Precise control method of linear motion module

A motion module and precise control technology, which is applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of vibration and noise of truss manipulators, the inability of manipulators to start and stop at the same time, and reduce the motion accuracy of truss manipulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

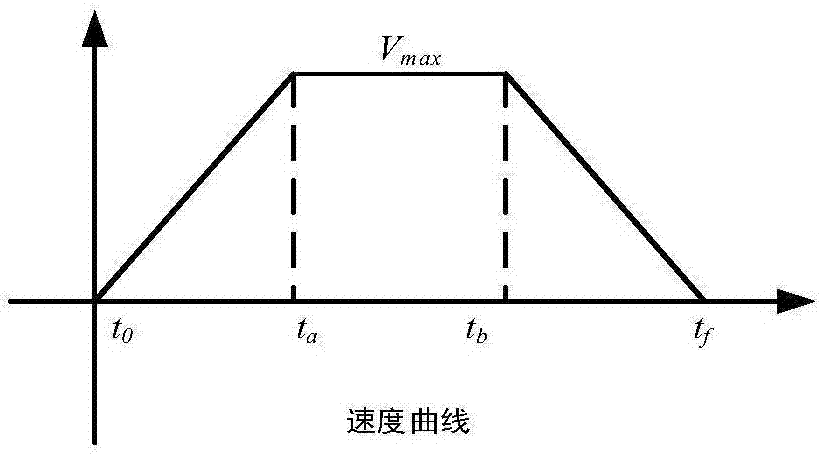

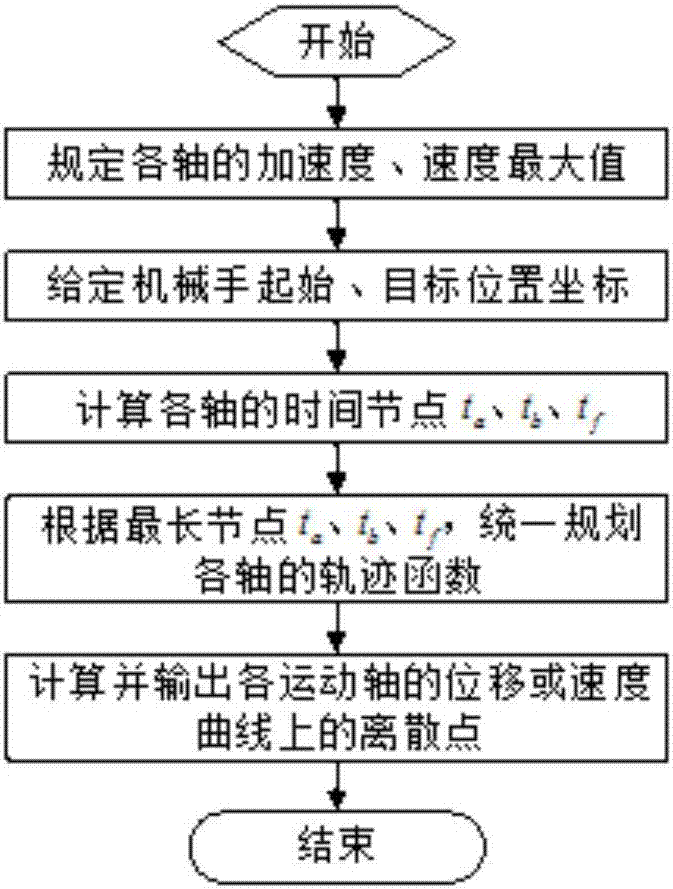

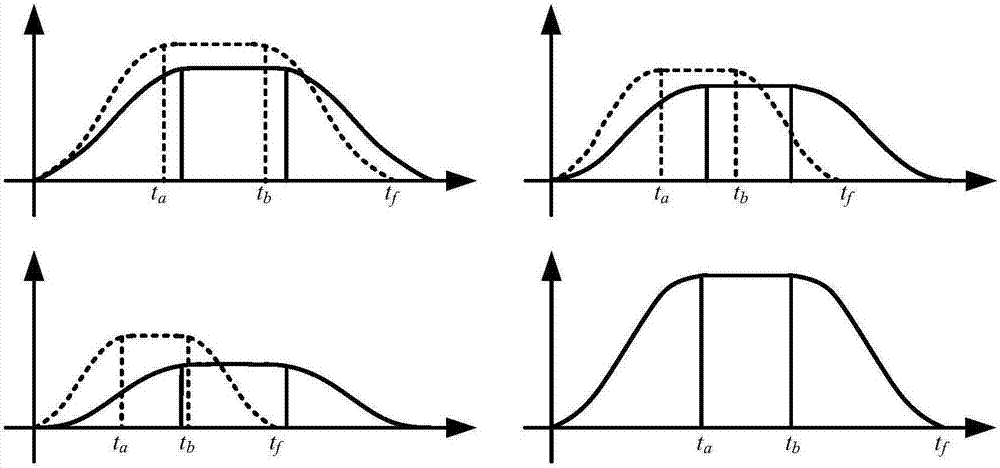

[0041] The invention provides a precise control method of a linear motion module. The control system of the truss manipulator combines two methods of S-shaped speed curve planning and multi-axis synchronous planning based on parabolic functions. Among them, the motion control method based on the parabolic function is based on the coordinates of the target position, and the motion trajectory is planned in combination with the requirements of speed and acceleration, including the parabolic acceleration phase, the constant speed phase, and the parabolic deceleration phase. The multi-axis synchronous planning is based on the S-shaped speed curve planning, unifying the time nodes of the acceleration, constant speed and deceleration stages of each motion axis, so as to realize "simultaneous start and stop".

[0042] see figure 2 , the specific steps of the linear motion module precise control method of the present invention are as follows:

[0043] S1. Input the maximum accelerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com