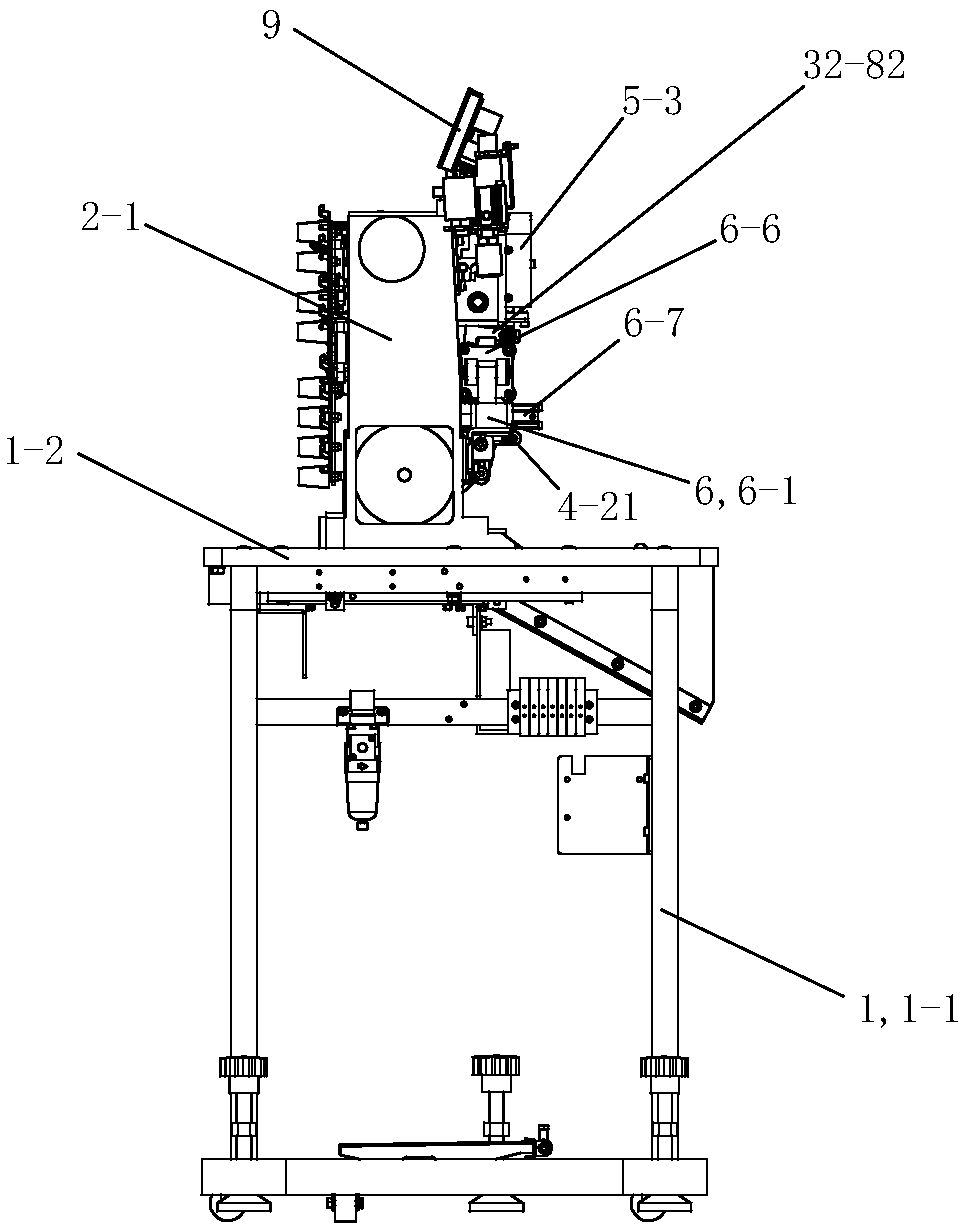

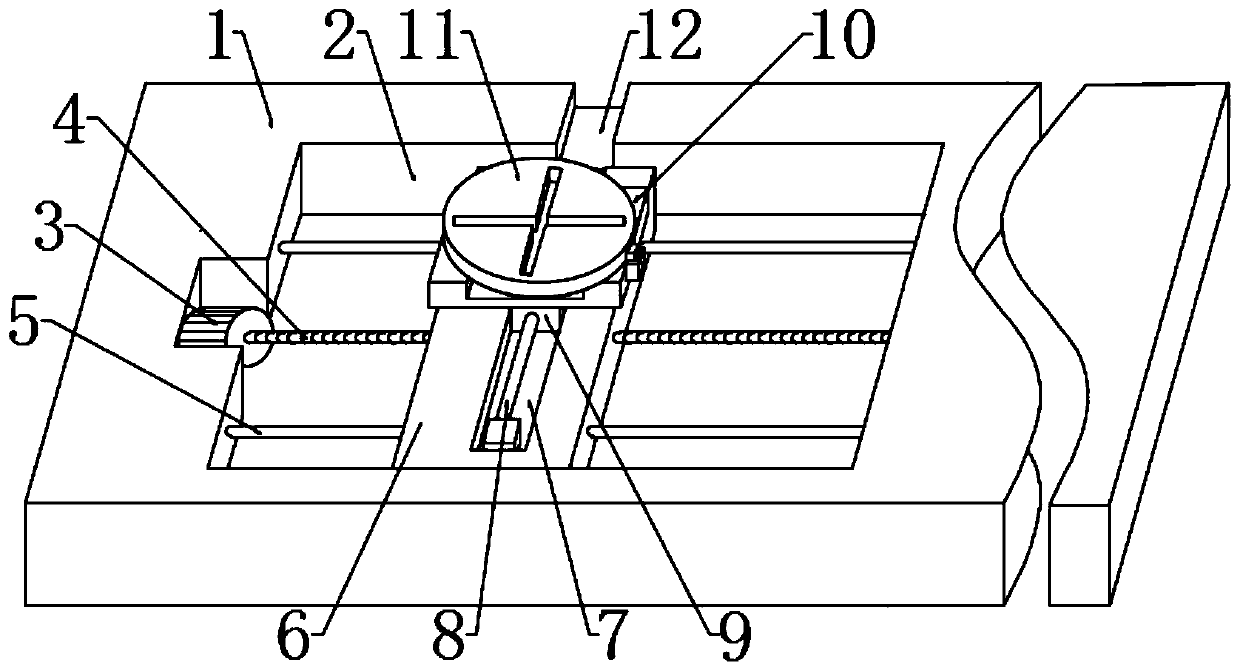

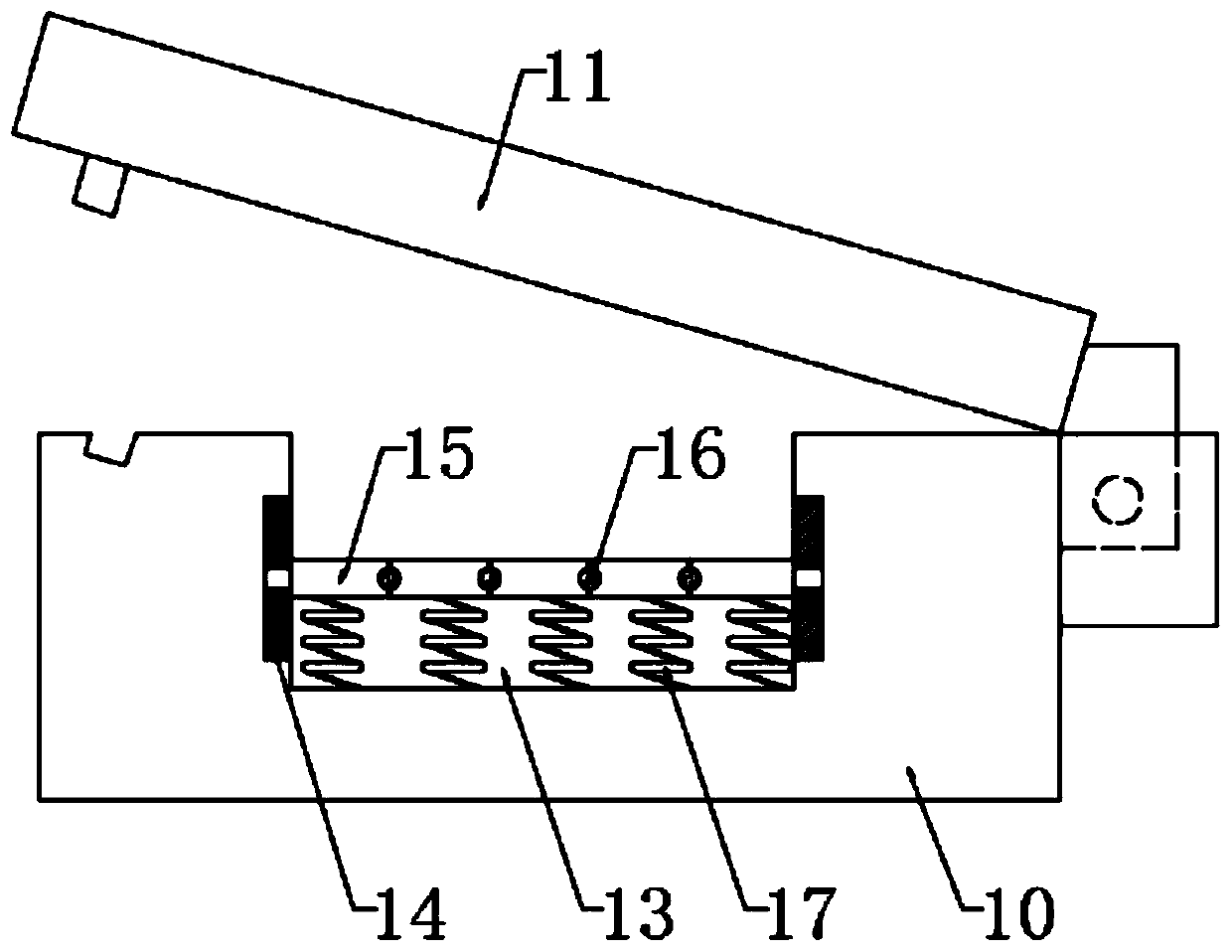

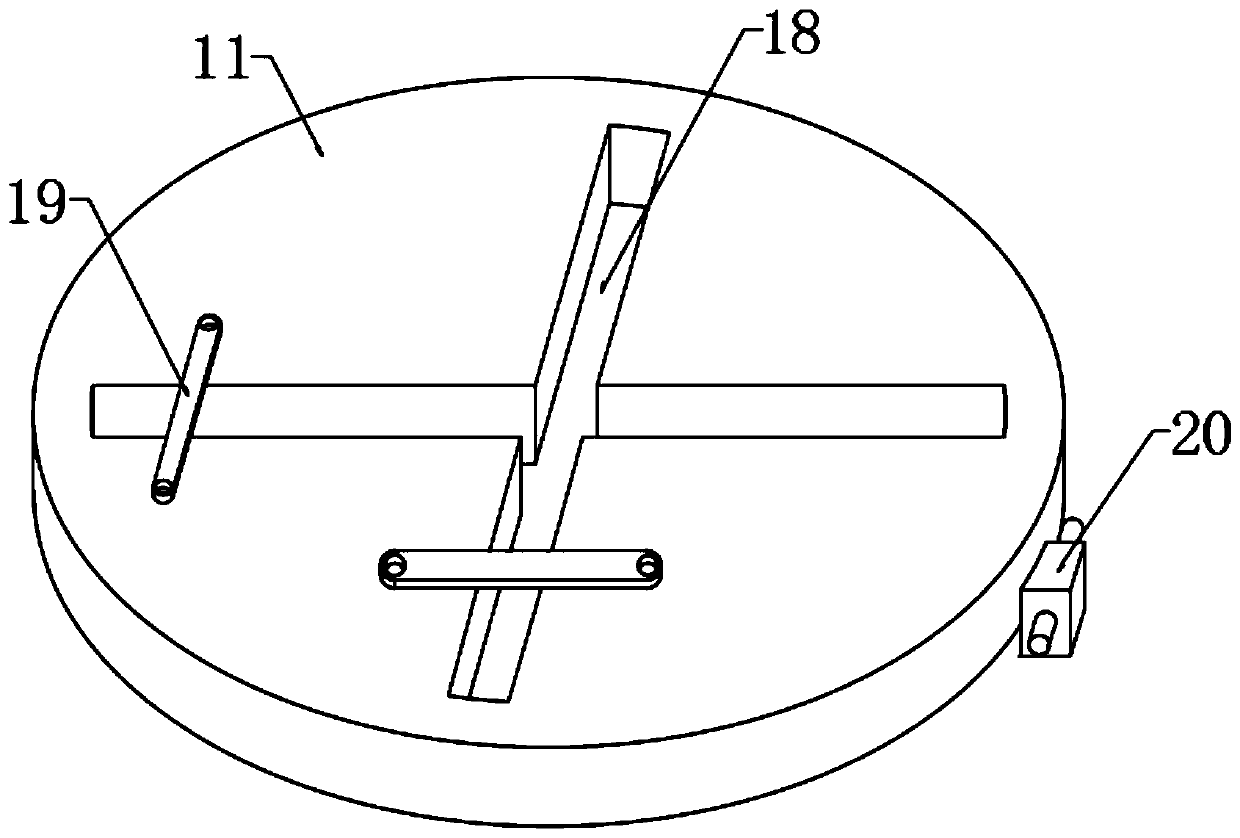

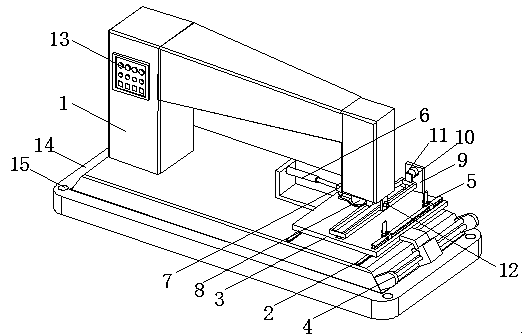

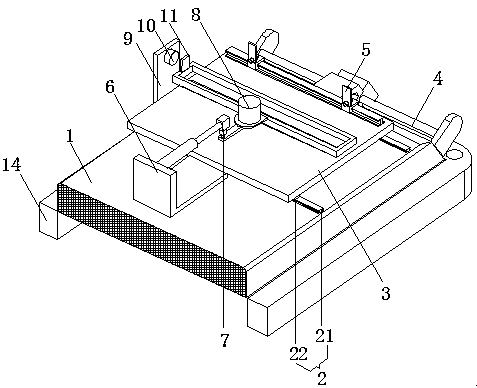

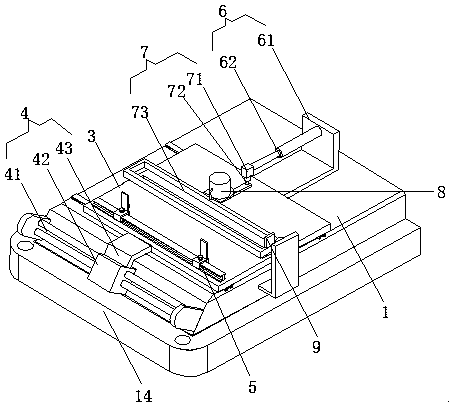

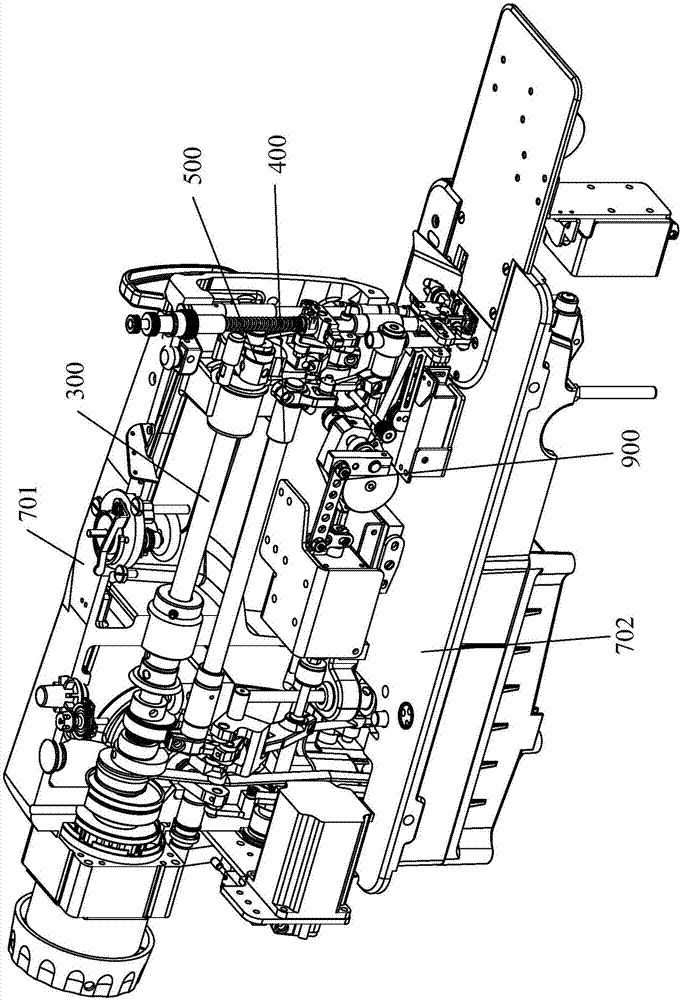

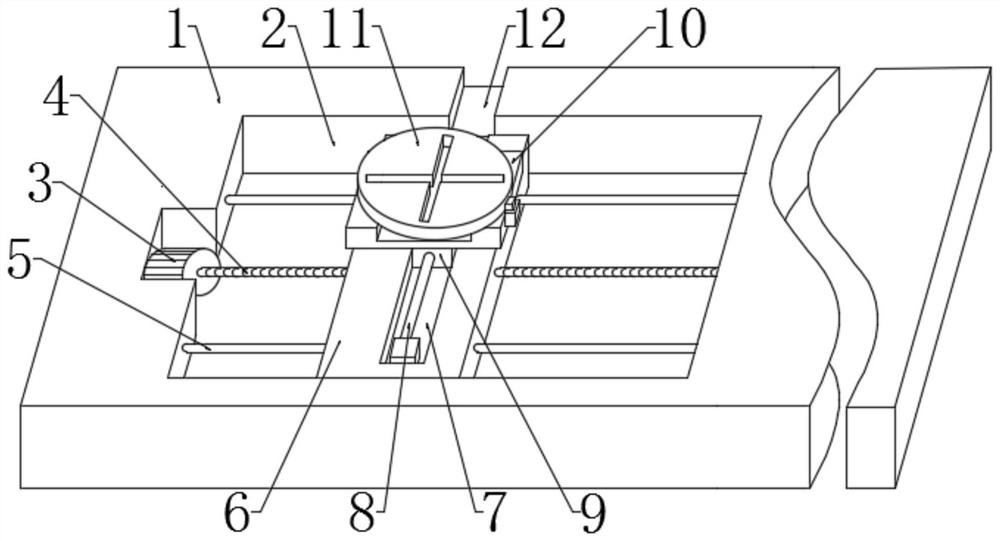

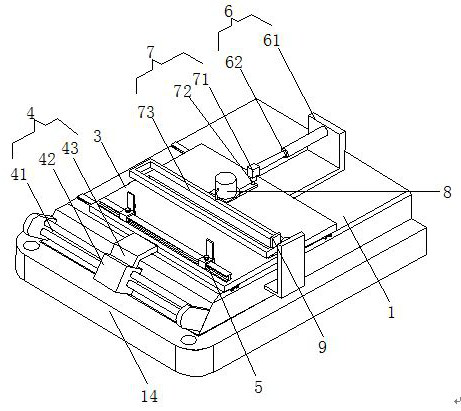

Pattern machine

The invention discloses a pattern machine. The pattern machine comprises a working table mechanism, a sewing mechanism, an X-direction driving mechanism, a Y-direction driving mechanism and a cloth pressing mechanism. The sewing mechanism comprises a sewing machine head and a sewing bed plate. The sewing bed plate is fixedly arranged on the sewing machine head. The sewing mechanism is arranged onthe working table mechanism. The cloth pressing mechanism is driven by the X-direction driving mechanism and the Y-direction driving mechanism to move in an X direction and a Y direction. The invention has the key points that in a transmission mode of a ball spline and a gear as well as a rack, a space occupied by the X-direction driving mechanism in the Y direction is greatly reduced; a sewing range of an original pattern machine in the Y direction can be enlarged in a case of not replacing the sewing machine head; meanwhile, a sewing range in the X direction is enlarged; and investment costof production equipment is greatly saved. According to the invention, an original sewing range is enlarged to 300 millimeters in the X direction from an original sewing range of 200 millimeters in theX direction and is enlarged to 250 millimeters from an original sewing range of 100 millimeters in the Y direction; the sewing range is greatly enlarged; and the application range is wider.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Frame for sewing

The invention relates to a frame for sewing. The frame comprises a support plate and four support legs. Connection lines of the four support legs form an isosceles trapezoid. A hinge seat is arranged at the lower end of the support plate and comprises a first hinge plate and a second hinge plate hinged to the first hinge plate. The support legs are fixed on the second hinge plate. Anti-vibration pads are arranged at the bottom ends of the support legs. The frame is simple in structure. The support legs can be folded and are not interfered by each other, the size is reduced, and transportation convenience is obtained. By means of a scrap storage groove, scraps can be collected quickly without mess. The anti-vibration pads are arranged at the bottom ends of the support legs, so that vibration is avoided, operators are protected from vibration effects, and sewing quality is guaranteed.

Owner:WUJIANG XILI MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com