Bind-off-machine presser foot for feeding shoulder strap

A presser foot and sidecar technology, which is applied in cloth press mechanism, textile and papermaking, sewing equipment, etc. It can solve the problems of poor manual adjustment accuracy, unqualified product quality, and difficult control of feeding direction, so as to ensure the sewing quality , Easy to load the shoulder strap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

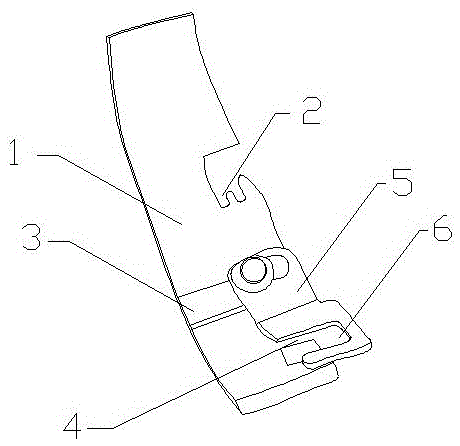

[0011] see figure 1 , the present invention relates to a presser foot of an overcoat car for upper shoulders, which includes a presser body 1 of an overcoat car, a pinhole 2 is arranged on the right side of the middle part of the presser body 1, and the presser foot The front part of the main body 1 is provided with a boss 3, and the right side of the presser body 1 in front of the boss 3 is provided with a presser foot opening 4, and the presser body 1 at the front part of the presser foot opening 4 is set as a slope, and the protrusion A material guide plate 5 is installed on the platform 3 by screws, the material guide plate 5 has a curvature suitable for the binder body 1 , and a material guide plate opening 6 is arranged on the left side of the material guide plate 5 . The opening 6 of the material guide plate is located at the upper front of the opening 4 of the presser foot. The material guide plate 5 is provided with a waist hole, and the material guide plate 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com