Control method of numerical control system of bag-sewing machine for realizing high-speed process without needle dragging

A technology of numerical control system and control method, which is applied in the processing control of numerical control machine tools and the control field of high-speed machining without dragging needles by the numerical control system of bag-stitching machines. It can solve the problems of increasing processing costs, reducing processing efficiency, and breaking sewing needles. Achieve the effects of improving processing efficiency, ensuring sewing effect, and avoiding needle dragging phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

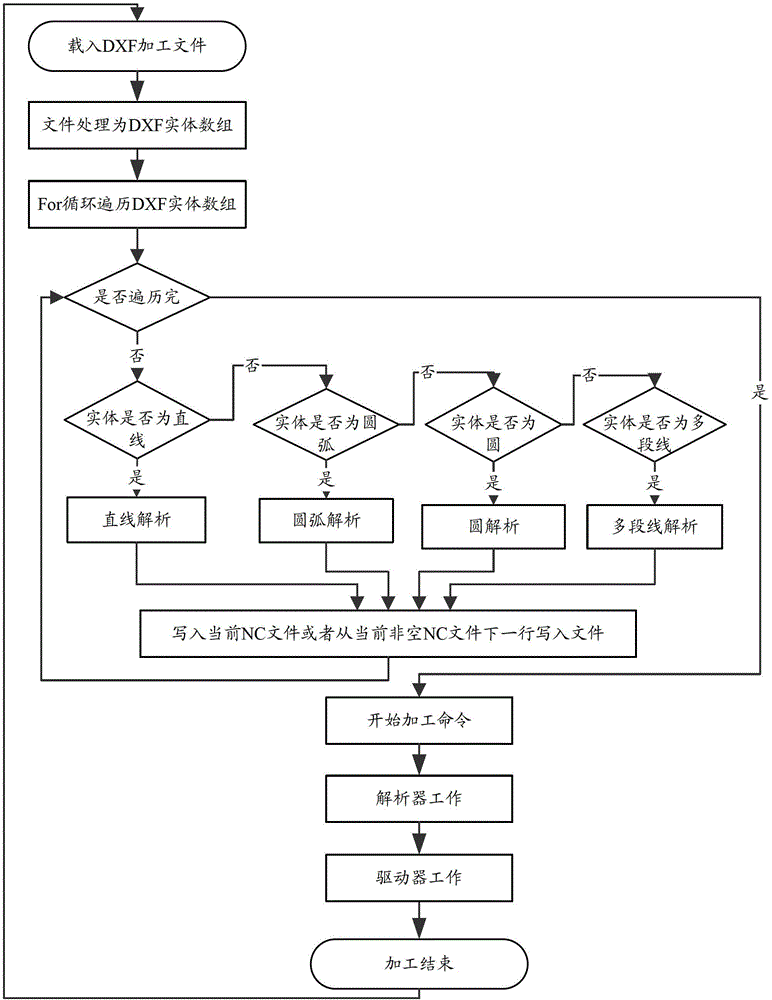

[0034] see figure 1 As shown, it is a schematic flow chart of the steps of the control method for realizing the high-speed machining without dragging the needle by the numerical control system of the bag-setting machine of the present invention.

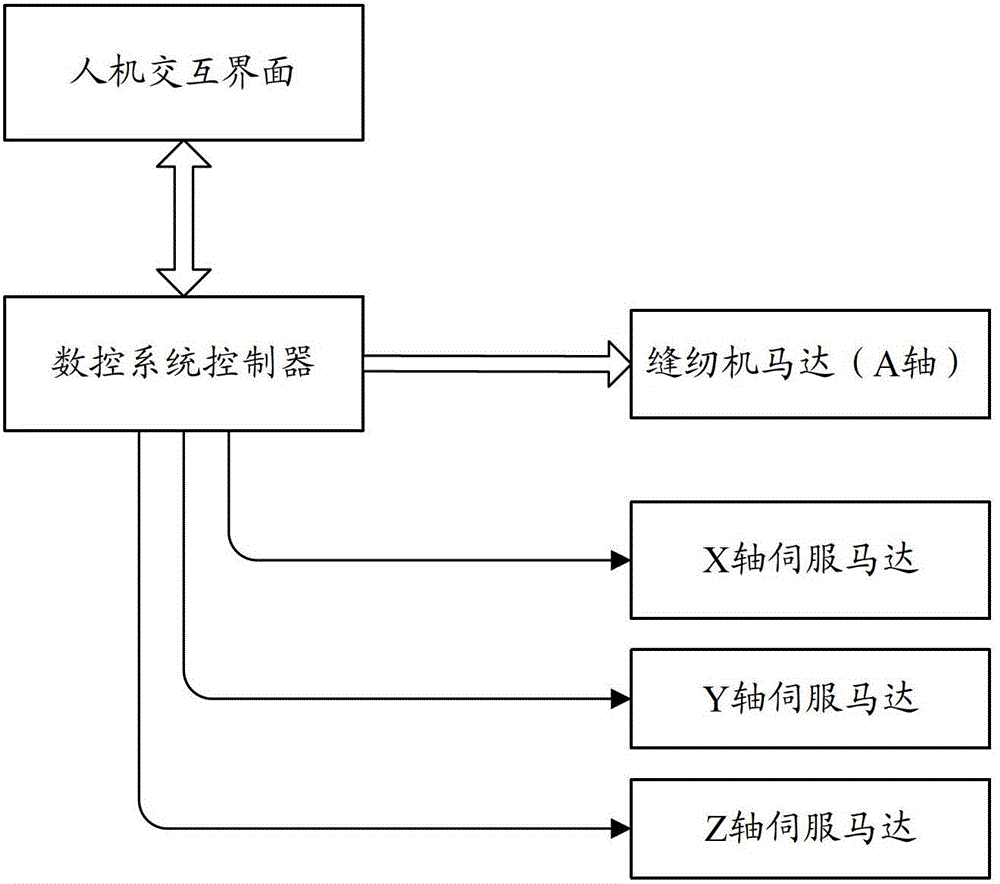

[0035] The numerical control system of the bag binding machine usually includes a controller and an X-axis motor, a Y-axis motor, a Z-axis motor and an A-axis motor connected to the controller. Among them, the X-axis motor and Y-axis motor are used to control the movement of the cloth feeding platform of the bag stitching machine, the Z-axis motor is used to control the up and down movement of the sewing needle, and the A-axis motor is used to control the movement of the remaining material removal scissors that move with the sewing needle. action.

[0036] In one embodiment, the control method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com