Patents

Literature

35results about How to "Increase or decrease speed" patented technology

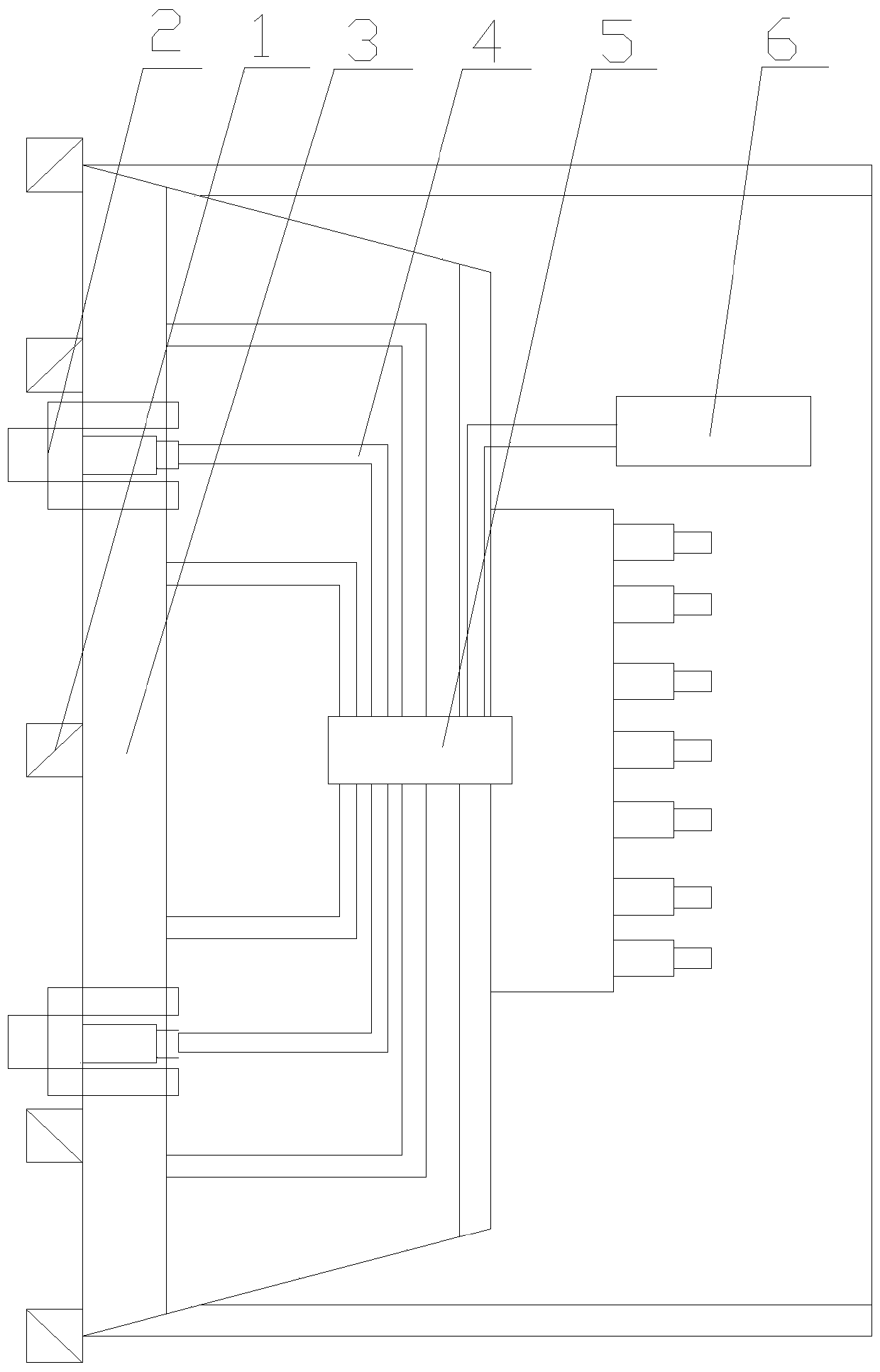

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

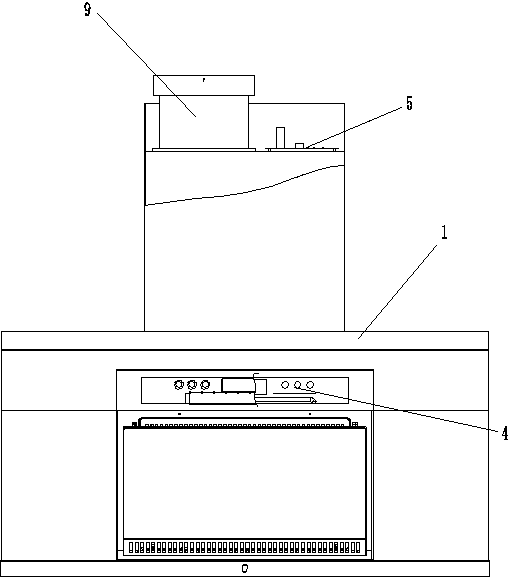

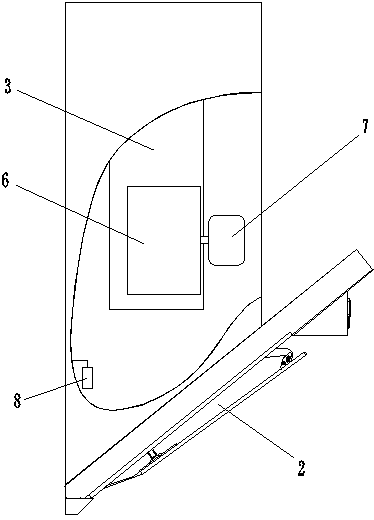

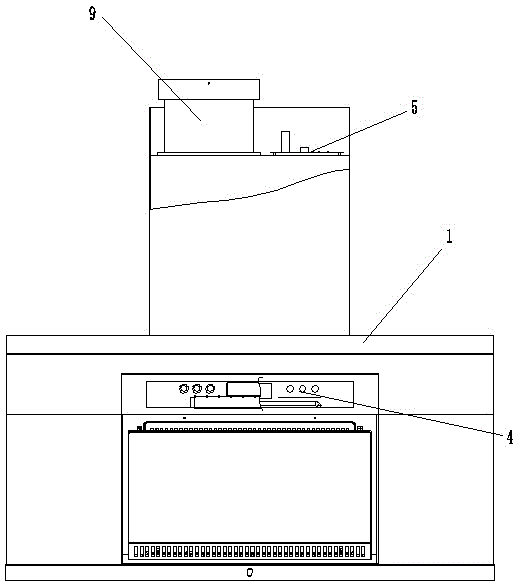

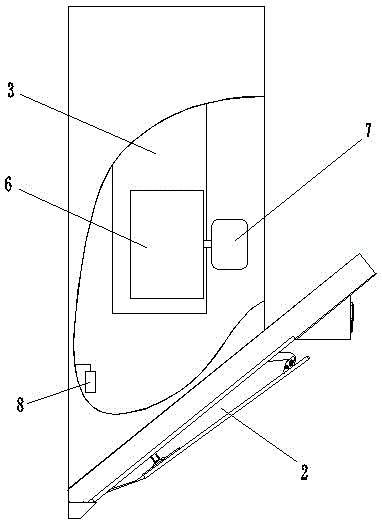

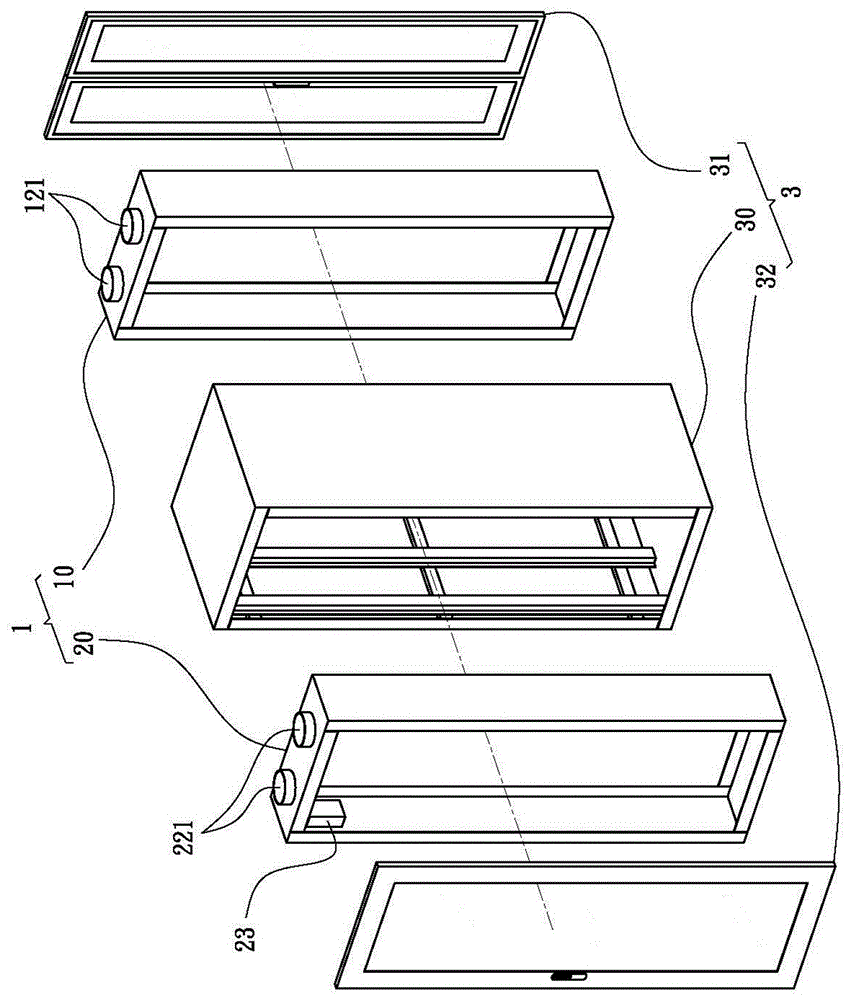

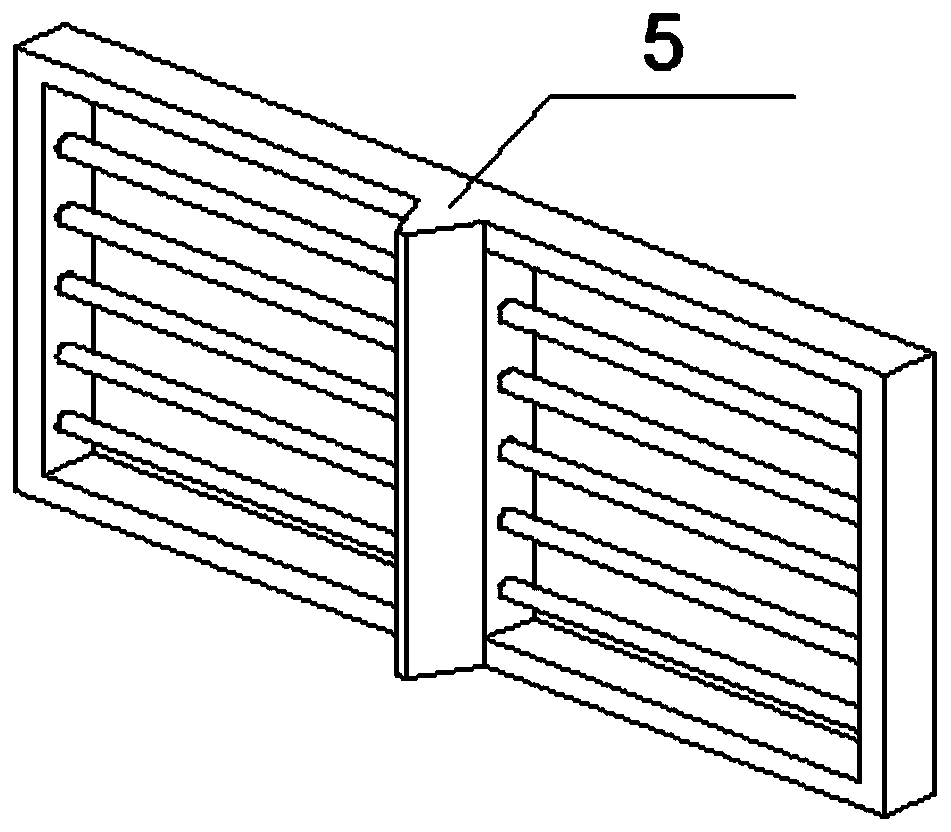

Range hood with air regulation function

ActiveCN103353137AGuaranteed compensationIncrease or decrease output powerDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

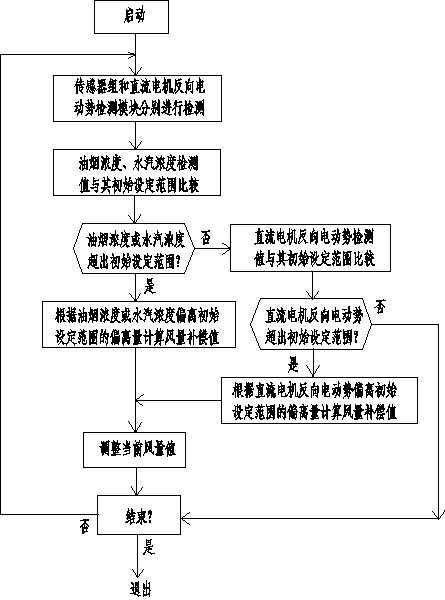

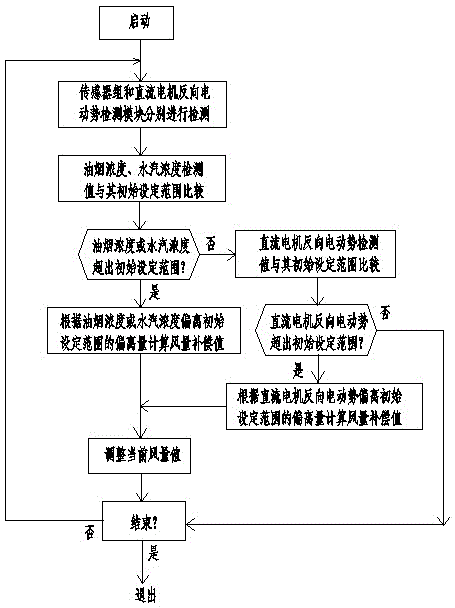

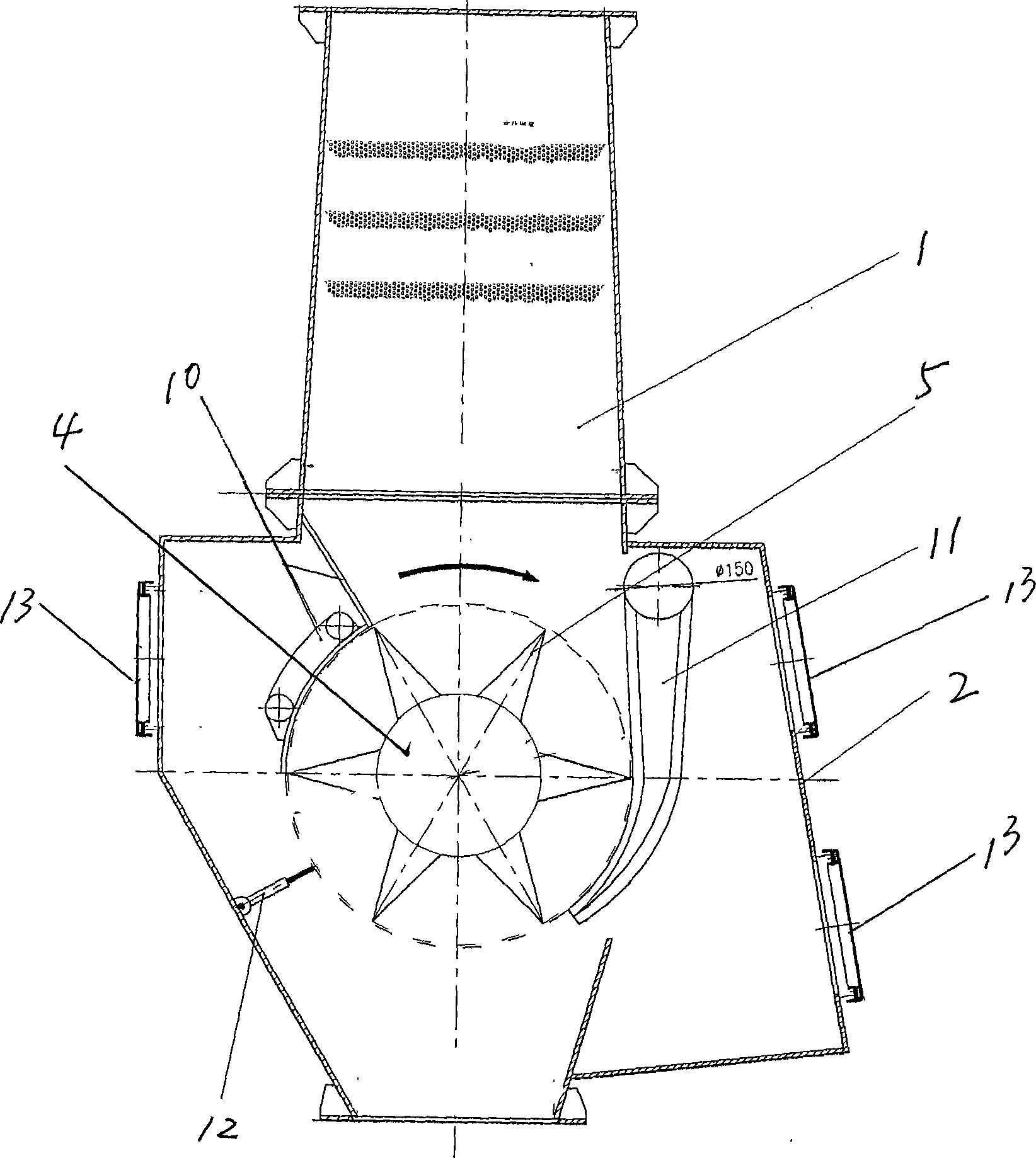

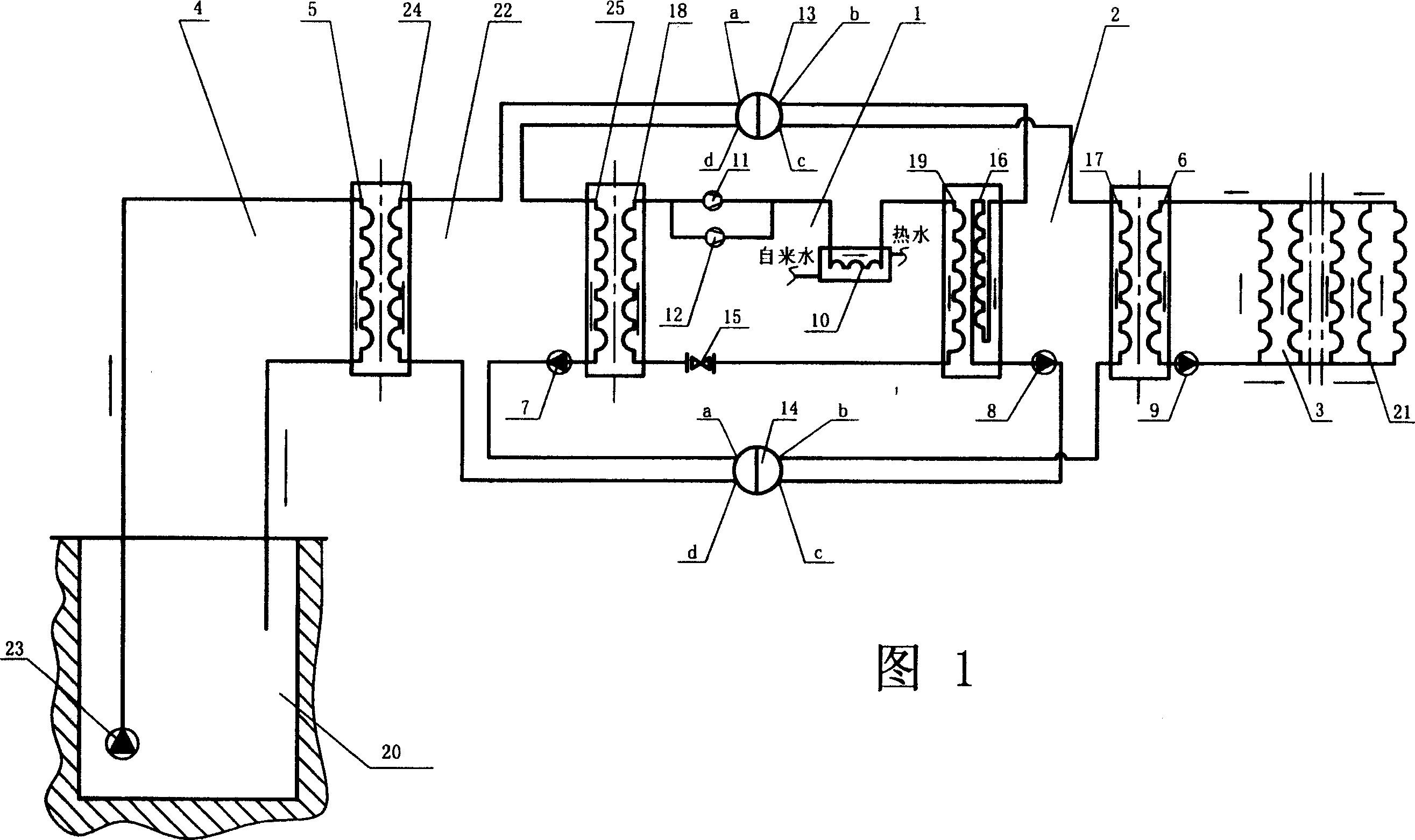

The invention discloses a range hood with an air regulation function. The range hood comprises a body, a sensor group, an air channel, an operation panel, a controller, a direct current motor and fan blades, wherein the air channel, the operation panel, the controller, the direct current motor and the fan blades are installed on the body. The range hood is characterized in that the sensor group is arranged, the controller comprises a central processor, the sensor group is installed at an air inlet, detects oil smoke and vapor concentrations at the air inlet during operation of the range hood and feeds back the oil smoke and vapor concentrations to the central processor, and the central processor carries out integrated computation so as to obtain an air volume value and controls the revolving speed of the direct current motor. The range hood provided by the invention overcomes the problem that a conventional range hood cannot integratedly handle influence of a kitchen environment and shared flues on oil smoke absorption effects and has the advantages of noise reduction, energy conservation and environment friendliness.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

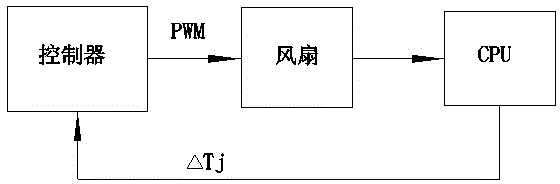

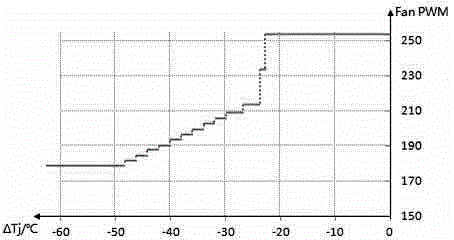

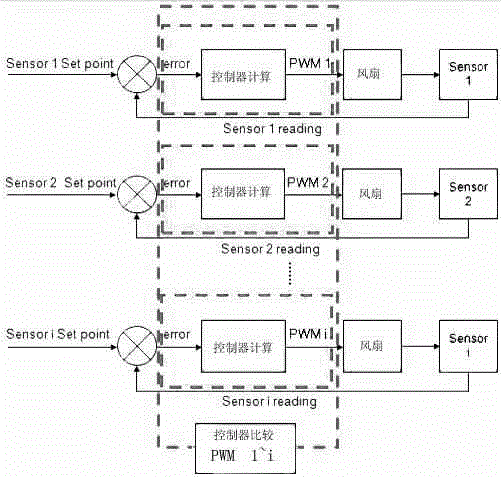

Method for accurately controlling rotating speed of fan

InactiveCN104454616AReduce fan noiseImprove timeliness and accuracyDigital data processing detailsEngine controlEngineeringFeedback control

The invention provides a method for accurately controlling the rotating speed of a fan and relates to the field of system heat dissipation. The method comprises the steps that difference values of actual temperatures read by a plurality of sensors and a preset temperature are simultaneously calculated and compared, the fan PWM capable of meeting the need for heat dissipation of all monitored heat emitting points at the same time is determined through certain mathematical calculation, and finally the PWM is transmitted to the fan through a mainboard to achieve the real-time monitoring and quick feedback control over the rotating speed of the fan.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

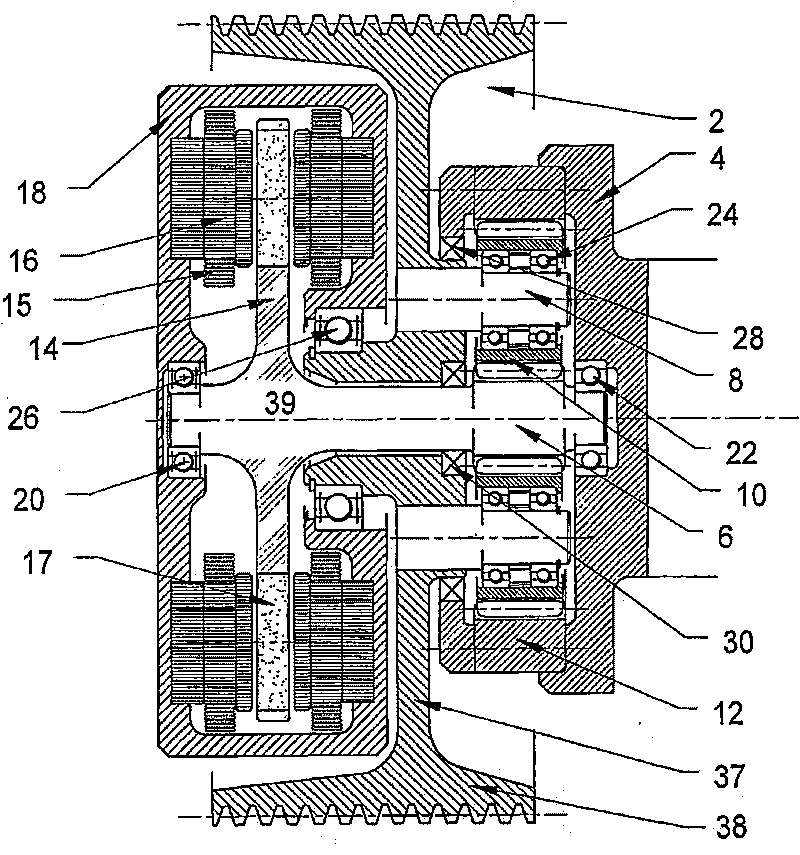

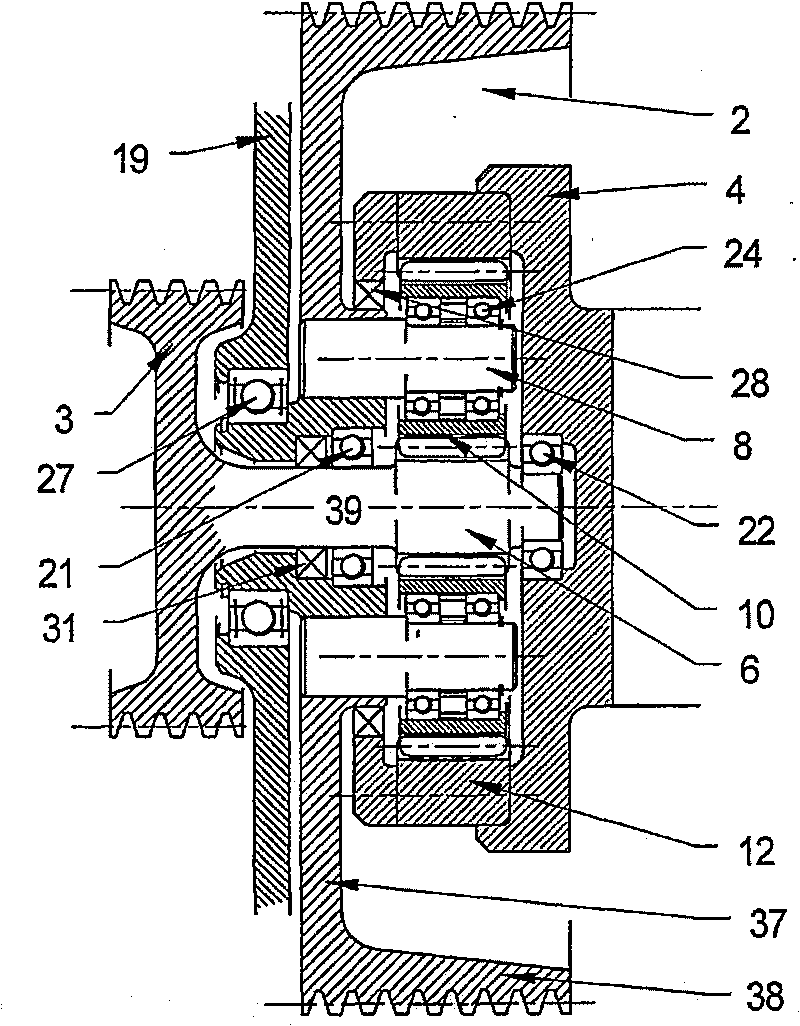

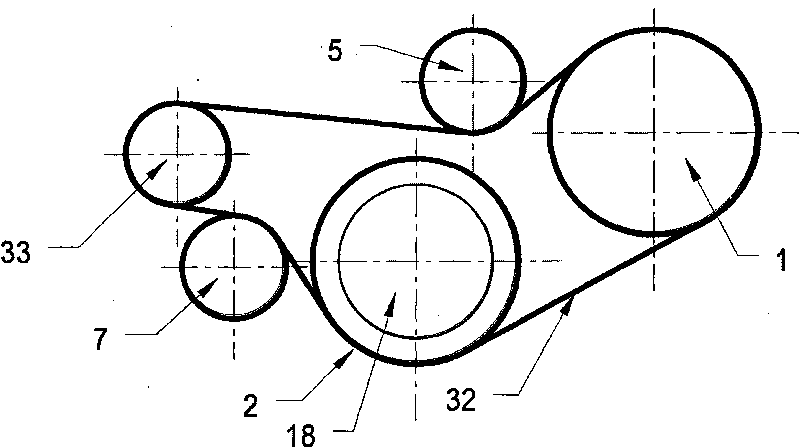

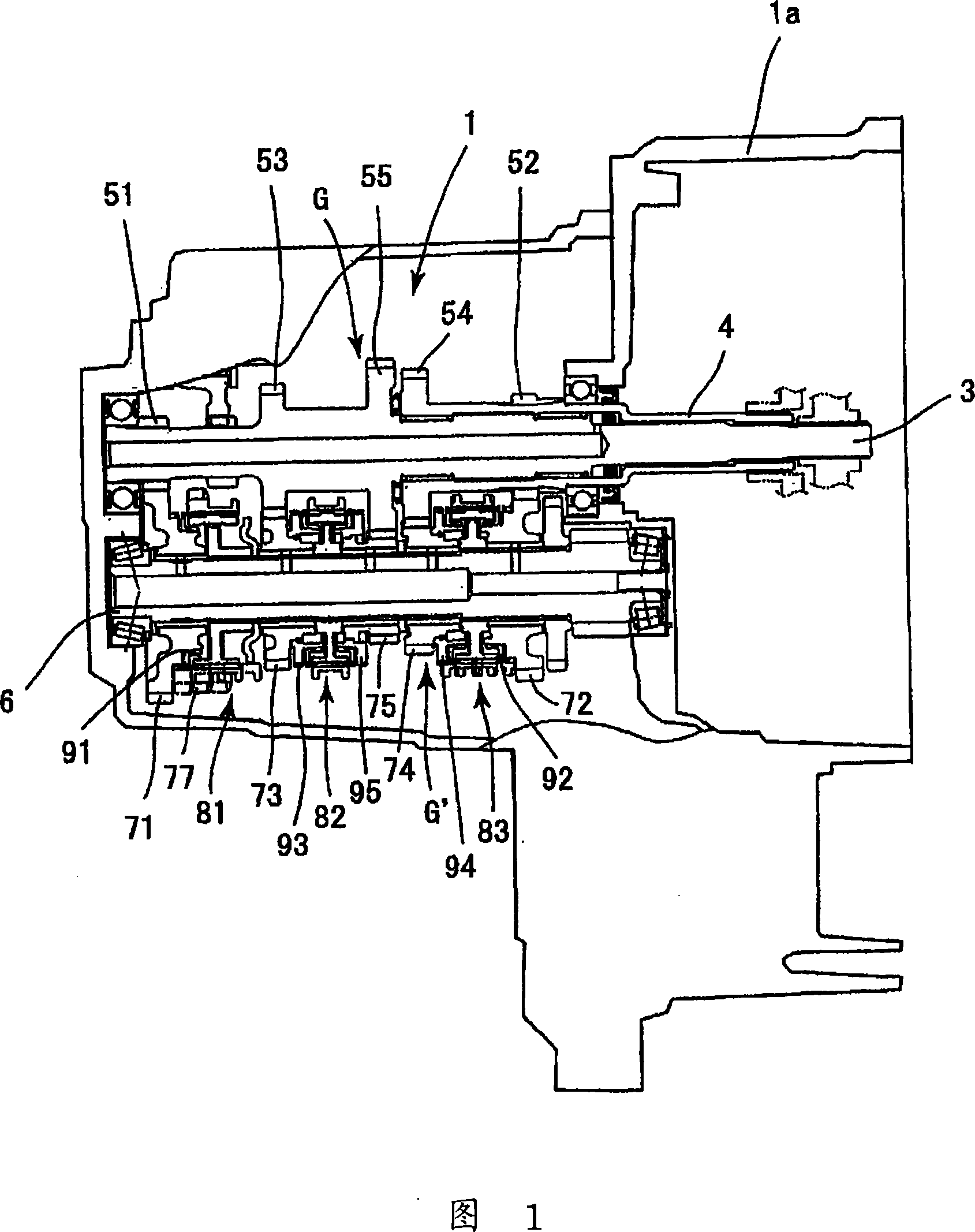

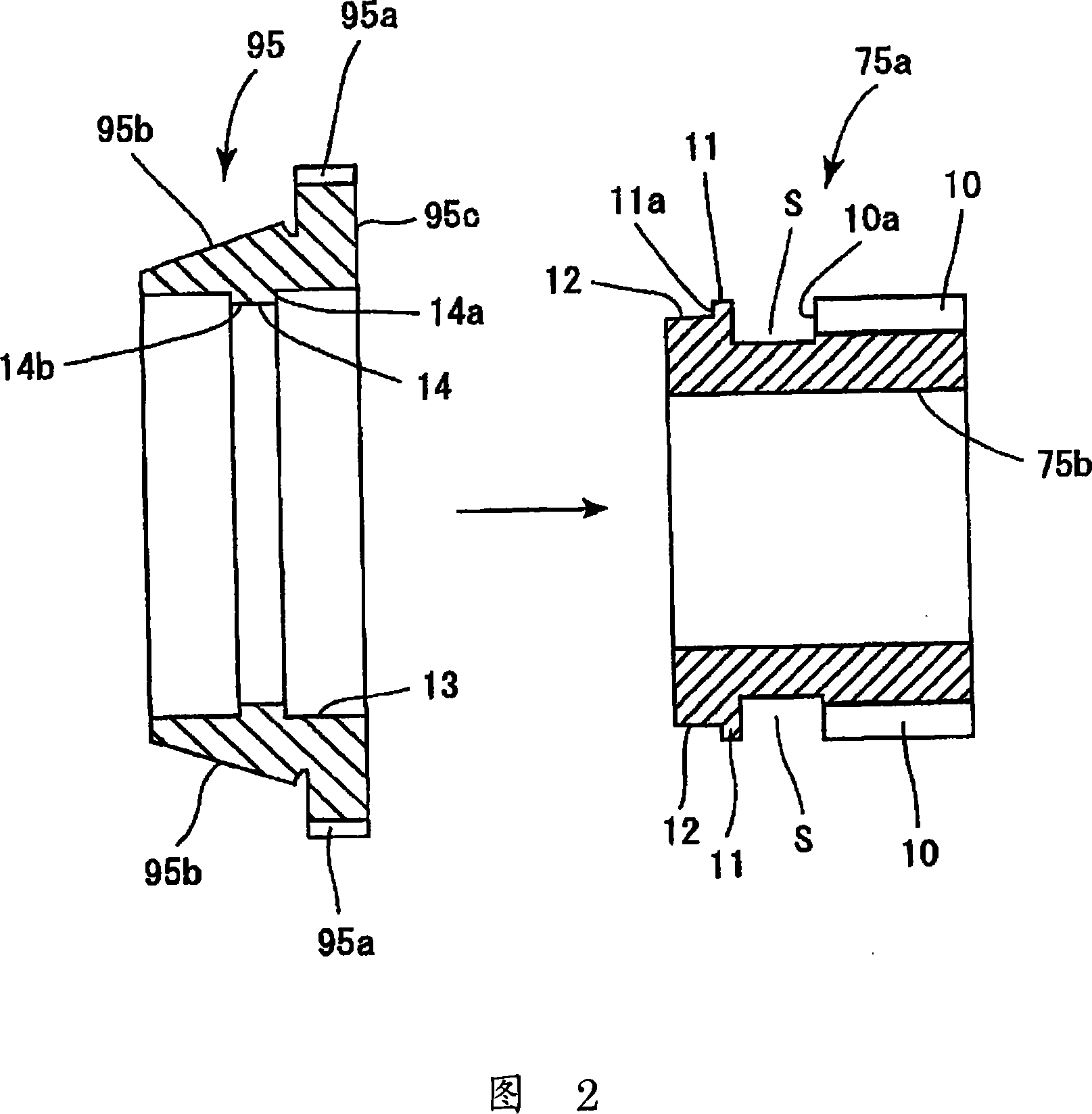

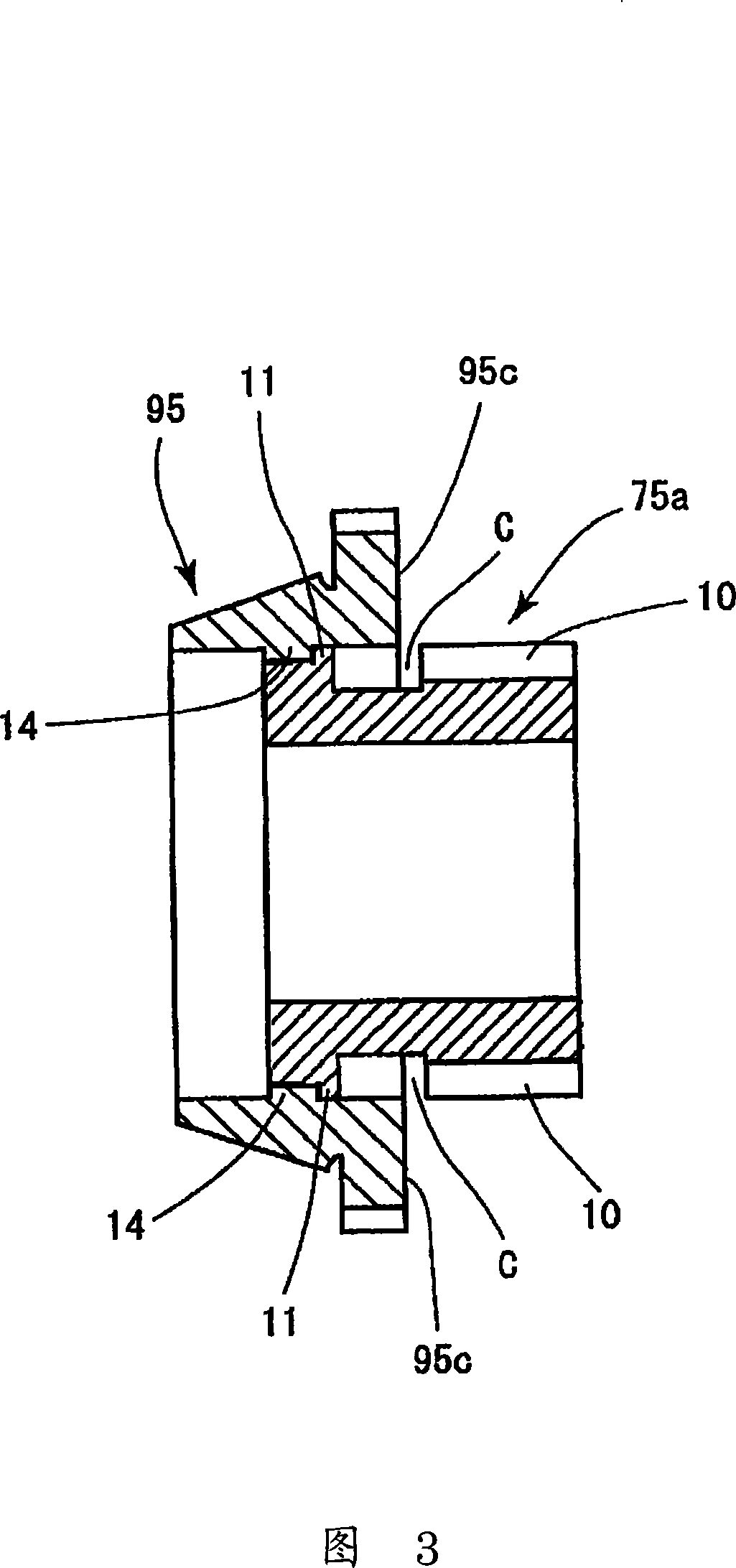

Drive pulleys

InactiveCN101720396AImprove efficiencyAvoid wastingToothed gearingsMechanical energy handlingCommon carrierElectrical connection

A drive pulley, particularly for automotive auxiliary equipment, includes an input for connection to an engine (80) and an output. One of the input and output comprises a hollow cylindrical member (38) whose outer surface constitutes a pulley belt engagement surface. The input and output are connected by a transmission system including an epicyclic gearset. The planet shafts (8) are connected to a common carrier (37). The system further includes two electric motor / generators, the rotors (14, 90) of which are connected to the output and a sun gear (6), respectively, the electrical connections on the stators (16, 94) of which are connected to a controller (85) arranged selectively to control the flow of electrical power between them. The transmission is at least partially accommodated within the hollow cylindrical member (38). The input is connected to an annulus gear (12) and the output is connected to the carrier (37). At least one of the motor / generators is remote from the hollow cylindrical member (38) and the gearset is at least partially accommodated within the hollow cylindrical member (38).

Owner:NEXXTDRIVE LTD

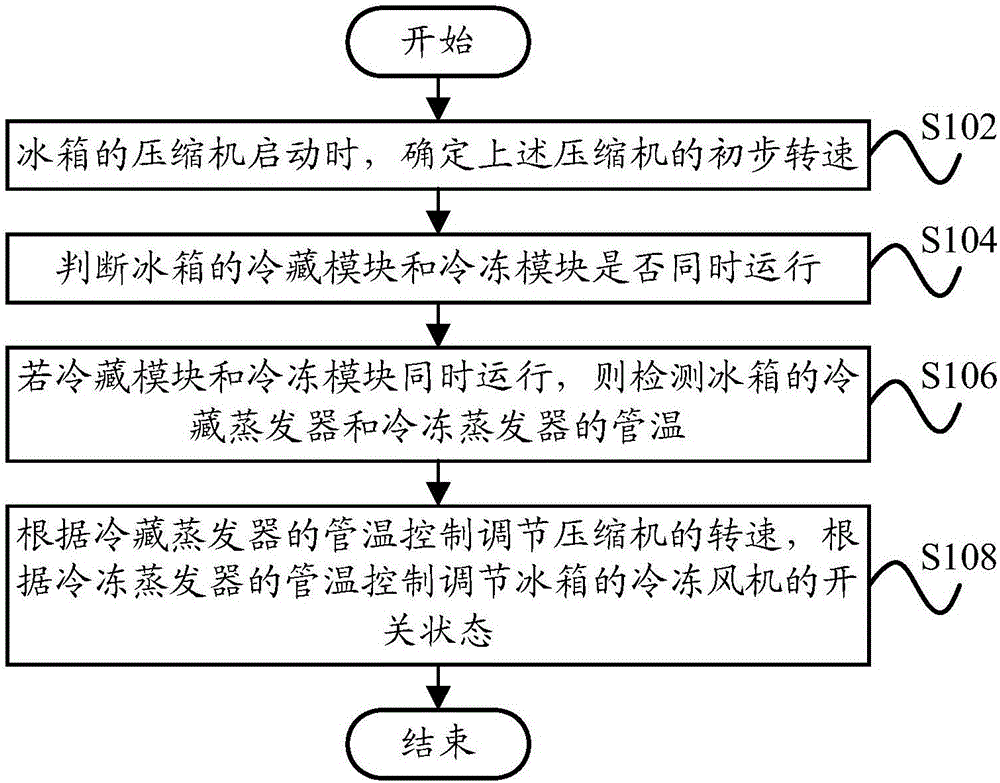

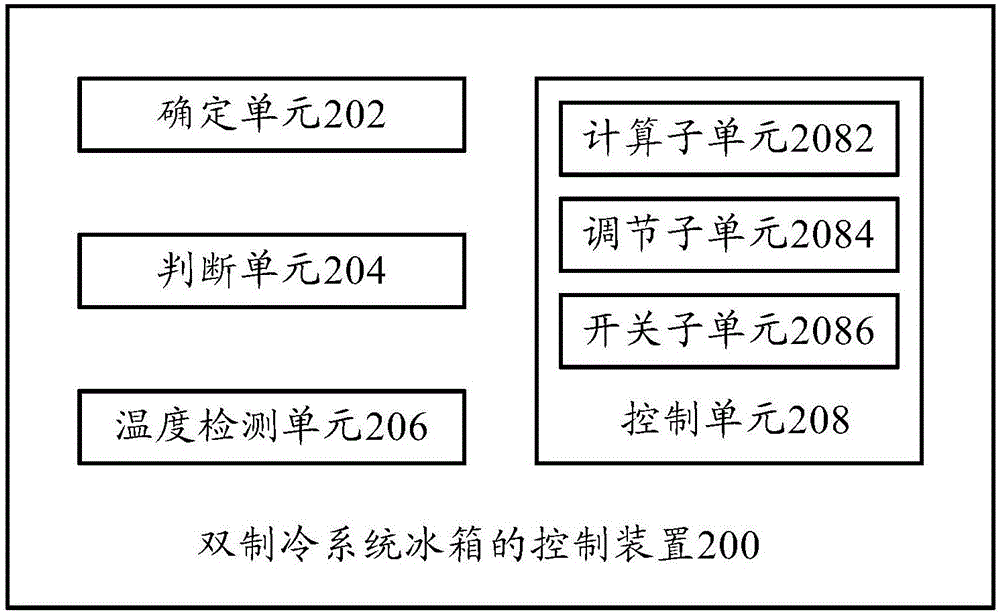

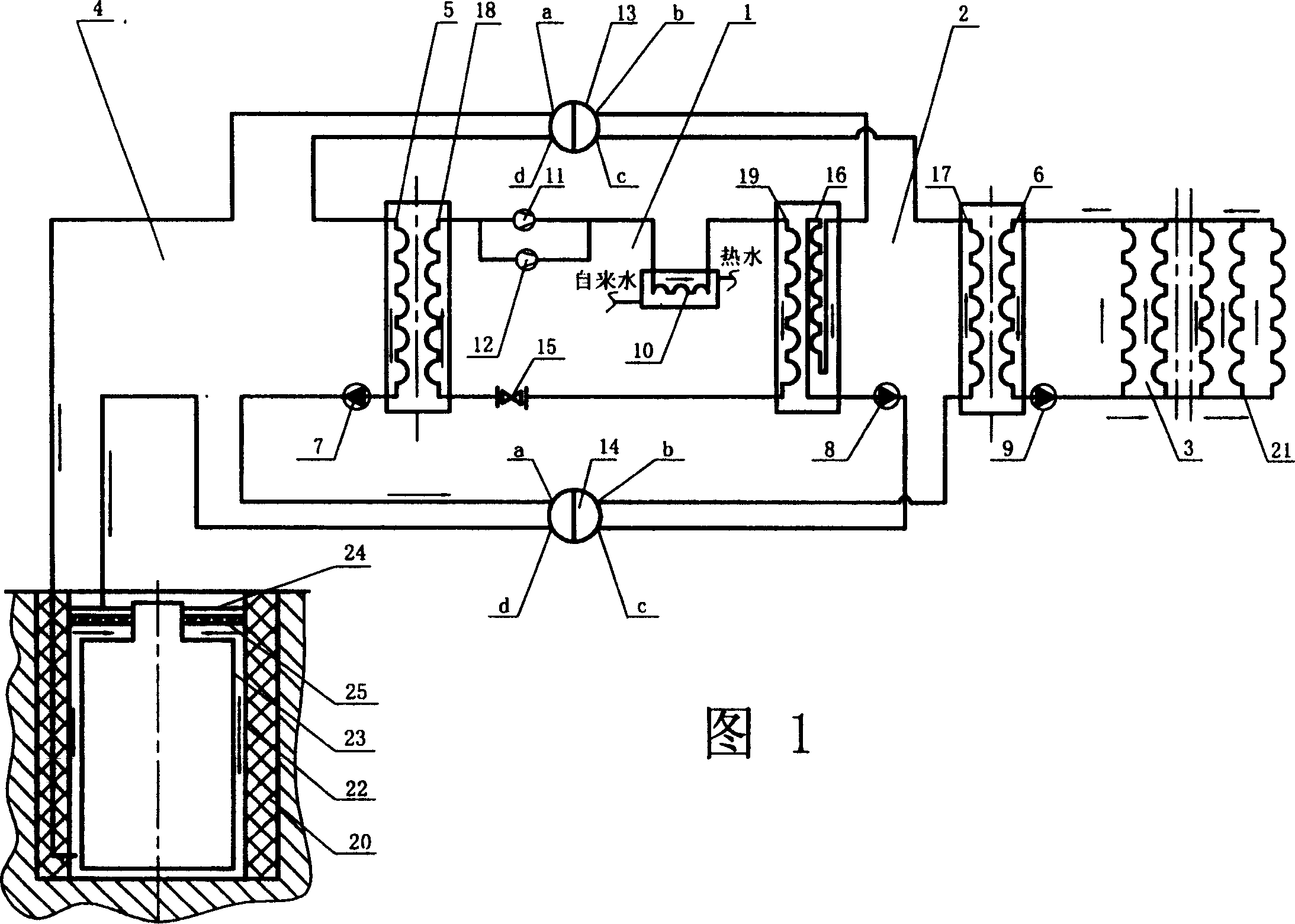

Control method and control device of dual-refrigeration system refrigerator and dual-refrigeration system refrigerator

InactiveCN106839640AImprove operational efficiencySave electricityLighting and heating apparatusCooling fluid circulationEngineeringRefrigeration

The invention provides a control method and control device of a dual-refrigeration system refrigerator and the dual-refrigeration system refrigerator. The control method of the dual-refrigeration system refrigerator comprises the following steps: when the compressor of the refrigerator is started, determining the initial rotating speed of the compressor; judging whether a cold storage module and a freezing module of the refrigerator run simultaneously; if yes, detecting tube temperature of a cold storage evaporator and a freezing evaporator of the refrigerator; and controlling and adjusting the rotating speed of the compressor according to the tube temperature of the cold storage evaporator, and controlling and adjusting the on-off state of a freezing draught fan of the refrigerator according to the tube temperature of freezing evaporator. According to the technical scheme, the refrigerating capacity of the compressor is matched with the thermal load of a system to improve the operating efficiency of the compressor, so that the operating efficiency of the refrigerator refrigerating system is improved, energy consumption is reduced, and electric energy is saved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

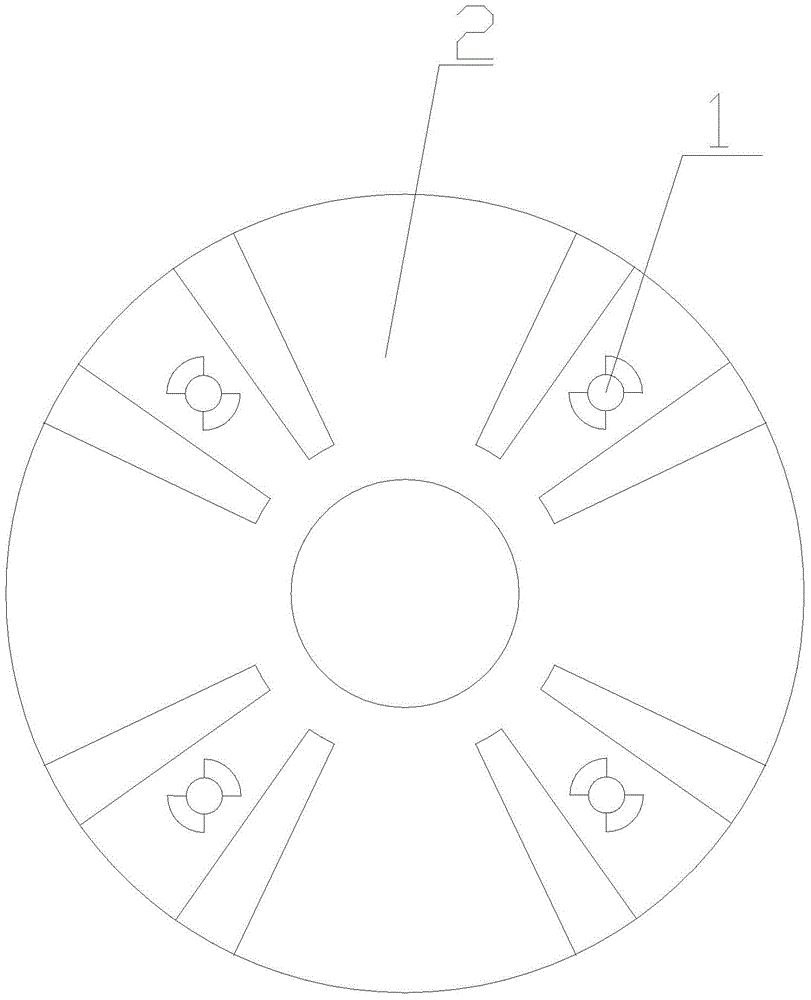

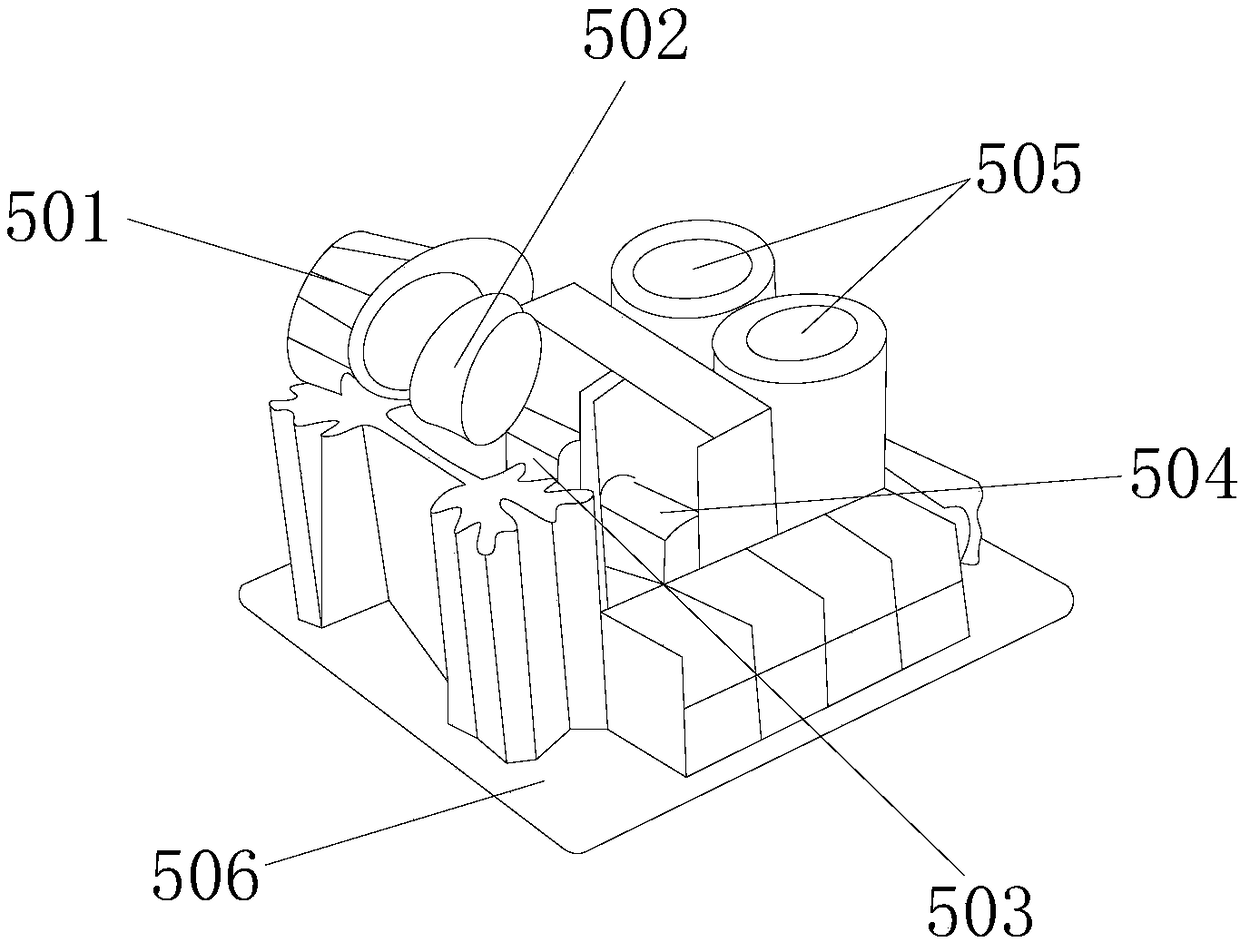

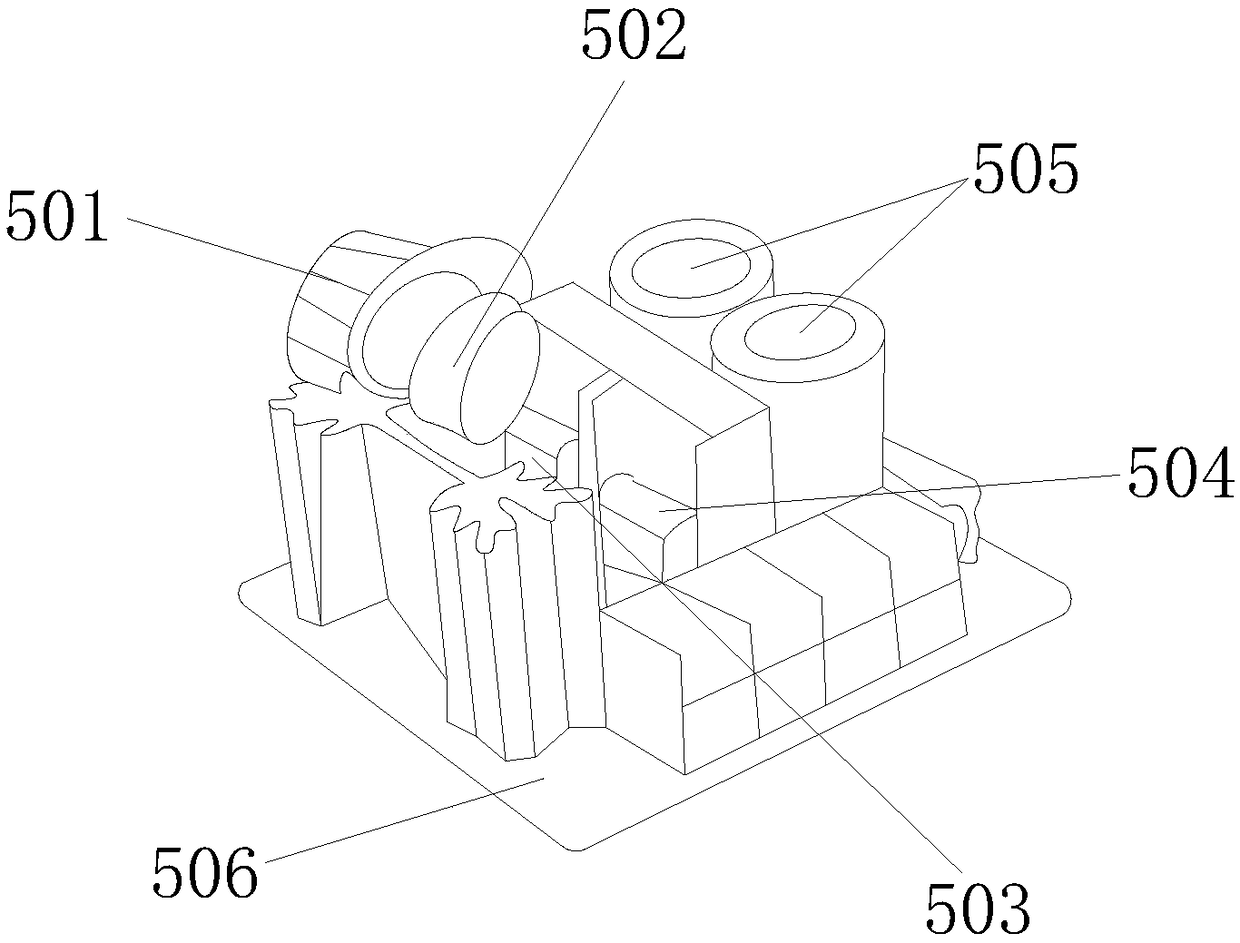

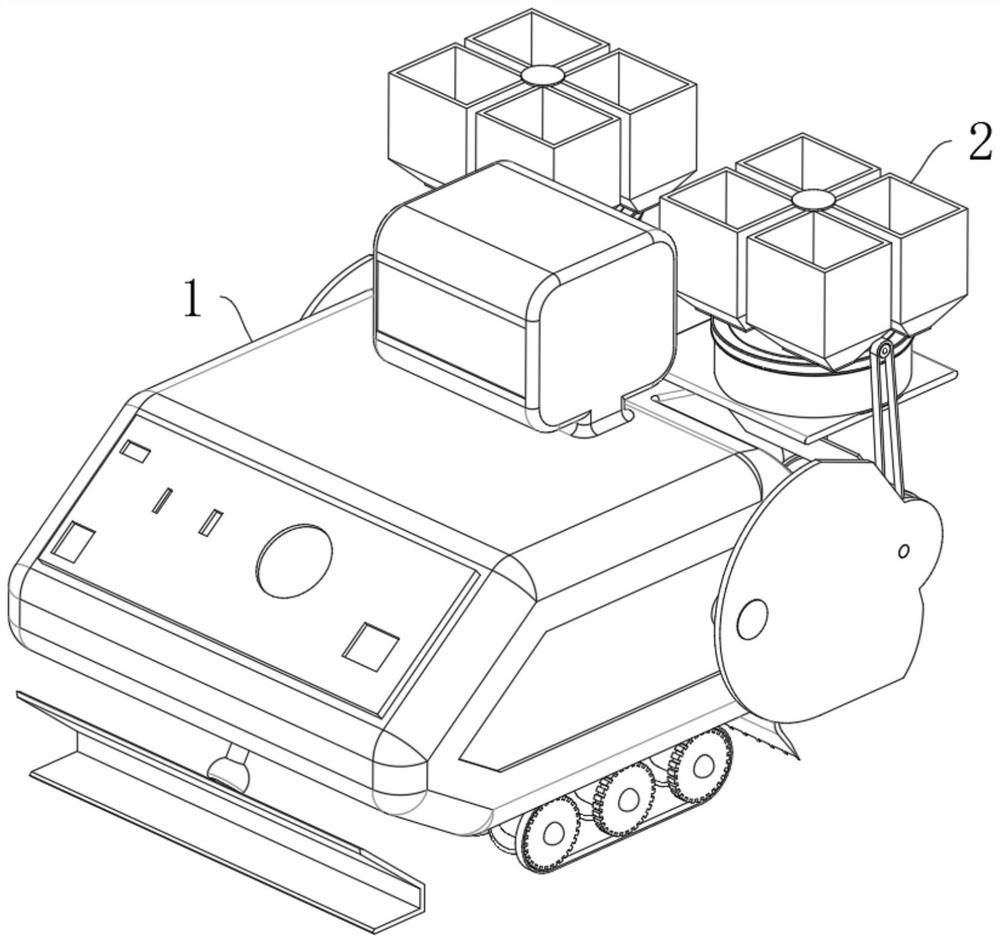

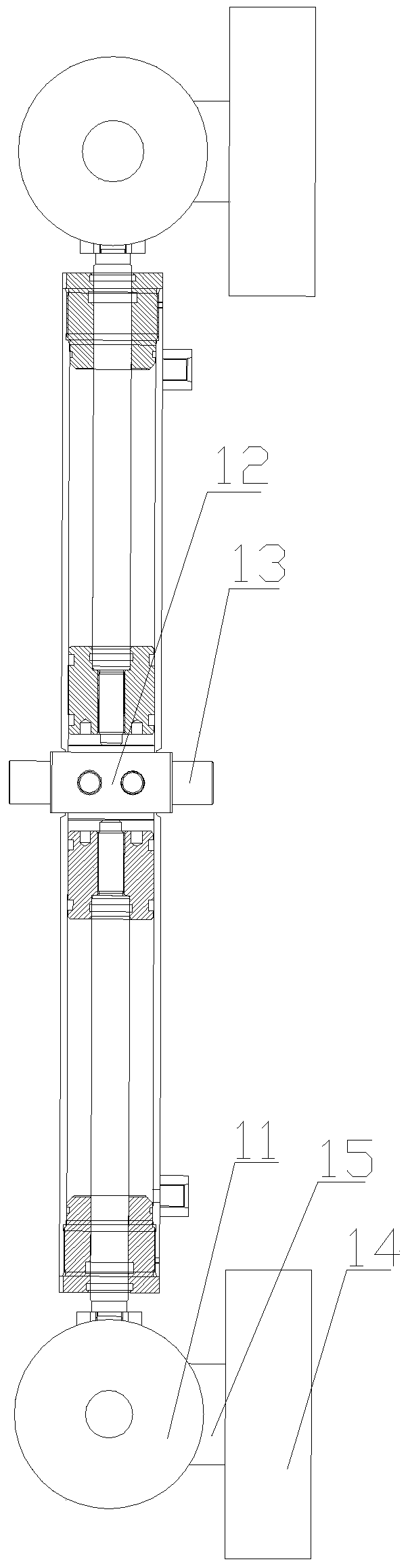

Active telescopic shield cutter mechanism

The invention relates to the field of manufacturing of shield cutters, in particular to an active telescopic shield cutter mechanism. A body comprises reamer assemblies and a cutter disc, the reamer assemblies are arranged on the cutter disc, and the four reamer assemblies are arranged in the center of the cutter disc in the circumferential direction at equal interval. Each reamer assembly comprises a cutter bit body, a speed reducer, a variable displacement motor and a sliding rail device, the cutter bit bodies are arranged in the sliding rail devices, the sliding rail devices are arranged in the cutter disc, the speed reducers are arranged on the rear sides of the cutter bit bodies, the variable displacement motors are arranged on the rear sides of the speed reducers, and hydraulic oil pipes are arranged on the rear sides of the variable displacement motors. The active telescopic shield cutter mechanism has the advantages that when a shield mechanism encounters large-diameter pumice stone, boulders and local hard rock in the tunneling process, an active telescopic cutter is adopted, the rotating speed of the cutter can be instantly improved or reduced easily, and breaking and tunneling can be carried out more easily.

Owner:蚌埠市行星工程机械有限公司

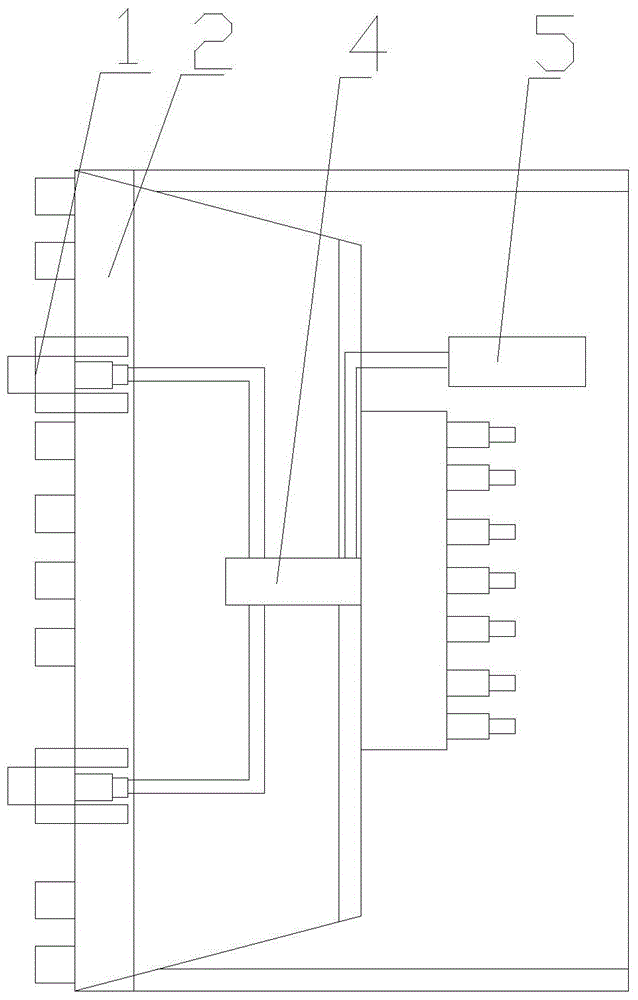

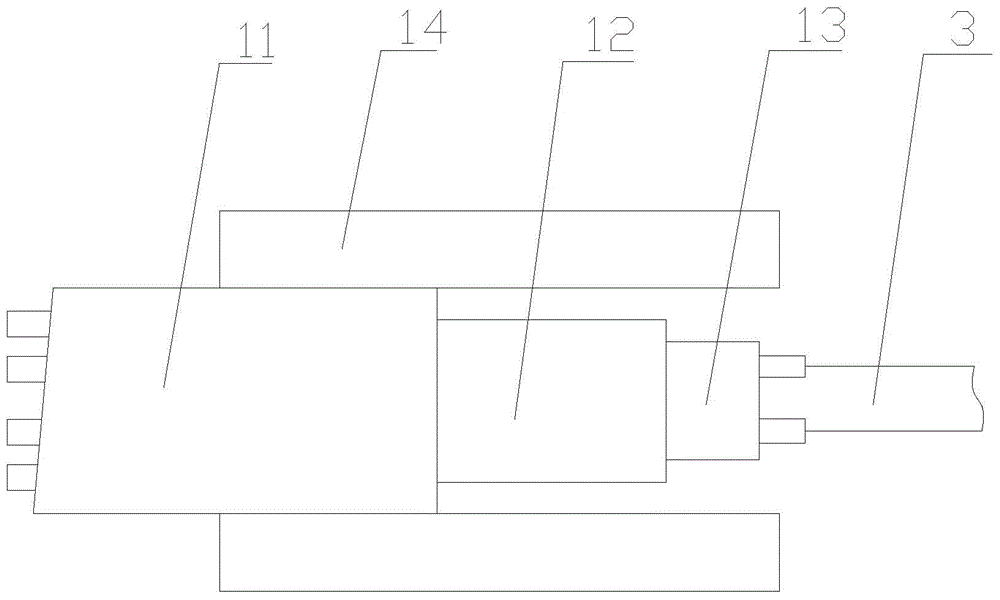

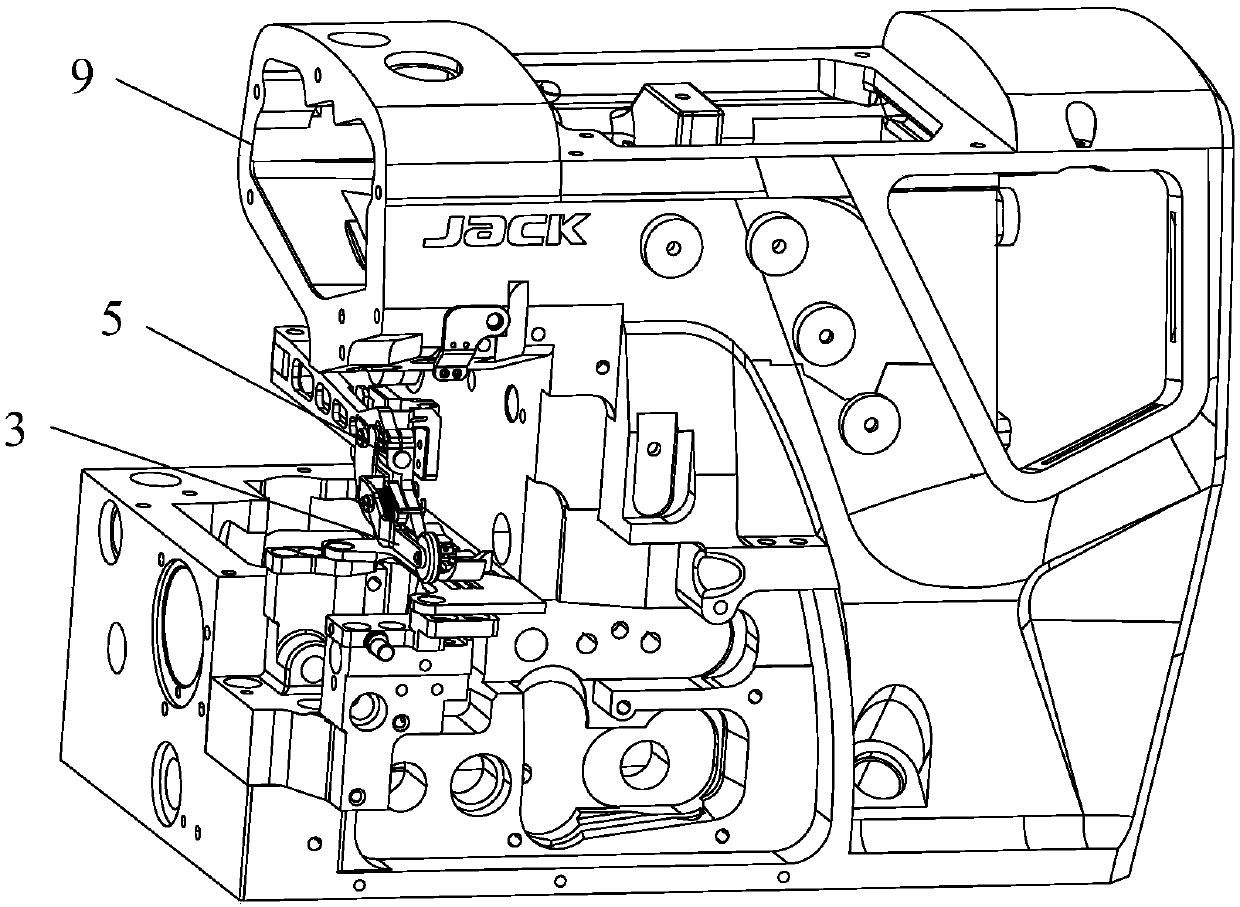

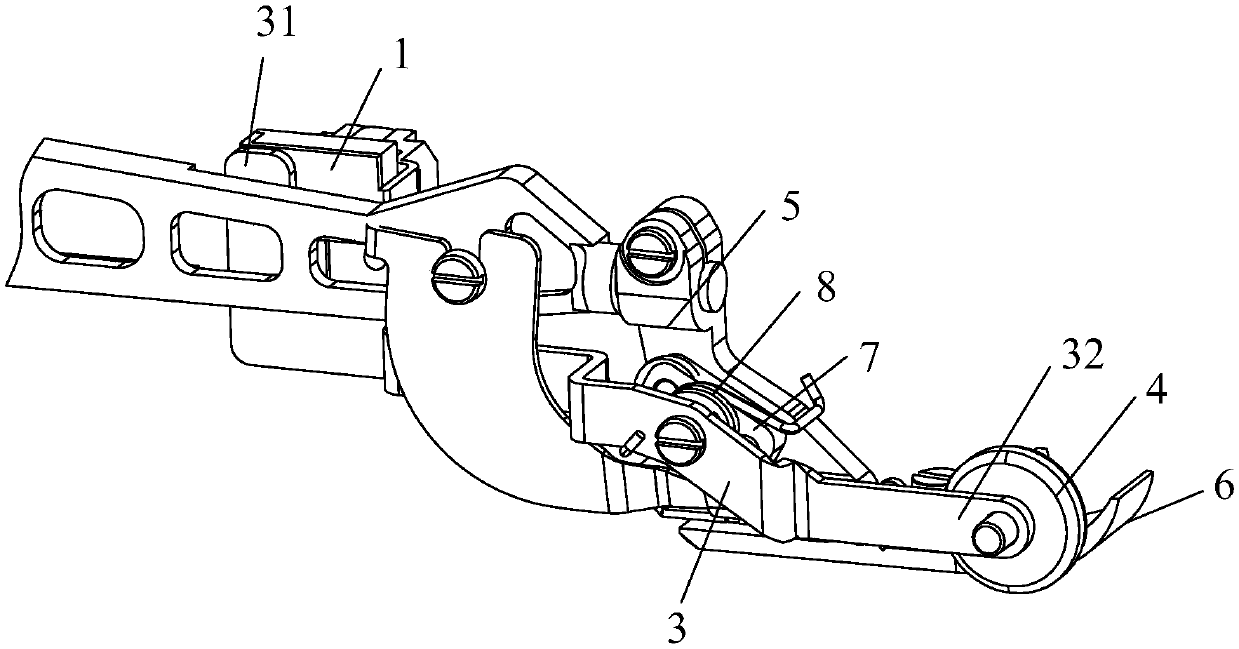

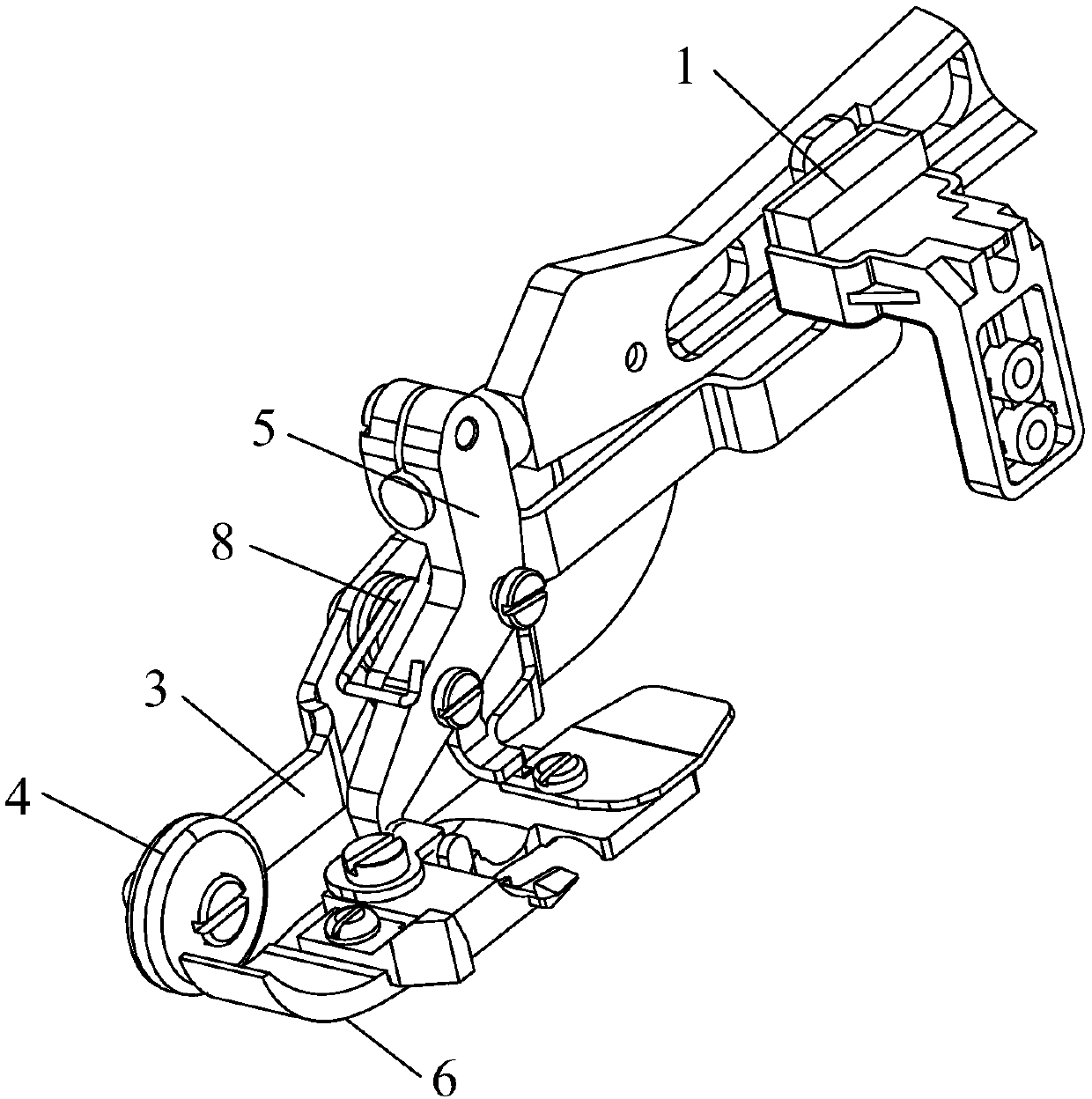

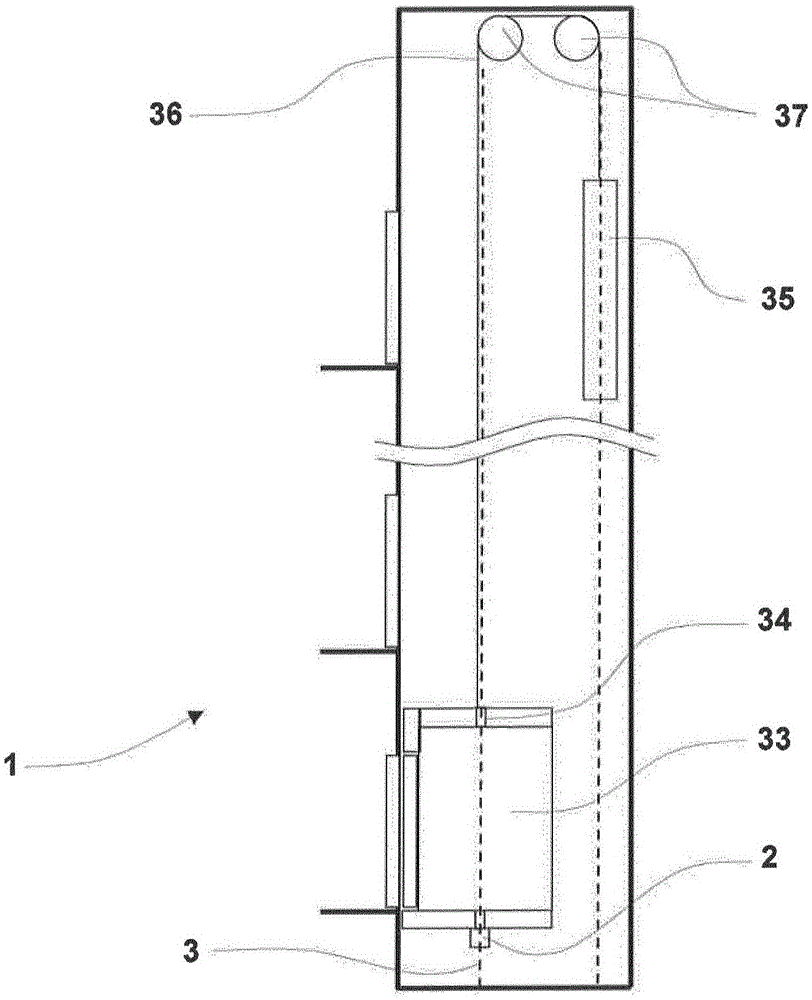

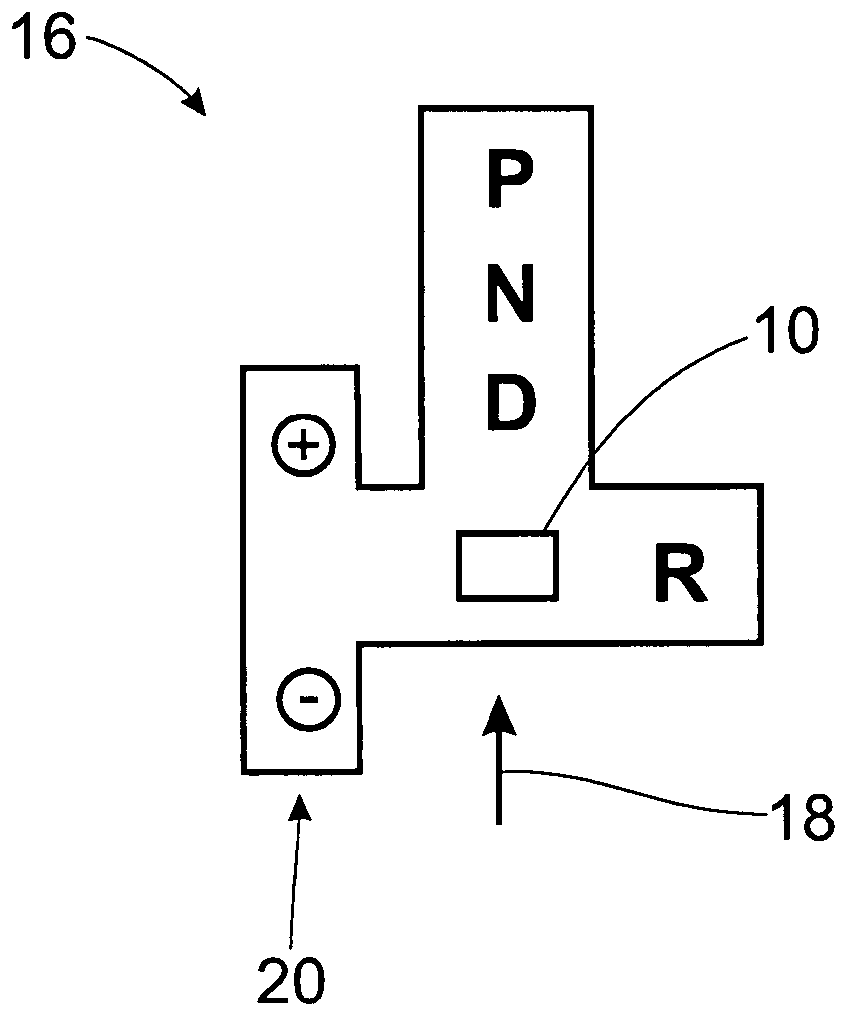

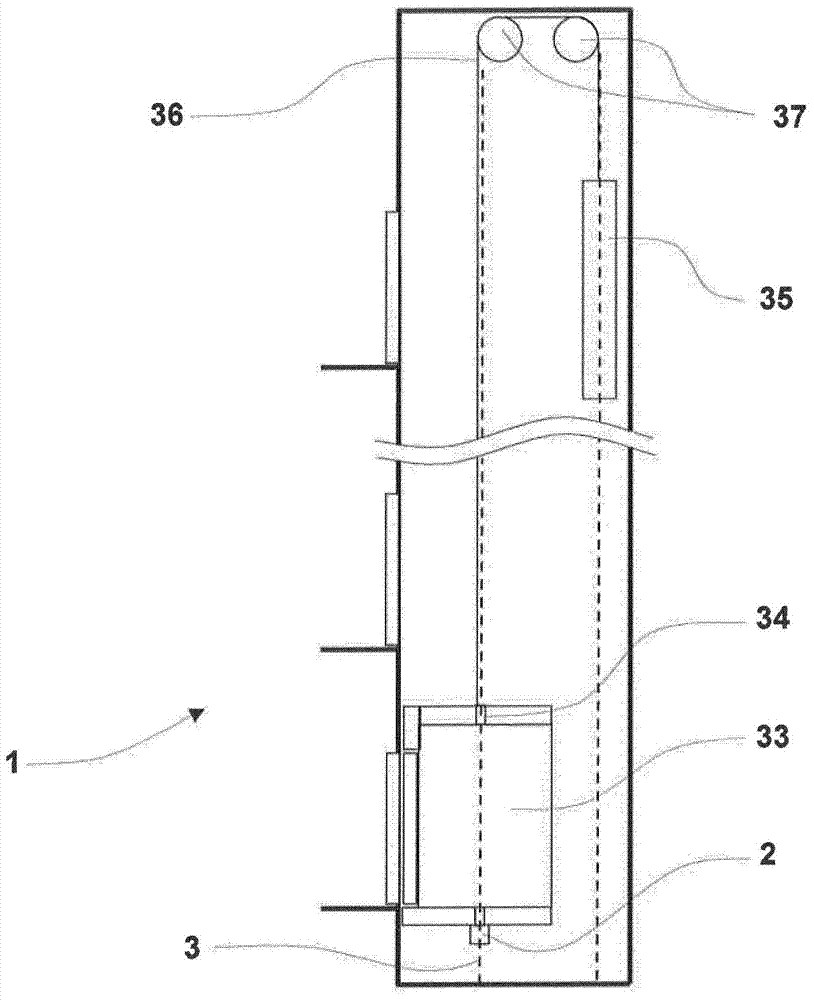

Sewing material thickness detection device and sewing machine

InactiveCN110042582AIncrease or decrease speedDecrease or increase speedSewing-machine control devicesElectric machineryComputer module

Owner:JACK SEWING MASCH CO LTD

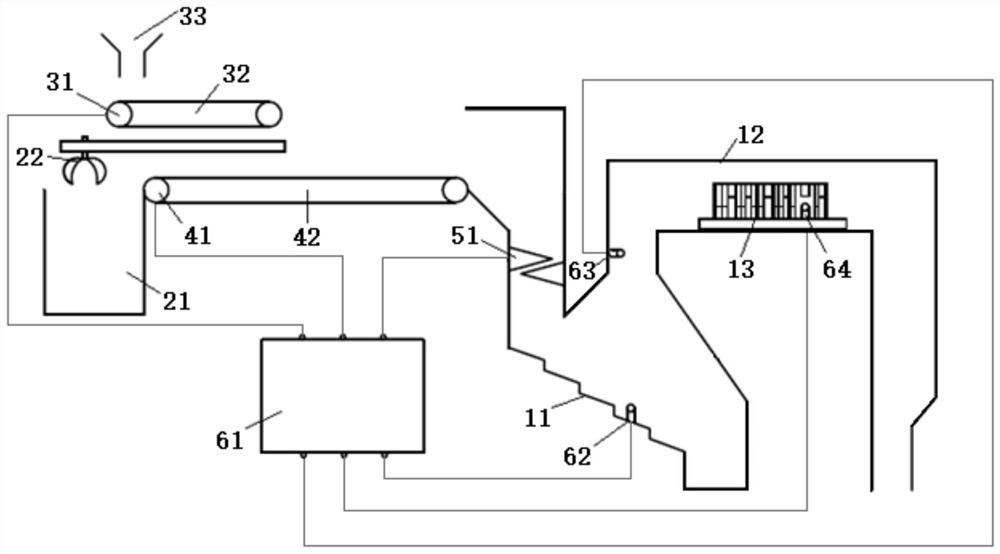

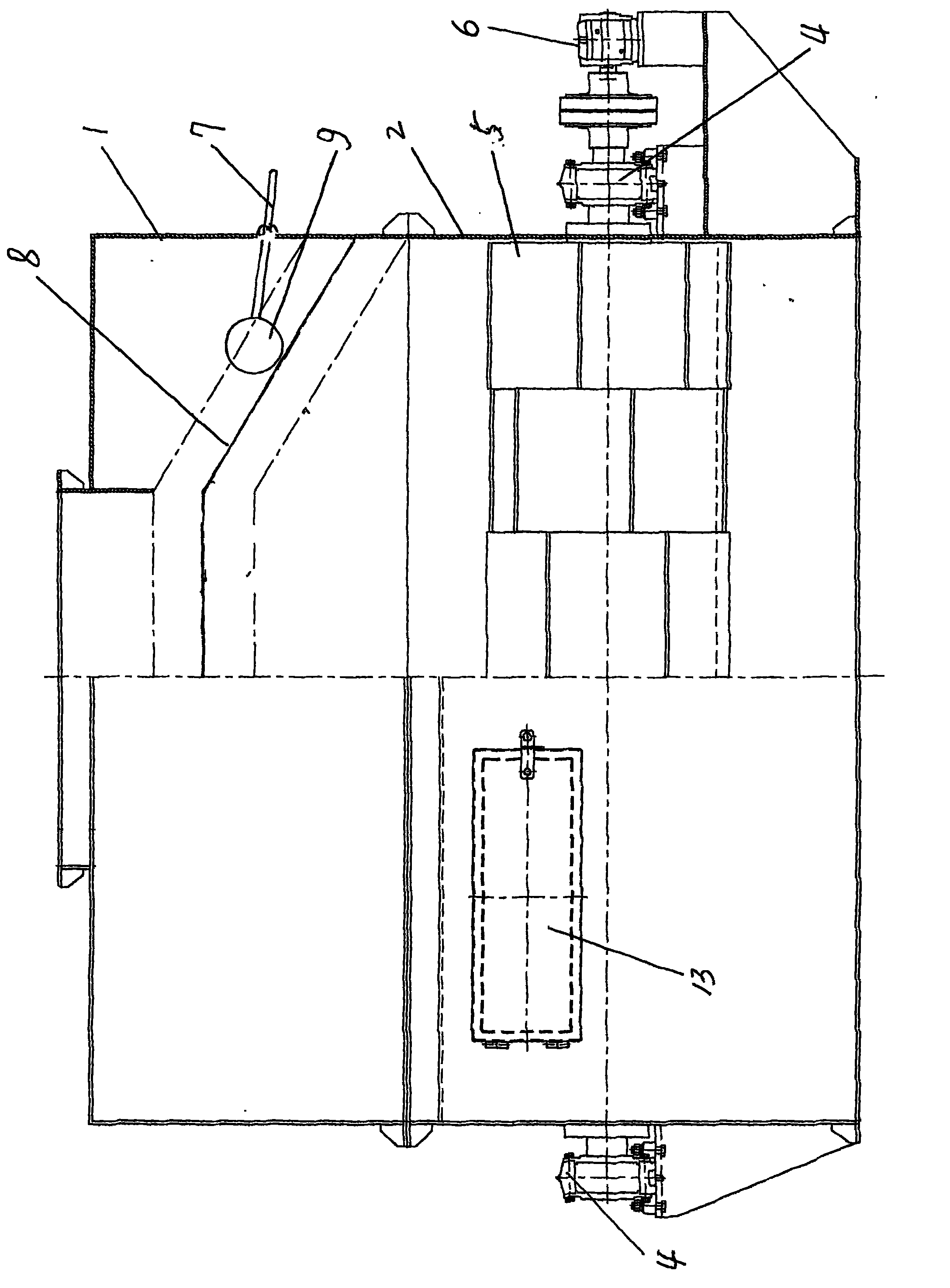

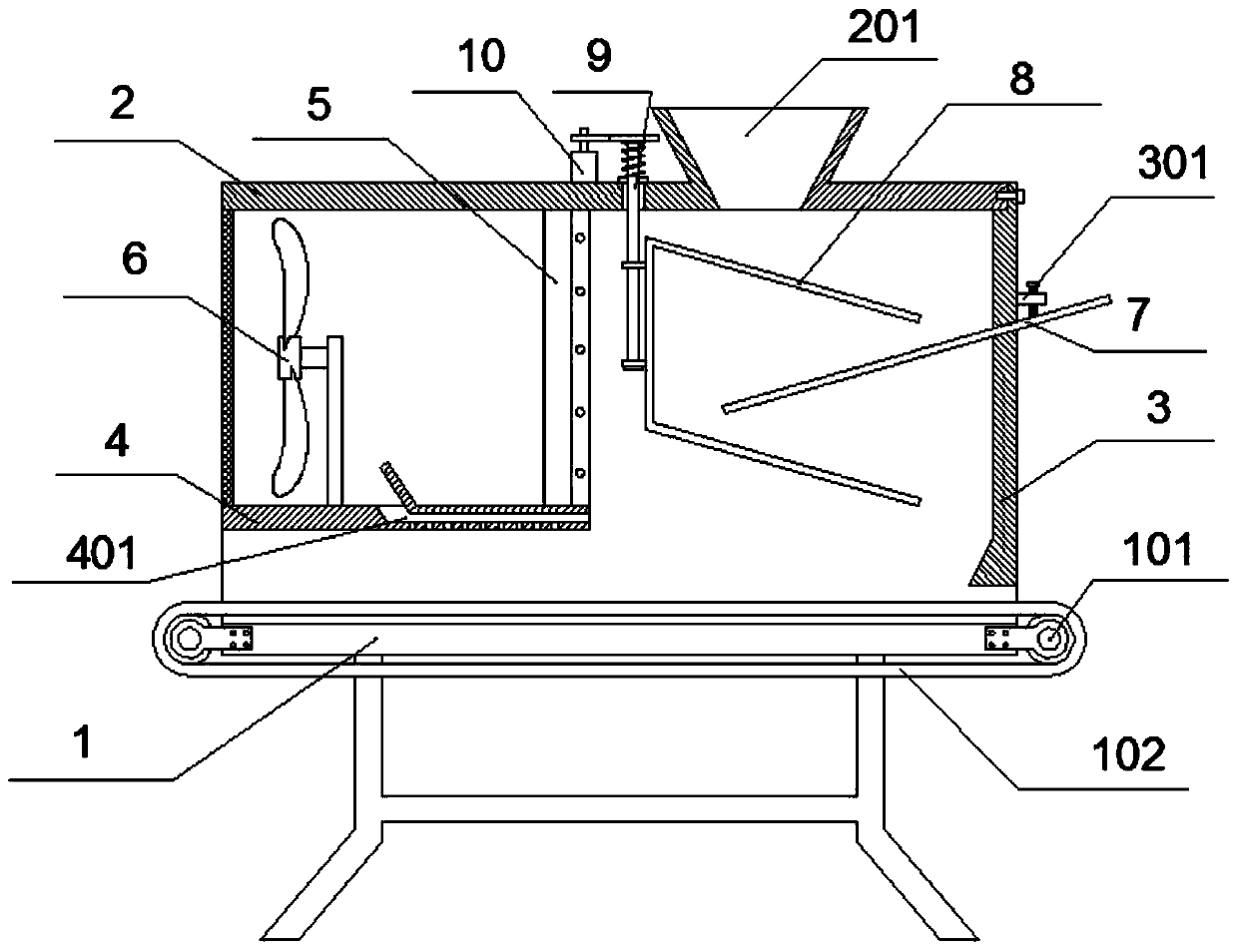

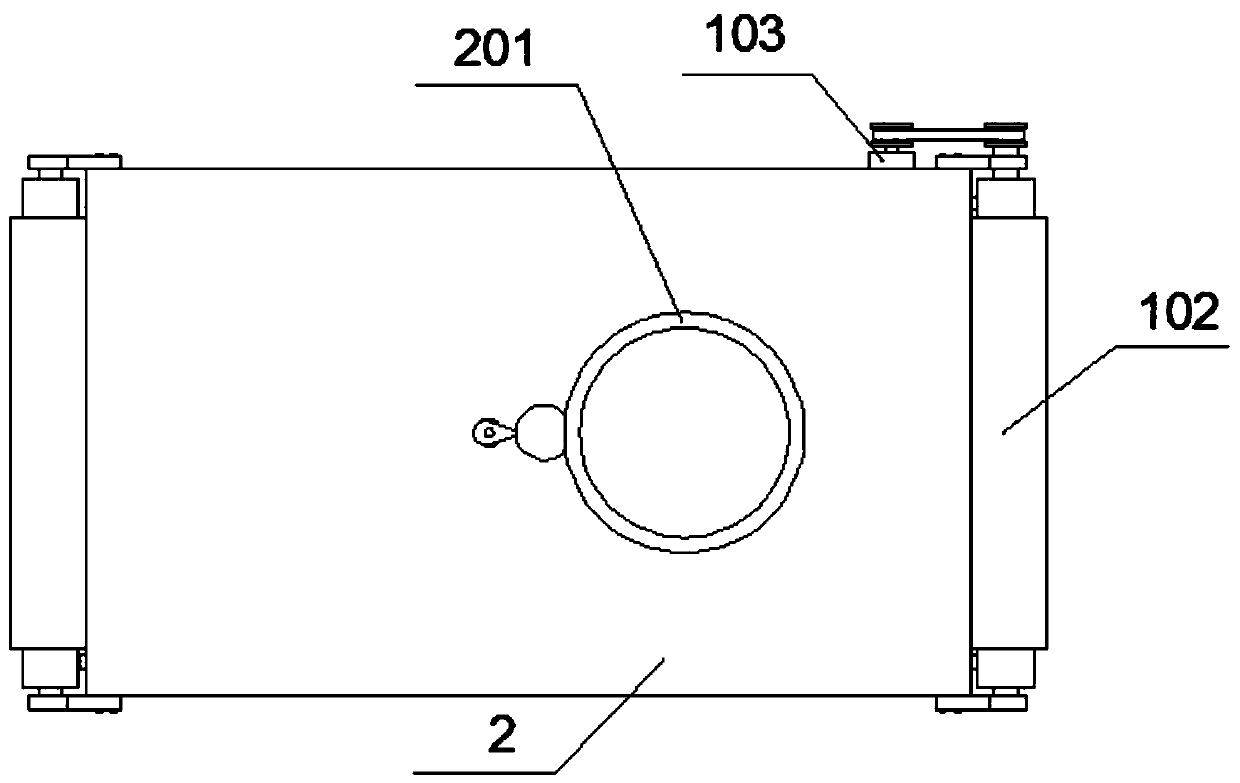

Mixed feeding device capable of automatically adjusting blending combustion amount of stale garbage

PendingCN112728554AIncrease the blending ratioSlow down the feed rateIncinerator apparatusThermodynamicsMixed feeding

The invention discloses a mixed feeding device capable of automatically adjusting the blending combustion amount of stale garbage. The mixed feeding device comprises a mechanical grate furnace, a mixed garbage conveying device, a raw garbage feeding device, a stale garbage feeding device, a mixed garbage crushing device and a control center. The raw garbage feeding device, the stale garbage feeding device and the mixed garbage conveying device are all connected with the control center. The stale garbage feeding device is used for transporting stale garbage to the raw garbage feeding device. The raw garbage feeding device is located between the stale garbage feeding device and the mixed garbage conveying device. The mixed garbage crushing device is used for chopping garbage and inputting the chopped garbage into the mechanical grate furnace. Multiple temperature sensors are arranged in the mechanical grate furnace, the multiple temperature sensors are connected with the control center, the multiple temperature sensors collect working parameters of the mechanical grate furnace and transmit the working parameters back to the control center, the control center transmits feedback signals to each device, and therefore the blending combustion ratio is controlled and adjusted.

Owner:SOUTH CHINA UNIV OF TECH

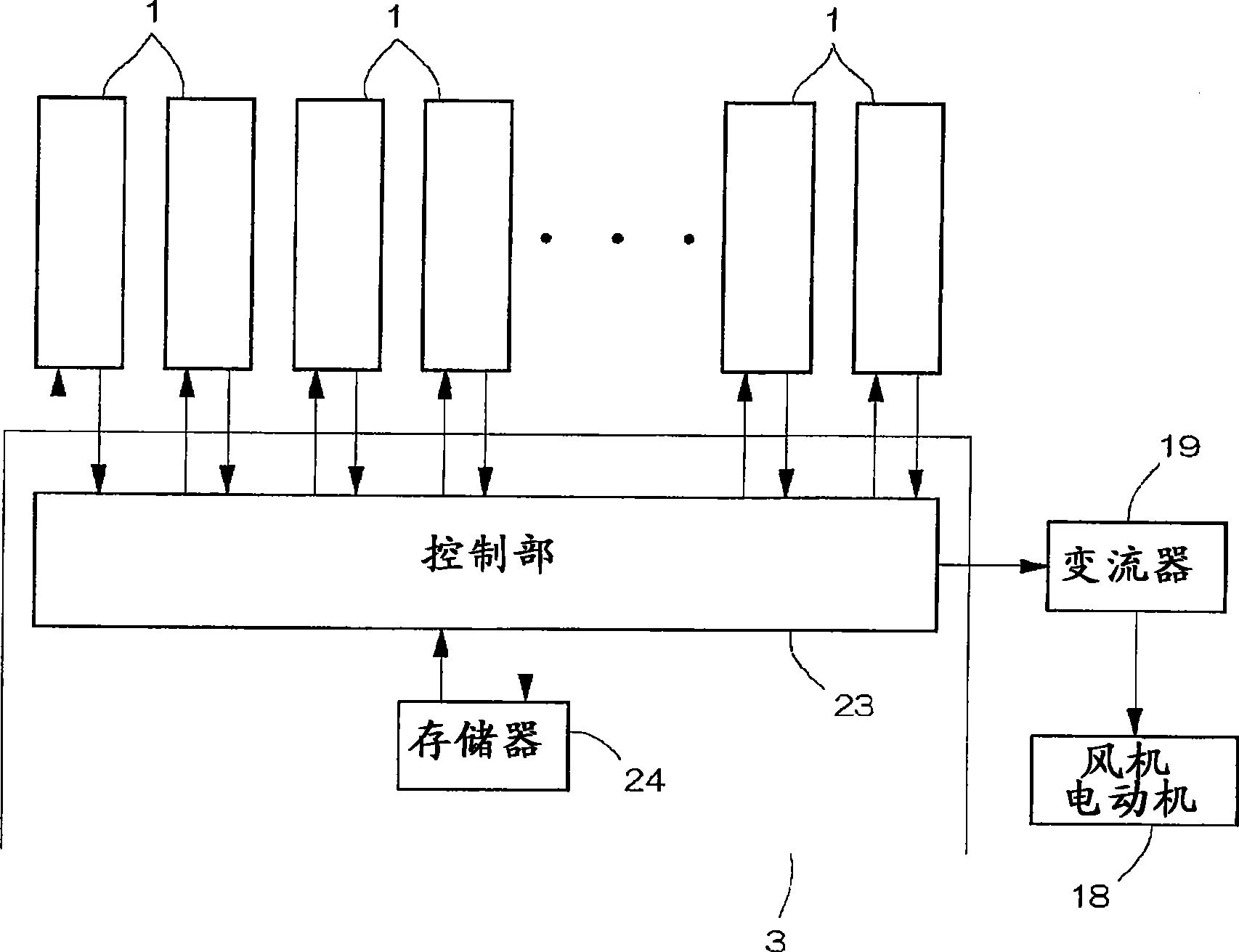

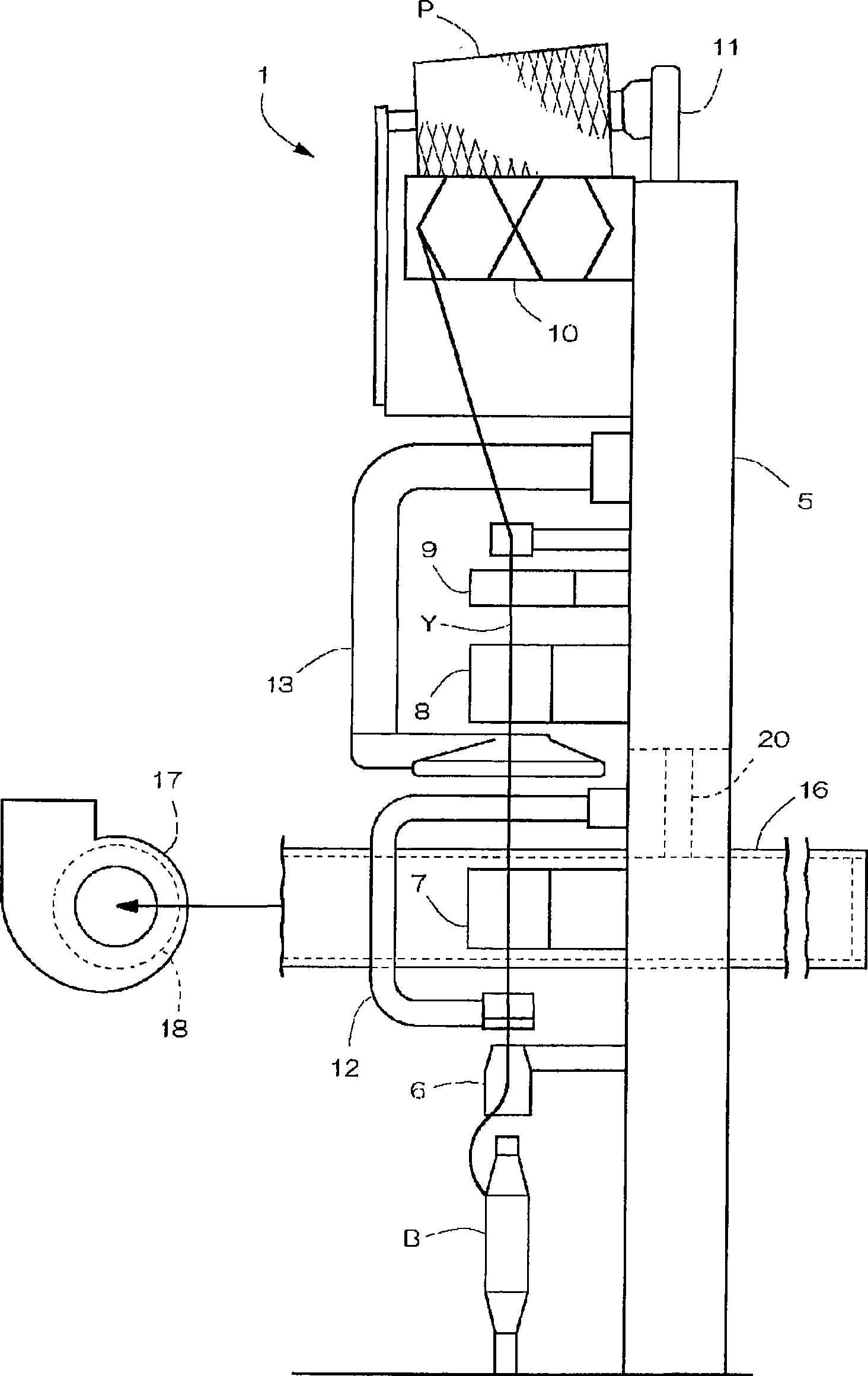

Control method of blower motor and blower motor system

InactiveCN101419473ALow costReduce maintenance costsAC motor controlFilament handlingYarnMotor drive

The present invention enables the rotation speed of a motor driving a blower to be controlled without the need for an additional device such as a sensor. The present invention enables the rotation speed of the motor driving the blower to be controlled while supplying a minimum required negative pressure. The present invention thus saves required energy while smoothly operating an automatic winder. The number of yarn splicing operation in each winding unit 1 and the number of failures in yarn splicing are counted to calculate the mistake rate of the whole system. On the basis of the calculated mistake rate, the output frequency of an inverter (19) supplying power to the blower motor (18) is controllably increased or reduced.

Owner:MURATA MASCH LTD

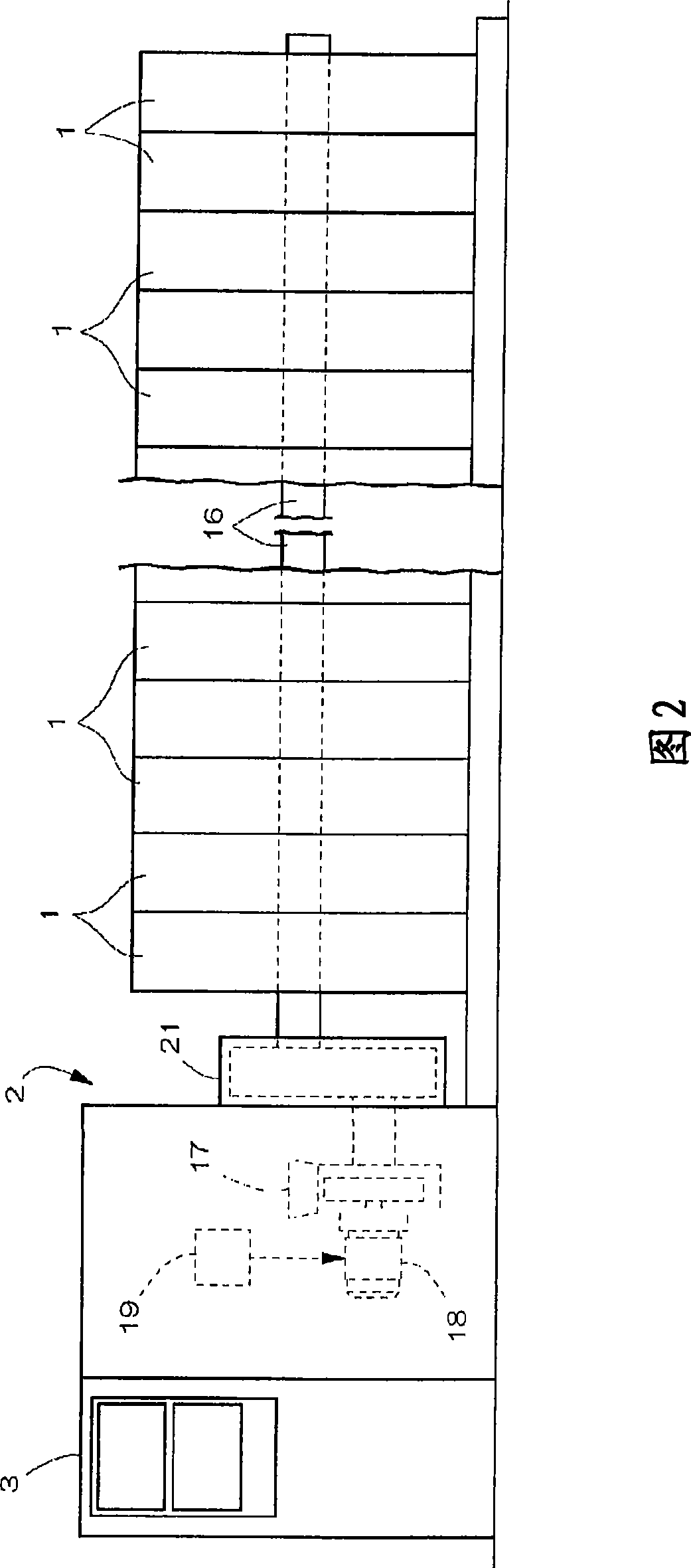

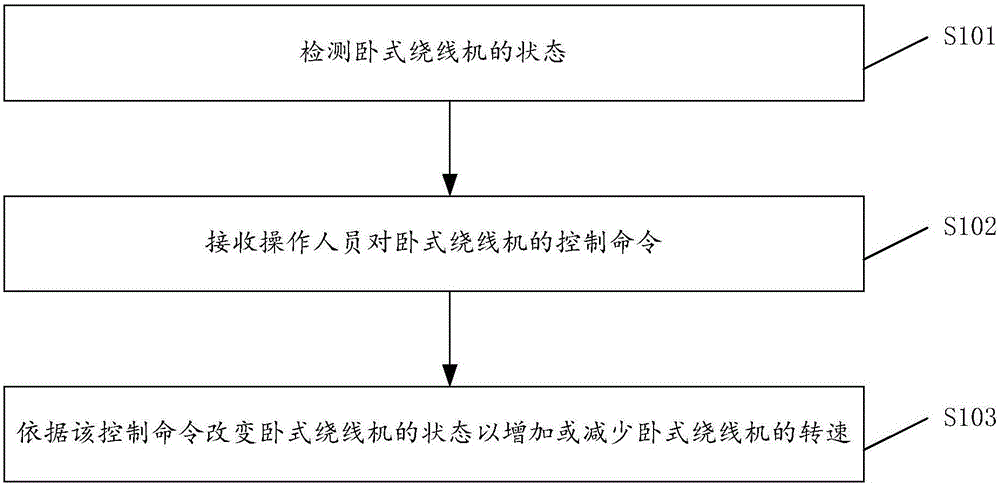

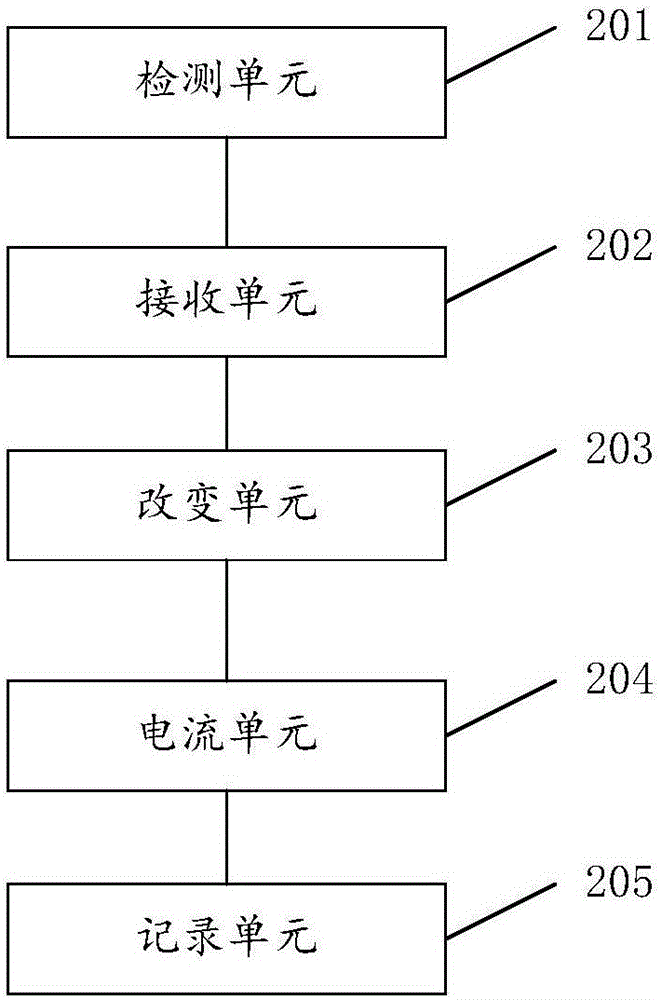

State rotating speed control method and system of horizontal coil winding machine

InactiveCN106253792AIncrease or decrease speedEasy to operateElectric motor controlWinding machineControl theory

The invention provides a state rotating speed control method and system of a horizontal coil winding machine. The method comprises a step of detecting the state of the horizontal coil winding machine, a step of receiving the control command of the horizontal coil winding machine by an operator, and a step of changing the state of the horizontal coil winding machine according to the control command so as to increase the rotation speed of the horizontal coil winding machine. The technical scheme provided with the invention has the advantage of convenient operation of a user.

Owner:廖建航

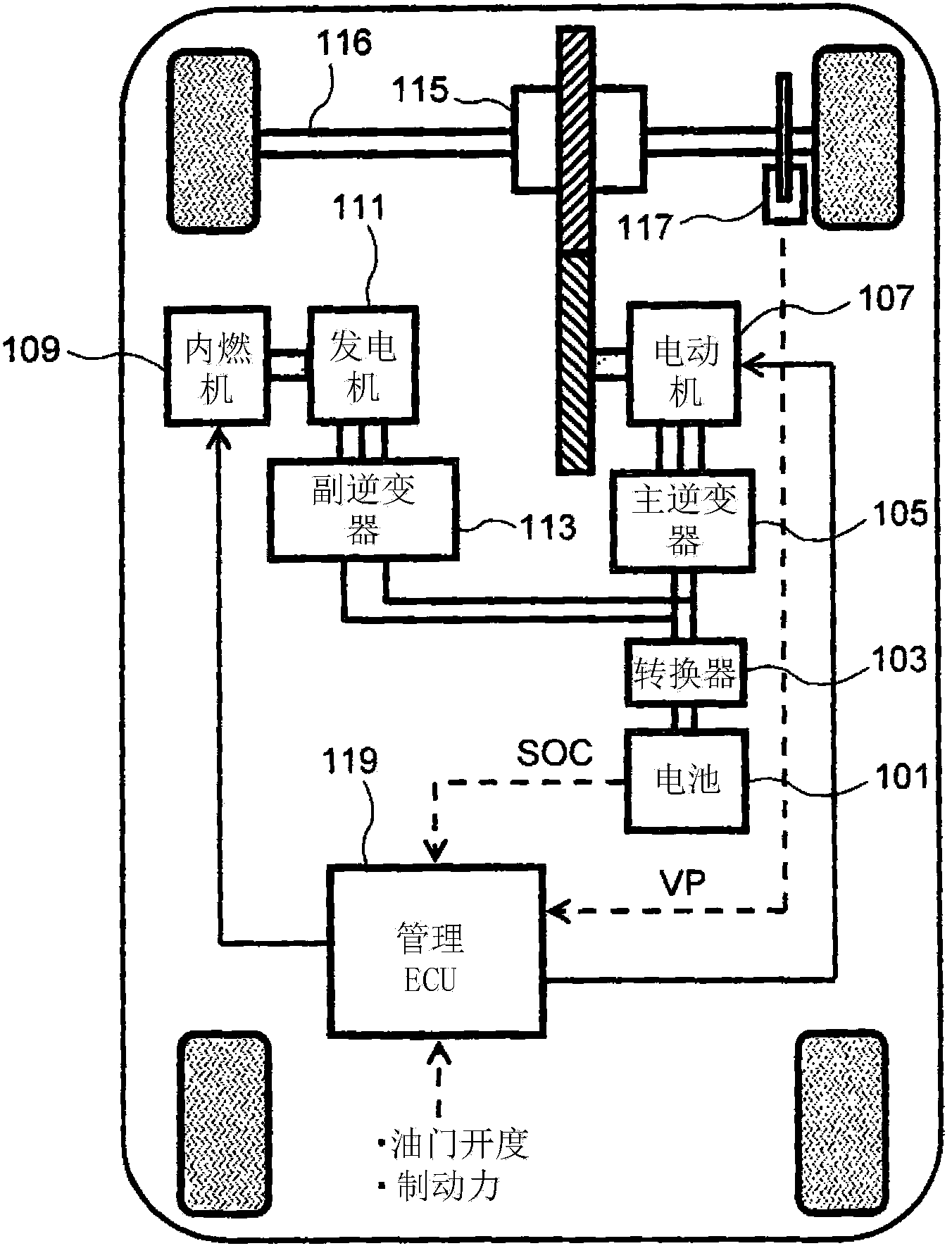

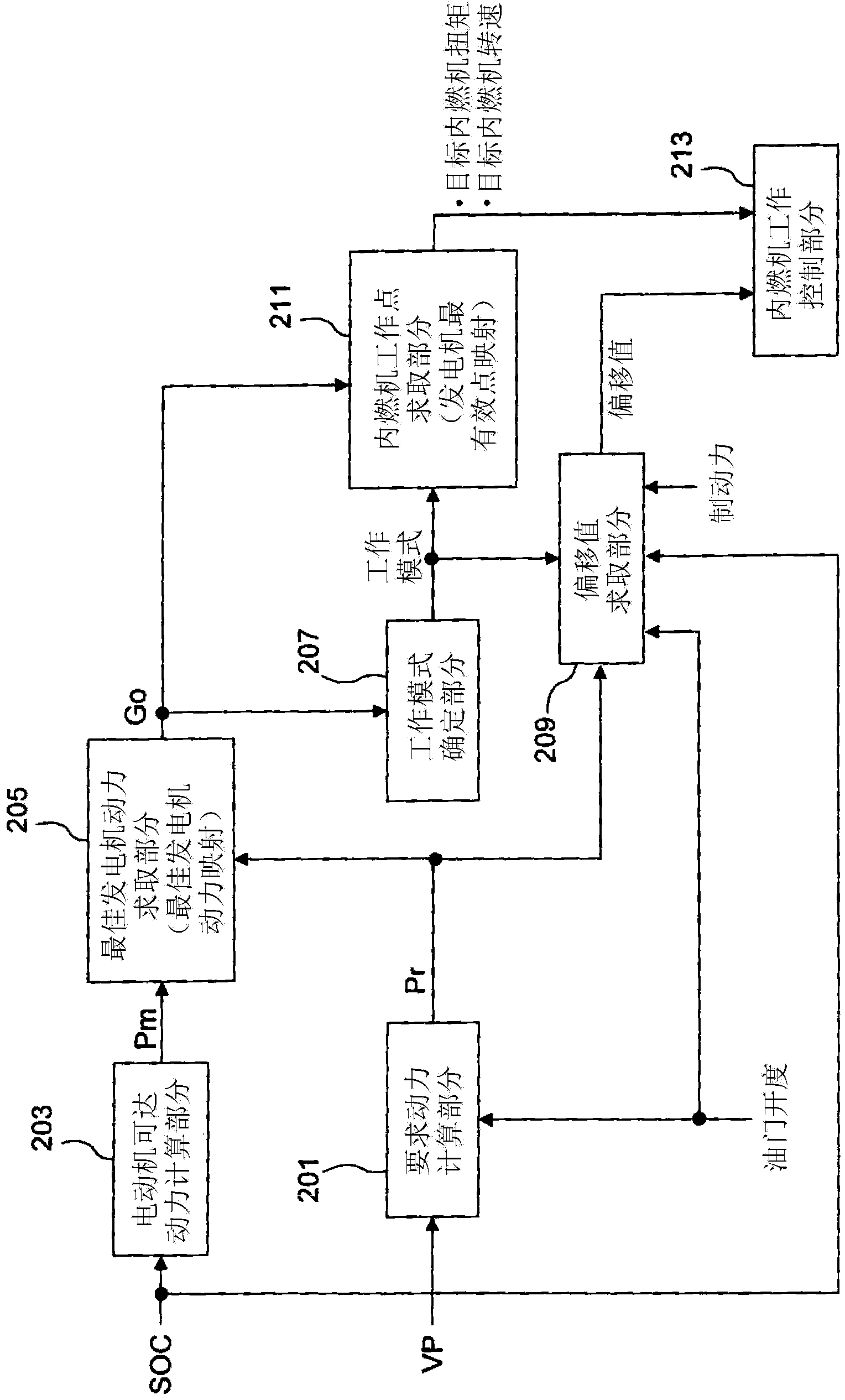

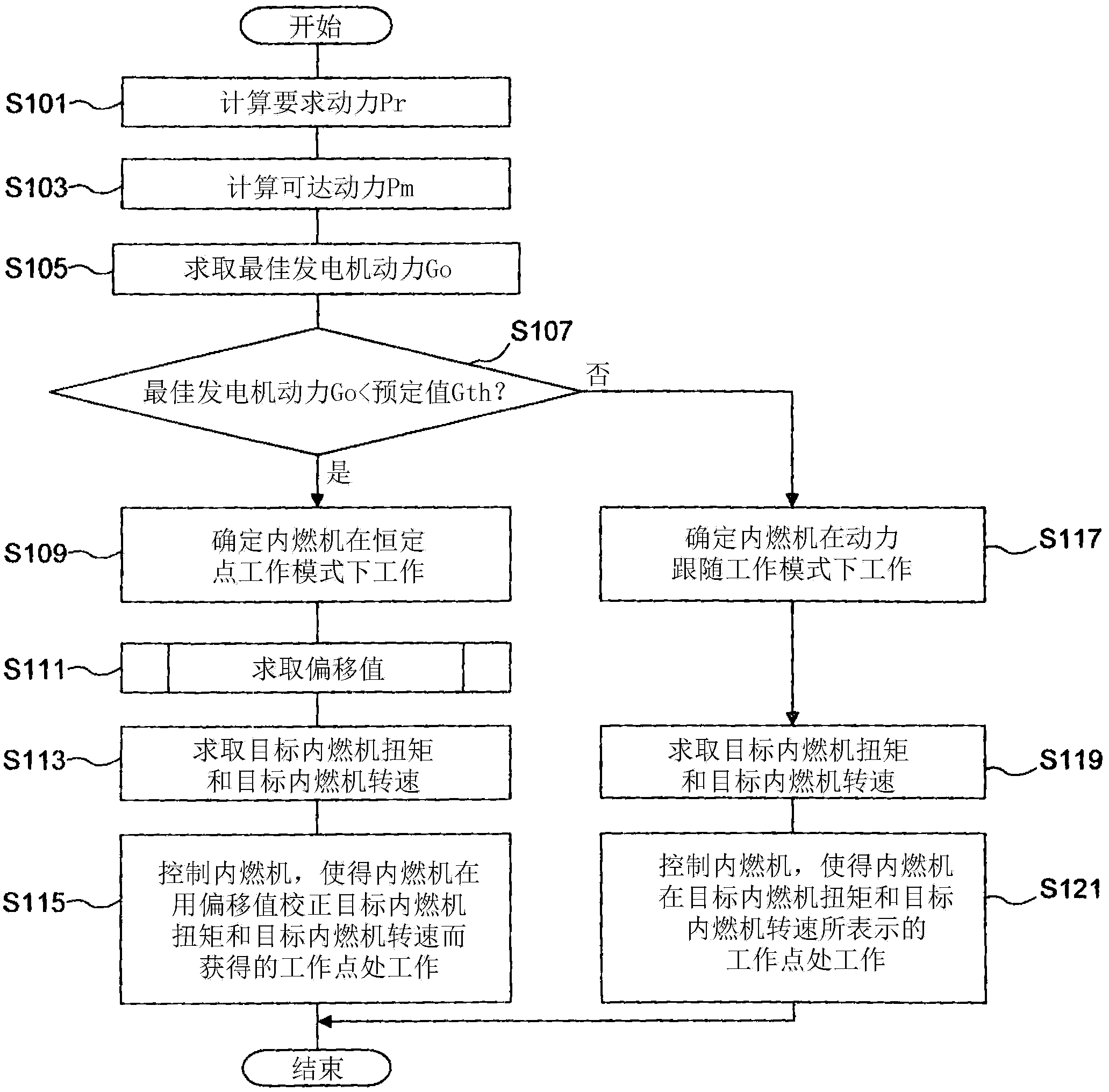

Internal combustion engine control apparatus and internal combustion engine control method

InactiveCN103619625APrevent dissonancePrevent overchargingGas pressure propulsion mountingPropulsion using engine-driven generatorsElectric machineEngineering

Th invention relates to control of an internal combustio engine (109), especially when used in a series hybrid vehicle, with a motor (107) delivering drive torque to the wheels. In a constant point operation of the engine (109), engine speed is not linked to accelerator pedal position or vehicle speed. When the driver in this constant point operation steps on the accelerator pedal or the brake pedal, a target engine speed is modified by an offset value. This ensure that the driver gets the same feeling as in a conventional vehicle, i.e. a change in engine speed in response to accelerator or brake pedal actuation. A feeling of incongruity is avoided.

Owner:HONDA MOTOR CO LTD

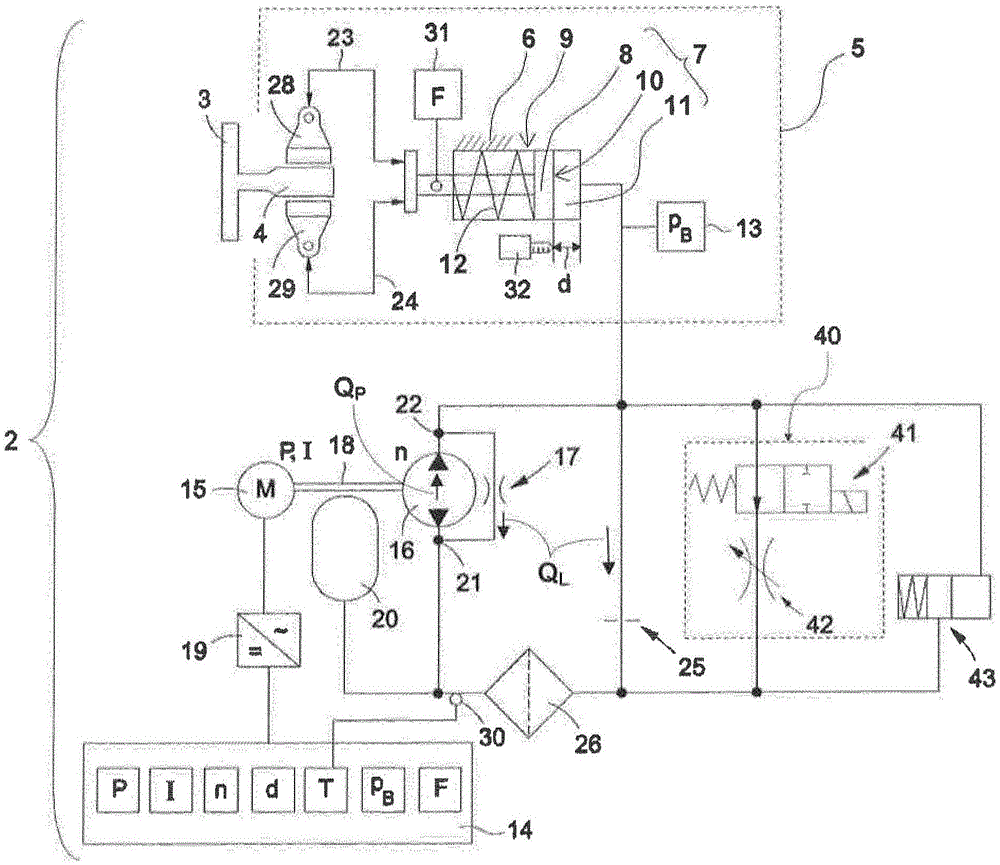

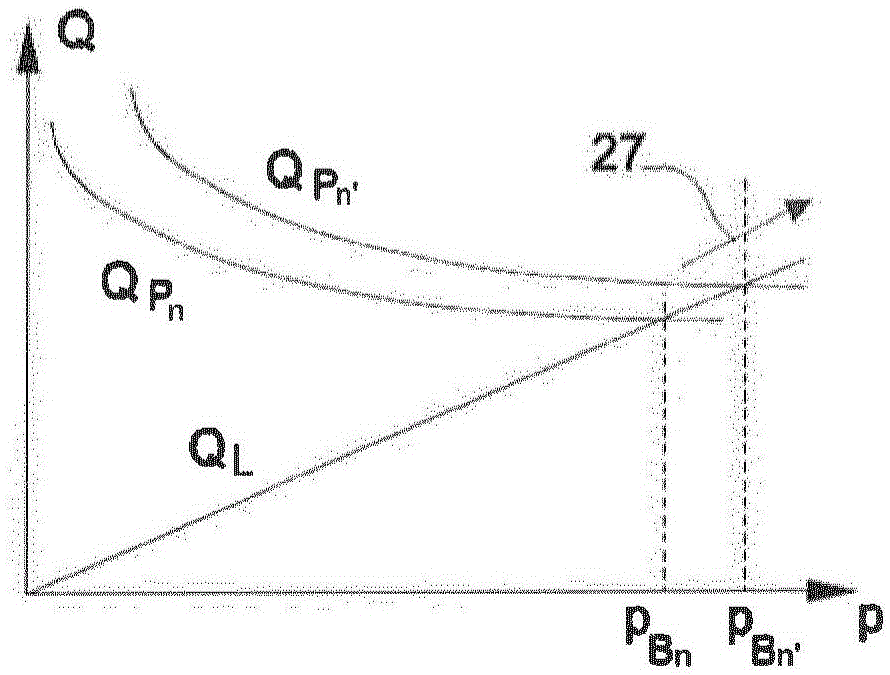

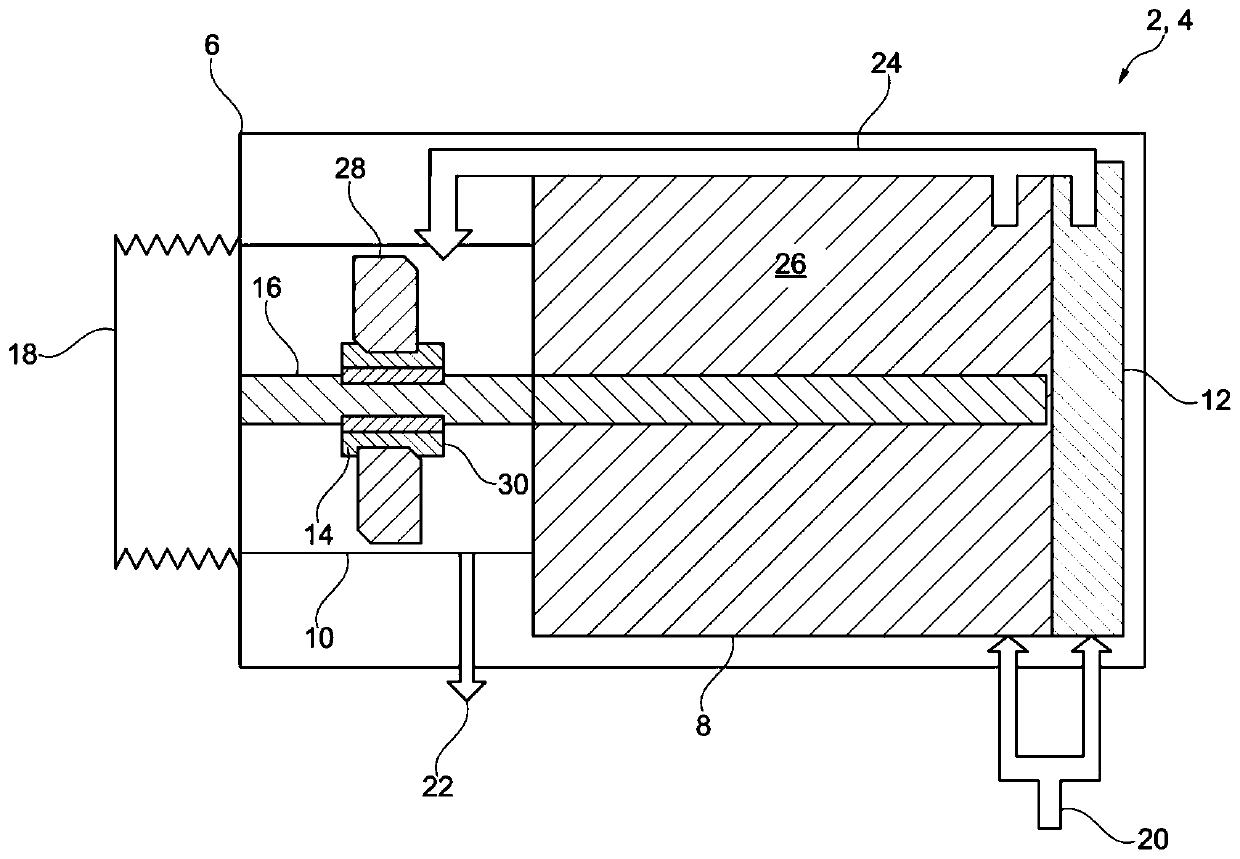

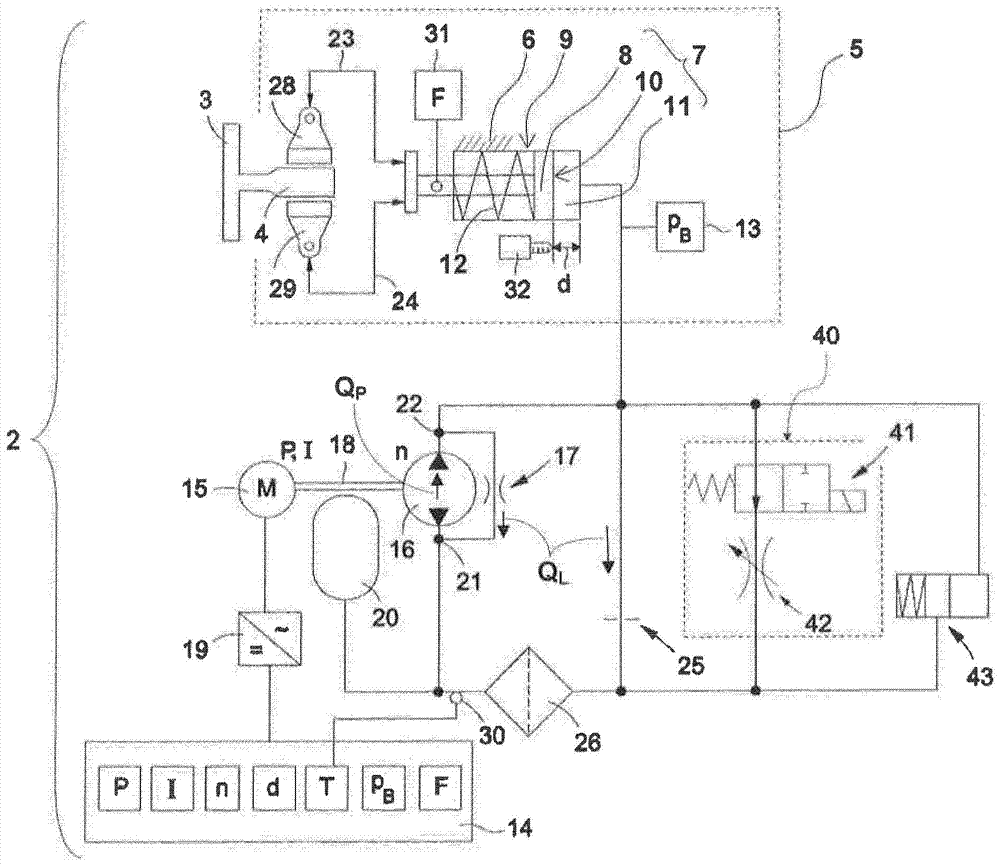

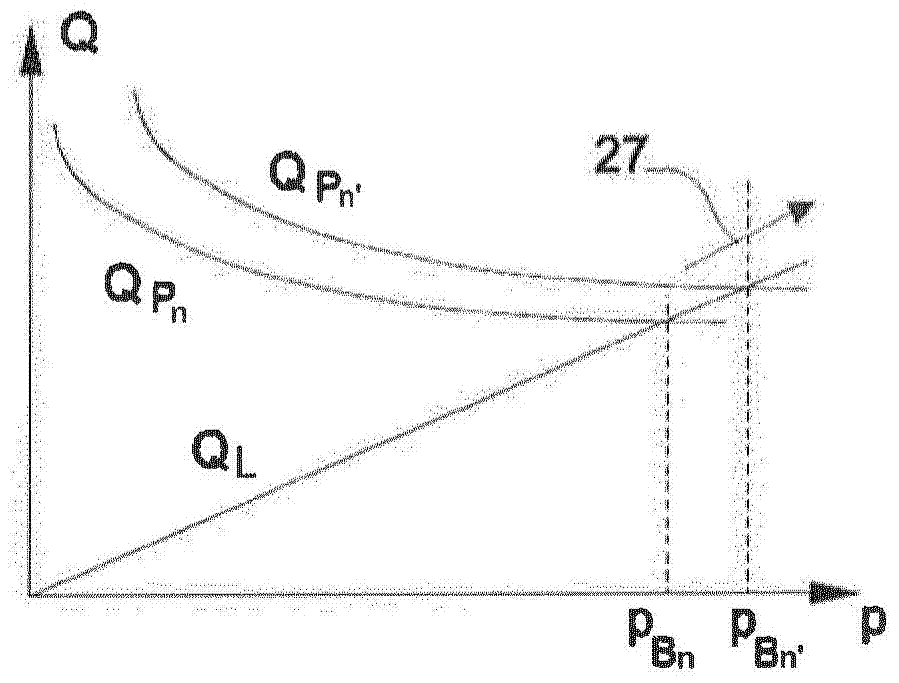

Hydraulic braking system

ActiveCN105164040AFeed volume flow adjustmentFeed volume flow changes and adjustmentsElevatorsEngineeringBrake fluid

A braking system (2) is used for a passenger transport installation (1) in the form of a lift, escalator or moving walkway. The braking device (5) comprising actuation equipment (7) is provided in this respect. Also provided are a pump (16) supplying a brake fluid to the piston space (11) of the actuation equipment (7) and a motor (15) which drives the pump (16). According to the invention, a control device (14) is also provided, which controls the motor (15) by way of a frequency inverter (19) in such a manner that the pump (16) supplies brake fluid at a delivery flow rate (QP) predetermined by the control device (14). A return flow rate (QL) is also made possible, wherein the pressure (pB) is set in the piston space (11) of the actuation equipment (7) corresponding to an equilibrium in which the delivery flow rate (Qp) is equal to the return flow rate (QL). The control device (14) sets the pressure (pB) in the piston space (11) of the actuation equipment (7) by way of the delivery flow rate (QP) of the pump (16). The invention also relates to a passenger transport installation (1) in the form of a lift, escalator or moving walkway having a braking system of this kind and to a method for controlling the braking force in a passenger transport installation (1) of this kind.

Owner:INVENTIO AG

A range hood with air volume adjustment function

ActiveCN103353137BGuaranteed compensationIncrease or decrease output powerDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention discloses a range hood with an air regulation function. The range hood comprises a body, a sensor group, an air channel, an operation panel, a controller, a direct current motor and fan blades, wherein the air channel, the operation panel, the controller, the direct current motor and the fan blades are installed on the body. The range hood is characterized in that the sensor group is arranged, the controller comprises a central processor, the sensor group is installed at an air inlet, detects oil smoke and vapor concentrations at the air inlet during operation of the range hood and feeds back the oil smoke and vapor concentrations to the central processor, and the central processor carries out integrated computation so as to obtain an air volume value and controls the revolving speed of the direct current motor. The range hood provided by the invention overcomes the problem that a conventional range hood cannot integratedly handle influence of a kitchen environment and shared flues on oil smoke absorption effects and has the advantages of noise reduction, energy conservation and environment friendliness.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

Gearwheel unit, transmission having gearwheel unit and gearwheel manufacturing method

InactiveCN101144527AIncrease or decrease speedShorten the axial lengthMechanical actuated clutchesToothed gearingsGear transmissionGear ratio

A gearwheel unit includes a gear body and a clutch gear. The gear body includes a gear part and a positioning part. The gear part is configured and arranged to transmit rotation of a rotational shaft with a prescribed change gear ratio. The positioning part is integrally formed with the gear part at a position spaced apart from the gear part by a prescribed distance in an axial direction so that a prescribed open space is formed between the positioning part and the gear part. The clutch gear is fixedly coupled to the gear body as being positioned with respect to the gear body by the positioning part so that at least a part of the clutch gear overlaps the prescribed open space formed between the positioning part and the gear part of the gear body when viewed in a radial direction.

Owner:AICHI MASCH IND CO LTD

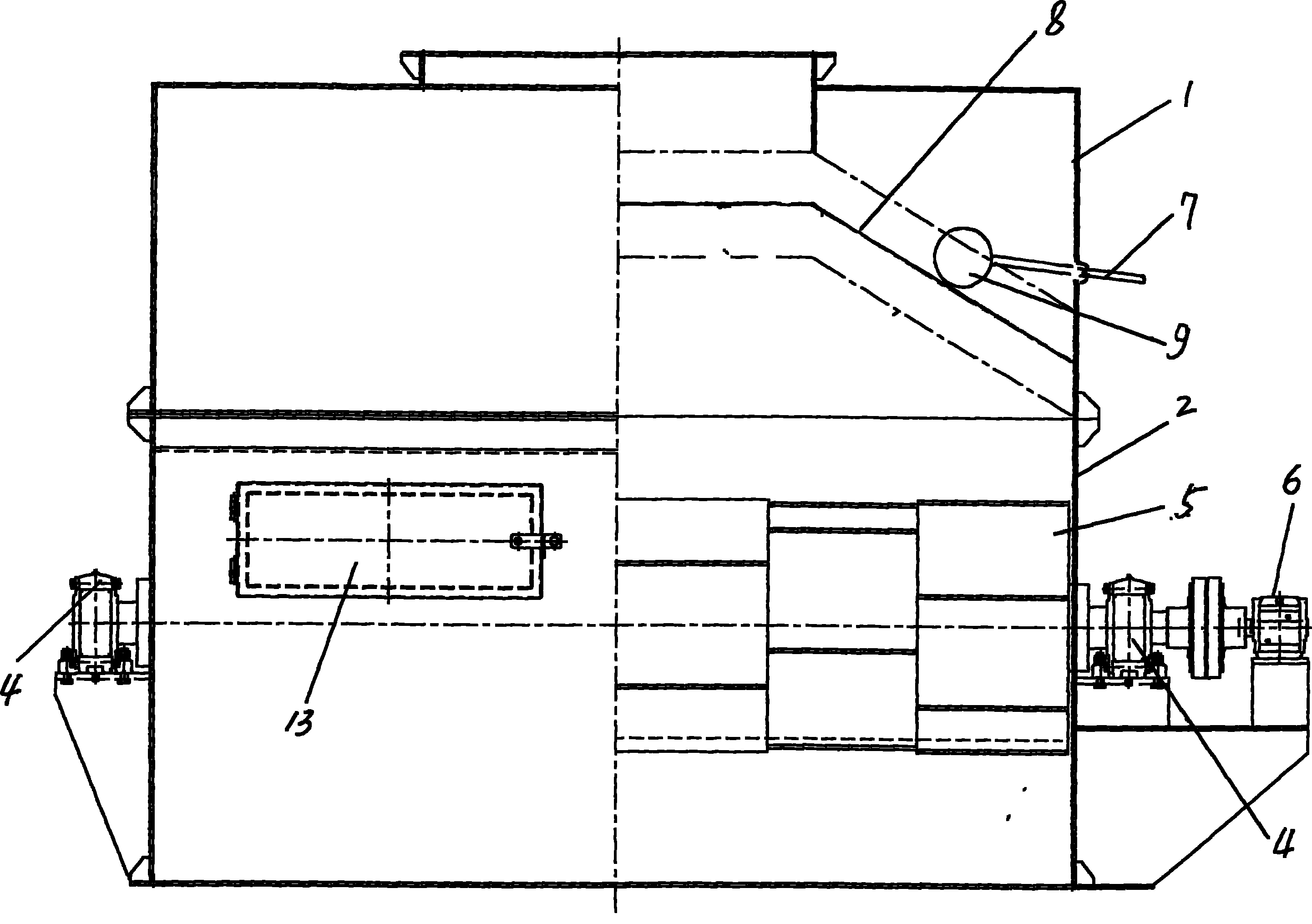

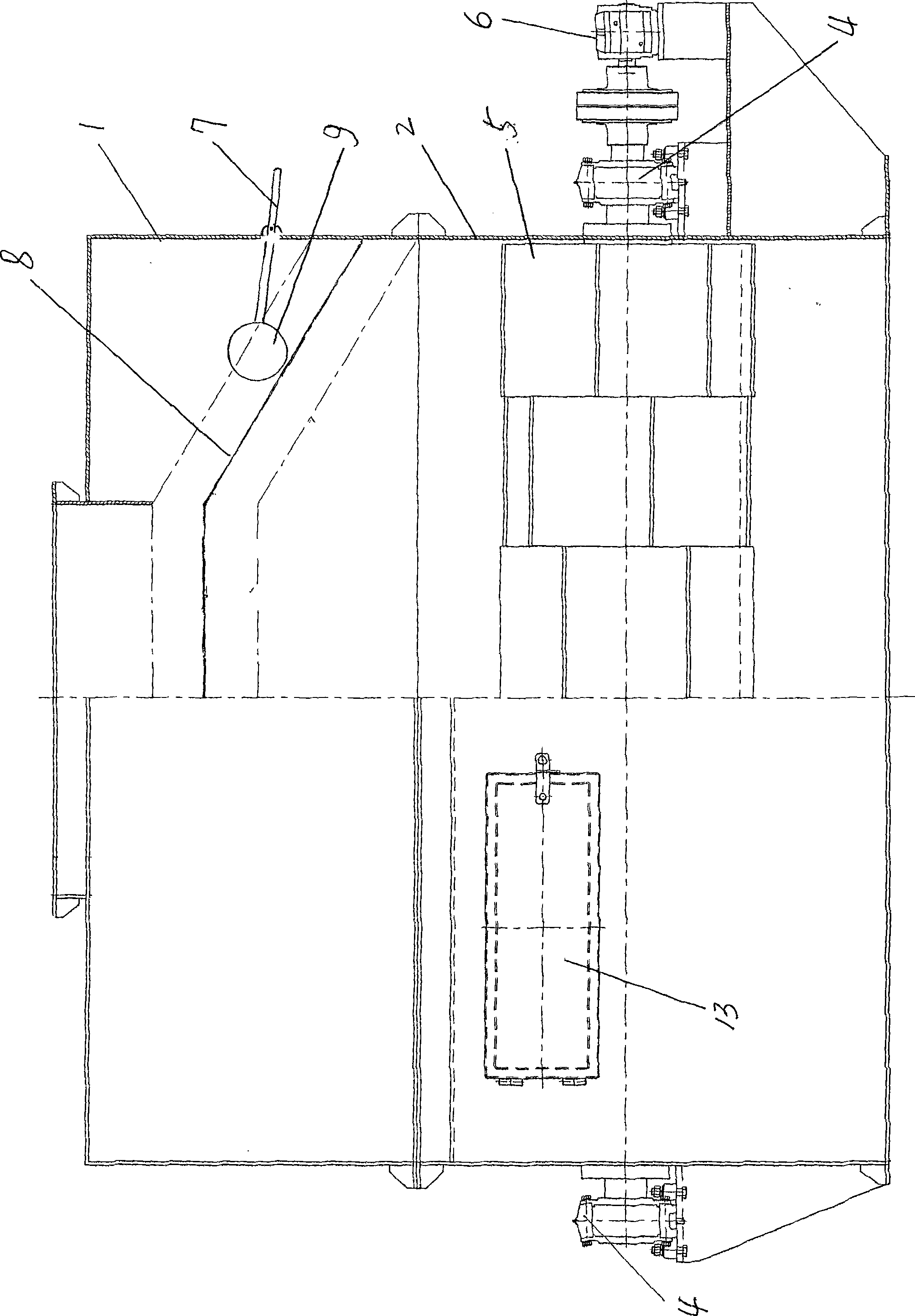

Constantly-uniform distributor for coal crusher of coal conveying system in heat-engine plant

InactiveCN102029210AOvercoming the problem of uneven blankingIncrease or decrease speedGrain treatmentsSignal processing circuitsMaterial balance

The invention discloses a constantly-uniform distributor for a coal crusher of a coal conveying system in a heat-engine plant, which belongs to the field of machinery, is used for supplying coal to the coal crusher and overcomes the defects of damage to coal conveying equipment and combustion equipment or waste of equipment materials and labor force caused by non-uniform wear of a hammer head of the coal crusher in the prior art. The constantly-uniform distributor comprises a material storage box, a material balancing box, material balancing rotors, a material balancing rotor drive motor and an intelligent material stack height control mechanism, wherein the material balancing box is connected to the lower end of the material storage box; the material balancing rotors of which the two ends are arranged on a box body through bearings and the circumferential surfaces are provided with switch-plates are arranged in the material balancing box; a material position sensor which consists of a rigid float ball, a lever and an inductive element on the outer end part of a lever box are arranged on the material storage box; and the intelligent material stack height control mechanism consists of the material position sensor and a signal processing circuit. The invention has the advantages that: the problem of non-uniform blanking on the rotor of the conventional coal crusher is solved; a material stack on the material storage box is kept at an appropriate height; coal passing through the distributor is non-sticky, blocking-resistant and sticking-resistant; and the constantly-uniform distributor is the optimal material balancing device for the coal crusher.

Owner:马奎山

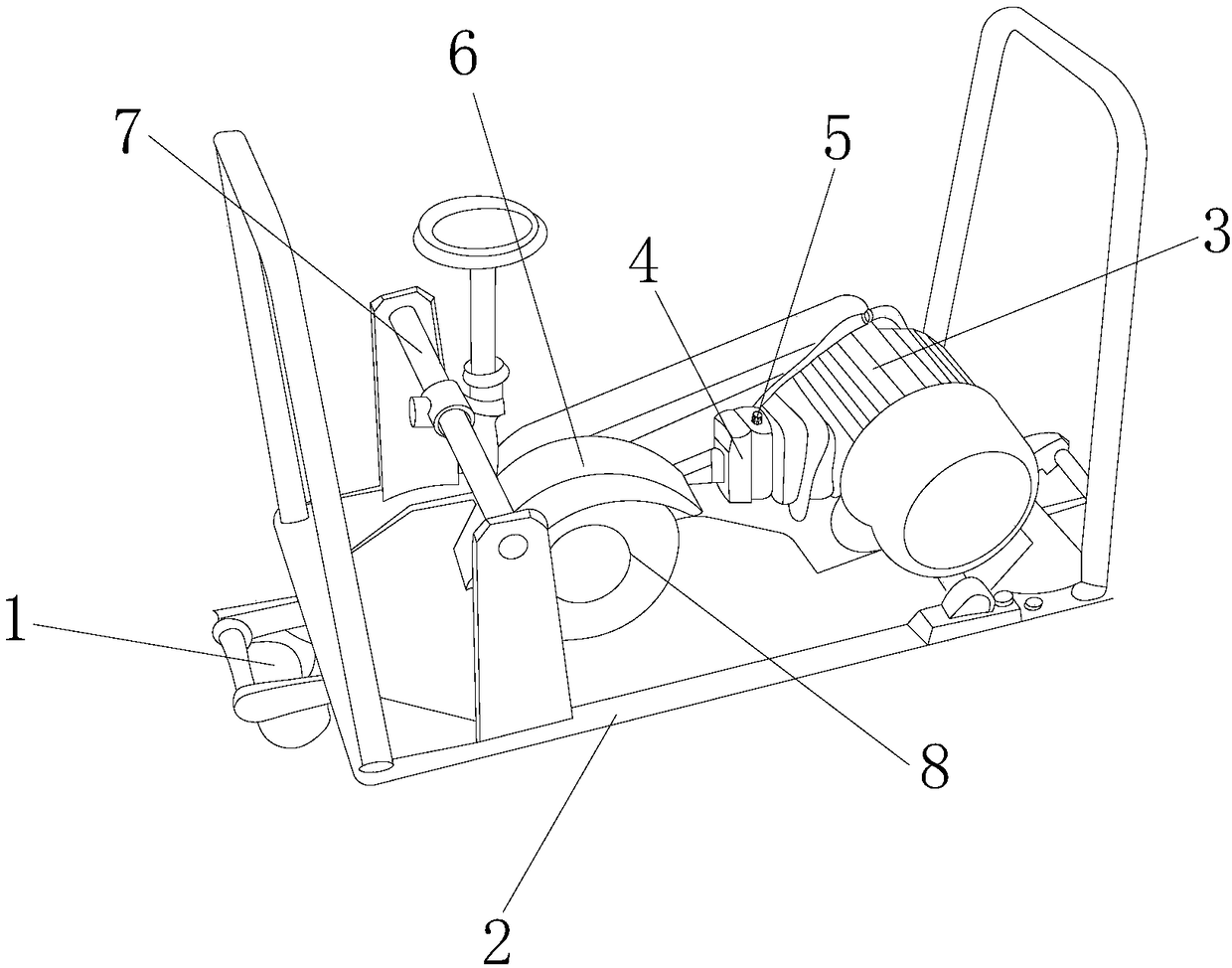

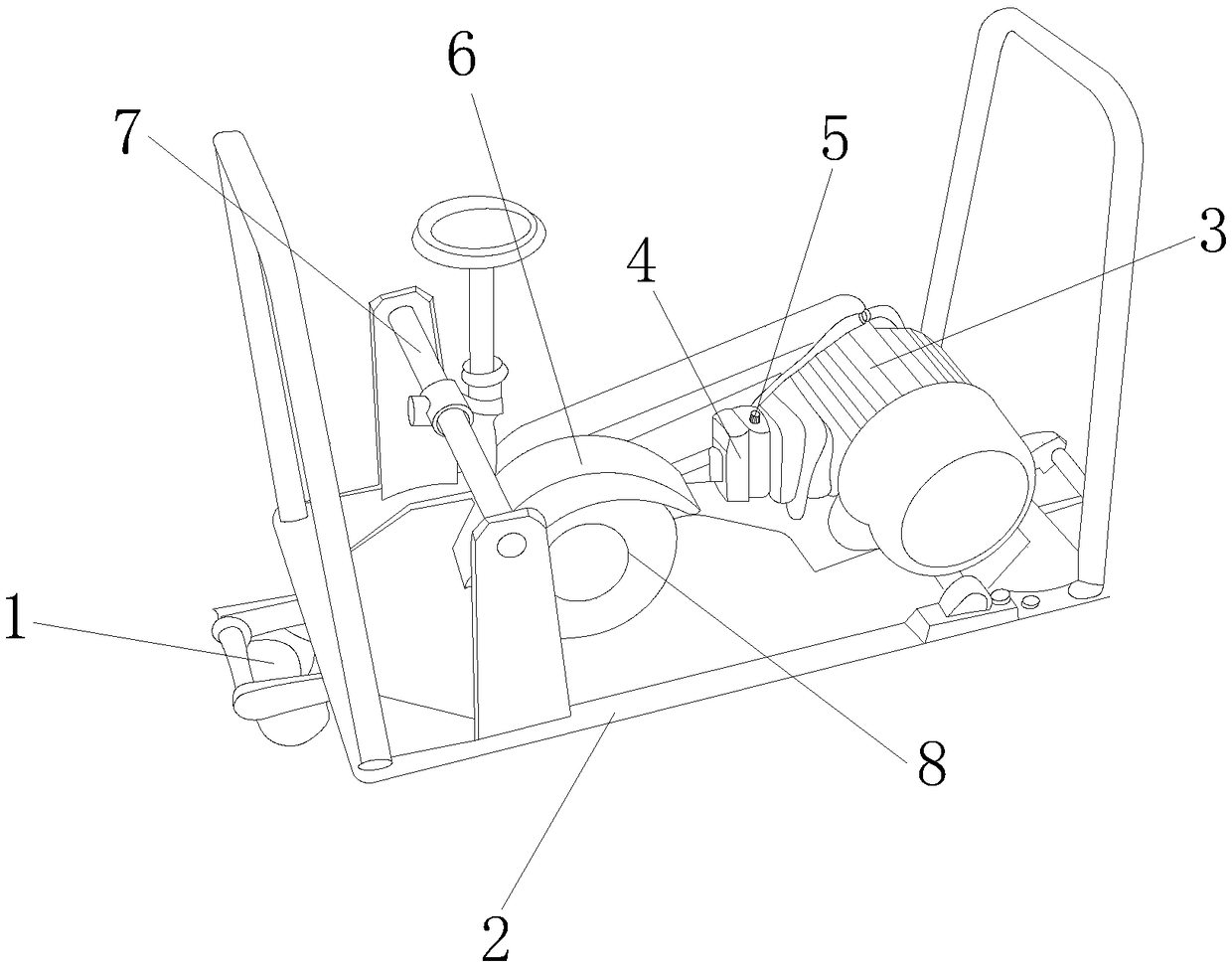

End grinding device for internal combustion engine air inlet and exhaust valve

InactiveCN108393750AHigh precisionImprove surface qualityGrinding carriagesRevolution surface grinding machinesExhaust valveEngineering

The invention relates to an end grinding device for an internal combustion engine air inlet and exhaust valve. The device structurally comprises a rolling wheel, a base frame, a motor, a controller, aspeed regulator, a protective cover, a limiting rod and a grinding wheel, wherein the base frame is of a concave shape, the outer surface of the base frame is hard, the middle part of the base frameis hollowed out, the left side and the right side of the base frame are equal and parallel, and the speed regulator is arranged on the controller. The end grinding device for the internal combustion engine air inlet and exhaust valve has the beneficial effects that the speed regulator is arranged, a rotating speed is changed by rotating a speed adjusting knob and then through a speed change chip,then processing is carried out by a processor, and then a controlled object is controlled to run through cooperation with an executor, so that the speed of end grinding can be increased or decreased according to the product condition, the precision of the grinding operation is enhanced, and therefore the end grinding can be completed only by single feeding, and the working efficiency is improved;and the surface quality of workpieces subjected to end grinding is further improved, the efficiency of the workpieces end grinding is improved, the labor intensity of workers is reduced, and the quality and the yield of end products can be considered.

Owner:安徽鼎立智能制造股份有限公司

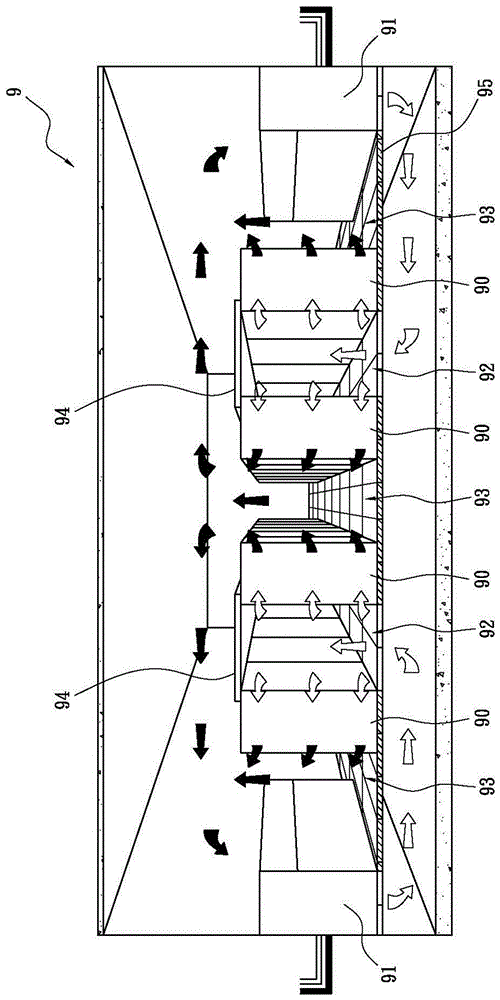

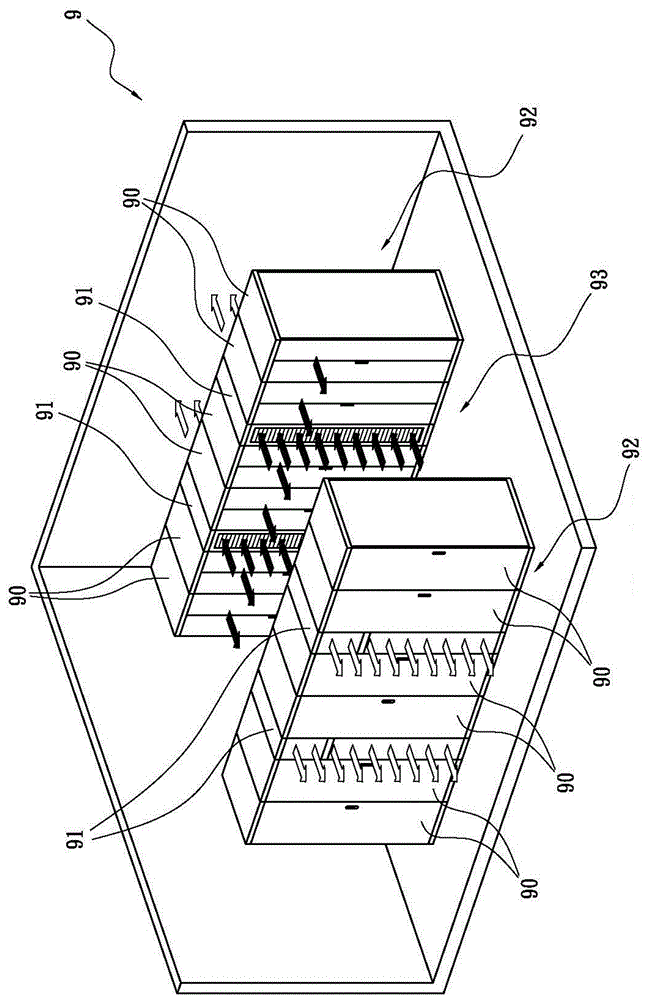

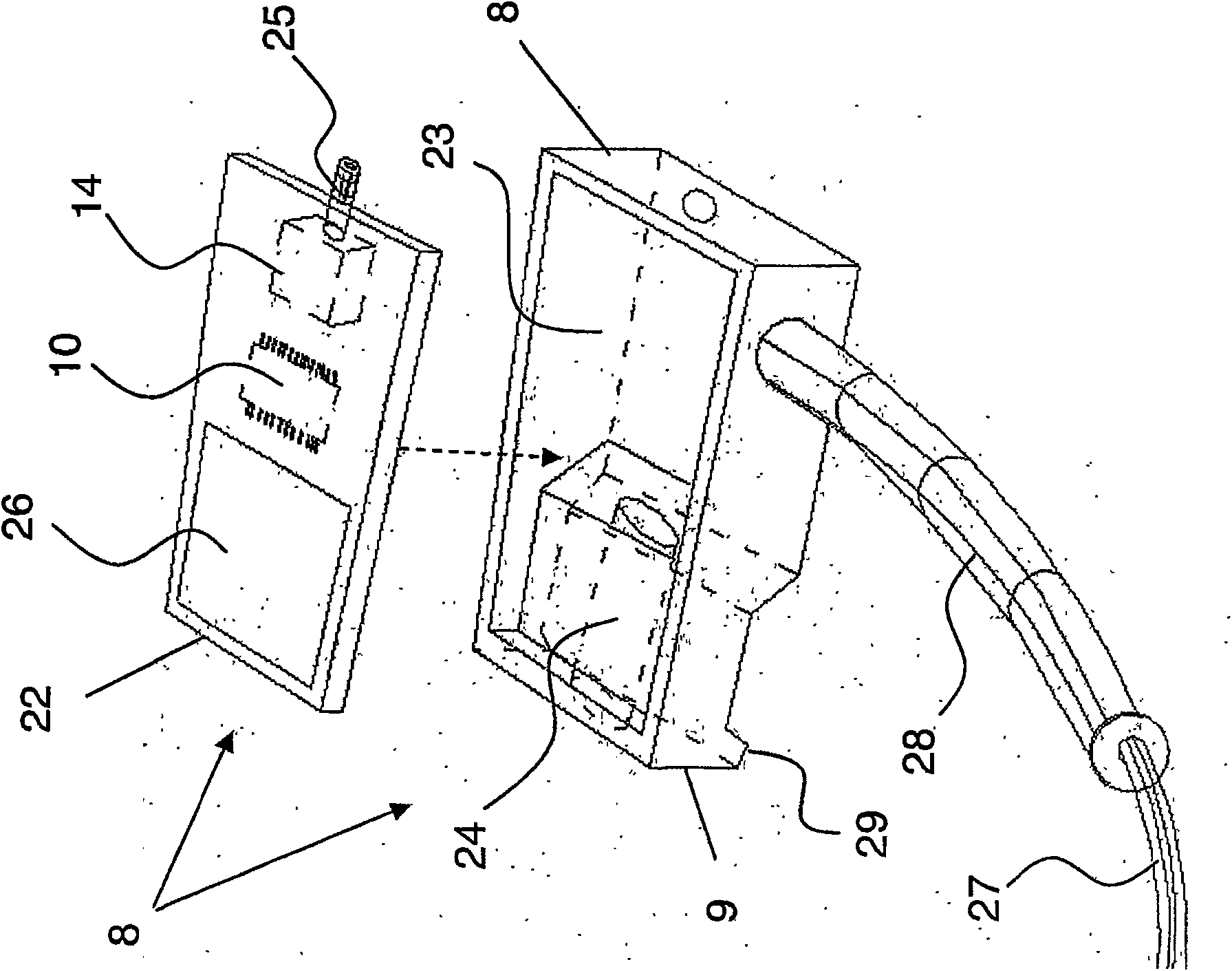

Cabinet Air-conditioning Guiding Mechanism

A cabinet air-conditioning guiding mechanism, a front frame and a rear frame are provided to connect to the cabinet to form an enclosed interior, cold air is guided inwards and hot air is guided outwards directly 5 to form an unidirectional flow mechanism directly applied to the interior of the cabinet, to achieve the purpose of rapid cooling, so that heat exchange efficiency and efficacy of air-conditioning management may be improved, and energy may be saved, space of electronic equipment room may be effectively used and cost of setting air-conditioning may be reduced.

Owner:曾庆照

Adjustable inclined type tea drying and cooling device

InactiveCN109717258ASpeed up dryingIncrease or decrease distancePre-extraction tea treatmentElectric machinerySlide plate

The invention provides an adjustable inclined type tea drying and cooling device. The device includes a base plate, rotating wheels, a conveyor belt, a transmission motor, a vibrating rod and a smallmotor; the two sides on the top of the base plate are fixedly provided with a shell through bolts; the bottom on one side of the shell is fixedly provided with a side plate through a bolt; the top ofthe shell is provided with a feeding inlet; the middle part on one side of the shell is integrally provided with a guide plate; and the top on the inner side of the guide plate and the shell are fixedly provided with a shunting frame directly through the bolts. Through the arrangement of a twitching slide plate and an inclined mesh, the spreading distance of tea can be lengthened; through the sieving of the inclined mesh and the guiding of air flow, and part of the tea can fall down from mesh holes of the inclined mesh, and part of the tea can fall down again after falling down to the twitching slide plate to perform expansion, so that gaps can be generated, and the drying speed of the tea can be accelerated; and the draw-off of the twitching slide plate can be performed through the bolts,and the flow distance and speed of the tea can be increased or decreased by adjusting the distance of the twitching slide plate, so that the drying time can be conveniently controlled.

Owner:GUIZHOU UNIV

End-face grinding device for air intake and exhaust valves of internal combustion engines

PendingCN108972193APrevent splashHigh precisionGrinding drivesPlane surface grinding machinesRam-air intakeExhaust valve

An end-face grinding device for air intake and exhaust valves of internal combustion engines structurally comprises a roller, an under carriage, a motor, a controller, a speed governor, a protective cover, a limit rod and a grinding wheel. The under carriage is concave, and has hard outer surface and hollow inside, and the left and right sides of the under carriage are the same and parallel to each other; the speed governor is arranged on the controller. The end-face grinding device has the advantages that, with the arrangement of the speed governor, rotation speed is changed through a variable-speed chip by turning a speed-adjusting knob and is subjected to parallel process through a processing unit, while an actuator is used for controlling operation of a controlled object, so that end-face grinding speed can be increased or decreased according to states of products, precision of the grinding work can be improved, and the work efficiency is improved as the end-face grinding can be completed with single feeding; besides, by application of the end-face grinding device, surface quality of the workpieces under end grinding can be improved, end-face grinding efficiency can be improved, labor intensity of workers can be reduced, and the purpose of guaranteeing both quality and productivity of finish products can be achieved.

Owner:安徽鼎立智能制造股份有限公司

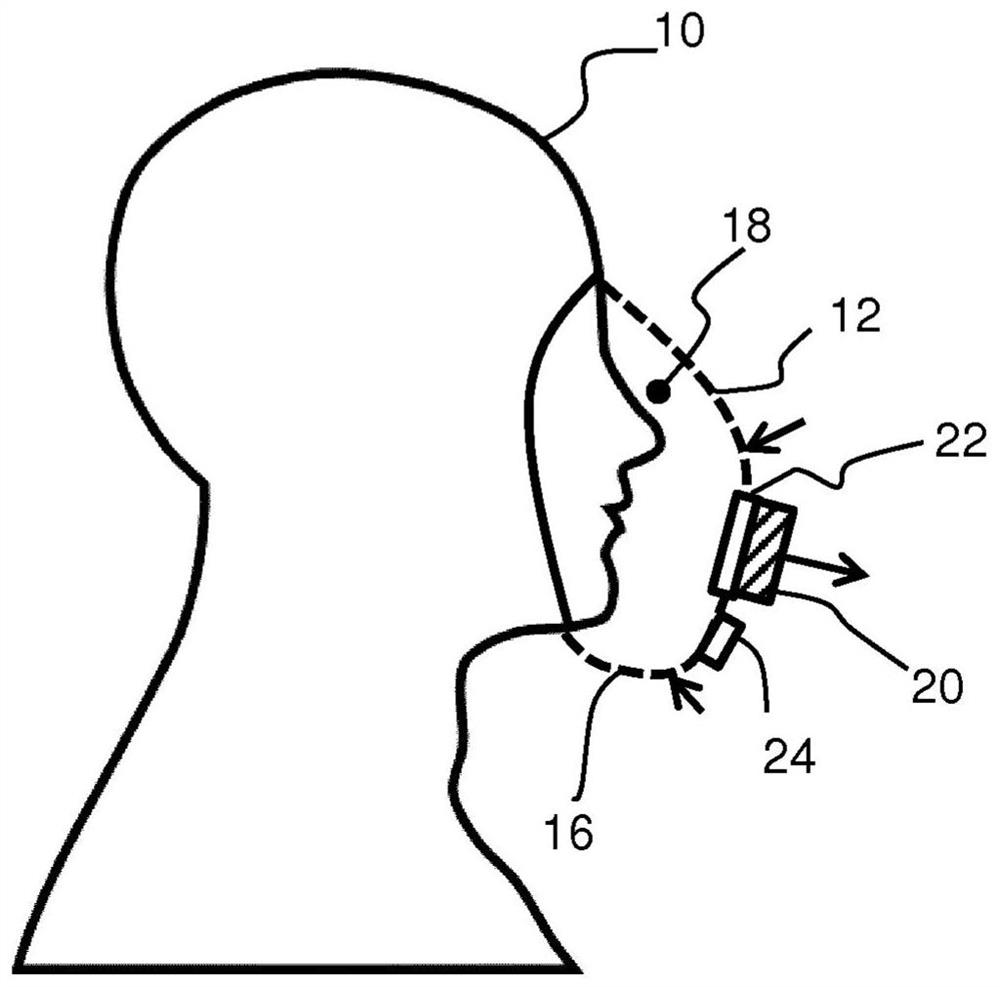

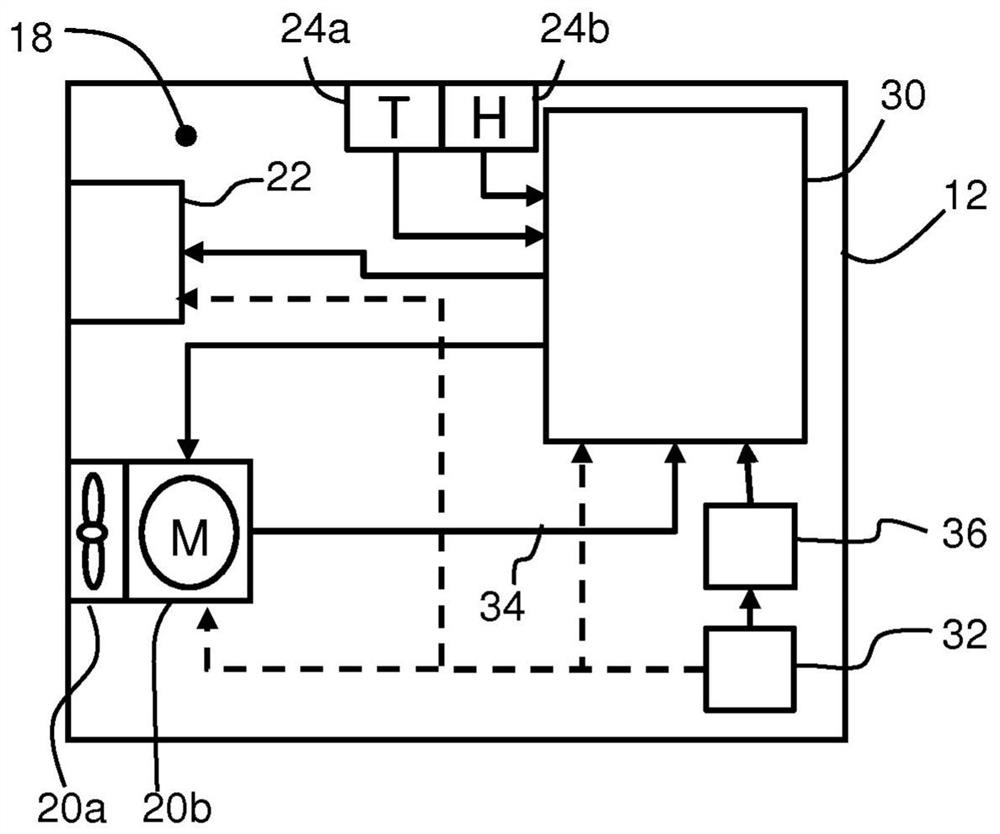

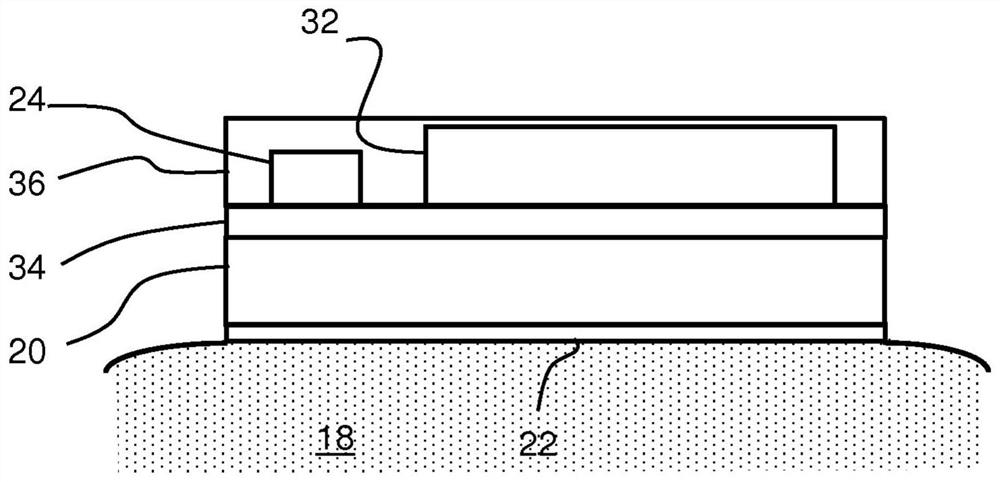

Pollution mask and control method

InactiveCN113038993AIncrease or decrease speedBreathing filtersBreathing masksEngineeringAtmospheric sciences

A pollution mask has a driven fan, wherein a rotation speed of the fan is monitored, as well as the external temperature and optionally also humidity levels. The fan rotation speed or change in fan rotation speed is used to obtain a first value which relates to a depth of breathing and a second value which relates to a rate of breathing. These are used, in combination with the ambient temperature and optionally also the ambient humidity level, to set the fan speed. Thus, the fan speed is set taking into account the breathing characteristics of the user as well as the ambient environmental conditions.

Owner:KONINKLJIJKE PHILIPS NV

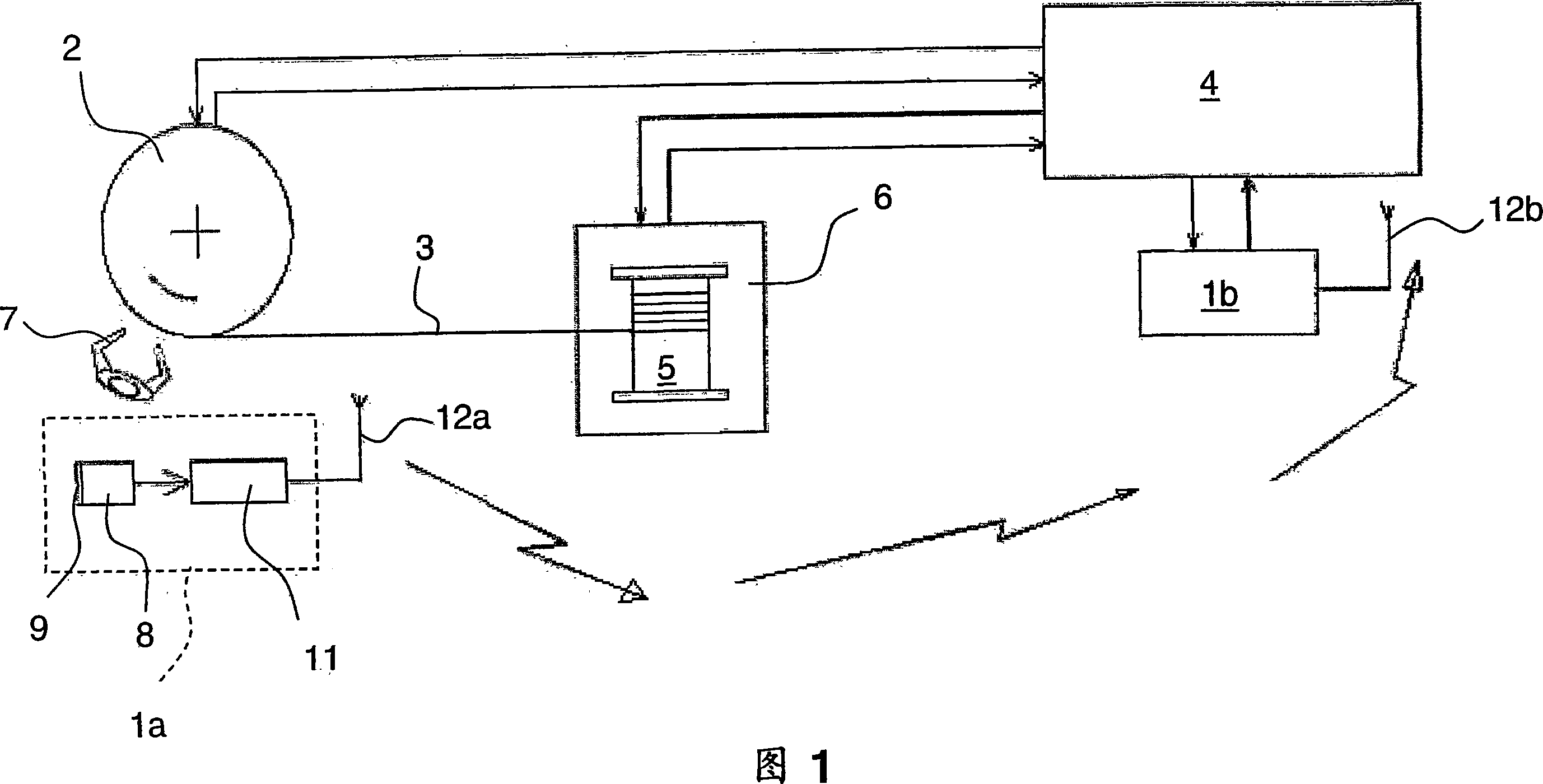

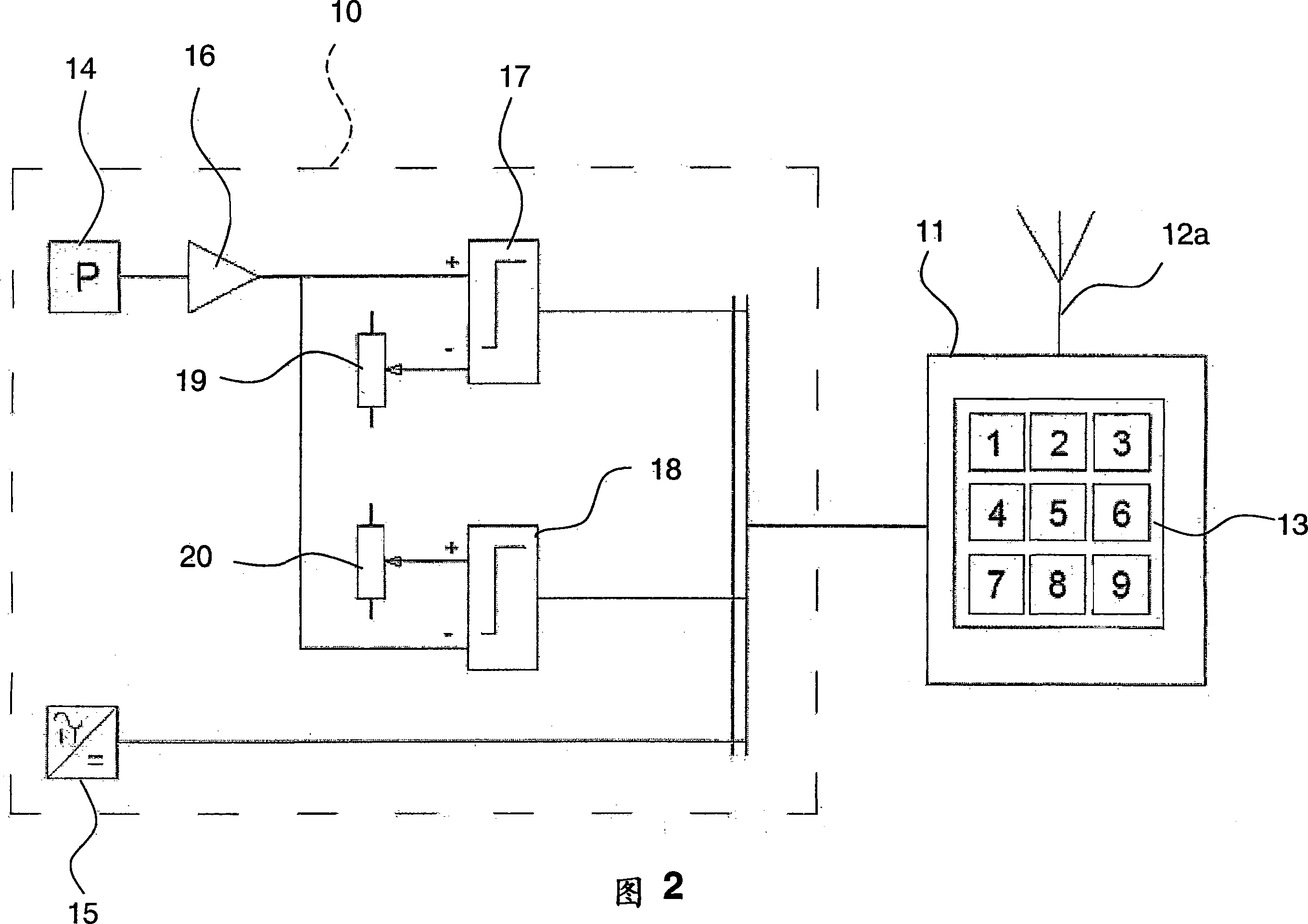

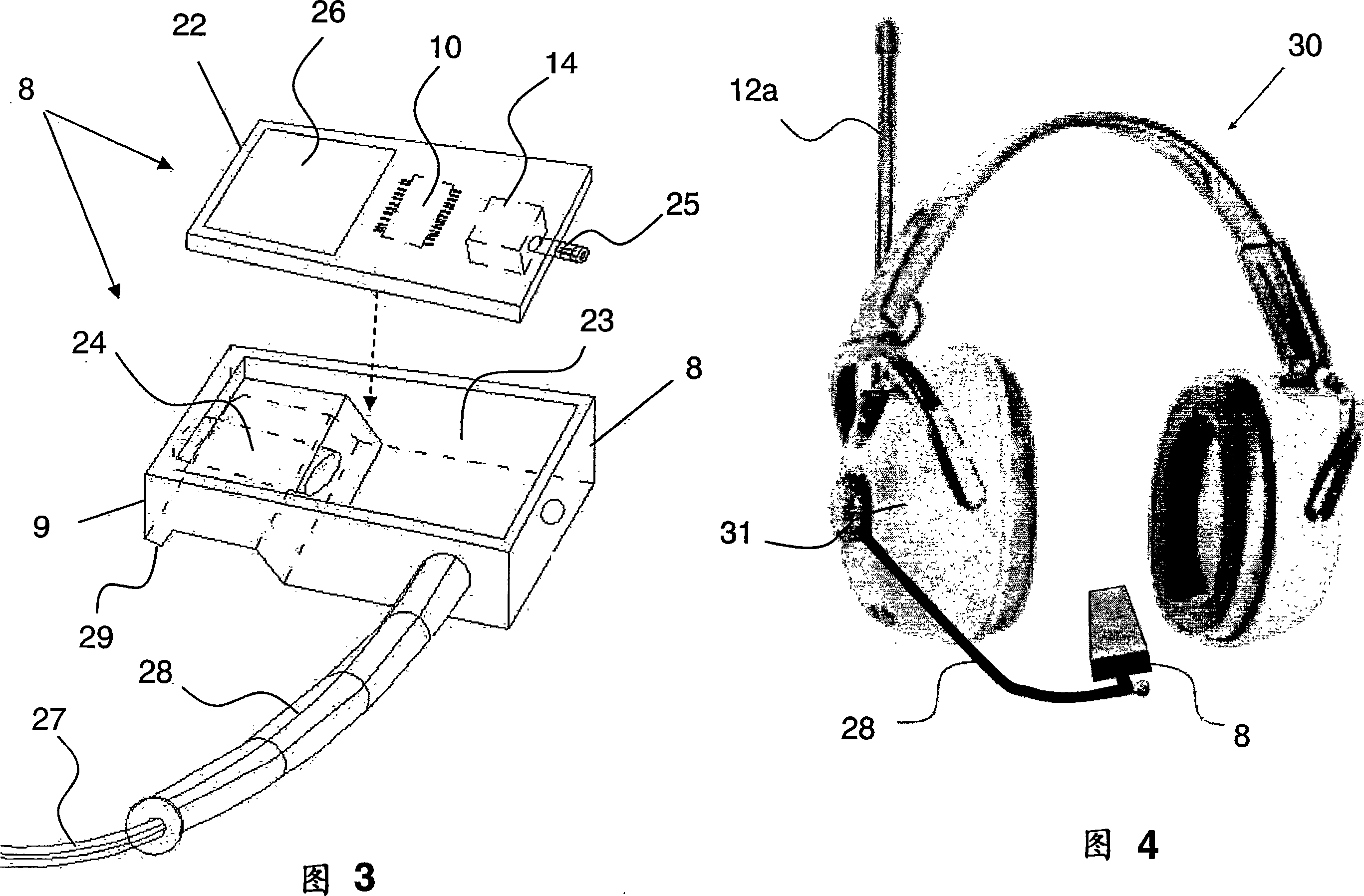

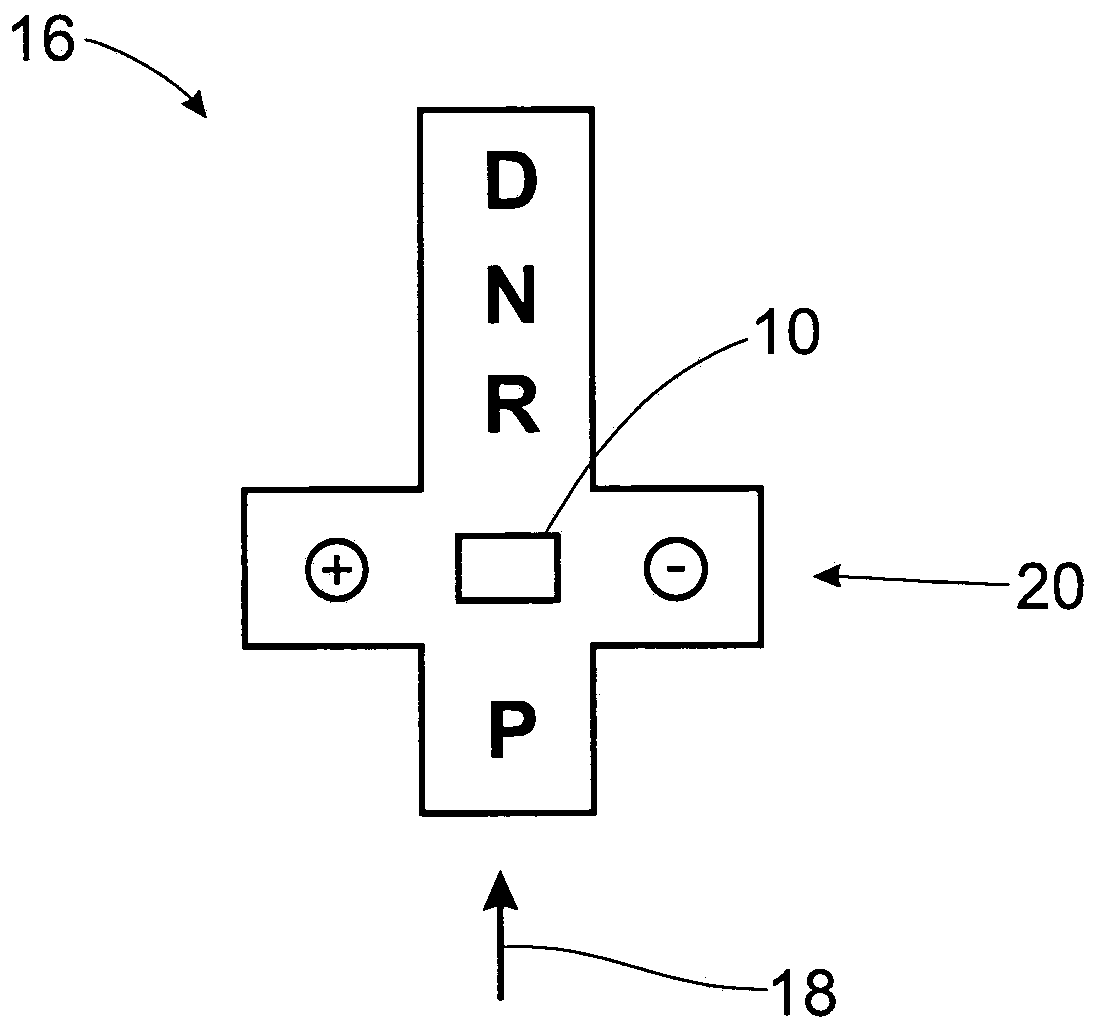

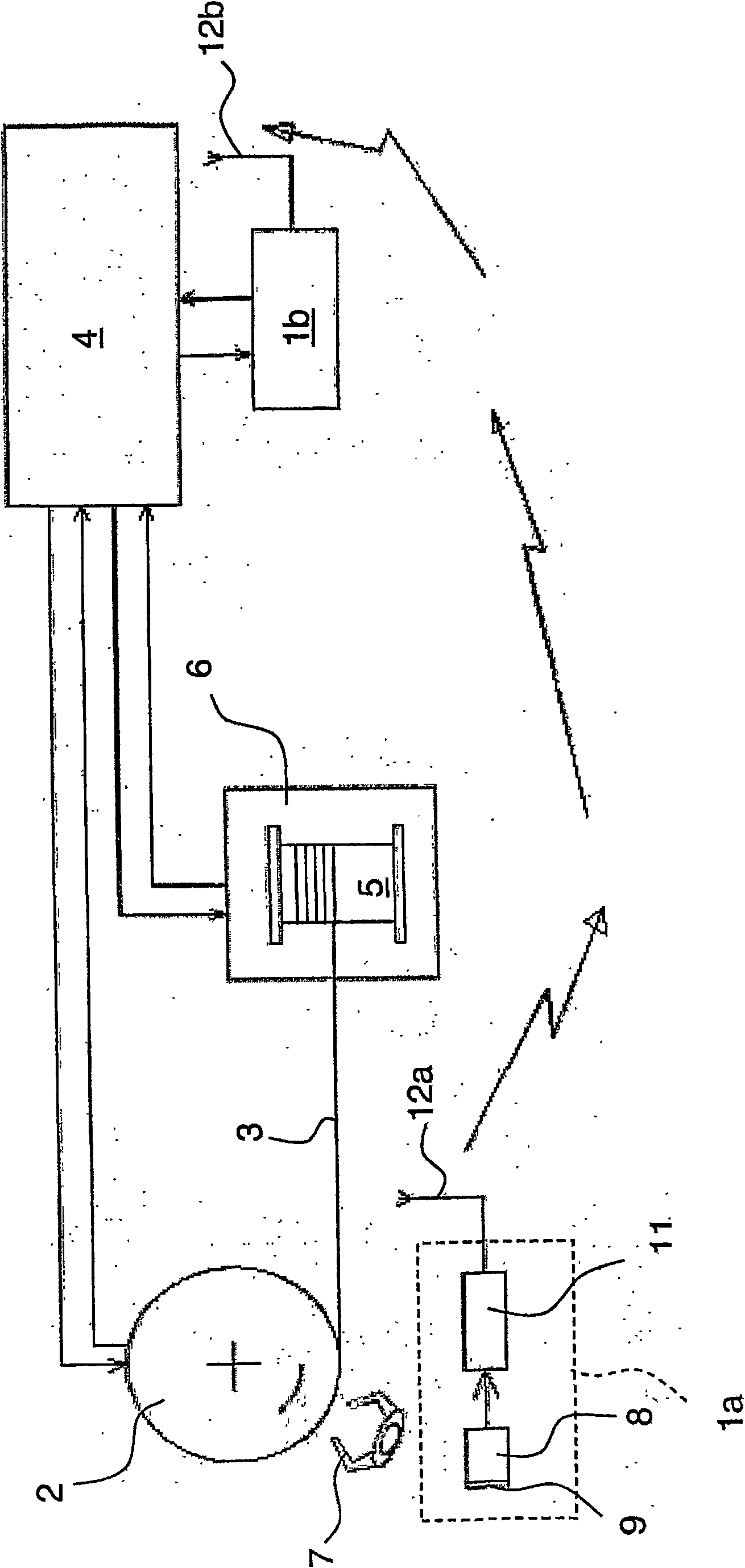

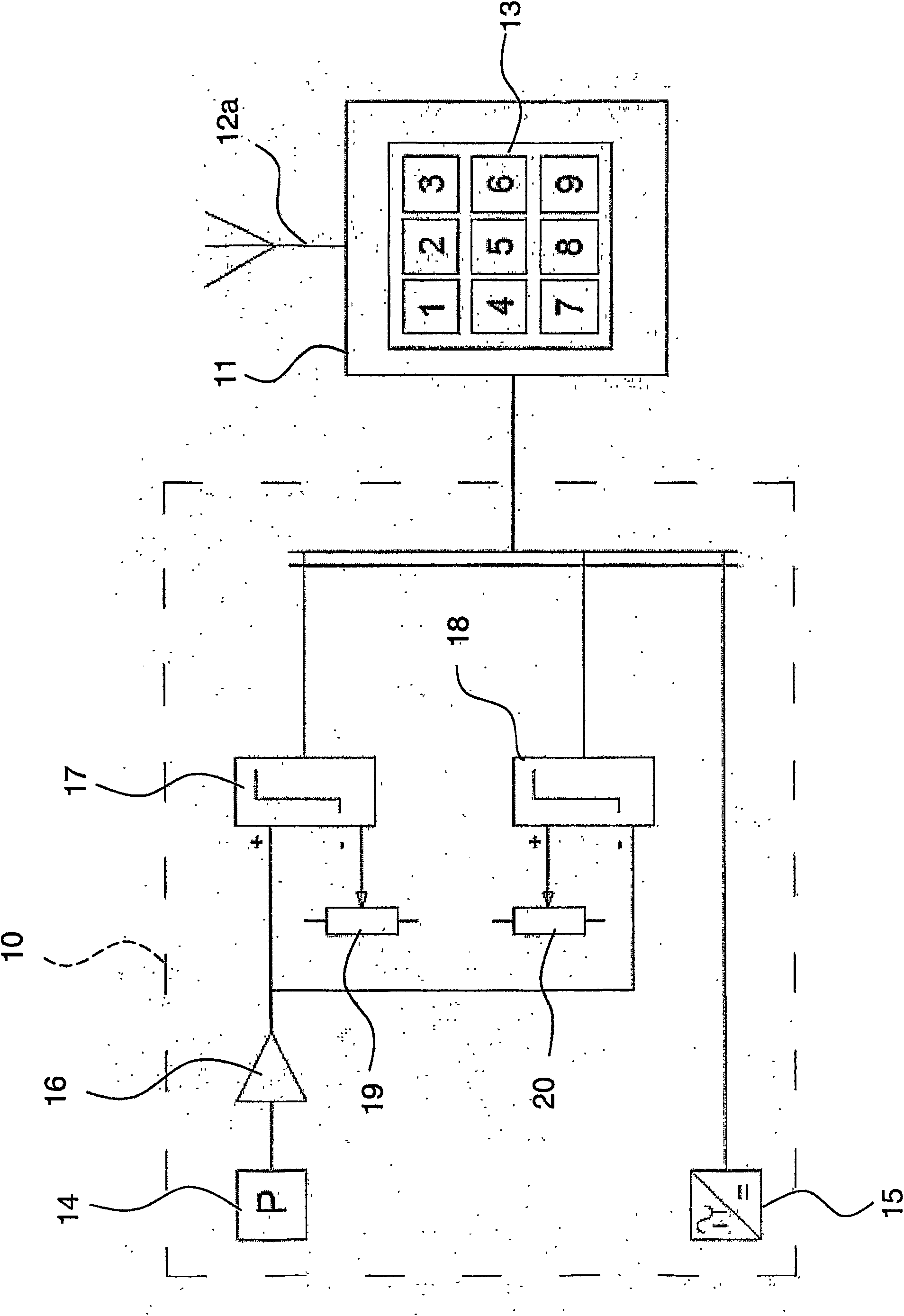

A method and a device for controlling an industrial process or production unit

InactiveCN101095092AEasy to controlIncrease or decrease speedControlling membersInvalid friendly devicesDesign controlProduction unit

The invention relates to a method for controlling a process and / or a production unit. The invention is achieved by the operator controlling the production unit by blowing or sucking a specially designed control device. The invention also relates to a system and an operating member for controlling a process and / or a production unit.

Owner:ABB POWER GRIDS SWITZERLAND AG

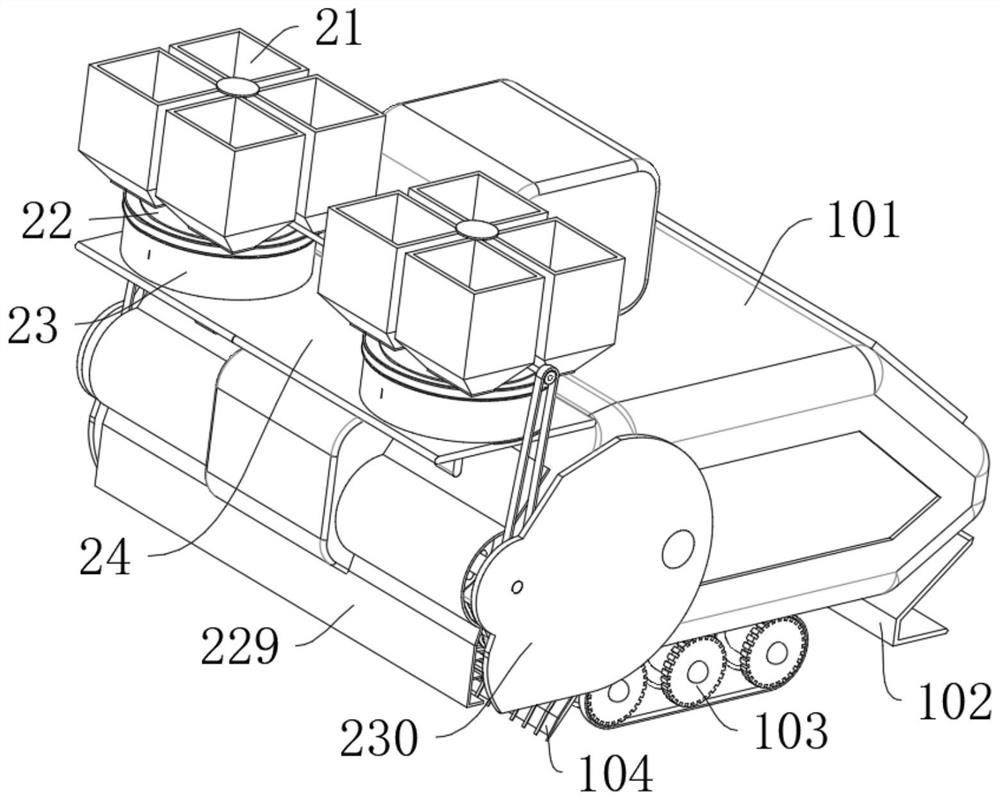

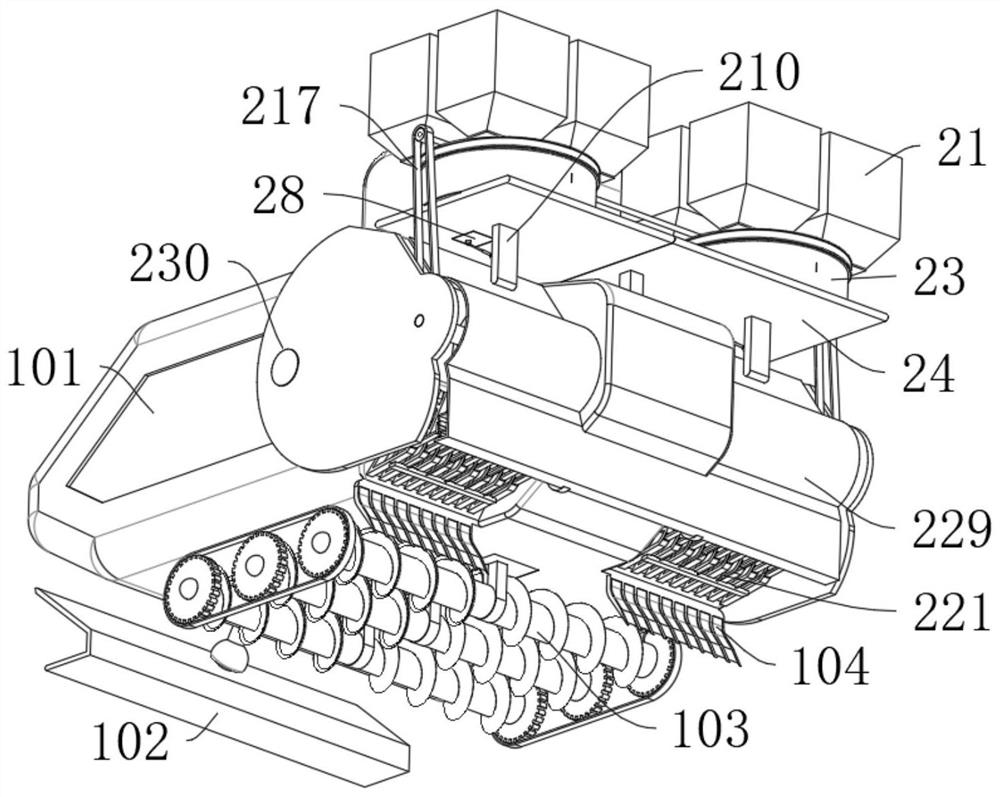

Agricultural rotary cultivator with automatic fertilization function

ActiveCN114503804ARealize mixed fertilizationPrevent sprayingSpadesPlantingRotational axisGear wheel

The invention discloses an agricultural rotary cultivator with an automatic fertilization function, and particularly relates to the field of agriculture, the agricultural rotary cultivator comprises a main body mechanism, a fertilization mechanism is fixedly mounted on one side of the main body mechanism, the main body mechanism comprises a rotary cultivator shell, a front scraper is arranged at the bottom of the rotary cultivator shell, and the fertilization mechanism at least comprises four storage bins; second discharging ports are formed in the bottoms of the four storage bins, a connection type supporting base is fixedly installed at the bottoms of the four storage bins, a moisture-proof sleeve is fixedly installed at the bottom of the connection type supporting base, and a moisture-proof bottom plate used for being connected with a rotary cultivator shell is fixedly installed at the bottom of the moisture-proof sleeve; and a first rotating shaft is rotationally mounted at the top of the moisture-proof bottom plate. According to the invention, the rotating drum enables a spiral limiting block to enable a gear disc to rotate through a third rotating shaft and a conveying belt, so that a rotating plate is driven to rotate, and rotary mixing and overturning work are carried out through a stirring pipe, so that mixed fertilization of various fertilizers is realized, and the working efficiency is improved.

Owner:LIANYUNGANG SHUANGYA MACHINERY CO LTD

Printing pattern length control method meeting color register stability

PendingCN114523756APrecise control position relationshipControl position relationshipRotary pressesPrinting press partsMechanical engineeringPhysics

The invention relates to a printing pattern length control method capable of meeting color register stability, which comprises the following steps: a printing material sequentially passes through a printing roller and n printing plate rollers, and each printing plate roller is used for printing; comprising the following steps that SA, the positions of all printing plate rollers are debugged and fixed; sB, calculating the arc length of an arc between the contact points of each adjacent printing plate roller and the printing roller on the printing roller; sC, the error detection system is used for measuring the real-time length of the pattern in the printing material conveying process, and the length of the printing pattern needing to be compensated is calculated; sD, the rotating speed of the first printing plate roller is increased or decreased according to the length of the error; sE, the rotating speeds of the second printing plate roller, the third printing plate roller to the nth printing plate roller in the conveying direction of the printing material are sequentially increased or decreased when the printing area of the printing material arrives, the time difference of changing the rotating speeds of the adjacent printing plate rollers is the ratio of the arc length of the arc between the contact points of the adjacent printing plate rollers and the printing roller on the printing roller to the conveying speed of the printing material, and color register is accurate and stable.

Owner:福建琦峰科技有限公司

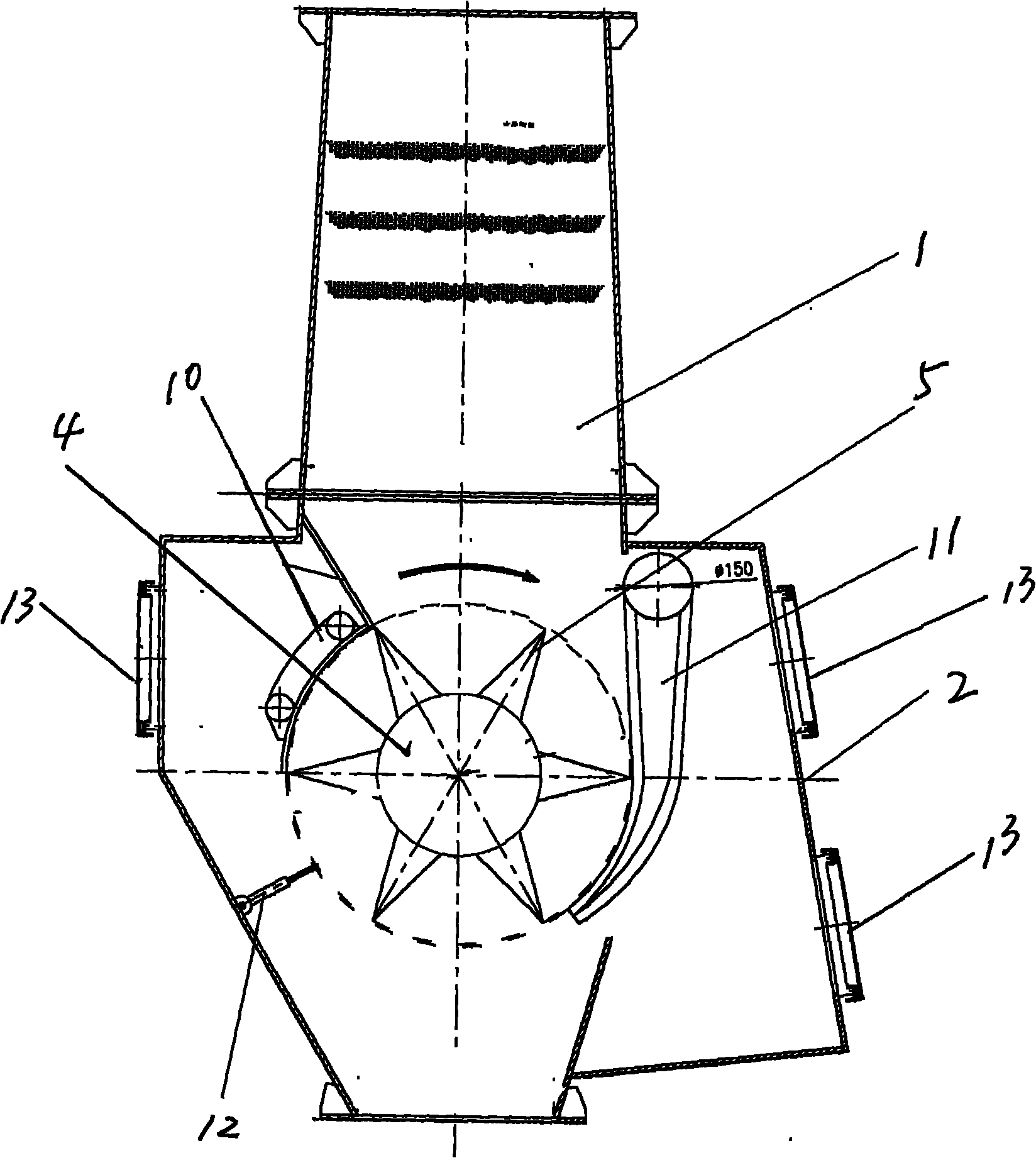

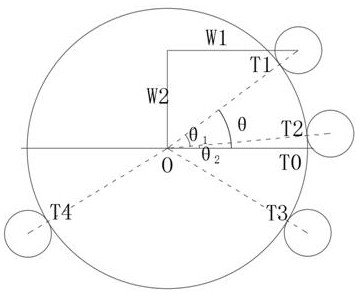

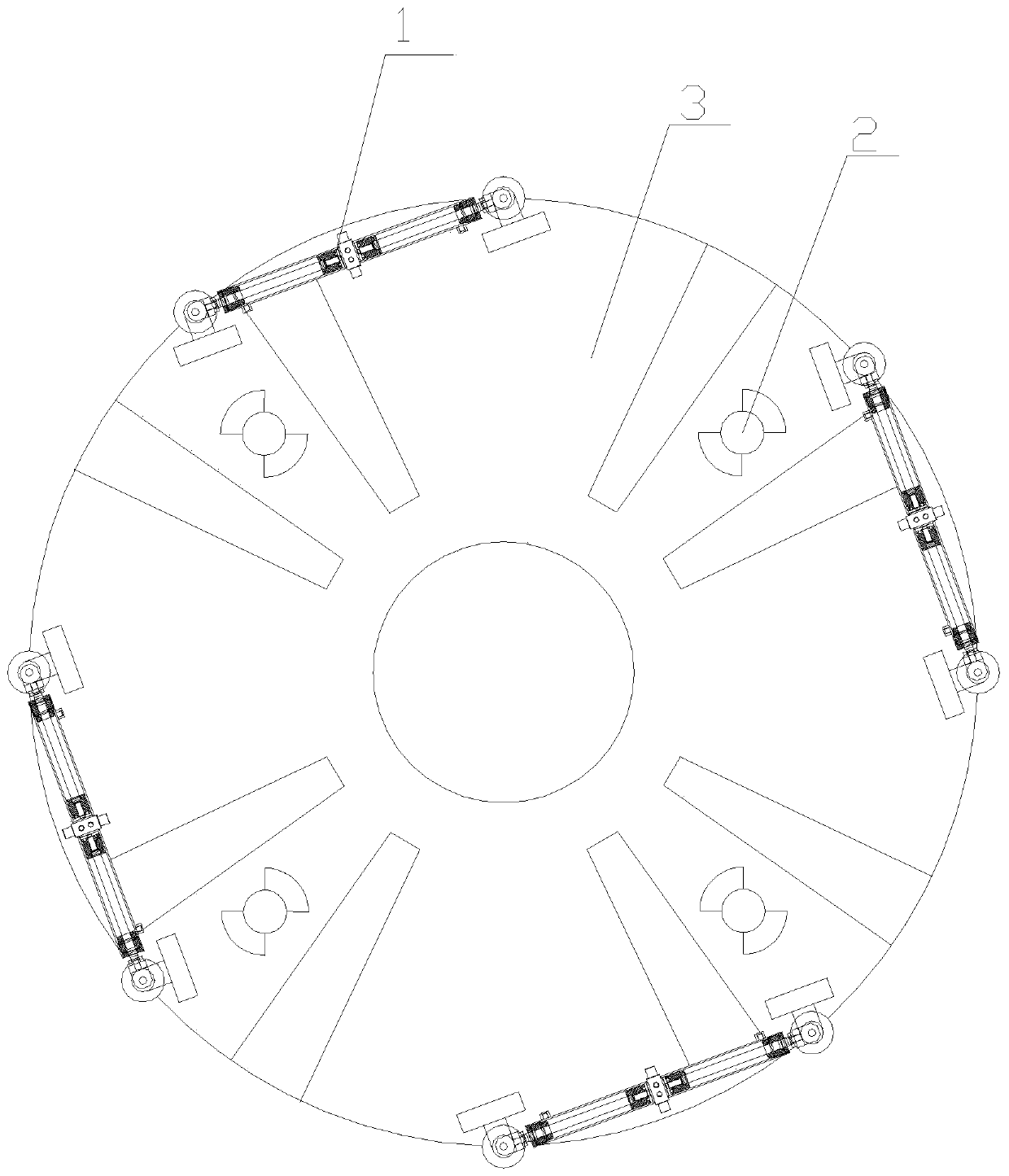

An adjustable tool mechanism for shield machine

An adjustable cutter mechanism for a shield tunneling machine comprises four sets of scraper assemblies and four sets of reamer assemblies which are arranged on a cutter disc. The adjustable cutter mechanism for the shield tunneling machine is characterized in that the scraper assemblies are circumferentially arranged at the edge of the cutter disc at equal intervals, and the reamer assemblies are circumferentially arranged in the middle of the cutter disc at equal intervals; each scraper assembly comprises scraper bodies and a two-way oil cylinder, wherein the middle of the two-way oil cylinder is fixed on the cutter disc through a positioning block, and the scraper bodies are arranged on the two end heads of the two-way oil cylinder; each reamer assembly comprises a reamer bit body, a speed reducer, a variable displacement motor and a sliding rail device, the reamer bit bodies are arranged in the sliding rail devices, the sliding devices are arranged in the cutter disc, the speed reducers are arranged on the back sides of the reamer bit bodies, the variable displacement motors are arranged on the back sides of the speed reducers, and the back sides of the variable displacement motors are provided with hydraulic oil pipes. According to the adjustable cutter mechanism for the shield tunneling machine, the cutter disc is adjustable, and the adaptability is stronger.

Owner:蚌埠市行星工程机械有限公司

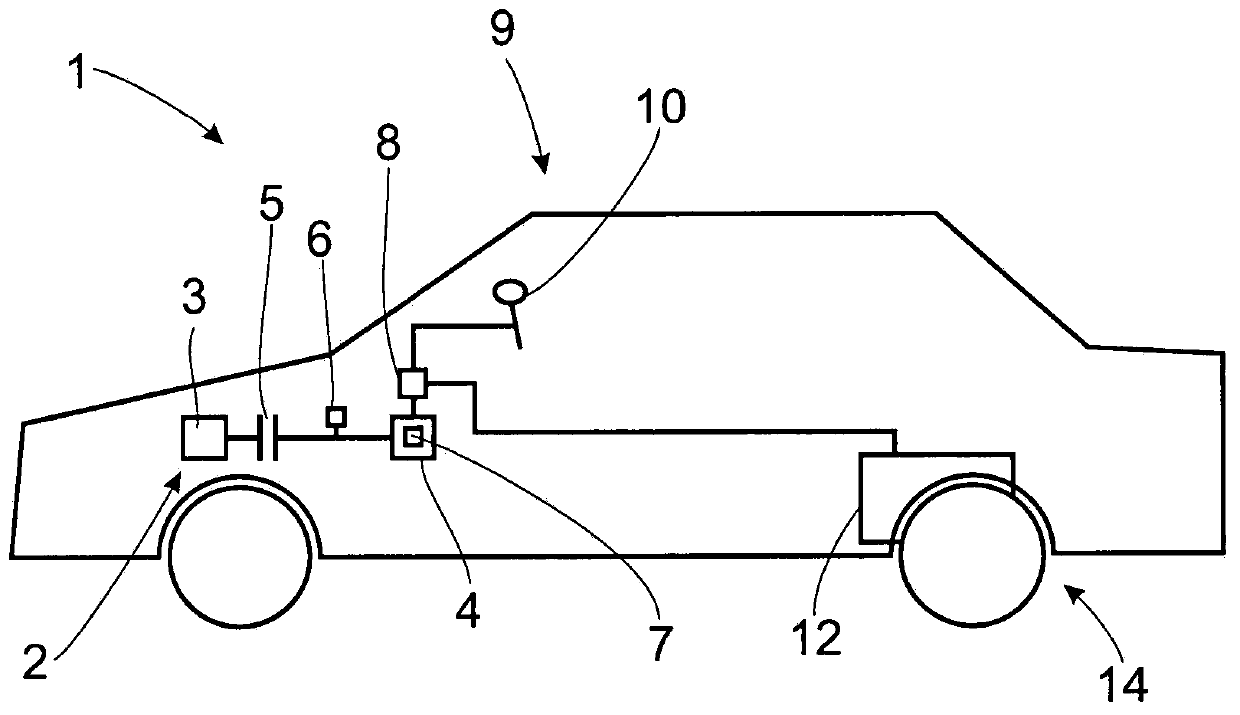

Method for operating a motor vehicle, control device and motor vehicle

PendingCN110588668AAchieve brakingVary the degree of energy recoveryDashboard fitting arrangementsGearing controlDriving mode

The invention relates to a method for operating a motor vehicle (1) with a first driving mode and a second driving mode, the motor vehicle having at least one control element (9), characterized in that the control element (9) of the motor vehicle (1) is dependent on the driving mode with different functions. In addition, the invention relates to a control device. In addition, the invention relatesto a motor vehicle.

Owner:ZF FRIEDRICHSHAFEN AG

Electrical machine with a machine assembly and a compressor assembly

PendingCN111086386AIncrease or decrease speedQuiet operationAuxillary drivesGas pressure propulsion mountingElectric machineEngineering

Owner:FORD GLOBAL TECH LLC

A method and a device for controlling an industrial process or production unit

InactiveCN100589061CEasy to controlIncrease or decrease speedControlling membersDesign controlProduction unit

The invention relates to a method for controlling a process and / or a production unit. The invention is achieved by the operator controlling the production unit by blowing or sucking a specially designed control device. The invention also relates to a system and an operating member for controlling a process and / or a production unit.

Owner:ABB POWER GRIDS SWITZERLAND AG

Constantly-uniform distributor for coal crusher of coal conveying system in heat-engine plant

InactiveCN102029210BOvercoming the problem of uneven blankingIncrease or decrease speedGrain treatmentsSignal processing circuitsDrive motor

The invention discloses a constantly-uniform distributor for a coal crusher of a coal conveying system in a heat-engine plant, which belongs to the field of machinery, is used for supplying coal to the coal crusher and overcomes the defects of damage to coal conveying equipment and combustion equipment or waste of equipment materials and labor force caused by non-uniform wear of a hammer head of the coal crusher in the prior art. The constantly-uniform distributor comprises a material storage box, a material balancing box, material balancing rotors, a material balancing rotor drive motor and an intelligent material stack height control mechanism, wherein the material balancing box is connected to the lower end of the material storage box; the material balancing rotors of which the two ends are arranged on a box body through bearings and the circumferential surfaces are provided with switch-plates are arranged in the material balancing box; a material position sensor which consists of a rigid float ball, a lever and an inductive element on the outer end part of a lever box are arranged on the material storage box; and the intelligent material stack height control mechanism consists of the material position sensor and a signal processing circuit. The invention has the advantages that: the problem of non-uniform blanking on the rotor of the conventional coal crusher is solved; a material stack on the material storage box is kept at an appropriate height; coal passing through the distributor is non-sticky, blocking-resistant and sticking-resistant; and the constantly-uniform distributor is the optimal material balancing device for the coal crusher.

Owner:马奎山

Heat pump for extracting soil energy

InactiveCN1306233CAccessibilityIncrease or decrease speedHeat pumpsOther heat production devicesEvaporationCollector device

A ground source heat pump system includes a geothermal energy collecting equipment, an energy exalting equipment and a radiator connected in series. The geothermal energy collecting equipment includes a circuit of a heat collector, a low-grade heat exchanger coil and a pump in series. The energy exalting equipment includes a circuit of an evaporation, two compressors, a condenser and a expansion valve in series, the said two compressors are connected in parallel. The radiator includes a circuit of a energy inputting coil, a pump and several radiation fin in series. A heat exchanger equipment is provided between the energy exalting equipment and the radiator. The fluid inside the geothermal energy collecting equipment and the heat exchanger equipment is antifreeze. The system of the invention has a simple structure, which is easily to install and maintain, and can work normally in any case.

Owner:北京永源热泵有限责任公司

Heat pump for extracting water energy

InactiveCN1320325CIncrease or decrease speedNo freezingMechanical apparatusHeat pumpsEvaporationEngineering

A heat pump system by using water as energy source, includes an energy-collecting equipment, a second heat exchanger, an energy-exalting equipment, a first heat exchanger and a radiator connected in series. The energy-collecting equipment includes a circuit of a low-grade heat exchanger coil, a collector well and a diving pump inside the well in series. The energy-exalting equipment includes a circuit of an evaporation, two compressors, a condenser and a expansion valve in series, the said two compressors are connected in parallel. The radiator includes a circuit of an energy-inputting coil, a pump and several radiation fin in series. Inside the first and second heat exchanger, there is antifreeze. The system has a simple structure, which is easily to install and maintain, and can supply heat or cold to users normally in any case.

Owner:北京永源热泵有限责任公司

hydraulic brake system

A hydraulic brake system for a passenger transport installation includes actuation equipment, a pump supplying brake fluid to a piston space of the actuation equipment and a motor driving the pump. A control device controls the motor by a frequency inverter whereby the pump supplies brake fluid at a predetermined delivery flow rate (QP). A pressure (pB) is set in the piston space corresponding to an equilibrium in which the delivery flow rate (QP) is equal to a return flow rate (QL). The control device sets the pressure (pB) by the delivery flow rate (QP) of the pump. The passenger transport installation can be a lift, an escalator or a moving walkway having this brake system operated according to the described method for controlling the braking force.

Owner:INVENTIO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com