Hemming sewing machine with automatic conveying function

A sewing machine and material feeding technology, which is applied in the field of curling sewing machines, can solve problems such as difficulty in adjusting the level, affecting sewing quality, displacement, etc., and achieves the effect of convenient installation and debugging, and guaranteed sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

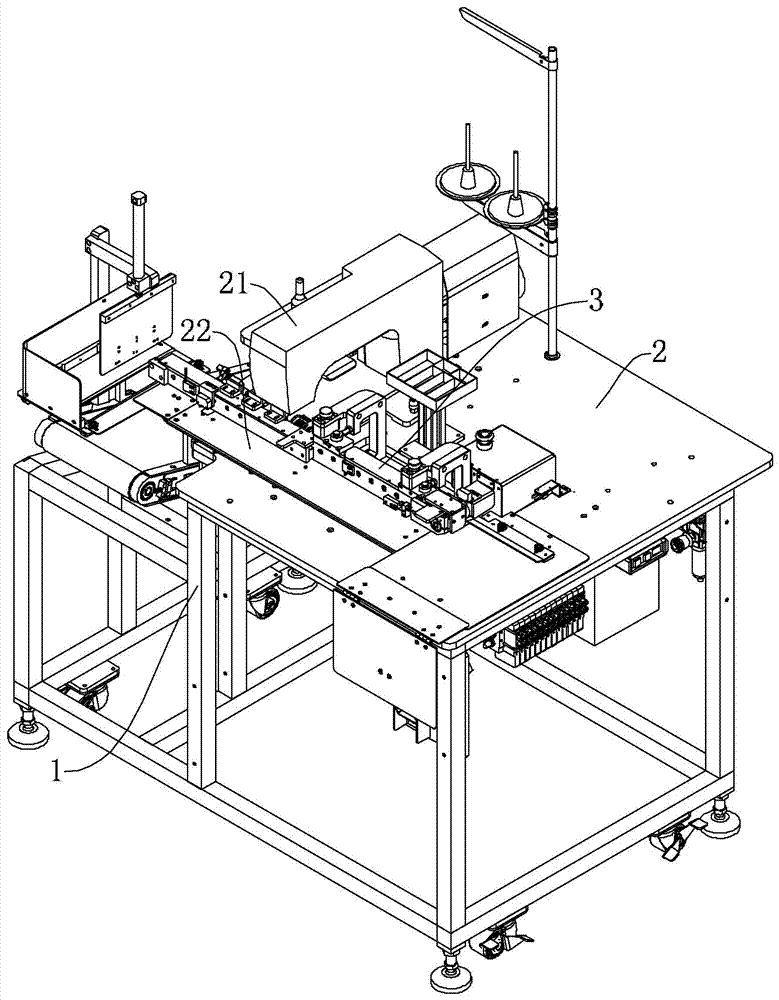

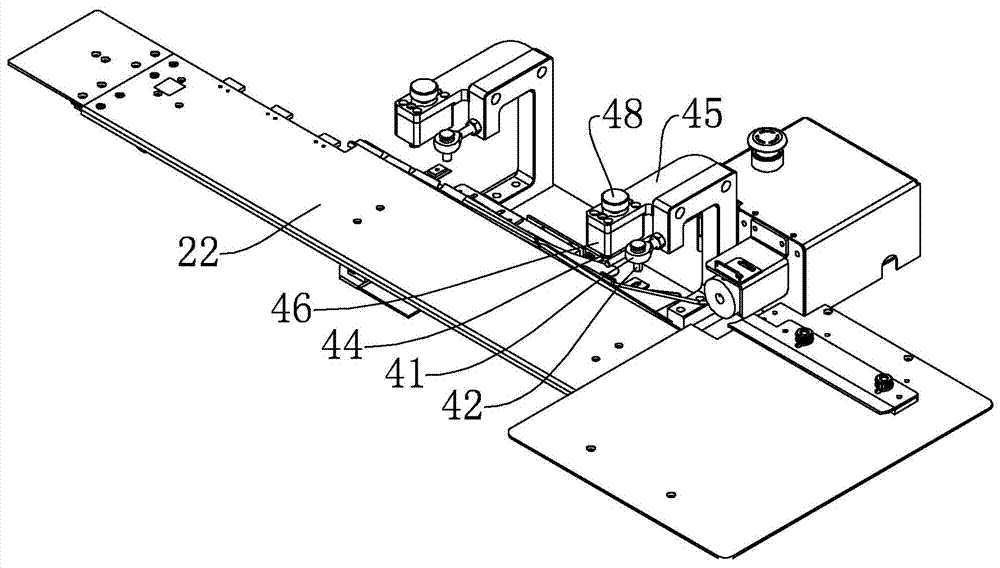

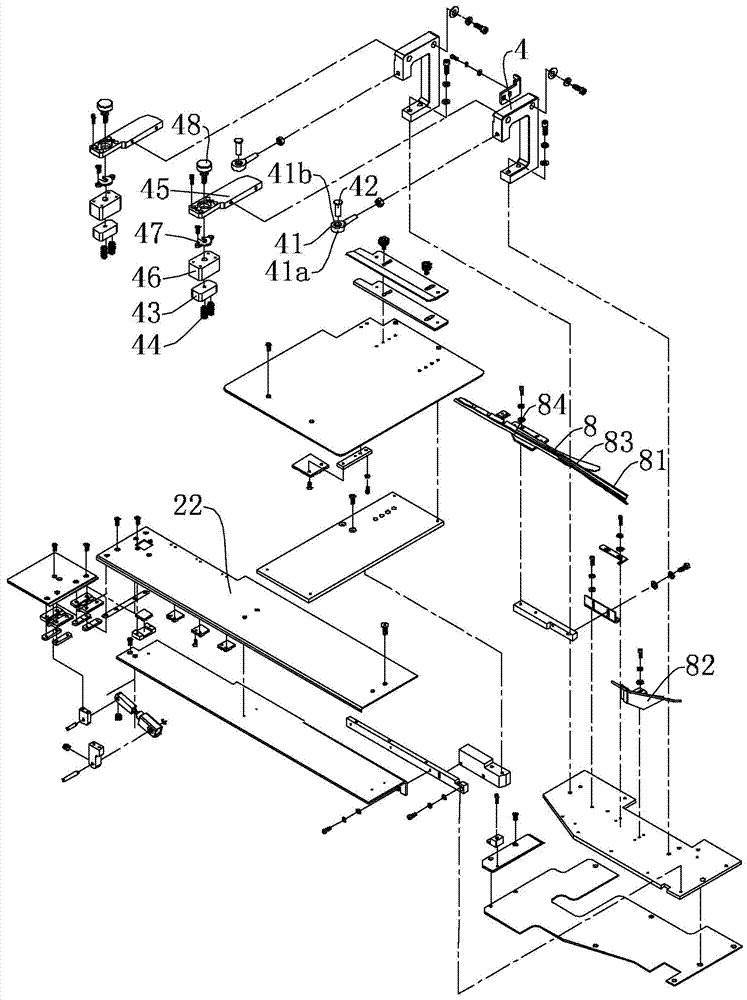

[0026] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0027] The reference signs wherein are: frame 1, workbench 2, sewing machine head 21, conveying bottom plate 22, synchronous belt conveying mechanism 3, first motor 30, housing 31, first synchronous wheel 32, second synchronous wheel 33, The third synchronous wheel 34, coupling 35, mounting column 37, mounting rod 38, roller 39, mounting bracket 4, universal bearing 41, bearing sleeve 41a, ball joint 41b, connecting shaft 42, balance pressing block 43, spring 44 , mounting arm 45, adjusting pressure block 46, clamping piece 47, connecting pin 48, receiving board 6, feeding trough 61, feeding cylinder 62, feeding board 63, receiving bracket 64, receiving rack 65, receiving Material roller 66, material receiving synchronous belt 7, material receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com