Tension control system and control method for multi-wire cutting of silicon wafer

A multi-wire cutting and tension control technology, which is applied in the field of measurement and control, can solve the problems that the accuracy of acceleration control cannot be improved, and the range of tension fluctuations cannot be reduced, so as to achieve the effect of improving response, improving accuracy, and simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

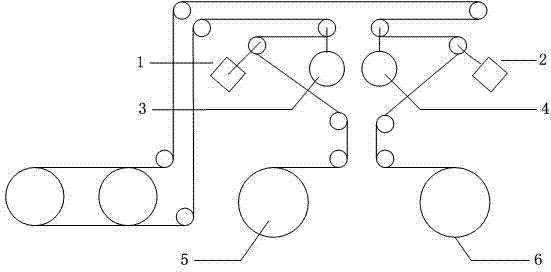

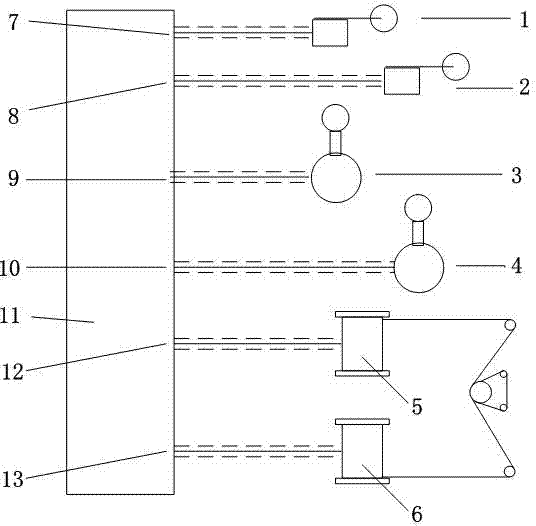

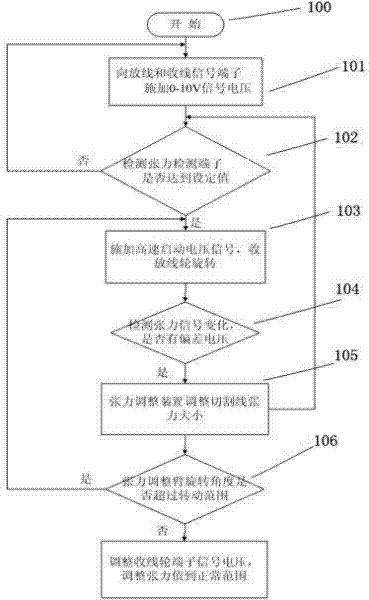

[0021] as attached figure 1 , 2 The multi-wire cutting tension control system according to the embodiment of the present invention includes a tension detection control device and a tension adjustment device: the tension detection control device includes a tension detection control main unit 11 composed of a main control computer and an analog I / O acquisition card , and the left and right tension detection devices 1, 2 connected with the tension detection control main unit 11, the pay-off signal terminal 14, and the take-up signal terminal 15, and the tension detection control main unit 11 adopts EVC language to compile a broken wire detection control program , collect the I / O signal in real time through the control software and the analog I / O acquisition card; the pay-off signal terminal 14 is arranged on the pay-off reel 5 to connect the pay-off reel motor, and the take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com