Feed lifting height adjusting method for sewing machine

A technology of height adjustment and height adjustment mechanism, applied in sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve problems such as affecting the sewing quality, changing the sewing machine feeding needle distance, reverse, and back dragging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

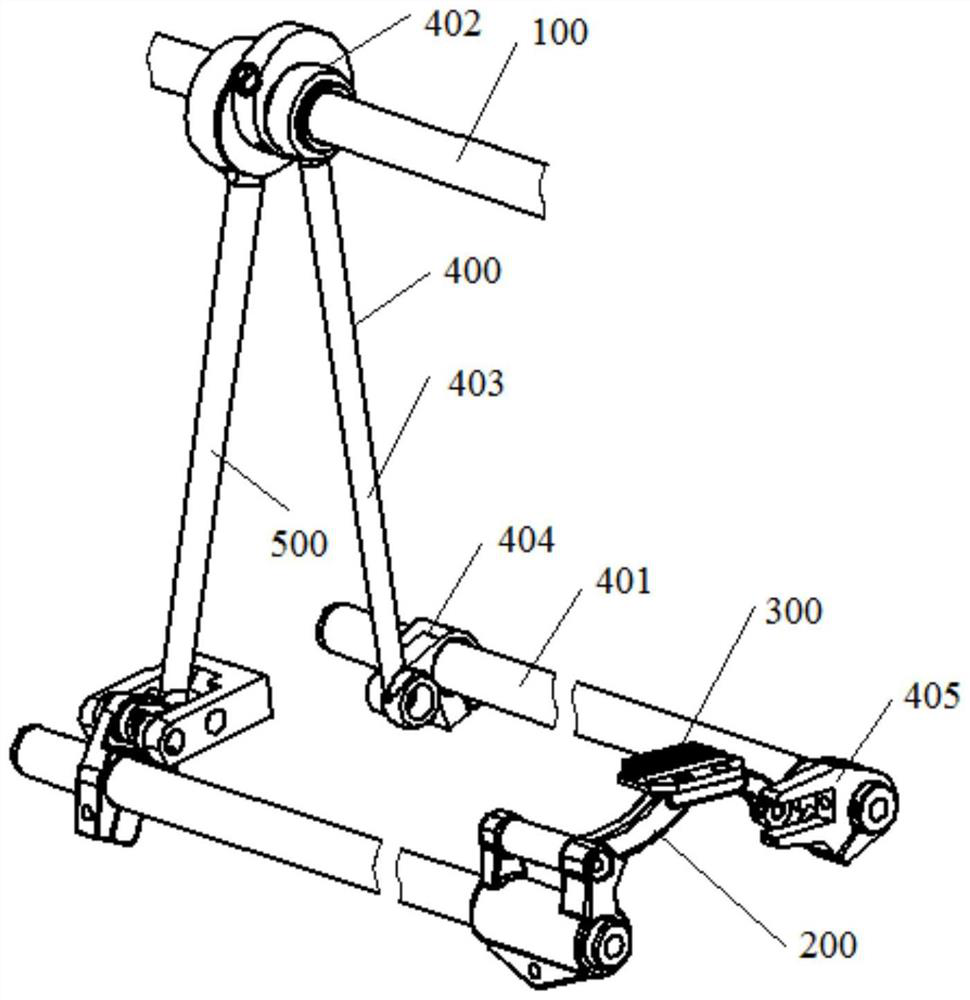

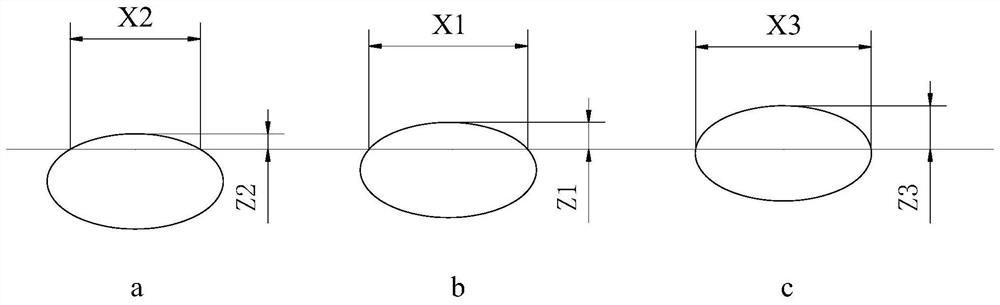

[0053] Embodiment 1 of the sewing machine: The tooth-lift height adjustment mechanism changes the first tooth-lift drive by changing the tooth-lift eccentricity W between the matching center O1 of the tooth-lift eccentric wheel 51 and the tooth-lift connecting rod 52, and the rotation center O2 of the main shaft 10. Component transmission efficiency.

[0054] Such as Figure 5 to Figure 9 As shown, in the first embodiment of the sewing machine, the tooth-lifting eccentric wheel 51 is sleeved on the main shaft 10, and the tooth-lifting height adjustment mechanism is a tooth-lifting eccentric adjustment assembly 60, and the tooth-lifting eccentric adjustment assembly 60 is connected with the main shaft 10 and the tooth-lifting eccentric wheel 51, and the right end of the main shaft 10 is fixedly equipped with a handwheel 130. Lifting teeth eccentric adjustment assembly 60 includes ratchet 61, adjusting slider 62 with ratchet portion 621 at the lower end, adjusting eccentric whe...

Embodiment 2

[0057] Embodiment 2 of the sewing machine: the tooth-lifting height adjustment mechanism changes the first tooth-lifting drive by changing the tooth-lifting eccentricity W between the matching center O1 of the tooth-lifting eccentric wheel 51 and the tooth-lifting connecting rod 52, and the rotation center O2 of the main shaft 10. Component transmission efficiency.

[0058] The difference between the second embodiment of the sewing machine and the first embodiment of the sewing machine is that the structure of the lifting eccentric adjustment assembly 60 is different; therefore, in the second embodiment of the sewing machine, as Figure 10 to Figure 12 As shown, the tooth-lifting eccentric wheel 51 is sleeved on the main shaft 10, and the tooth-lifting height adjustment mechanism is a tooth-lifting eccentric adjustment assembly 60, and the tooth-lifting eccentric adjustment assembly 60 is connected with the main shaft 10 and the tooth-lifting eccentric wheel 51. The right end ...

Embodiment 3

[0061] Embodiment 3 of the sewing machine: the height adjustment mechanism of the tooth lift changes the transmission efficiency of the first tooth lift transmission assembly by changing the transmission efficiency between the tooth lift connecting rod 52 and the tooth lift crank 53 .

[0062] In the third embodiment of the sewing machine, as Figure 13 to Figure 16 As shown, the tooth lifting height adjustment mechanism includes an adjustment drive assembly and an adjustment operation part 120; the tooth lifting eccentric wheel 51 is fixed on the main shaft 10 through screw locking; the upper end of the tooth lifting connecting rod 52 is rotatably sleeved on the tooth lifting eccentric wheel 51 The outer periphery of the tooth lift transmission assembly also includes a tooth lift adjustment seat 54, a first swing plate 55 and a second swing plate 56, and the lower end of the tooth lift connecting rod 52 passes through the tooth lift adjustment seat 54, the first swing plate 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com