Gearwheel unit, transmission having gearwheel unit and gearwheel manufacturing method

A technology of gear sets and gears, which is applied in the field of gear sets, can solve the problems of inability to form positioning parts of variable speed gears, failure to ensure target strength, poor manufacturability, etc., to prevent embedding of spray particles, ensure strength, and shorten axial length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

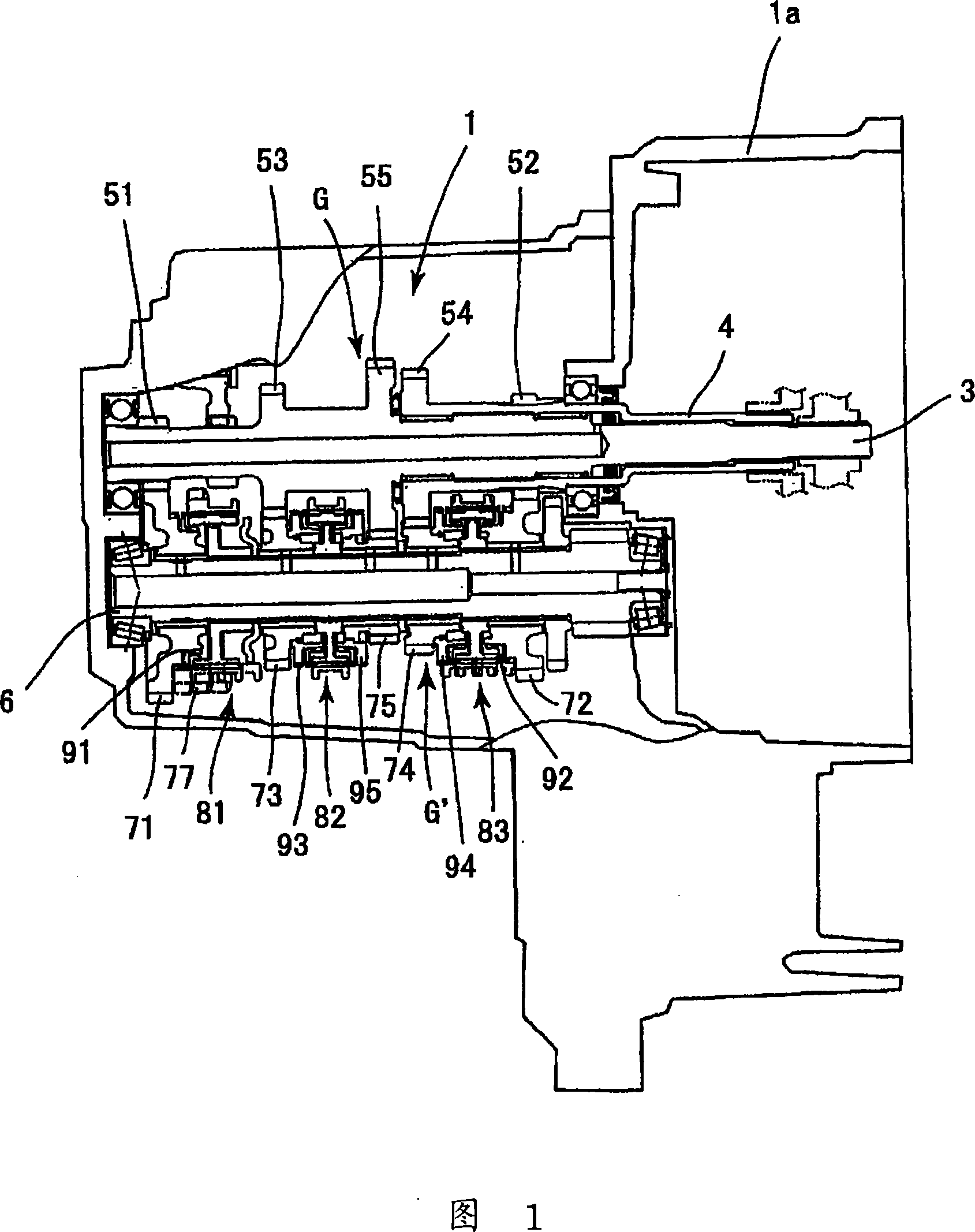

[0026] FIG. 1 is a configuration diagram showing a schematic configuration of a transmission case 1 equipped with a gear set as an embodiment of the present invention.

[0027] The gearbox 1 of the embodiment has a first input shaft 3, a second input shaft 4, and an output shaft 6. The first input shaft 3 is connected to a crankshaft of an engine not shown in the figure through a first clutch, and the second input shaft 4 Connected to the crankshaft of the engine not shown in the figure through the second clutch, and coaxially overlaid on the first input shaft 3, the output shaft 6 is connected to the first input shaft 3 and the second input shaft 4 through the transmission mechanism TM .

[0028] The transmission mechanism TM is composed of a driving gear set G, a driven gear set G′ and a synchronizing device 80. The driving gear set G is fixedly arranged on th...

Embodiment 2

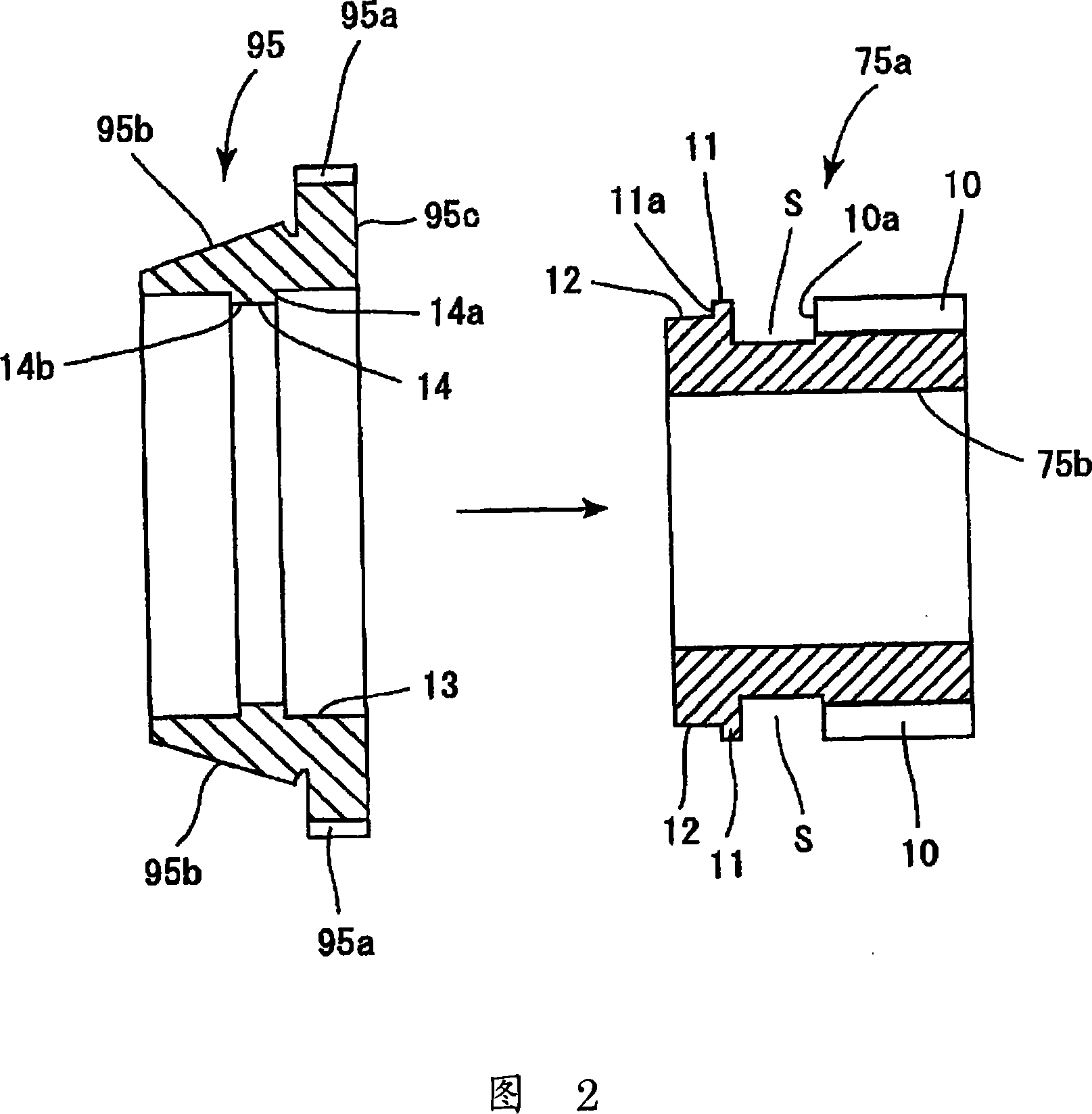

[0045] Hereinafter, what is shown in the exploded view of FIG. 4 and the assembled view of FIG. 5 is the second embodiment. In this second embodiment, the best method of positioning the clutch gear 95 well in the gearbox 1 of FIG. 1 is also adopted. The gear body 75 a of the driven gear 75 for the small gear, that is, the 5th speed has a structure in which the clutch gear 95 is assembled and fixed to the driven gear 75 by shortening the axial length.

[0046] In the second embodiment, a space S is formed on the left side of the tooth portion 10 of the gear main body 75a in the drawing, and protrudes radially outward from the left side of the space S in the drawing to the left end surface 75c of the gear main body 75a. Protruding portion 11 is integrally formed. In the gear main body 75 a , the vertical surface at the right end of the protruding portion 11 becomes the abutment surface 11 a against which the clutch gear 95 abuts, and the outer peripheral surface of the protruding...

Embodiment 3

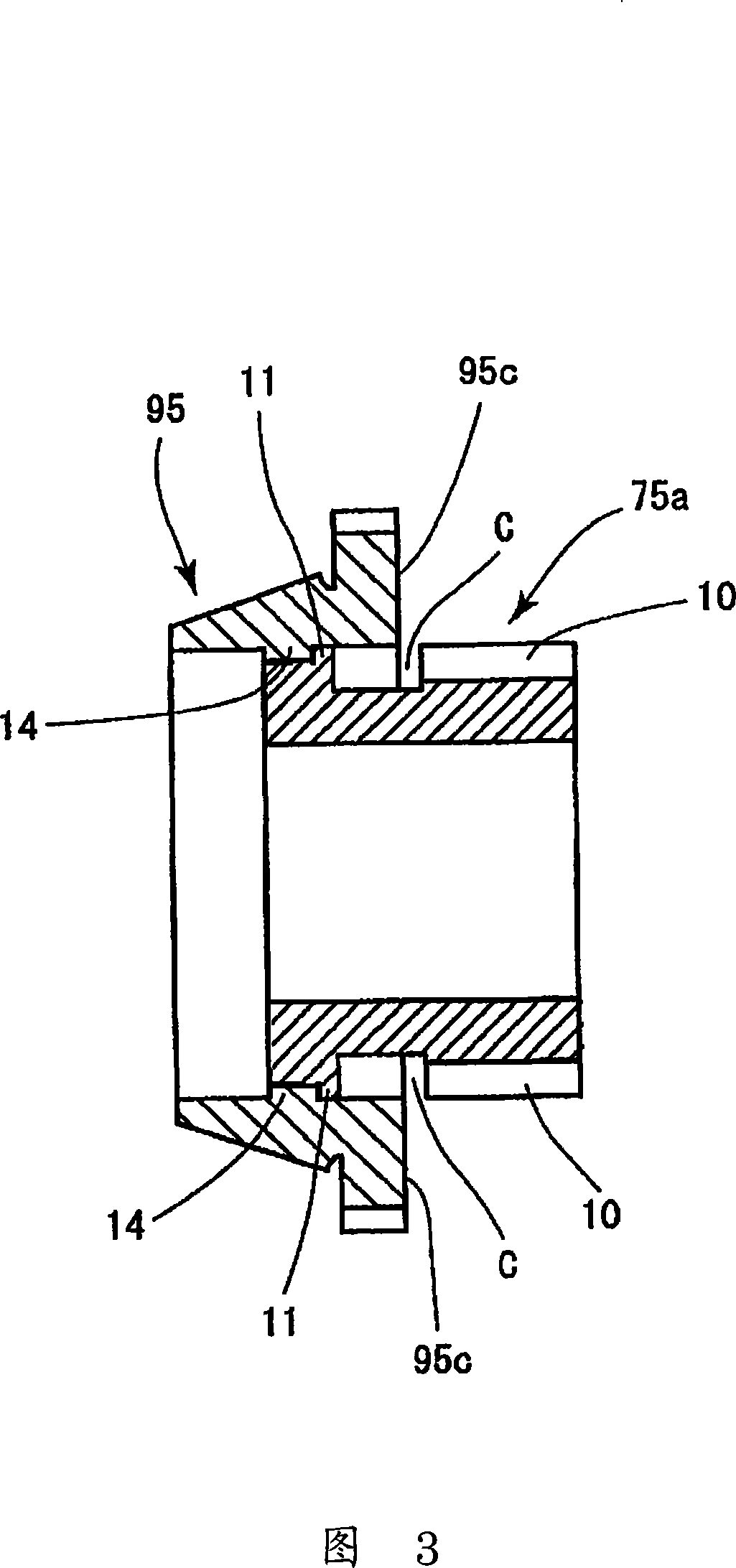

[0050] Hereinafter, the third embodiment is shown by the exploded view of FIG. 6 and the assembled view of FIG. 7 .

[0051] The gear main body 75a of the third embodiment has the same shape as the gear main body 75a of the second embodiment, and a space S is formed on the left side of the gear end surface 10a of the outer peripheral tooth portion 10 in the drawing, and a space S is formed on the left side of the space S in the drawing. A protrusion 11 is formed extending to the left end surface 75c and protruding outward in the radial direction. The outer periphery of the protrusion 11 becomes the fitting surface 12. In the example, it is set as the contact surface 11a on the side of the gear main body 75a.

[0052] On the other hand, in the clutch gear 95, an inner protrusion 14 is integrally formed on the inner peripheral side of the tapered portion 95b formed on the outer periphery to protrude in the inner diameter direction. The inner periphery of the right engaging hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com