A sewing material length detection device for automatic sewing equipment and automatic sewing equipment

A detection device and sewing material technology, applied in the direction of measuring devices, sewing equipment, sewing machine components, etc., can solve the problems of not having the function of rejecting short-length waste materials and affecting the performance of automatic sewing equipment, so as to ensure sewing efficiency and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

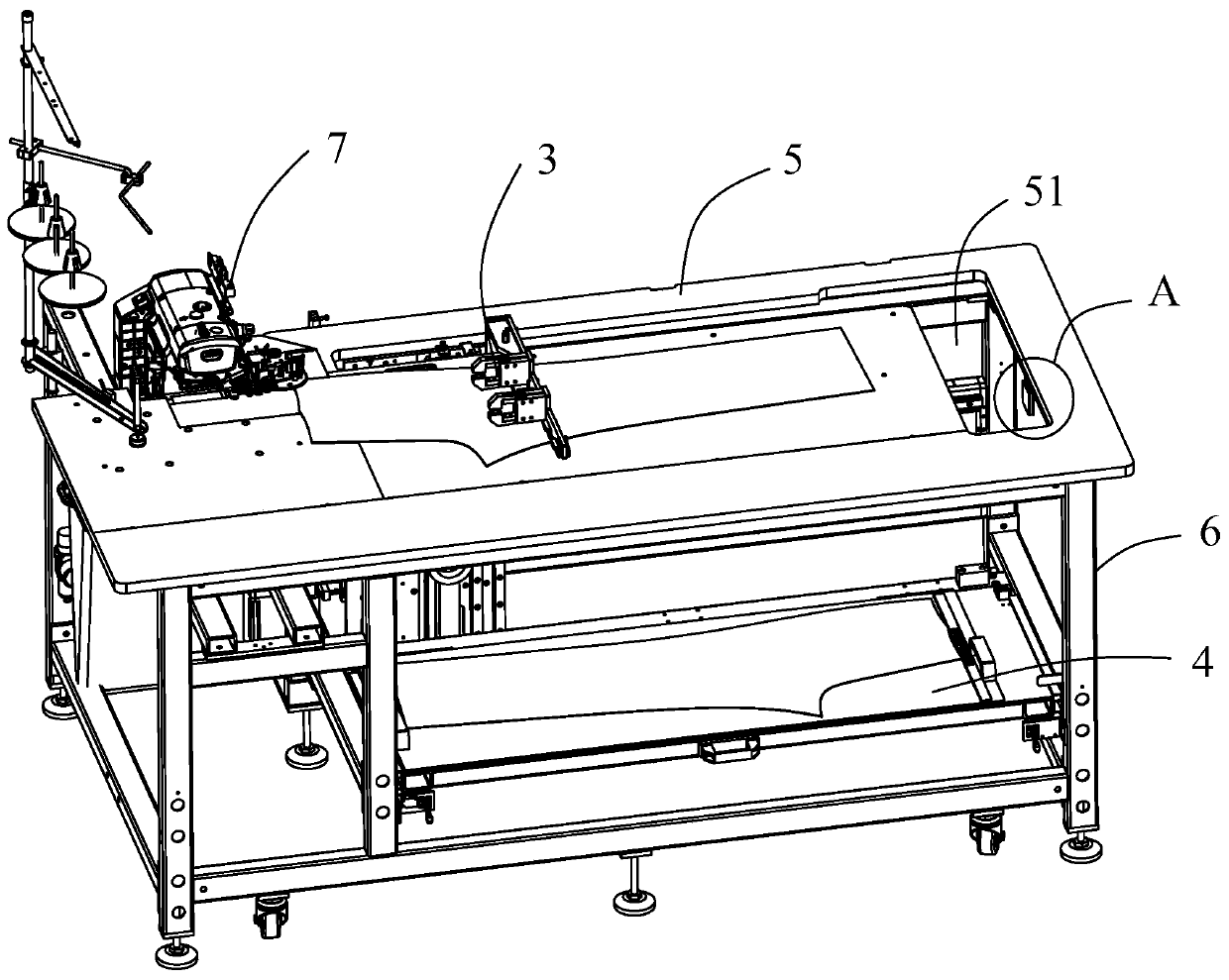

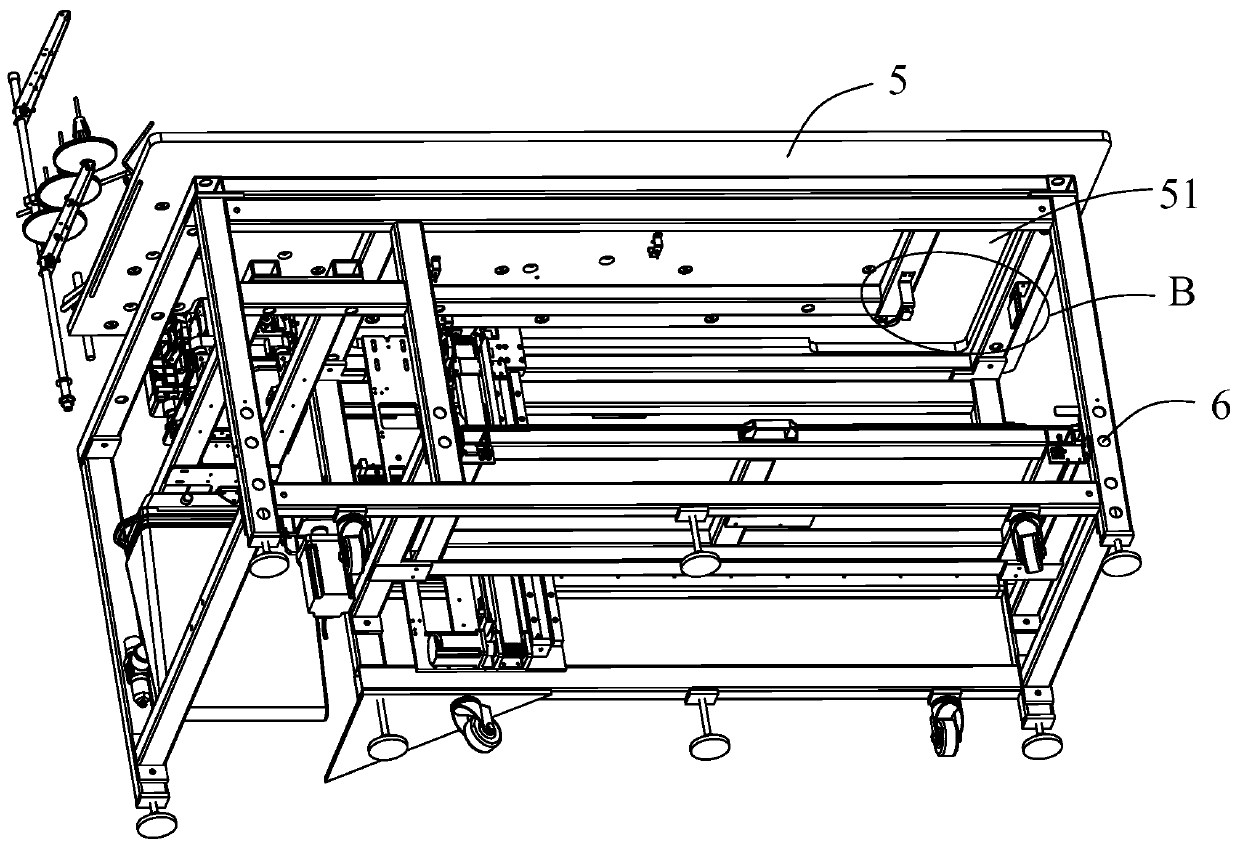

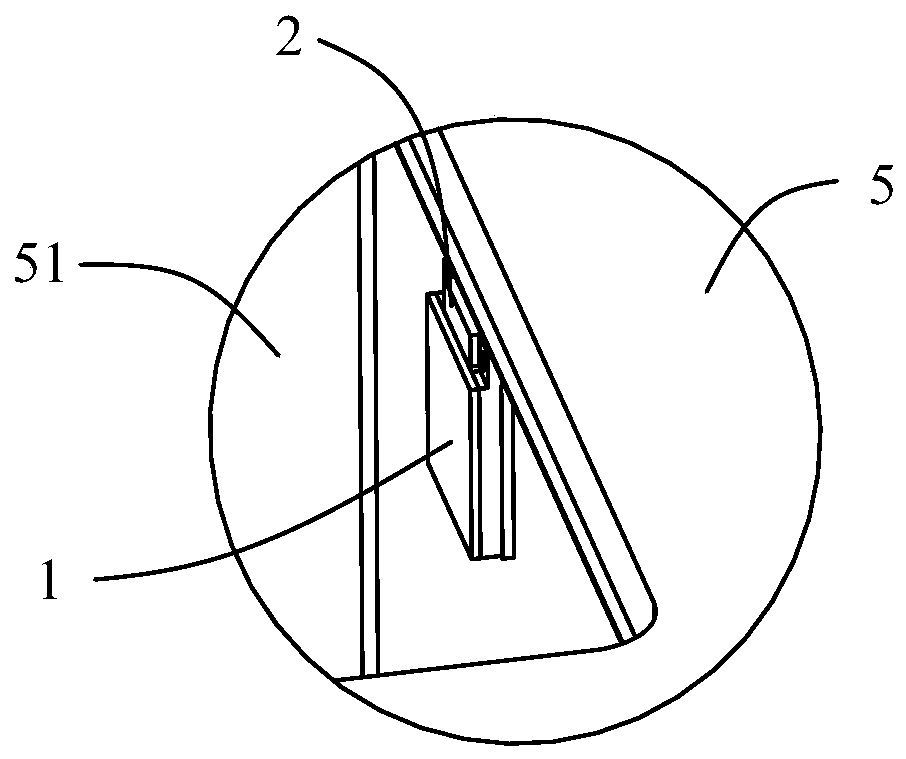

[0043] Embodiment one, as Figure 1 to Figure 4 As shown, the sewing material detection sensor 1 is installed at the channel opening 51 and is fixed on the lower end side of the table 5 . At this time, the sewing material detection sensor 1 can be a through-beam photoelectric sensor, which has a transmitting part 11 and a receiving part 12 that are independent from each other and arranged opposite to each other left and right, such as Figure 4 As shown, the transmitting part 11 and the receiving part 12 are all fixed on the mounting bracket 2, and the two mounting brackets 2 are installed on the left edge and the right edge of the channel opening 51 respectively, and are fixed on the lower end surface of the platen 5, and then the The sewing material detection sensor 1 is installed at the passage opening 51 places. Alternatively, the sewing material detection sensor 1 can also be a reflective photoelectric sensor, such as Figure 5 As shown, the sewing material length detec...

Embodiment 2

[0045] Embodiment two, such as Figure 6 and Figure 7 As shown, the sewing material detection sensor 1 is installed on the lower end surface of the right end of the platen 5, and is adjacent to the channel opening 51, and the platen 5 is provided with a through hole 52 that penetrates up and down and exposes the seam material detection sensor 1; at this time , The sewing material detection sensor 1 is a reflective photoelectric sensor. Since the sewing material detection sensor 1 is installed on the lower end surface of the right end of the table 5, when the sewing material clamping device 3 transfers the sewing material to the specified position on the table 5, the sewing material must go over the sewing material detection to the left. The sensor 1 makes the table 5 must be able to accommodate a whole piece of sewing material, thereby relatively increasing the length of the table 5 and the overall length of the automatic sewing equipment. However, since the movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com