Three-dimensional mould with lifting degree for sewing shoes and boots and sewing method for pressing toe part on heel part

A front-end, three-dimensional technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems that the sewing effect cannot meet the requirements of the process, the work efficiency is low, and the intelligent automation equipment cannot be used, so as to improve production. Effect of skill level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

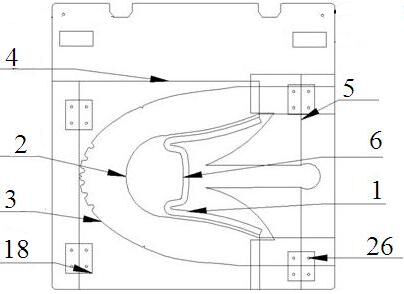

[0036] This embodiment provides a three-dimensional mold with sway for sewing shoes and boots, including a bottom plate 1, a rear upper limiting plate 2, a front upper limiting plate 3, a front upper pressing plate 4 and a rear upper three-dimensional separation pressing plate 5. The bottom plate 1 is provided with a wire groove 6, and the three-dimensional separation pressing plate 5 of the rear side forms a sway;

[0037] The bottom plate 1, the rear side limiting plate 2, the front side limiting plate 3, the front side pressing plate 4 and the rear side three-dimensional separation pressing plate 5 are arranged in sequence from bottom to top and the wire groove 6 is exposed in the middle, and the rear side limiting plate 2 It is fixedly connected with the bottom plate 1, the front side limiting plate 3 is connected to the left side of the rear side limiting plate 2, the front side pressure plate 4 is hinged to the left side of the front side limiting plate 3, and the rear si...

Embodiment 2

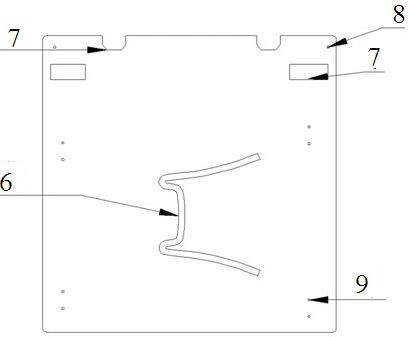

[0040] On the basis of Embodiment 1, this embodiment provides a three-dimensional mold with sway for sewing shoes and boots. The two sides of the upper end of the bottom plate 1 are symmetrically opened with a quick-change card slot-7 and a positioning hole-8. A plurality of hinge positioning holes 9 are arranged symmetrically on both sides of the bottom plate 1 .

[0041] Such as figure 2 As shown, the quick-change clamp of the pattern machine can clamp the three-dimensional mold through the quick-change card slot 7, thereby ensuring that the three-dimensional mold will not move. Positioning hole one 8 is used for positioning up and down, and hinge positioning hole one 9 is used for the calibration positioning of the front side limiting plate 3 and the back side limiting plate 2 bonding.

Embodiment 3

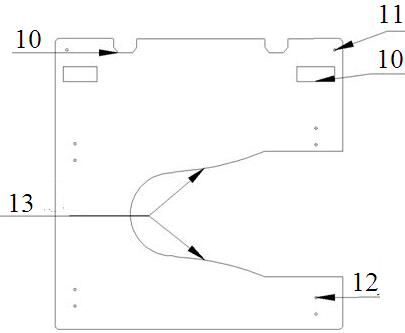

[0043] On the basis of Embodiment 1, this embodiment provides a three-dimensional mold with sway for sewing shoes and boots. The two sides of the upper end of the back limit plate 2 are symmetrically opened with two quick-change card slots 10 and two positioning holes. 11. A plurality of hinge positioning holes 12 are arranged symmetrically on both sides of the rear panel limiting plate 2, and the right side of the rear panel limiting plate 2 is open, and the inner edge of the opening forms a rear panel limiting arc 13, so The arc 13 of the back gang limiting arc 13 coincides with the radian that the inner and outer ankles of the back gang need to be pressed by the front gang to make up the sewing position.

[0044] Such as image 3 As shown, the back stop limiting plate 2 is bonded on the base plate 1, and its function is to fix the back sheet to prevent the sheet from shifting. Hinge positioning hole two 12 is used for the calibration positioning of the front side limiting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com