Waist portion pulling machine

A technology of waist-drawing machine and machine head, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

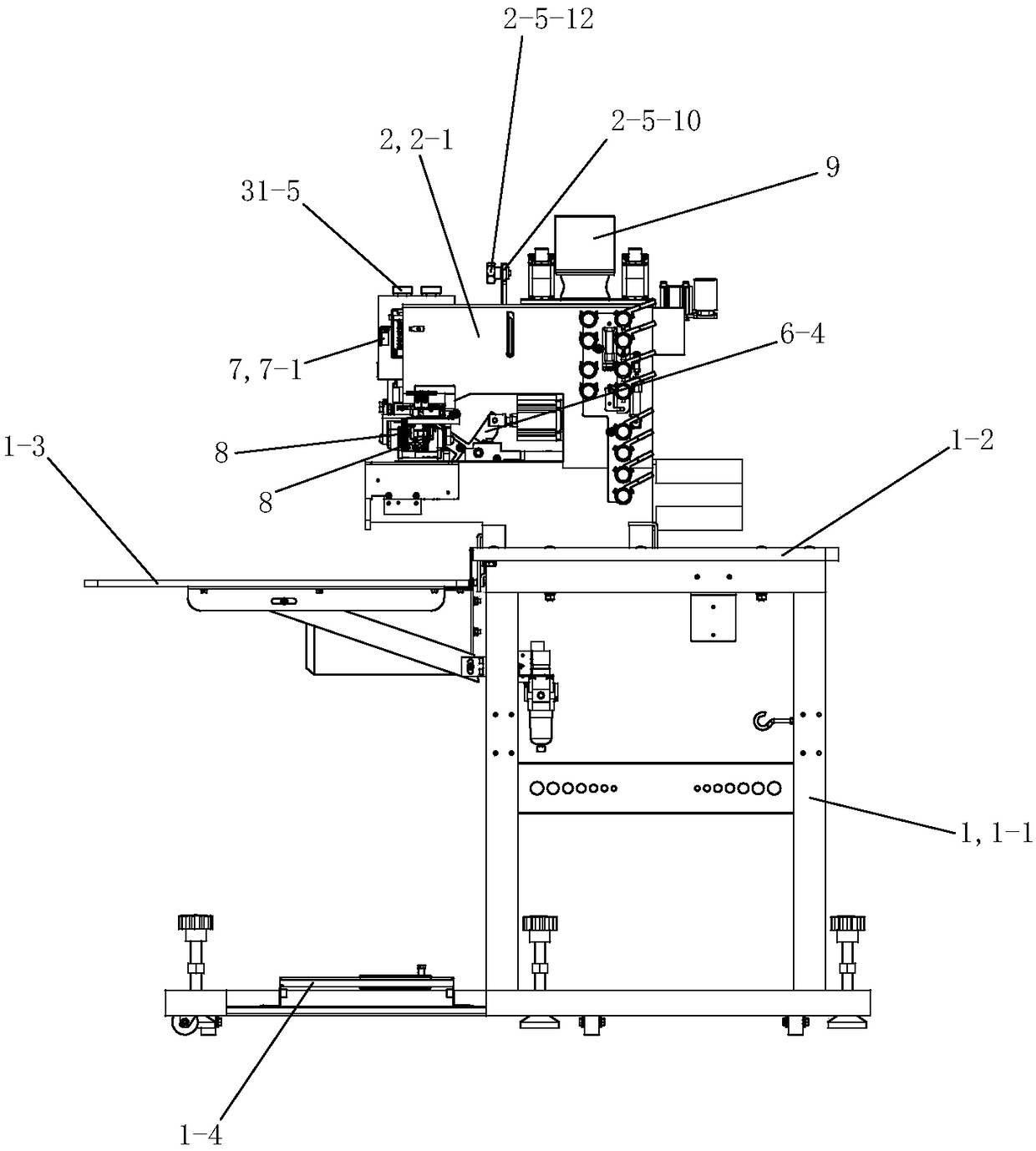

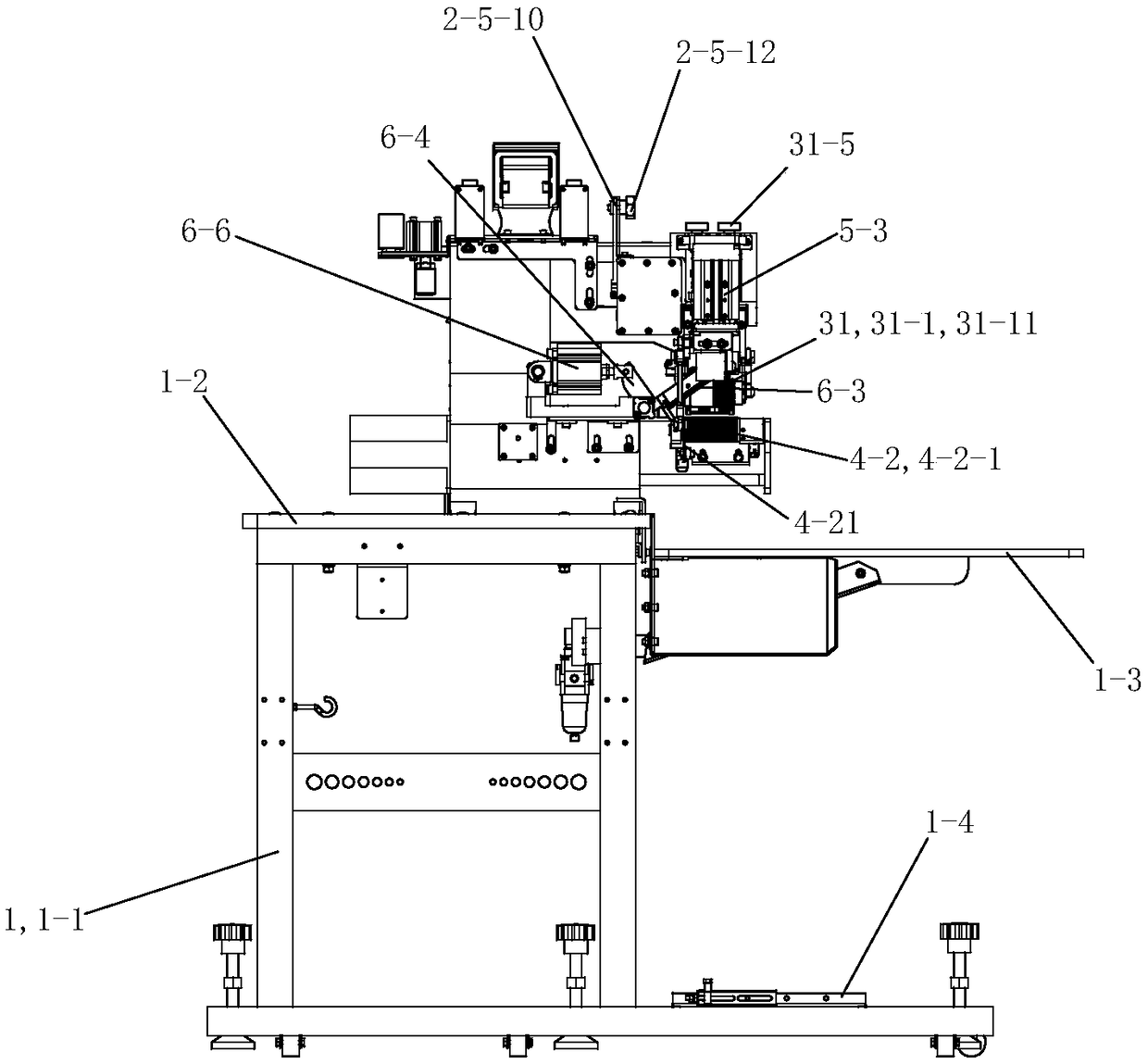

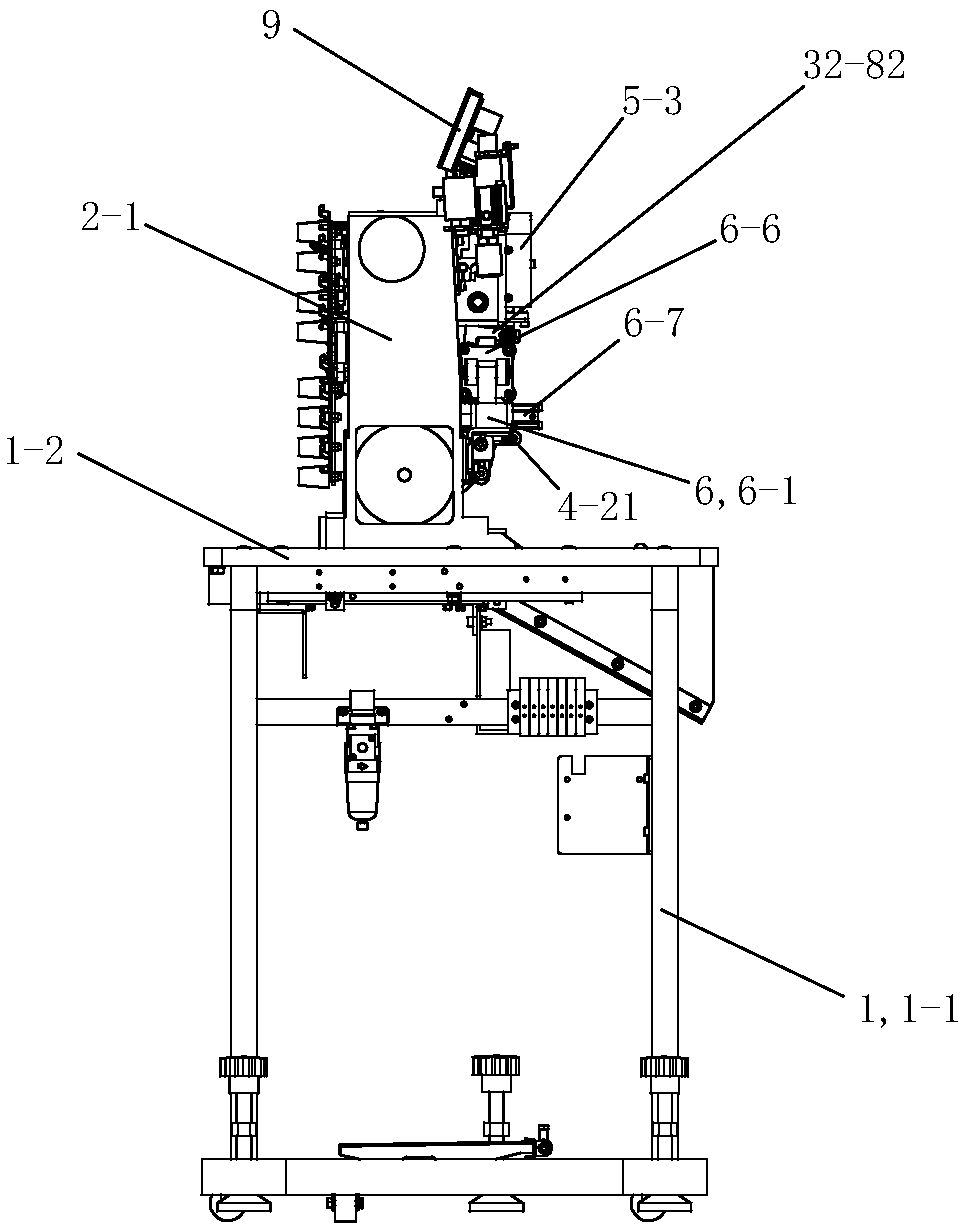

[0076] See Figure 1 to Figure 26 , the waist pulling machine of the present invention includes a workbench 1, a sewing assembly 2, an upper tugboat assembly 3, a lower tugboat assembly 4, a pressing wheel assembly 5, a shearing device 6, a detection and positioning assembly 7, a cooling assembly 8 and a control panel 9 . The control panel 9 is provided with a human-computer interaction interface for controlling the waist-drawing machine, which can display the state of the waist-drawing machine and set corresponding parameters.

[0077] See Figure 1 to Figure 7 , The workbench 1 includes a frame 1-1, a main platen 1-2, an auxiliary platen 1-3 and a pedal 1-4. The main platform 1-2 is fixedly arranged on the upper right side of the frame 1-1. The auxiliary platen 1-3 is fixedly arranged on the upper left part of the frame 1-1. Pedal 1-4 rotation is arranged on the bottom right part of frame 1-1, is positioned at the below of auxiliary platform 1-3, and its axis of rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com