A sewing method for sleeve and shoulder joints

A sleeve shoulder joint and sewing technology, which is applied in the field of garment processing, can solve the problems that automatic sewing processing is difficult to meet the processing quality requirements, it is difficult to ensure the complete closure of sleeve shoulder joint sewing, and the consistency and stability are difficult to be guaranteed. Automated sewing processing, good processing feasibility, and reduced sewing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

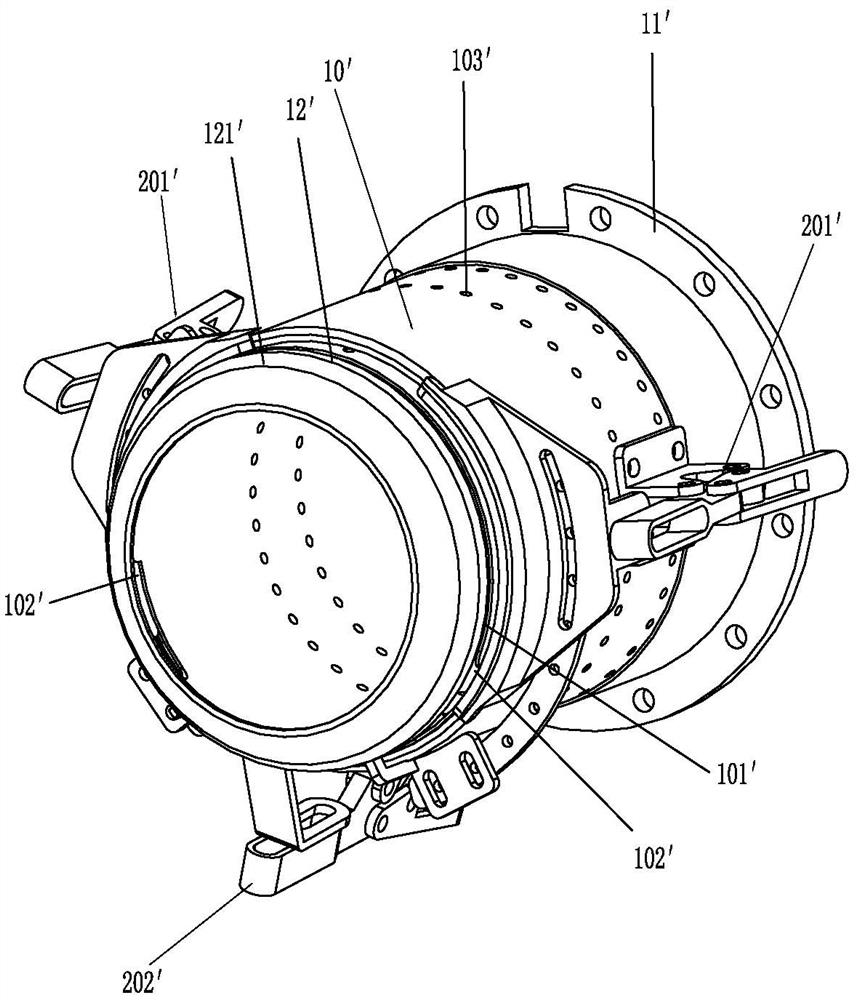

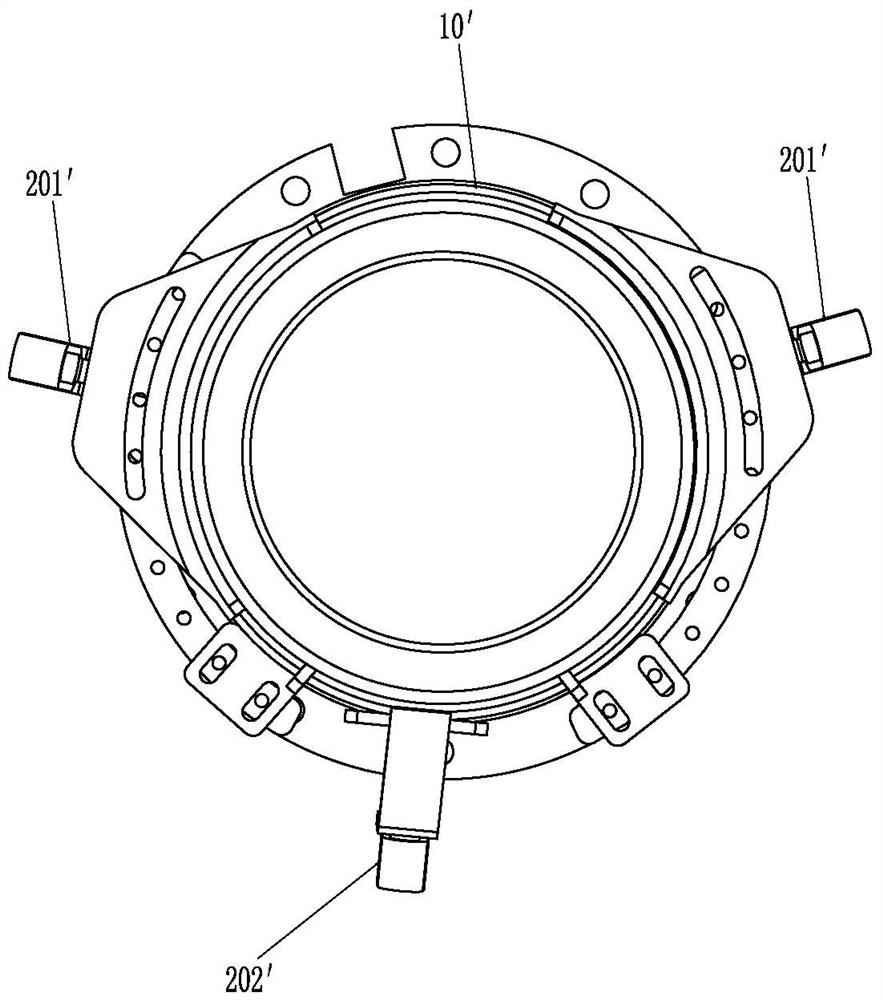

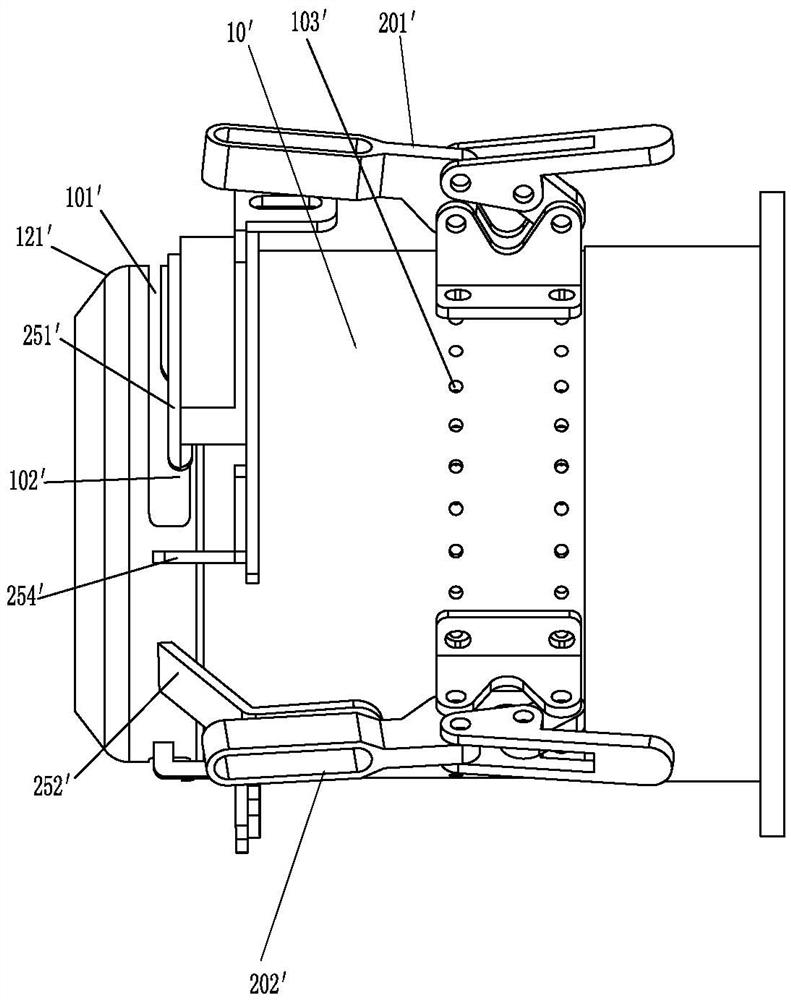

[0071] Please refer to Figure 1 to Figure 15 Shown, it has shown the specific structure of the sleeve shoulder seam sewing method of the present invention and two kinds of embodiments.

[0072] First, if Figure 8 , Figure 14 and Figure 15 As shown, a sewing method for the sleeve shoulder joint, the sewing track of the sleeve shoulder joint is divided into an upper sewing track 31' and a lower sewing track 32'; wherein: the upper sewing track 31' is set to extend upwards, and the lower sewing track 32' It is arranged as a downward arched extension; the left and right ends of the upper sewing track 31 ′ have a first extending edge 311 ′ extending toward the sewing edge 301 ′, and the left and right ends of the lower sewing track 32 ′ have a first extending edge 311 ′ extending toward the sewing edge 301 ′. Two extended sides 321', the second extended side 321' is located above the first extended side 311', so that: the left and right ends of the upper sewing track 31' and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com