Control method of blower motor and blower motor system

A fan system and control method technology, applied in the direction of AC motor control, control system, auxiliary non-electric fluid pressure control, etc., can solve the problems of pressure sensor failure in abnormal state, increase the motor speed, cost, etc., and achieve simple structure reduction of maintenance costs and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

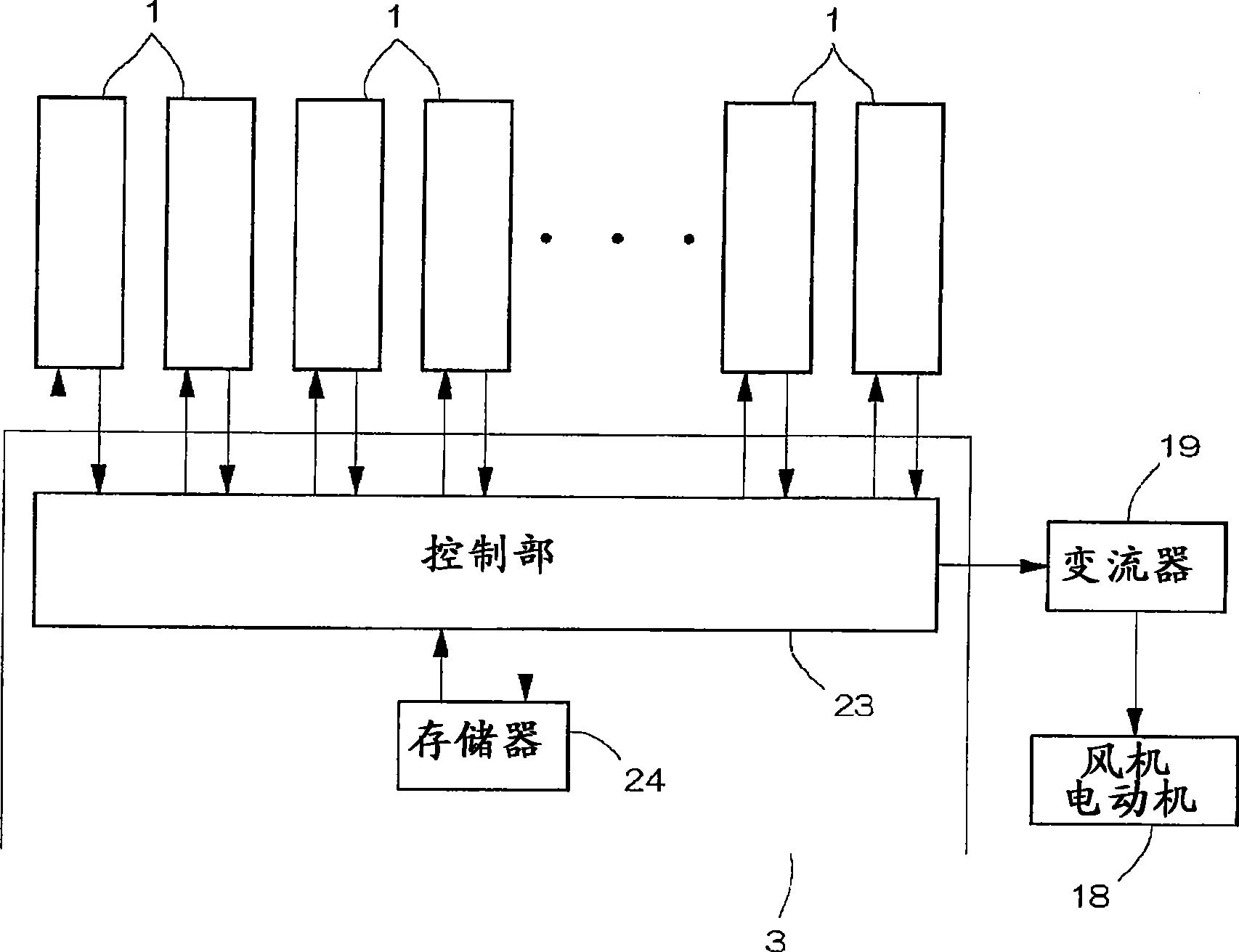

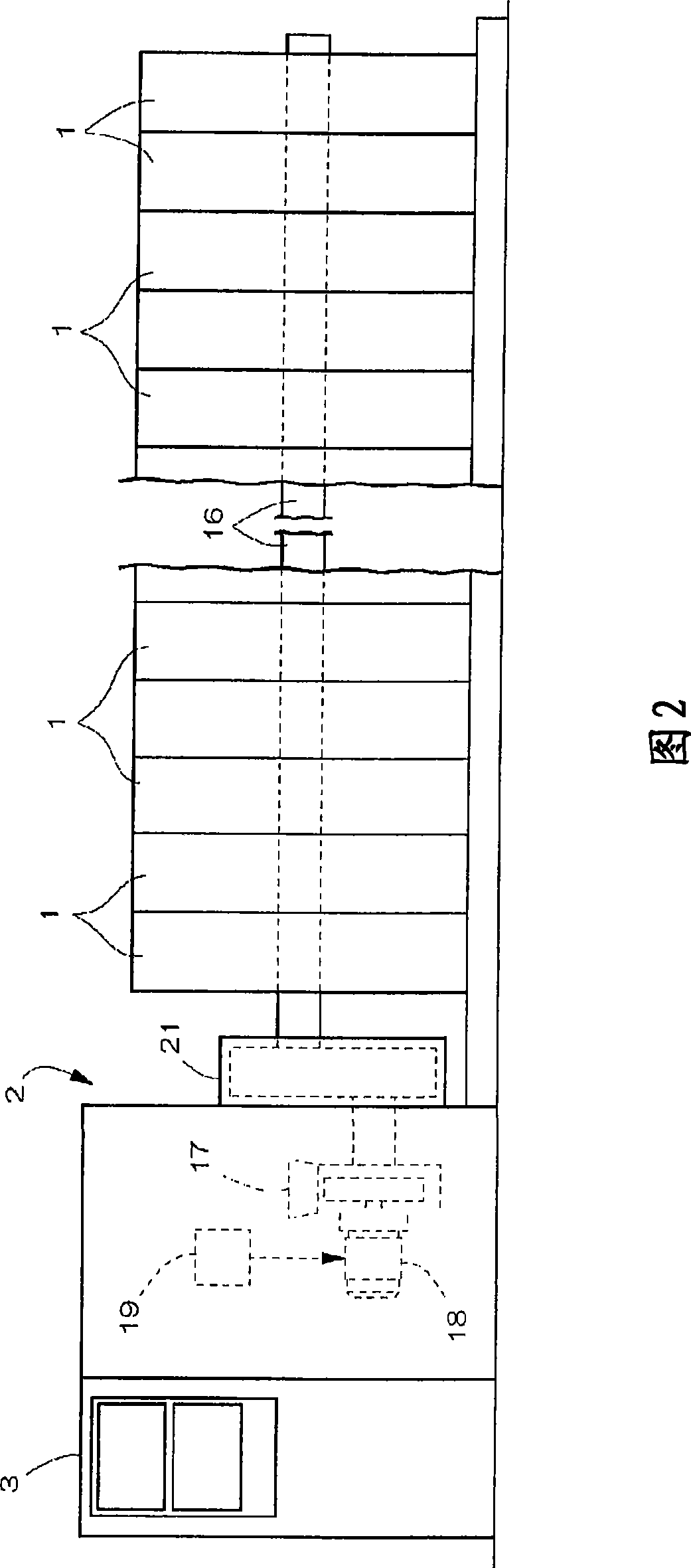

[0025] based on Figure 1 to Figure 4A first embodiment of an automatic winding machine to which the fan motor control method according to the present invention is applied will be described. As shown in Figure 2, the automatic winding machine includes: a group of winding units 1 configured in a row, a fan system 2 for supplying negative pressure to each winding unit 1, and a set of winding units 1 and the fan system. A control device 3 that performs operation management of the system 2 .

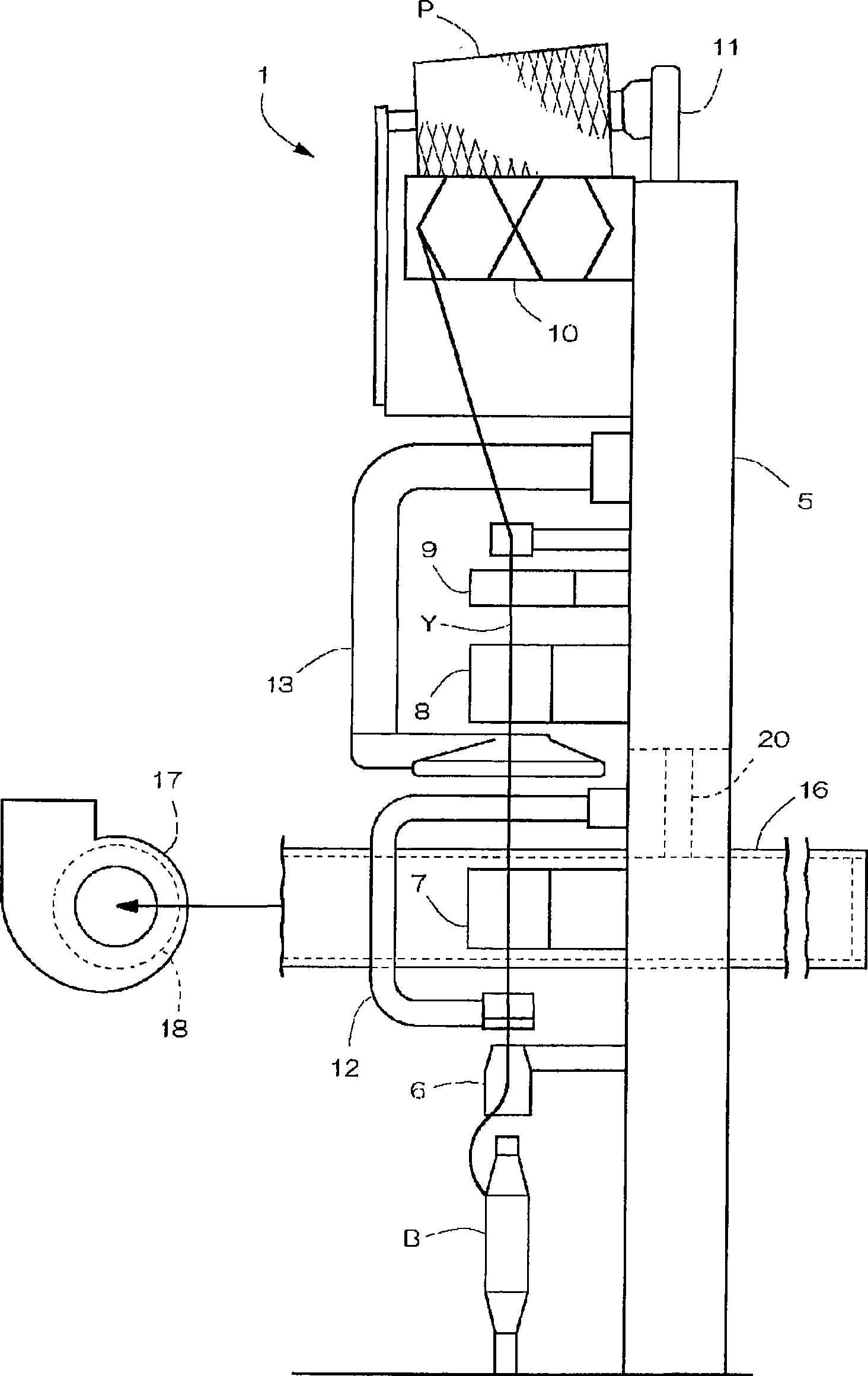

[0026] image 3 Among them, the winding unit 1 is constructed with a vertically long box-shaped main body frame 5 fixed upright as a base. The balloon breaker 6, the tension device 7, the piecing device 8, the yarn clearer 9, etc. are arranged on one side of the main frame 5 in the order described above from the lower part of the frame to the upper part of the frame. On one side of the upper part of the main body frame 5 are arranged a reciprocating drum 10 for moving and operating the ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com