Knurling and sharp corner rubbing integrated forming method

A molding method and technology with sharp corners, applied in the direction of connecting members, nails, pins, etc., can solve the problems of unsatisfactory molding efficiency, and achieve the effect of improving molding effect, high molding efficiency and good molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

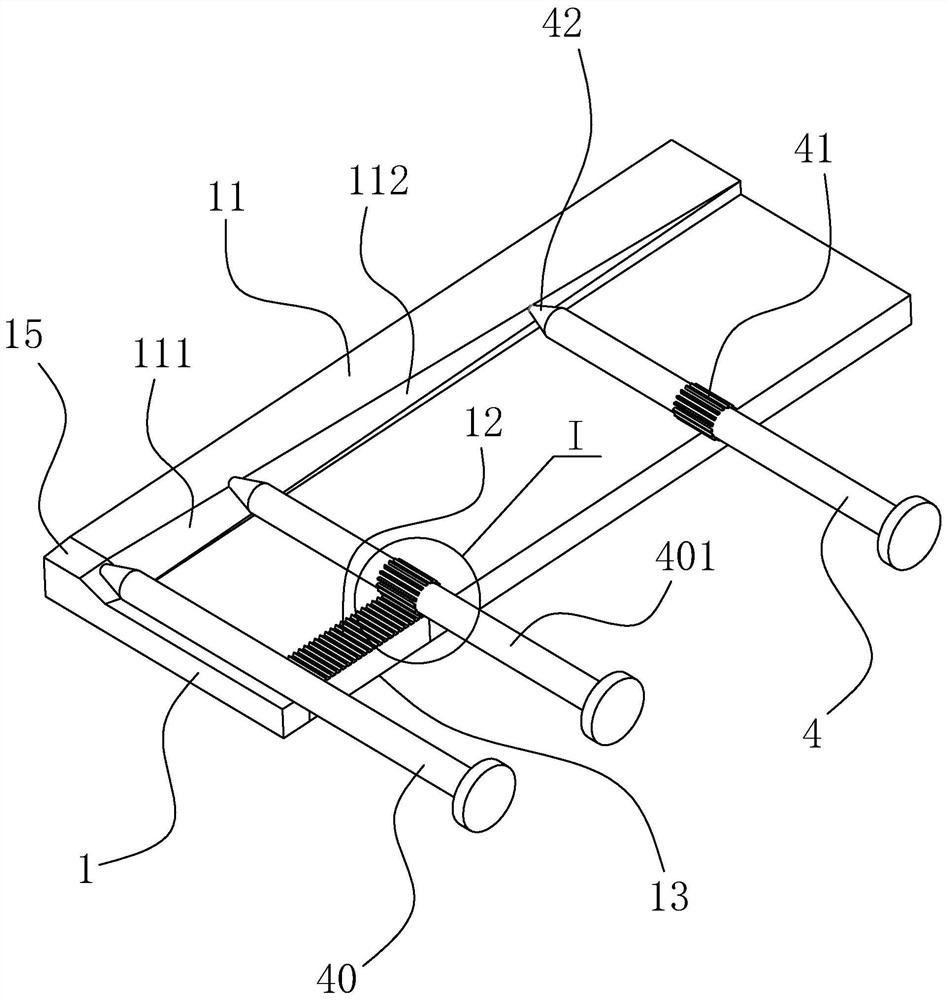

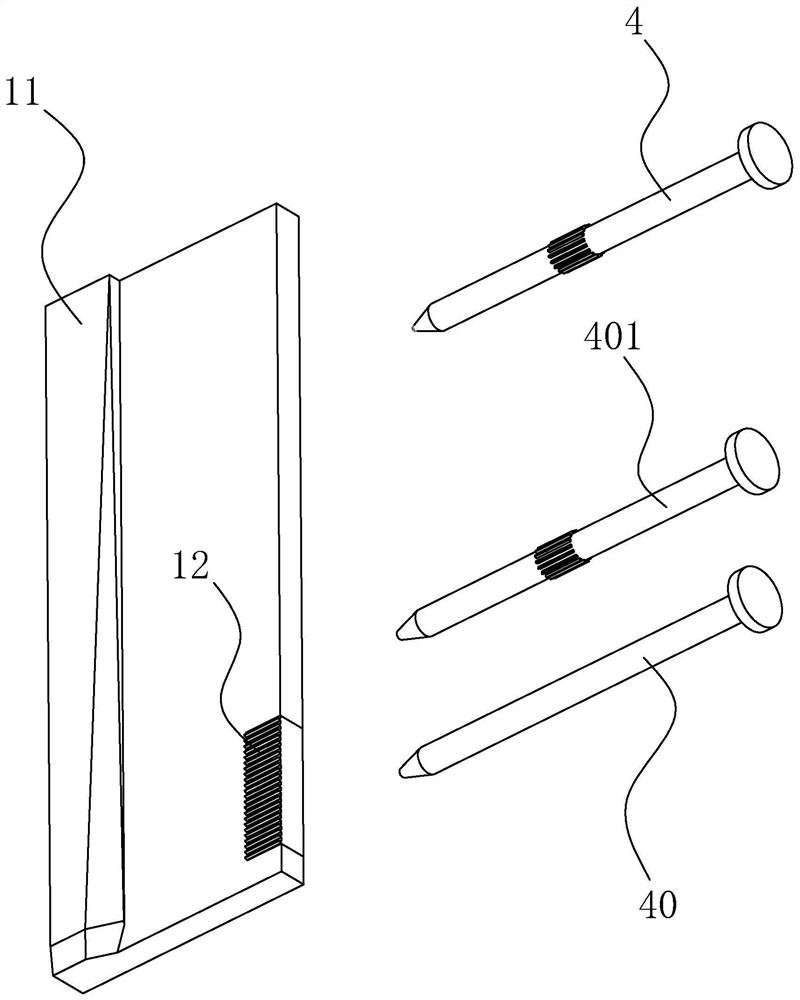

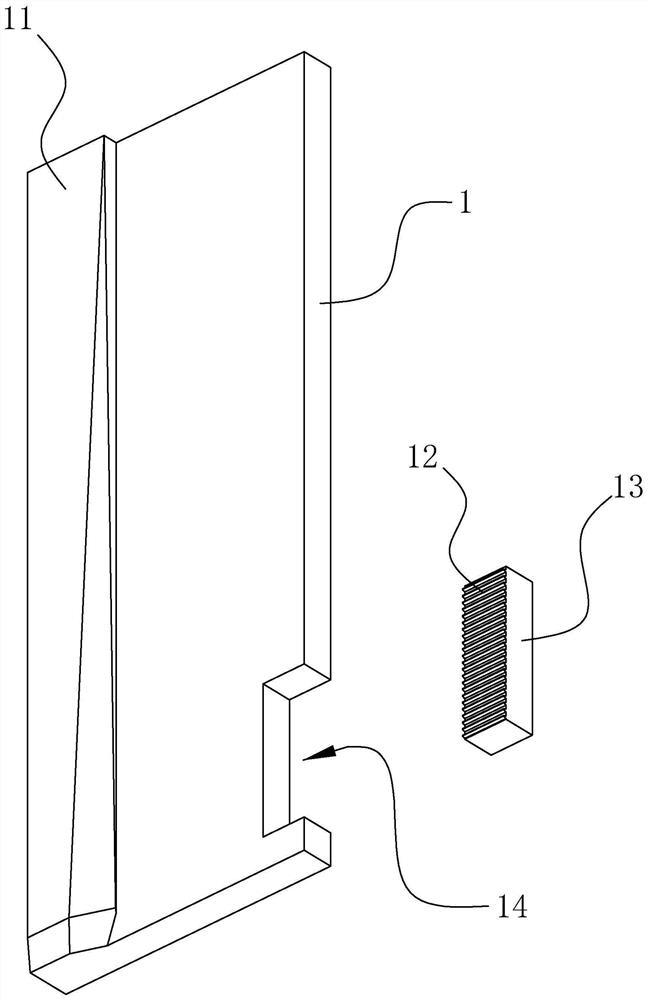

[0026] Such as Figure 1 to Figure 5 As shown, the knurling and sharpening method of the present embodiment includes the following steps: 1. Place the pin blank body 40 formed by cold heading on the feed end of the forming plate 1;

[0027] 2. Roll the pin embryo body 40 forward to process the flower teeth 41 on the rod body of the pin embryo body 40;

[0028] 3. Continue to roll the pin blank body 40 forward, so that the pin part 401 processed with flower teeth 41 rolls along the cutting surface 112 of the forming plate 1, thereby processing a sharp corner 42 at the end of the pin part 401;

[0029] 4. Roll the forming pin 4 with the sharp angle 42 out of the forming plate 1 from the discharge end of the forming plate 1 to complete the processing of the flower teeth 41 and the sharp angle 42 on the pin.

[0030] On the surface of the cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com