Double-acting retarder

A retarder, double-acting technology, applied in the direction of brakes, etc., can solve the problems of the engine speed not too low, the quality of the eddy current retarder is large, and the stability of continuous operation is poor, so as to achieve good heat dissipation effect, simple structure, slow speed good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

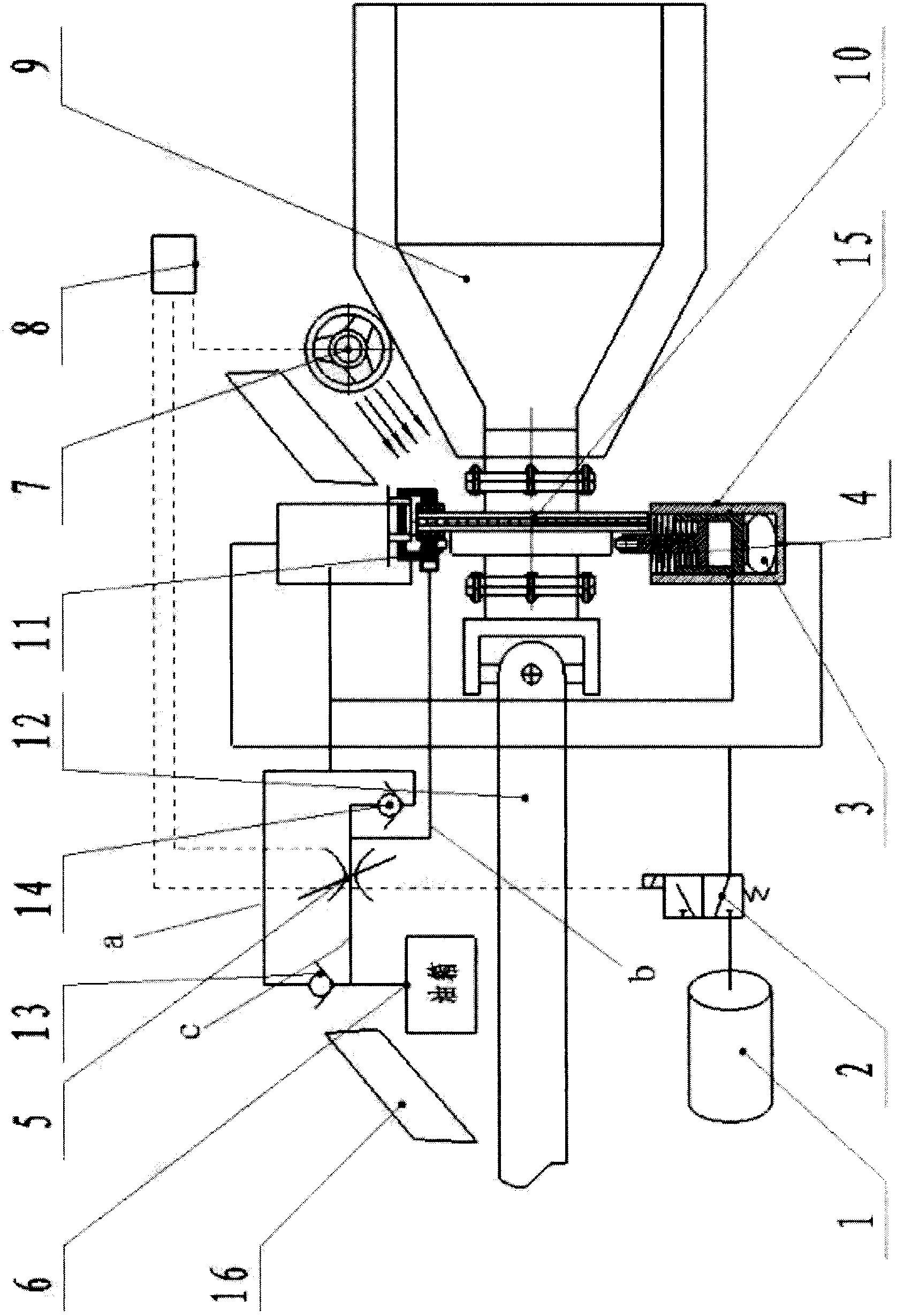

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0026] 1. Installation of cam and brake disc body

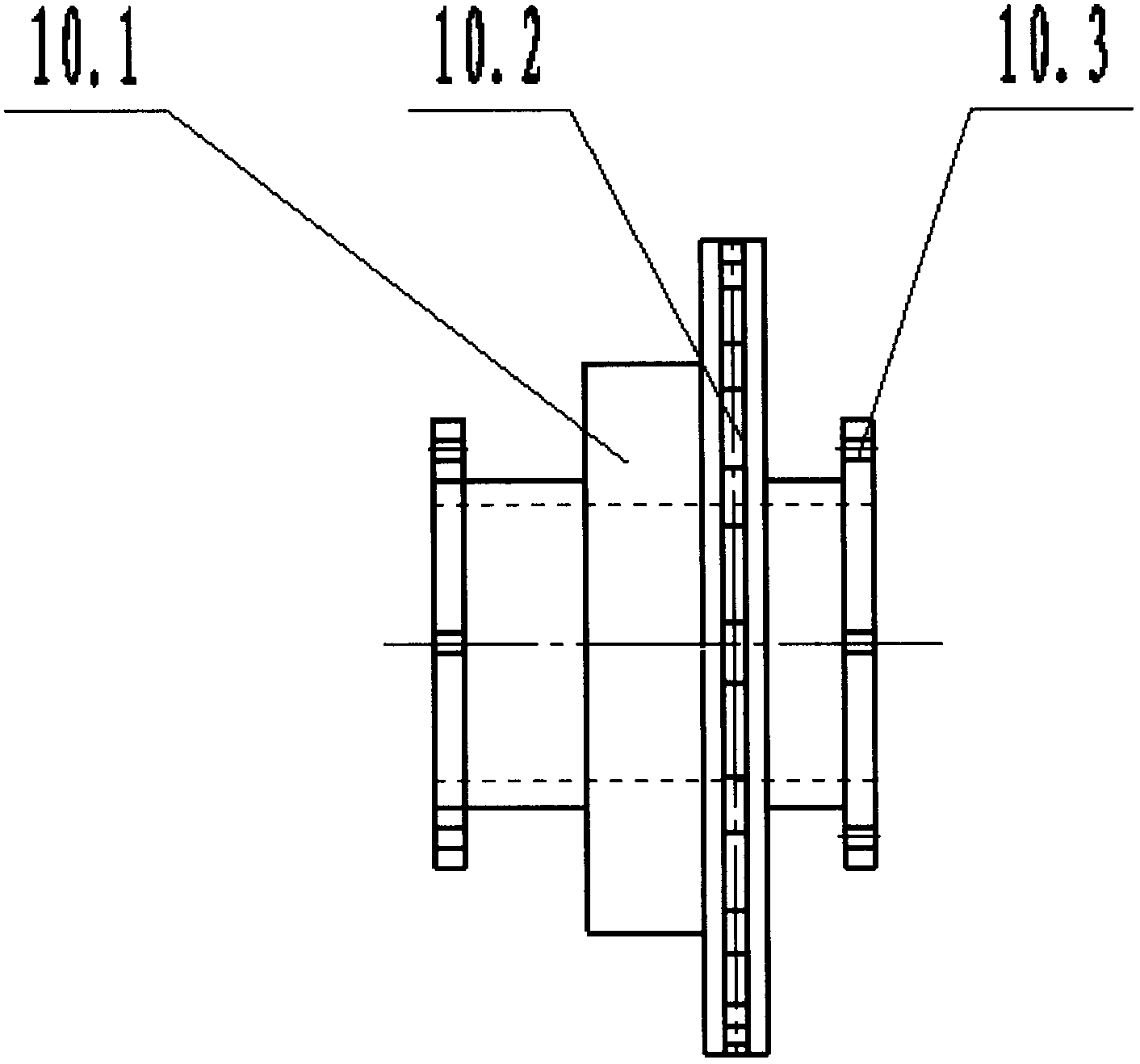

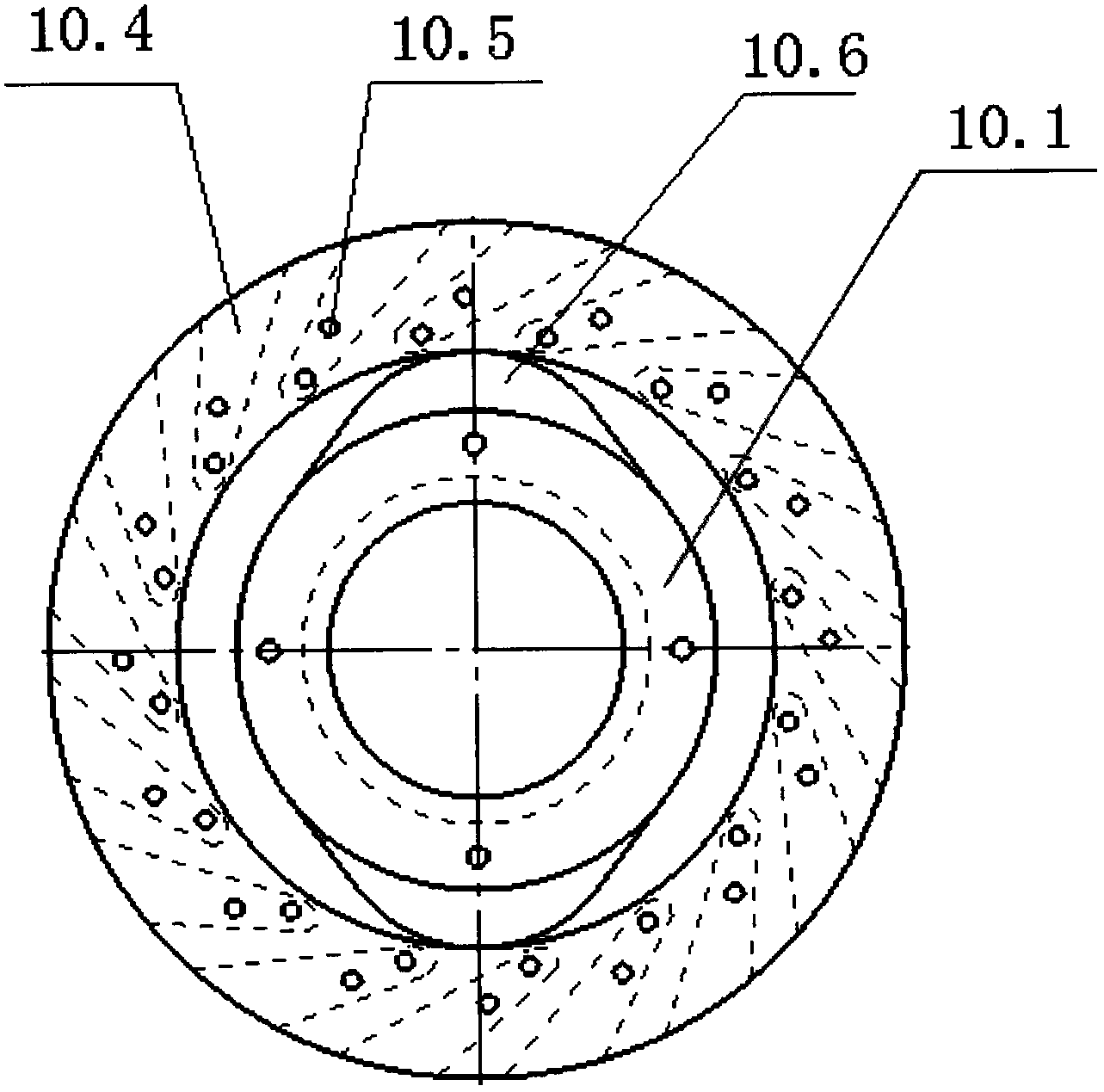

[0027] The cam and the brake disc are cast together, and the cam and the brake disc body 10 are formed by machining, which can be divided into a cam 10.1, a brake disc 10.2, a connecting flange 10.3, an air intake fan 10.4, an air outlet 10.5 and a convex portion 10.6. Wherein the connecting flange 10.3 is divided into left and right parts, and there are meshing tooth grooves on the surface, and the shape of these meshing tooth grooves should be determined according to the specifications of the installation vehicle.

[0028] When installing, first install the cam and the brake disc body 10 on the output shaft of the transmission 9, then connect the transmission shaft 12 to the flange at the other end, and at the same time fix the brake disc 10.2 on the frame according to the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com