An apparatus and a method of producing pulp moulded products

A technology for molding products and pulp, which is applied in the field of improving the forming process of pulp molding products, and can solve the problems of clogging of the mesh layer, lengthening the forming time, slowing down the water flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

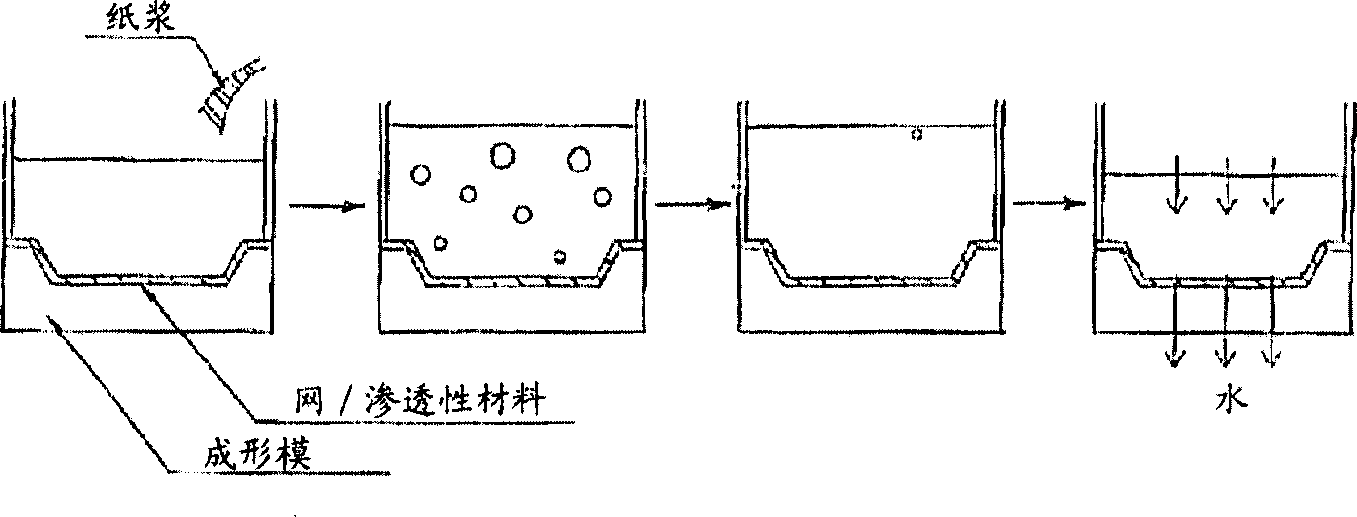

Method used

Image

Examples

no. 1 example

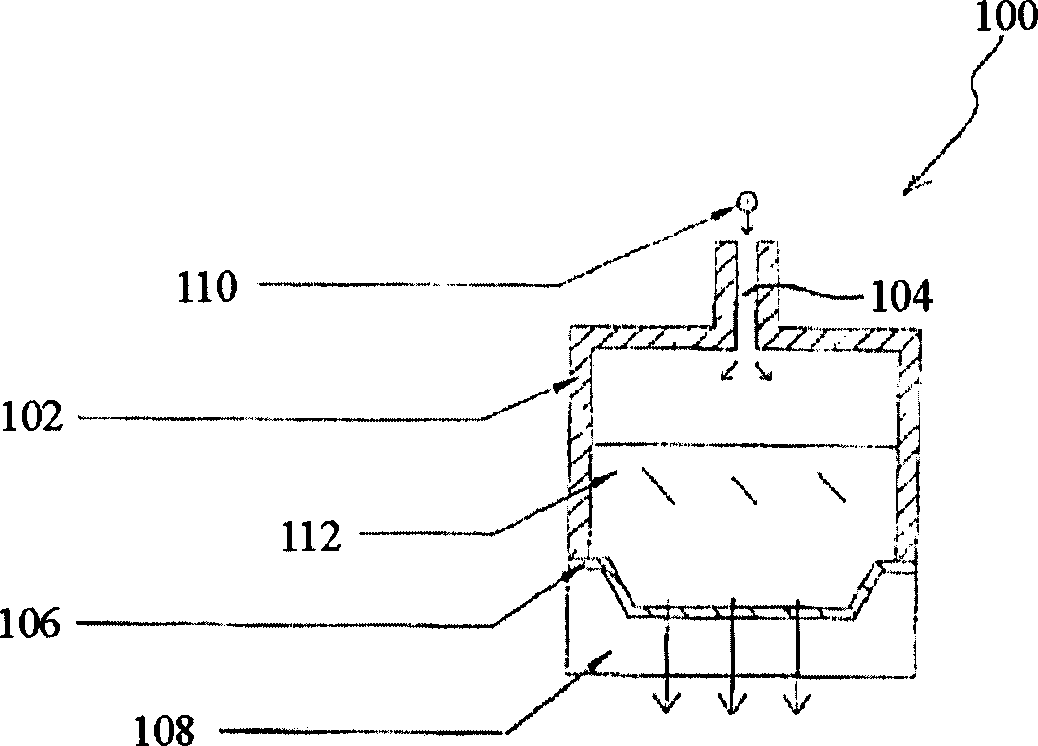

[0028] The first embodiment, such as image 3 As shown, apparatus 100 is a forming process utilizing "time pressure". The apparatus 100 includes a pressure chamber 102, a conduit 104 on the chamber and a mesh or porous mass 106 below the chamber. Beneath the screen 106 is a forming die 108 (this die is made of metal) with drainage holes for the liquid to flow through. For example: water can flow out from the forming hood 102, while the conduit 104 is connected to an air source; such as compressed air 110, used to provide positive pressure to the pulp in the forming hood 102.

[0029] In order to apply the present invention to the forming process, pulp 112 is injected into the forming hood 102 through an inlet (not shown) next to the forming hood, and then the air source 110 is activated to release the compressed air. For example: air pressure rises to 10 kilograms per square centimeter (kg / cm 2 ), the air pressure enters the forming hood 102 through the conduit 104, positiv...

no. 2 example

[0038] Second embodiment, such as Figure 7 The apparatus 200 shown can use: the forming process of "displacement-volumetric" (displacement-volumetric), which can also be called "positive displacement" forming method. In this apparatus 200 a piston is mounted in a grouted forming housing. And this piston is connected with motor and screw rod 206, is used as the usefulness of pushing piston 202, applies pressure on the pulp 208 by the piston, and moisture will pass through the net or porous material (porous material) on the metal mold to remove moisture from the pulp. extrude. And the activity of piston 202 can be preset with microprocessor. In this way, the strength and time of the pressure can be preset, and the pressure and time changes shown in the profile can be set. In addition, these data can also be used as a basis for errors and experiments.

[0039] The third embodiment, such as Figure 8 The device 300 shown is in close proximity to the device 100 described abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com