Improved sewing machine take-up lever structure

A thread take-up lever and sewing machine technology, which is applied to the sewing machine thread take-up device, sewing machine components, sewing equipment, etc., can solve the problems such as affecting the sewing effect and sewing quality of clothing, unstable clothing stitches, affecting the sewing stitches, etc. , to achieve the effect of ensuring the sewing effect, the stitch stability and the sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

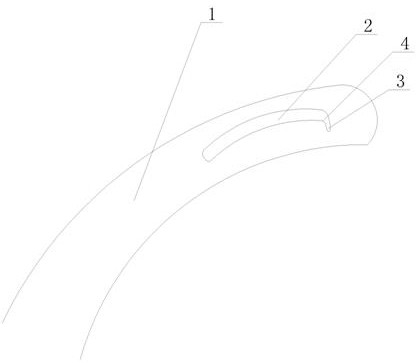

[0008] See figure 1 , an improved sewing machine thread take-up lever structure, which includes a sewing machine thread take-up lever body 1, a threading hole 2 is set on the sewing machine thread take-up lever body 1, the threading hole 2 is a long slot hole, and a transverse notch 3 is set on the long slot hole 2, and the line When running to the end of the long slot hole, the thread will stay in the transverse gap for a certain period of time to ensure the thread take-up during the sewing process and better ensure the thread amount matching the thread passing amount, so that the thread take-up lever can run to different positions The feeding amount of the upper thread and the pulling force of the upper thread are kept stable, so that the tension of the suture is more stable, and the stitches in the sewing of the clothes are more stable, which further ensures the sewing effect and quality of the clothes, and further avoids the upper thread the break,.

[0009] The threading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com