CFB boiler system capable of combusting waste gas and waste liquid in blending manner

A boiler and waste liquid technology, which is applied in the direction of burning fuels, incinerators, and combustion methods in a molten state, can solve the problems of high overall energy consumption of chemical plants, complex treatment systems, and environmental pollution, and achieves the realization of consumption, treatment and operation. Convenience, flexibility and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

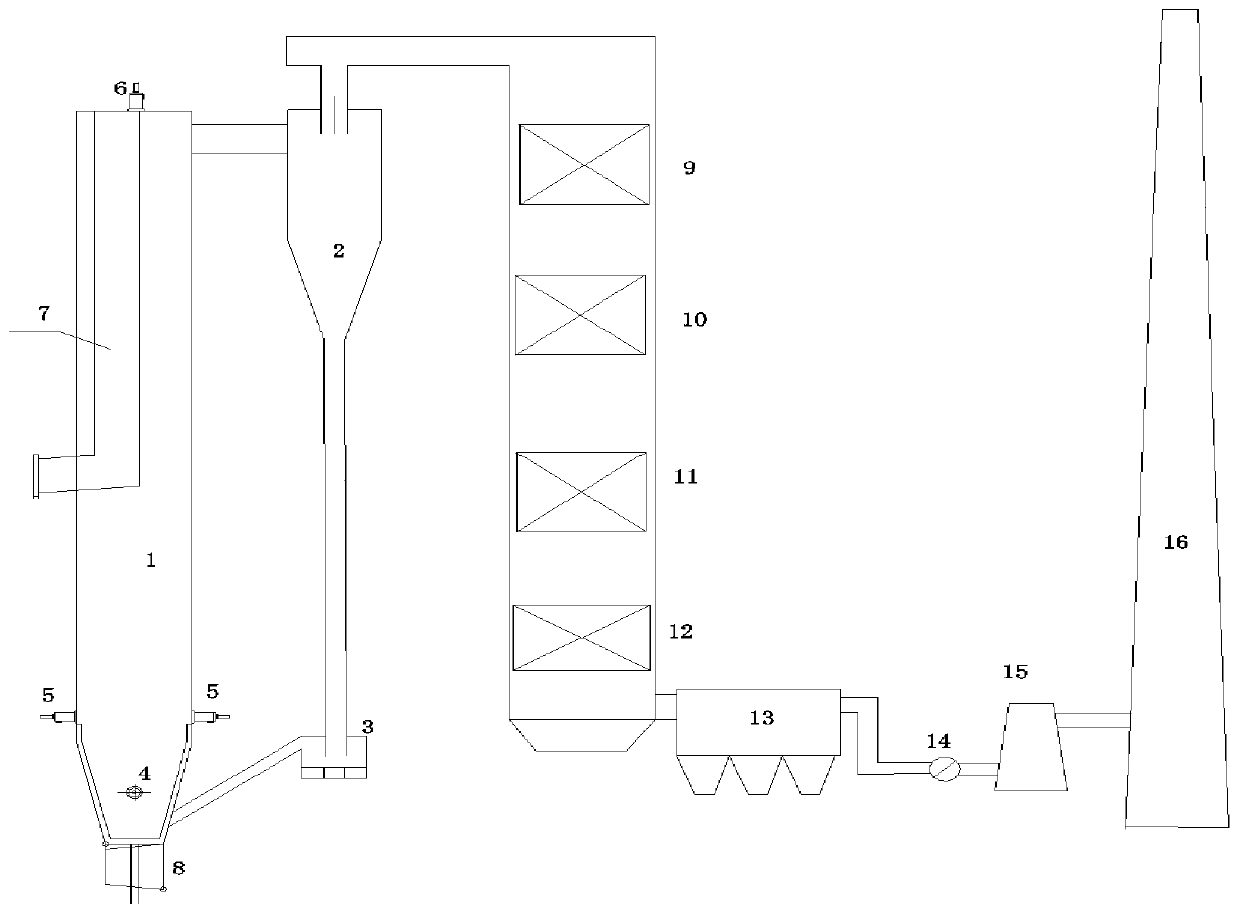

[0016] refer to figure 1 The CFB boiler system for burning waste gas and waste liquid according to the present invention includes a CFB boiler furnace 1, a boiler tail flue and a separator 2, the dense phase area on both sides of the CFB boiler furnace 1, the secondary tuyere area on the front and rear walls, and The top of the boiler is respectively provided with a first burner 4, a second burner 5 and a third burner 6; the flue gas outlet of the CFB boiler furnace 1 is connected to the inlet of the separator 2, and the flue gas outlet of the separator 2 is connected to the boiler The tail flue is connected, the bottom outlet of the separator 2 is connected with the inlet of the feeder 3, the outlet of the feeder 3 is connected with the inlet of the CFB boiler furnace 1, and the bottom of the CFB boiler furnace 1 is provided with an air distribution device 8 , wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com