End-face grinding device for air intake and exhaust valves of internal combustion engines

A technology for intake and exhaust of internal combustion engines and end grinding, which is applied in the direction of grinding drive devices, machine tools suitable for grinding workpiece planes, and parts of grinding machine tools. The effect of taking into account the quality and output of finished products and enhancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

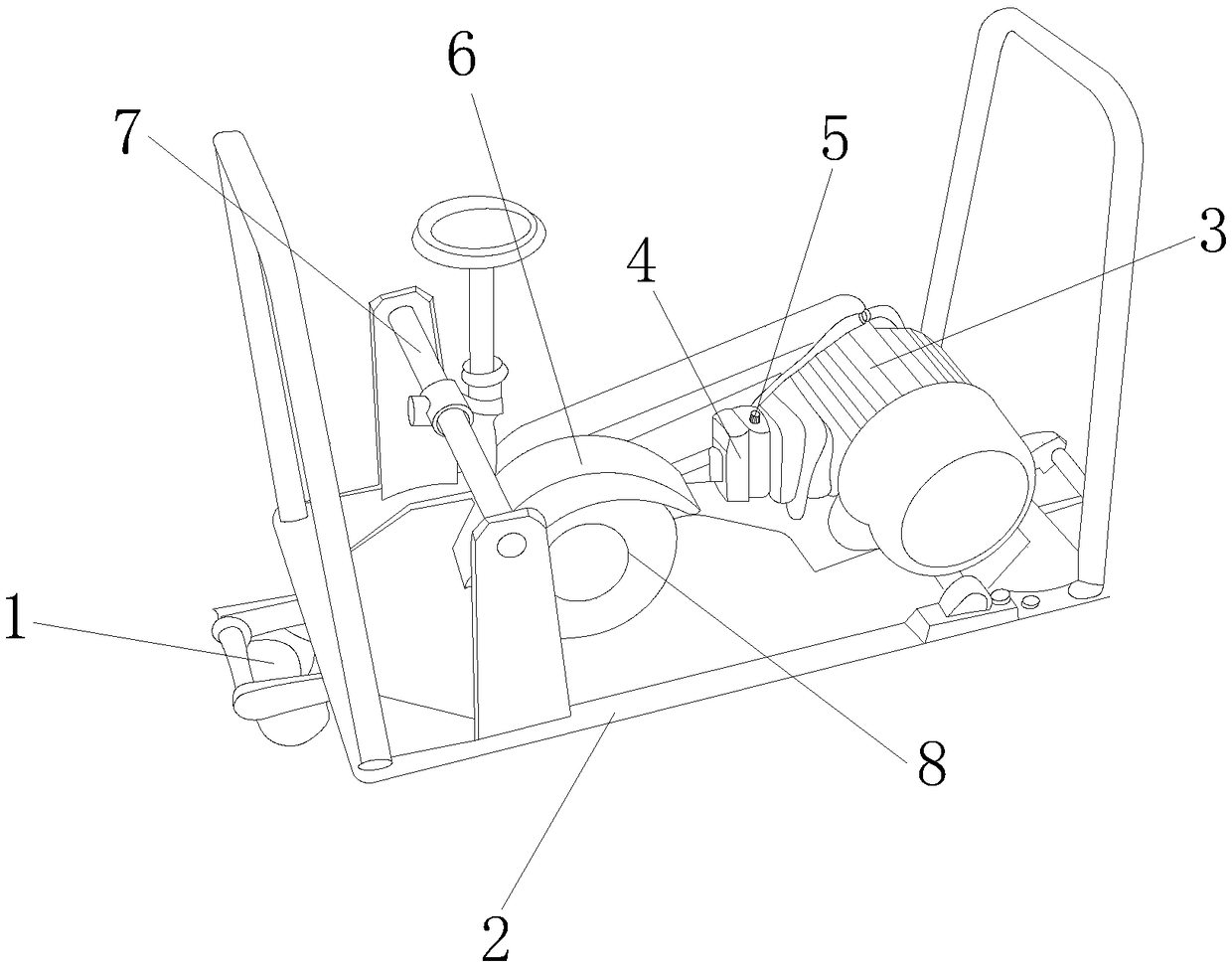

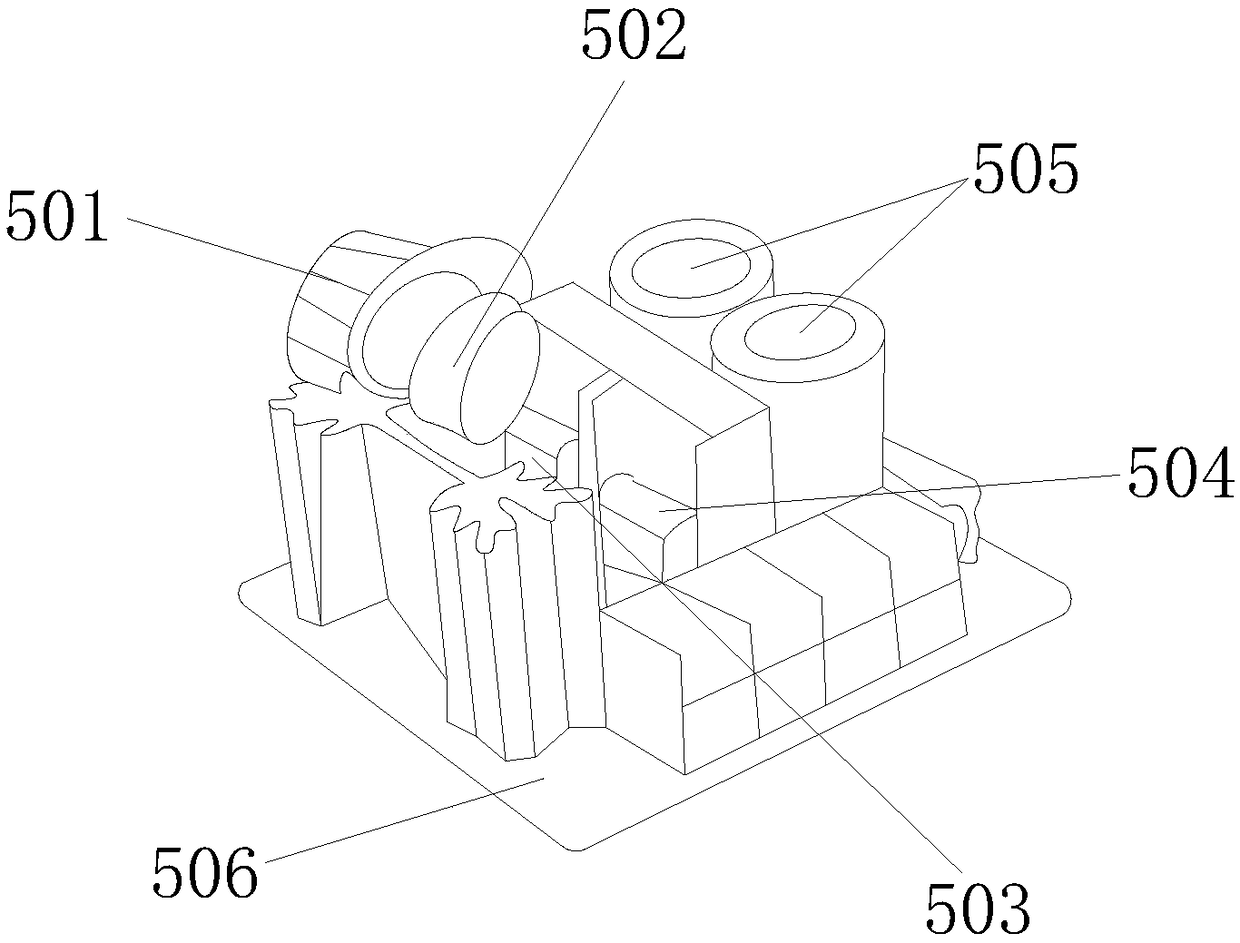

[0019] see Figure 1-Figure 2 , the present invention provides a technical solution: an end grinding device for the intake and exhaust valves of an internal combustion engine, the structure of which includes a roller 1, a chassis 2, a motor 3, a controller 4, a governor 5, a shield 6, a limiter Bit bar 7, grinding wheel 8, described underframe 2 is concave shape, and described underframe 2 is hard on the outside and hollow inside, and the middle part of described underframe 2 is hollowed out, and the left and right sides of described underframe 2 are equal and parallel, and the bottom of described underframe 2 It is rectangular, and the front end of the chassis 2 and the roller 1 adopt an interference fit. The roller 1 is a cylindrical structure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com