Constantly-uniform distributor for coal crusher of coal conveying system in heat-engine plant

A technology for a coal conveying system and a coal crusher, applied in the field of machinery, can solve the problems of wasting equipment materials and labor, harming combustion equipment, etc., and achieve the effects of stable operation, uniform distribution, and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

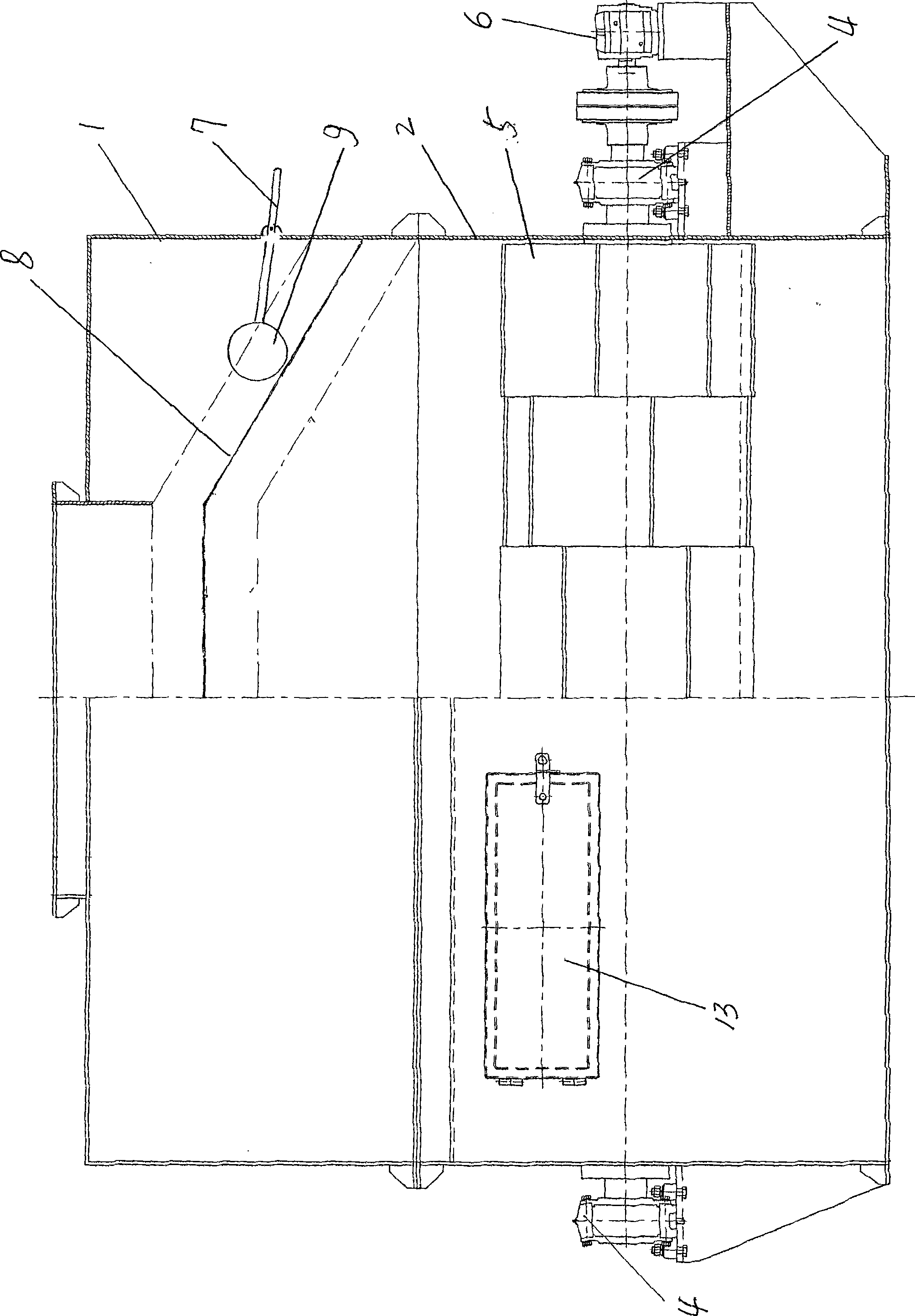

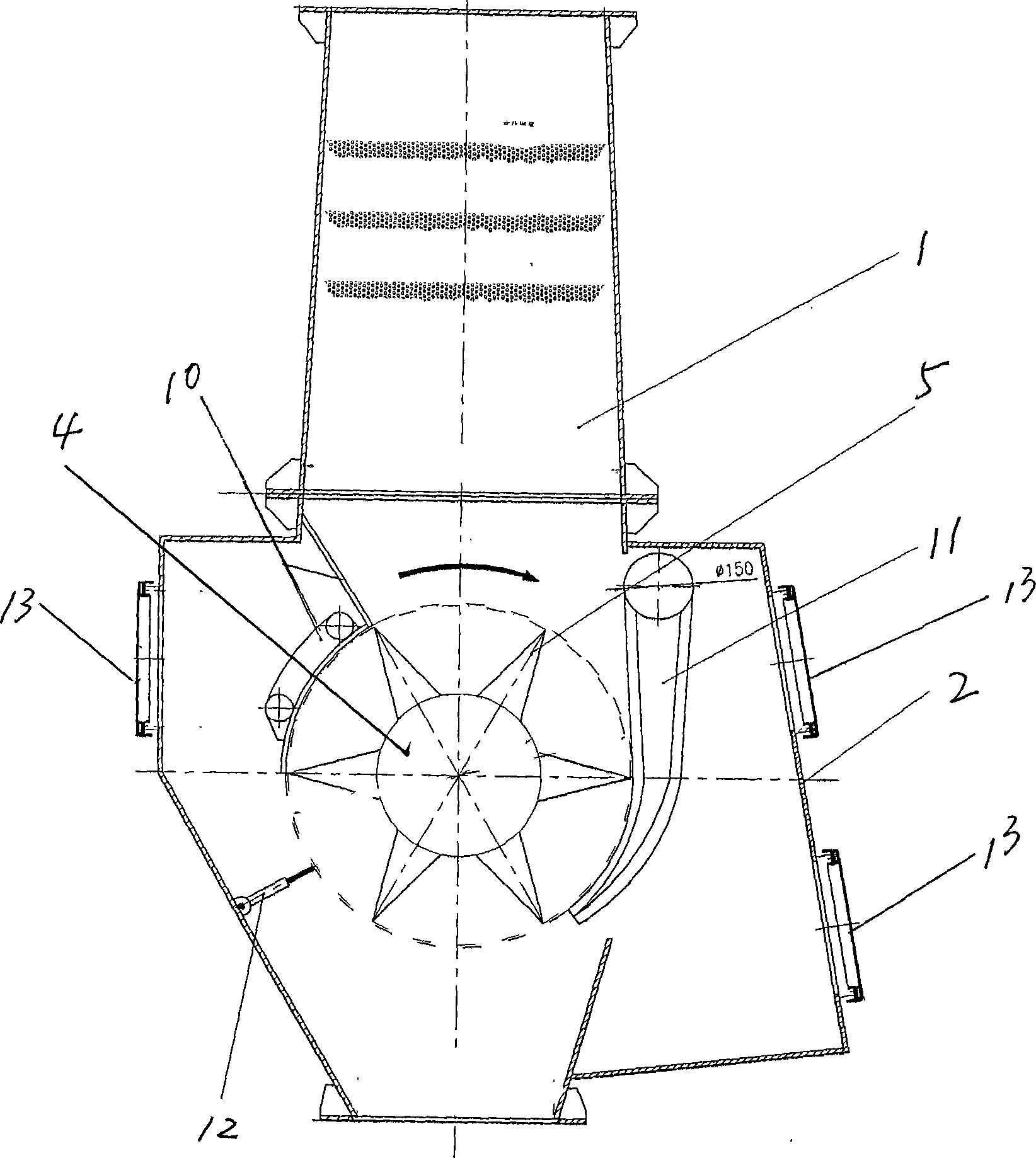

[0014] refer to figure 1 , figure 2 According to the size of the matched coal crusher, the material storage box 1 is made, the material storage box 2 is connected with the lower end of the material storage box, and the material uniform rotor 3 is installed in the material storage box 2 through the bearing 4 fixed on the wall of the material storage box. . Material shifting plates 5 are distributed on the circumferential surface of the uniform material rotor, and the uniform material rotor drive motor 6 is installed outside the material uniform box. Wherein, the length of the uniform material box 2 in the axial direction of the material uniform rotor is the same as the length of the coal crusher casing in the axial direction of the coal crushing rotor. The length of the feed port at the upper end of the uniform material box 2 and the discharge port at the lower end is the length of the casing cavity, and the feed port of the coal crusher docked with the constant uniform dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com