Printing pattern length control method meeting color register stability

A technology of printing patterns and control methods, applied in printing, printing presses, rotary printing machines, etc., can solve the problems of inaccurate color registration of patterns, and achieve the effect of accurate and stable color registration, ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

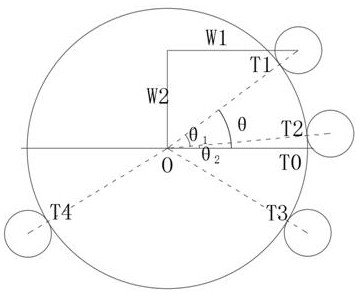

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

[0027] like figure 1 As shown, this embodiment provides a printing pattern length control method that satisfies color registration stability. In this printing method, the printing material passes between the printing roller and n printing plate rollers in sequence, and each printing plate roller performs corresponding color matching. Group printing; wherein n is greater than or equal to 2, specifically, the number of printing plate rollers is two, three, four, five or six, and the method includes the following steps:

[0028] SA: Debug and fix the position of each printing plate roller, so as to facilitate the subsequent measurement of the positional relationship between each printing plate roller and the printing cylinder;

[0029] SB: Calculate the arc length on the printing roller between the contact points of each adjacent printing plate roller and the printing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com