Elastic cord positioning sewing device and sewing method in garment processing

An elastic rope and sewing technology, applied in sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of low processing efficiency, cumbersome operation, inability to press clothes and elastic ropes, etc., to achieve easy placement and ensure sewing quality. , the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

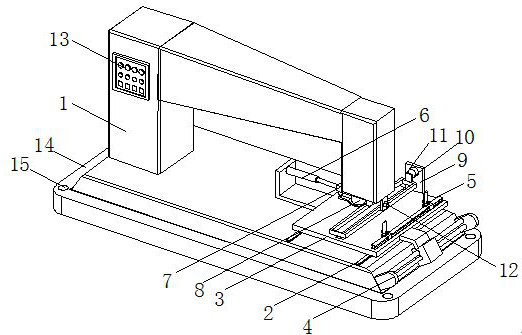

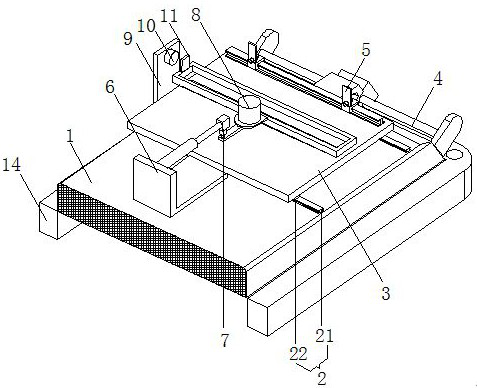

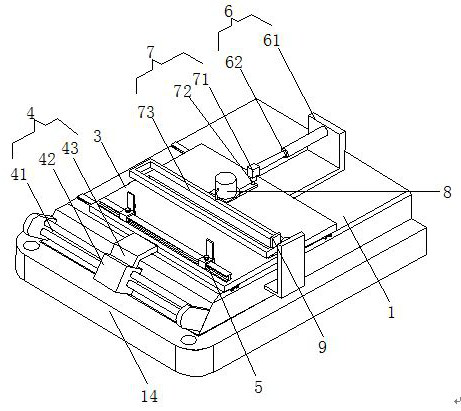

[0030] see Figure 1-5, The present invention provides a technical solution: an elastic rope positioning and sewing device in garment processing, comprising an electric sewing machine 1, a guide support mechanism 2, a sewing guide mechanism 4, a sewing positioning mechanism 5, a conveying mechanism 6, a pressing mechanism 7 and an adsorption mechanism The fixing mechanism 8; the electric sewing machine 1 is divided into a body and a machine base to realize the sewing operation; the guiding support mechanism 2 is arranged on the right side of the upper end of the base of the electric sewing machine 1, and the upper end of the guiding support mechanism 2 is provided with a working plate 3, which plays the role of guiding support Function; the sewing guide mechanism 4 is arranged on the right side of the base of the electric sewing machine 1, and is fixedly connected with the right side of the work board 3 to ensure that the garment and the elastic rope are stitched together along...

Embodiment 2

[0032] This embodiment differs from Embodiment 1 in that:

[0033] The guide support mechanism 2 includes a guide rail 21 and a rail slider 22. The guide rail 21 is arranged on the right side of the upper end of the base of the electric sewing machine 1. There are two guide rails 21. The rail slider 22 is slidably connected to the guide rail 21. The upper end of the slide rail 21 and the upper end of the rail slider 22 are fixedly connected to both sides of the bottom surface of the work plate 3, and the rail slider 22 slides on the guide rail 21 to serve as a guide support; the sewing guide mechanism 4 includes a guide rail 41 and a rail motor. 42 and the support plate 43, the guide rail 41 is arranged on the right side of the base of the electric sewing machine 1 through the frame body, the track motor 42 is slidably connected to the upper end of the guide rail 41, the support plate 43 is arranged on the right side of the track motor 42, and the support plate 43 To the funct...

Embodiment 3

[0035] This embodiment differs from Embodiment 1 in that:

[0036] Install the frame plate 14 and the installation holes 15, and screw the installation holes 15 on the installation frame plate 14 to the installation part through bolts. The installation frame plate 14 is arranged at the bottom end of the outer side of the base of the electric sewing machine 1, and the installation holes 15 are evenly arranged in The four corners of the upper end of the frame plate 14 are installed to facilitate the installation of the sewing device.

[0037] A sewing method for elastic ropes in garment processing, comprising the following steps:

[0038] Step 1: Thread the mounting holes 15 on the mounting frame plate 14 to the mounting parts with bolts, place the garment on the upper end of the work board 3, and align the seam of the garment with the sewing opening 16, and place the elastic cord on the adsorption rubber cover Right below 82, through the control of the PLC controller 13, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com