Patents

Literature

40results about How to "Speed increase or decrease" patented technology

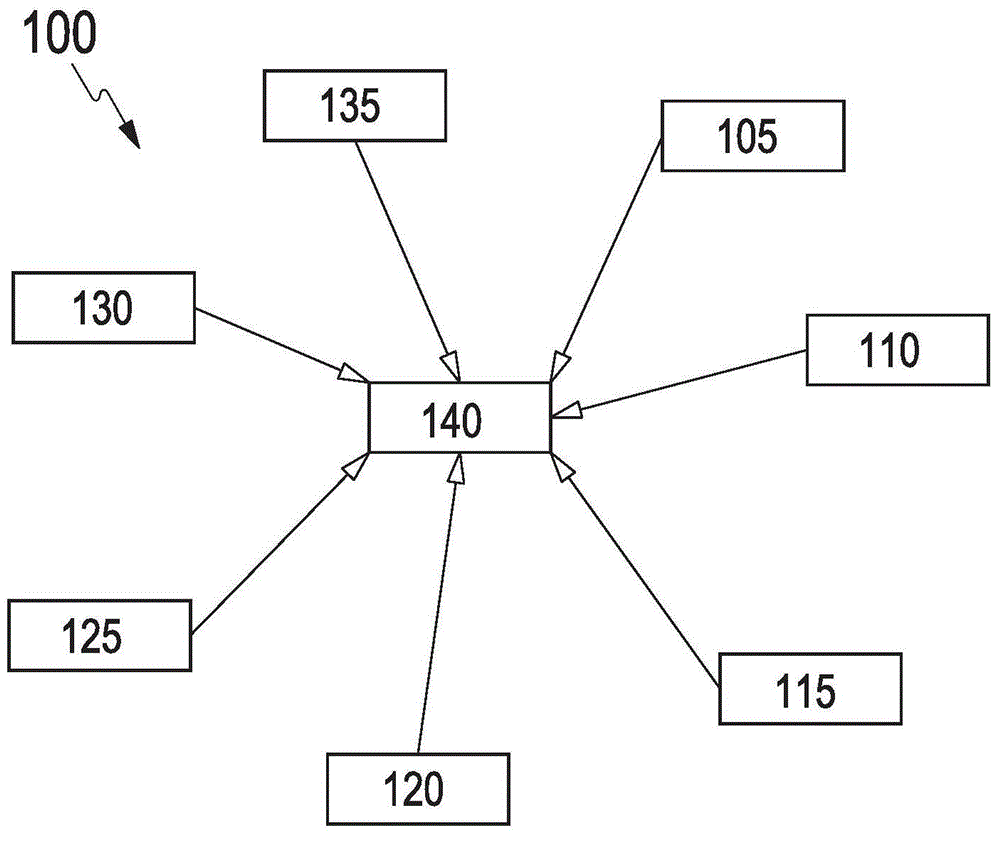

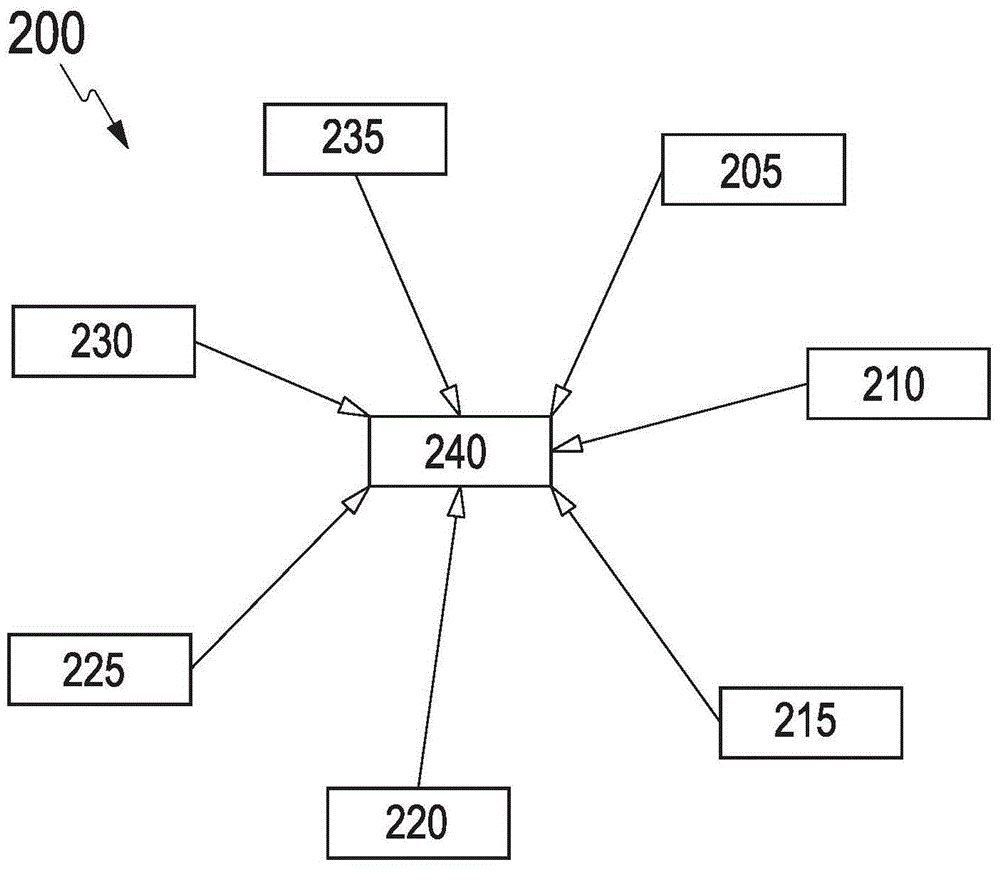

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

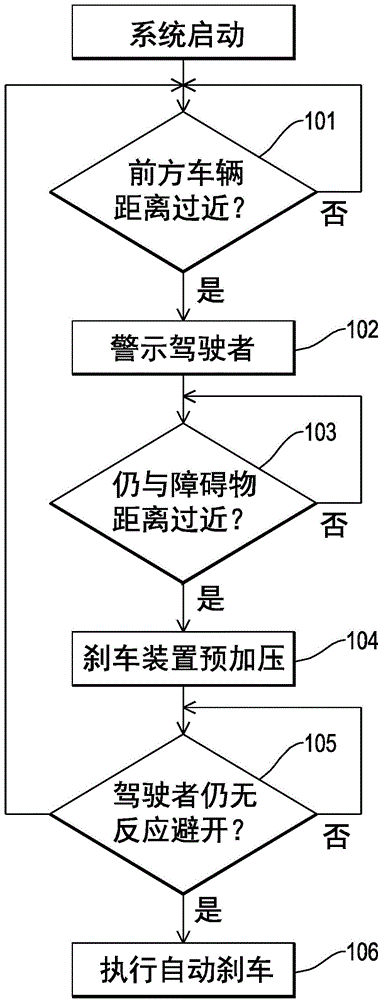

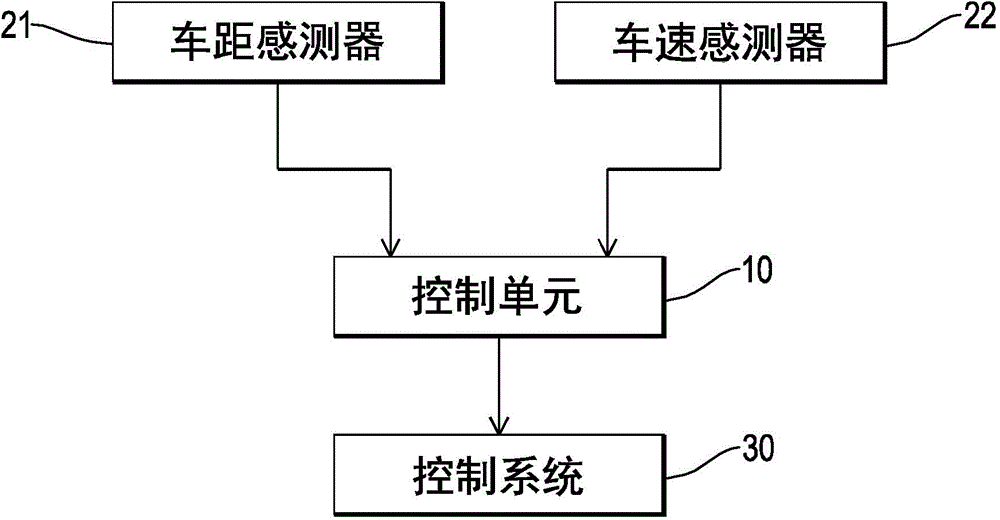

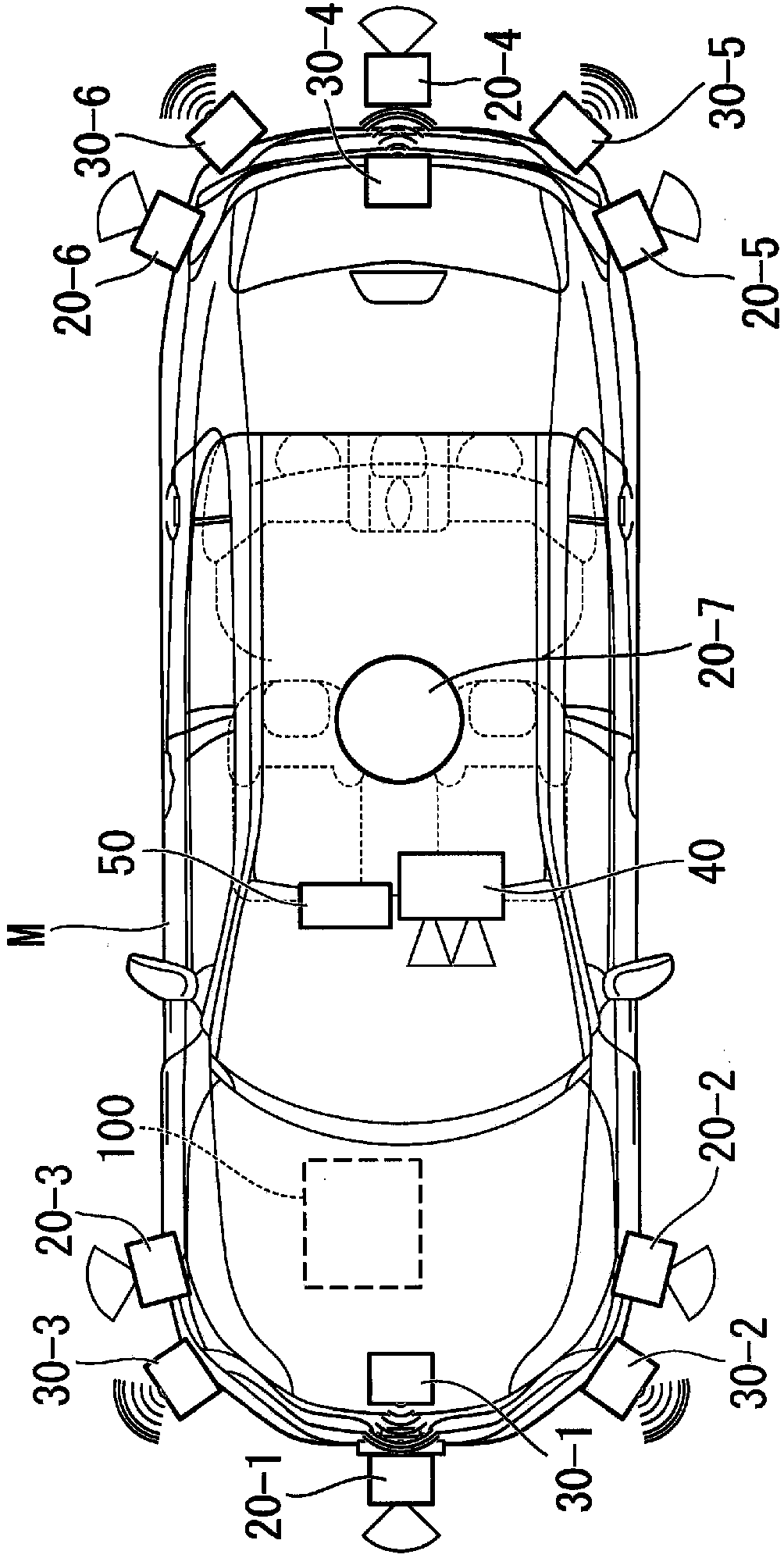

Adaptive vehicle anti-collision method

ActiveCN104691545AIn line with driving habitsSpeed increase or decreaseExternal condition input parametersCollision systemElectronic control unit

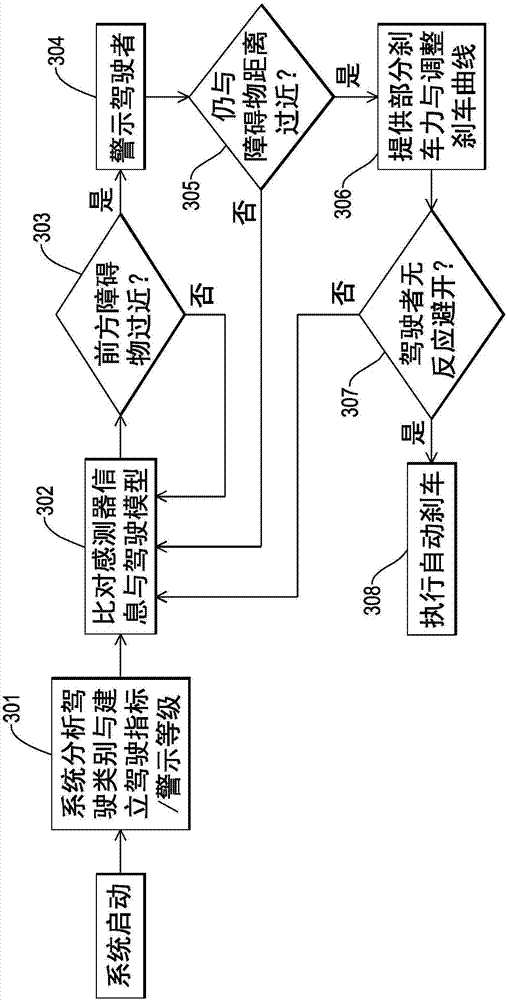

The invention discloses an adaptive vehicle anti-collision method. A plurality of vehicle speed parameters, vehicle distance parameters and braking distance parameters at different driving types are pre-established by a control system of a vehicle, longer vehicle distances are set when the vehicle speeds are higher, the vehicle distances are increased or decreased appropriately according to different road conditions, sensors on the vehicle obtain dynamic information, such as the vehicle speeds or accelerations, analysis is performed by combining driving behaviors, a driver is classified into a certain driving type through statistical analysis and an artificial neural network, control parameters of the vehicle are adjusted by referring to the driving type of the vehicle driver, and thus an electronic control unit of the vehicle can perform warning or control to brake in an appropriate time in accordance with the driving habits of the driver. By adopting the adaptive vehicle anti-collision method, the problem that the safety vehicle distance and a brake device cannot be adjusted by an anti-collision system of the existing vehicle by aiming at different vehicle speeds, road conditions, habits of the driver or vehicle conditions is solved.

Owner:AUTOMOTIVE RES & TESTING CENT

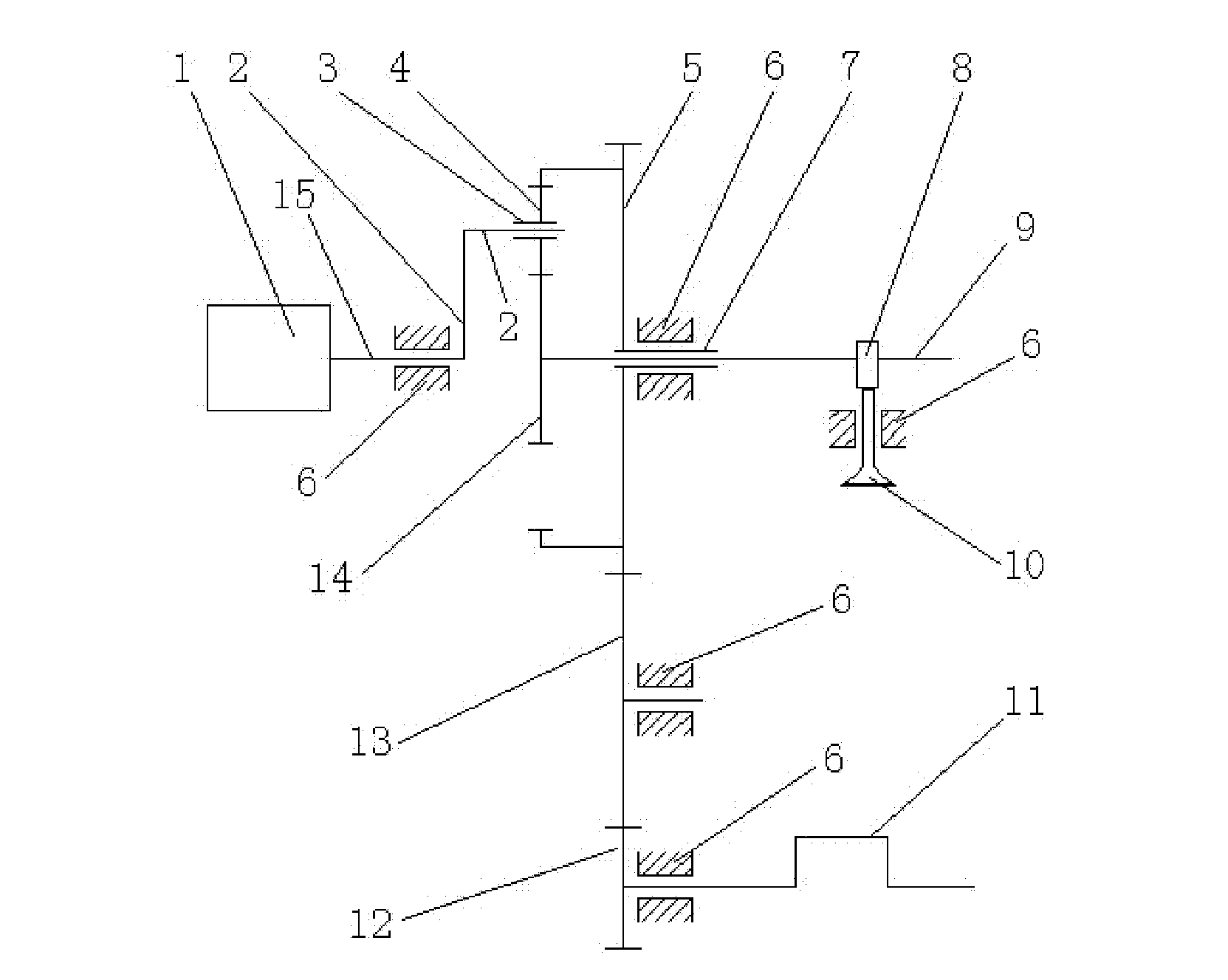

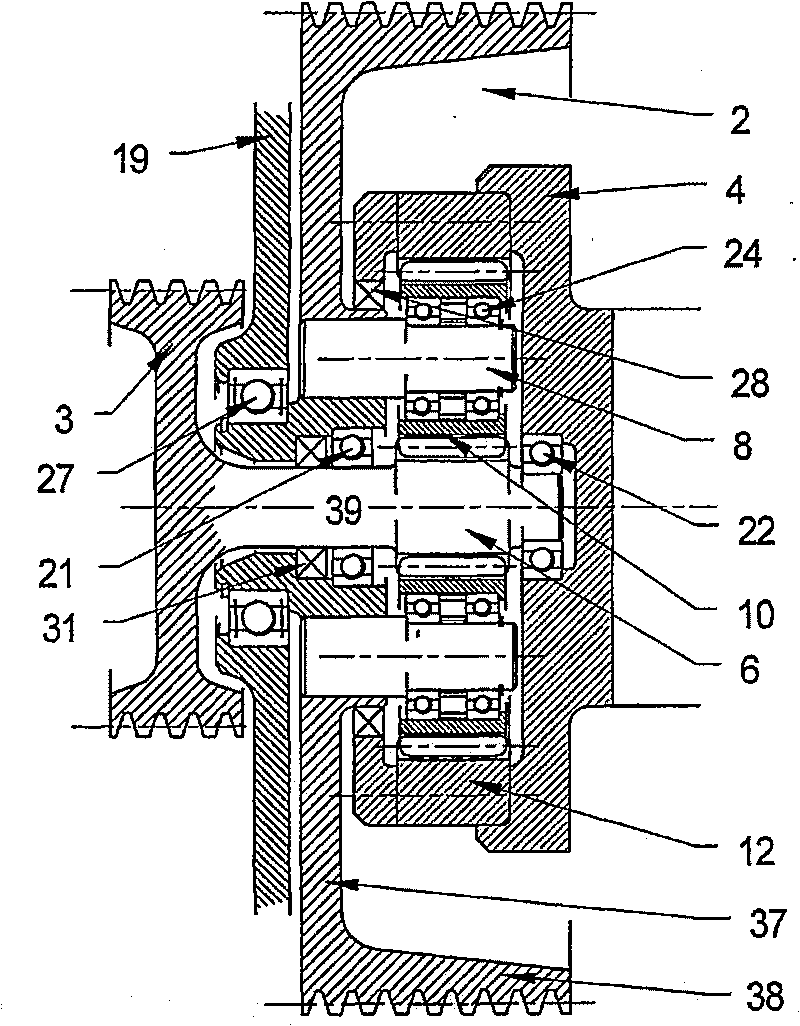

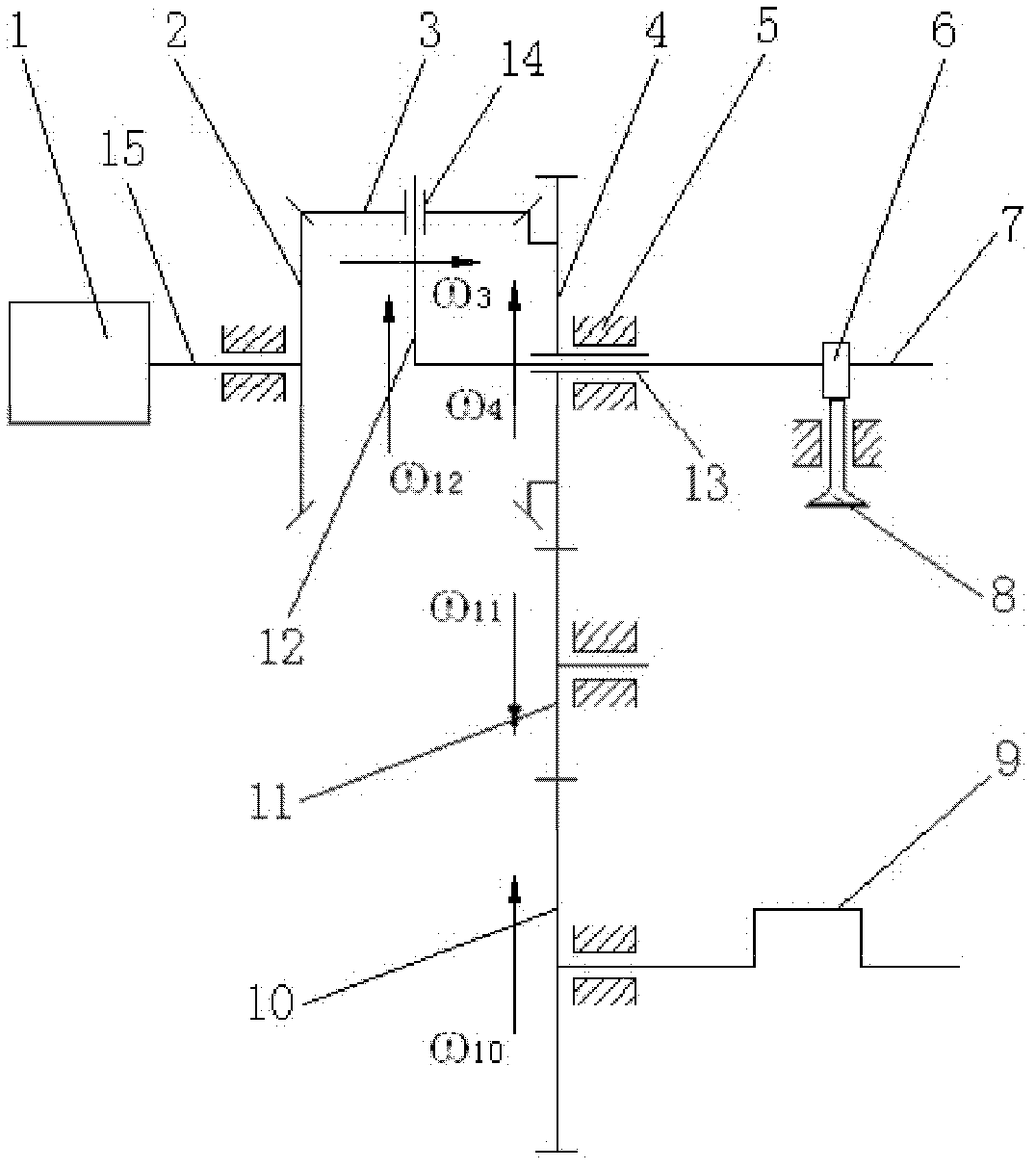

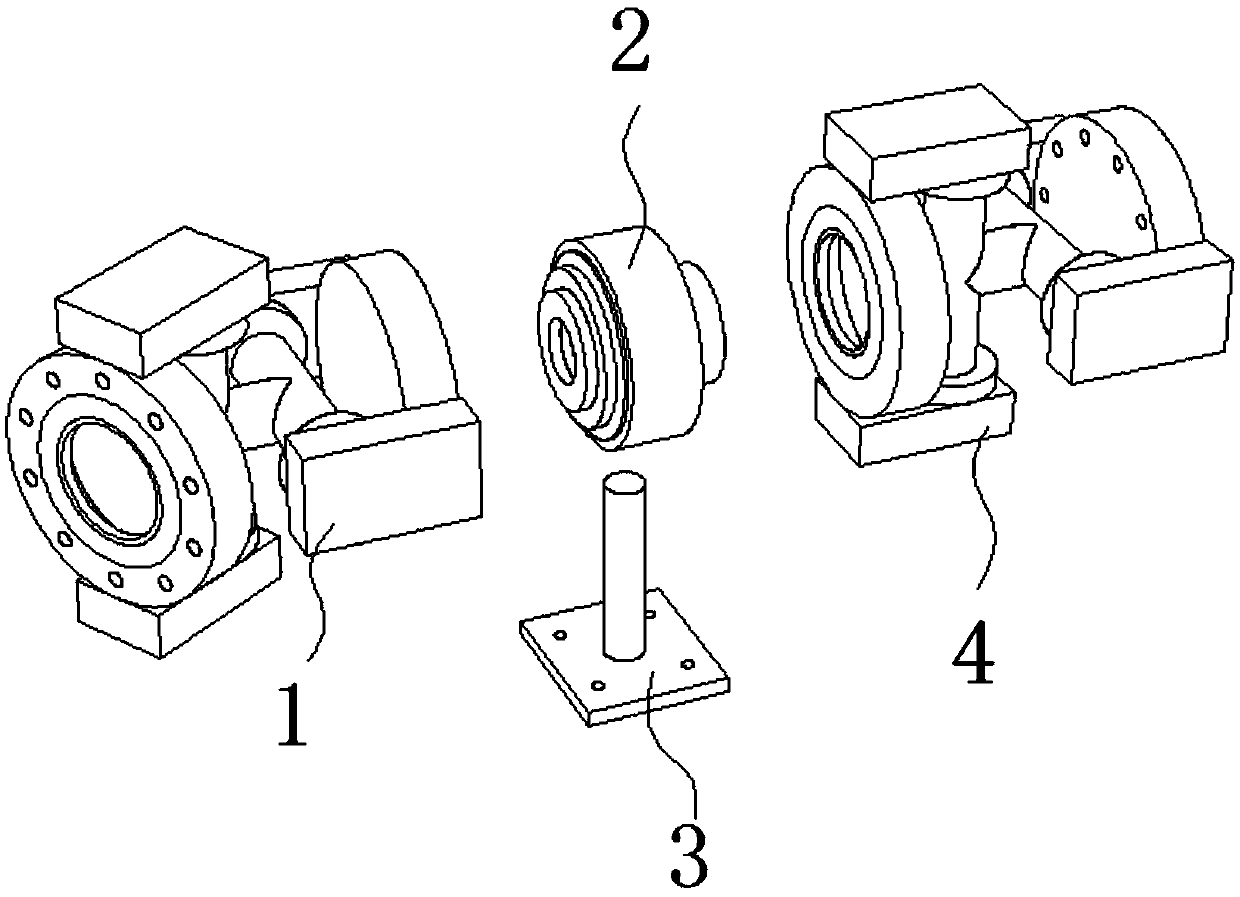

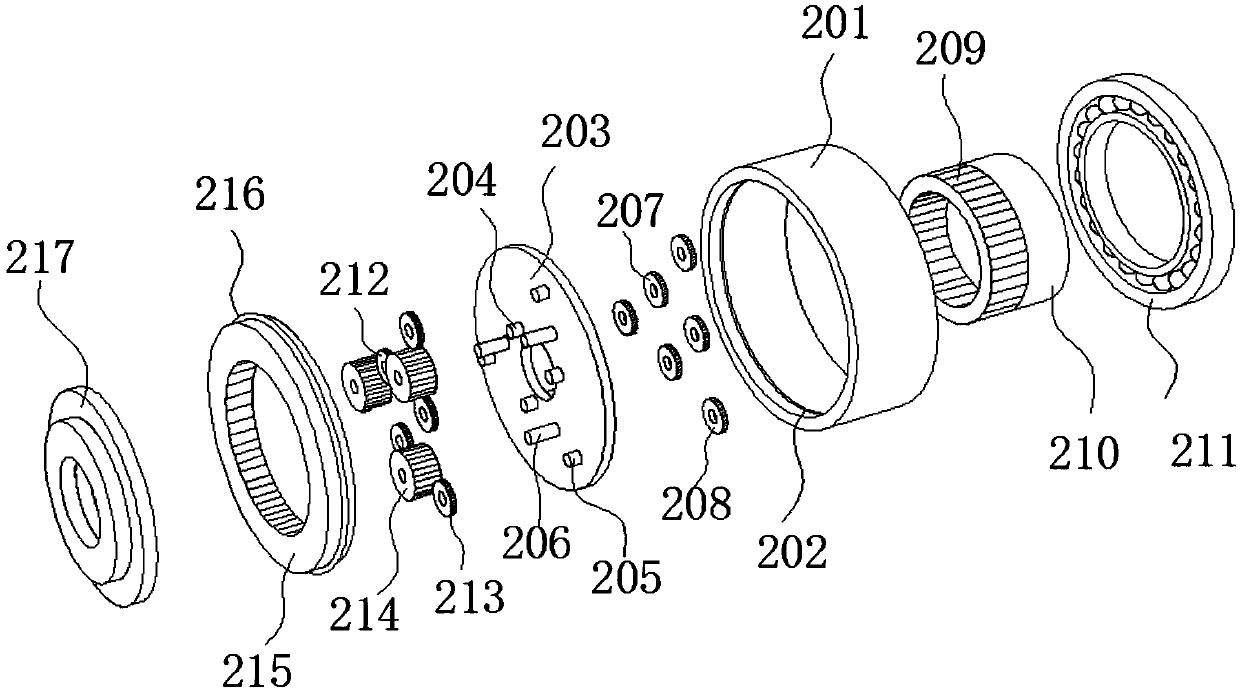

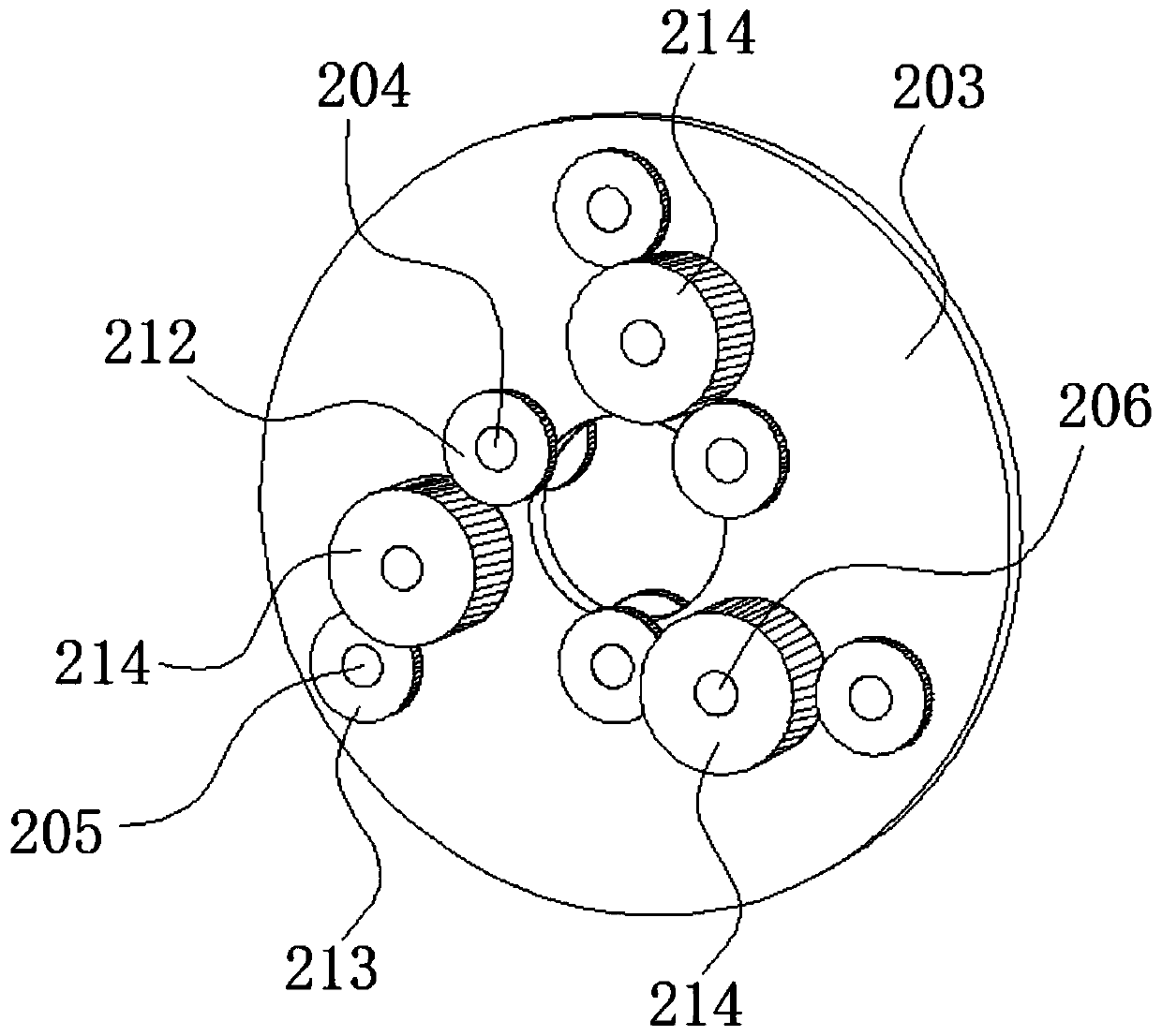

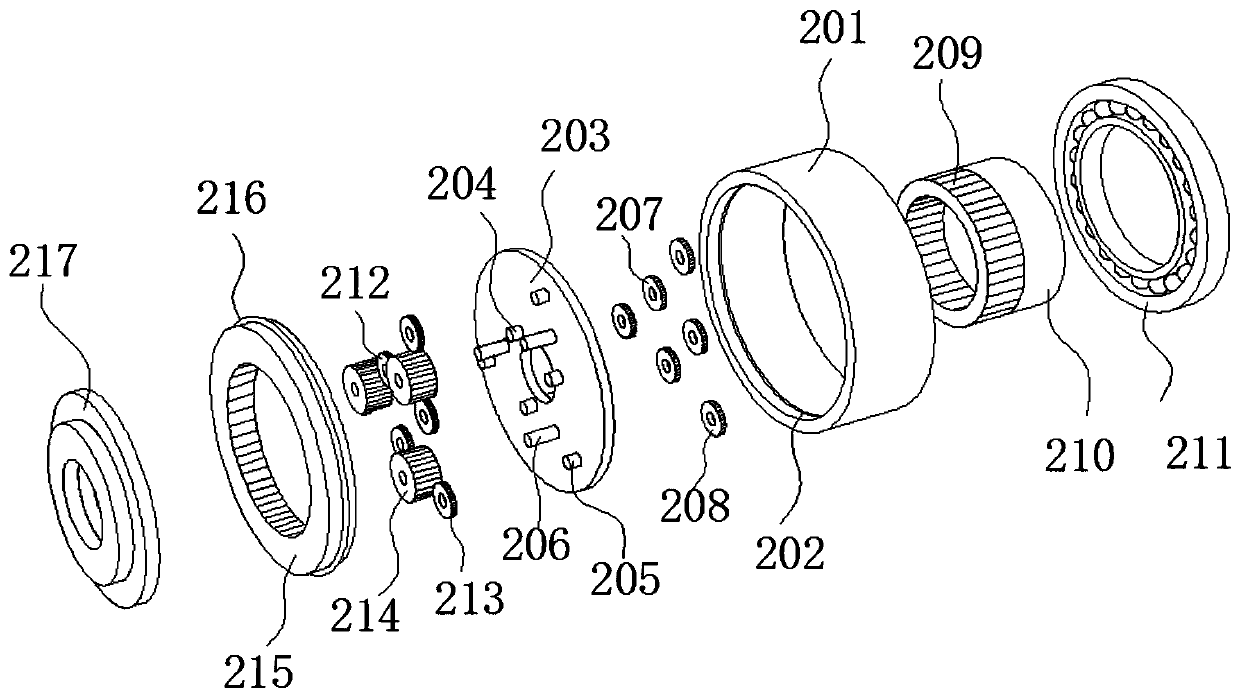

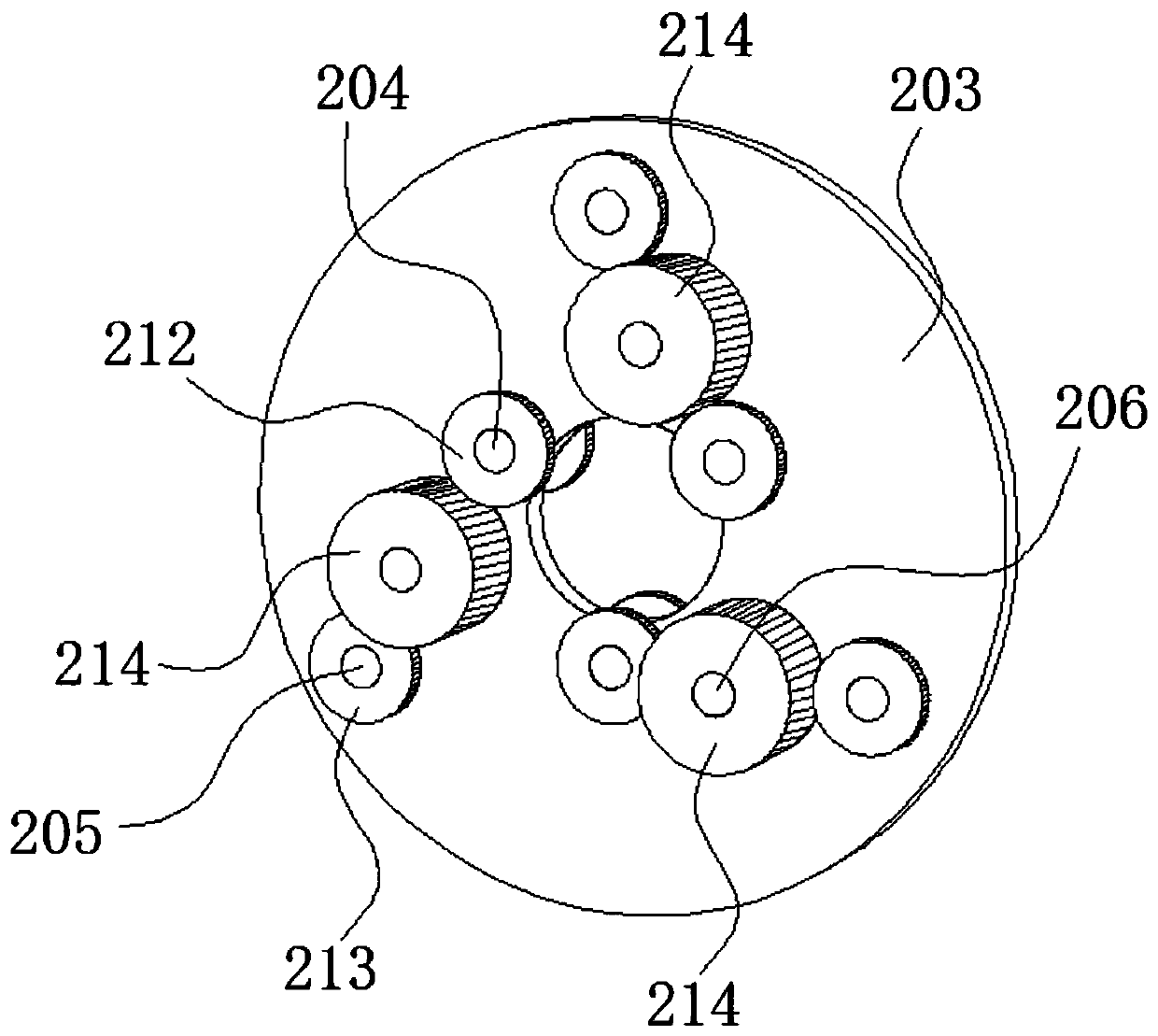

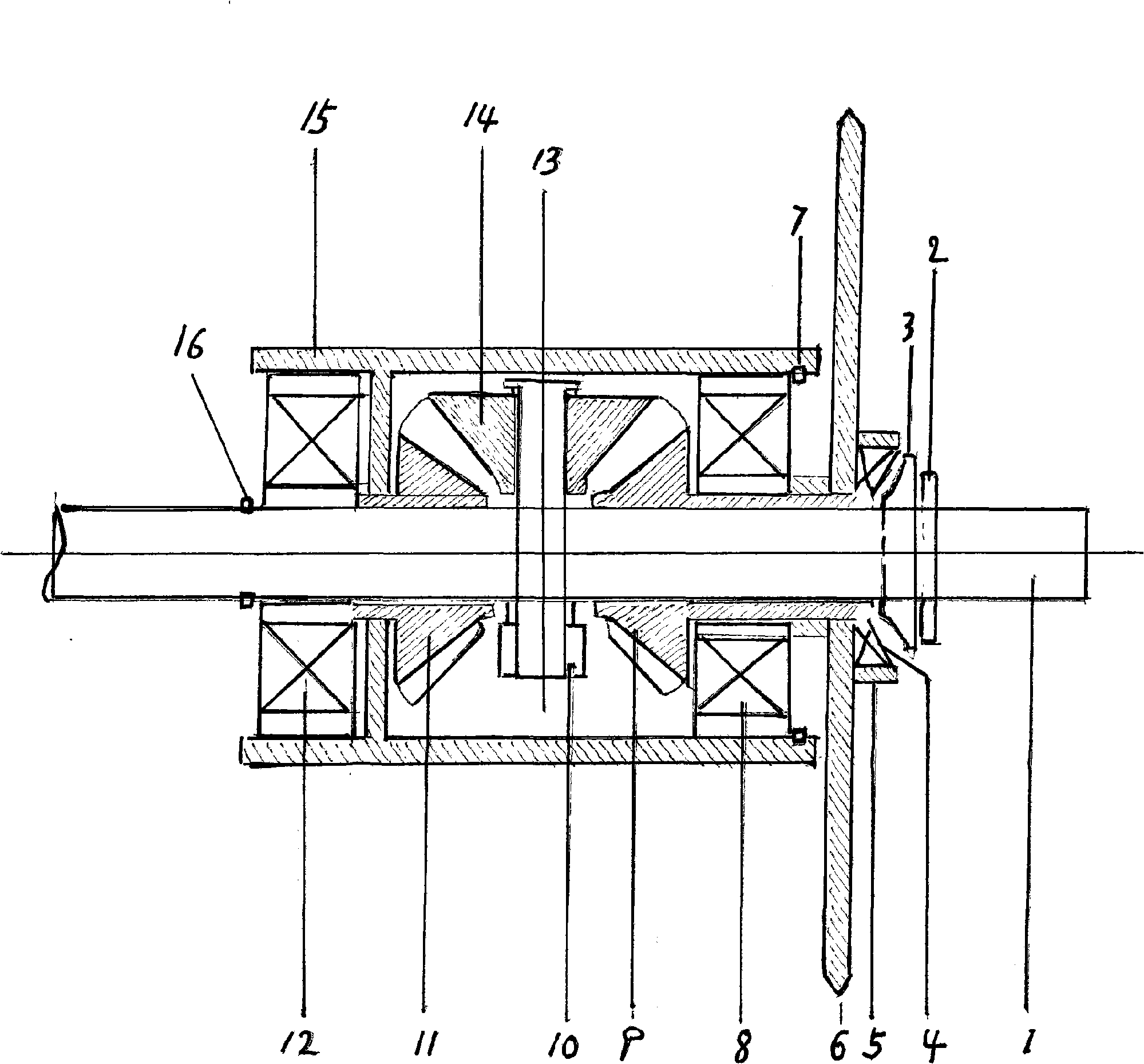

Continuous and mechanical variable valve timing adjusting device for internal combustion engine

InactiveCN102425468AEasy to installImprove economyValve arrangementsMachines/enginesCombustionVariable valve timing

The invention provides a continuous and mechanical variable valve timing adjusting device for an internal combustion engine, belonging to the technical field of internal combustion engines. The device comprises a crankshaft, a cam shaft, a cam, a driving gear, an intermediate gearing, an input center gear, a planet gear, a planet gear carrier, an output center gear and an adjusting device, wherein the front end of the crankshaft is installed at the axle center of the driving gear; the intermediate gearing is meshed with the driving gear and an outer gear ring of the input center gear respectively; the planet gear is meshed with an inner gear ring of the input center gear and the output center gear respectively; the front end of the cam shaft is installed at the axle center of the output center gear; and the adjusting device is connected with the planet gear carrier by a connecting shaft. In the working process of the device, when the planet gear carrier rotates in a certain direction,the rotating speed of the output center gear is increased or decreased, thus changing the rotation phase between the cam shaft and the crankshaft and realizing adjustment of valve timing. The device has reasonable design, simple structure, good reliability and higher adjustment precision and is easy to add on the original engine.

Owner:SHANGHAI JIAO TONG UNIV

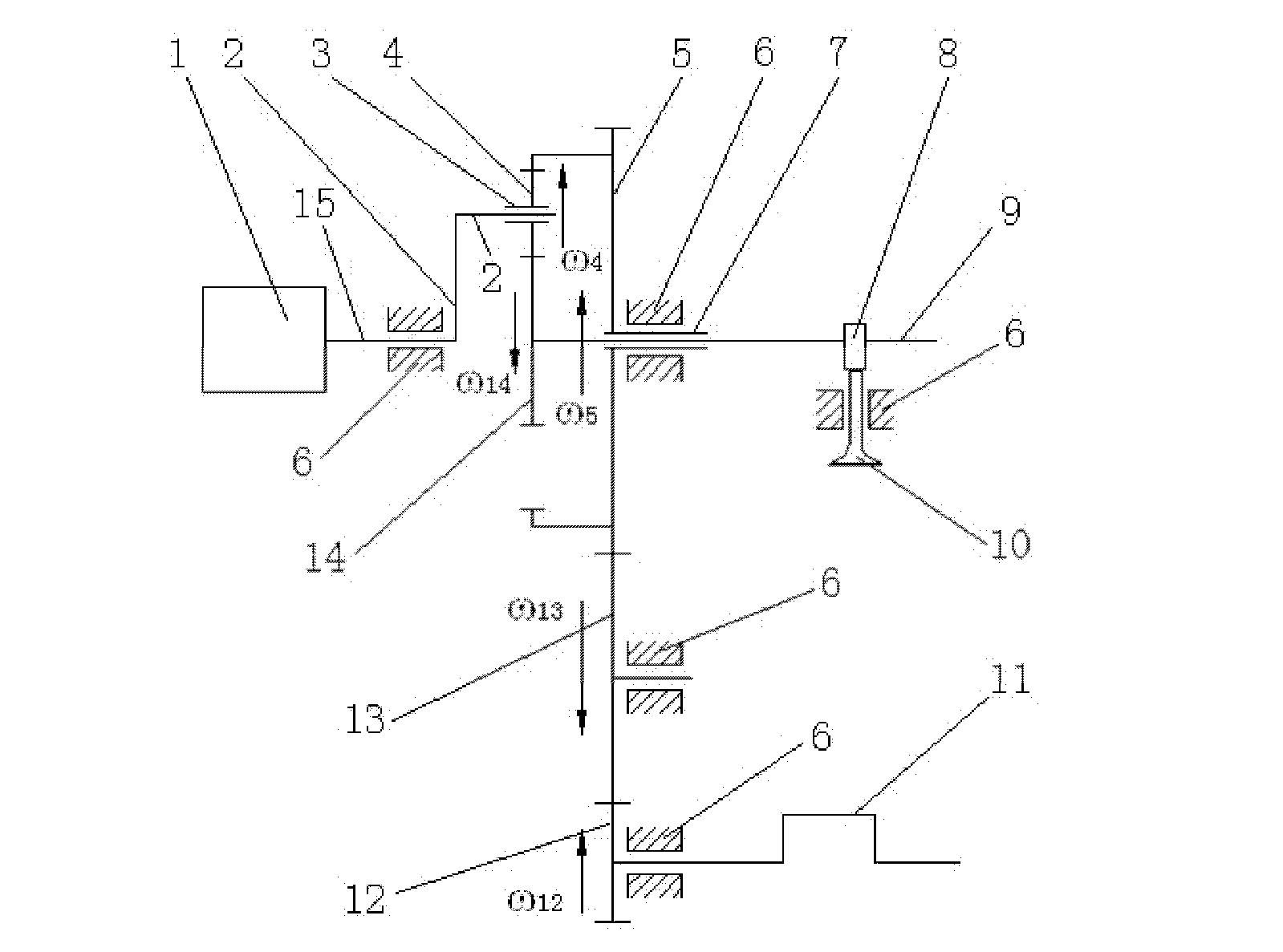

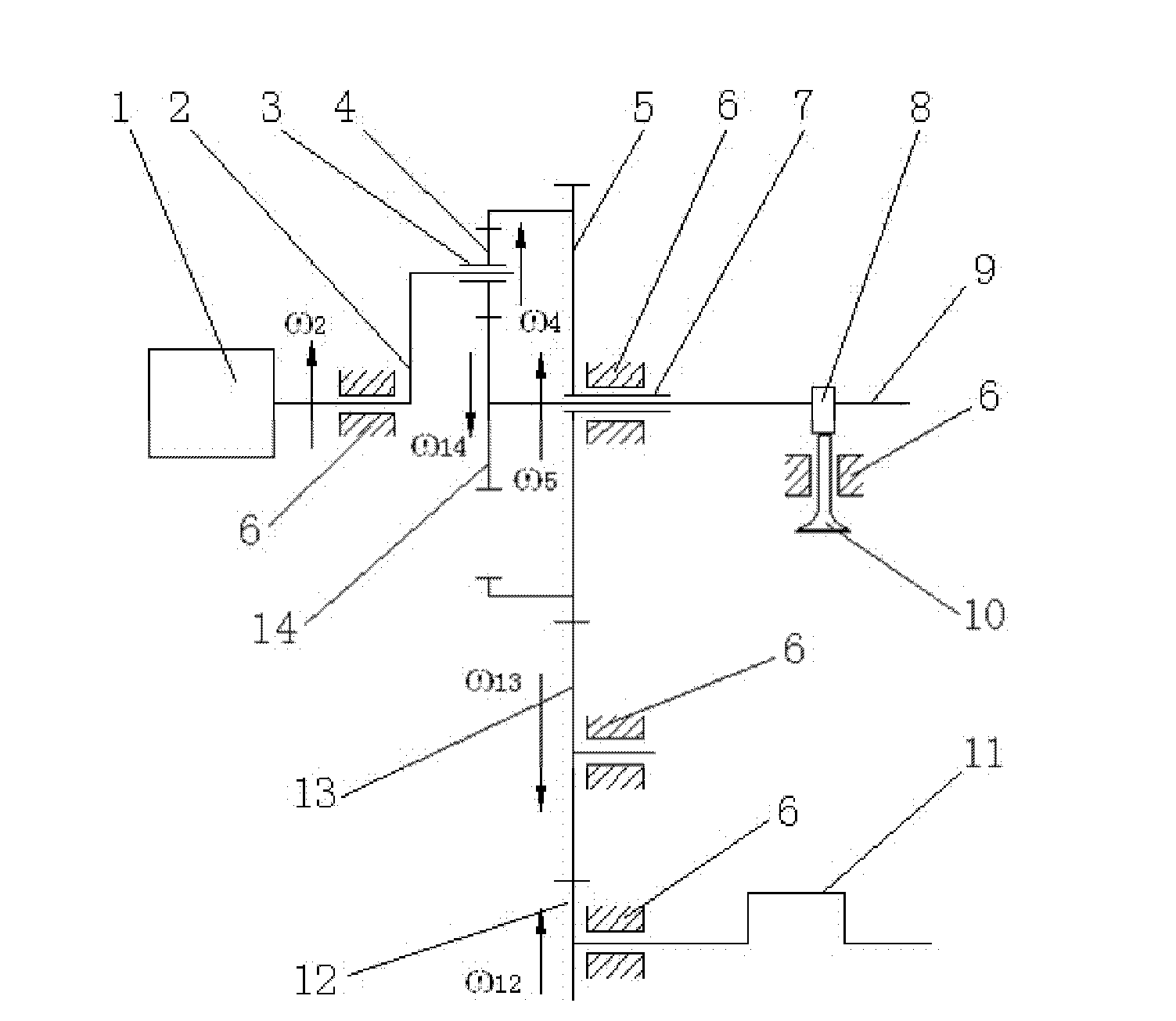

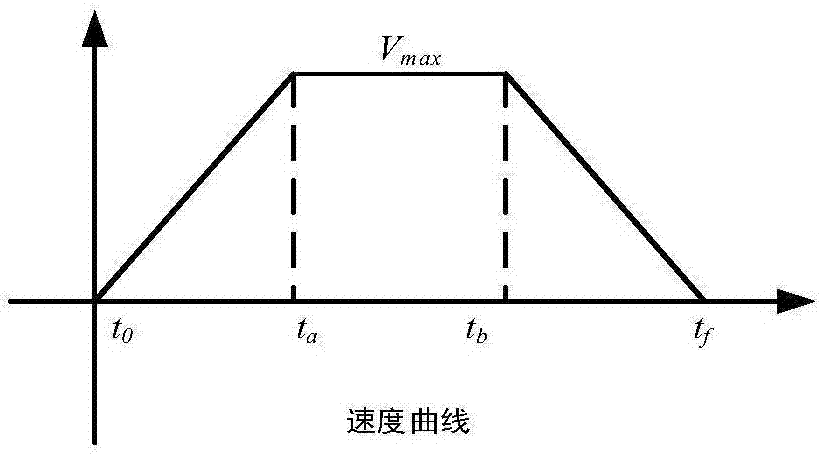

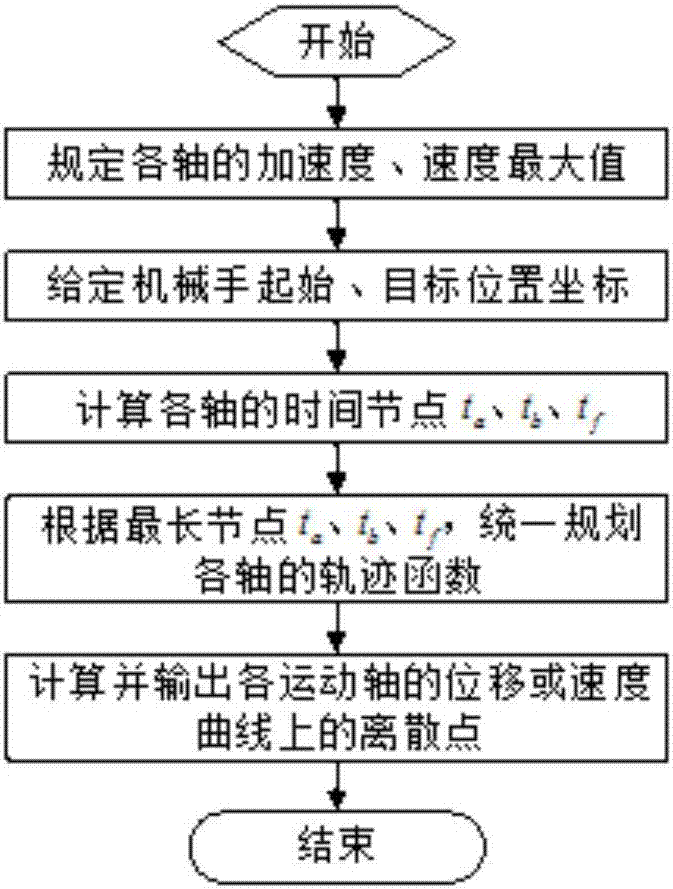

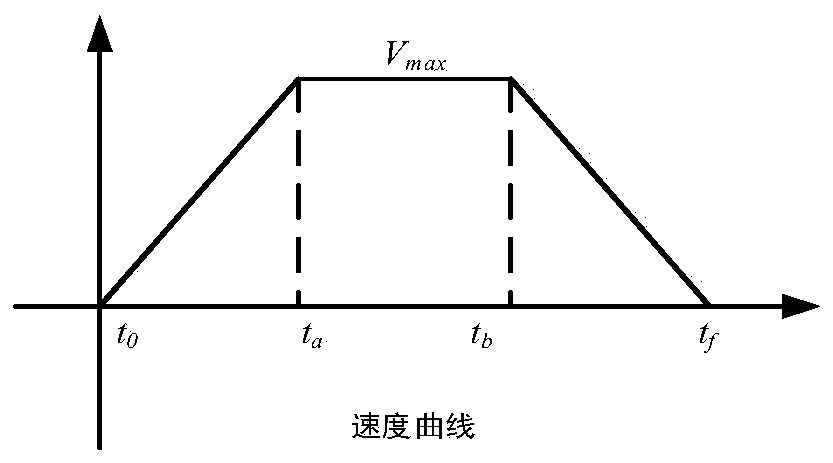

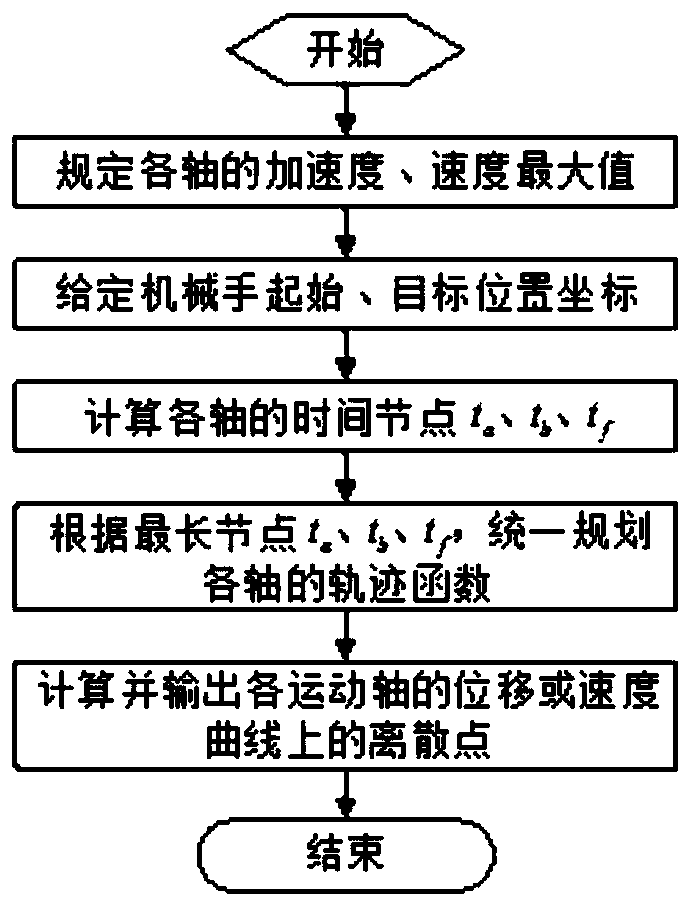

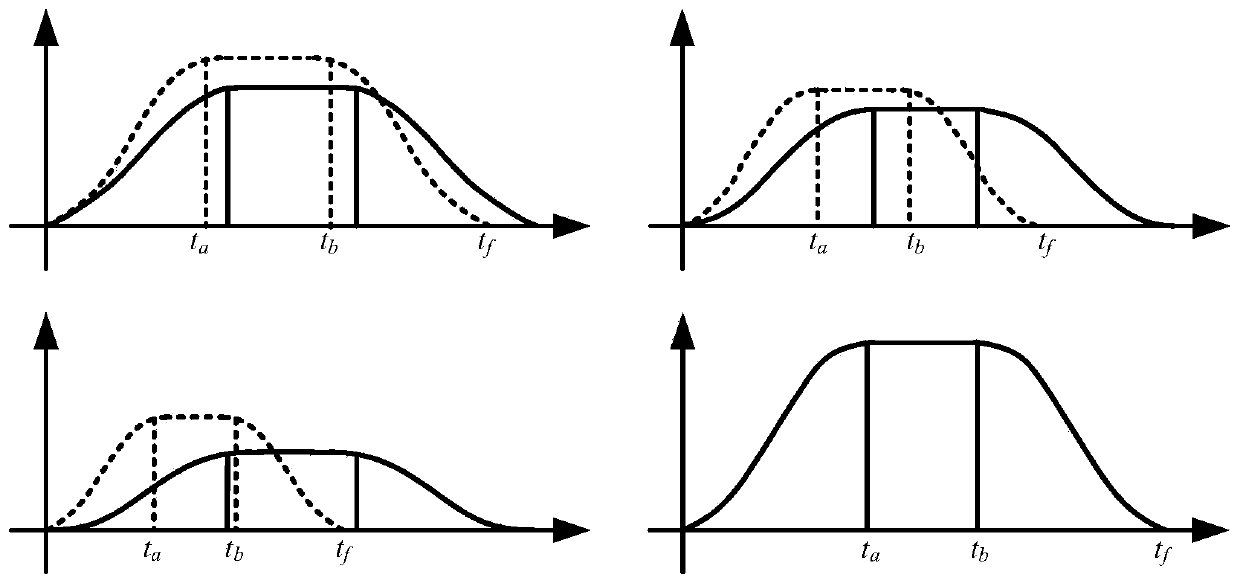

Precise control method of linear motion module

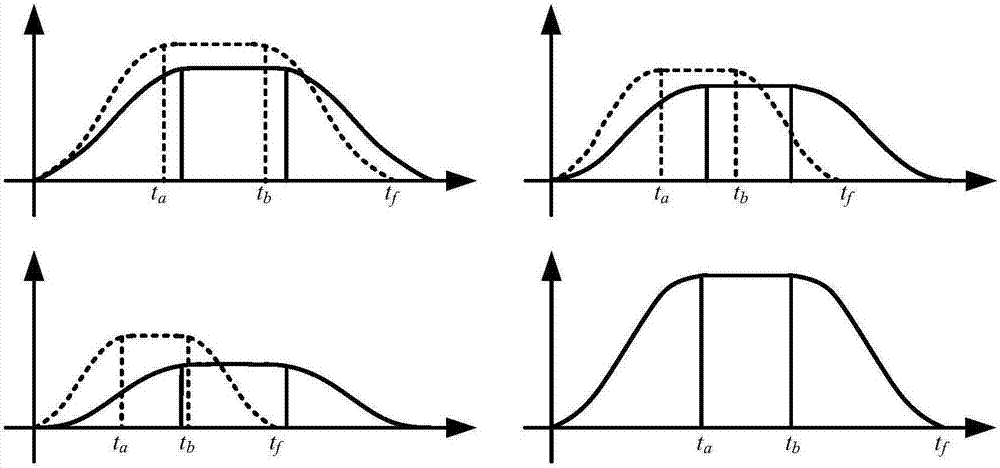

ActiveCN107160394AMovement precisionGuaranteed normal movementProgramme-controlled manipulatorEngineeringConstant speed

The invention discloses a precise control method of a linear motion module. A motion control method based on S-shaped speed curve planning and synchronous planning of parabolic functions is adopted to precisely control the linear motion module; an acceleration maximum value and a speed maximum value of each motion shaft of a truss manipulator are input; an initial pose and a target pose of the truss manipulator are given to obtain a displacement variation of each motion shaft of the manipulator; time function nodes of each motion shaft are calculated; longest time nodes are selected as unified planning nodes to calculate actual maximum speed and maximum acceleration of each motion shaft; displacement, speed and acceleration functions at an acceleration phase, a deceleration phase and a constant-speed phase are respectively calculated according to the actual maximum speed and the maximum acceleration of each motion shaft; and the displacement of each motion shaft or discrete points on speed curves are output. The method can prevent the manipulator vibration or noise problem caused by sudden change of the speed or the acceleration, guarantees the motor motion precision, and can control the motion trajectory.

Owner:西安精雕软件科技有限公司

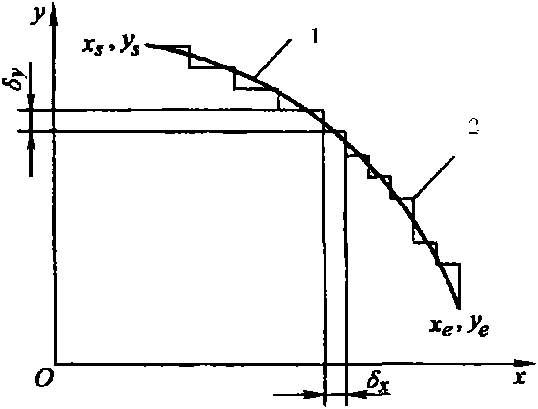

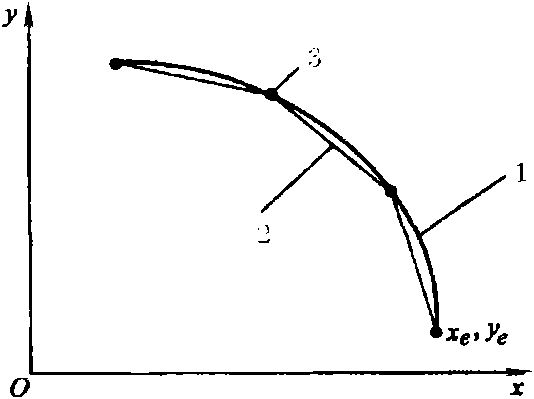

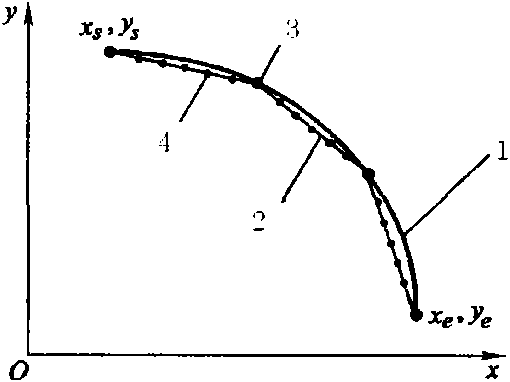

Controlling computerized numerical control (CNC) high-quality aspheric surface forming control method and hardware system

InactiveCN102049717AGuaranteed synchronizationNo change in dynamic performanceLensNumerical controlControl system

The invention provides a digital control method for realizing tangent-process forming of high-quality aspheric surface by three-axis linkage based on a speed interpolation principle, and a hardware system. The hardware control system adopts a universal motion and automation controller (UMAC) with a multi-axis linkage function and an electronic cam algorithm to acquire accurate time interval to ensure the synchronization of three-axis linkage, and adopts a position-velocity-time (PVT) speed interpolation algorithm to eliminate inflection point smooth transition of actual machining curve at the positions of nodes and position overstrike and to make interpolation nodes constantly keep the continuous change in the feeding speed of grinding wheels and the moving direction and the tangent direction at a point consistent to form a high-precision continuous smooth aspheric surface, and thus, the machining efficiency of the aspheric surface is increased and the machining cost of the aspheric surface is lowered.

Owner:CHANGCHUN UNIV OF SCI & TECH +2

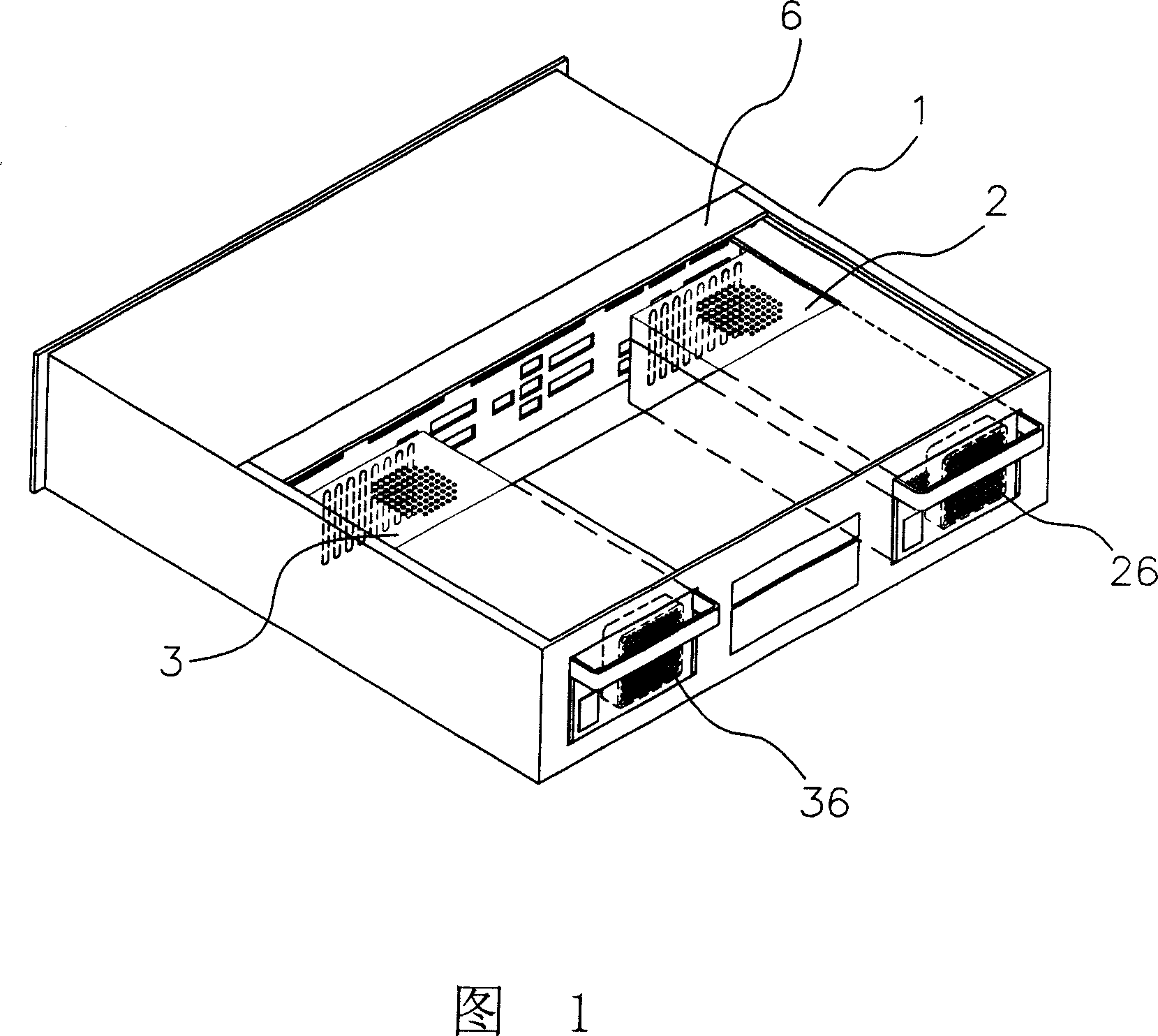

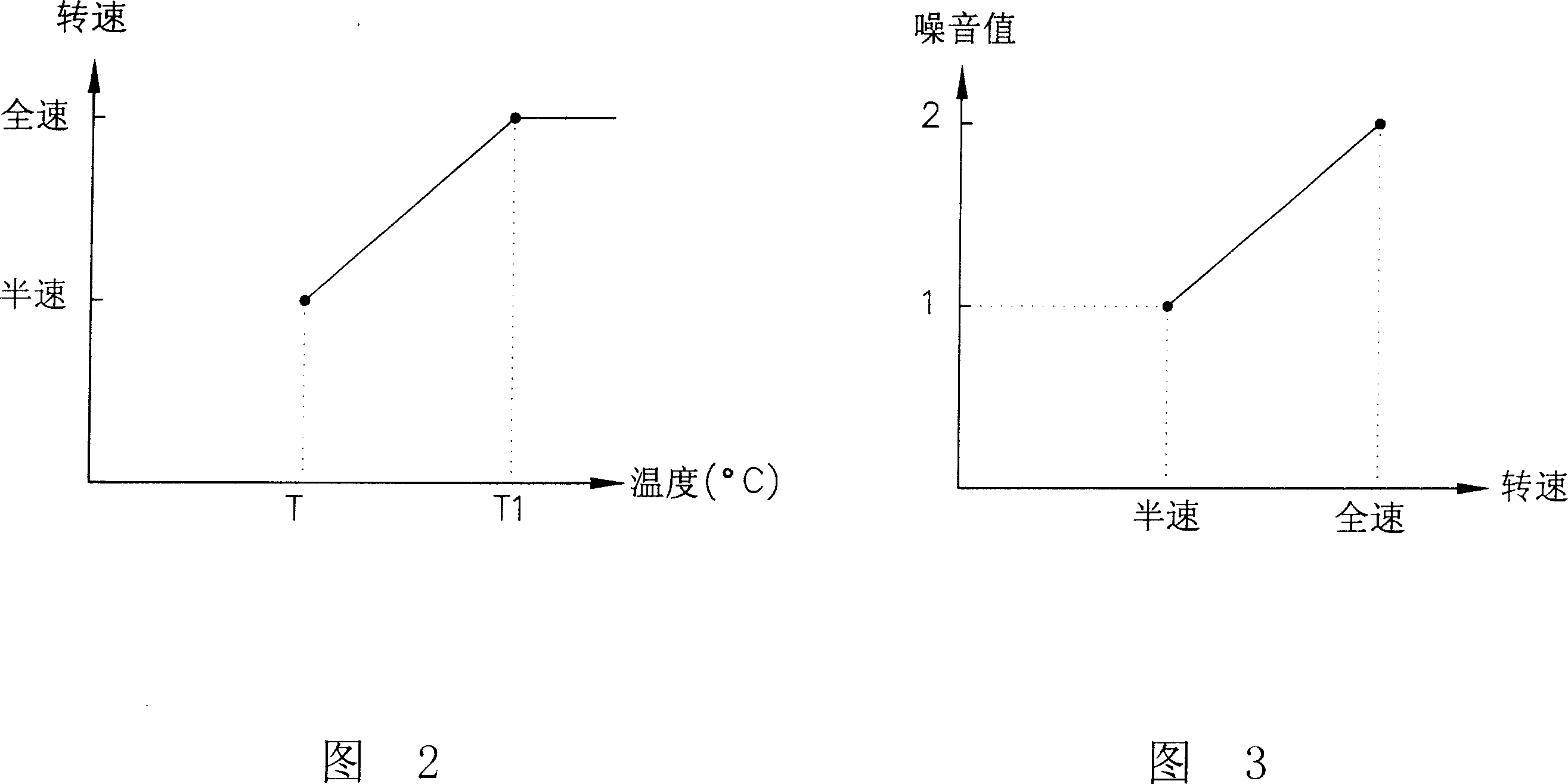

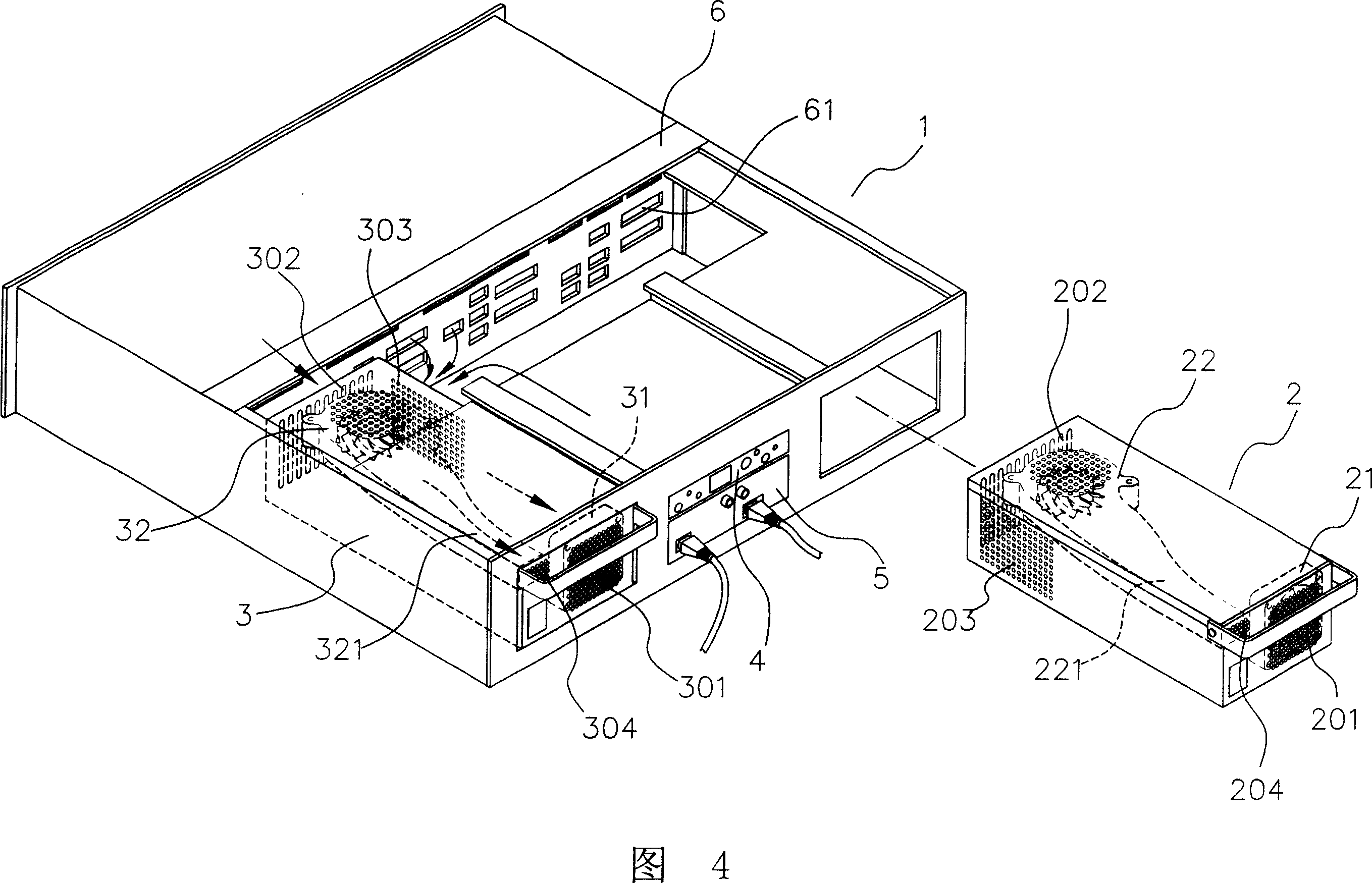

Structure of heat elimination module of computer, and optimized regulate and control method for air quantity and noise value

InactiveCN101093409ASlow downSpeed increase or decreaseDigital data processing detailsError detection/correctionAir volumeOperation mode

A computer heat radiation module consists of host shell, monitor unit for collecting system operation information and for controlling operation mode of heat radiation module, the first heat radiation fan and the second heat radiation fan. It is featured as enabling to automatically start up and to speed up the first or the second heat radiation fan when temperature-rise of said system is detected by monitor module and enabling to realize optimum balance between wind amount and noise value of said fans by carrying out parameter-setting with monitor module.

Owner:普桦科技股份有限公司

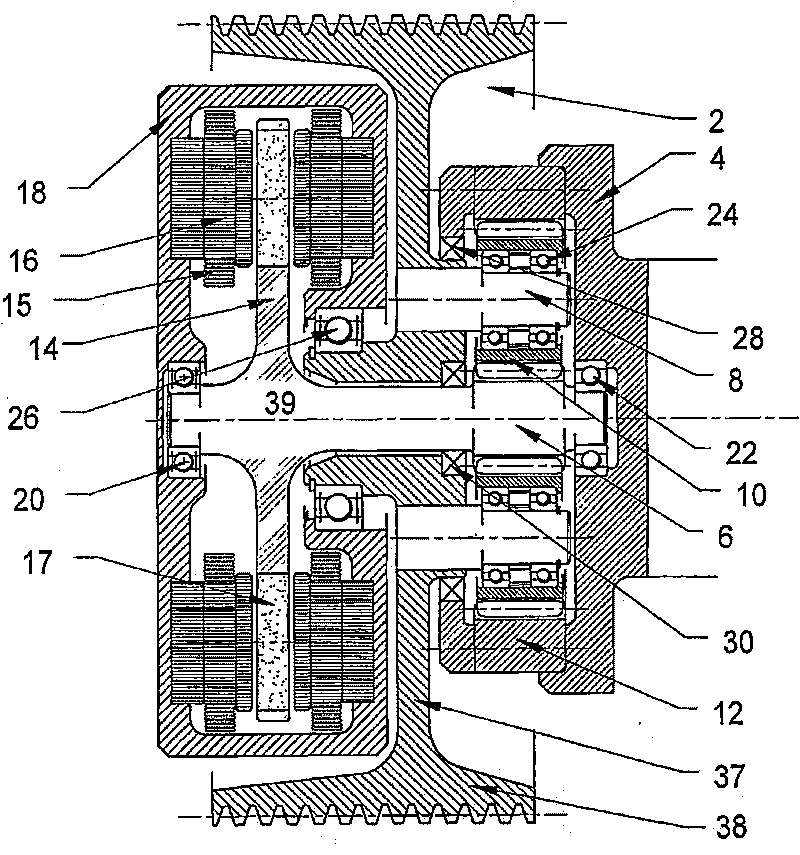

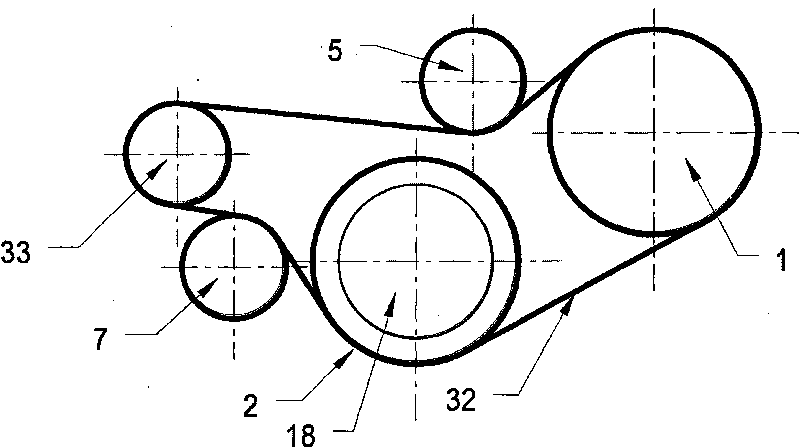

Drive pulleys

InactiveCN101720396AImprove efficiencyAvoid wastingToothed gearingsMechanical energy handlingCommon carrierElectrical connection

A drive pulley, particularly for automotive auxiliary equipment, includes an input for connection to an engine (80) and an output. One of the input and output comprises a hollow cylindrical member (38) whose outer surface constitutes a pulley belt engagement surface. The input and output are connected by a transmission system including an epicyclic gearset. The planet shafts (8) are connected to a common carrier (37). The system further includes two electric motor / generators, the rotors (14, 90) of which are connected to the output and a sun gear (6), respectively, the electrical connections on the stators (16, 94) of which are connected to a controller (85) arranged selectively to control the flow of electrical power between them. The transmission is at least partially accommodated within the hollow cylindrical member (38). The input is connected to an annulus gear (12) and the output is connected to the carrier (37). At least one of the motor / generators is remote from the hollow cylindrical member (38) and the gearset is at least partially accommodated within the hollow cylindrical member (38).

Owner:NEXXTDRIVE LTD

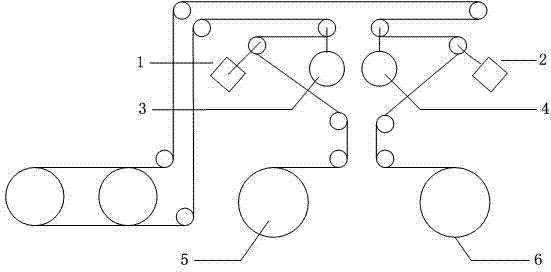

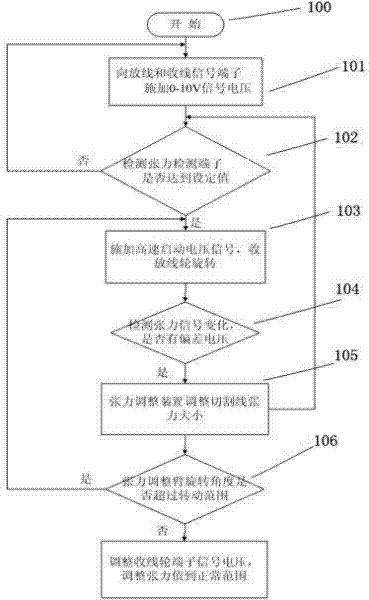

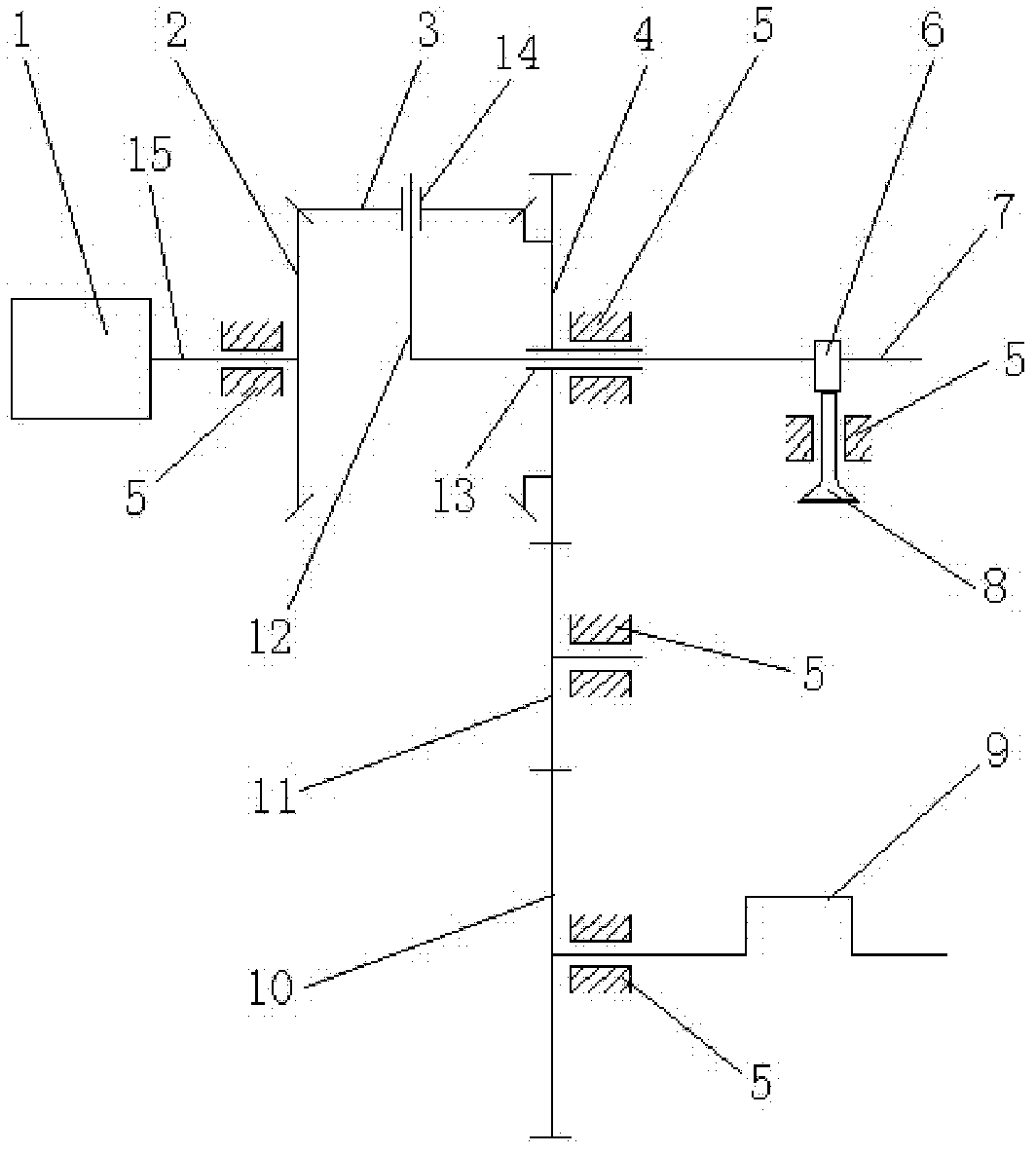

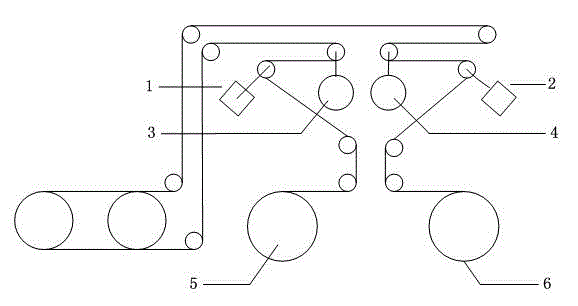

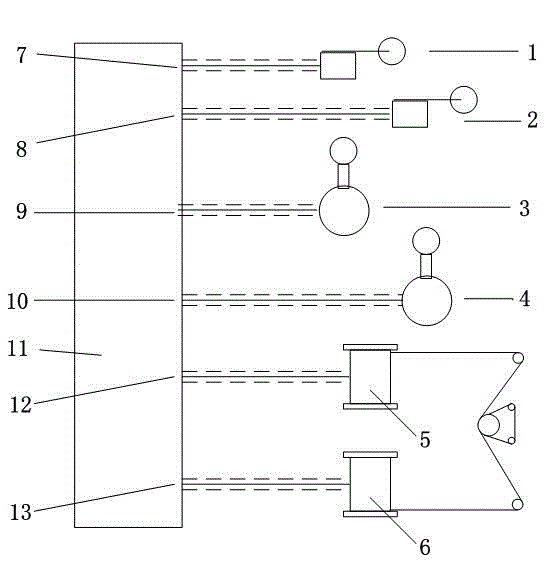

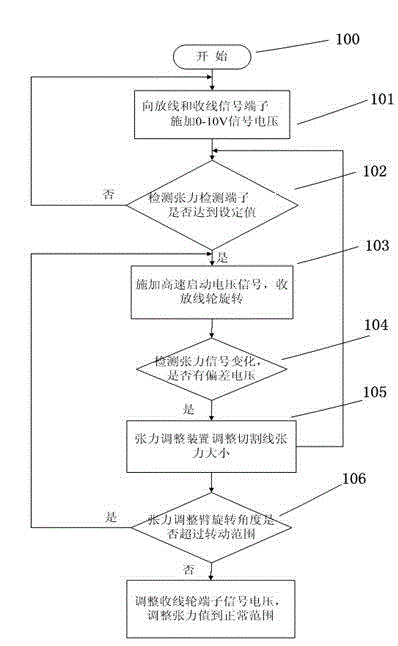

Tension control system and control method for multi-wire cutting of silicon wafer

InactiveCN102555093AQuick responseHigh speedWorking accessoriesFine working devicesControl systemWire cutting

The invention relates to a tension control system and a control method for multi-wire cutting of silicon wafer. The system comprises a tension detecting and controlling device and a tension regulating device, wherein the tension detecting and controlling device comprises a tension detecting and controlling main unit, left and right tension detecting devices, a paying-off signal terminal and a takeup signal terminal; the tension detecting and controlling main unit is composed of a main control computer and an analog quantity I / O (Input / Output) acquiring card; the left and right tension detecting devices, the paying-off signal terminal and the takeup signal terminal are connected with the detecting and controlling main unit. The tension control method for the multi-wire cutting of the silicon wafer performs detecting and controlling by adopting the tension control system for the multi-wire cutting and comprises the steps of: applying signal voltage to the signal terminals of a takeup pulley and a paying-off pulley; detecting that whether the tension signal is up to a set tension value or not, if not, returning to the first step; starting the pulley to rotate if the tension is up to the set value; and detecting the changes of the tension signal and driving the tension regulating unit to carry out the tension regulation at the same time. The system and the method disclosed by the invention have the advantages that: through the programmed control by a computer, the tension fluctuation of the cutting wire is decreased and the accuracy and the reliability of the tension control of the multi-wire cutting are greatly increased.

Owner:THE 45TH RES INST OF CETC

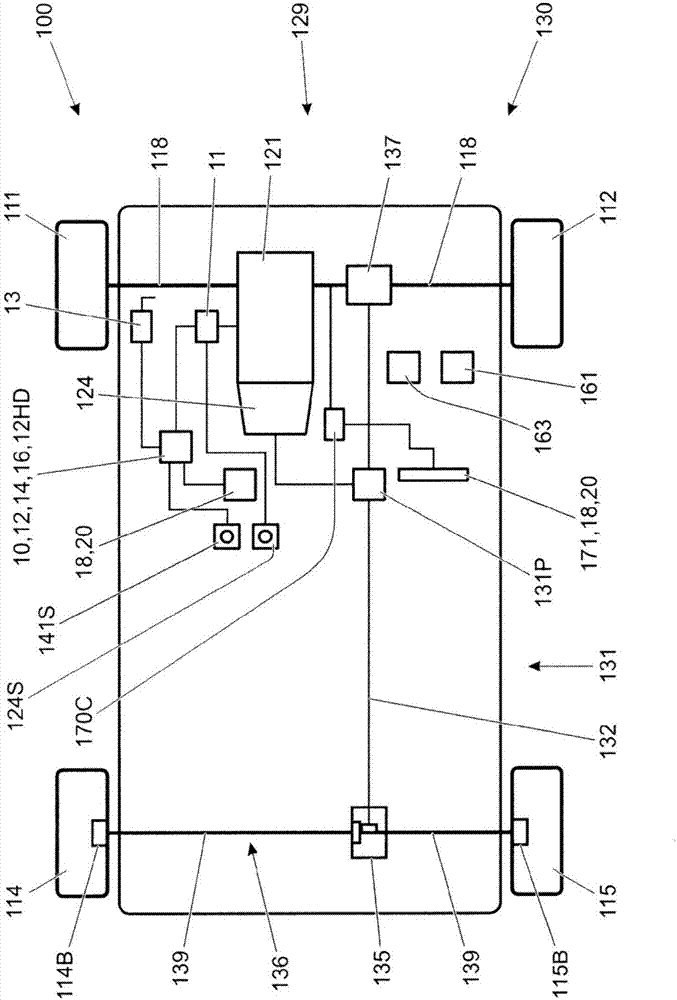

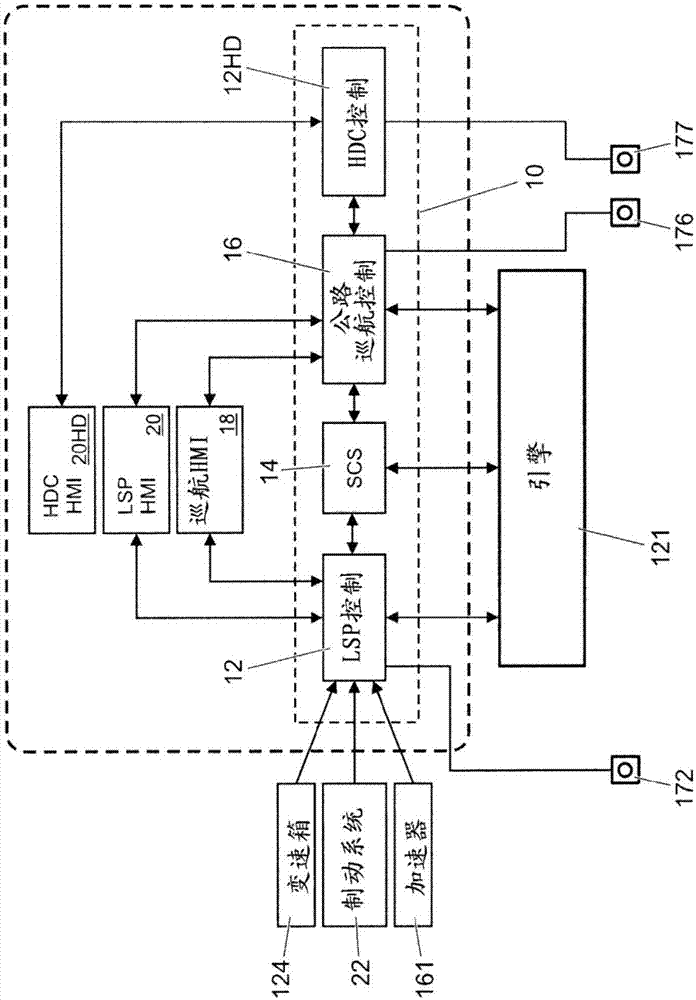

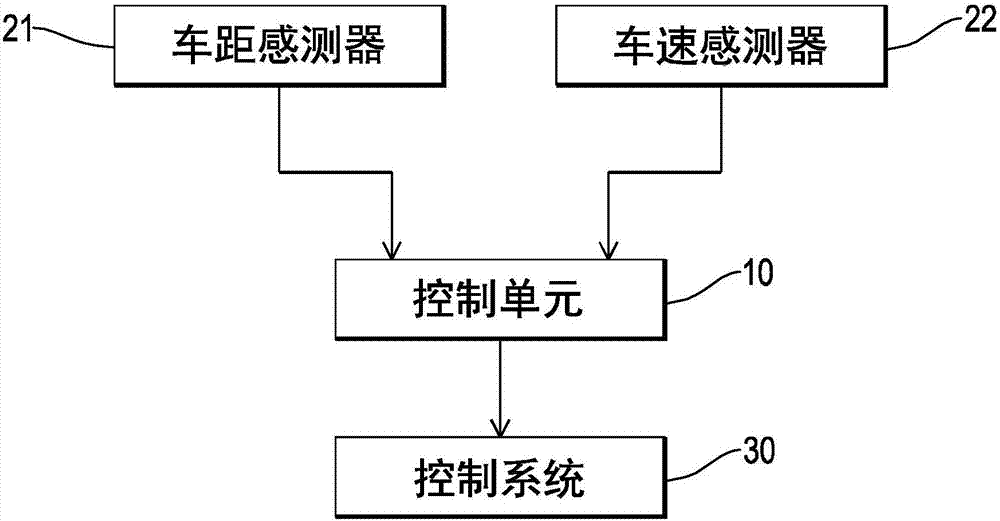

Vehicle speed control system and method of operating same

ActiveCN107351825AUseful comfort indexIncreased comfort levelBrake system interactionsVehicle fittingsSpeed control systemControl system

The invention provides A Vehicle speed control system and method of operating same. The system comprises an operating unit for automatically causing a vehicle to operate in accordance with a target speed value; a receiving unit which receives information relating to movement of a portion of a body of an occupant relative to the vehicle; and a device which automatically adjusting value of target speed according to hte information. The operating unit for automatically causing a vehicle to operate in accordance with a target speed value includes an electric-controller, which is configured to automatically operate the vehicle at the target speed; the receiving unit which receives information relating to movement of a portion of a body of an occupant relative to the vehicle includes the electric-controller, which is configured to receive the electric-signals, that a part of body of the passenger moves relative to the vehicle.

Owner:JAGUAR LAND ROVER LTD

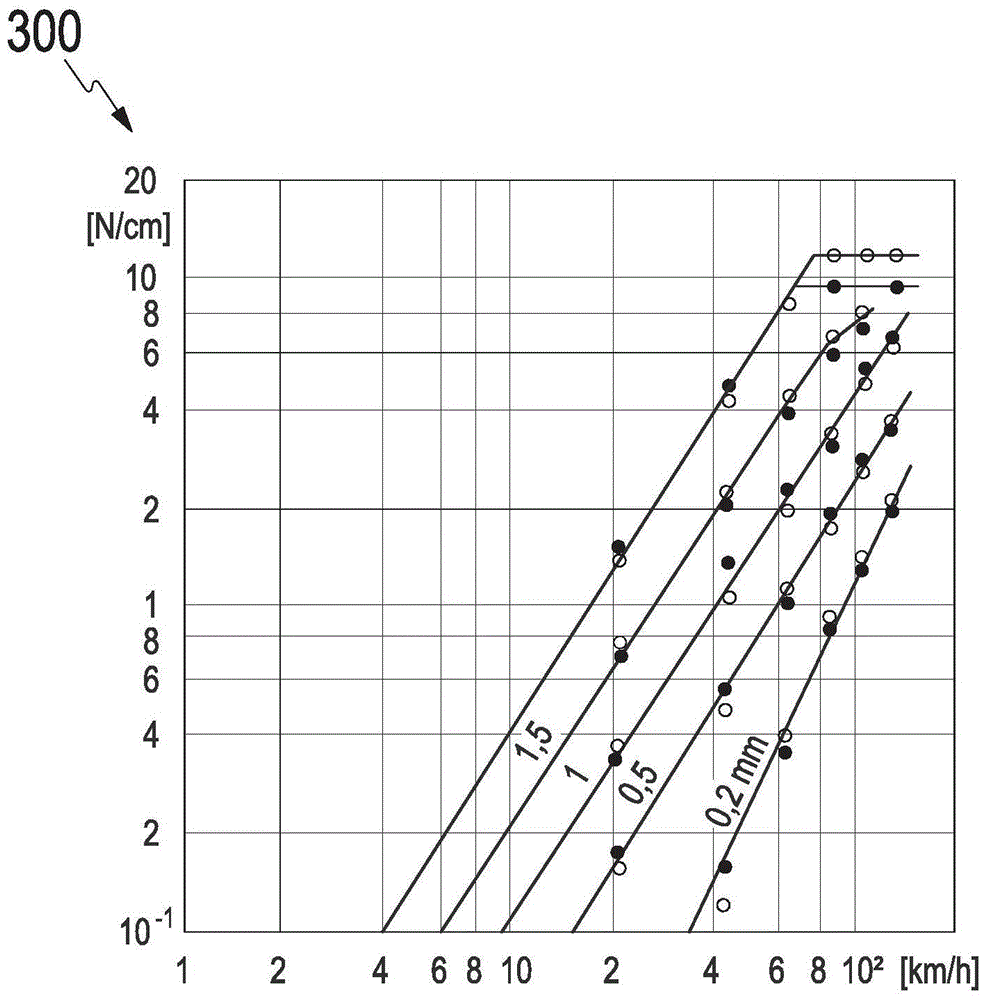

Determining a risk of aquaplaning

InactiveCN104691550ADetermine appropriateEasy to determineRainfall/precipitation gaugesExternal condition input parametersPrecipitationCoefficient of friction

A method for determining a risk of aquaplaning for a motor vehicle comprises steps of determining water on a road on which the motor vehicle is traveling, determining a coefficient of friction between a tire of the motor vehicle and the road being traveled on, determining tire properties, determining precipitation, determining cartographic information items of the road being traveled on, and determining, on the basis of the determined information, whether there is a risk of aquaplaning.

Owner:DR ING H C F PORSCHE AG

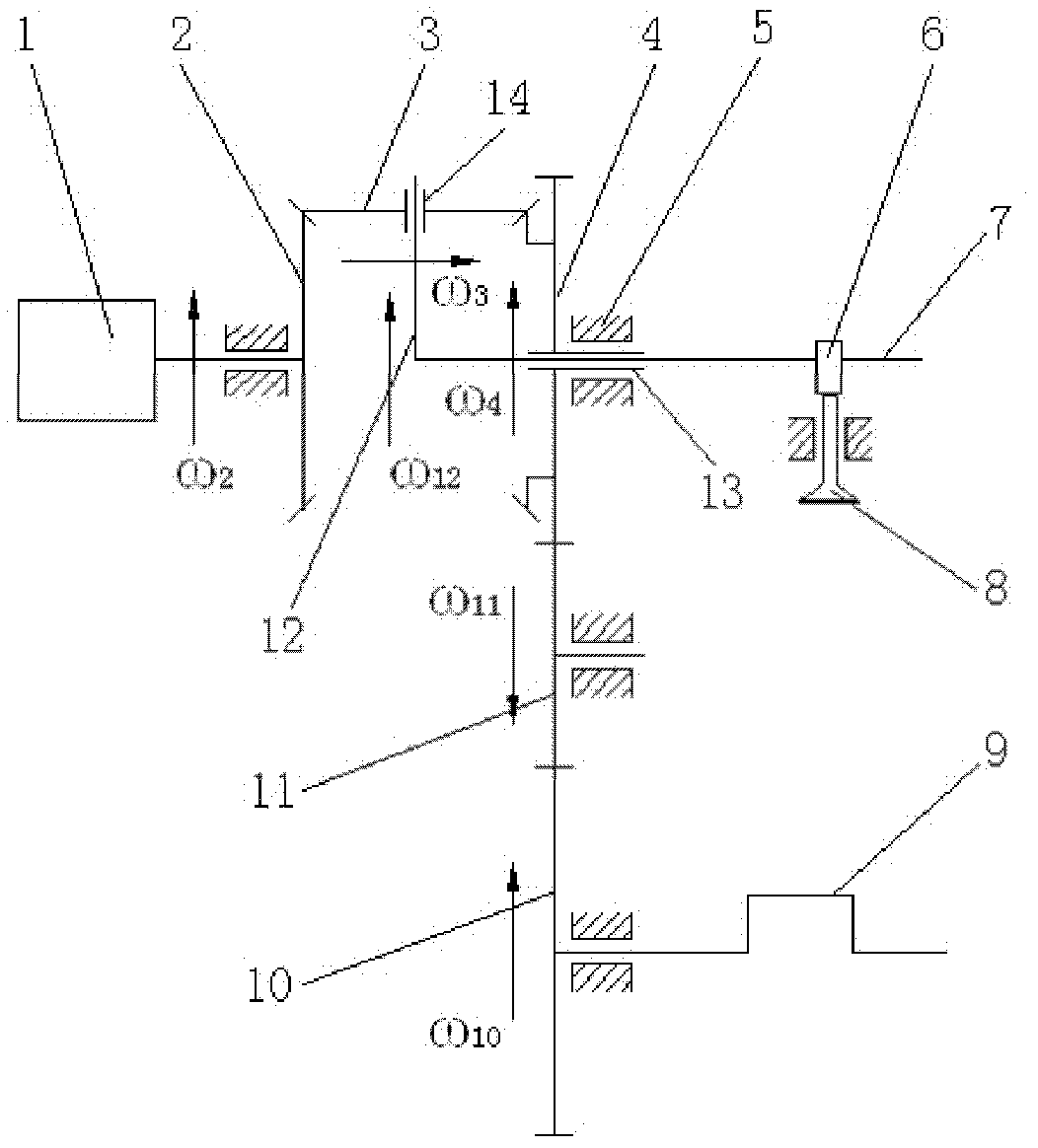

Continuous variable valve timing adjusting system for internal combustion engine

InactiveCN102425469AEasy to installImprove economyValve arrangementsMachines/enginesCombustionVariable valve timing

The invention provides a continuous variable valve timing adjusting system for an internal combustion engine, belonging to the technical field of internal combustion engines. The system comprises a crankshaft, a cam shaft, a cam, a driving gear, an intermediate gearing, an input center gear, a differential gear, a differential gear carrier, an adjusting center gear and an adjusting device, wherein the front end of the crankshaft is installed at the axle center of the driving gear; the intermediate gearing is meshed with the driving gear and an outer gear ring of the input center gear respectively; the differential gear is meshed with an inner conical gear ring of the input center gear and the adjusting center gear respectively; the differential gear carrier passes through a differential gear sleeve and is connected with the cam shaft into a whole; and the adjusting device is coaxially connected with the adjusting center gear. In the working process of the system, when the adjusting center gear rotates in a certain direction, the rotating speed of the differential gear carrier is increased or decreased, thus changing the rotation phase between the cam shaft and the crankshaft and realizing adjustment of valve timing. The system has reasonable design, simple structure, good reliability and higher adjustment precision and is easy to add on the original engine.

Owner:SHANGHAI JIAO TONG UNIV

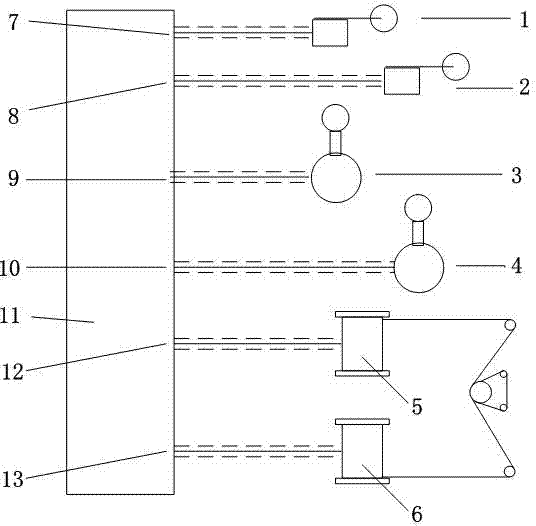

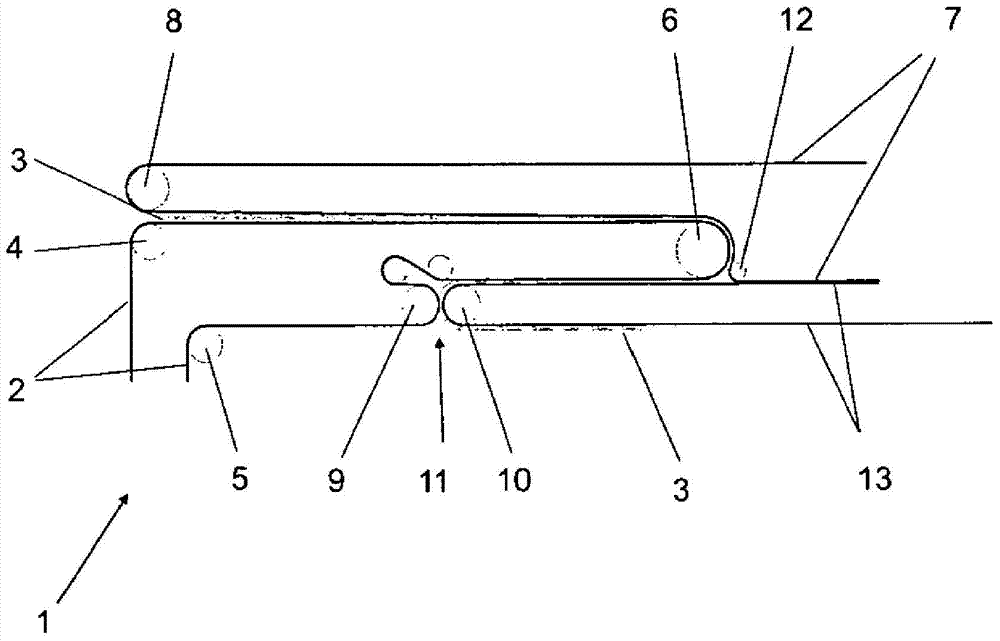

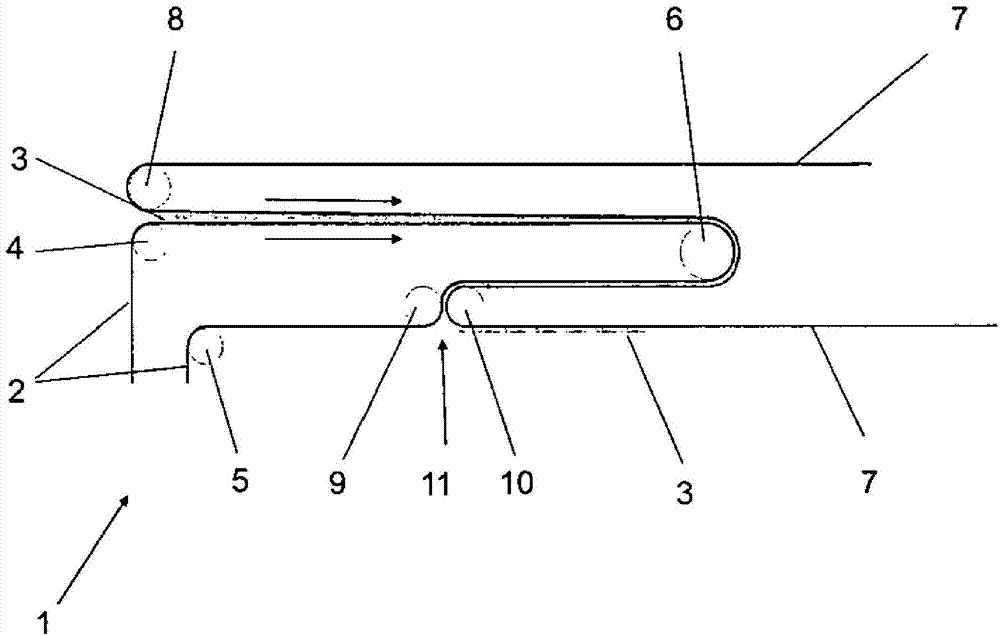

Crosslapper and method for operating crosslapper

The invention relates to a crosslapper used for formation of a fleece made of many layers of fibrous web. The crosslapper comprises at least one continuously revolving input belt (2) which supplies the fibrous web (3) from the inlet region of the crosslapper up to a laying gap (11) of the laying carriage, and a continuously circulating cover belt (7) which fixes the fibrous web (3) on the input belt (2). The crosslapper is characterized in that the cover belt (7) fixes the fibrous web (3) from the inlet region of the crosslapper (1) up to the laying gap on the input belt(2).

Owner:TRUETZSCHLER GRP SE

Double-acting retarder

The invention discloses a double-acting retarder, which comprises a frame, a speed changer and a transmission shaft, and the double-acting retarder is characterized in that an output shaft of a speed changing box is connected with a cam and a brake disc body, two sides of the cam and the brake disc body are respectively and symmetrically provided with a plunger pump, the plunger pumps are connected with a heat radiating oil tank through an oil inlet pipe with a one-way valve A, the oil inlet pipe is connected with a one-way valve B through a tee joint, the other end of the one-way valve B is connected with a brake device through an oil outlet pipe, the oil outlet pipe is also connected with a throttling valve through a tee joint, the throttling valve is connected with the heat radiation oil tank through an oil return pipe, the outer side of each plunger pump is wrapped by a brake slide groove, a thrusting air chamber is arranged between the bottom end of each plunger pump and the brake slide groove, the front end of each plunger pump is provided with a guide wheel, the guide wheel is matched with the came and the brake disc body, the thrusting air chamber is connected with an air storage tank through a retarding switch, and both the retarding switch and the throttling valve are connected with a control unit.

Owner:森田(济南)模型有限公司

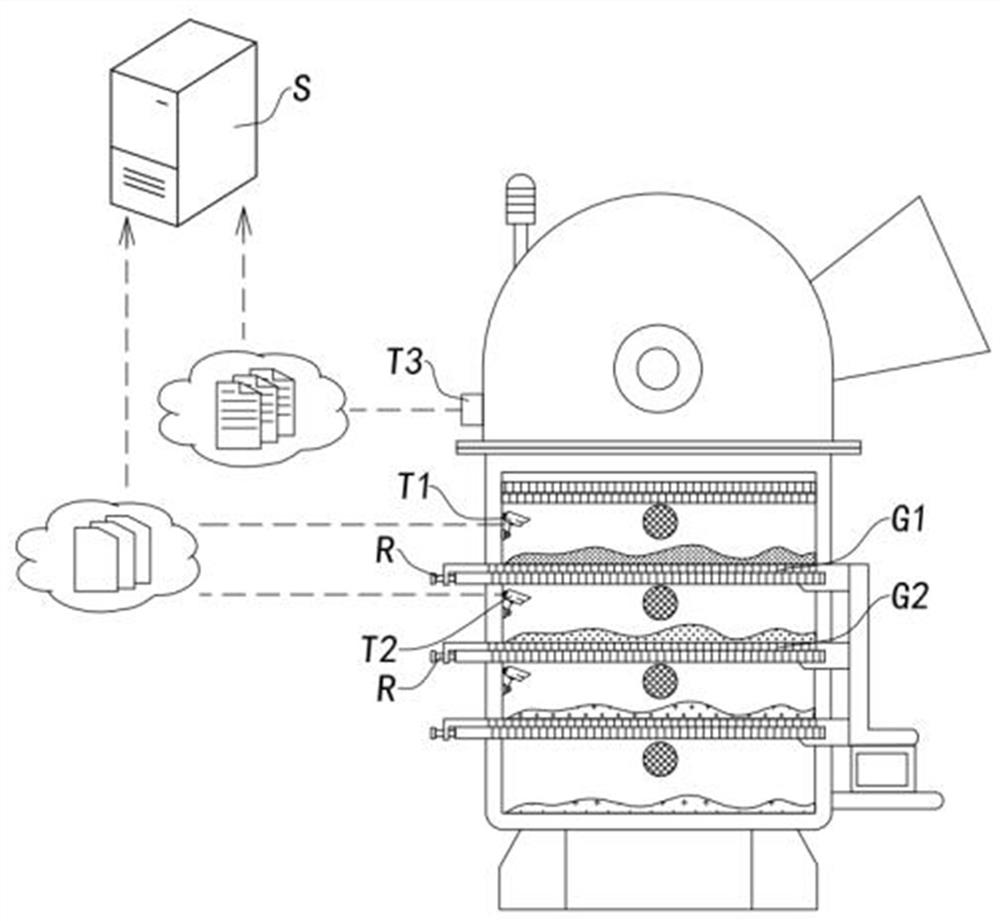

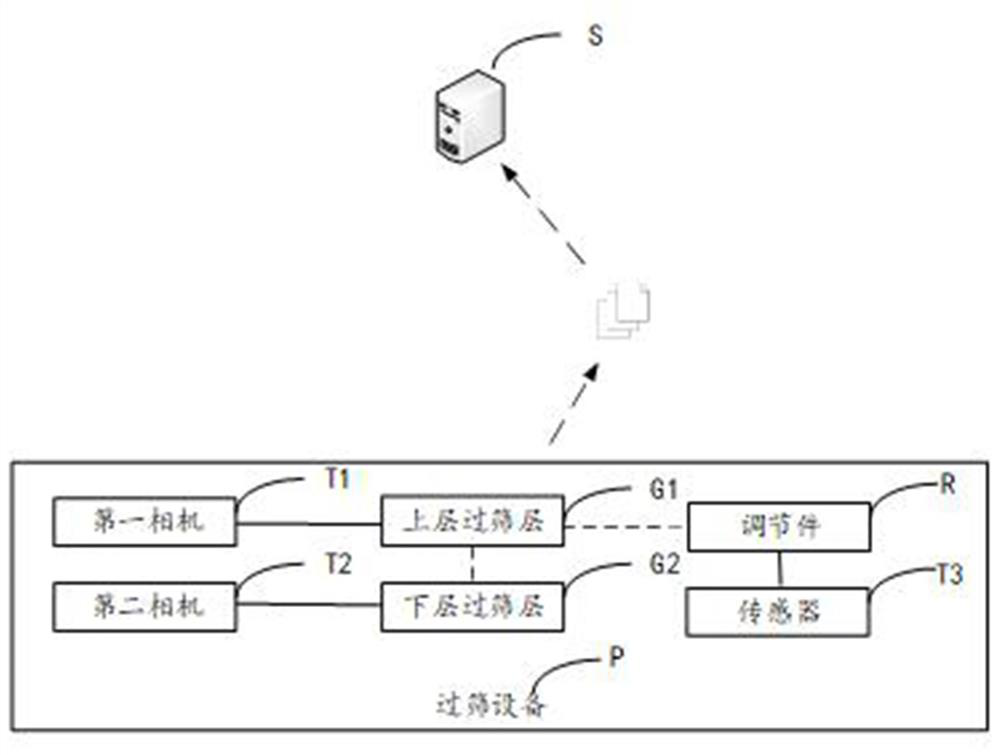

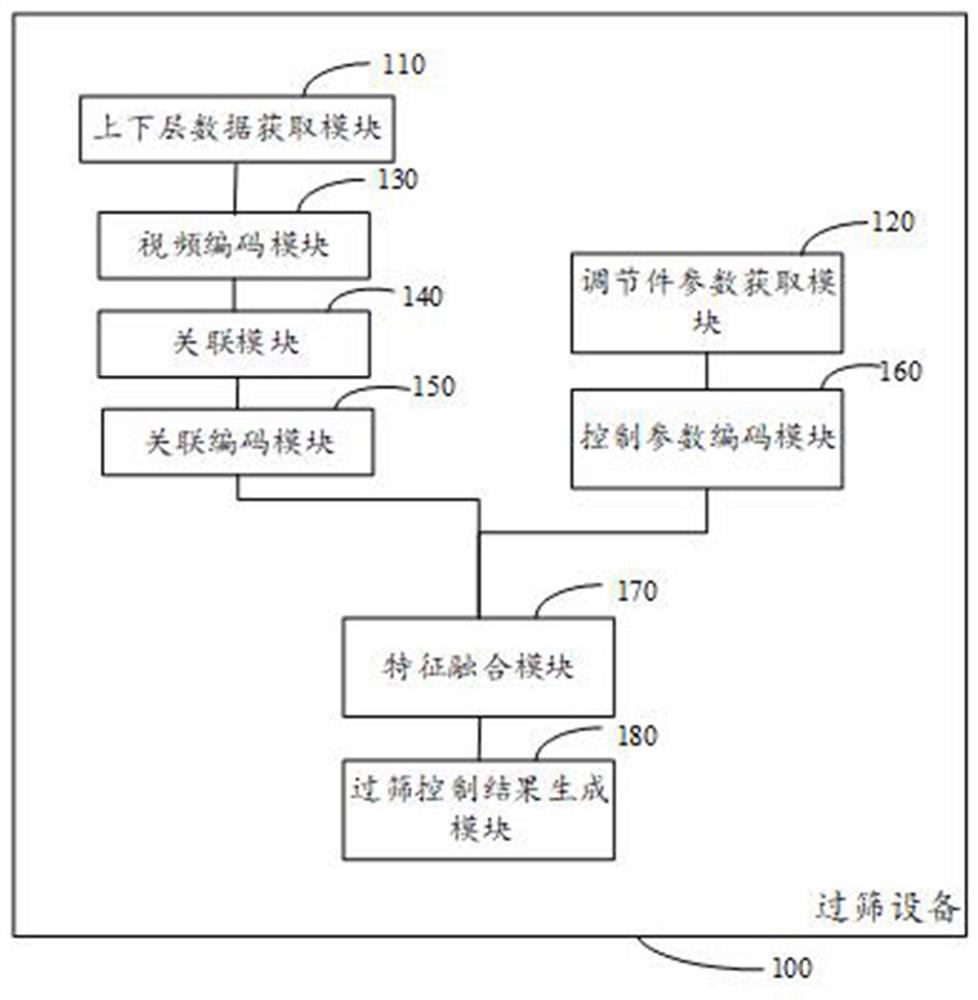

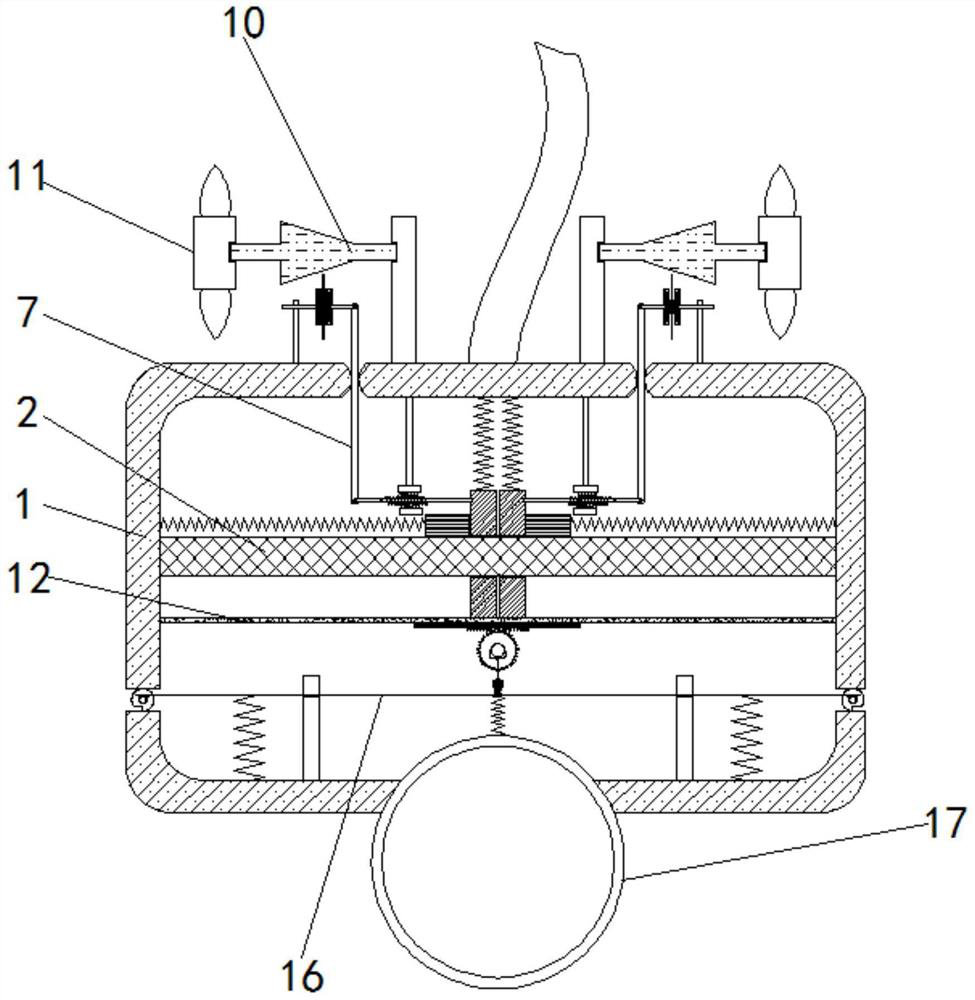

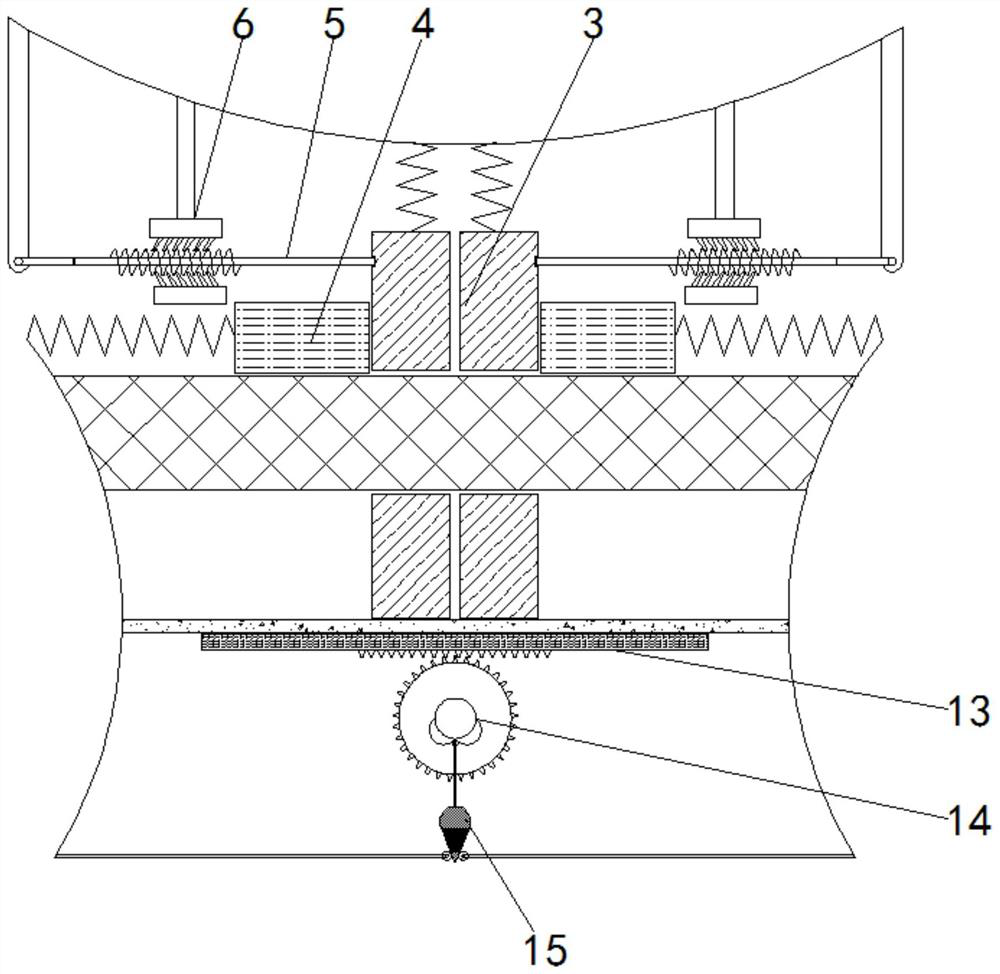

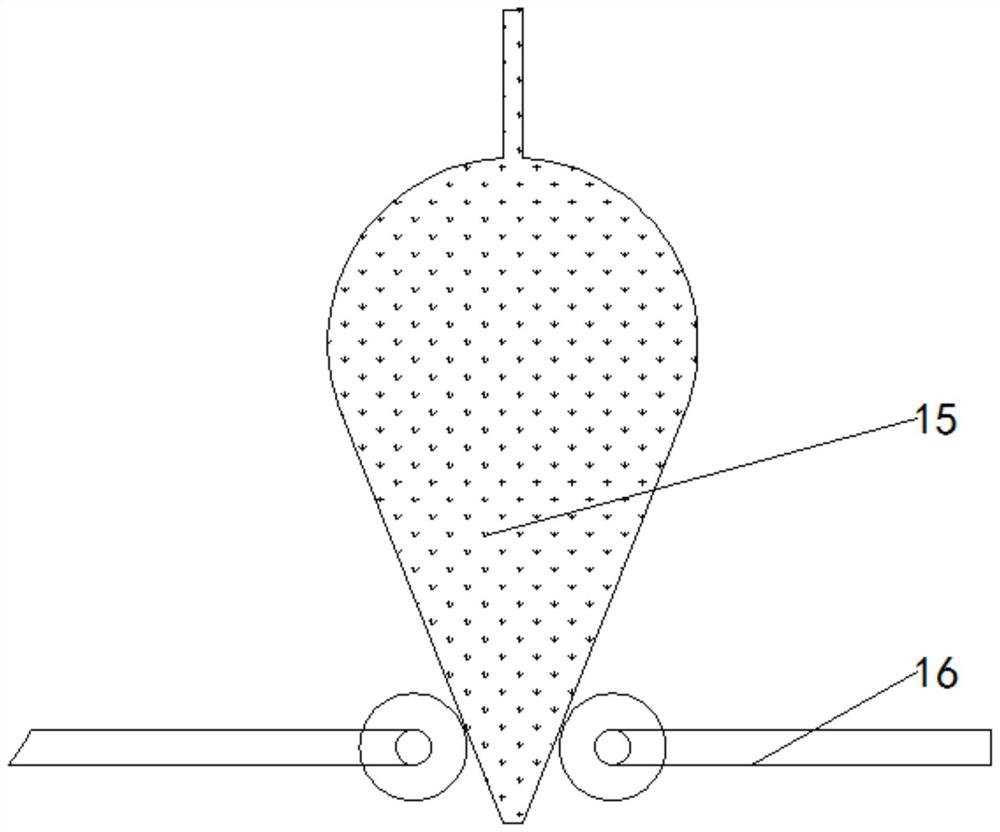

Sieving equipment for high-purity rounded quartz powder and sieving control method of high-purity rounded quartz powder

ActiveCN114758304ASpeed increase or decreaseHigh precisionSievingGas current separationFeature vectorEngineering

According to the screening equipment for the high-purity rounded quartz powder and the screening control method of the screening equipment, the multi-stage screening and crushing functions are achieved, and the screening effect and the screening efficiency are both considered by controlling the speed of the adjusting piece of the screening equipment. Specifically, the method comprises the following steps: encoding a first monitoring video and a second monitoring video of an upper screening layer and a lower screening layer which are acquired in a preset time period to obtain a collaborative feature vector for representing collaborative characterization of an upper and lower screening dynamic effect; the method comprises the following steps: encoding obtained moving speeds of an adjusting part at a plurality of preset time points in a preset time period through a time sequence encoder comprising a one-dimensional convolution layer and a full connection layer to obtain a control feature vector; and then fusion based on smooth transition is performed on the collaborative feature vector and the control feature vector to obtain a classification feature vector, and a classification result used for representing increasing or decreasing of the speed of the adjusting part is obtained through classification, so that the accuracy of speed control of the adjusting part is improved.

Owner:SINOTENG SILICA MATERIALS TECH (JIANGSU) CO LTD

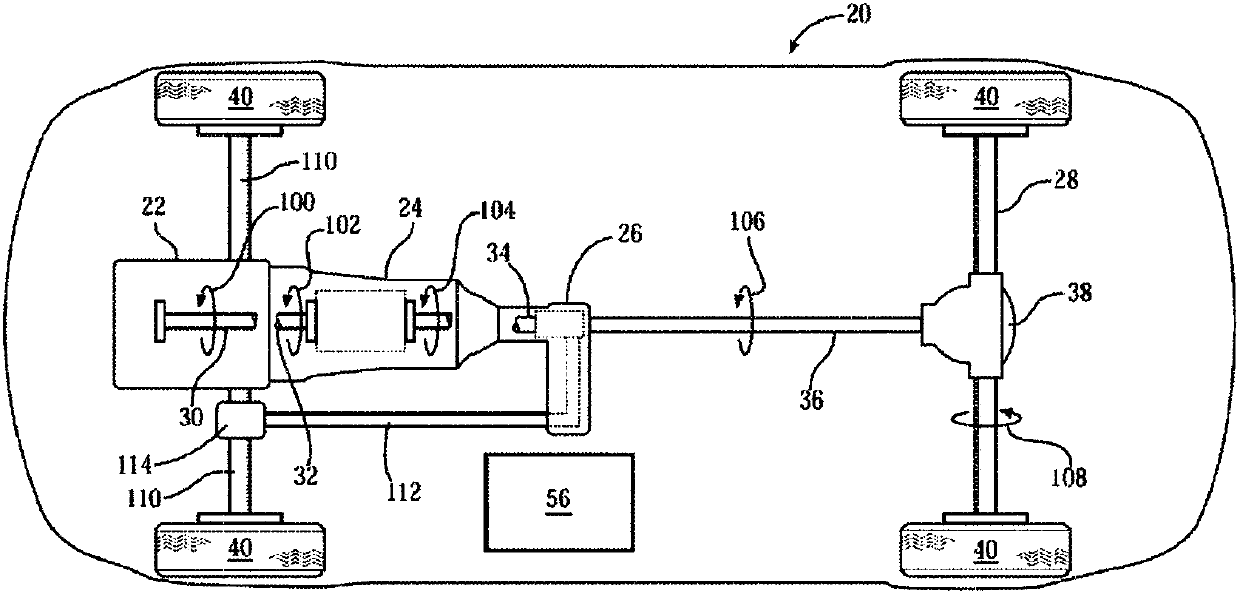

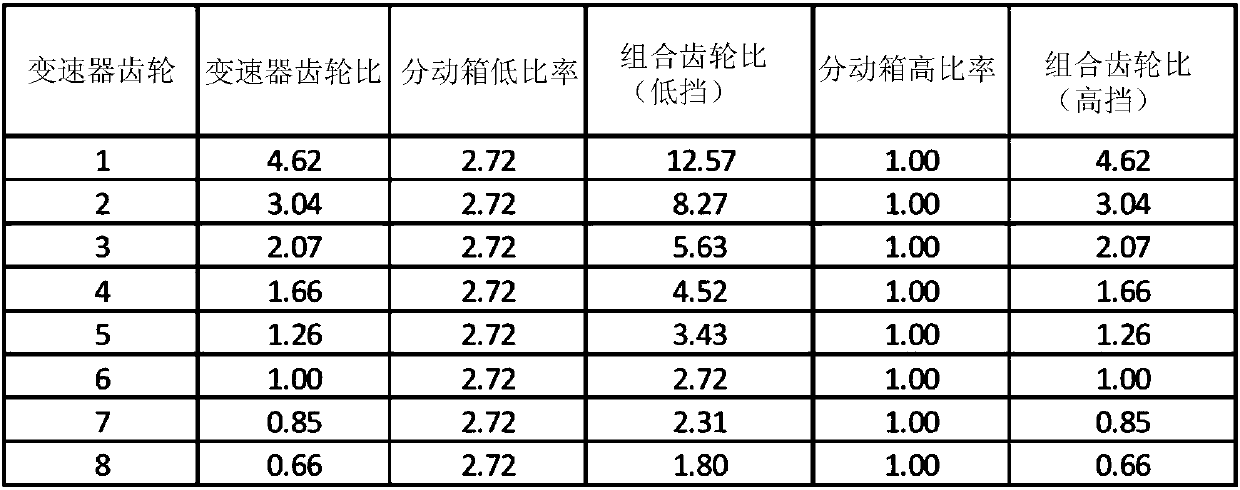

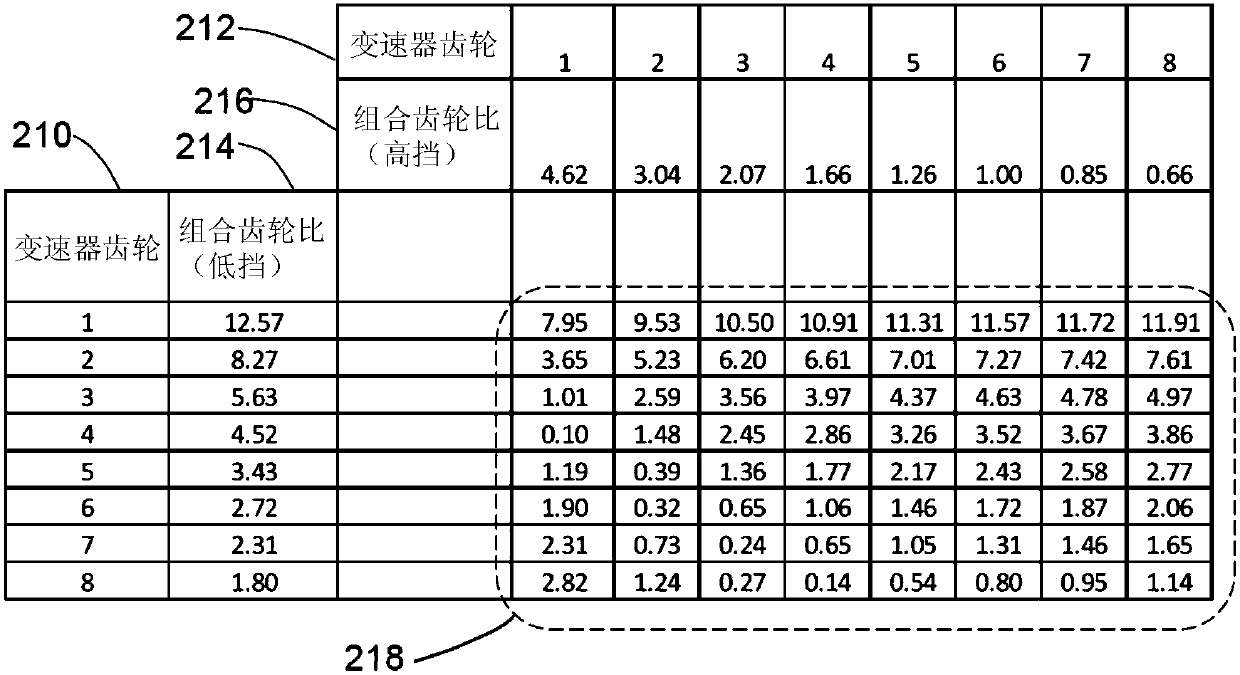

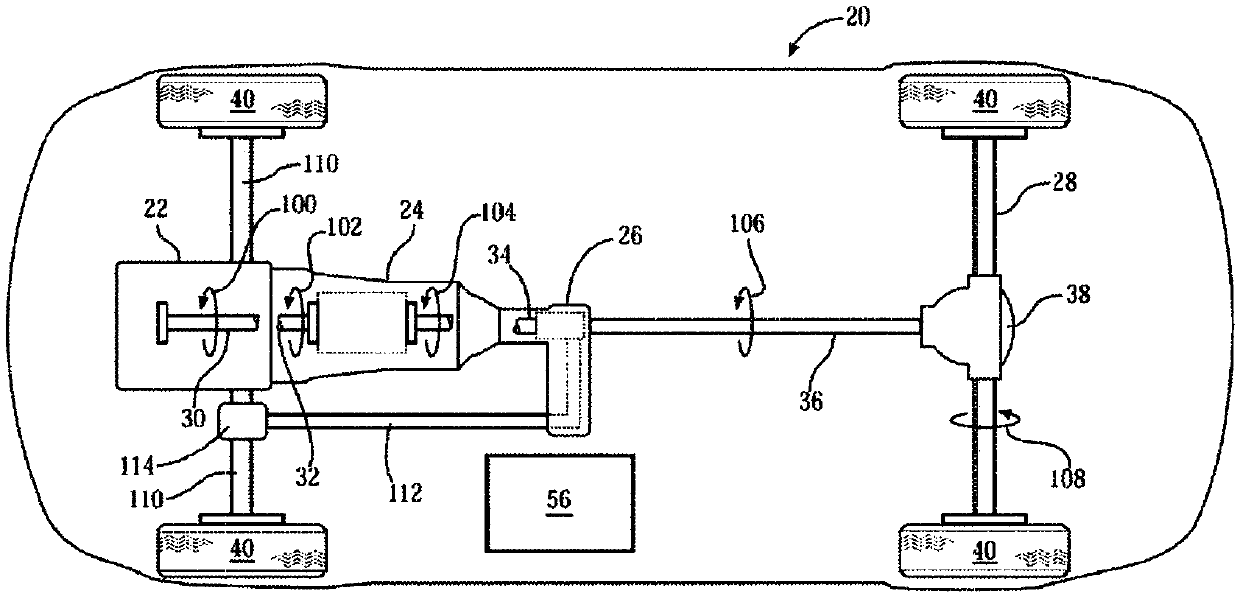

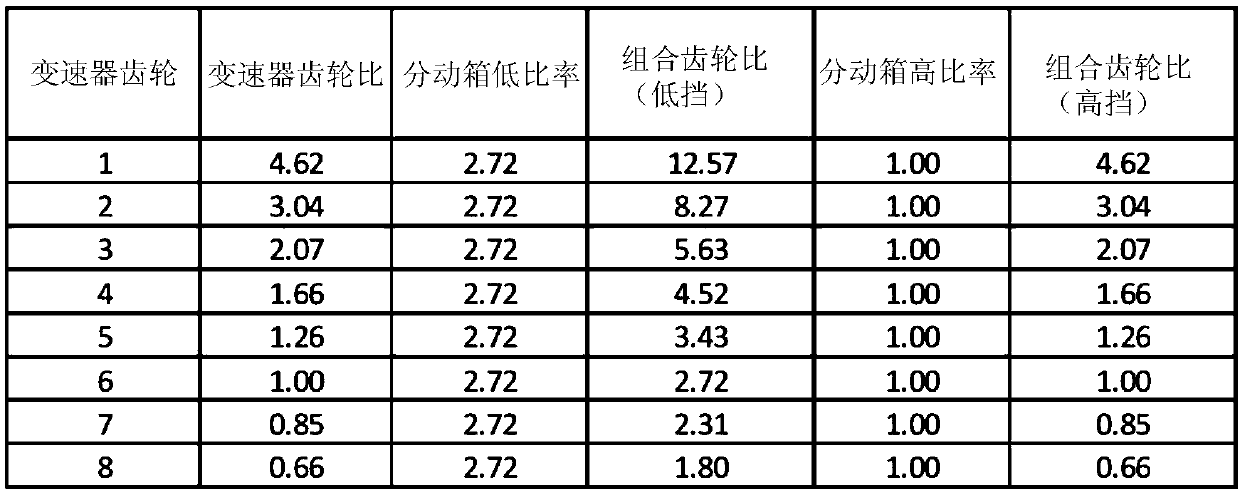

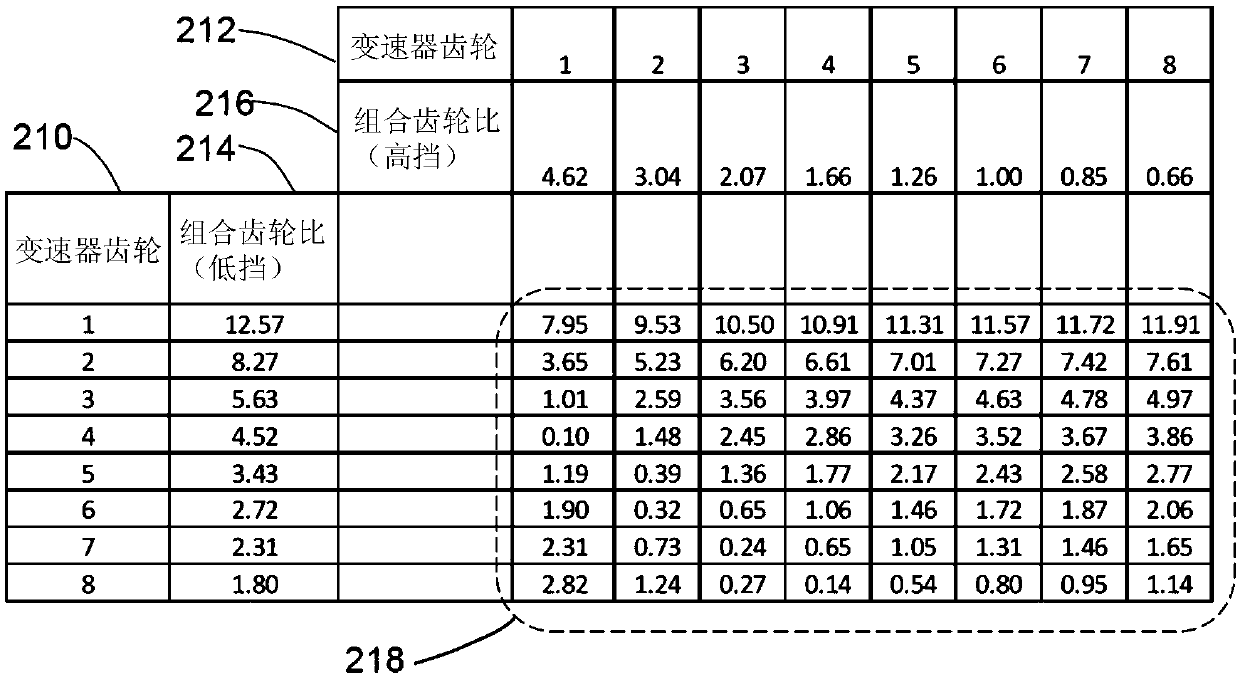

Method for a synchronous range shift on an electronically controlled two-speed transfer case with an electronically controlled engine and transmission

A method for shifting between a low speed range and a high speed range for a two-speed transfer case in a four-wheel drive vehicle includes determining a target transmission gear ratio and a desired transfer case range based on the current vehicle speed and the initial transfer case range. The transmission is shifted to the target transmission gear ratio when it is determined that the vehicle speed is in an appropriate range. The transfer case input torque is reduced to a minimum value, and the transfer case is shifted to neutral. The method further includes adjusting the engine speed and transmission gear setting to control the transmission output shaft speed to a desired range. The transfer case is shifted from neutral to the desired transfer case range when the transmission output shaftspeed is within the desired range of transmission output shaft speed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Universal connecting device for rotating pipeline

ActiveCN109630778AChange the direction of the transmission axisFacilitate transmissionAdjustable jointsFixed frameEngineering

The invention discloses a universal connecting device for rotating a pipeline. The universal connecting device comprises an output angle adjusting assembly, the fixed end of the output angle adjustingassembly is fixedly connected to the output end of a rotating direction adjusting assembly, the input end of the rotating direction adjusting assembly is connected with an input angle adjusting assembly, and the lower end face of the rotating direction adjusting assembly is fixedly connected with a fixing frame. A driven pipeline and a driving pipeline are connected with the universal connectingdevice in a through mode, after liquid in the pipelines flows through the universal connecting device, the flow direction is changed, the deviation angle can be adjusted according to the needs, usingis convenient, the transmission axis direction can be changed while the flow direction of the liquid is changed, and transmission is conveniently conducted by using the pipelines. Through the rotatingdirection adjusting assembly, a circuit is controlled to be opened and closed, the rotating direction of the driven pipeline can be controlled freely, and the application range is further expanded. By changing the ratio of the inner diameter of a second outer gear to the diameter of a center gear to the inner diameter of a rotating ring, the rotating speed of the driven pipeline is increased or decreased.

Owner:TAIZHOU SANYANG TAI SANITARY WARE CO LTD

Tension control system and control method for multi-wire cutting of silicon wafer

InactiveCN102555093BSpeed increase or decreaseQuick responseWorking accessoriesFine working devicesControl systemWire cutting

The invention relates to a tension control system and a control method for multi-wire cutting of silicon wafer. The system comprises a tension detecting and controlling device and a tension regulating device, wherein the tension detecting and controlling device comprises a tension detecting and controlling main unit, left and right tension detecting devices, a paying-off signal terminal and a takeup signal terminal; the tension detecting and controlling main unit is composed of a main control computer and an analog quantity I / O (Input / Output) acquiring card; the left and right tension detecting devices, the paying-off signal terminal and the takeup signal terminal are connected with the detecting and controlling main unit. The tension control method for the multi-wire cutting of the silicon wafer performs detecting and controlling by adopting the tension control system for the multi-wire cutting and comprises the steps of: applying signal voltage to the signal terminals of a takeup pulley and a paying-off pulley; detecting that whether the tension signal is up to a set tension value or not, if not, returning to the first step; starting the pulley to rotate if the tension is up to the set value; and detecting the changes of the tension signal and driving the tension regulating unit to carry out the tension regulation at the same time. The system and the method disclosed by the invention have the advantages that: through the programmed control by a computer, the tension fluctuation of the cutting wire is decreased and the accuracy and the reliability of the tension control of the multi-wire cutting are greatly increased.

Owner:THE 45TH RES INST OF CETC

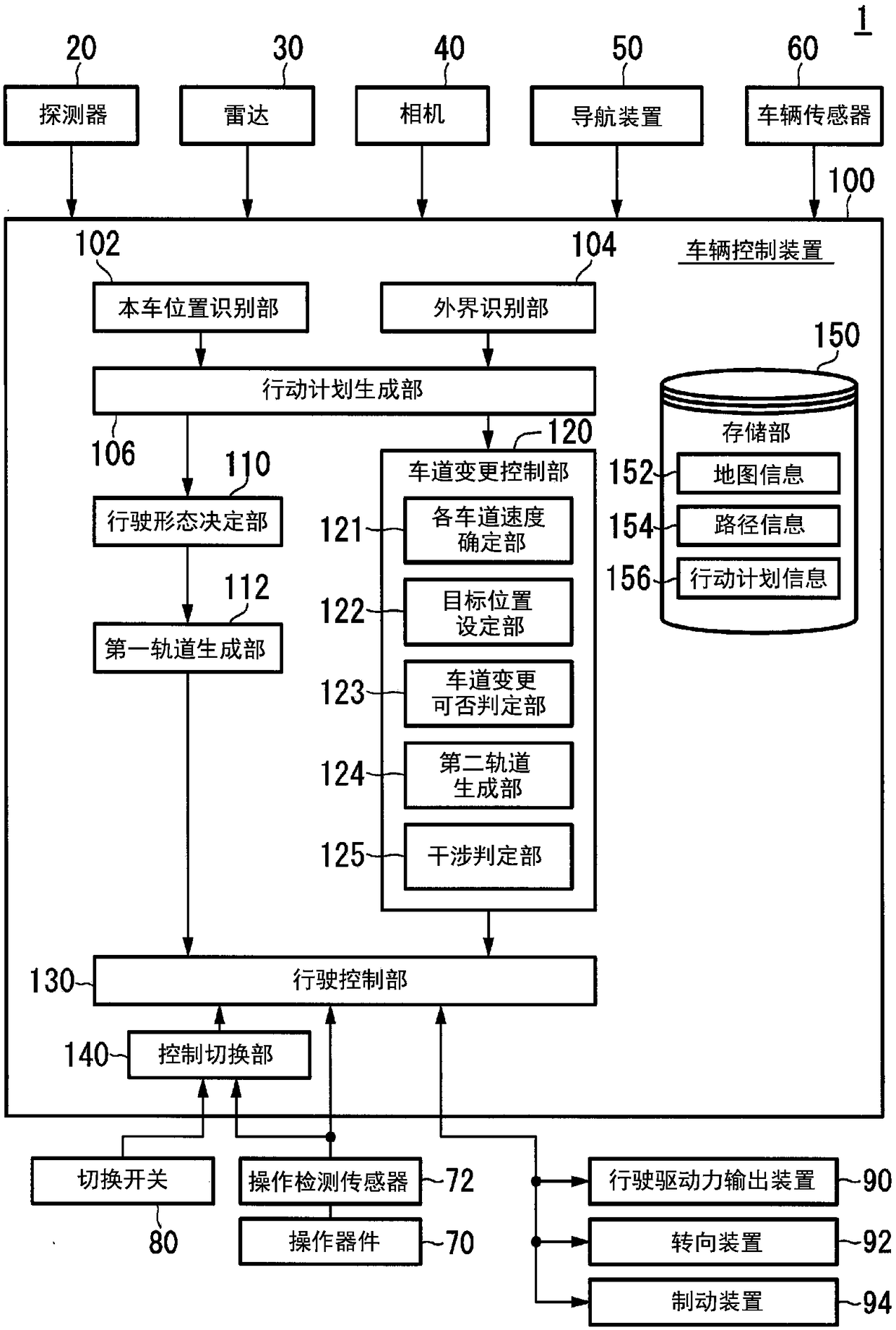

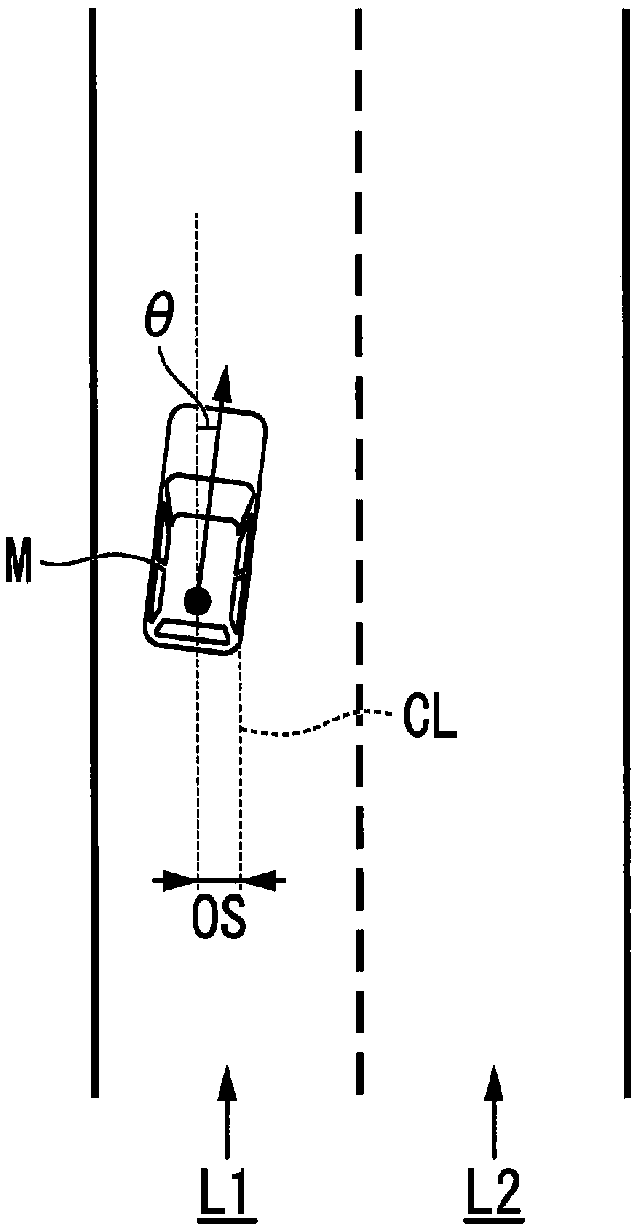

Vehicle control device, vehicle control method, and vehicle control program

InactiveCN108475473AAppropriate settingDetermine the speedInstruments for road network navigationPedestrian/occupant safety arrangementCarriagewayVehicle control

This vehicle control device is provided with: a recognition unit that recognizes the position of a nearby vehicle traveling in the vicinity of a host vehicle; a respective-lane-speed specification unit that specifies a first vehicle speed related to a vehicle travelling in a lane in which the host vehicle is traveling and a second vehicle speed related to the nearby vehicle traveling in a lane which is a lane-change destination of lane change to be performed by the host vehicle; a target position setting unit that sets a lane-change target position on the lane-change destination lane on the basis of a comparison result between the first vehicle speed and the second vehicle speed; and a control unit that causes the host vehicle to move to the target position by lane change.

Owner:HONDA MOTOR CO LTD

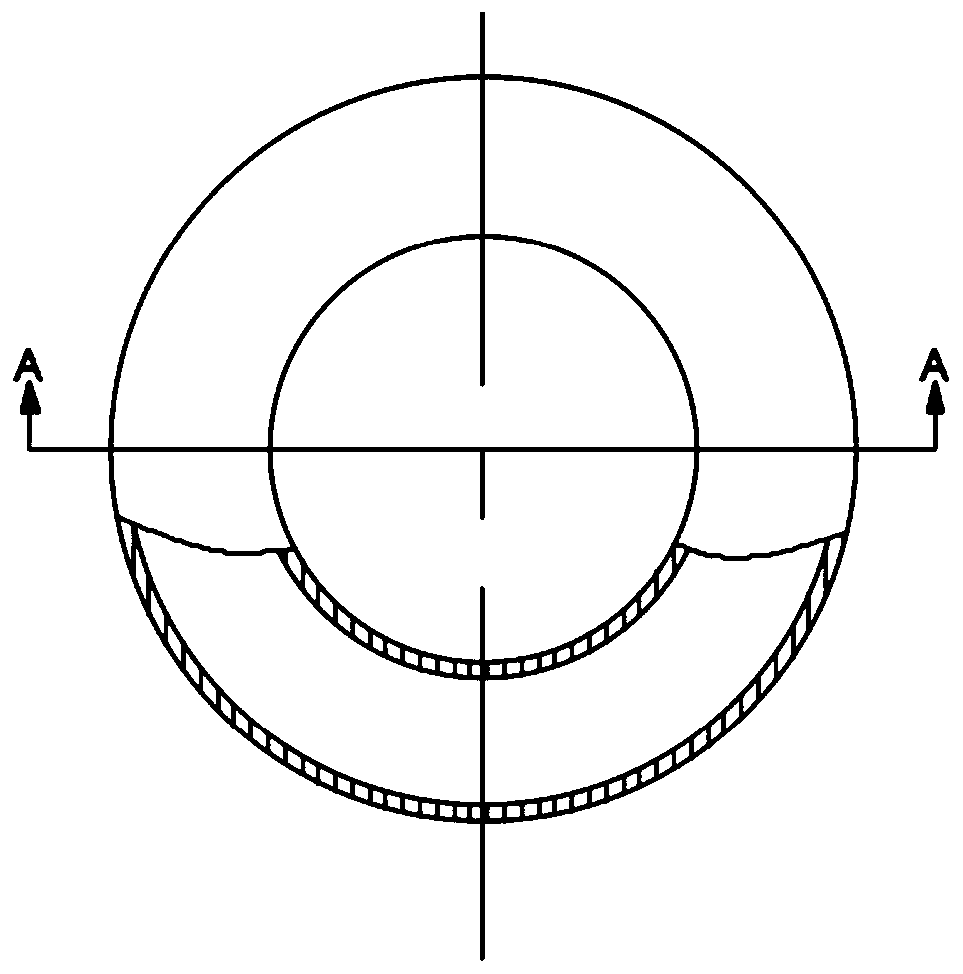

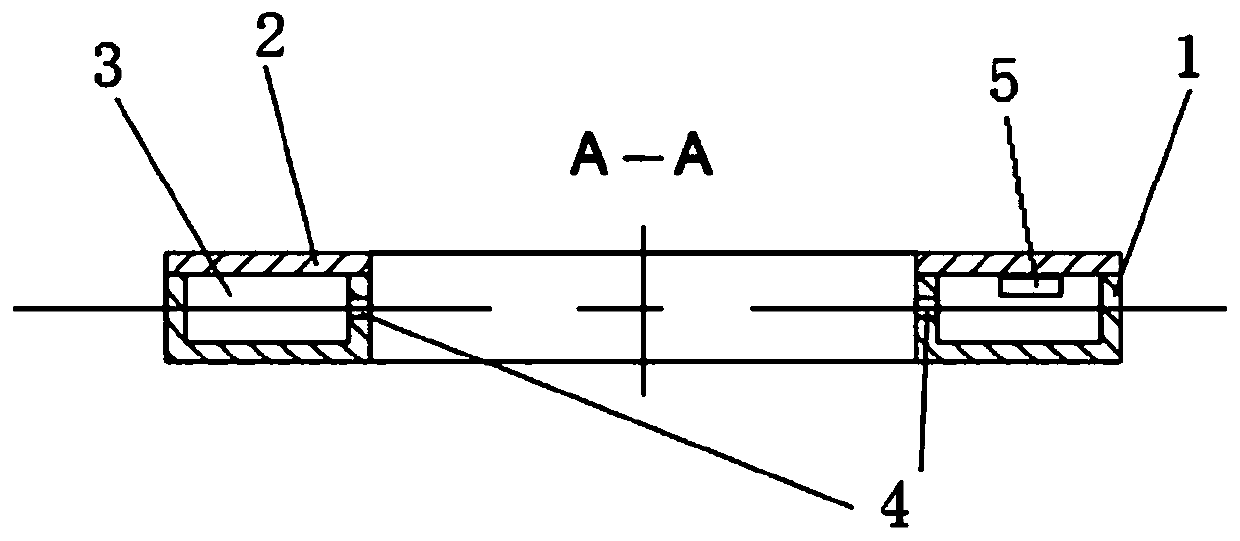

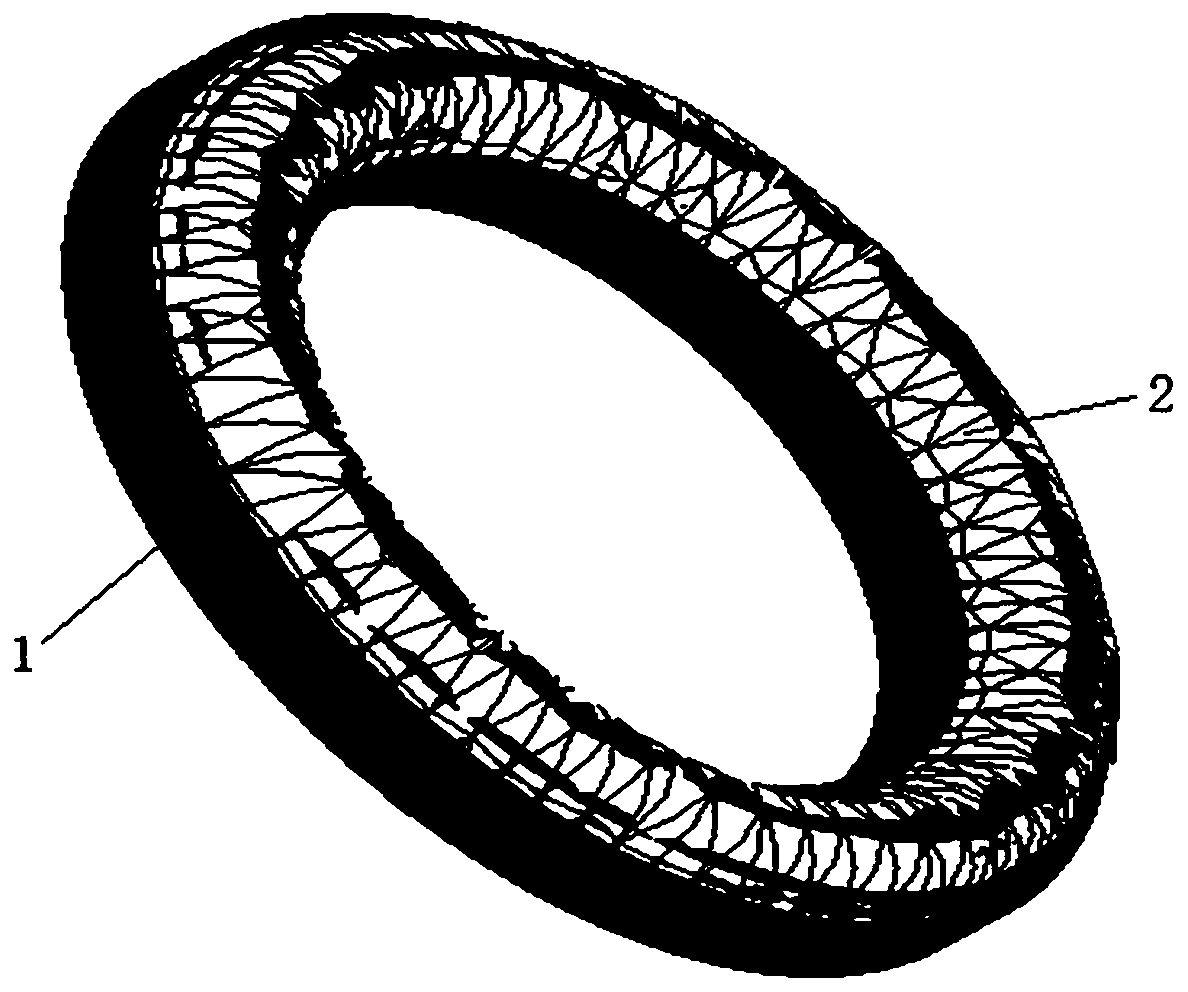

Oil pressure adjusting type friction plate capable of realizing oil film thickness micro adjustment

InactiveCN110454516AReduce mistakesHigh adjustment accuracyCouplingsFluid clutchesElastomerOil pressure

The invention discloses an oil pressure adjusting type friction plate capable of realizing oil film thickness micro adjustment. The oil pressure adjusting type friction plate comprises a friction plate base plate, an elastic body and an oil pressure sensor; the friction plate base plate is of an annular shape, and an annular groove is coaxially formed in the friction plate base plate; the elasticbody covers the position, above the groove, of the friction plate base plate, and the elastic body and the groove form a sealed oil filling cavity; the elastic modulus of the elastic body is smaller than the elastic modulus of the friction plate base plate; the friction plate base plate is provided with an oil inlet communicating with the oil filling cavity, and the oil inlet is connected with anoil cylinder through an oil pipe; and the oil pressure sensor is used for detecting oil pressure borne by the elastic body. According to the friction plate, the thickness of an oil film is adjusted byutilizing the friction plate, so that mechanical transmission is simplified, and micro accurate adjustment of the thickness of the oil film is realized.

Owner:YANCHENG INST OF TECH

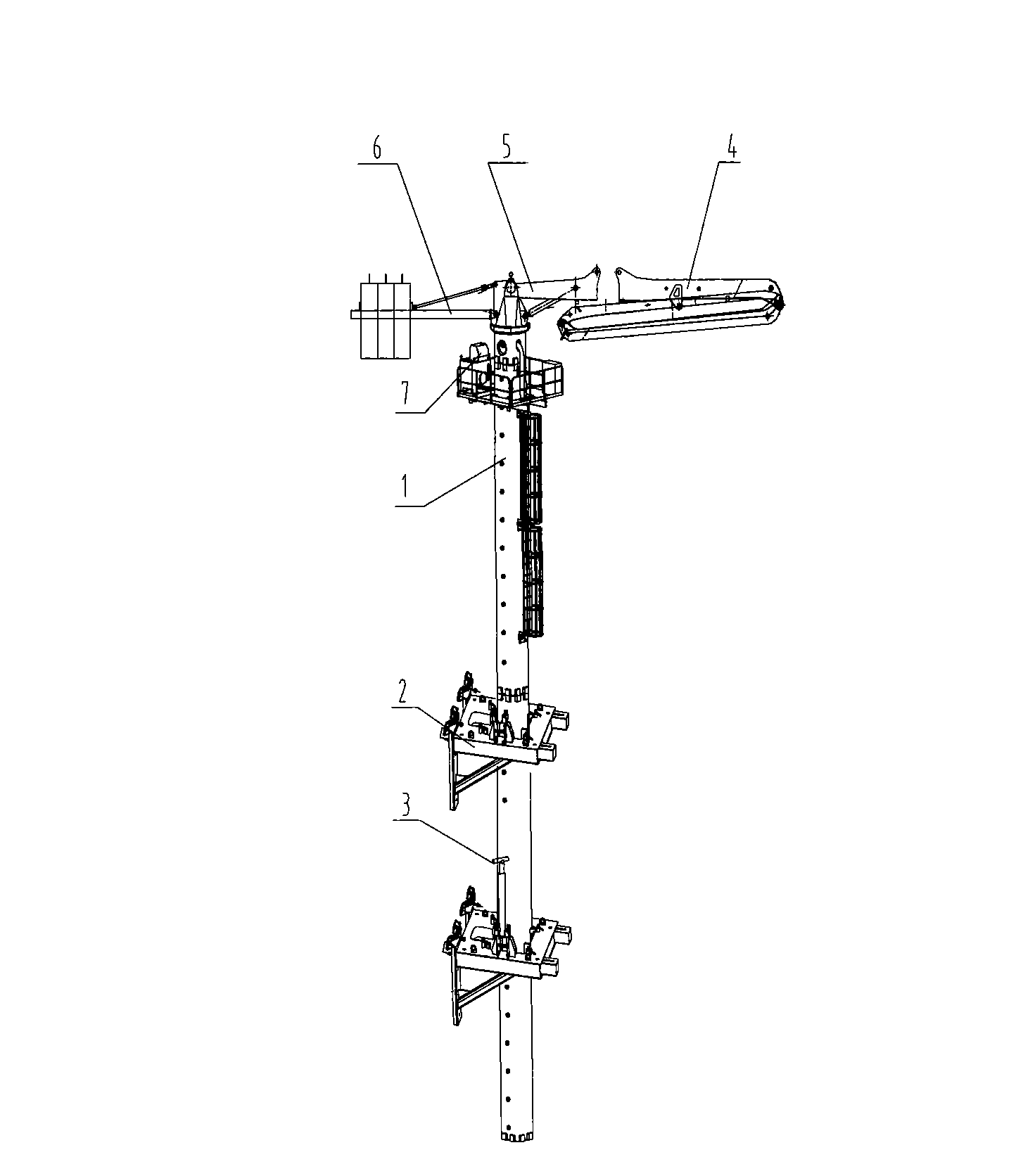

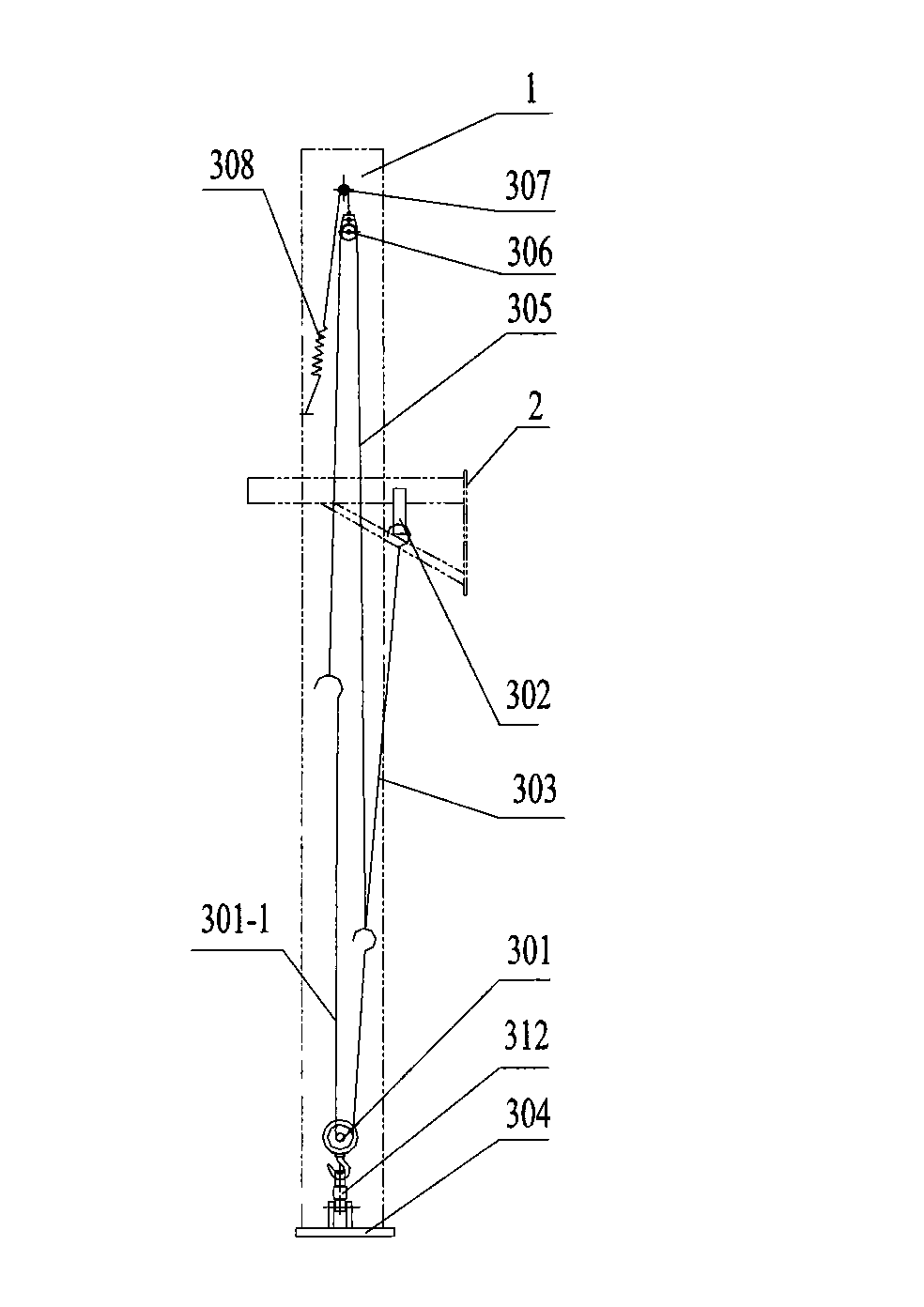

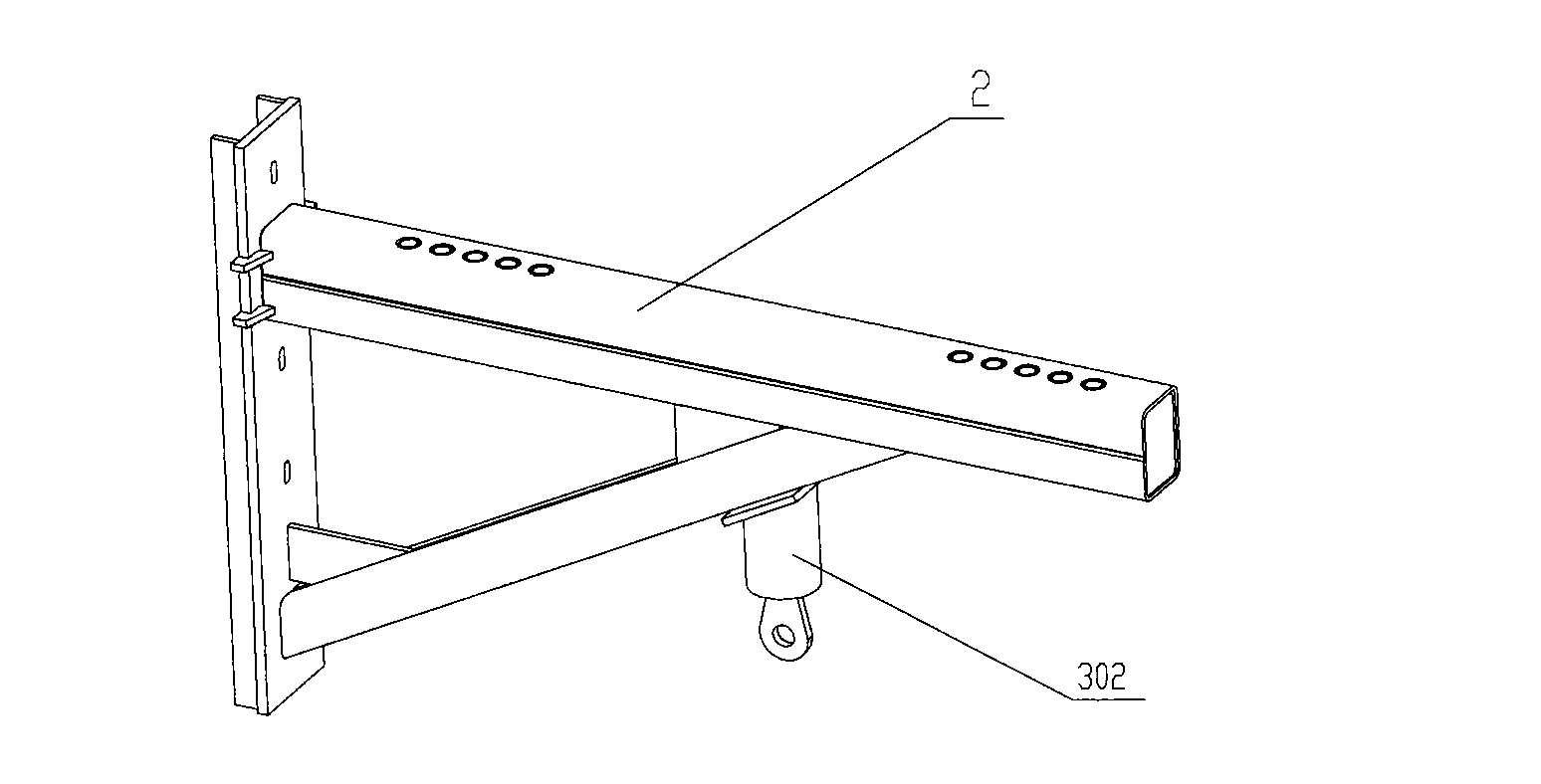

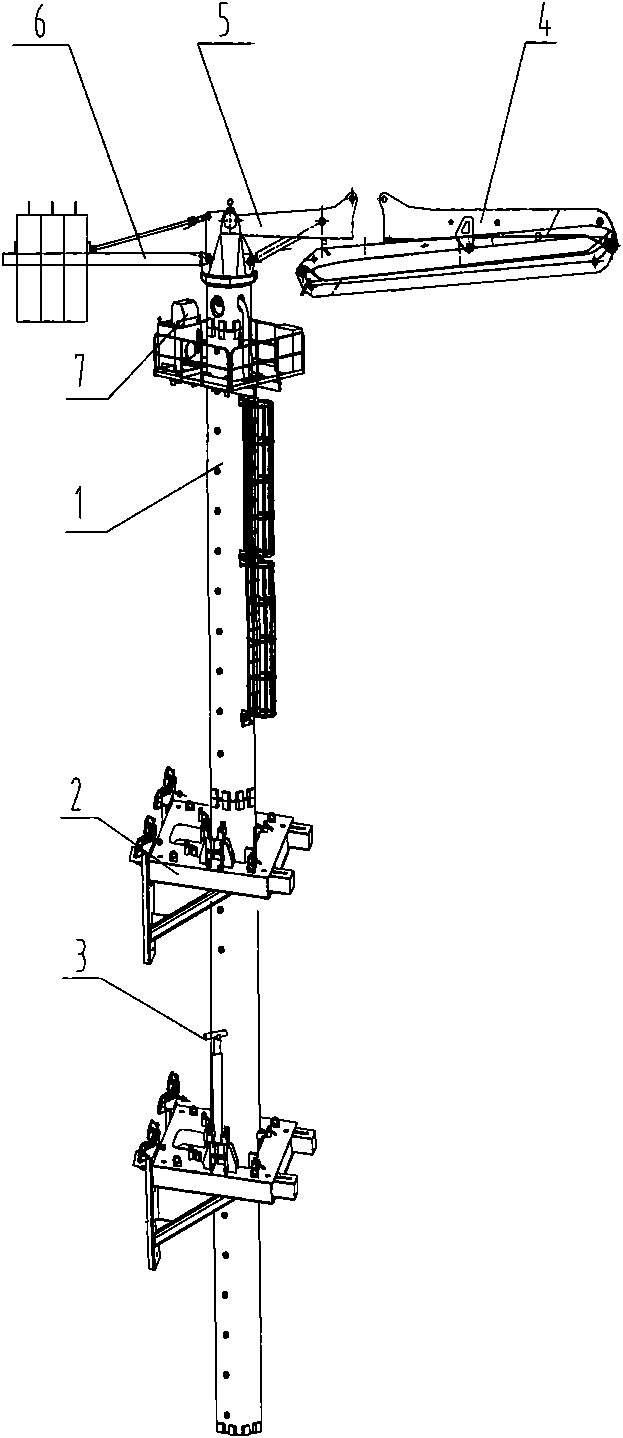

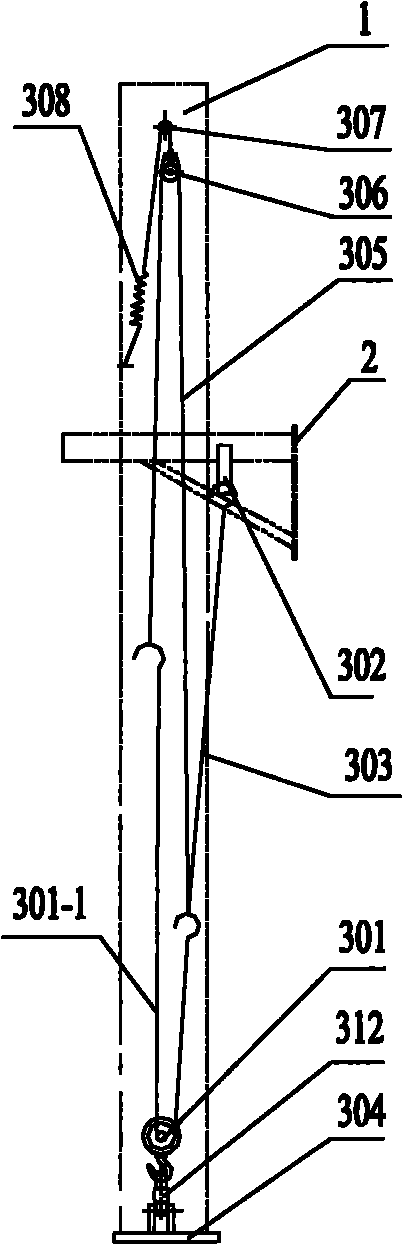

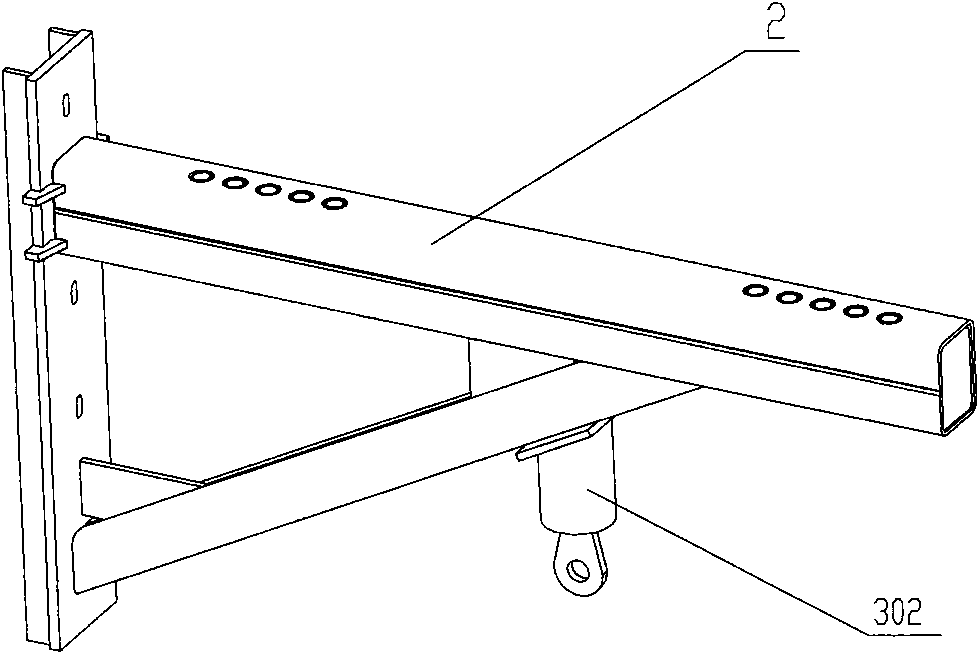

Wall-hanging placing boom

InactiveCN101566009AReduce labor intensityImprove efficiencyBuilding material handlingLifting capacityIndustrial engineering

The present invention relates to the filed of construction engineering machine, and provides a wall-hanging placing boom. The wall-hanging placing boom comprises an upright post, a lifting frame and a placing arm support. The wall-hanging placing boom also comprises an upright post hoisting device which comprises the following components: a hoisting device driven by a power plant; and a hoisting bracket which is installed on the lifting frame. The hoisting device is fixed on the upright post. The hoisting end of the hoisting device is connected with the hoisting bracket. The upright post lifts through the hoisting device. The lifting of the upright post is stepless full-automatic lifting. The lifting capacity of the upright post each time is not restricted and the lifting efficiency is high. Simultaneously as the lifting of the upright post is full-automatic lifting, the labor intensity of the worker is low.

Owner:SANY AUTOMOBILE MFG CO LTD

Ultrasonic range finder for ocean depth measurement

ActiveCN111610527AStop moving awayEase of thrustWaterborne vesselsSpecial purpose vesselsEngineeringMechanical engineering

The invention relates to the technical field of ultrasonic ranging. The invention further discloses an ultrasonic range finder for ocean depth measurement. The ultrasonic range finder comprises a caisson; a sliding rod is arranged in the caisson; the surface of the sliding rod is slidably connected with a gravity block; a pressure-sensitive switch is arranged on the side surface of the gravity block; the side surface of the gravity block is rotationally connected with a screw rod; conical shafts are arranged above a meshing wheel; fans are rotationally connected with the opposite sides of thetwo conical shafts; a magnetic toothed plate is slidably connected with the bottom of a water baffle; a cam is connected with the bottom of the magnetic toothed plate in a meshed mode; an ejector rodis slidably connected with the surface of an inner wheel of the cam; an extrusion toothed rod is slidably connected to the side face of the ejector rod; and a water passing wheel is connected with theside face of the extrusion toothed rod in a meshed mode. According to the ultrasonic range finder for ocean depth measurement, through cooperative use of the sliding rod and the gravity block, the effect of preventing an ultrasonic transmitter from moving away from the original position when undercurrent occurs is achieved.

Owner:玉环震浪超声股份有限公司

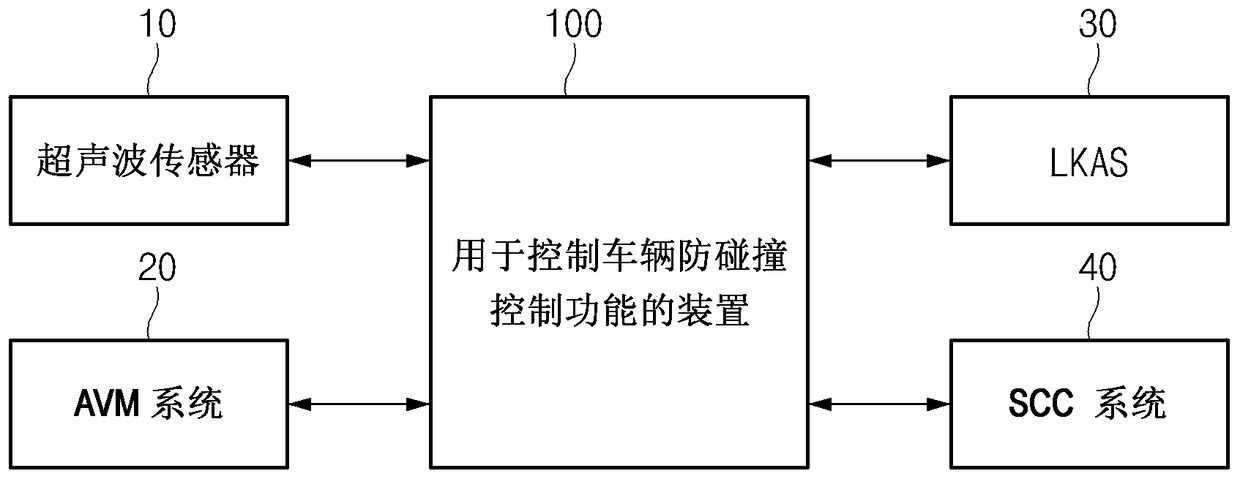

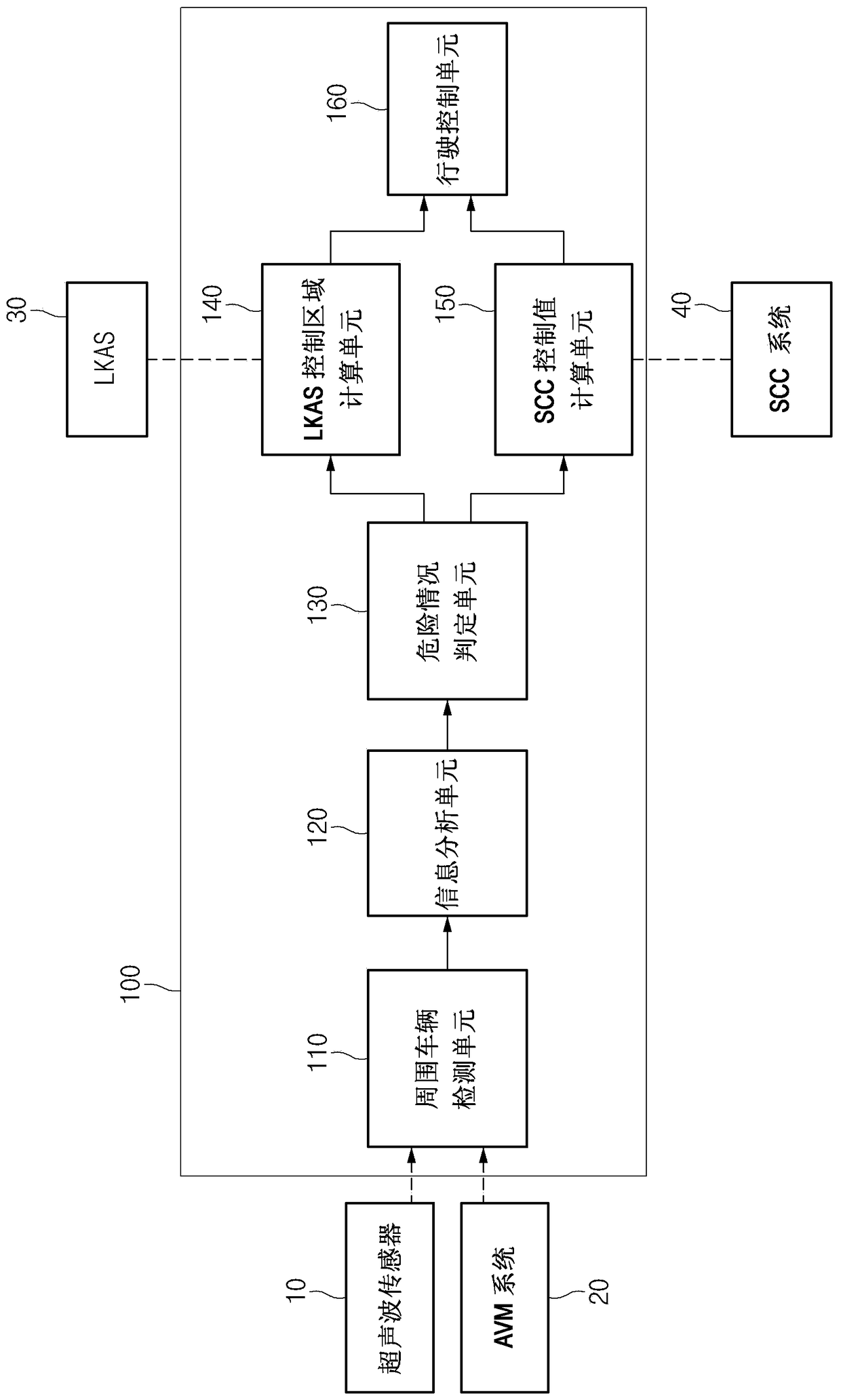

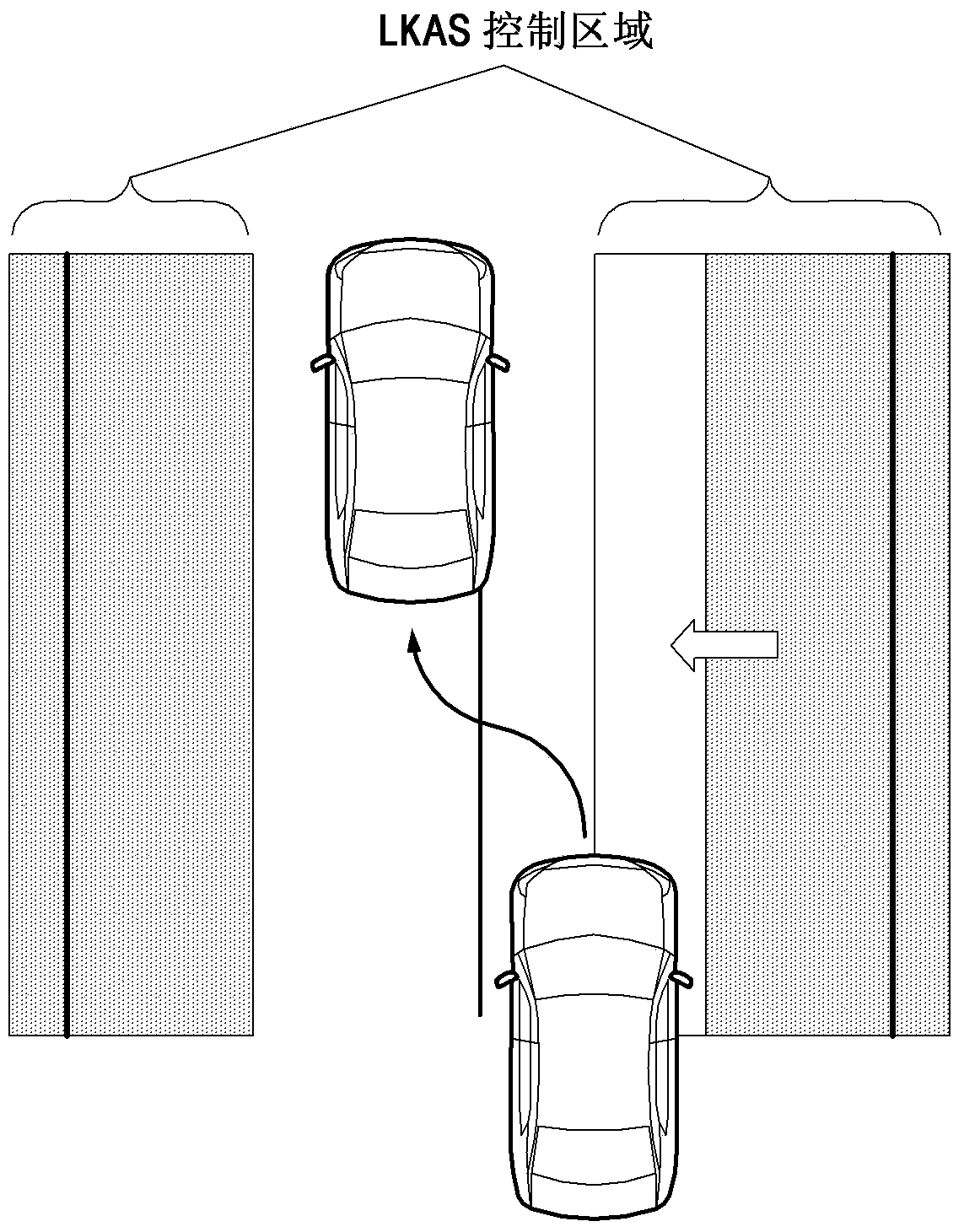

Device and method for providing vehicle with anti-collision control function

ActiveCN103895644BIncrease set speedIncrease or decrease the set speedRoad vehicles traffic controlSteering partsCruise controlControl signal

The invention provides a device and method for providing a vehicle anti-collision control function. The apparatus includes: a dangerous situation judging unit configured to judge whether a dangerous situation related to a side approaching vehicle is emerging based on information about a side approaching vehicle approaching the vehicle from the side; a lane keeping assist system (LKAS) control area a calculation unit configured to calculate a control area to apply to the LKAS when judging that a side approaching vehicle is causing a dangerous situation according to a result of the determination, so as to avoid the side approaching vehicle; a smart cruise control (SCC) control value calculation unit configured to calculating a control value to be applied to the SCC system so as to avoid the side approaching vehicle when it is determined according to the result of the determination that the side approaching vehicle is causing a dangerous situation; and a travel control unit configured to output the control signal according to the result of the calculation to at least one of the LKAS and SCC systems.

Owner:HYUNDAI MOTOR CO LTD

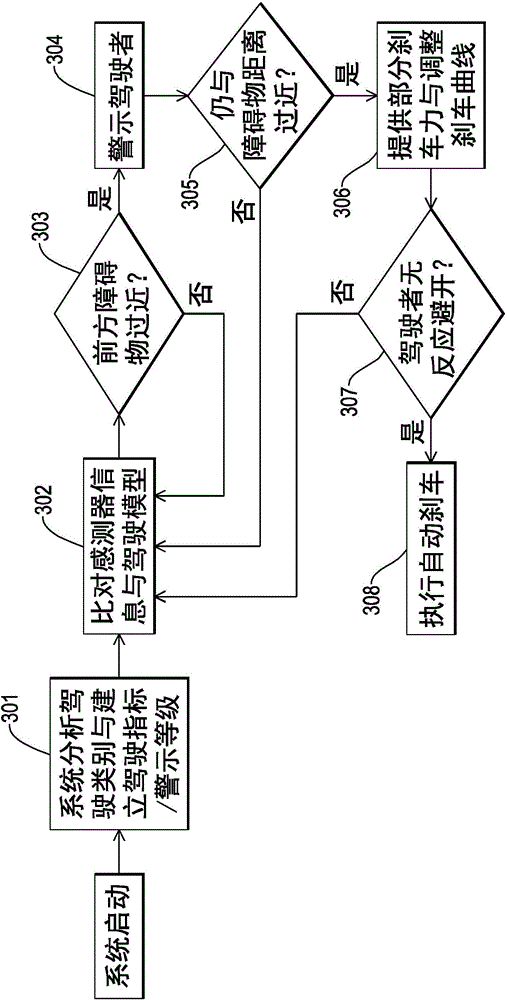

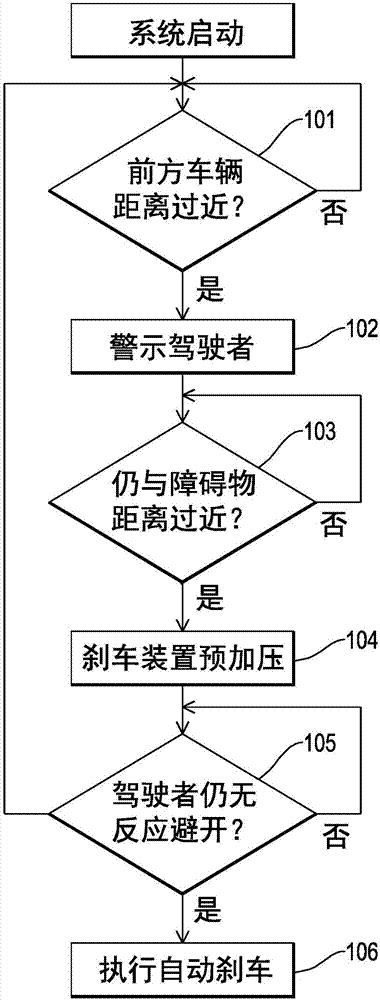

Adaptive Vehicle Collision Avoidance Method

ActiveCN104691545BIn line with driving habitsSpeed increase or decreaseExternal condition input parametersStatistical analysisControl system

The invention discloses an adaptive vehicle anti-collision method. A plurality of vehicle speed parameters, vehicle distance parameters and braking distance parameters at different driving types are pre-established by a control system of a vehicle, longer vehicle distances are set when the vehicle speeds are higher, the vehicle distances are increased or decreased appropriately according to different road conditions, sensors on the vehicle obtain dynamic information, such as the vehicle speeds or accelerations, analysis is performed by combining driving behaviors, a driver is classified into a certain driving type through statistical analysis and an artificial neural network, control parameters of the vehicle are adjusted by referring to the driving type of the vehicle driver, and thus an electronic control unit of the vehicle can perform warning or control to brake in an appropriate time in accordance with the driving habits of the driver. By adopting the adaptive vehicle anti-collision method, the problem that the safety vehicle distance and a brake device cannot be adjusted by an anti-collision system of the existing vehicle by aiming at different vehicle speeds, road conditions, habits of the driver or vehicle conditions is solved.

Owner:AUTOMOTIVE RES & TESTING CENT

Method for synchronous shifting on an electronically controlled two-speed transfer case utilizing an electronically controlled engine and transmission

A method for shifting a two-speed transfer case between a low range and a high range in a four wheel drive vehicle, the method comprising: determining a target transmission gear ratio based on a current vehicle speed and an initial transfer case range and the desired transfer case gear. When it is determined that the vehicle speed is within the proper range, the transmission is shifted to the target transmission gear ratio. Reduce transfer case input torque to minimum and shift transfer case to neutral. The method further includes adjusting the engine speed and the transmission gear setting to control the transmission output shaft speed to a desired range. The transfer case is shifted from neutral to the desired transfer case range when the transmission output shaft speed is within a desired range of transmission output shaft speeds.

Owner:GM GLOBAL TECH OPERATIONS LLC

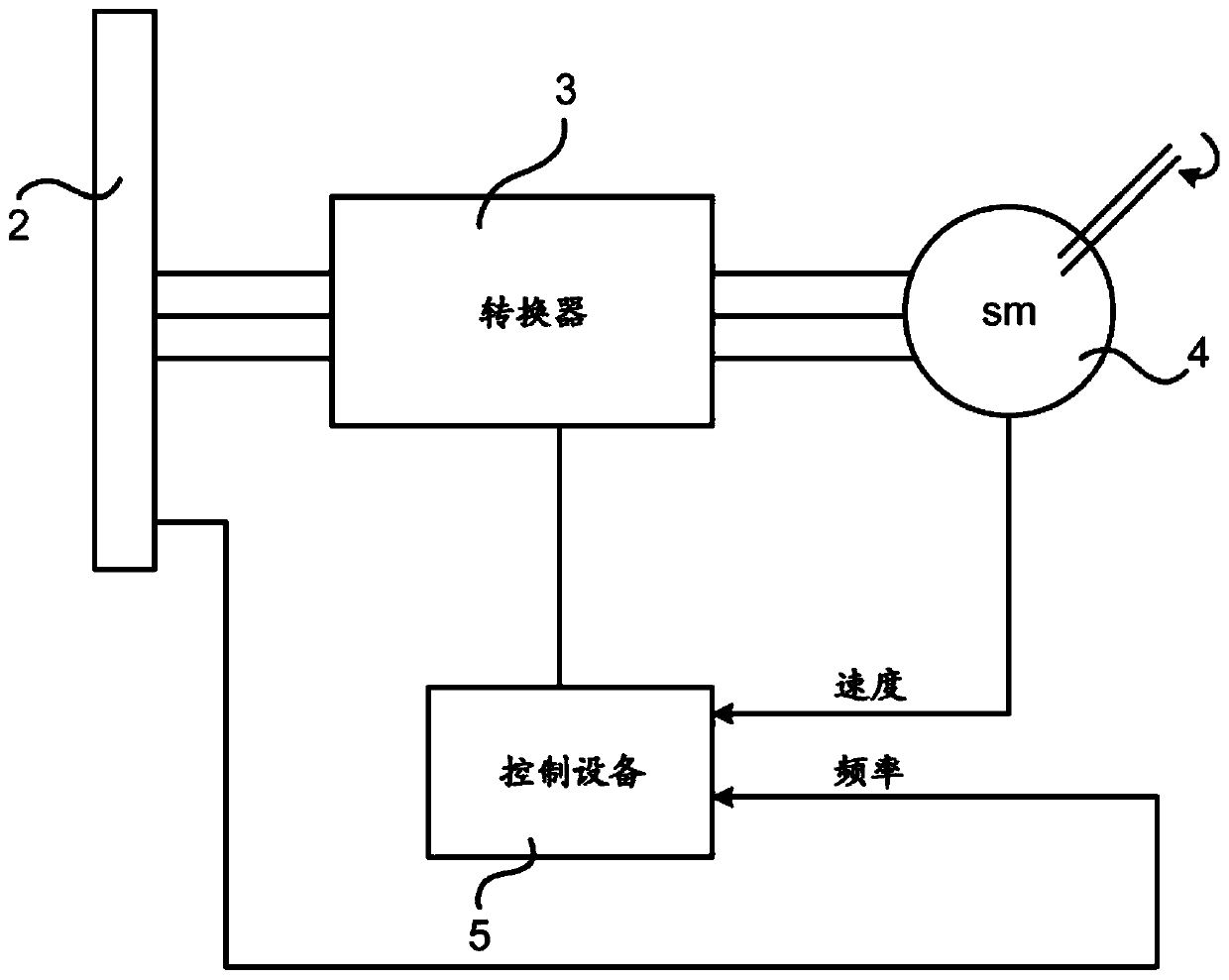

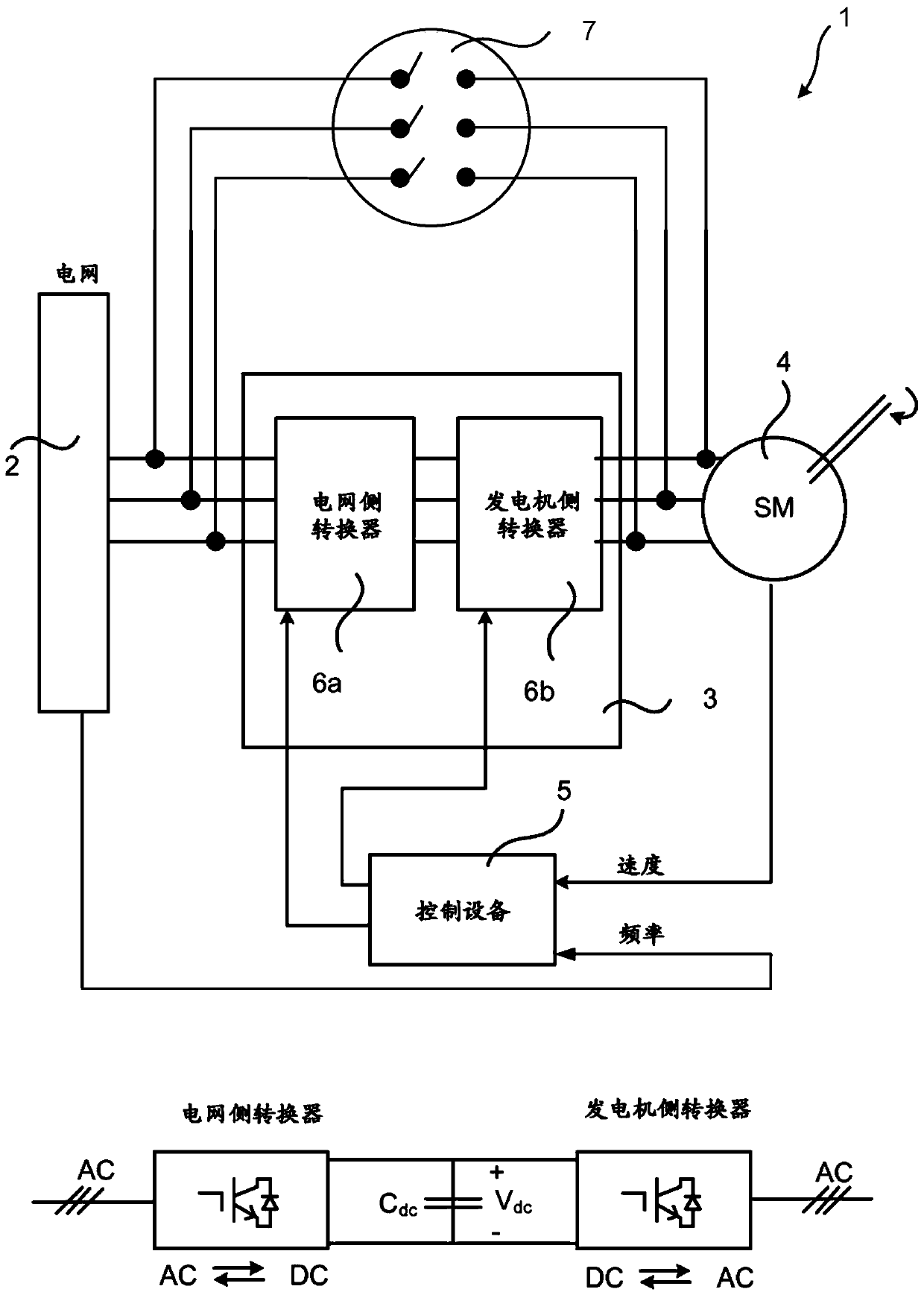

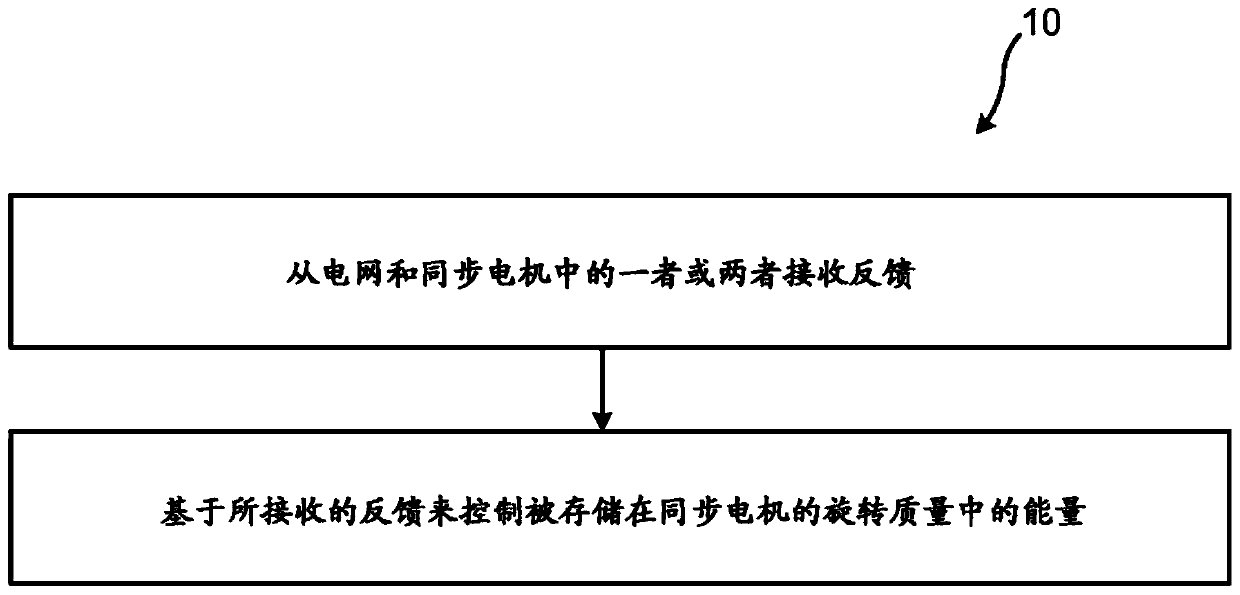

A method of providing power support to an electrical power grid

ActiveCN110024254AGuaranteed uptimeSpeed increase or decreaseContigency dealing ac circuit arrangementsAc network load balancingConvertersControl engineering

A method (10) of providing power support to an electrical power grid (2) is provided. The power support is provided by an arrangement (3, 4) comprising a synchronous machine (4) connected to a converter (3), the converter (3) in turn being connected to the electrical power grid (2). The method (10) is performed in a control device (5) controlling the arrangement (3, 4) and comprises: receiving (11) feedback from one or both of the electrical power grid (2) and the synchronous machine (4), and controlling (12) the converter (3) such that power support is provided to or absorbed from the electrical power grid (2) by means of the synchronous machine (4) based on the received feedback. A control device (5), an arrangement (3, 4), a computer program and computer program products are also provided.

Owner:HITACHI ENERGY SWITZERLAND AG

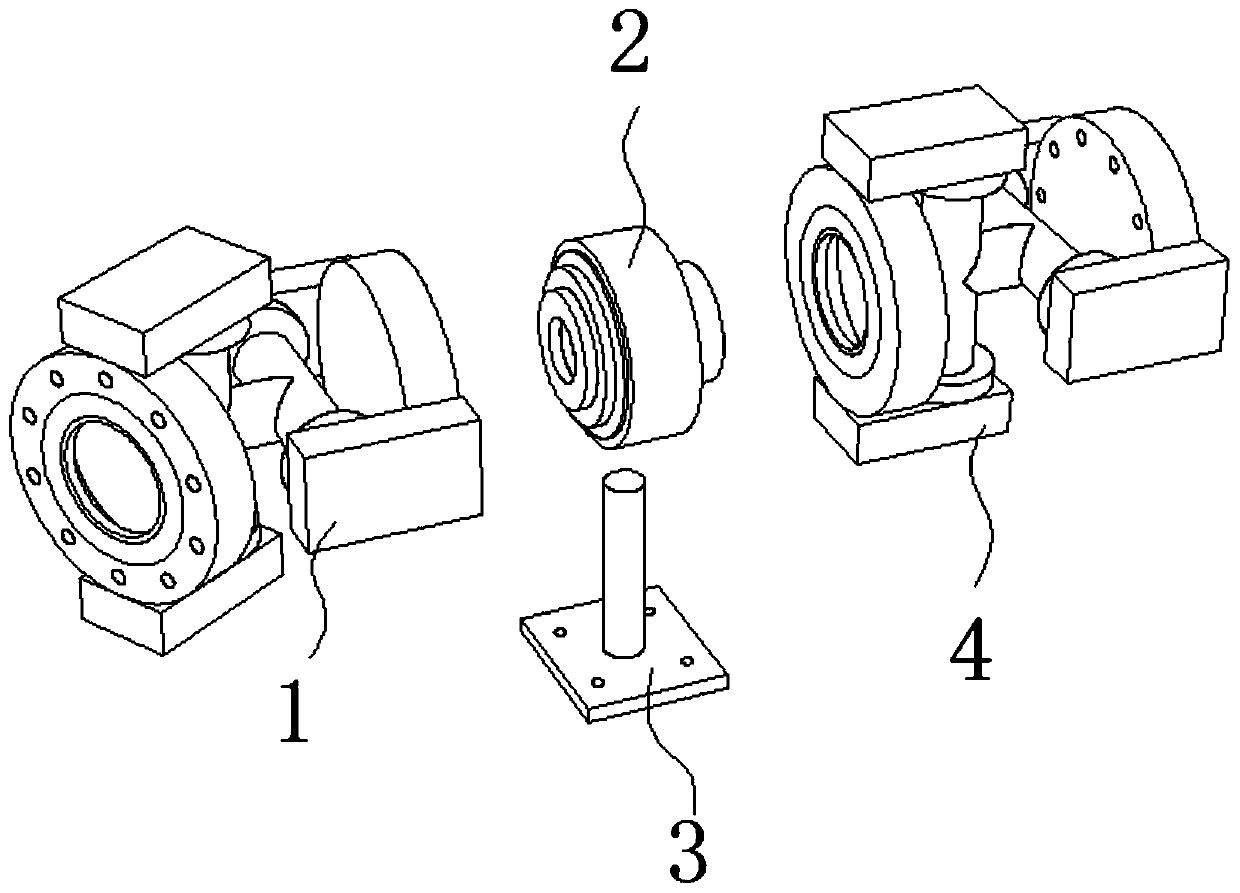

A universal connection device for rotating pipes

ActiveCN109630778BChange the direction of the transmission axisFacilitate transmissionAdjustable jointsDrive shaftGear wheel

The invention discloses a universal connecting device for rotating a pipeline. The universal connecting device comprises an output angle adjusting assembly, the fixed end of the output angle adjustingassembly is fixedly connected to the output end of a rotating direction adjusting assembly, the input end of the rotating direction adjusting assembly is connected with an input angle adjusting assembly, and the lower end face of the rotating direction adjusting assembly is fixedly connected with a fixing frame. A driven pipeline and a driving pipeline are connected with the universal connectingdevice in a through mode, after liquid in the pipelines flows through the universal connecting device, the flow direction is changed, the deviation angle can be adjusted according to the needs, usingis convenient, the transmission axis direction can be changed while the flow direction of the liquid is changed, and transmission is conveniently conducted by using the pipelines. Through the rotatingdirection adjusting assembly, a circuit is controlled to be opened and closed, the rotating direction of the driven pipeline can be controlled freely, and the application range is further expanded. By changing the ratio of the inner diameter of a second outer gear to the diameter of a center gear to the inner diameter of a rotating ring, the rotating speed of the driven pipeline is increased or decreased.

Owner:TAIZHOU SANYANG TAI SANITARY WARE CO LTD

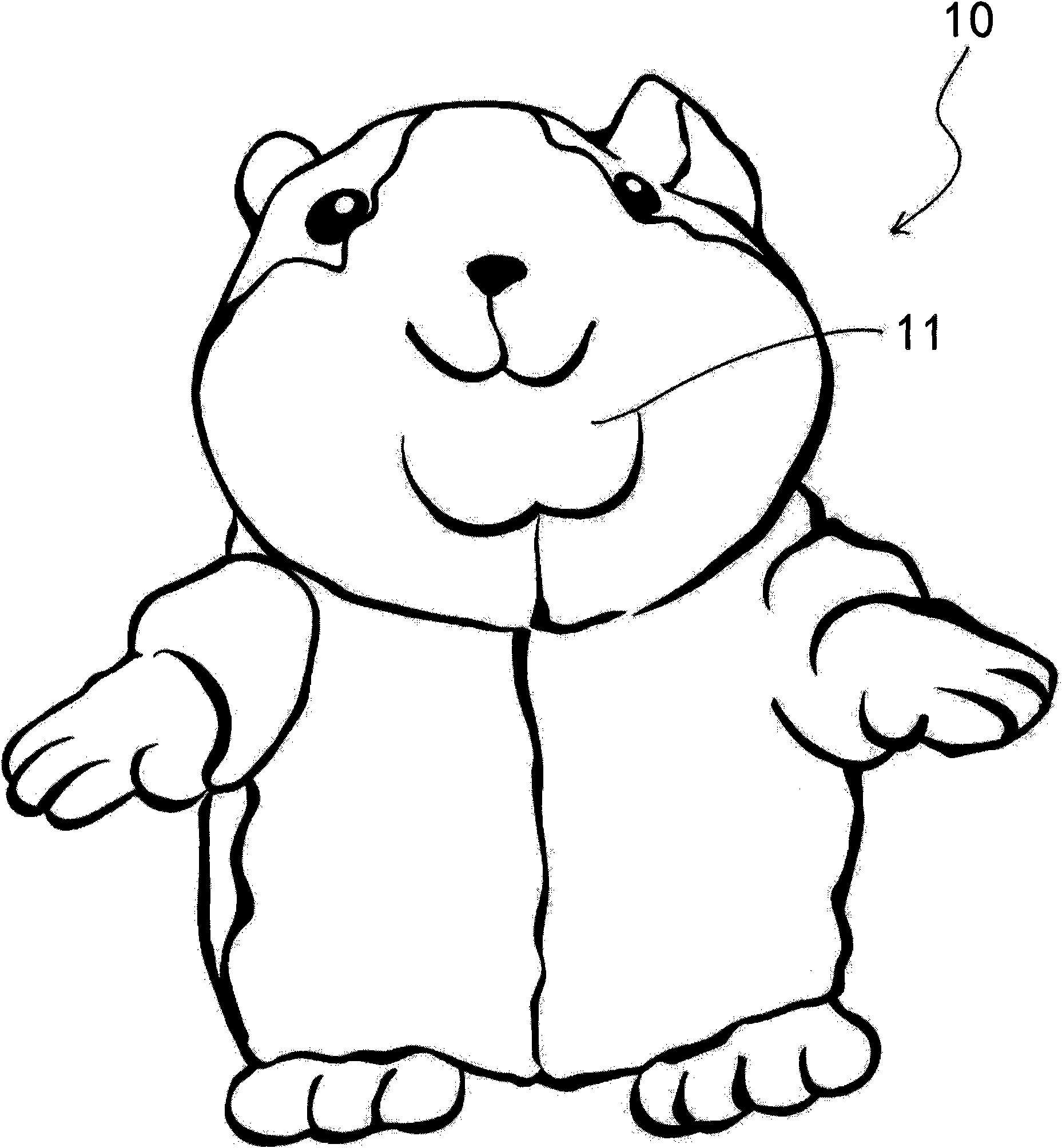

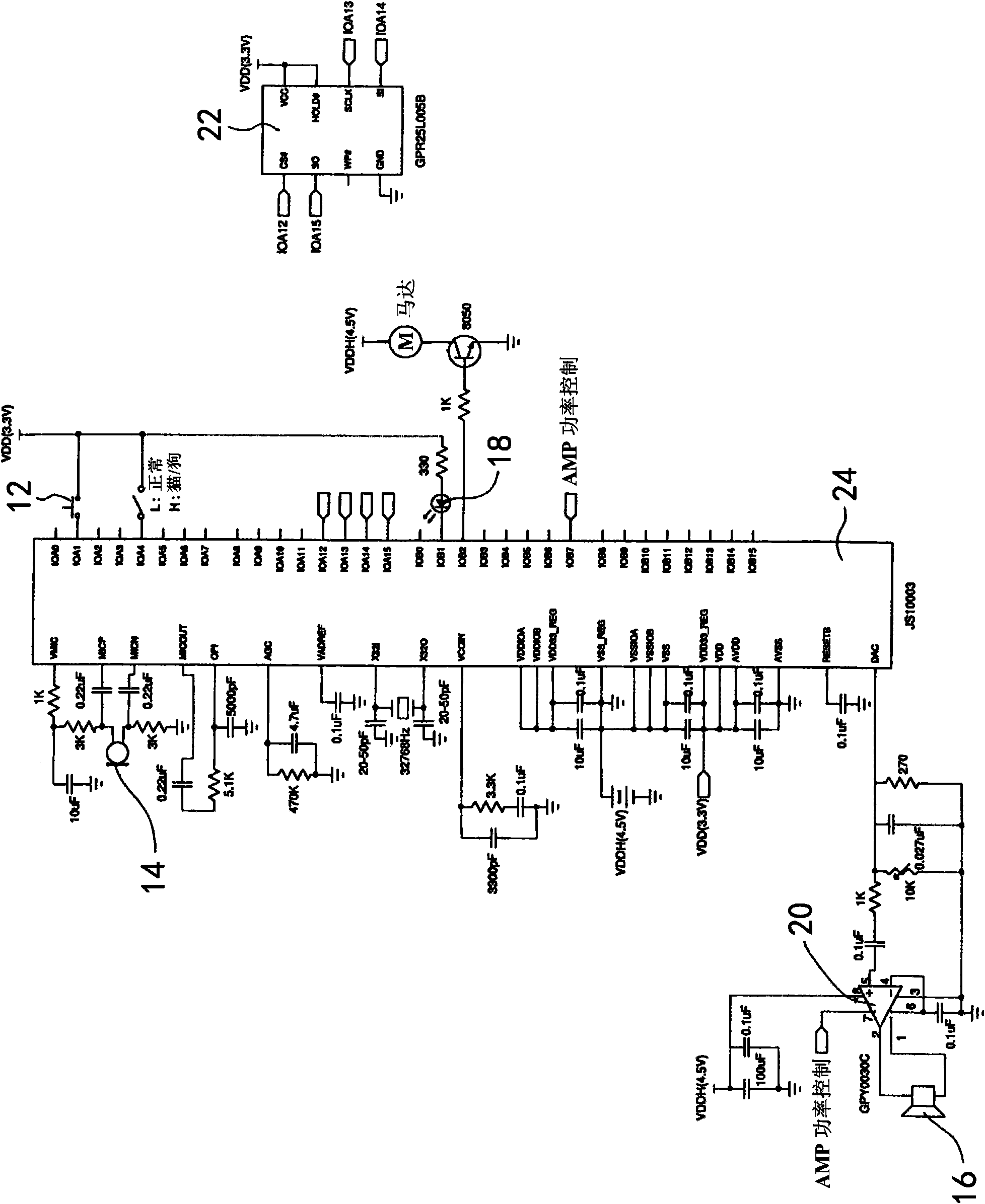

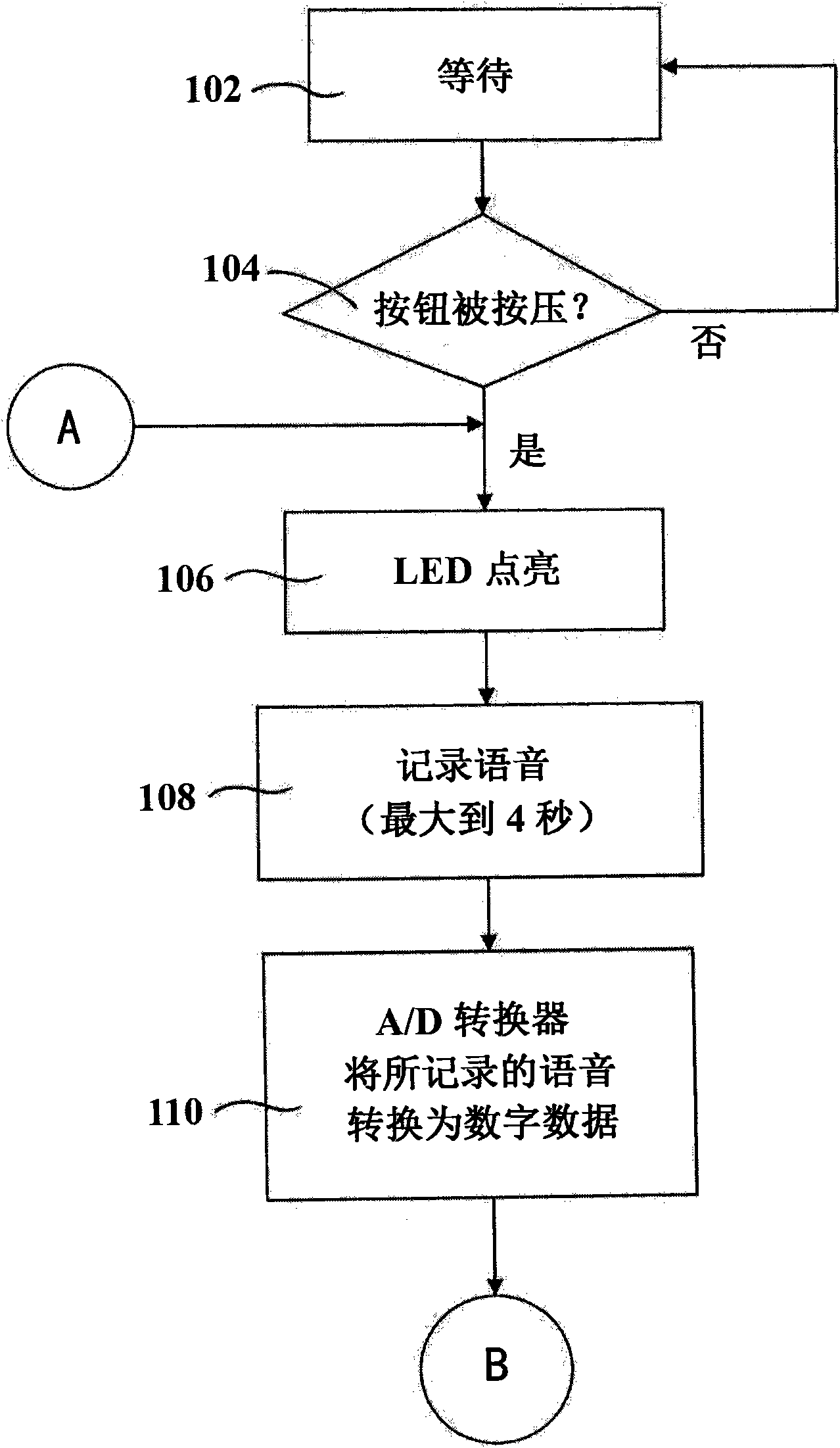

Toy

The invention discloses an electric toy (10). The electric toy (10) comprises a microphone (14), a loudspeaker (16) and a sound controller (24), wherein the microphone (14) is used for recording sound; the loudspeaker (16) is used for automatically playing back the recorded sound at different velocity and / or different tone after the recording is stopped; and the sound controller (24) is used for randomly improving or reducing the velocity of the recorded sound and / or raising or reducing the tone of the recorded sound.

Owner:DRAGON I TOYS

Wall-hanging placing boom

InactiveCN101566009BReduce labor intensityImprove efficiencyBuilding material handlingLifting capacityArchitectural engineering

The present invention relates to the filed of construction engineering machine, and provides a wall-hanging placing boom. The wall-hanging placing boom comprises an upright post, a lifting frame and aplacing arm support. The wall-hanging placing boom also comprises an upright post hoisting device which comprises the following components: a hoisting device driven by a power plant; and a hoisting bracket which is installed on the lifting frame. The hoisting device is fixed on the upright post. The hoisting end of the hoisting device is connected with the hoisting bracket. The upright post liftsthrough the hoisting device. The lifting of the upright post is stepless full-automatic lifting. The lifting capacity of the upright post each time is not restricted and the lifting efficiency is high. Simultaneously as the lifting of the upright post is full-automatic lifting, the labor intensity of the worker is low.

Owner:SANY AUTOMOBILE MFG CO LTD

Bicycle pedal step-up gear

InactiveCN101293558AThe speed-up function is obviousSpeed increase or decreaseWheel based transmissionEngineeringMechanical engineering

Owner:张补元

A precise control method for linear motion modules

ActiveCN107160394BSmooth motionReduce sports shockProgramme-controlled manipulatorLinear motionParabolic function

The invention discloses a precise control method of a linear motion module. A motion control method based on S-shaped speed curve planning and synchronous planning of parabolic functions is adopted to precisely control the linear motion module; an acceleration maximum value and a speed maximum value of each motion shaft of a truss manipulator are input; an initial pose and a target pose of the truss manipulator are given to obtain a displacement variation of each motion shaft of the manipulator; time function nodes of each motion shaft are calculated; longest time nodes are selected as unified planning nodes to calculate actual maximum speed and maximum acceleration of each motion shaft; displacement, speed and acceleration functions at an acceleration phase, a deceleration phase and a constant-speed phase are respectively calculated according to the actual maximum speed and the maximum acceleration of each motion shaft; and the displacement of each motion shaft or discrete points on speed curves are output. The method can prevent the manipulator vibration or noise problem caused by sudden change of the speed or the acceleration, guarantees the motor motion precision, and can control the motion trajectory.

Owner:西安精雕软件科技有限公司

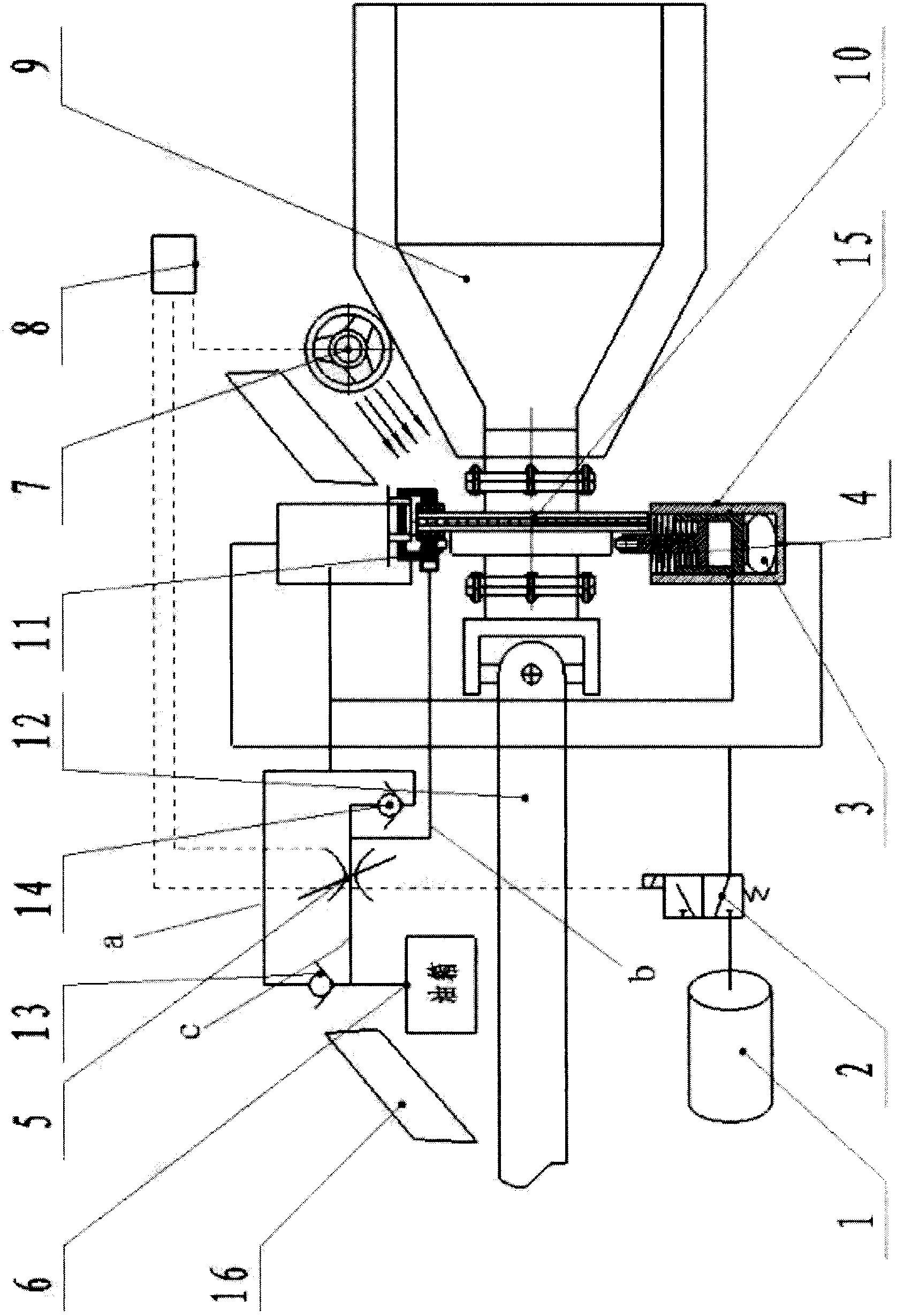

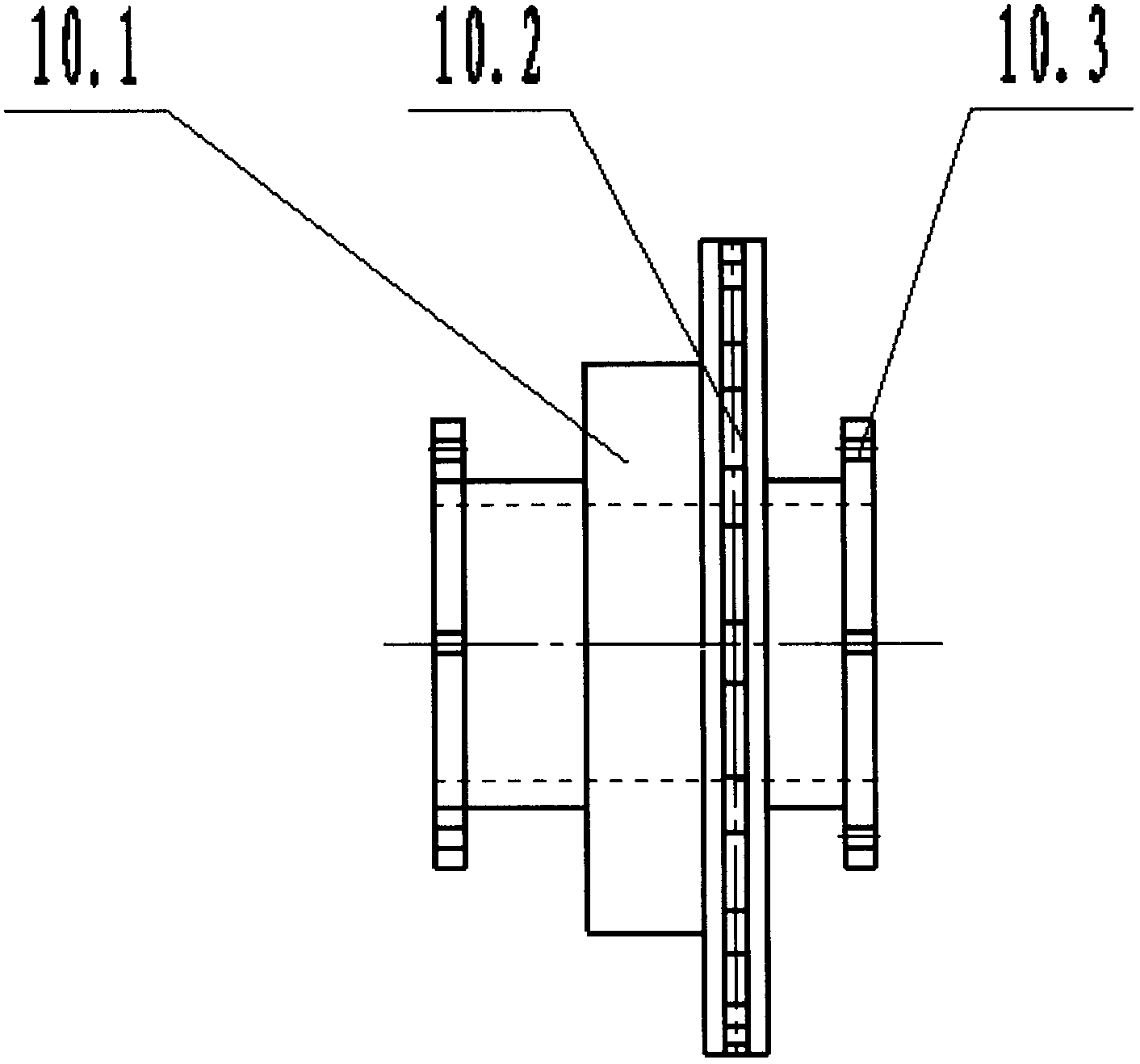

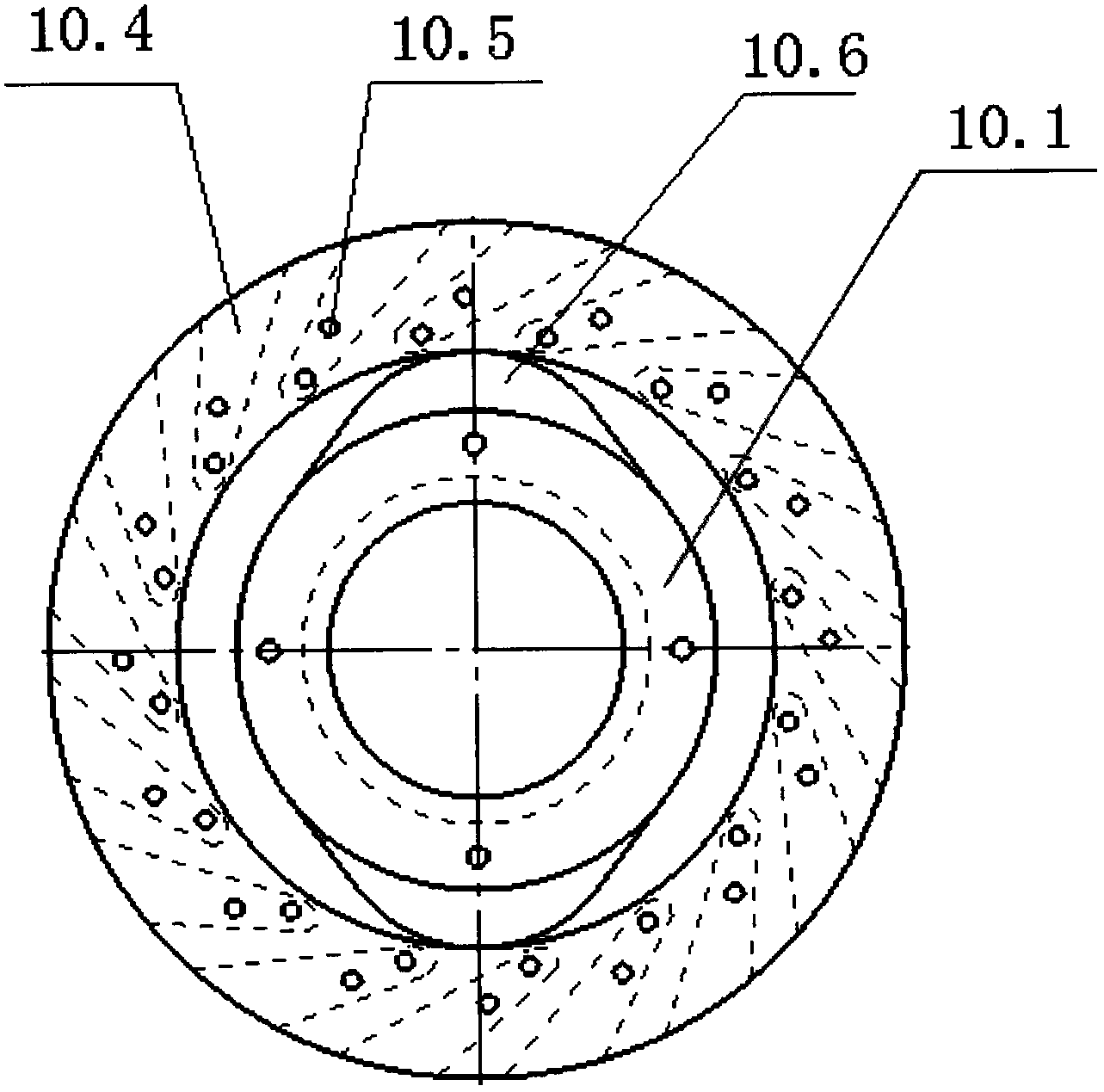

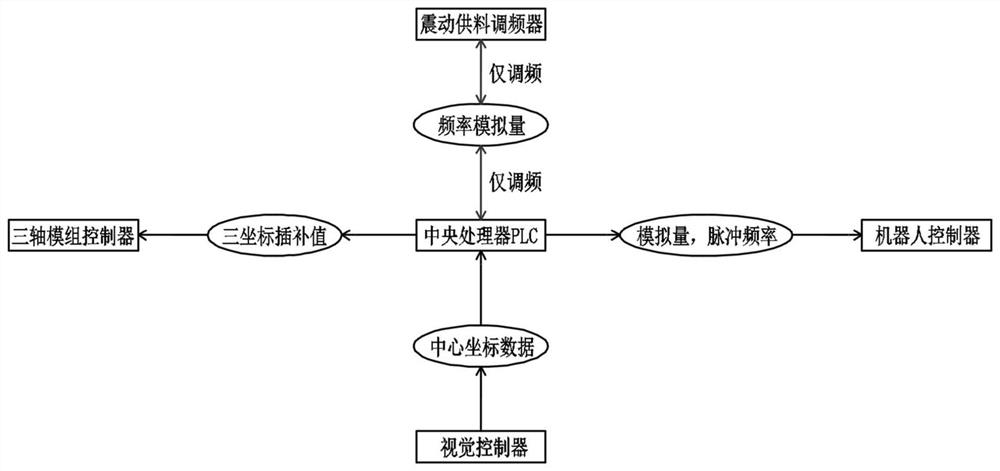

A flexible screw automatic feeding device and method

ActiveCN109986323BReduce targeting requirementsImprove stabilityMetal working apparatusJigging conveyorsGraphicsControl engineering

The invention discloses an automatic flexible screw feeding device and method. The device comprises a central processing unit PLC, a vibration feeding frequency modulator, a visual controller, a three-axis module controller and a robot controller; the output end of the visual controller is connected with the central processing unit PLC; the visual controller is used for performing visual analysisand providing visual analysis results to the central processing unit PLC; the central processing unit PLC carries out data interaction with the vibration feeding frequency modulator, the three-axis module controller and the robot controller, and is used for controlling and adjusting the vibration frequency to realize the control of a three-axis module and a robot. The device and method are capableof automatically adjusting the power and adjusting the feeding frequency to improve the stability and usability; the visual inspection is automatic, so that the manual visual inspection and monitoring are avoided, and the assembly abnormality detection also can be judged and eliminated through the visual graphic integrity analysis; and through visual judgment and adjustment, the positioning requirements of the placed workpieces is reduced, and the unnecessary waste caused by repetitive tool manufacturing and technical modification are saved.

Owner:南京睿易智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com