A double tension thread gripper

A thread tensioner and tension technology, applied in the direction of tension devices, sewing equipment, sewing machine components, etc., can solve problems such as difficult to achieve fine-tuning, unsightly sewing stitches, and affecting sewing quality, so as to ensure sewing quality and tightness Consistency, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

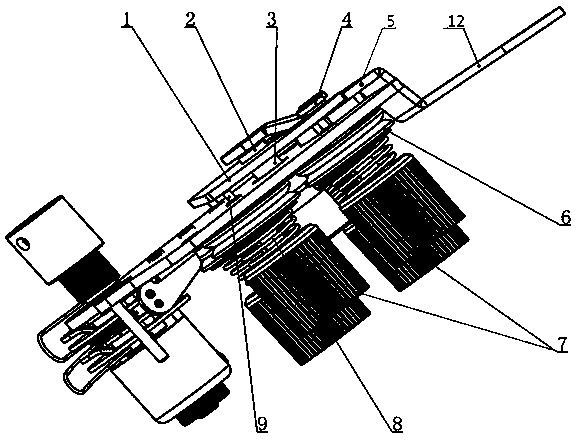

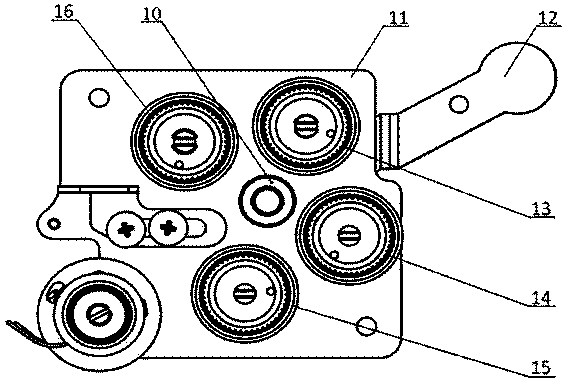

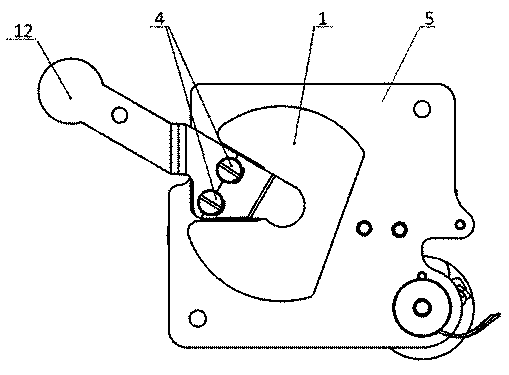

[0016] refer to Figure 1 to Figure 4 , a double tension tensioner, comprising a thread tensioner, a thread tensioner fixing plate 11, a thread loosening plate A5, a thread loosening plate B1, a thread loosening plate shaft pin 3, a thread loosening plate shaft pin sleeve 10, a screw 4, Screw two 2, the thread tensioner has four groups, respectively the first coarse adjustment thread tensioner 13, the second coarse adjustment thread tensioner 16, the first fine adjustment thread tensioner 14 and the second fine adjustment thread tensioner 15, the The thread loosening plate A5 is fixed on the thread clamp fixing plate 11 by screw one 4, and the thread loosening plate B1 is arranged between the thread loosening plate A5 and the thread clamp fixing plate 11, and conflicts with the thread loosening plate A5, The loosening plate B1 is fixed on one end of the pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com