Mixed feeding device capable of automatically adjusting blending combustion amount of stale garbage

A feeding device, automatic adjustment technology, applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., can solve problems such as combustion instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] What is described in the following description is only a preferred embodiment of the present invention. All equivalent changes or simple changes made according to the structural features and principles of the concept of the present invention are included in the protection scope of the present invention. Those of ordinary skill in the art can understand the implementation of all or part of the processes of the following embodiments, and equivalent changes made by the claims of the present invention, and similar promotions without violating the connotation of the present invention, still belong to the scope of the present invention scope.

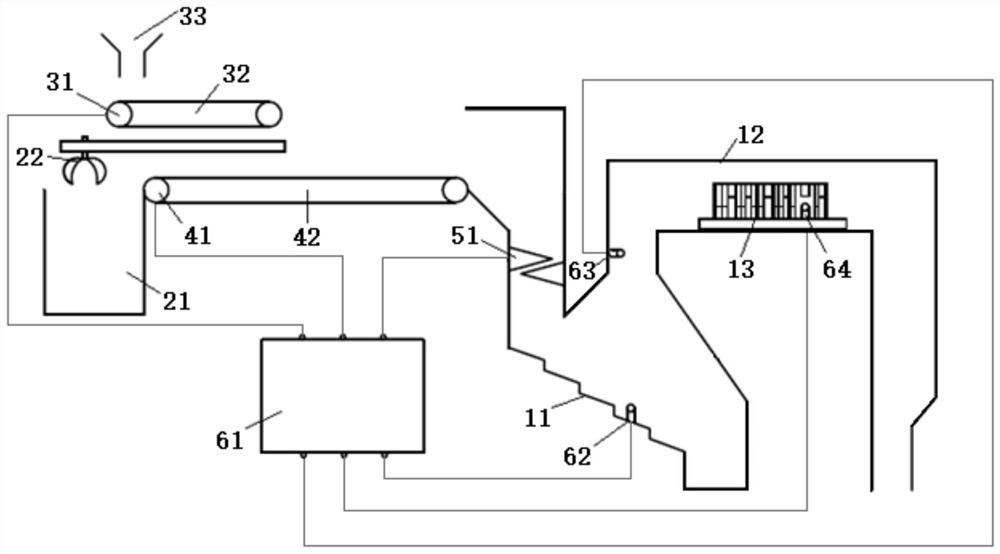

[0028] Such as figure 1 As shown, this embodiment provides a mixed feeding adjustment device that automatically adjusts the amount of old waste mixed with combustion, including a mechanical grate furnace, a primary waste feeding device, an old waste feeding device, a mixed waste conveying device, and a mixed waste crushing device , c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com