A method and a device for controlling an industrial process or production unit

A control process and control device technology, applied in the direction of mechanical control devices, control components, control/adjustment systems, etc., can solve the problems of unnatural working position of pedals, low efficiency utilization of machines, low time utilization of machines, etc., and achieve good results Ergonomics, efficient operation, and the effects of improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

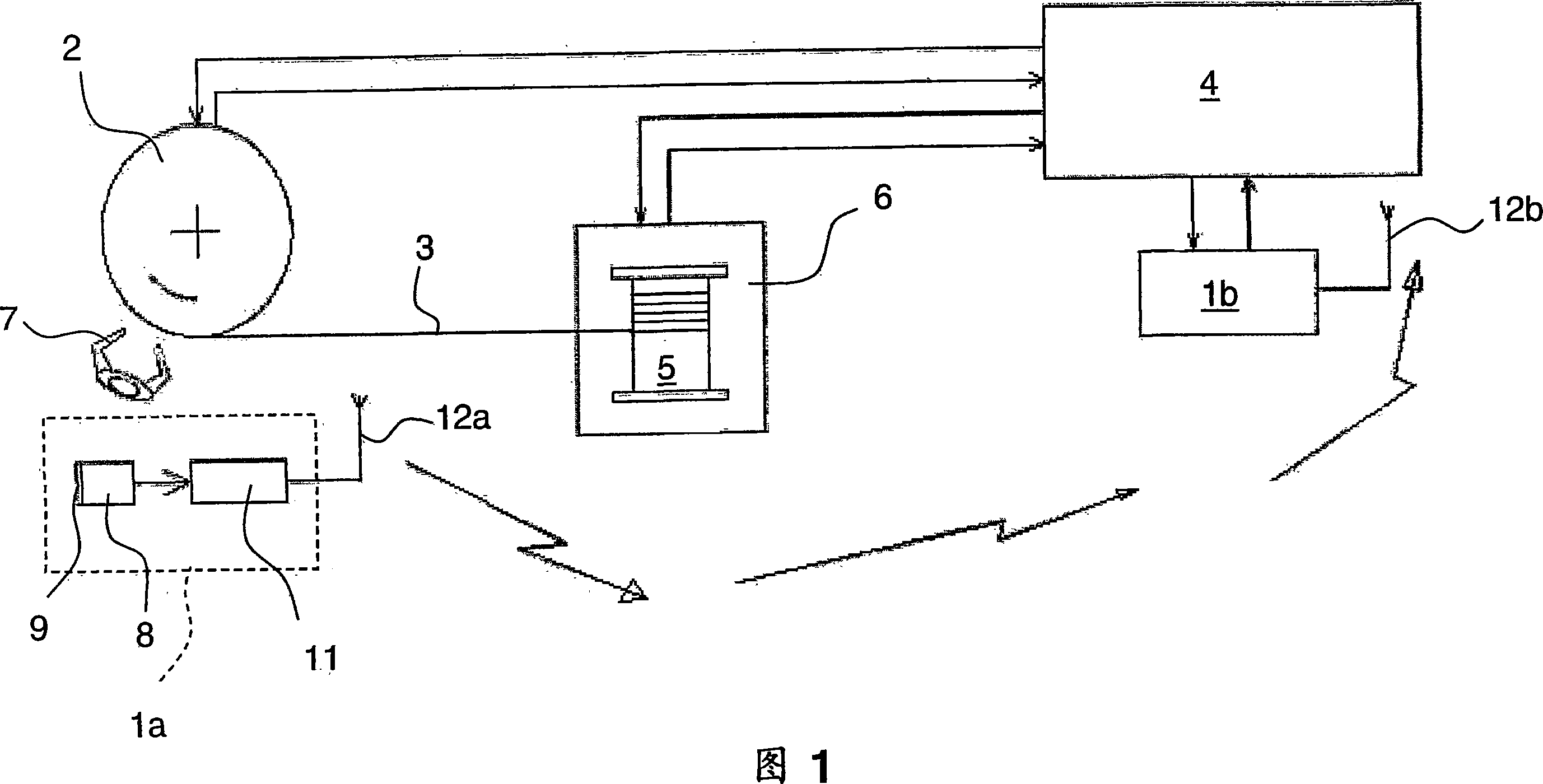

[0016] FIG. 1 thus shows a block diagram of a control device 1a, b according to the invention, showing how it is connected and cooperates electrically with, in this case, a winding machine for manufacturing a transformer winding. The winding machine itself consists of a vertically standing / rotating cylinder 2 powered by an electric motor, around which copper wire 3 is wound. The motorized cylinder 2 is controlled by an automatic control unit 4 which supplies electric power to an electric motor (not shown) and controls and monitors the necessary functions in the production facility. When the manufacture of a new transformer winding is to start, the ends of the copper wire 3 from the drum 5 with copper wire placed in the unwinding unit 6 are attached to the cylinder 2, and then the operator 7 via the control device 1a, b Set cylinder 2 to rotate.

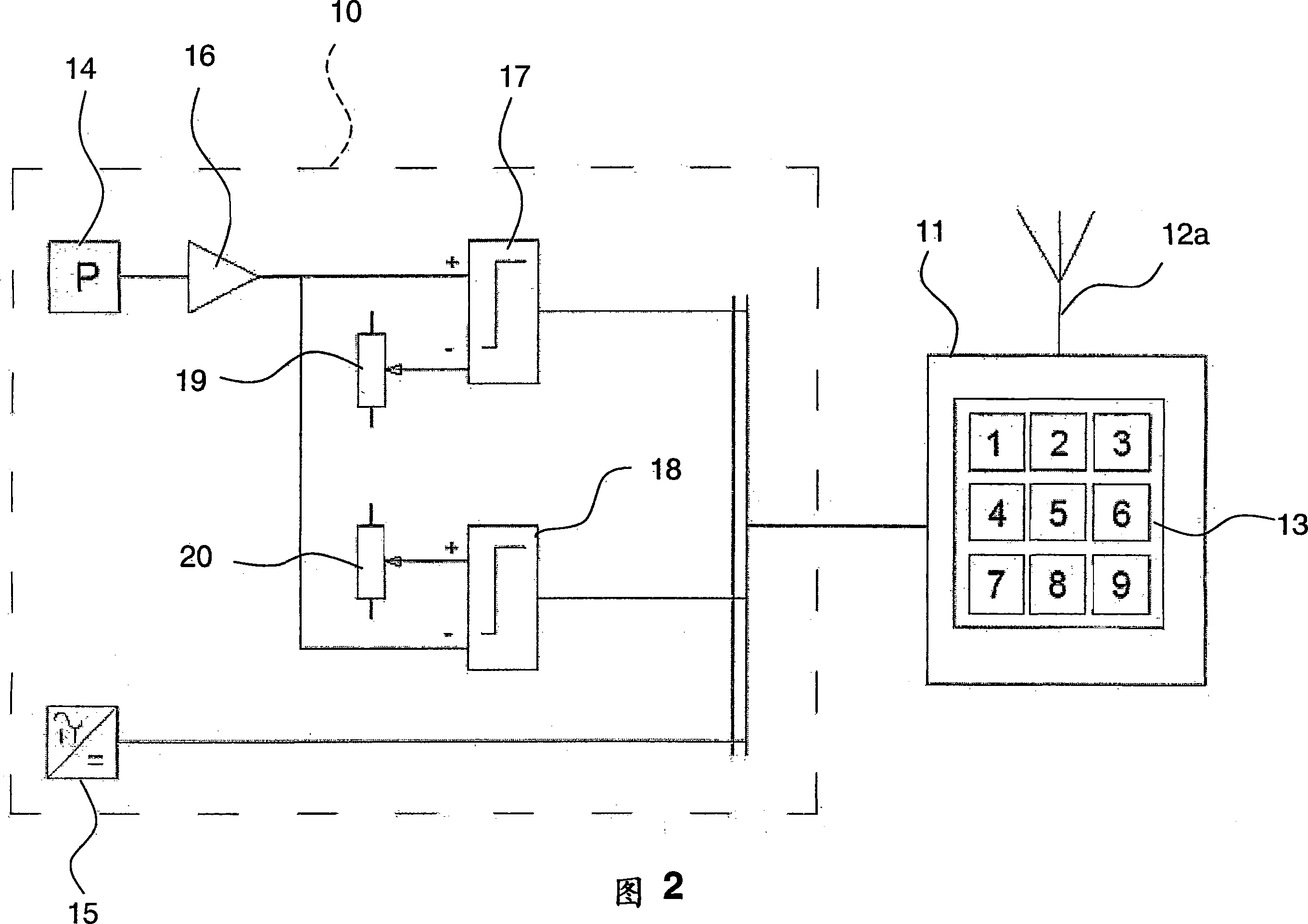

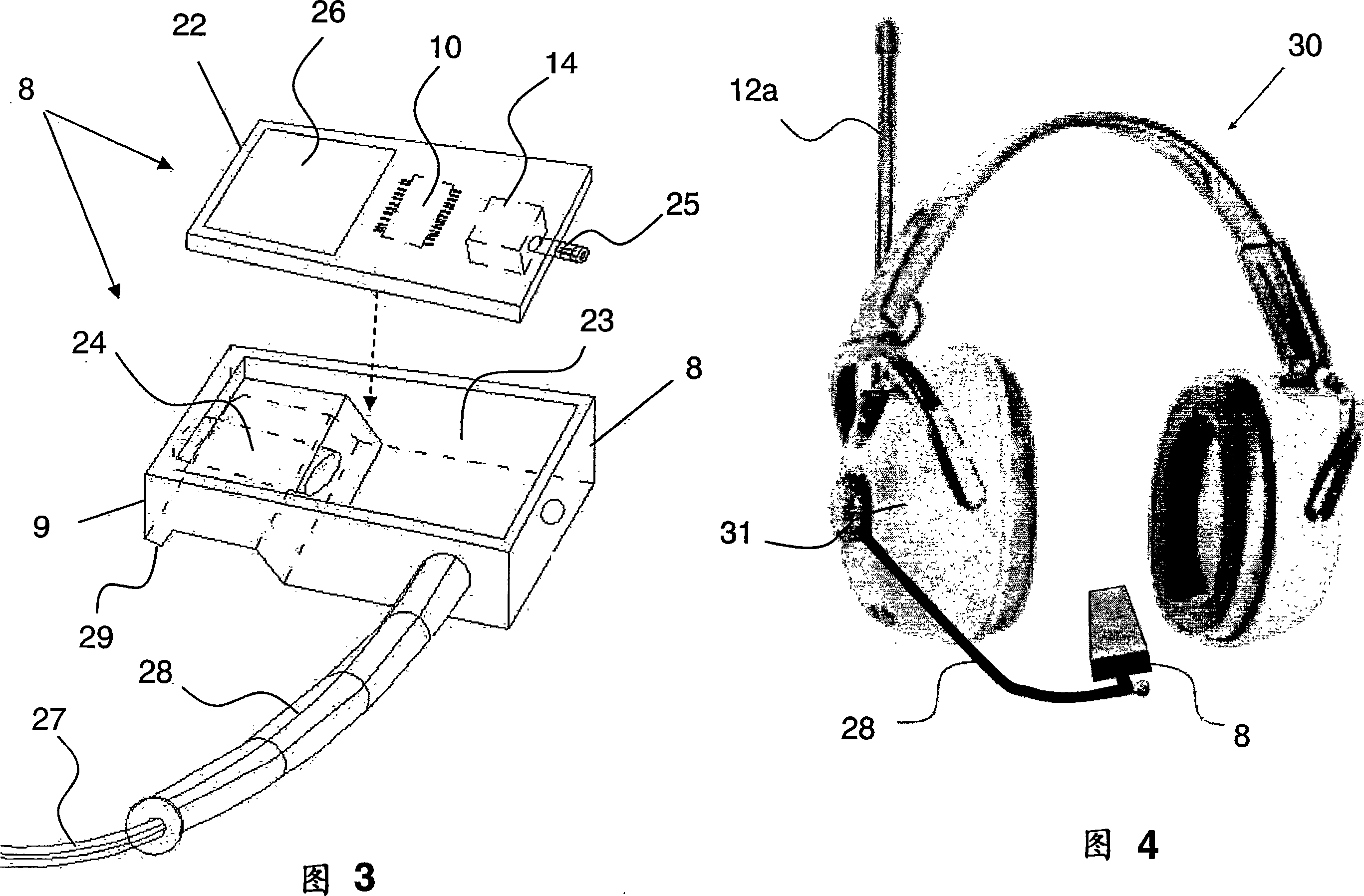

[0017] The control device comprises a transmitter part 1a and a receiver part 1b. The transmitter part 1a in turn consists of a wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com