Patents

Literature

52results about How to "Improve fold quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

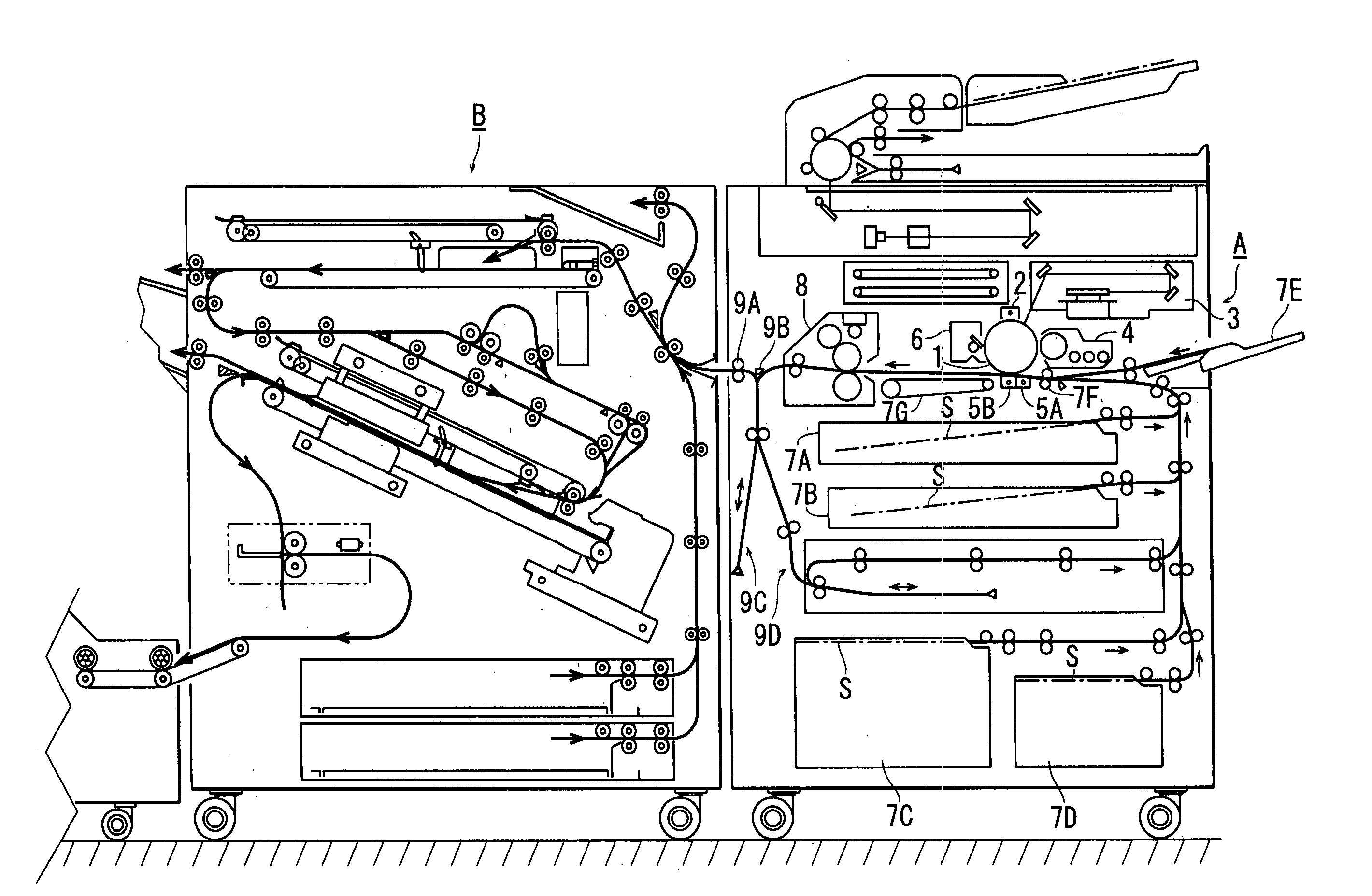

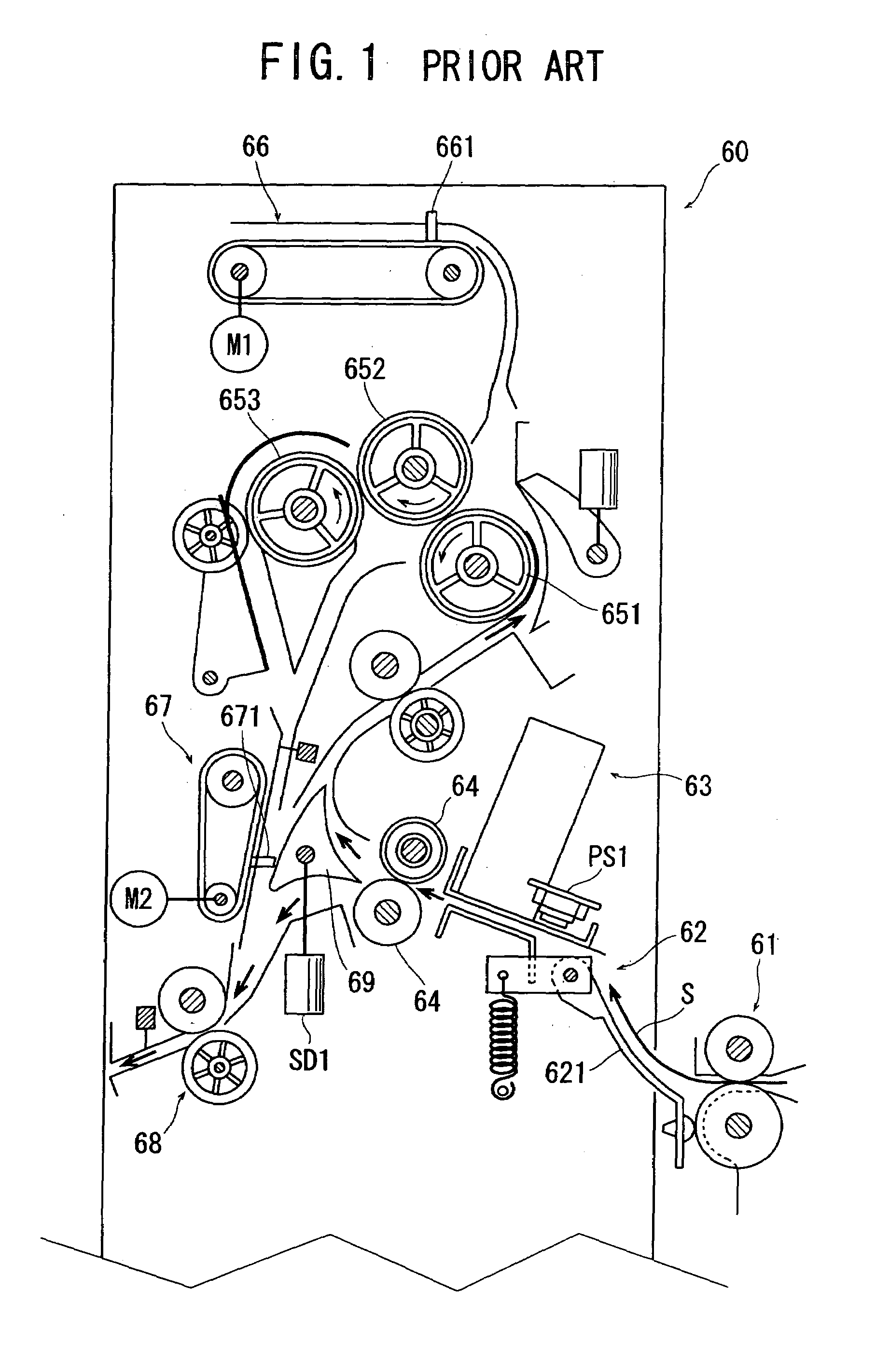

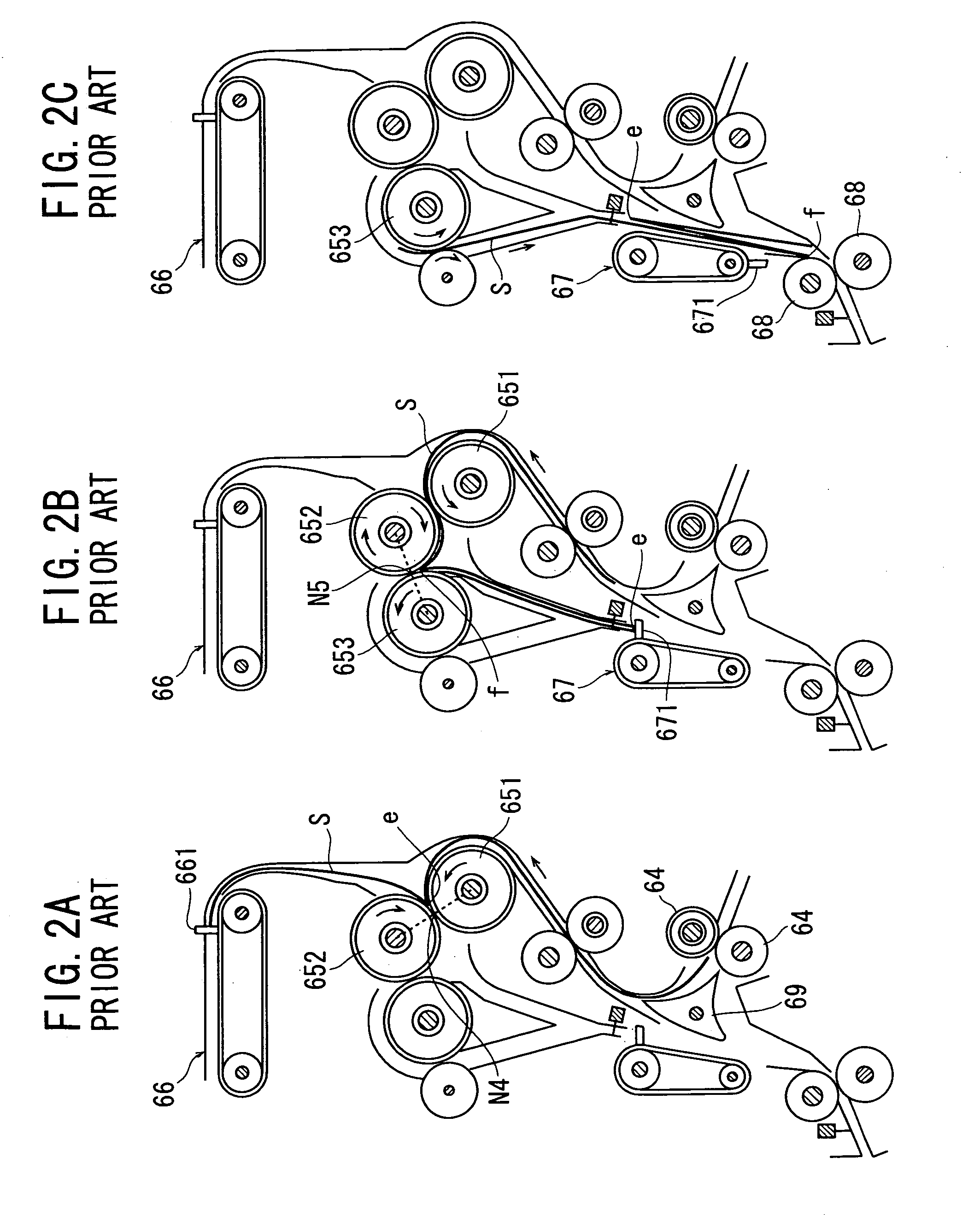

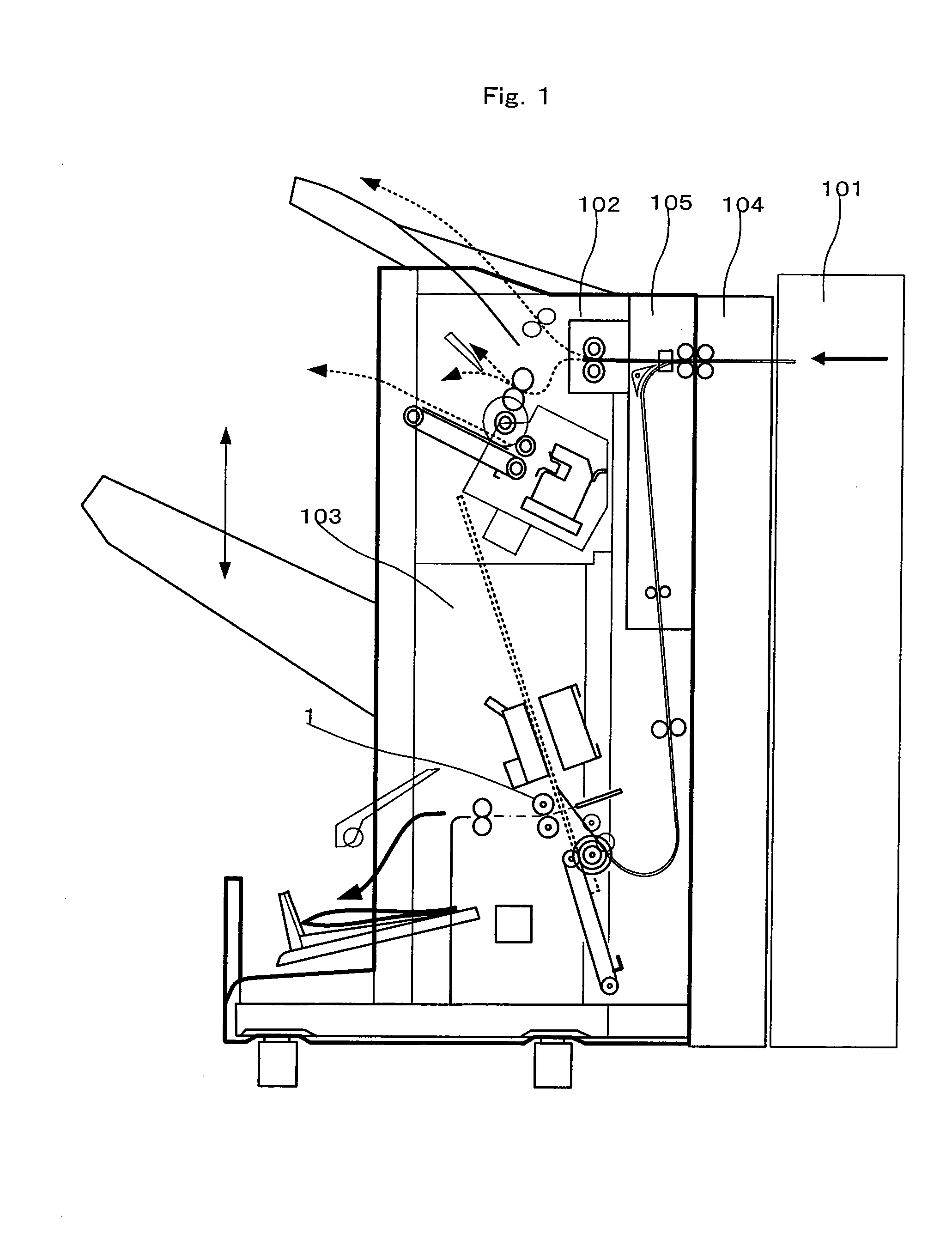

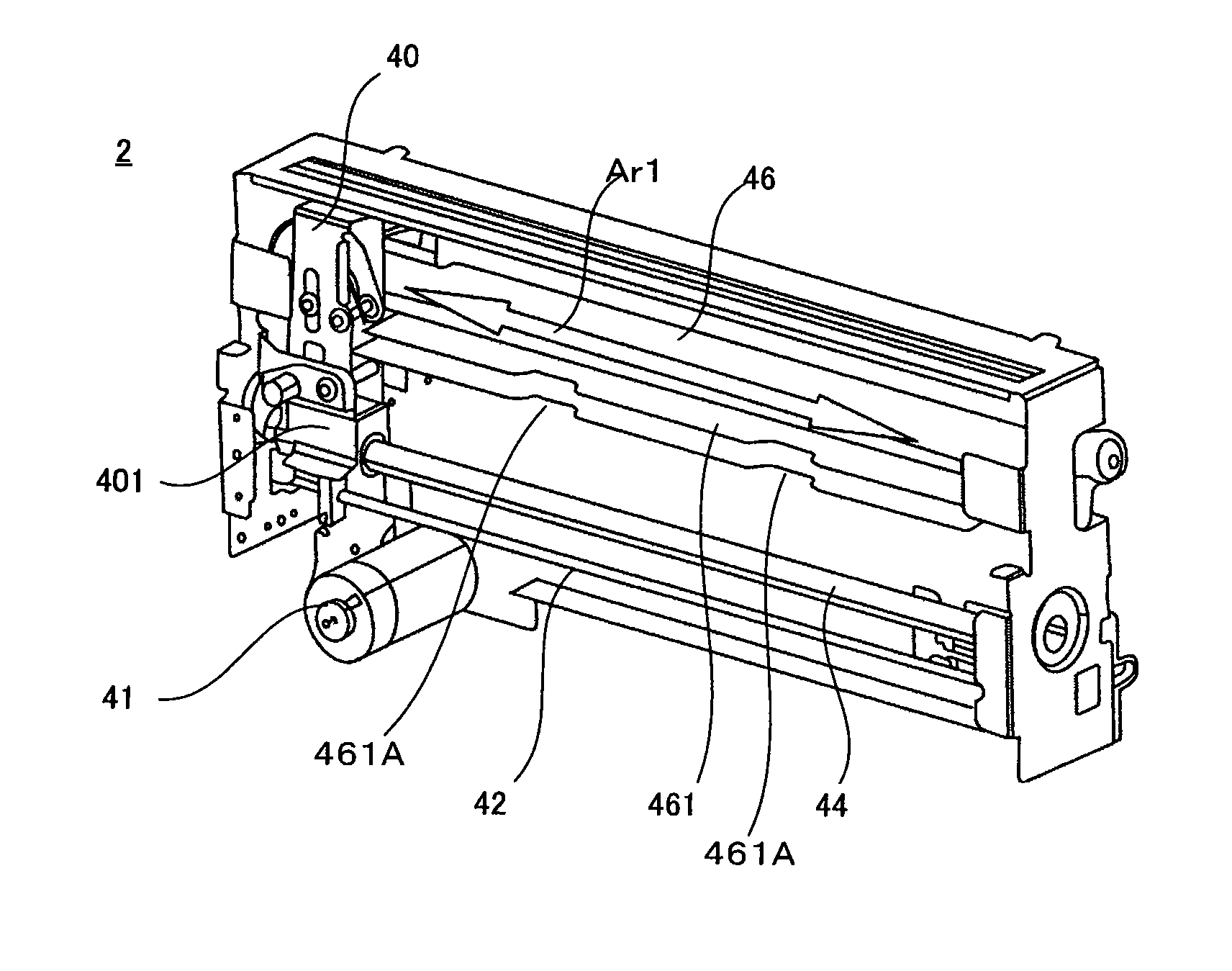

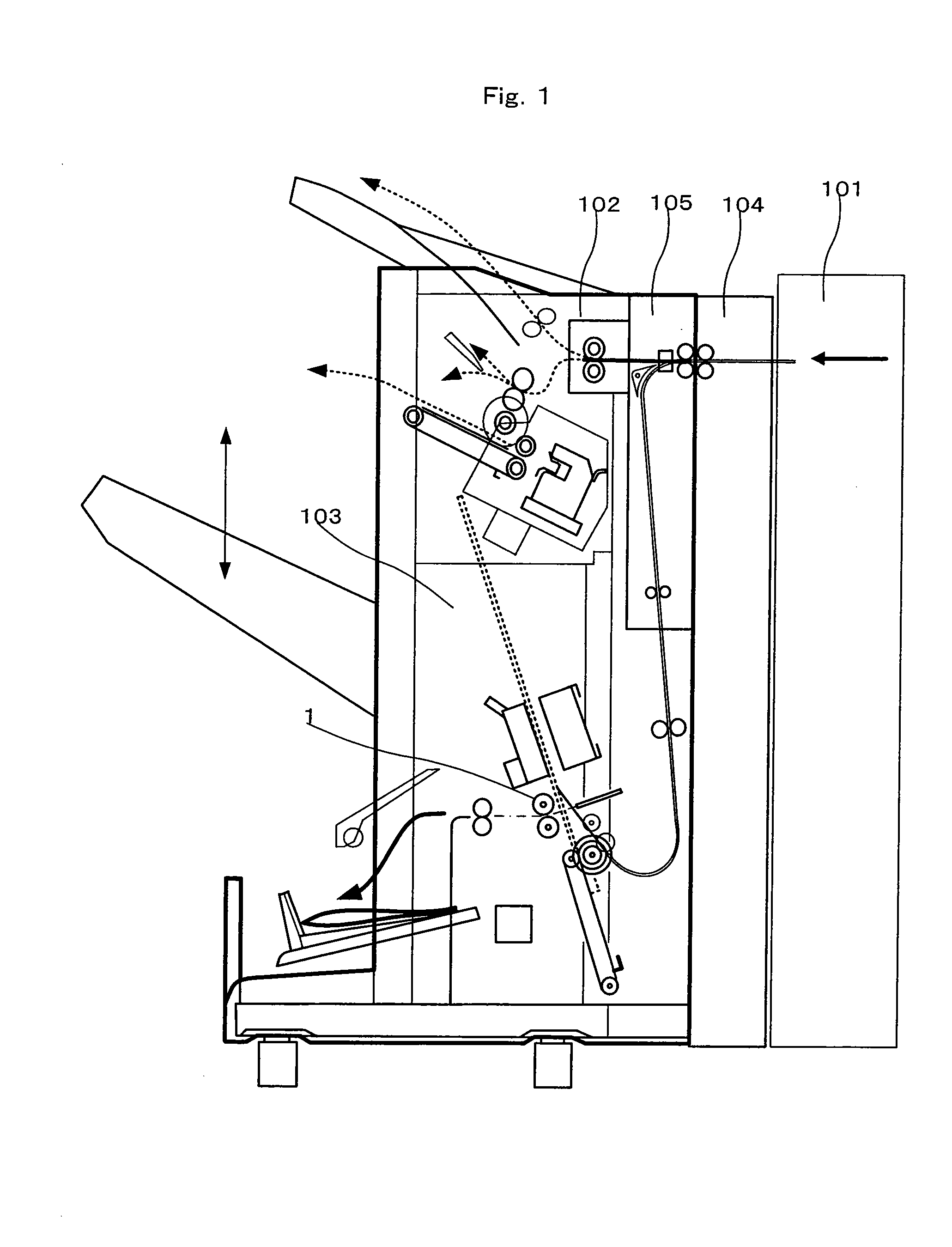

Sheet postprocessing apparatus for use with image forming apparatus and folding method

ActiveUS7052005B2Avoid damageImprove fold qualityMechanical working/deformationFolding thin materialsPunchingImage transfer

This invention relates to a sheet postprocessing apparatus for executing postprocessing including a punching process, folding process, binding process, and the like, midway along a sheet convey path, for sheets discharged from an image forming apparatus, and a folding method. This sheet postprocessing apparatus includes a sheet folding section having the first and second folding sections which are arranged in series in a sheet convey direction to execute folding processes for sheets. The sheet folding section is configured such that the first folding section performs the first folding process in a Z-fold process, the first folding process in an internal three-fold process, and a center folding process with an image-transferred surface facing outside, and the second folding section performs the second folding process in the Z-fold process, the second folding process in the internal three-fold process, and a center folding process with an image-transferred surface facing inside.

Owner:KONICA CORP

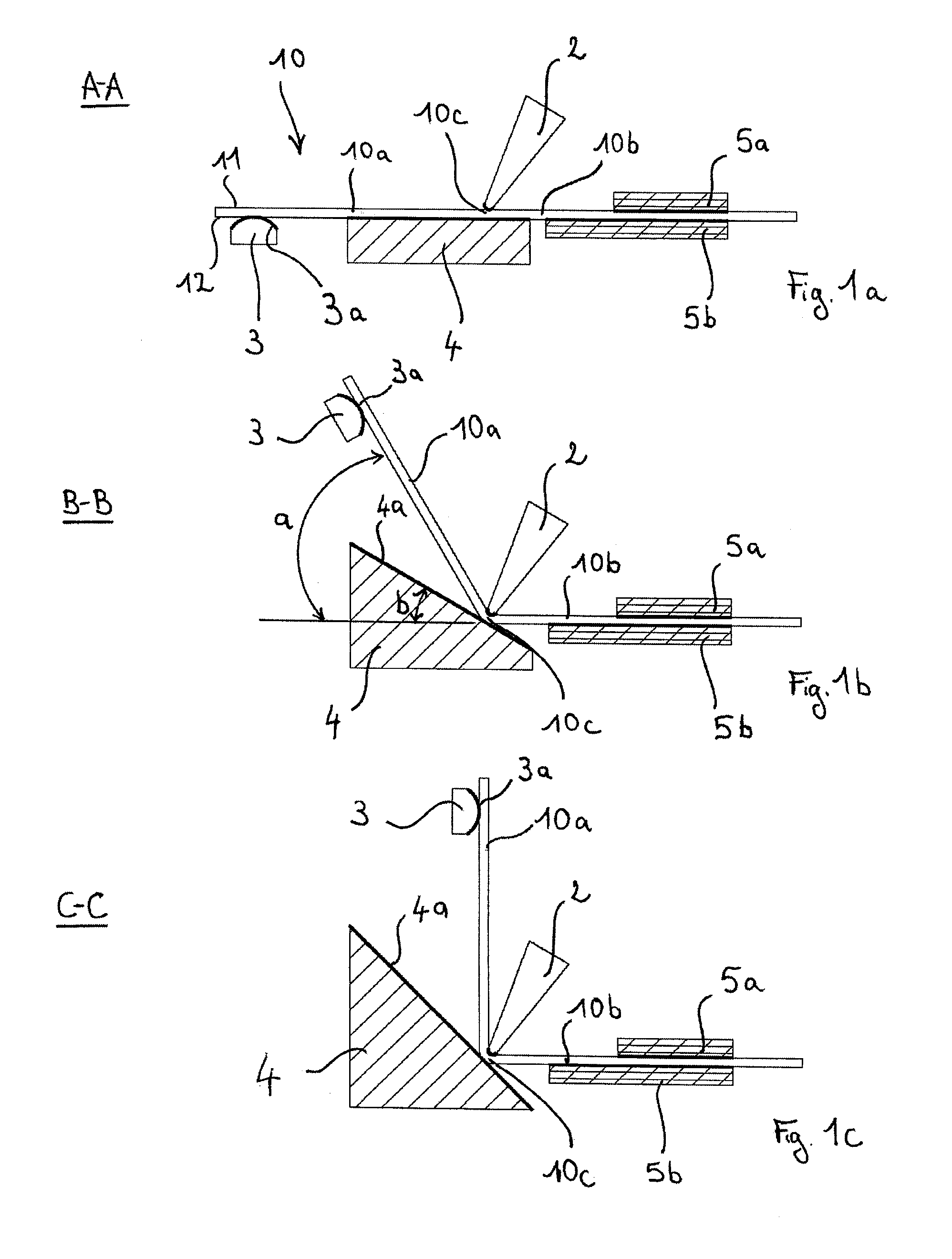

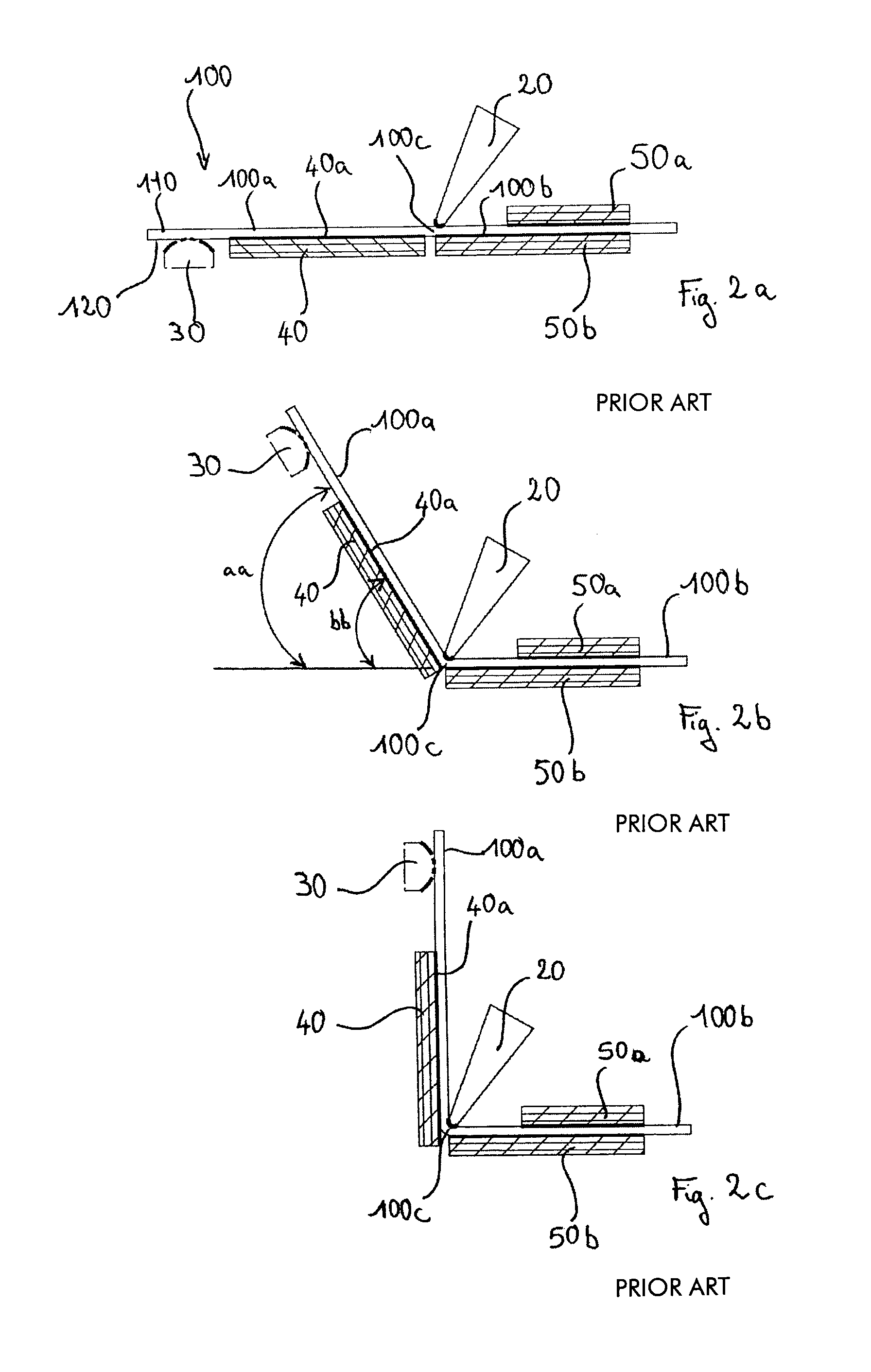

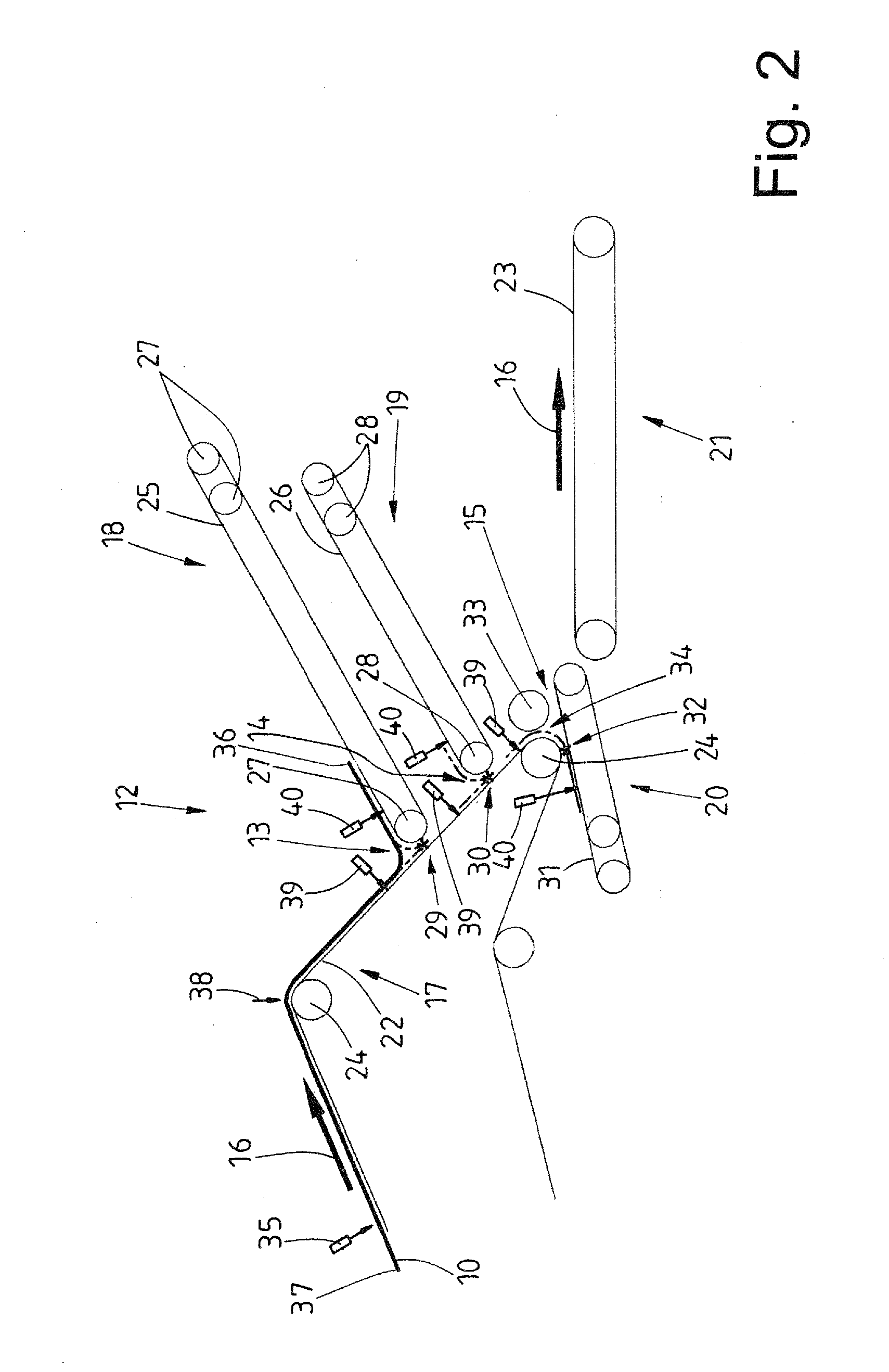

Folding device for a folding and gluing machine

ActiveUS7708679B2Stable characteristicsStable positionMechanical working/deformationBox making operationsEngineeringMechanical engineering

Owner:BOBST SA

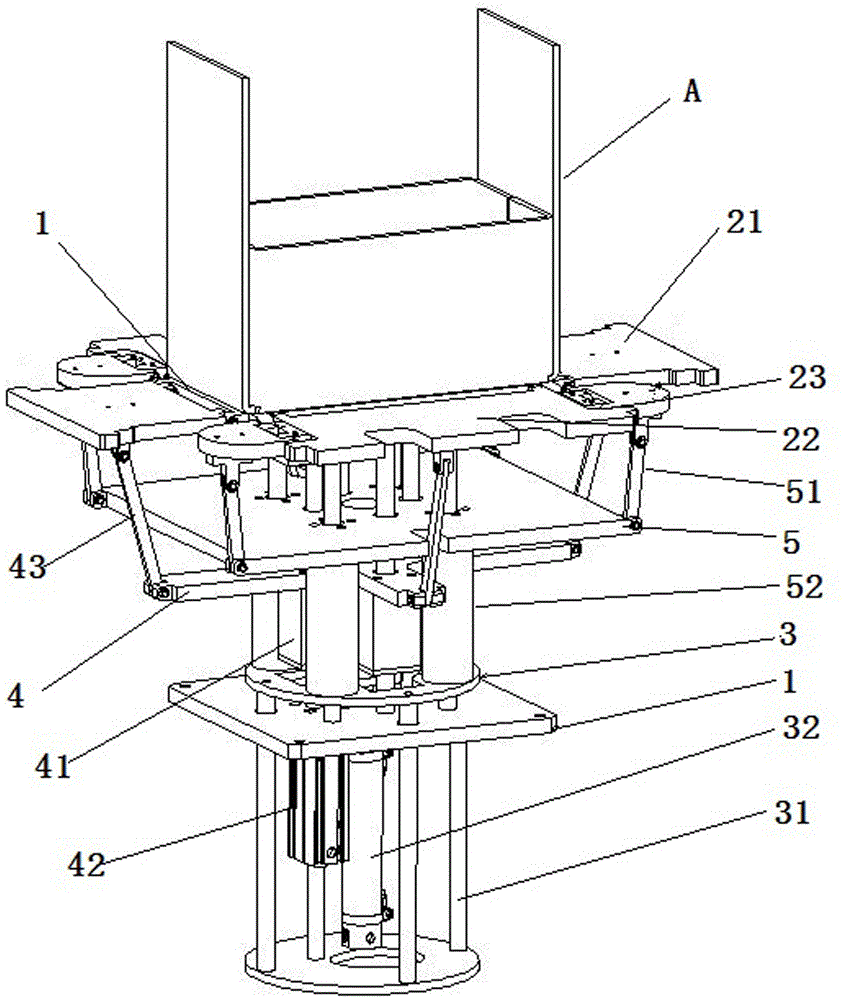

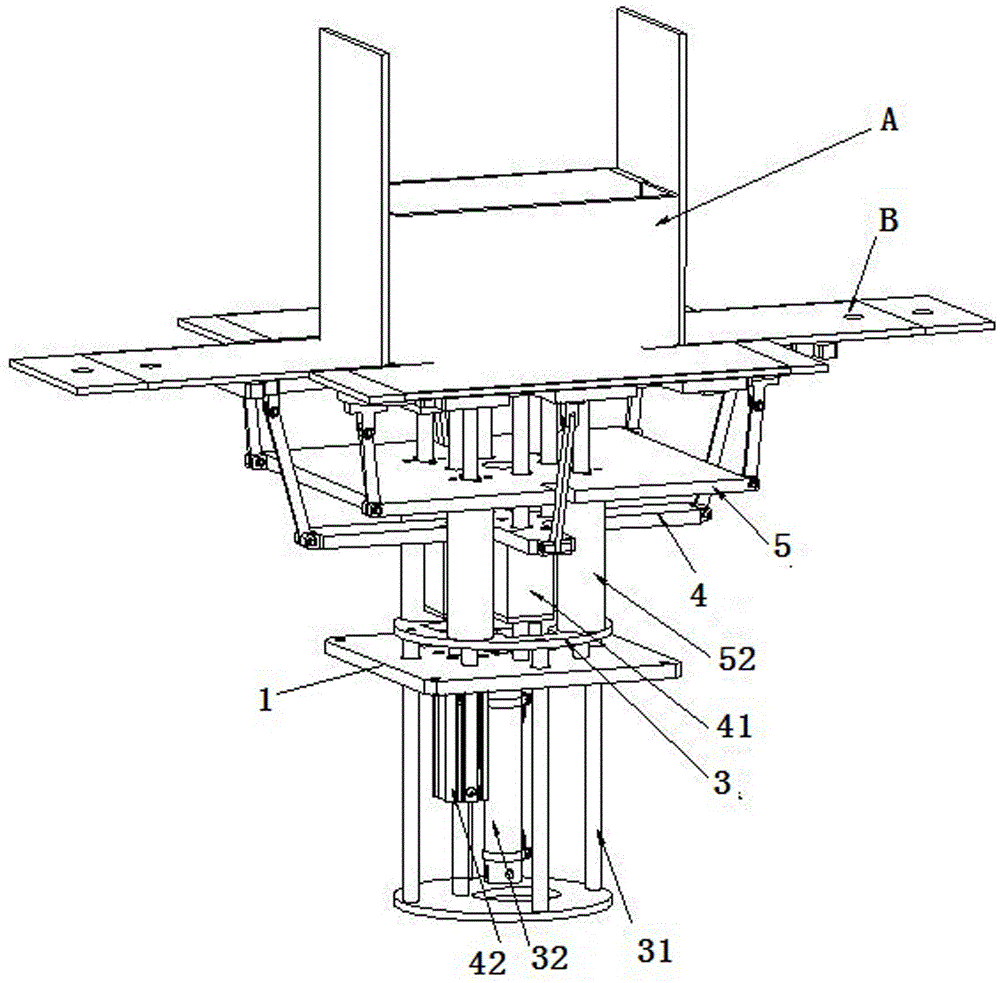

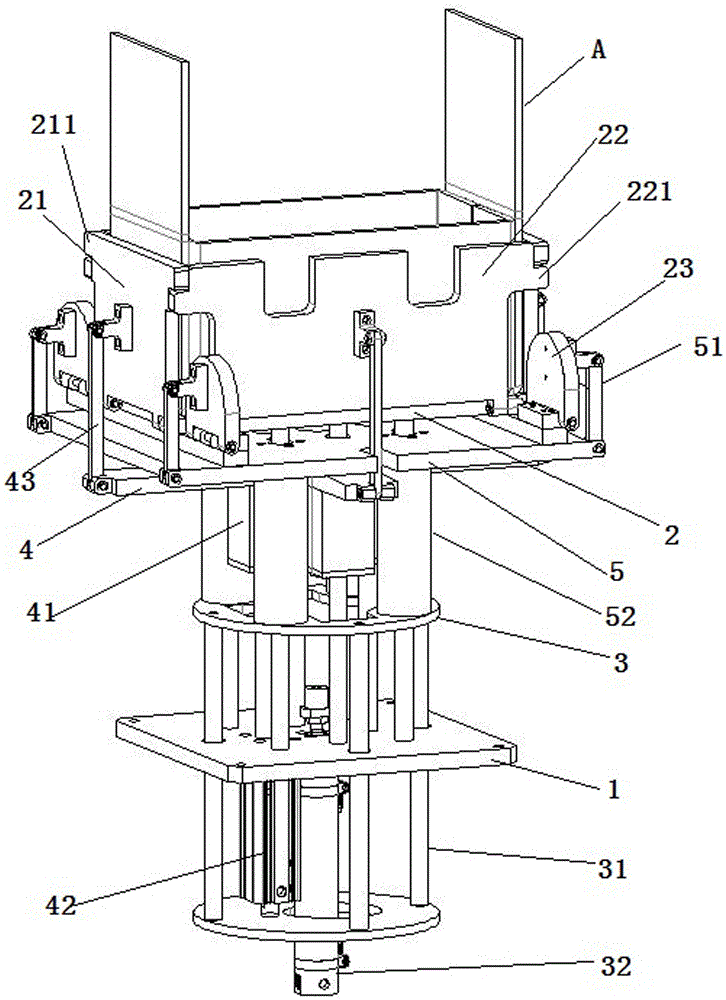

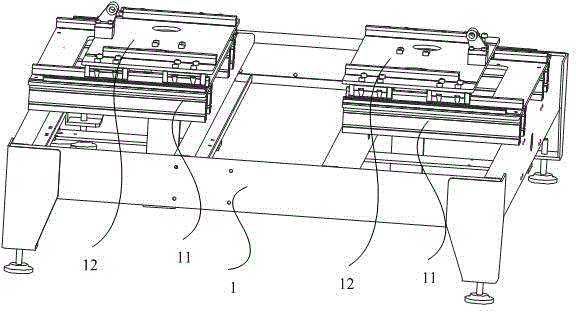

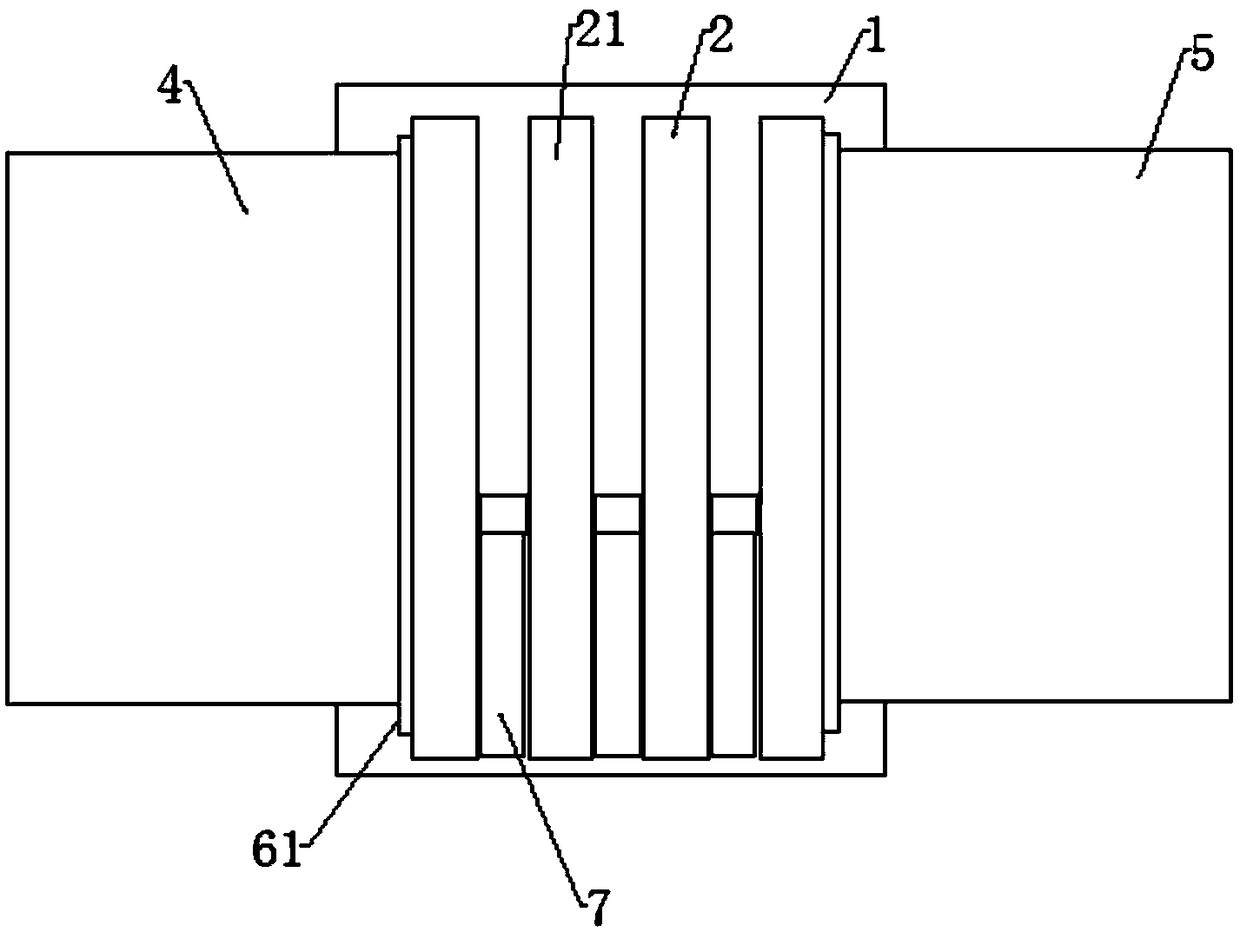

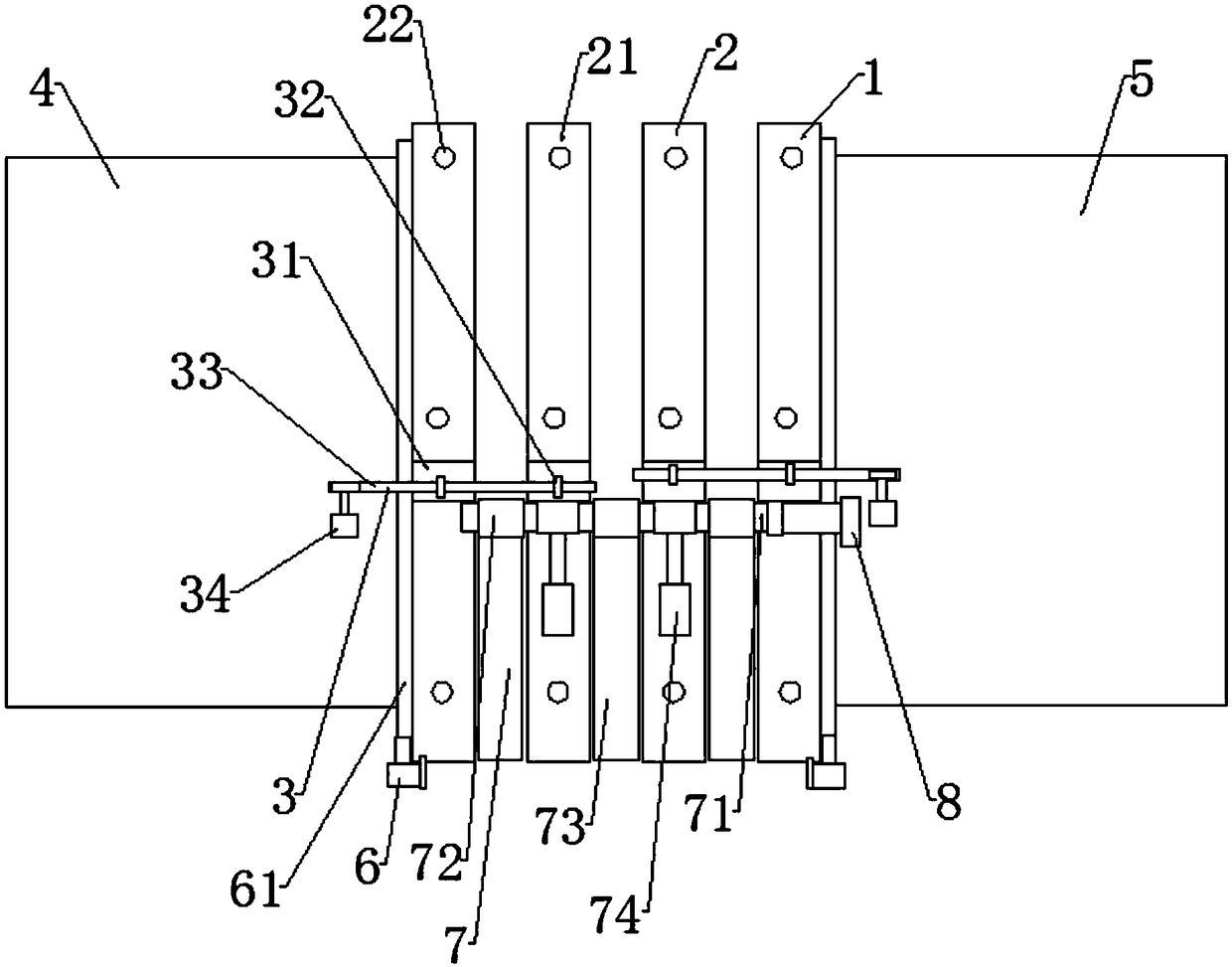

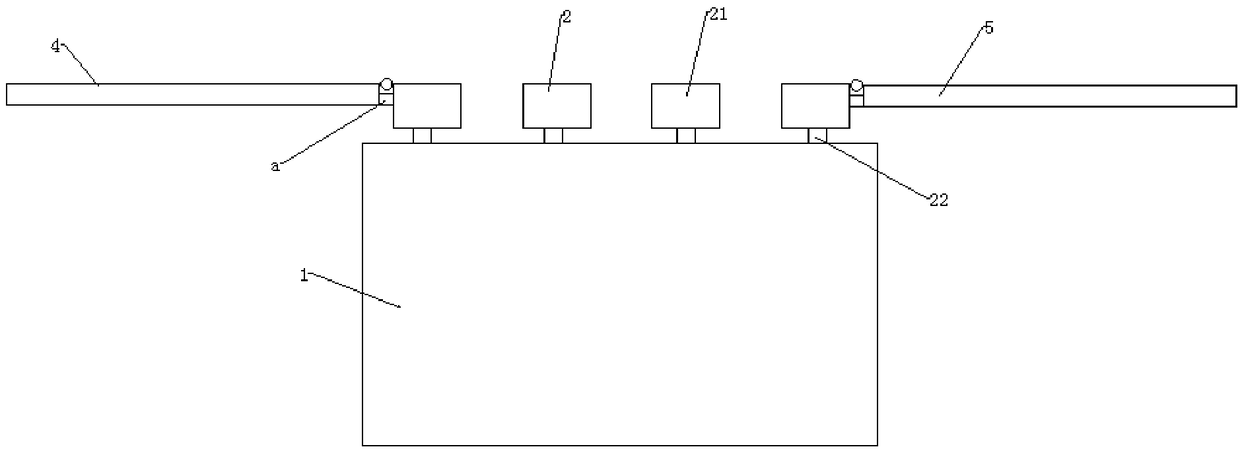

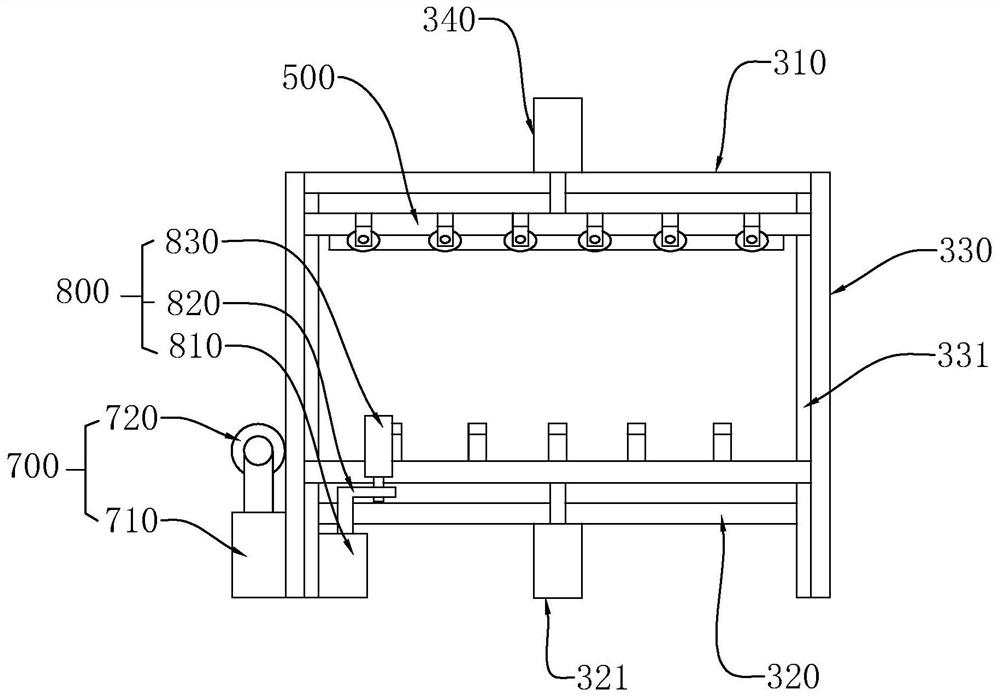

Box folding mechanism

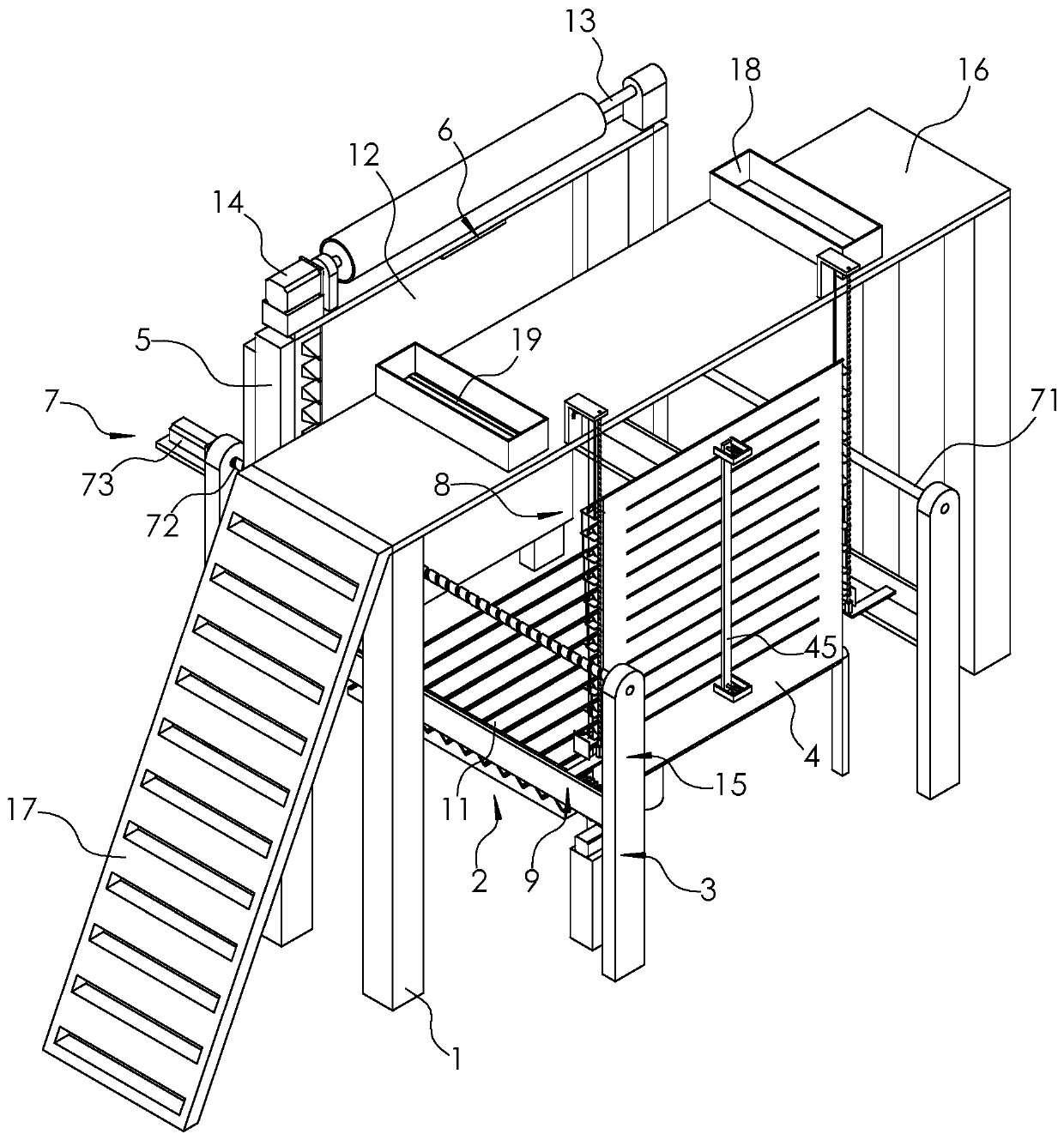

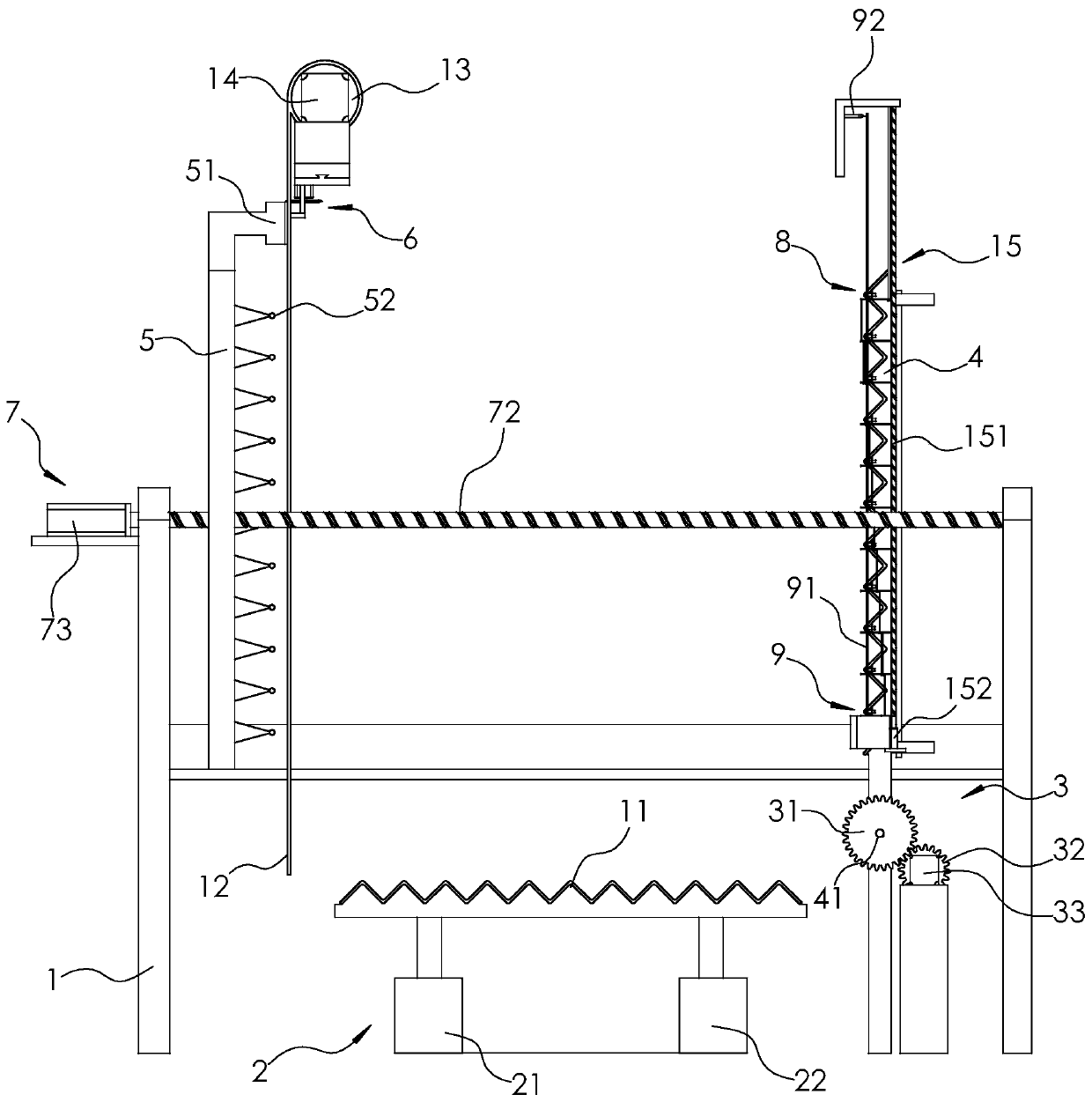

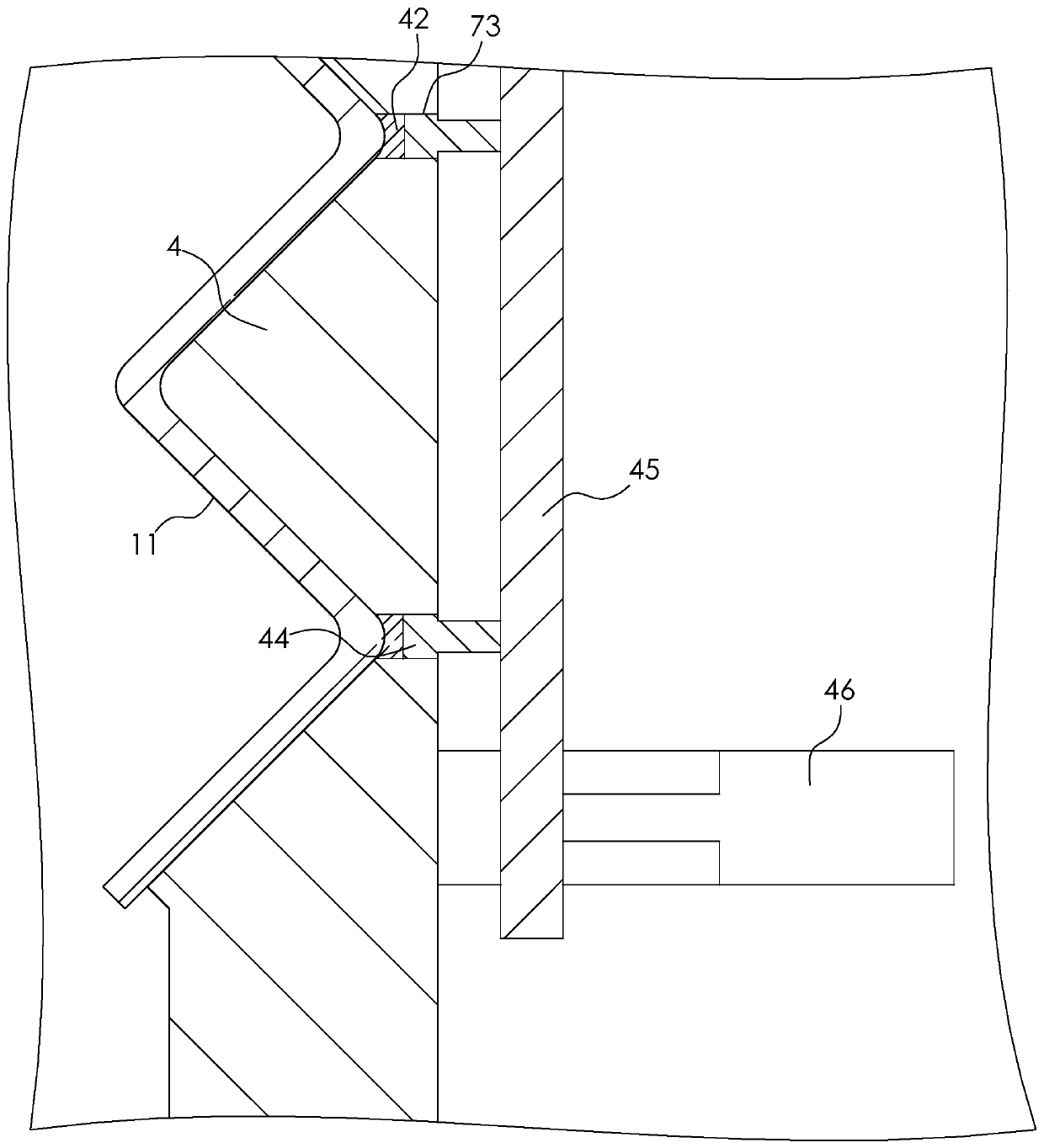

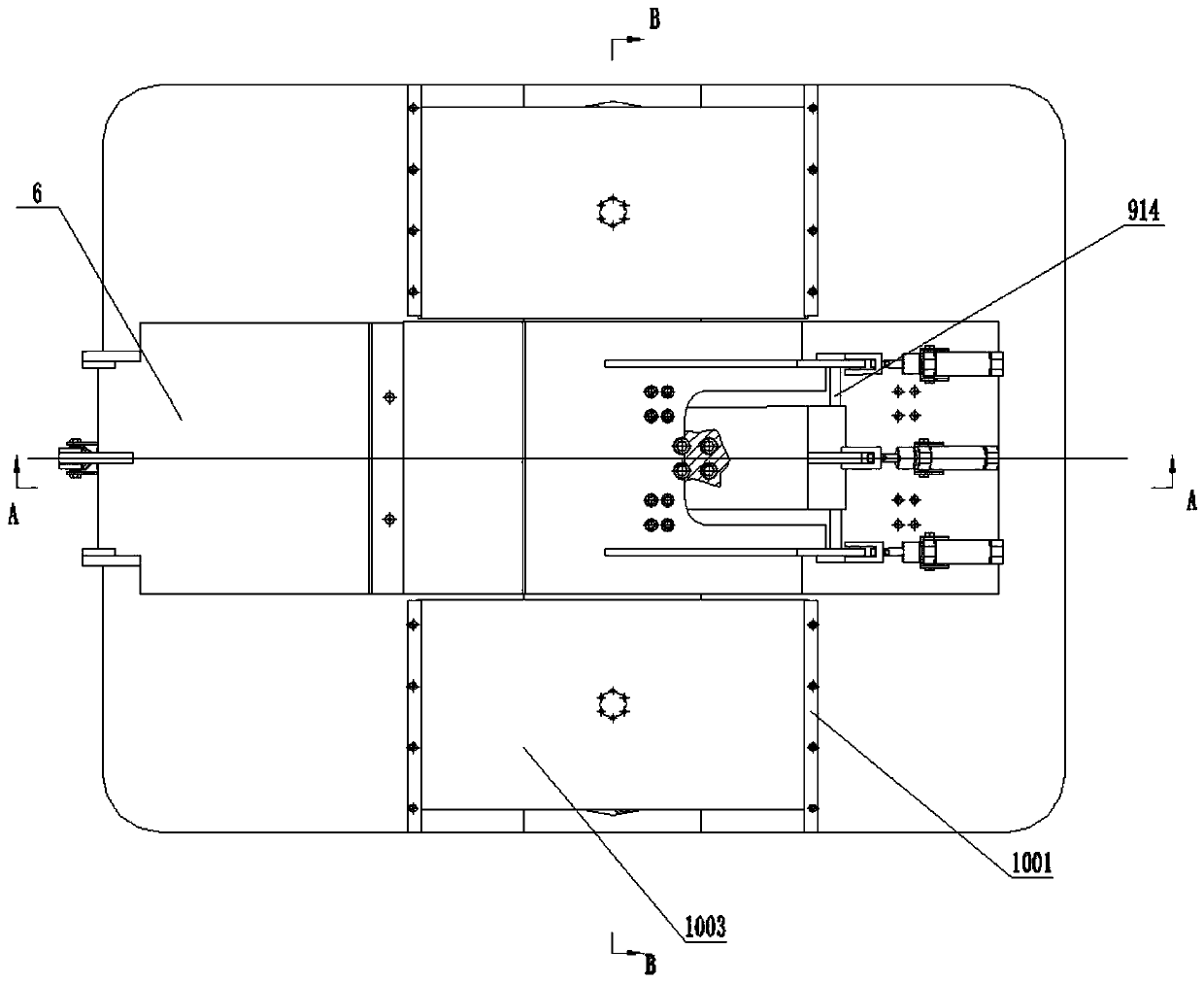

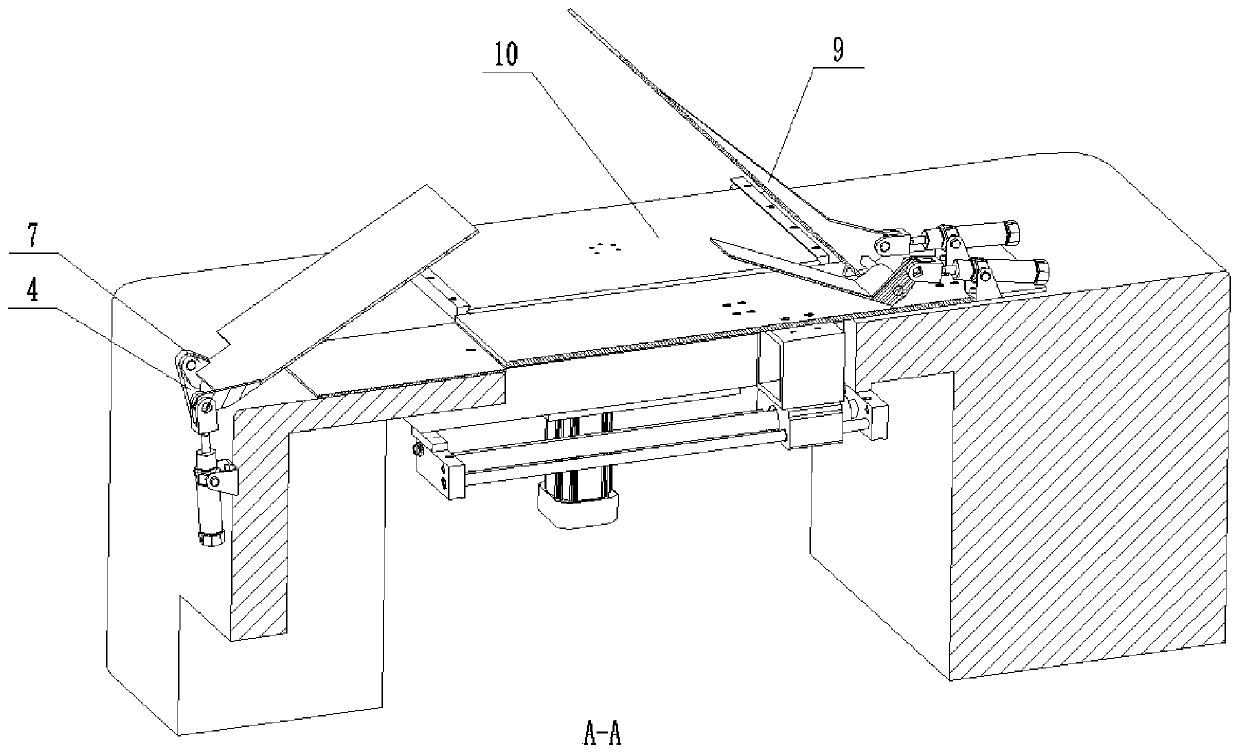

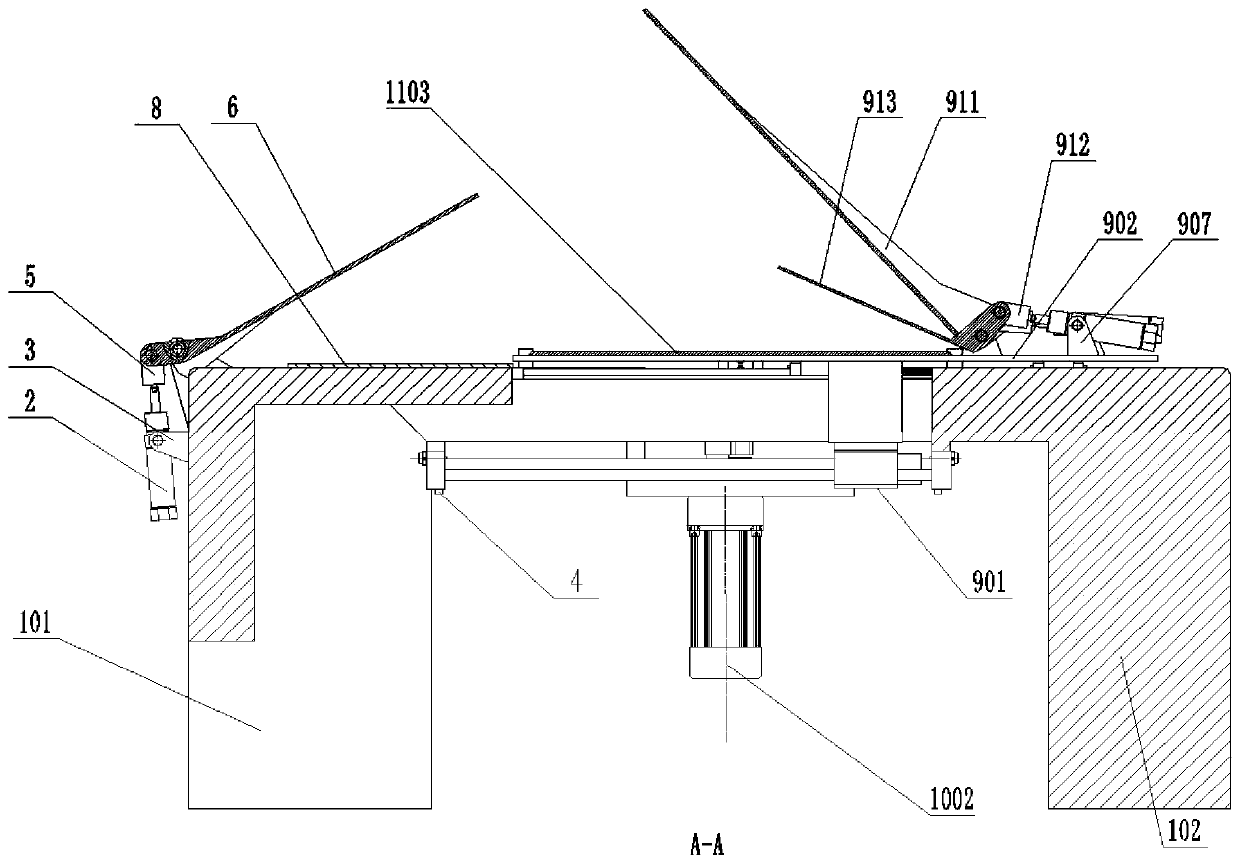

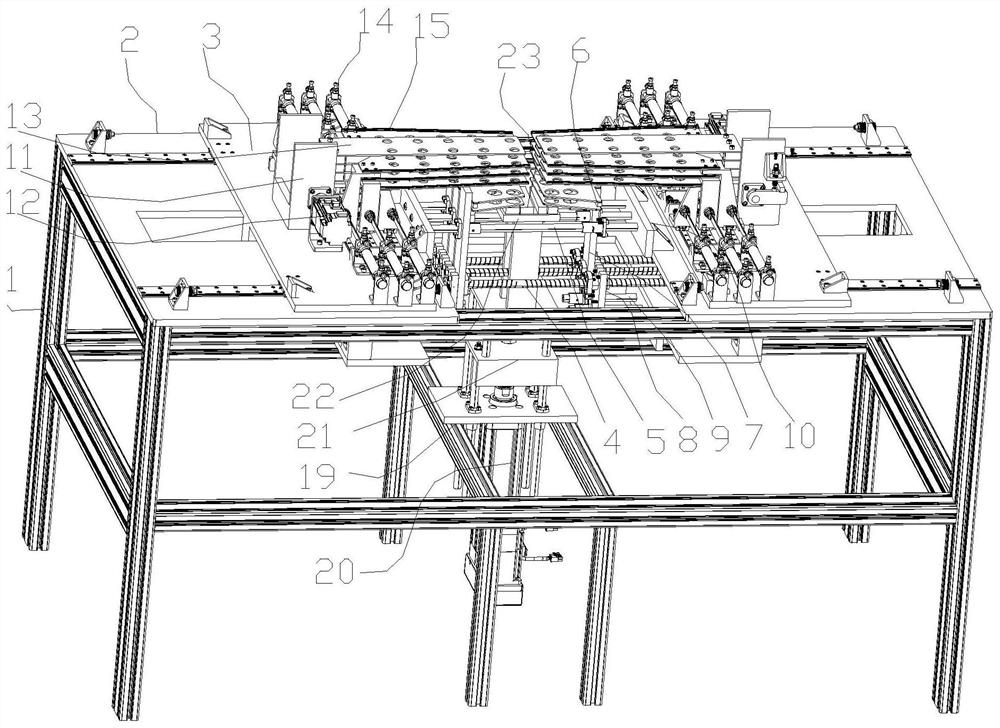

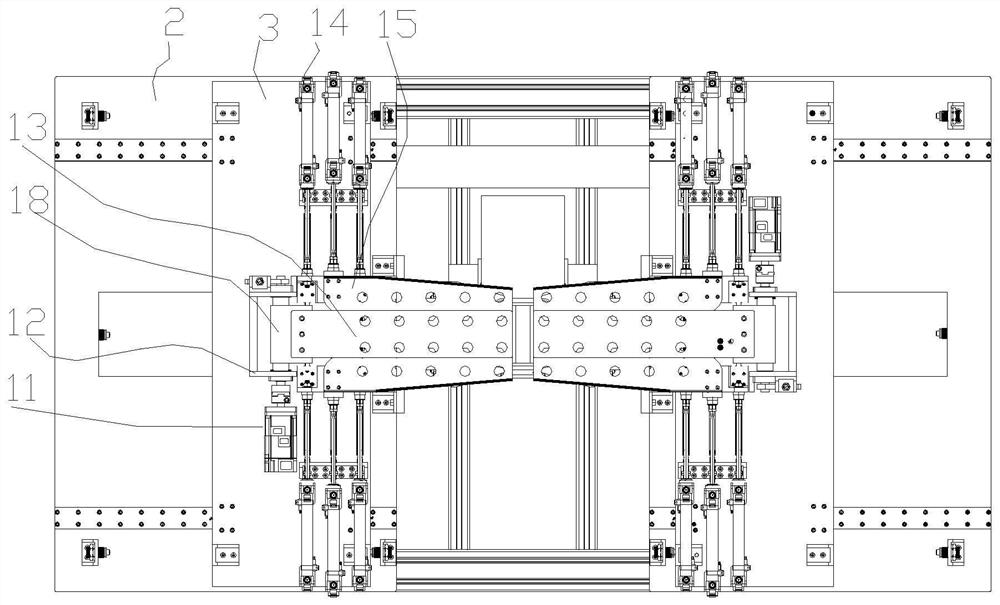

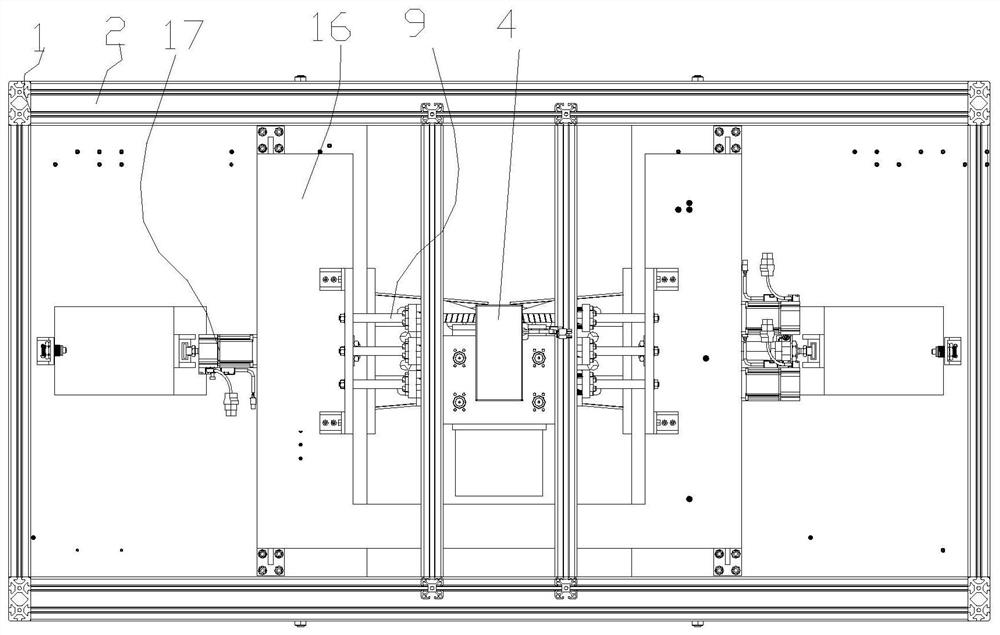

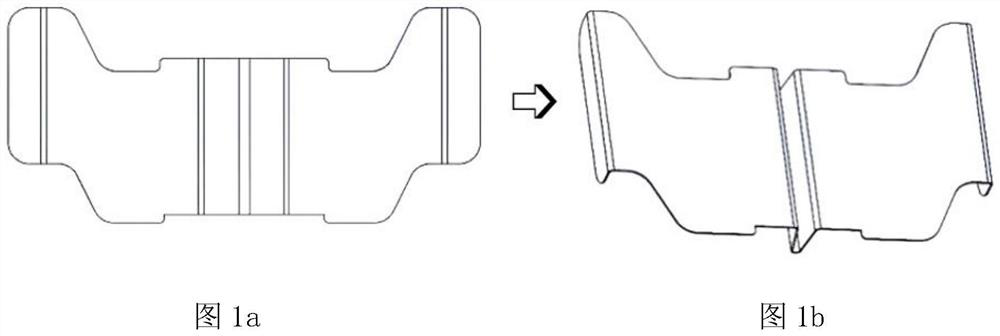

The invention relates to a box folding mechanism. The box folding mechanism comprises a rack, wherein a square folding platform is fixed on the rack, two groups of folding plates are separately hinged to two opposite sides of the folding platform, and ear folding plates are separately hinged to the rack at two opposite sides of one group of folding plates; a folding plate jacking mechanism and an ear folding plate jacking mechanism are separately arranged on the rack below the folding platform, the folding plates are movably connected with the folding plate jacking mechanism separately through links, and the ear folding plates are movably connected with the ear folding plate jacking mechanism separately through links, two pressing mechanisms are further arranged on the rack above the folding platform, one pressing mechanism is used for pressing ear folding parts of carton boards, and the other pressing mechanism is used for pressing carton boards parts, which do not need folding, located on the folding platform. According to the box folding mechanism, all corners of each cut planar carton board can be automatically folded as required according to box folding requirements. The folding efficiency is high, the folding quality is high, and the space occupied by the box folding mechanism is small.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

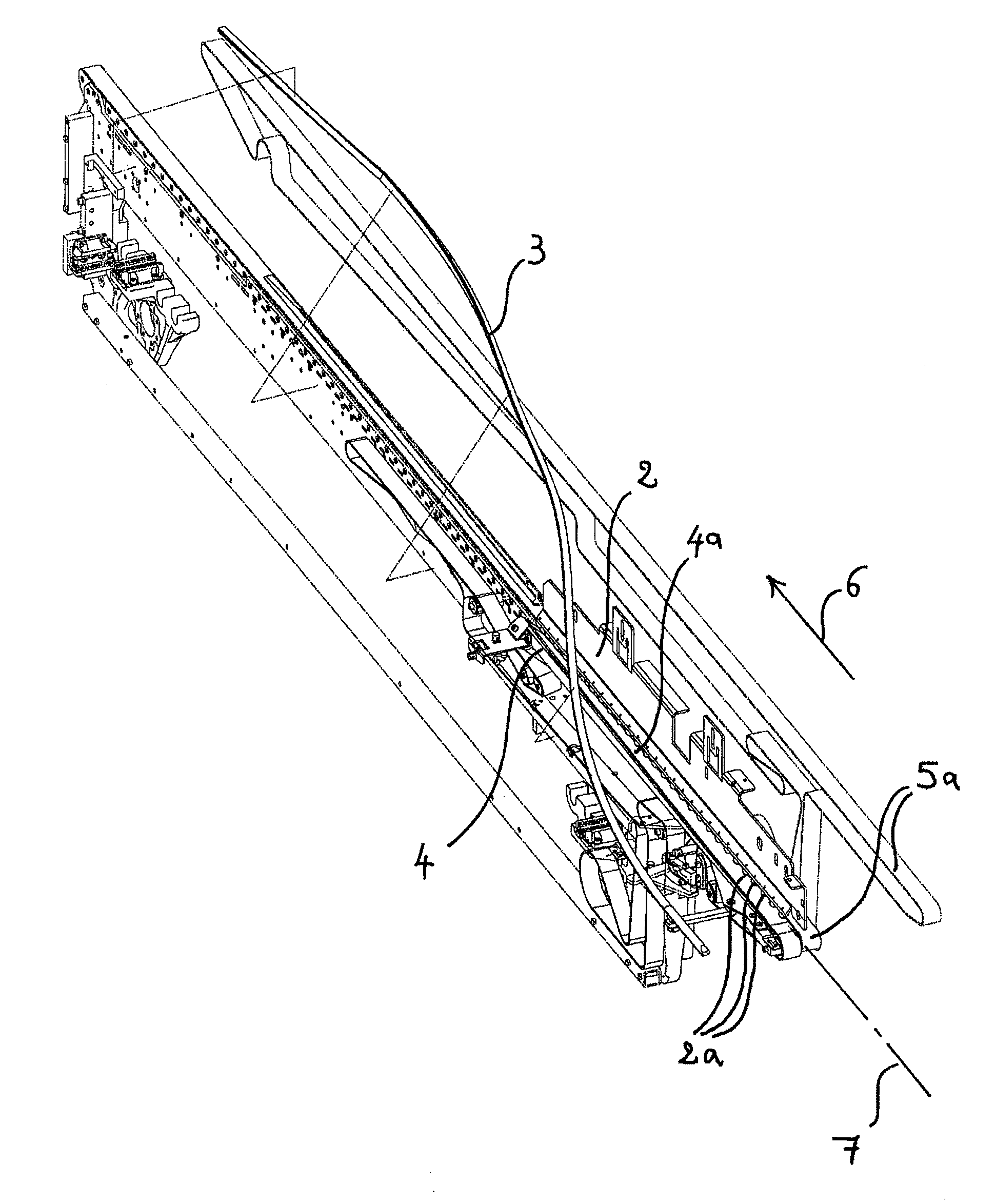

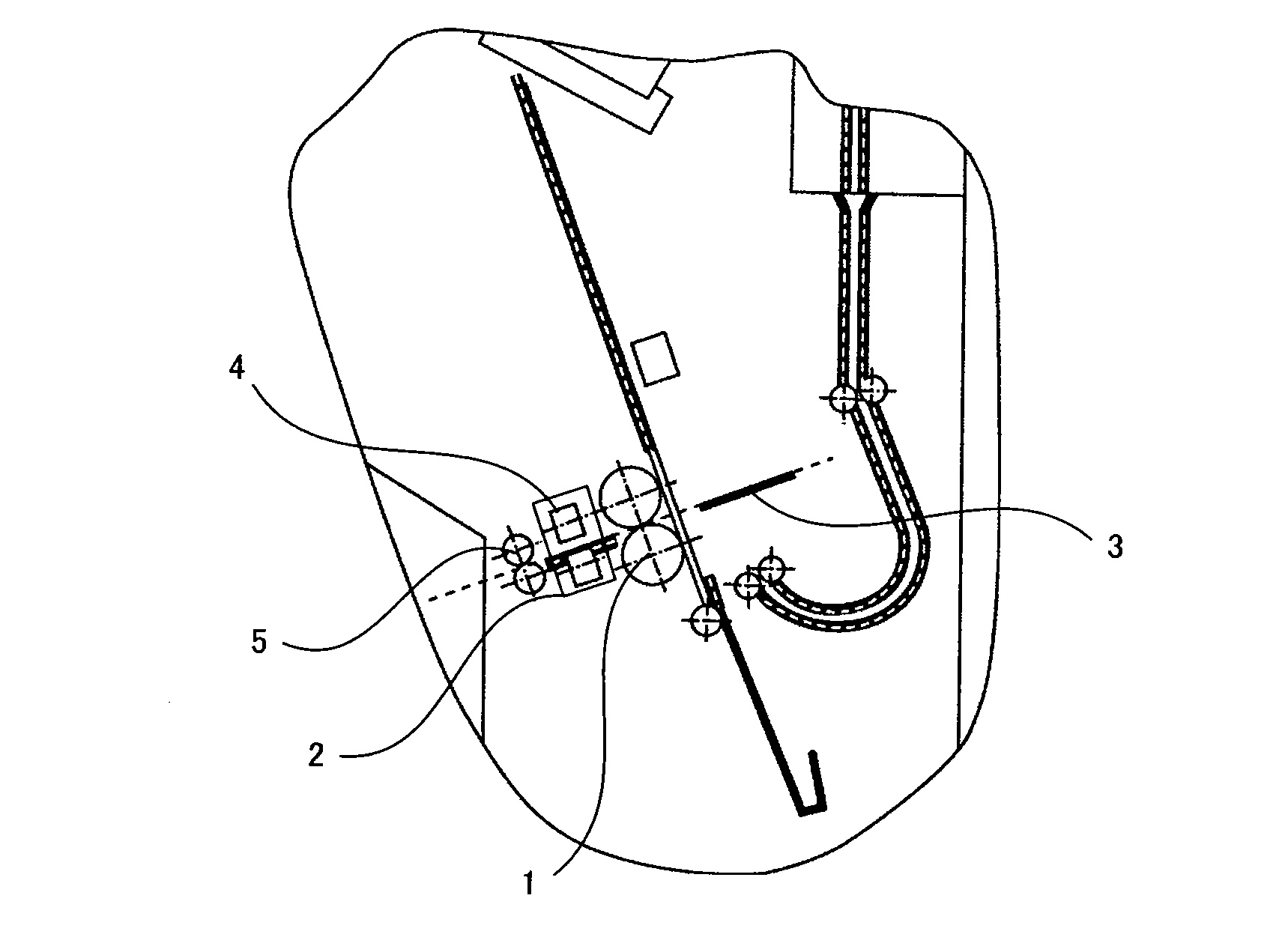

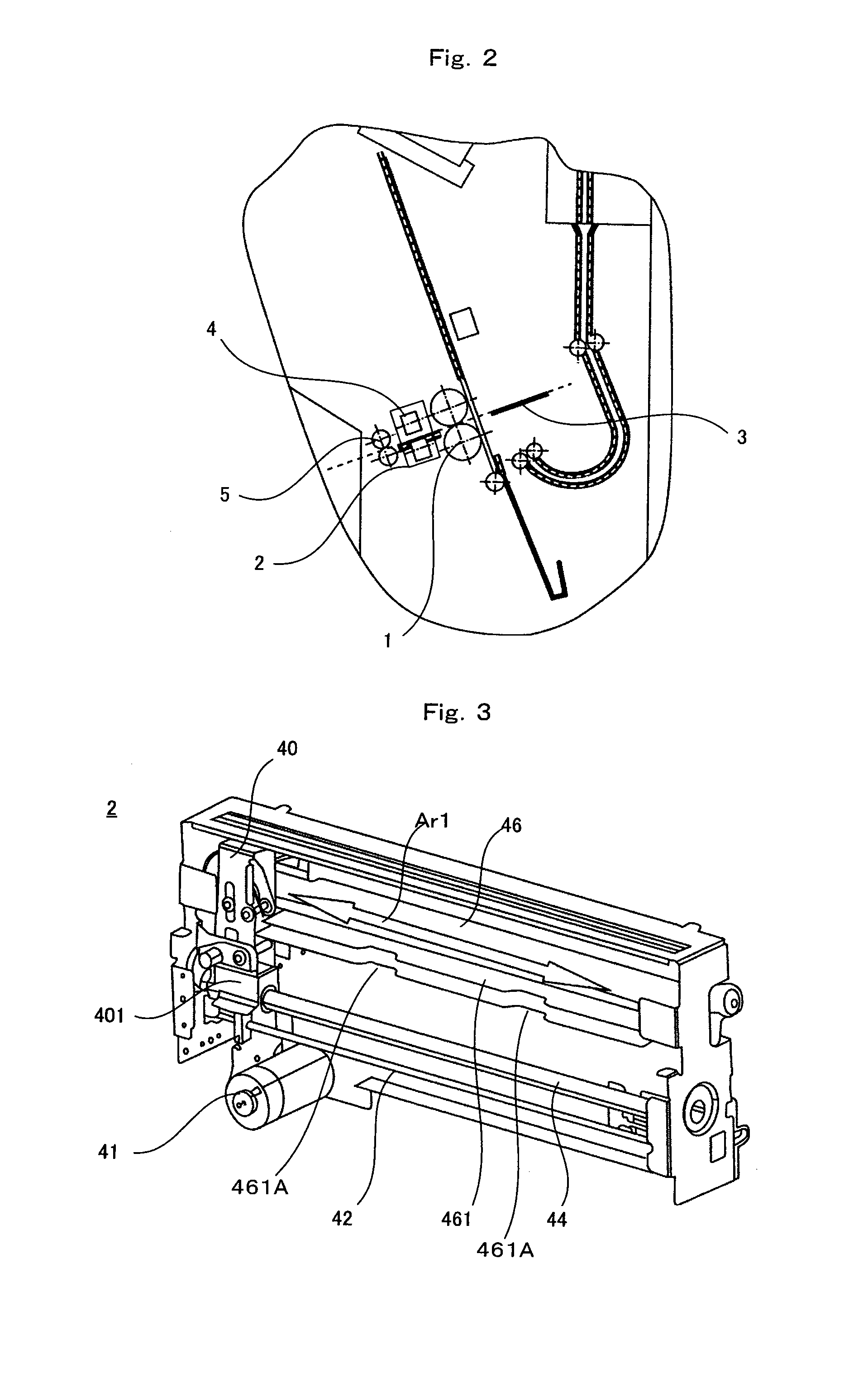

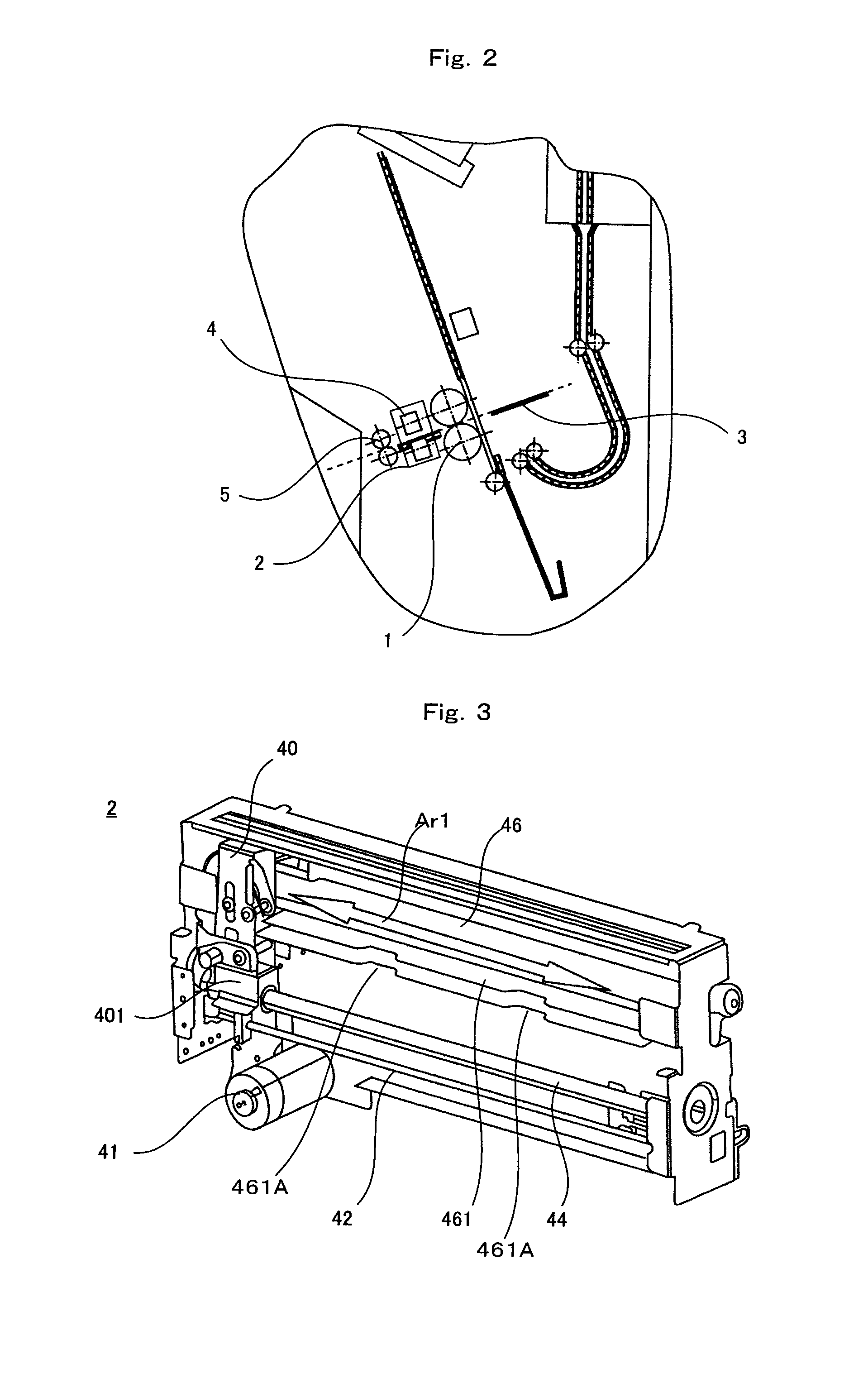

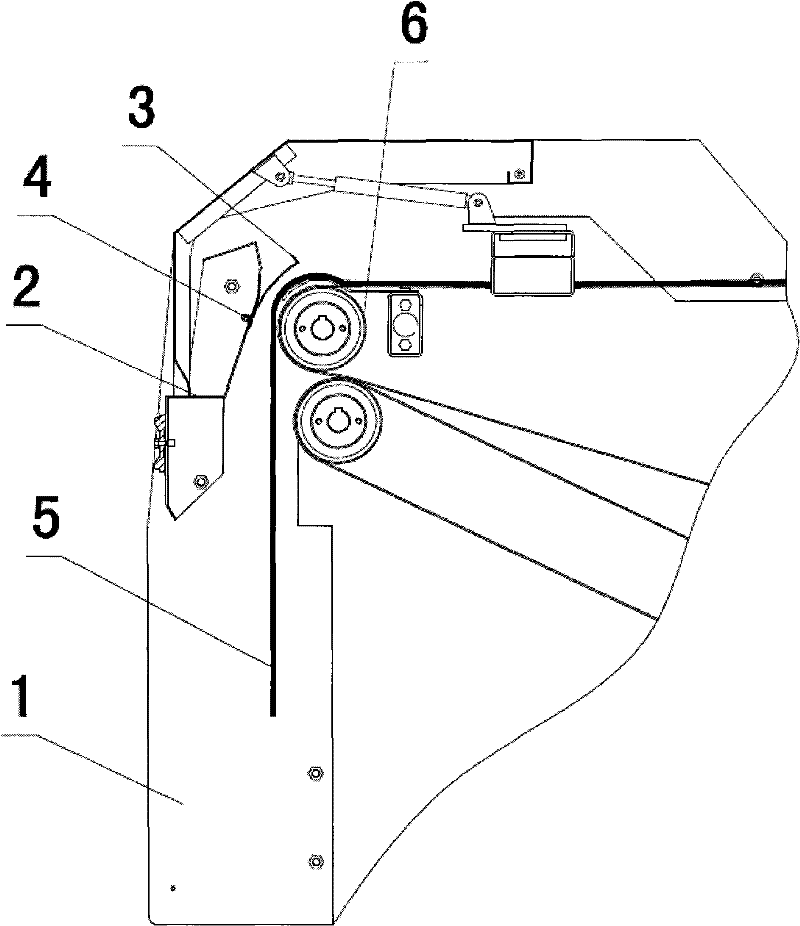

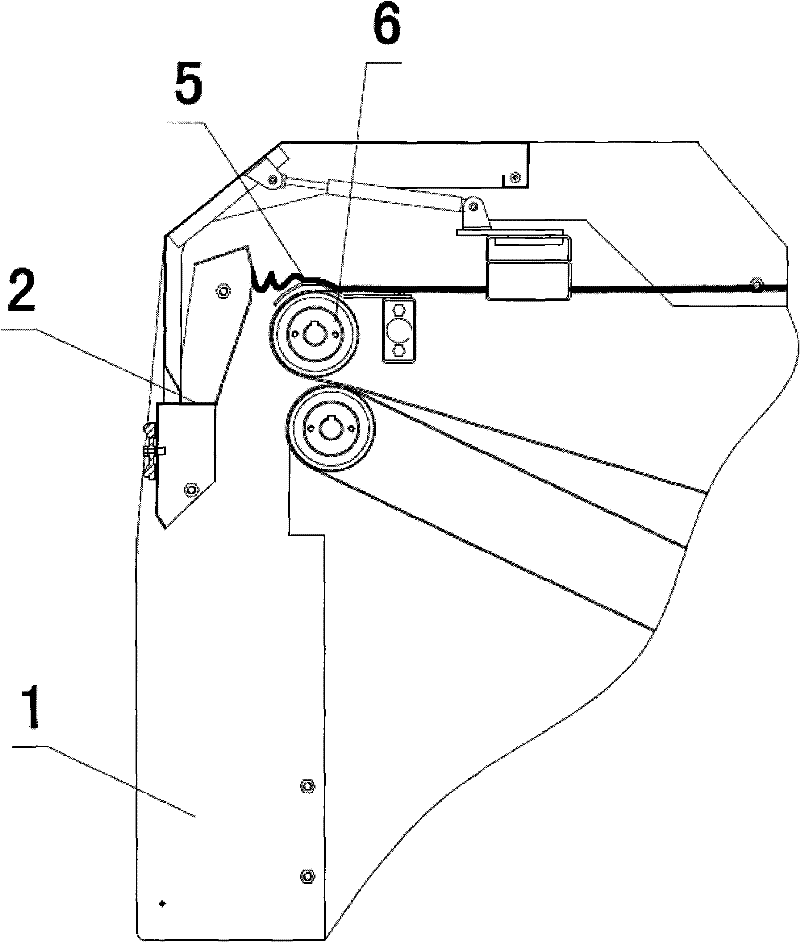

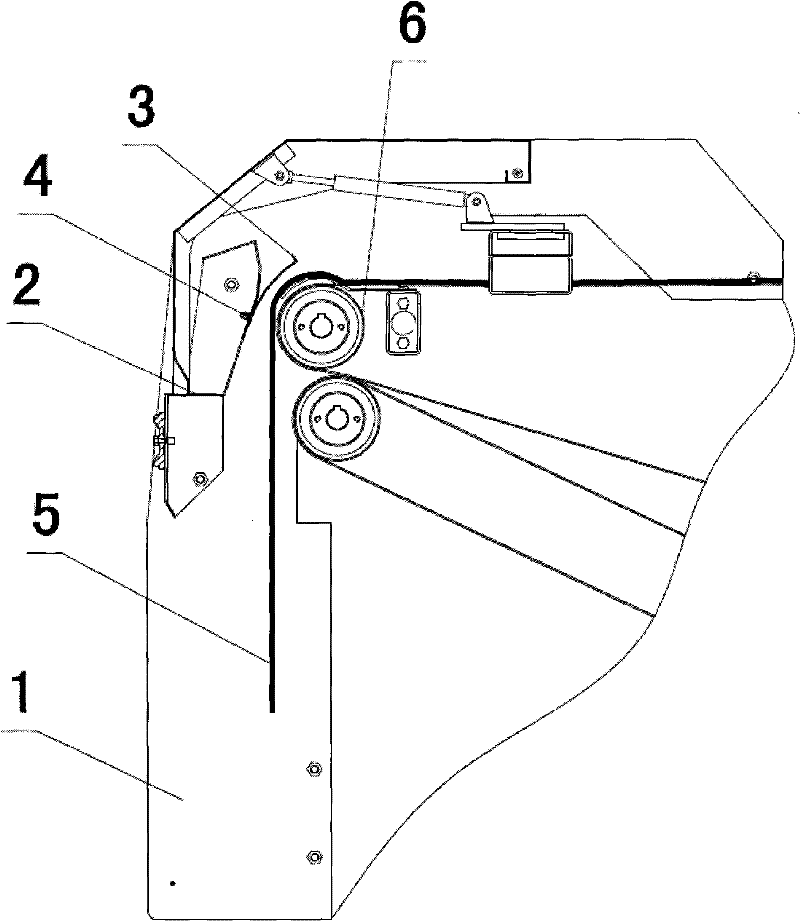

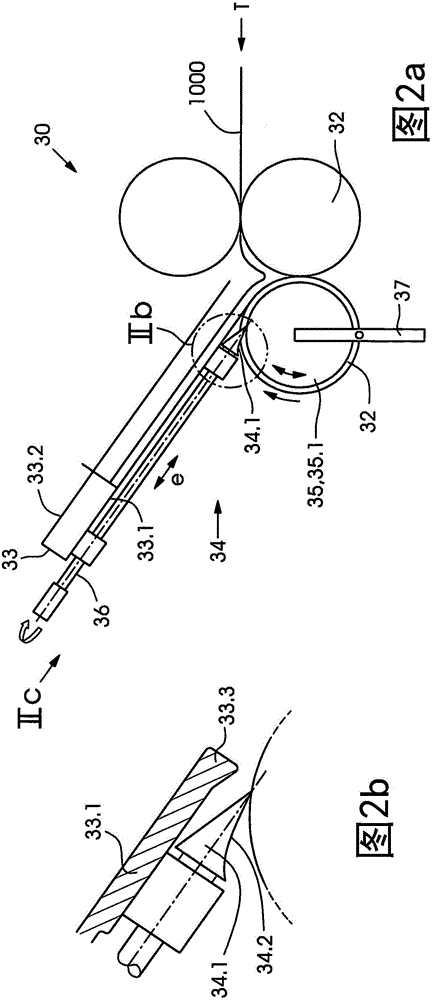

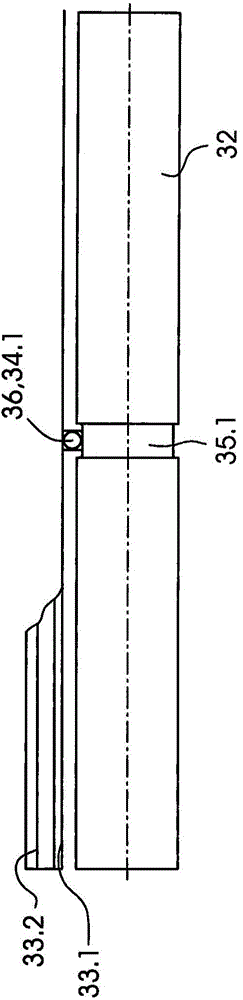

Method of folding in the middle and sheet post-processing apparatus provided with saddle unit

ActiveUS20090036287A1Improve accuracyEnhancing the folded of the sheetsMechanical working/deformationFolding thin materialsEngineeringPersonal computer

A saddle unit provided with a fold-enhancing unit for performing fold enhancement of sheets of paper folded in the middle. The fold-enhancing unit includes a fold-enhancing roller mechanism which performs the fold-enhancing operation in the direction orthogonal to the sheet carrying direction. The fold-enhancing roller mechanism includes a fold-enhancing roller pair that pinches and presses a bundle of sheets at a nip. The roller guide pair provided in the fold-enhancing roller mechanism guides the sheets of paper to the nip of the fold-enhancing roller pair when enhancing the fold of the sheets of paper. The saddle unit changes one or both of the number of times and the velocity of the reciprocating movement according to one or both of the number of sheets of paper and the quality mode which is entered and set by the user from the operation panel of an image forming apparatus or job-set by the personal computer by a user.

Owner:KK TOSHIBA +1

Method of folding in the middle and sheet post-processing apparatus provided with saddle unit

ActiveUS8002255B2Improve accuracyEnhancing the folded of the sheetsMechanical working/deformationFolding thin materialsReciprocating motionPersonal computer

A saddle unit provided with a fold-enhancing unit for performing fold enhancement of sheets of paper folded in the middle. The fold-enhancing unit includes a fold-enhancing roller mechanism which performs the fold-enhancing operation in the direction orthogonal to the sheet carrying direction. The fold-enhancing roller mechanism includes a fold-enhancing roller pair that pinches and presses a bundle of sheets at a nip. The roller guide pair provided in the fold-enhancing roller mechanism guides the sheets of paper to the nip of the fold-enhancing roller pair when enhancing the fold of the sheets of paper. The saddle unit changes one or both of the number of times and the velocity of the reciprocating movement according to one or both of the number of sheets of paper and the quality mode which is entered and set by the user from the operation panel of an image forming apparatus or job-set by the personal computer by a user.

Owner:KK TOSHIBA +1

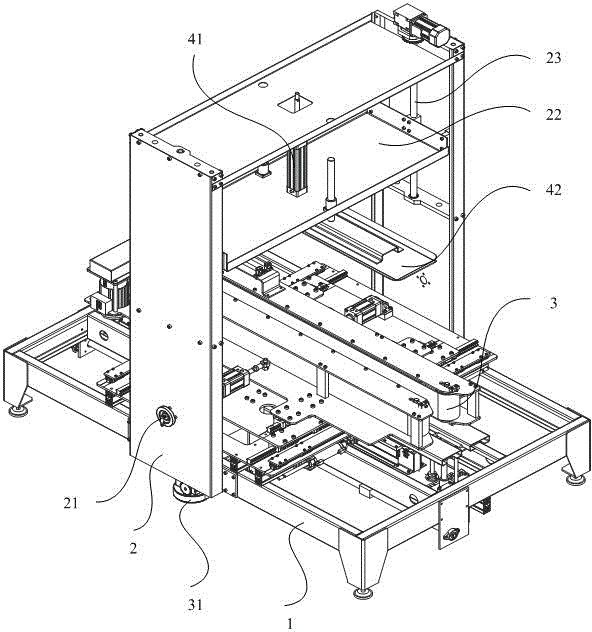

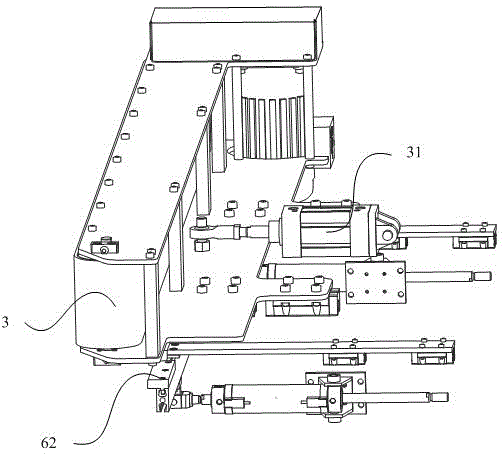

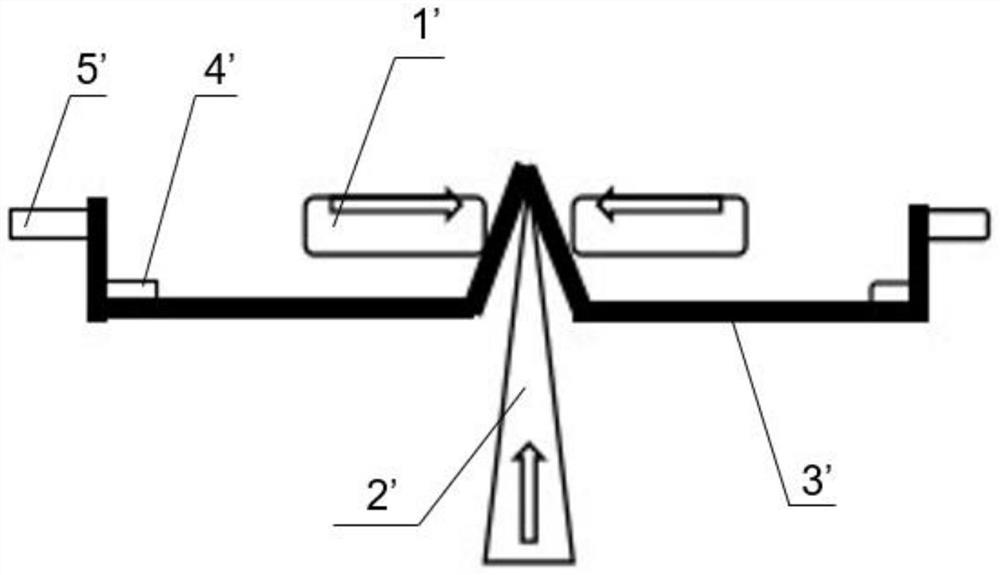

Automatic bottom folding equipment for packing case

ActiveCN104909007AReduce packaging costsImprove packaging efficiencyPackagingPiston rodSupport plane

The invention provides automatic bottom folding equipment for a packing case. The automatic bottom folding equipment comprises a foundation bed, a supporting frame, a press-down system, a jack-up system and a bottom folding system, wherein the supporting frame is fixed on the foundation bed; the press-down system is arranged on the upper part of the supporting frame; the jack-up system is positioned below the press-down system and arranged on the foundation bed; the press-down system comprises a press-down air cylinder and a press-down plate; the press-down plate is fixed on a piston rod of the press-down air cylinder; a cylinder body of the press-down air cylinder is arranged on the supporting frame; the jack-up system comprises a mounting bracket, two side supporting plates, a middle supporting plate and two side supporting plates; the bottom folding system comprises long swing cover pushing plates and short swing cover pushing plates; the long swing cover pushing plates are provided with long swing cover air cylinders; the short swing cover pushing plates are provided with short swing cover air cylinders; the long swing cover pushing plates are arranged below a longitudinal conveyor belt; and the short swing cover pushing plates arranged at the outer sides of the side supporting plates. By adopting the automatic bottom folding equipment for the packing case, the packing cost of the display equipment is reduced and the packing efficiency is improved.

Owner:HISENSE VISUAL TECH CO LTD

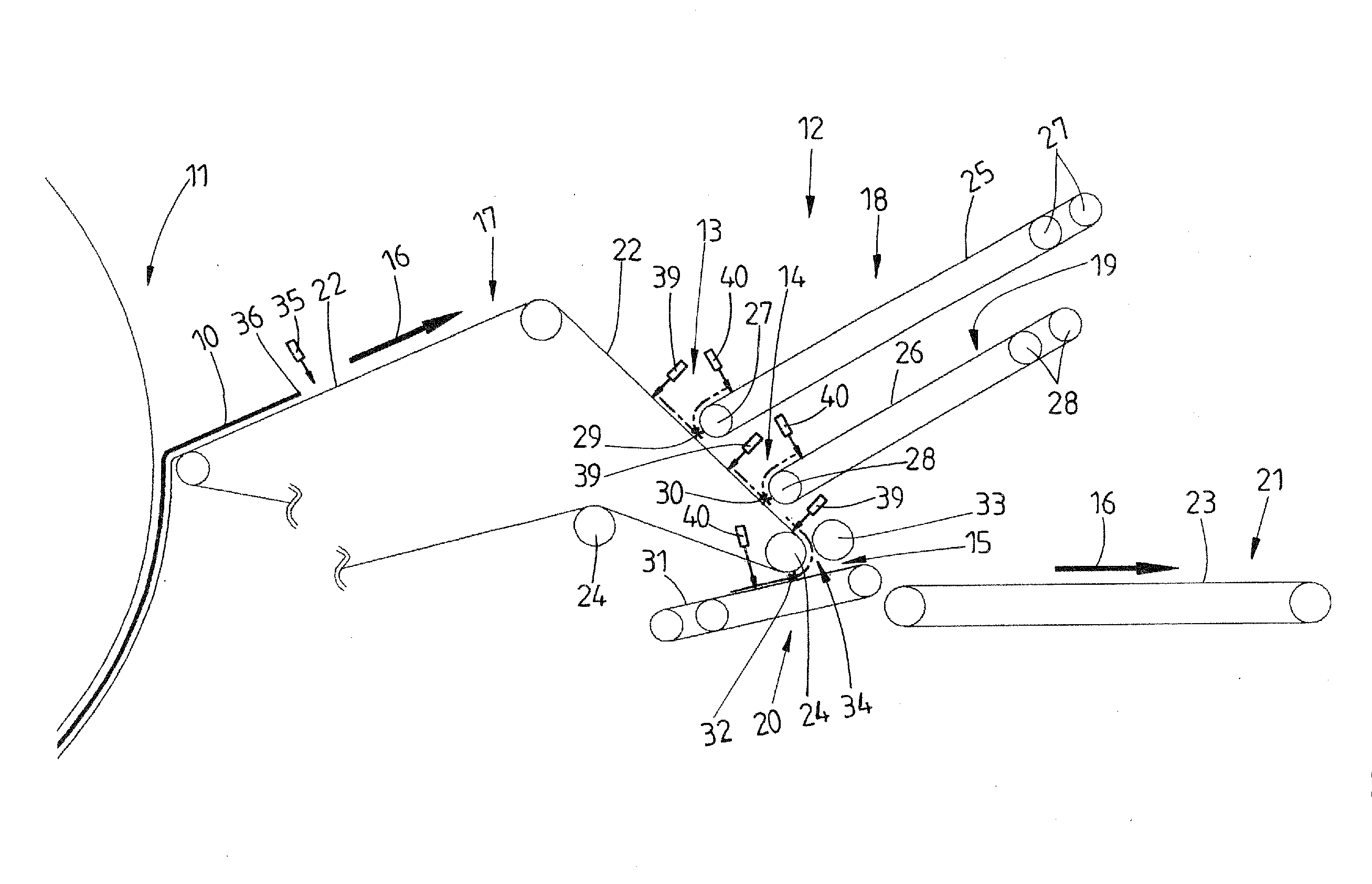

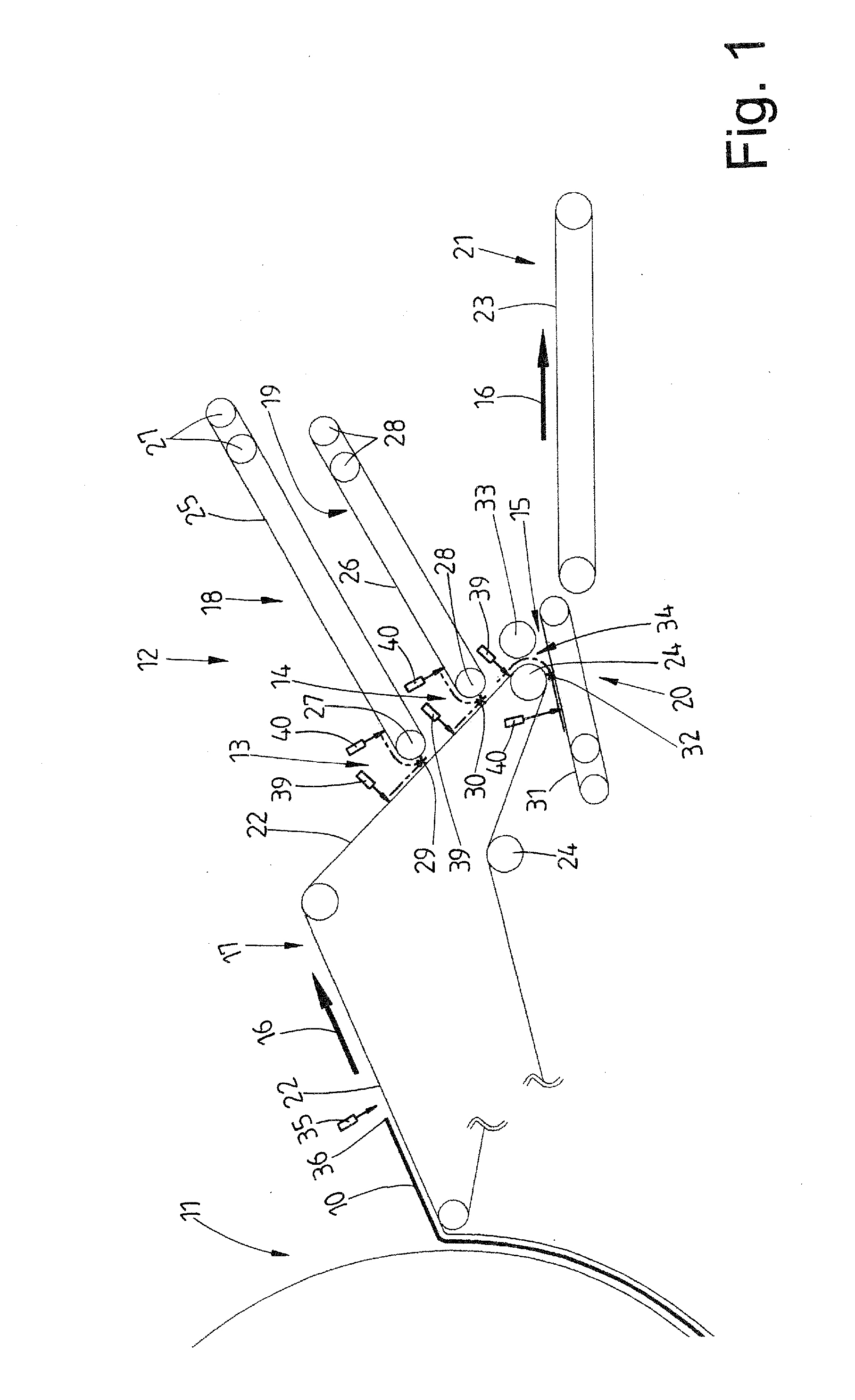

Method of, and apparatus for, folding items of laundry

ActiveUS20150191867A1Improve reliabilityImprove fold qualityPaper-makingFolding thin materialsStructural engineeringLaundry

During the transverse-folding operation of items of laundry, a number of layers are positioned one above the other so as to overlap one another. In order to achieve optimum folding quality, the aim is for layers of equal length to overlap, which is only rarely possible in practice. It is usually the case that the layers are of unequal length, and this gives rise to a difference in overlap. The invention makes provision for the difference in overlap to be eliminated, or at least to be minimized, in that it is determined whether a difference in overlap is present and the difference in overlap which may be established is corrected for the transverse-folding operation of the next-following item of laundry, which allows established differences in overlap to be compensated for automatically at least for the most part.

Owner:KANNEGIESSER GMBH CO HERBERT

Folding device for a folding and gluing machine

ActiveUS20080171644A1Stable characteristicsStable positionMechanical working/deformationBox making operationsEngineeringMechanical engineering

Owner:BOBST SA

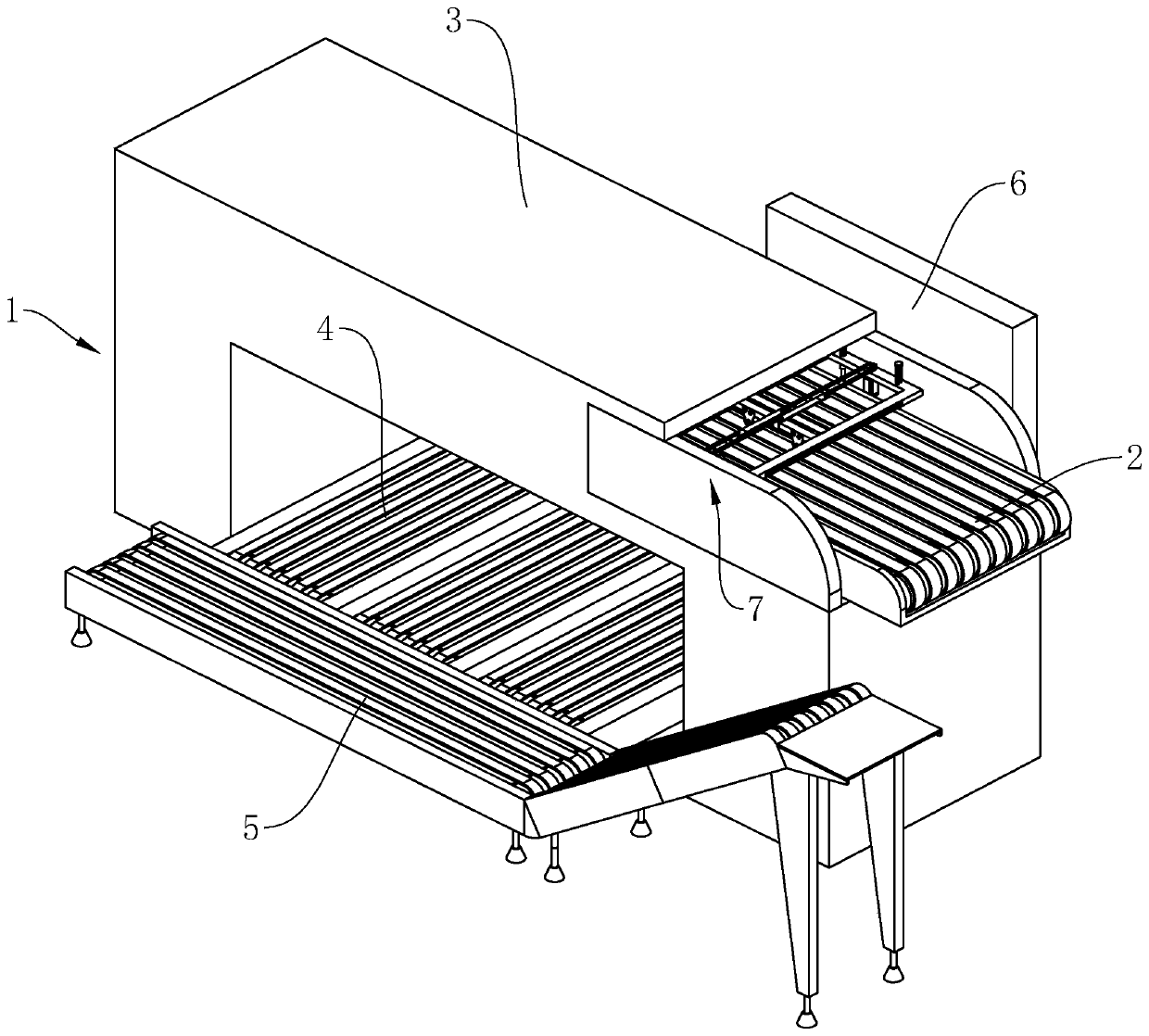

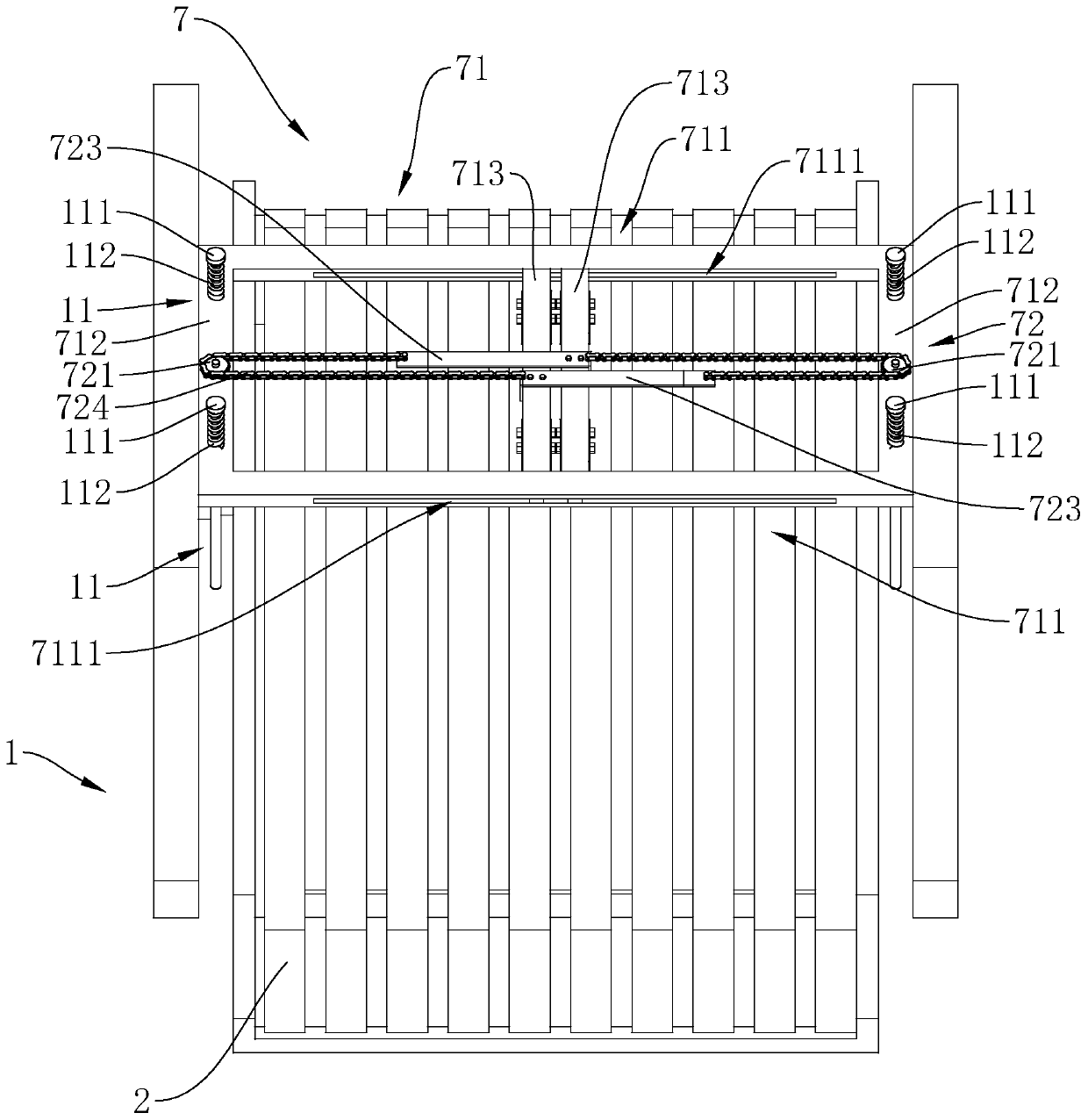

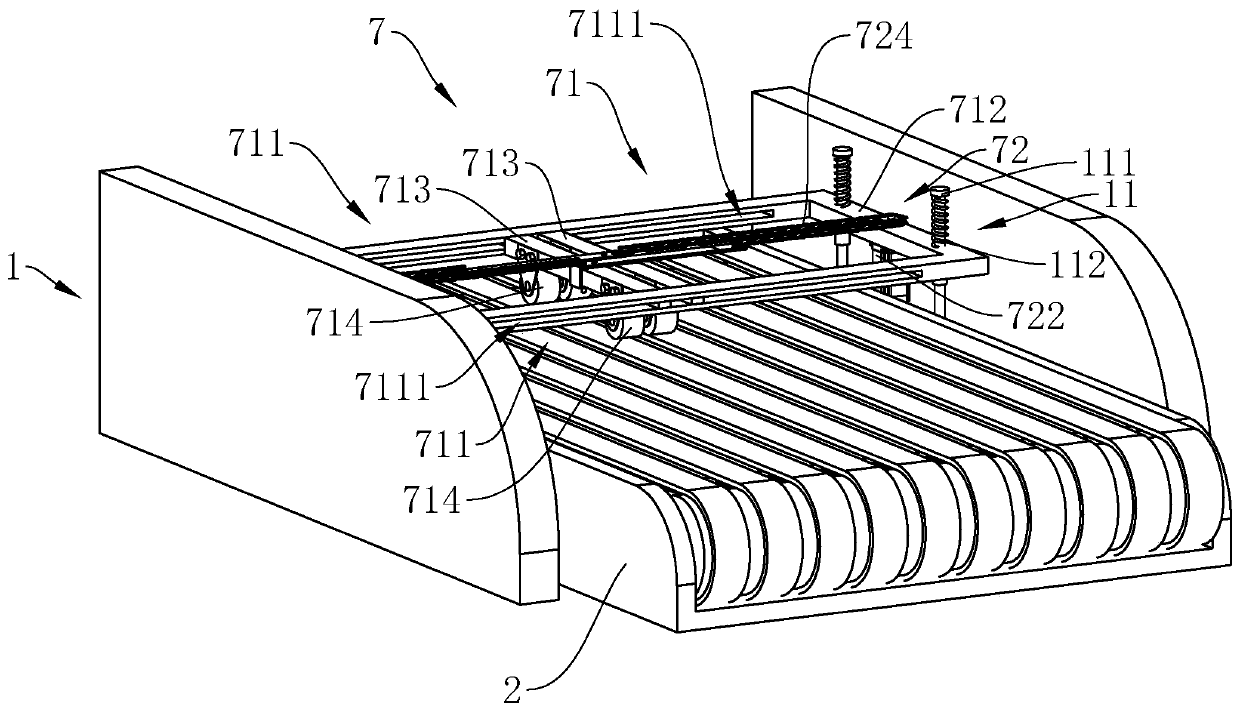

Feeding mechanism for shaping steam box

ActiveCN111485349ARealize automatic fitImprove feeding efficiencyTextile treatment containersSevering textilesPaperboardStructural engineering

The invention discloses a feeding mechanism for shaping steam box. The feeding mechanism comprises a support, a lifting table and a pushing frame; a plurality of thin paperboards are stacked on the lifting table, and a wavy surface is arranged on the upper side of the lifting table; a wavy plate and a rotating assembly are arranged on the support, the wavy plate is rotationally connected to the support through a horizontal shaft, and a plurality of first pasting strips are arranged on the wavy plate; a second pasting strip and a plurality of pressing rods are fixed to the pushing frame, a driving assembly is arranged on the support, and the moving direction of the pushing frame is parallel to the rotating plane of the wave plate; a plurality of clamping units are arranged at the two ends of the horizontal shaft, a penetrating column is fixed to each clamping unit, and the lower end of each penetrating column is fixedly sleeved with a baffle ring; and driving assemblies are arranged atthe two ends of the horizontal shaft. By means of the mechanism, automatic attaching of curtain cloth and a thin paper board, automatic clamping of the curtain cloth and the thin paper board and automatic folding of the curtain cloth and the thin paper board are achieved, and therefore the cloth feeding efficiency is improved; and the feeding efficiency of cloth is improved.

Owner:杭州富阳数马装饰工艺品有限公司

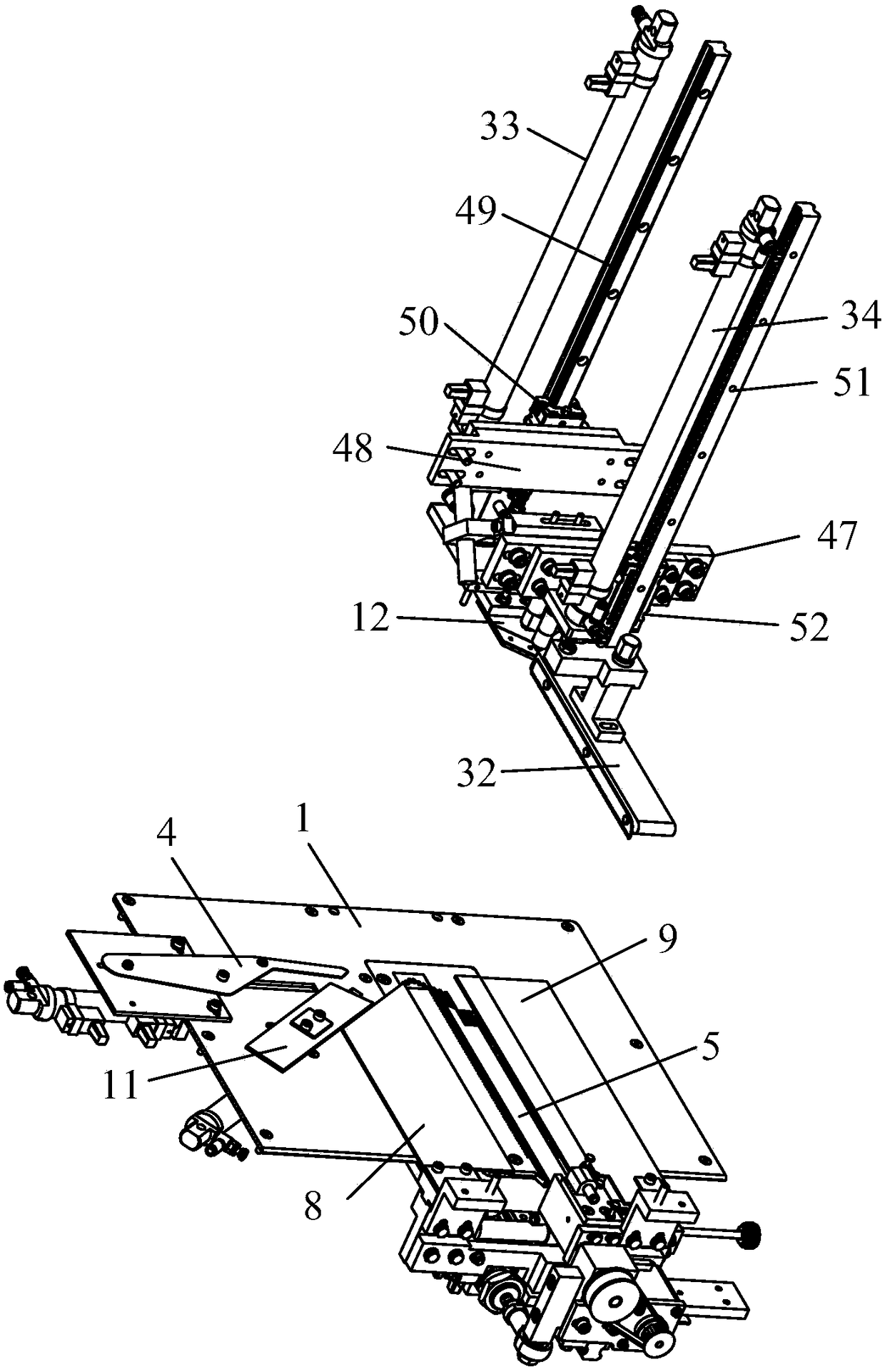

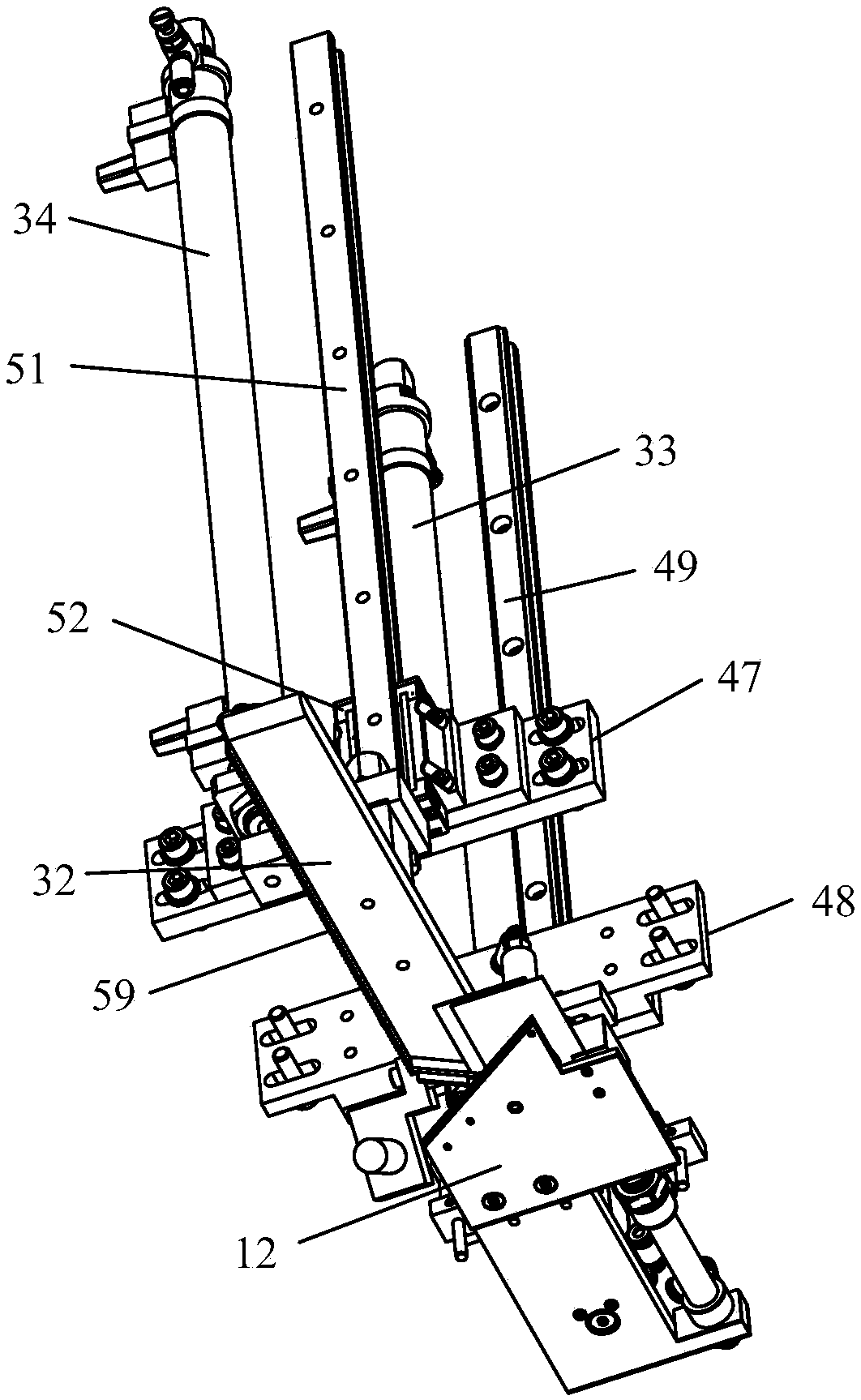

Garment turning-over folding device for garment automated production line

InactiveCN110359262AImprove folding efficiencyImprove fold qualityFolding thin materialsTextiles and paperEngineeringProduction line

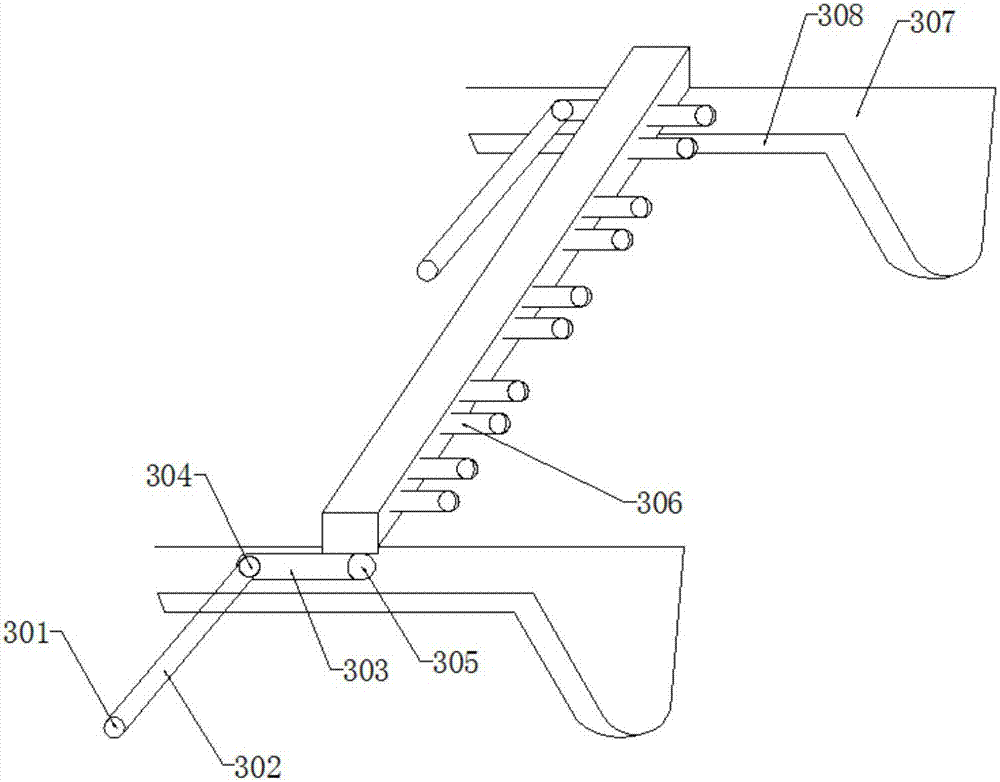

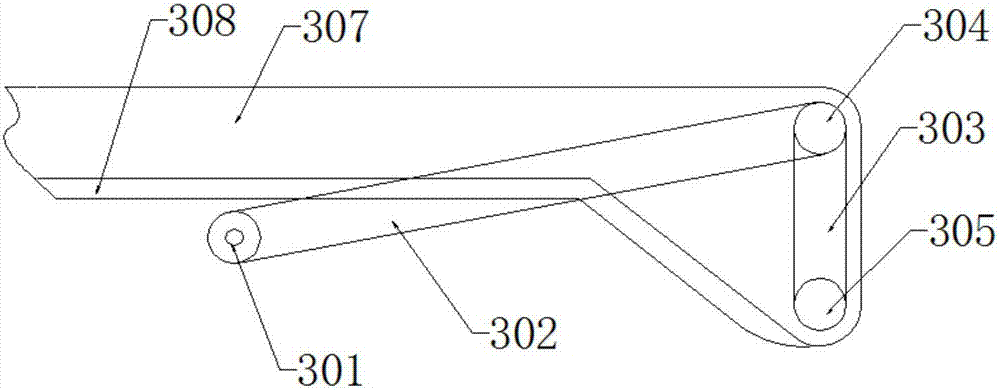

A garment turning-over folding device for a garment automated production line comprises a workbench which comprises a first supporting portion and a second supporting portion. The first supporting portion and the second supporting portion are connected through a U-shaped connection plate, a first connection seat and two first lug plates are arranged on the outer surface of the first supporting portion of the workbench respectively, the first connection seat is connected with a cylinder body of a first cylinder through a pin shaft, the tail end of an extensible rod of the first cylinder is rotatably mounted with a head plate through a second connection seat and a pin shaft, second lug plates are symmetrically arranged at two ends of one side, close to the first connection seat, of the headplate and connected with the two first lug plates through pin shafts respectively, a sealing plate is arranged on the upper surface of the first supporting portion of the workbench, a middle plate component and two press plate components are arranged on the workbench, and the press plate components are symmetrically arranged relative to the middle plate component. By the device, automated production of garment folding is realized, garment folding unification is realized, and worker cost and production cost are lowered.

Owner:NORTHEASTERN UNIV

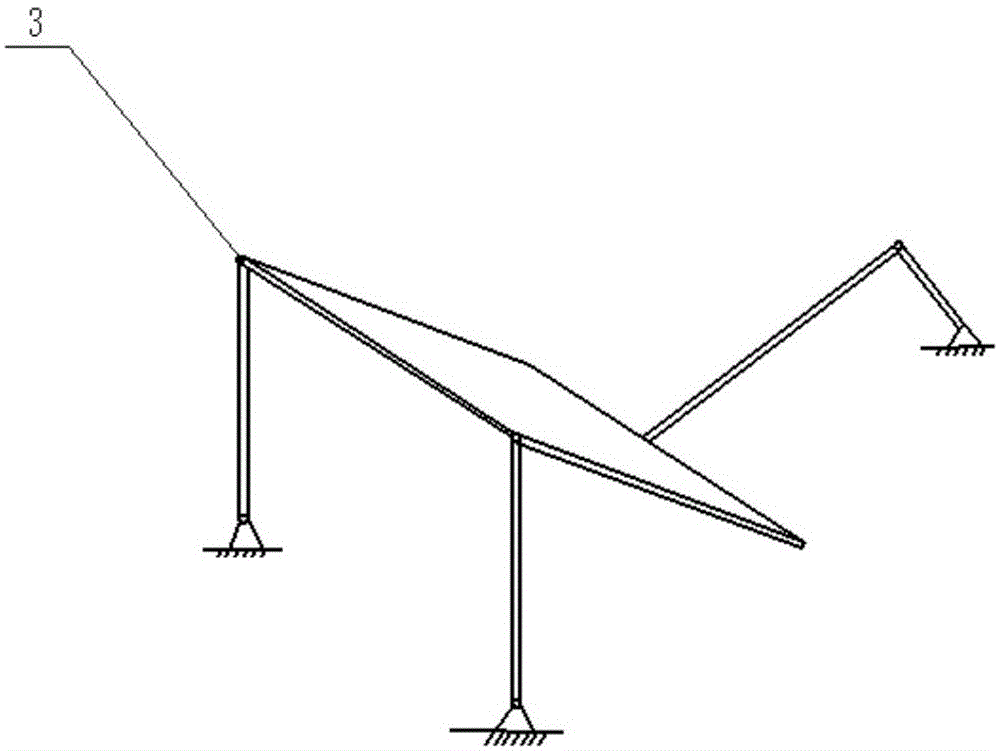

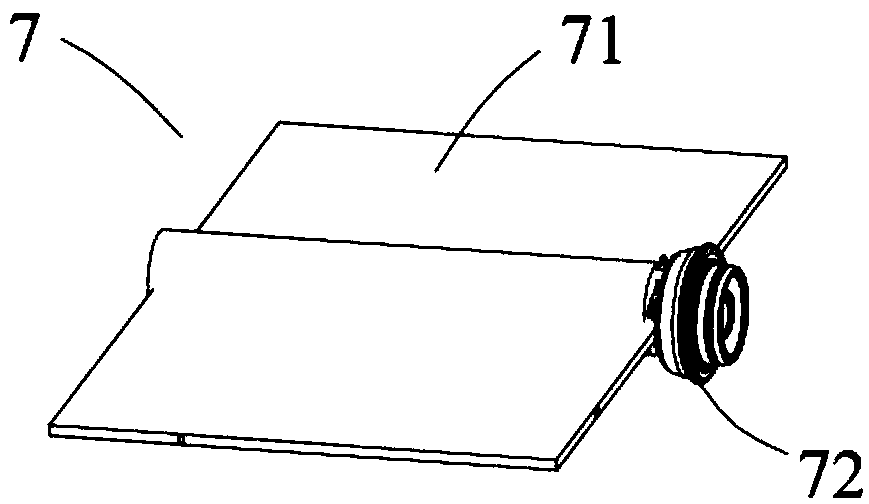

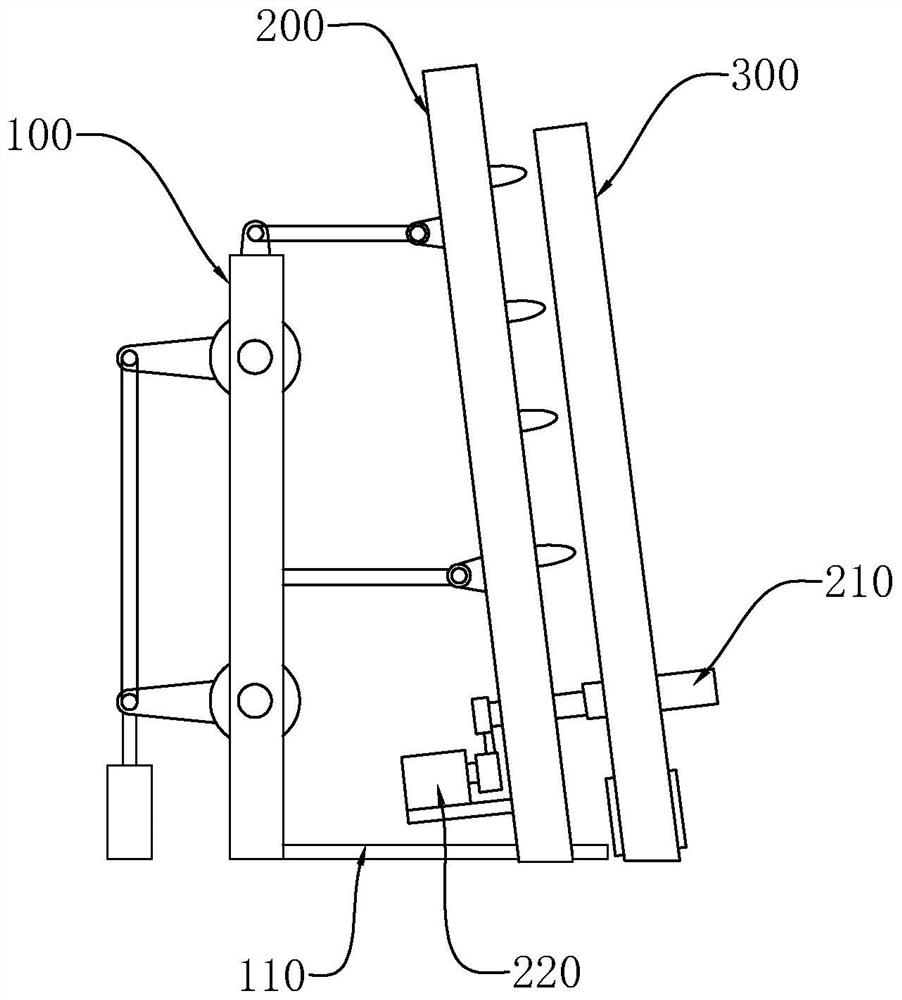

Facial mask folding and conveying device and facial mask folding equipment with same

The invention belongs to the technical field of facial mask production equipment and relates to a facial mask folding and conveying device and facial mask folding equipment with the same. The facial mask folding and conveying device provided by the invention comprises a rack, a moving and overturning mechanism and a lifting mechanism; the lifting mechanism is arranged at one side of the rack and is used for upwards moving a facial mask layer; the moving and overturning mechanism is arranged on the rack and can be used for overturning and moving the facial mask layer on the lifting mechanism; and the moving and overturning mechanism comprises a first driving assembly, a first connecting rod, a second connecting rod, a suction cup rack and a sliding chute. The facial mask folding and conveying device is simple in structure, convenient to operate, use and maintain, capable of effectively reducing manual operation and the possibility of artificial product pollution and guaranteeing more stable quality of the produced product, high in automation degree and production efficiency and low in production cost.

Owner:宋福文

Automatic folding mechanism of clothes

ActiveCN109402998AFully automaticImprove fold qualityFolding thin materialsTextiles and paperEngineeringMechanical engineering

The invention provides an automatic folding mechanism for clothes. The mechanism comprises a base, a clothes support, a width adjusting mechanism, a left sleeve folding plate, a right sleeve folding plate, a folding motor, a tail folding plate, a tail folding motor and a controller; the clothes support comprises a plurality of a strip-shaped support members arranged in parallel, and the strip-shaped support members are slidably arranged on the base; the width adjusting mechanism is fixed on the lower end face of all the strip-shaped support members to adjust gaps between the strip-shaped support members; the left sleeve folding plate and the right sleeve folding plate are rotationally fixed on the two sides of the clothes support respectively; the tail folding plate comprises a plurality of strip-shaped pressing plates, and the strip-shaped pressing plates can be folded in the gaps between the strip-shaped support members; the width adjusting mechanism, the folding motor and the tail folding motor are in signal connection with the controller. The automatic folding mechanism of the clothes has the advantages that the arrangement of the width adjusting mechanism achieves the automatic adjustment of creases corresponding to different widths of clothes of different sizes, thereby improving the automatic folding quality of the clothes.

Owner:JIHUA LAB

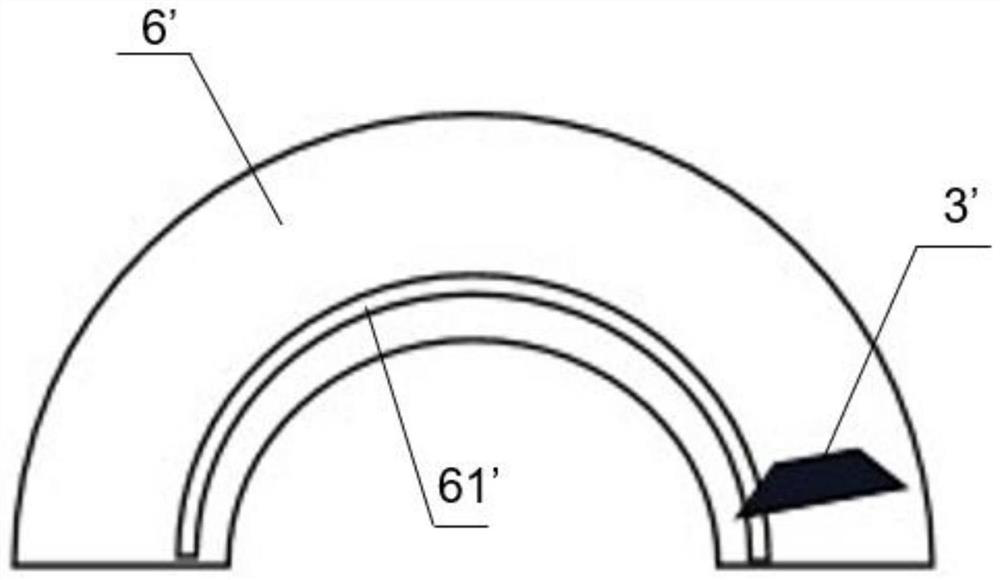

fabric folding machine

InactiveCN102260997AAvoid accumulationImprove folding efficiencyFolding thin materialsTextiles and paperAgricultural engineering

The invention discloses a fabric folding machine, which comprises a frame, a first folding assembly fixed on the frame, and an air blowing pipe support arranged at the output end of the first folding assembly and fixed on the frame , further comprising at least one arc-shaped anti-seize plate, the anti-seize plate is fixedly connected to the blowing pipe support, and the opening direction of the anti-seize plate faces the output end of the first folding assembly. The invention can effectively prevent the fabric to be folded from being piled up or jammed at the first folding component, thereby improving the efficiency and quality of fabric folding; and the structure is simple and the cost is low. The present invention can be widely applied to fabric folding machines.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

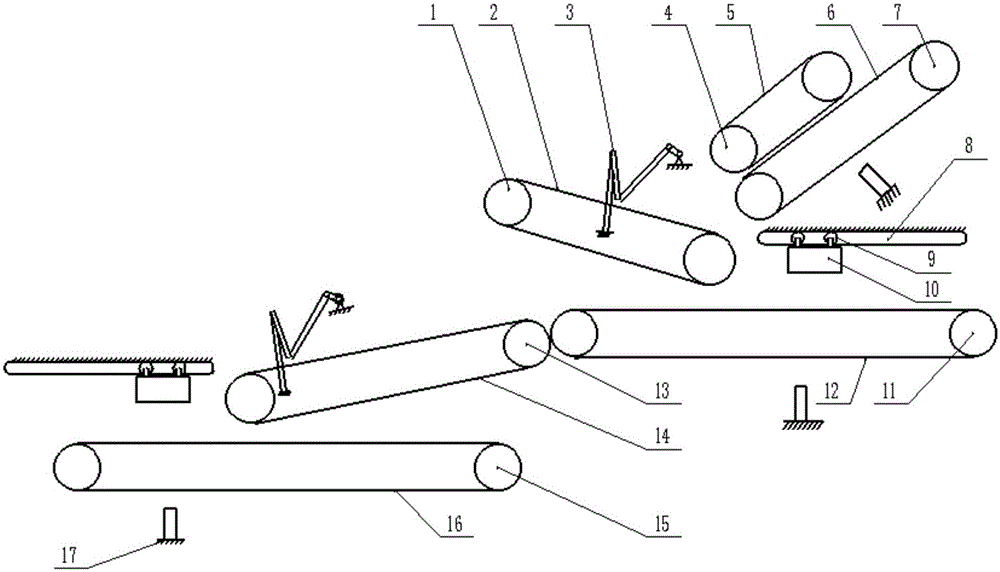

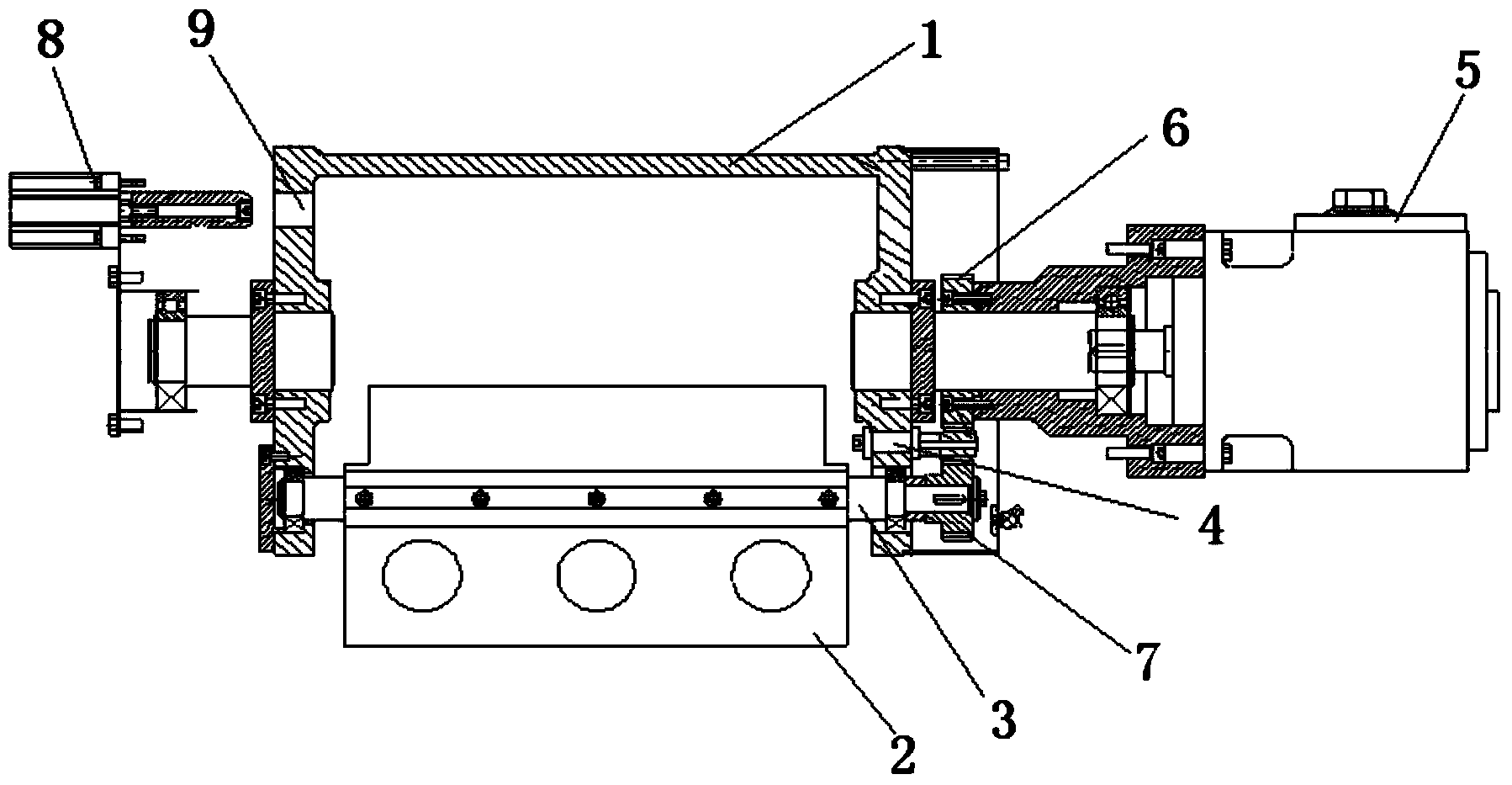

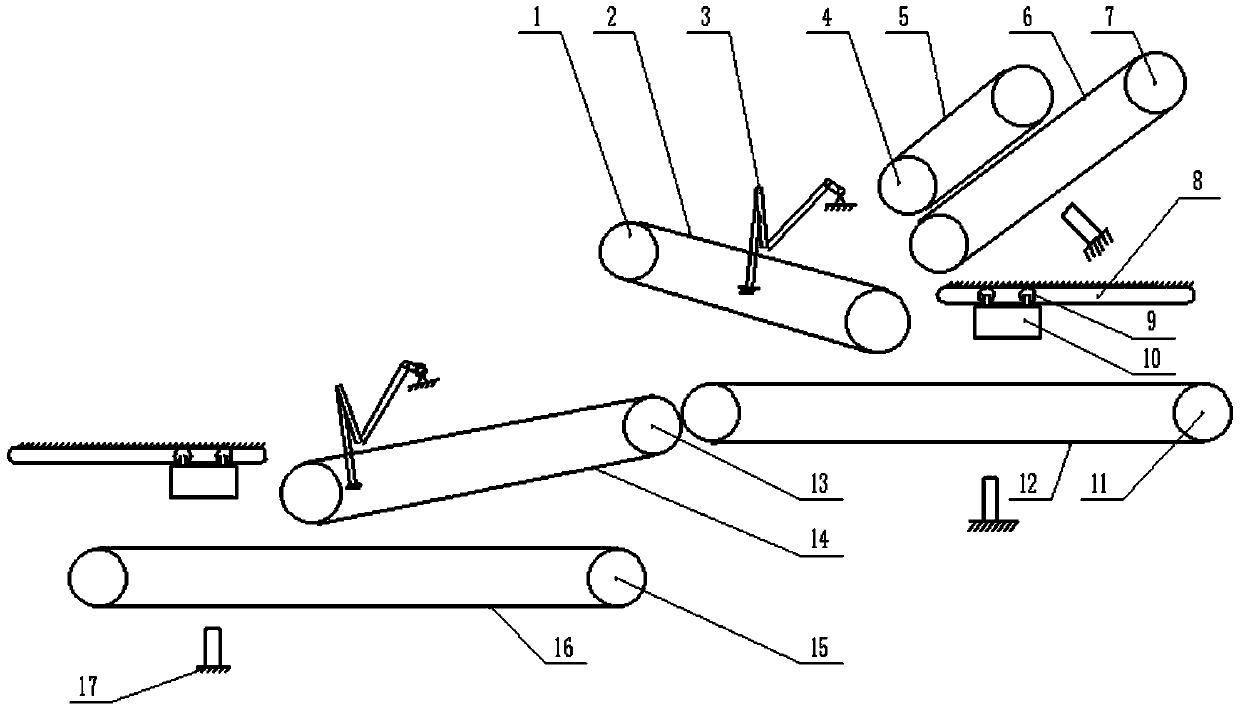

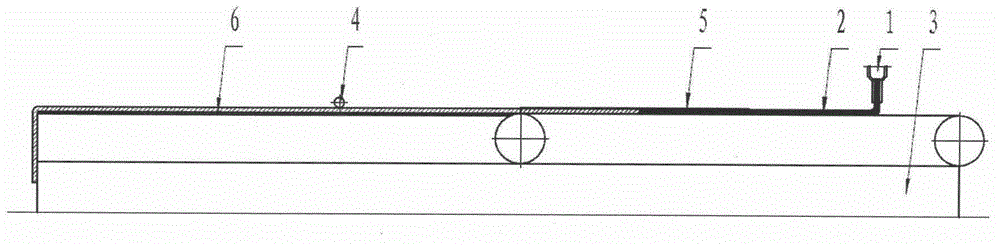

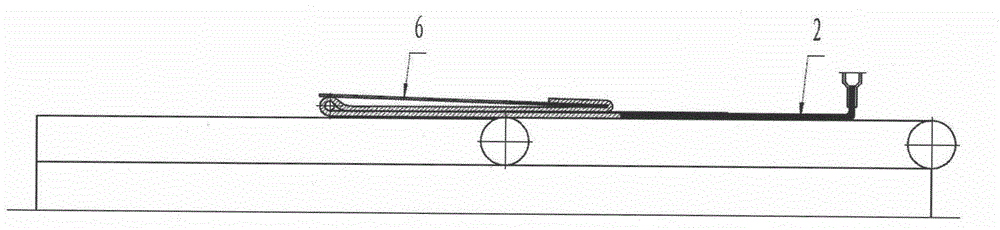

Silk stocking automatic folding mechanical structure and folding method thereof

The invention discloses a silk stocking automatic folding mechanical structure and a folding method thereof. The mechanical structure comprises conveyor belts, belt pulleys, a motor, a crank mechanism, an inner paperboard conveying rail, a vacuum adsorption disc, a guide pulley and a photoelectric sensor. The motor drives the crank mechanism so as to drive crank to rotate. An inner paperboard adding mechanism comprises the inner paperboard conveying rail, the vacuum adsorption disc and the guide pulley. The silk stocking automatic folding mechanical structure is simple and reasonable, the folding method is simple, the whole operation performance is good, and high efficiency is achieved. A silk stocking folding machine can work through complicated equipment such as manipulators, but the cost of the silk stocking folding machine is high, so that common enterprises do not have integration capability. The silk stocking automatic folding mechanical structure is low in cost, so that the enterprises can perform integrated arrangement. According to the design of the mechanical structure and by employing the mechanical structure, the labor intensity of workers can be hopefully reduced, and the folding efficiency and quality of silk stockings can be improved.

Owner:QUZHOU COLLEGE OF TECH

Towel folding machine

ActiveCN110438786AReduces wrinkles and cornersImprove fold qualityFolding thin materialsTextiles and paperEngineeringMechanical engineering

The invention relates to a towel folding machine, comprising a rack and a control system. A feeding device and a folding device are mounted sequentially on the rack. A discharging device is arranged at the bottom of the rack, a stacking device is arranged on one side of the rack, and all the feeding devices, the folding device, the discharging device and the stacking device are electrically connected with the control system; an unfolding device electrically connected with the control system is mounted on the frame and comprises a square frame, two sliding rods are slidably connected inside thesquare frame, a driving assembly is mounted on the square frame, the control system drives the two sliding rods to reach each other or leave each other through the driving assembly, a moving direction of the two sliding rods is perpendicular to a conveying direction of the feeding device, the bottom of each sliding rod is rotationally connected with a roller, the axial direction of every roller is perpendicular to the conveying direction of the feeding device, and the lower edge of every roller is lower than the lower surface of the square frame. The towel folding machine helps unfold towels,so that fewer wrinkles and folded corners occur, and folding quality is higher.

Owner:北京朝露洗涤服务有限公司

Folding device of printing machine

InactiveCN103587227ASolve Vibration ProblemsStable jobFolding thin materialsRotary pressesEngineeringPrinting press

The invention discloses a folding device of a printing machine. The folding device comprises a roller, a folding knife, a folding knife shaft, an idler shaft, a planetary gear train and a power mechanism. The roller is hollow, only the semi roller face above a roller shaft is arranged between the printing machine and a wallboard. The folding knife is arranged on the folding knife shaft, the folding knife shaft is arranged between the two end faces of the roller and located below the roller shaft, the planetary gear train comprises a sun wheel, a planet wheel and an idle wheel, the idle wheel is respectively meshed with the sun wheel and the planet wheel, the idle wheel is arranged on the end face of the roller through the idler shaft, the sun wheel is arranged at one end of the roller shaft of the roller, and the planet wheel is arranged at one end of the folding knife shaft. The power mechanism is arranged at one end of the roller shaft of the roller. The folding device solves the vibration problem of the printing machine in the folding process, is stable in work, improves the folding quality, meanwhile, is simple and compact in structure, saves space and reduces cost.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

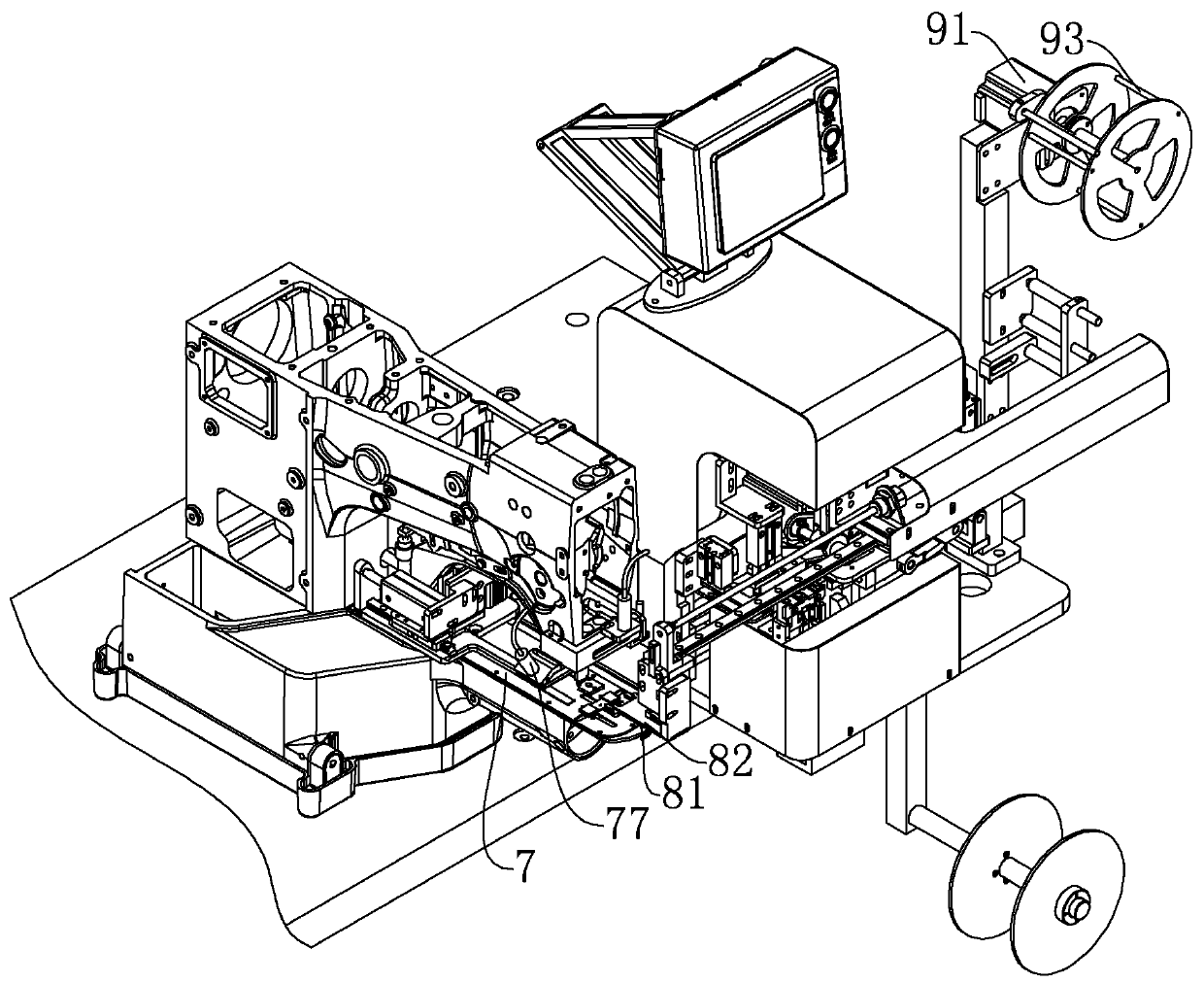

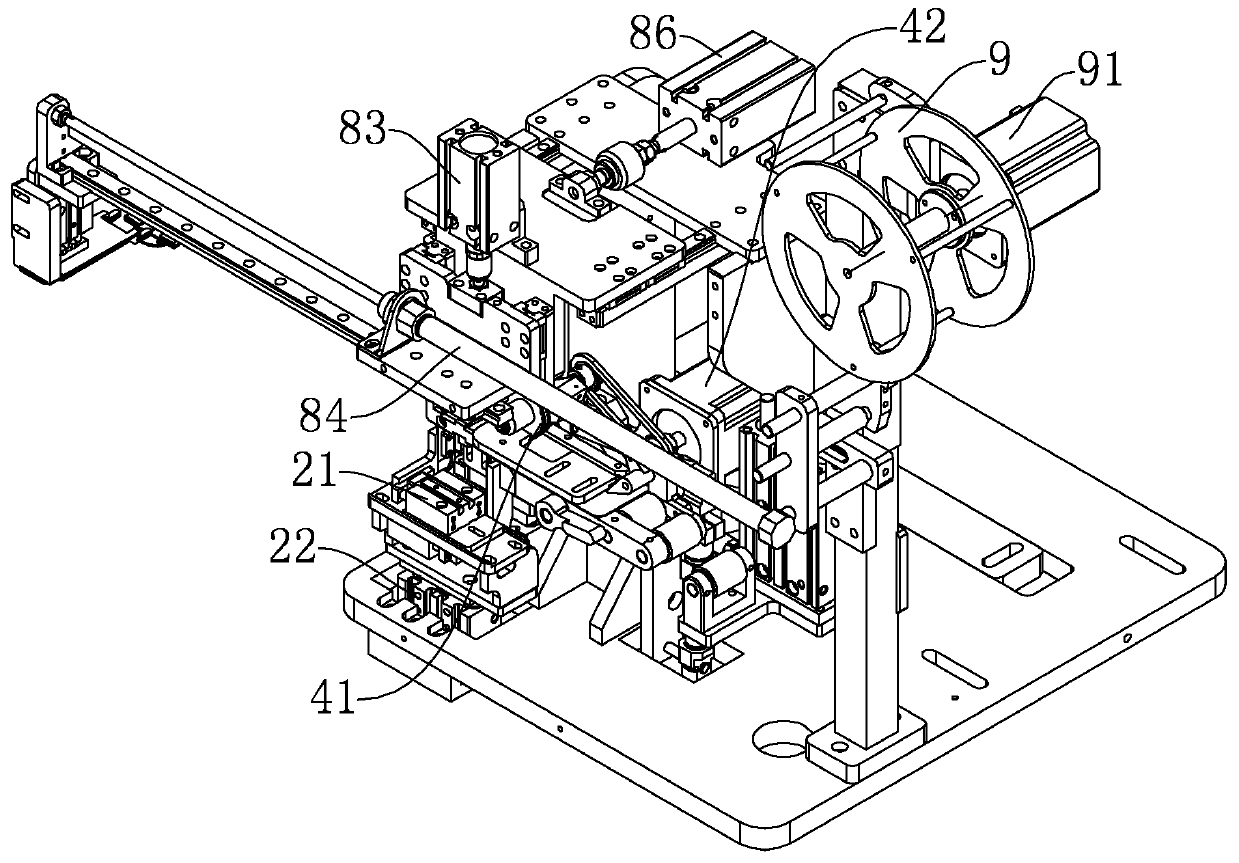

Red wine bag automatic folding machine

ActiveCN108373069AAutomatic folding implementationIncrease productivityFolding thin materialsEngineeringMechanical engineering

The invention discloses a red wine bag automatic folding machine. The red wine bag automatic folding machine comprises a machine table, a fixing device, a folding device, an adhesive tape feeding device and a taping device, wherein the machine table is provided with a machine frame and an installation platform on the machine frame; the fixing device is arranged on the installation platform; the folding device is arranged on the installation platform, and is positioned at one side of the fixing device; the adhesive tape feeding device is arranged on the installation platform; the taping deviceis arranged on the installation platform, and is positioned above the fixing device and the adhesive tape feeding device; the fixing device is used for fixing a red wine bag, and controlling the red wine bag to rotate around the center of axis; the folding device is used for folding the pressed bag body, the adhesive tape feeding device is used for feeding coiled adhesive tapes, and the taping device is used for taping and fixing the folded bag body. The red wine bag automatic folding machine has the advantages that the red wine bag can be automatically folded, the production efficiency of enterprises is improved, the artificial factor is reduced in the folding process, the folding quality is improved, the labor intensity of a worker is reduced, and the labor cost is reduced.

Owner:惠州市南方智能制造产业研究院

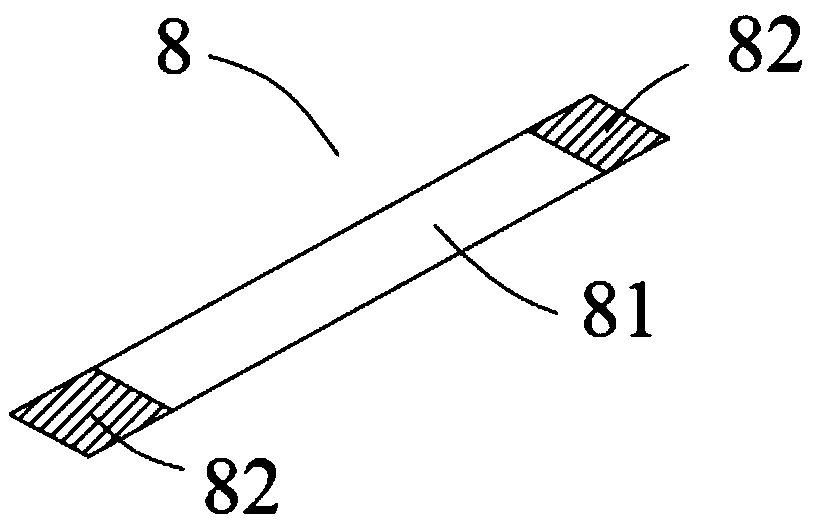

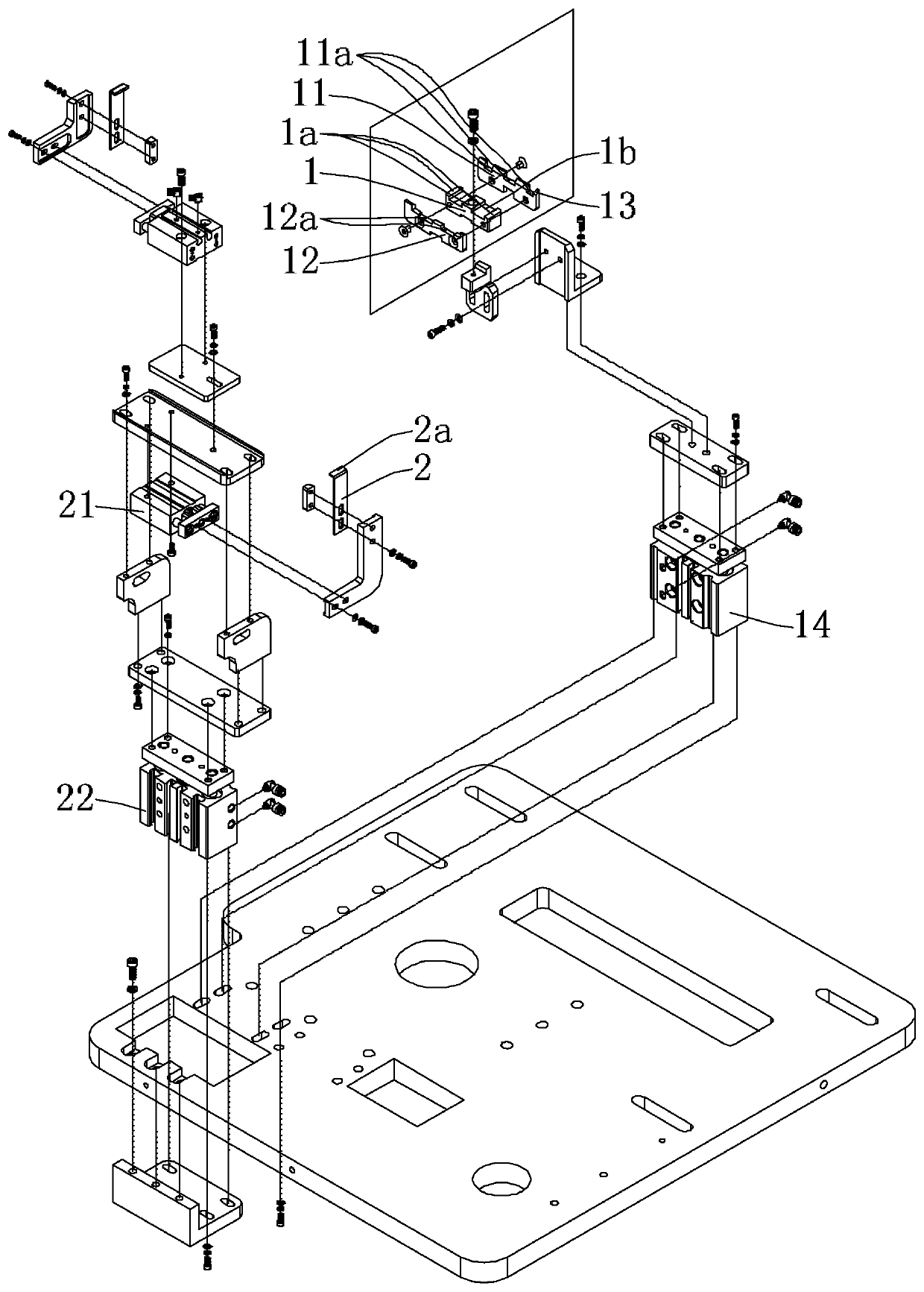

Automatic folding mechanism and method and sleeve placket sewing device

ActiveCN108505226AImprove folding efficiencyImprove fold qualityWork-feeding meansEngineeringMechanical engineering

The invention provides an automatic folding mechanism and method and a sleeve placket sewing device. The automatic folding mechanism comprises a fixing base plate, a discharging plate, a baffle assembly, a discharging cavity formed by the discharging plate and the baffle assembly, a turnover clamping assembly located in the discharging cavity and a fold material shifting piece. One end of the discharging cavity is provided with a sleeve placket end forming part, a plurality of first suction holes distributed in the peripheral direction of the discharging cavity at intervals are formed in the discharging plate, the clamping assembly comprises a movable clamping plate and a fixed clamping plate which are stacked, and a clamping cavity formed in the movable clamping plate and the fixed clamping plate, the movable clamping plate can move close to or away from the fixed clamping plate, the fold material shifting piece is located at the upper side of the baffle assembly and can move close toor away from the sleeve placket end forming part. The small cutting pieces and large cutting pieces are automatically folded into sleeve plackets, operators just need to place the small cutting pieces and the large cutting pieces, time and labor are saved during operation, and the cutting piece folding efficiency and quality are greatly improved.

Owner:JACK SEWING MASCH CO LTD

Hollow glass pressing and glue-sealing equipment set

The invention relates to a hollow glass pressing and glue-sealing equipment set. The hollow glass pressing and glue-sealing equipment set sequentially comprises alaminating device, a hot pressing device and a glue sealing device. The laminating device comprises a fixed frame, a movable frame and an isolation frame which are arranged in sequence, an elastic driving mechanism for driving the movableframe to move is arranged on the fixed frame, and the fixed frame and the movable frame are connected through the elastic driving mechanism; a first sliding rail is arranged at the bottom end of thefixed frame, and the lower end of the movable frame is connected to the sliding rail in a clamped mode. The laminating quality and the glue sealing effect of the glass are improved.

Owner:济南国伟旗玻璃有限公司

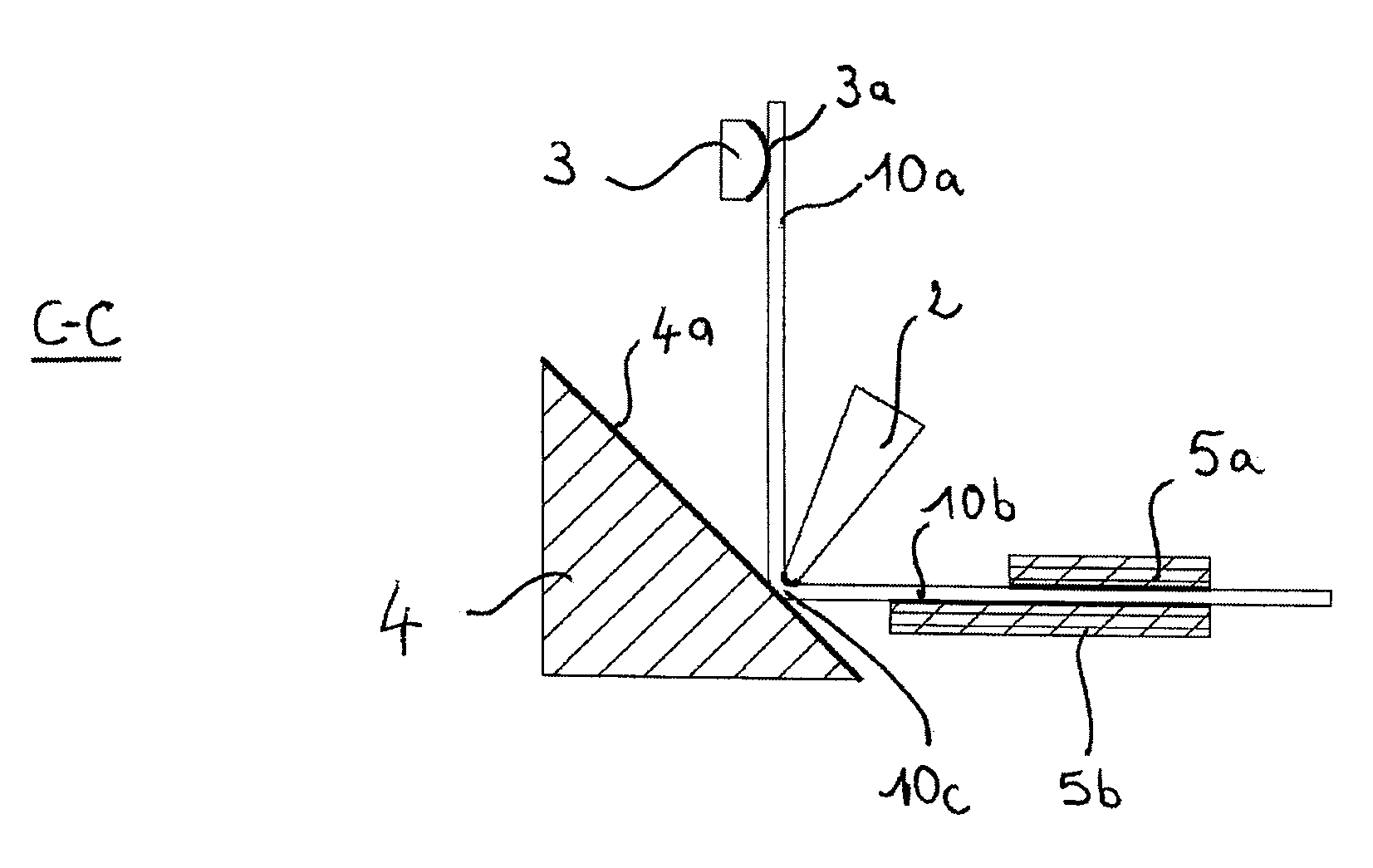

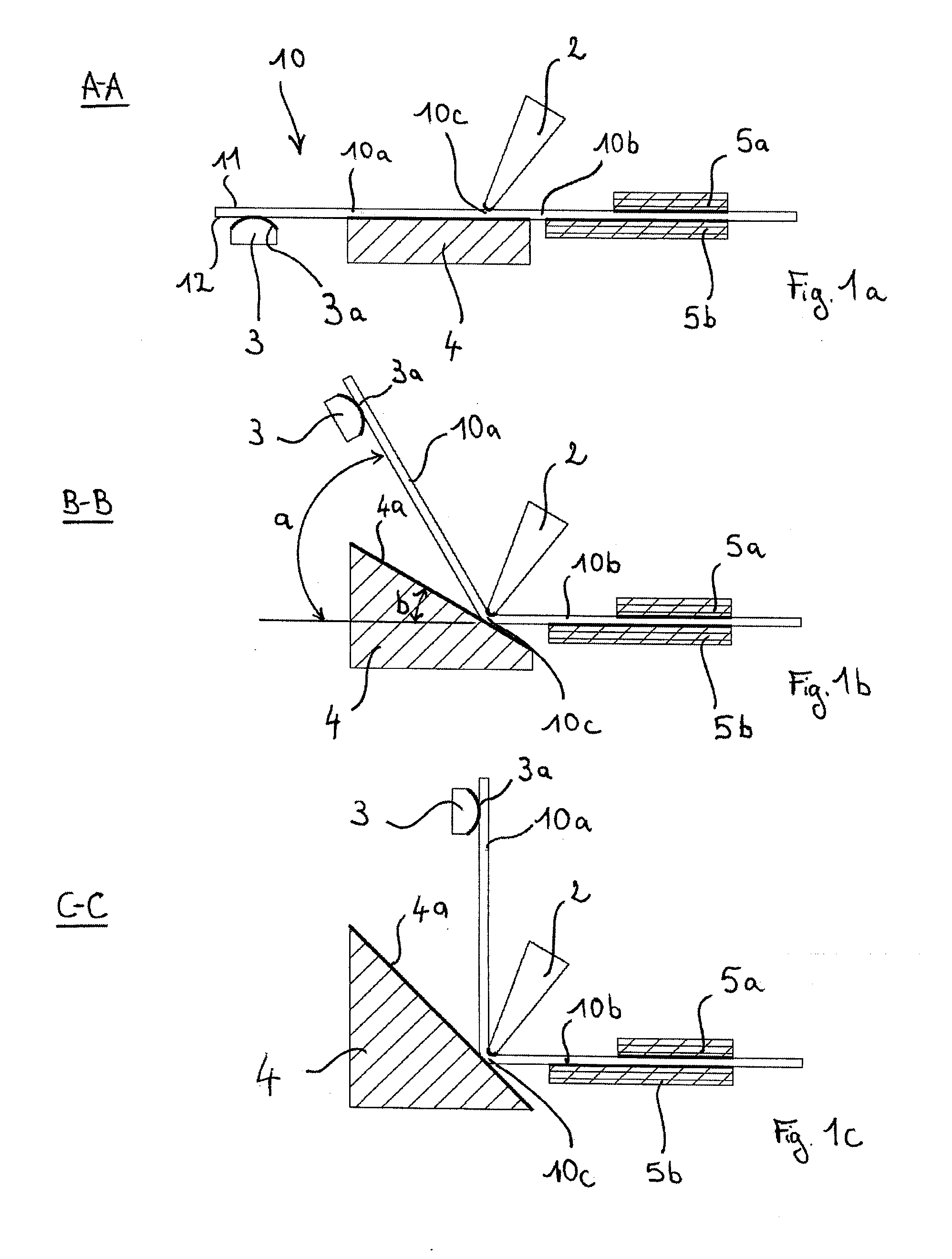

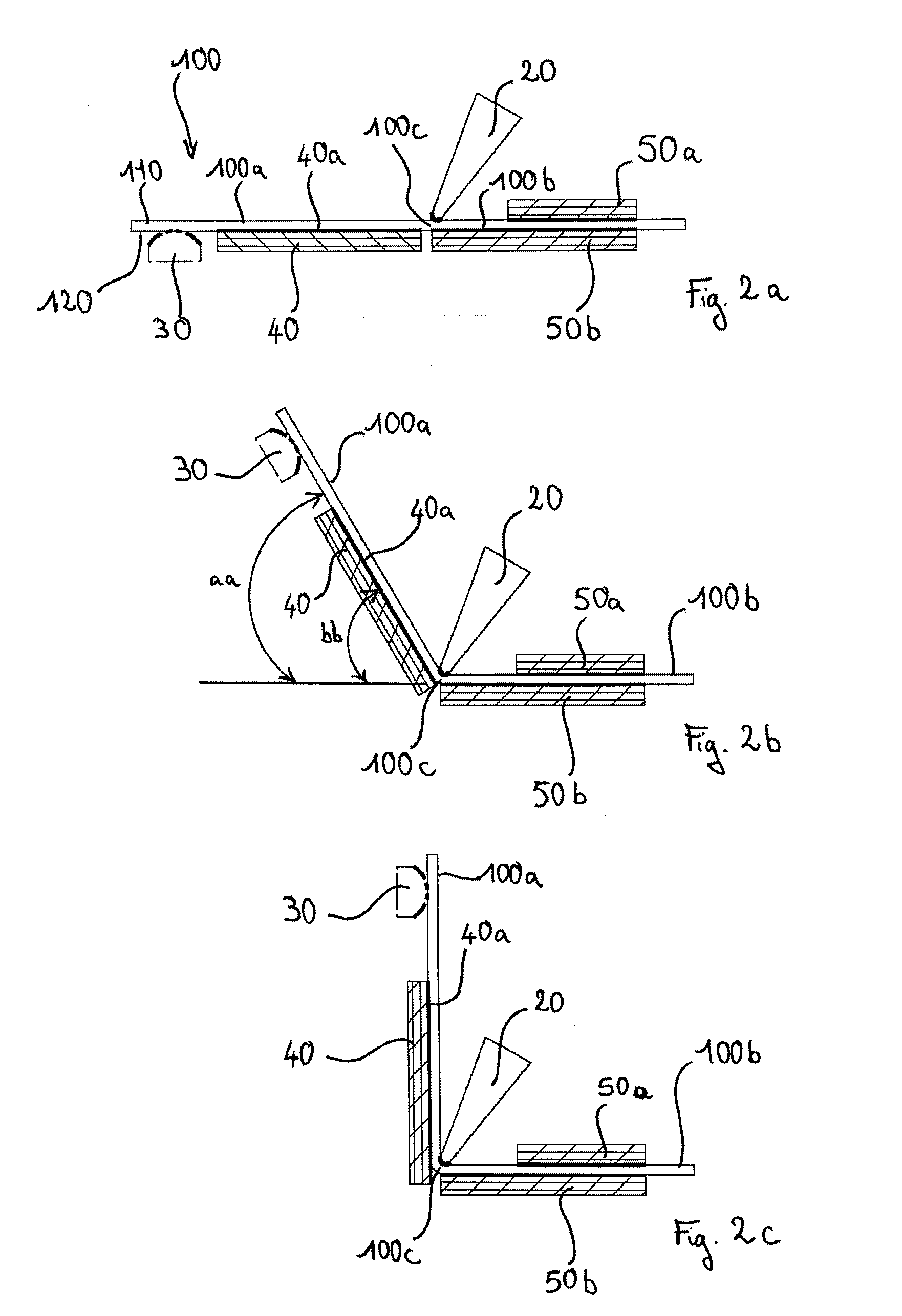

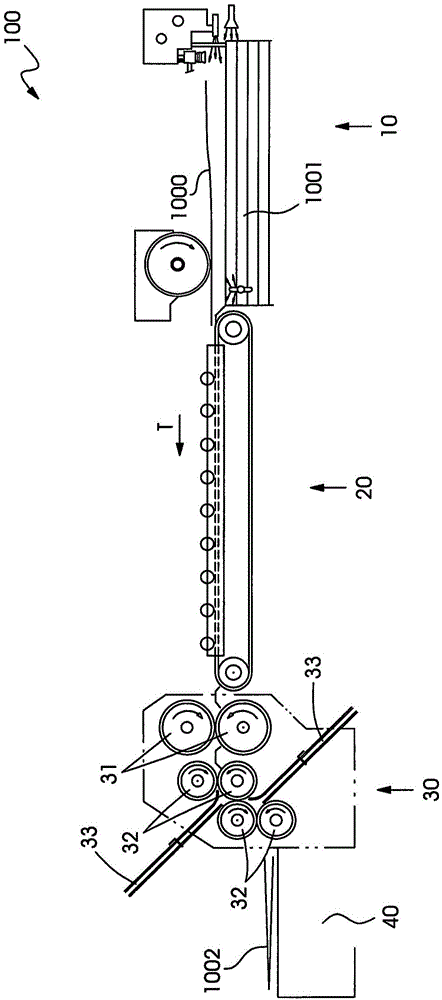

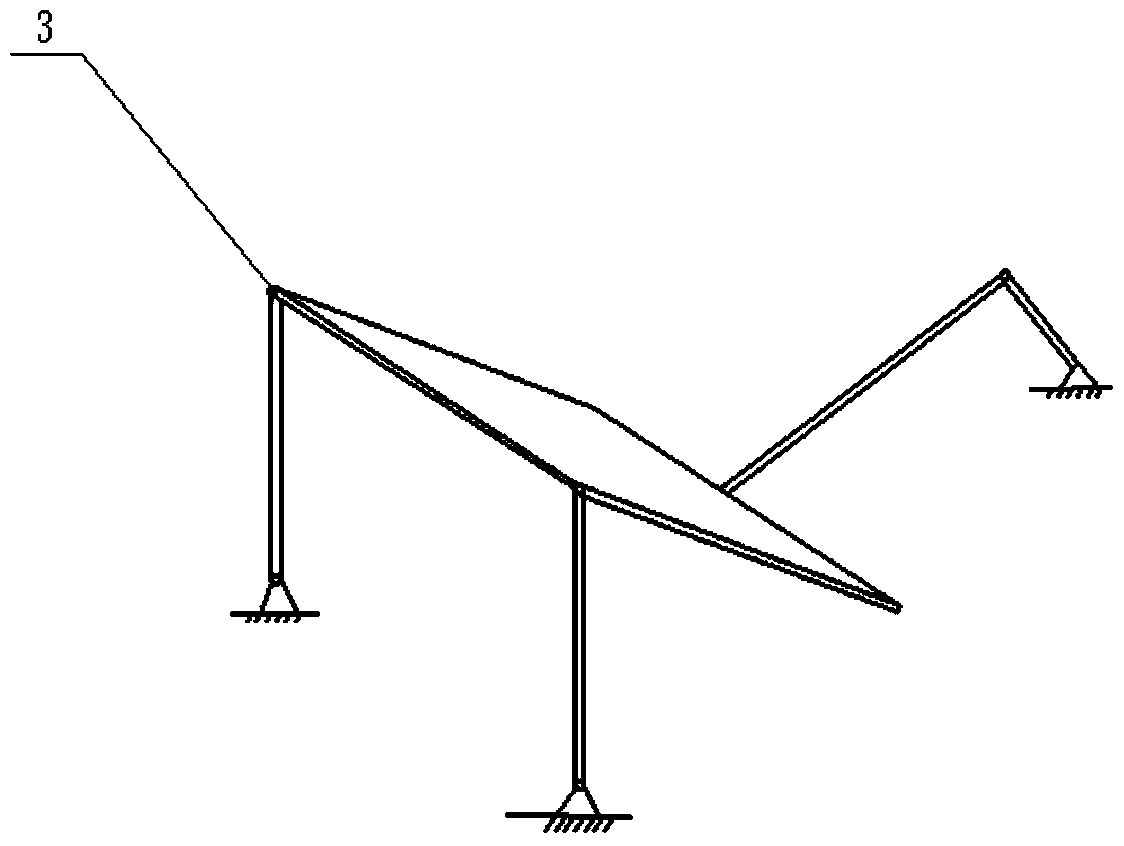

Fence type folding station used for support element of folding fence

InactiveCN103848267AEasy to guideReduce deflectionFolding thin materialsRotary pressesEngineeringLower lip

The invention relates to a fence type folding station and a pages fold machine. The fence type folding station is provided with at least one folding fence and a plurality of folding rollers for folding page-shaped elements, wherein a respective folding fence is provided with an upper guiding surface and a lower guiding surface, the corresponding page-shaped elements enter and leave the space between the upper guiding surface and the lower guiding surface, and the lower guiding surface is provided with a lower lip arranged on the end part of the folding roller side and used for guiding the corresponding page-shaped elements to enter and leave the folding fence. According to the invention, the lower guiding surface is provided with at least one support element, and at least folding roller is provided with at least one bearing element on the peripheral region, wherein the support element is supported on the bearing element. In this way, an advantageous manner is adopted to substantially reduce the bending of the lower lip, to substantially improve page guiding and further to improve the folding quality.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

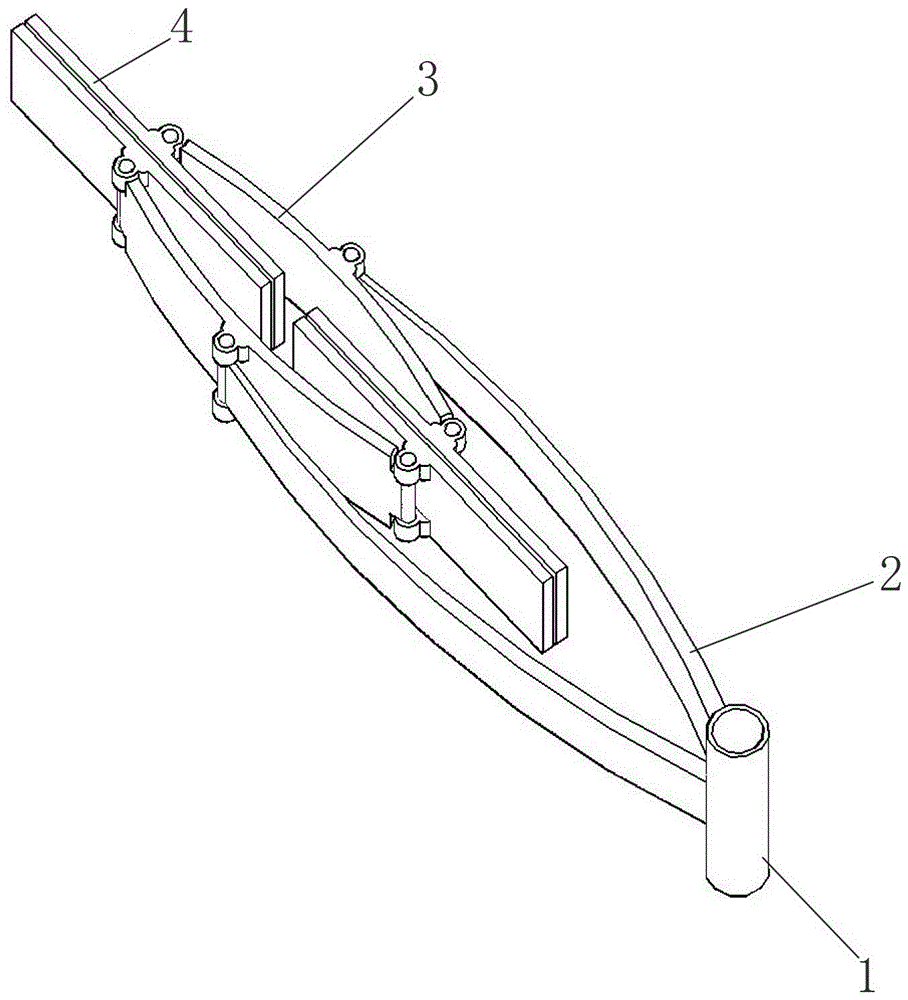

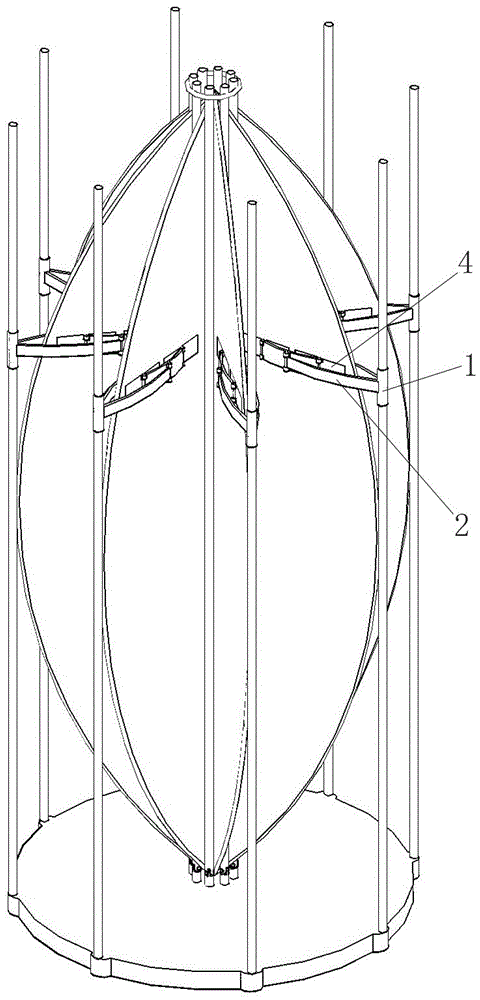

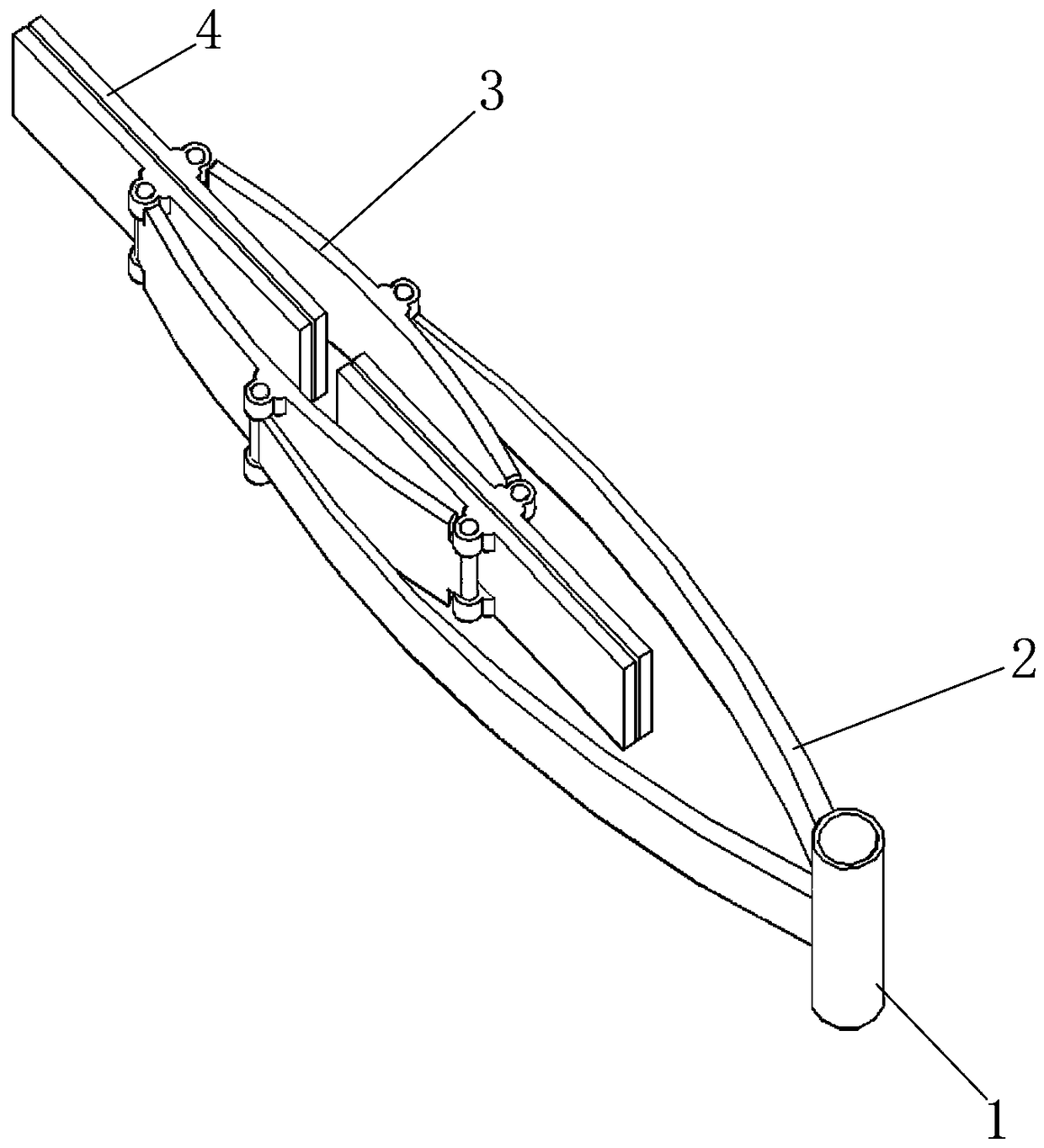

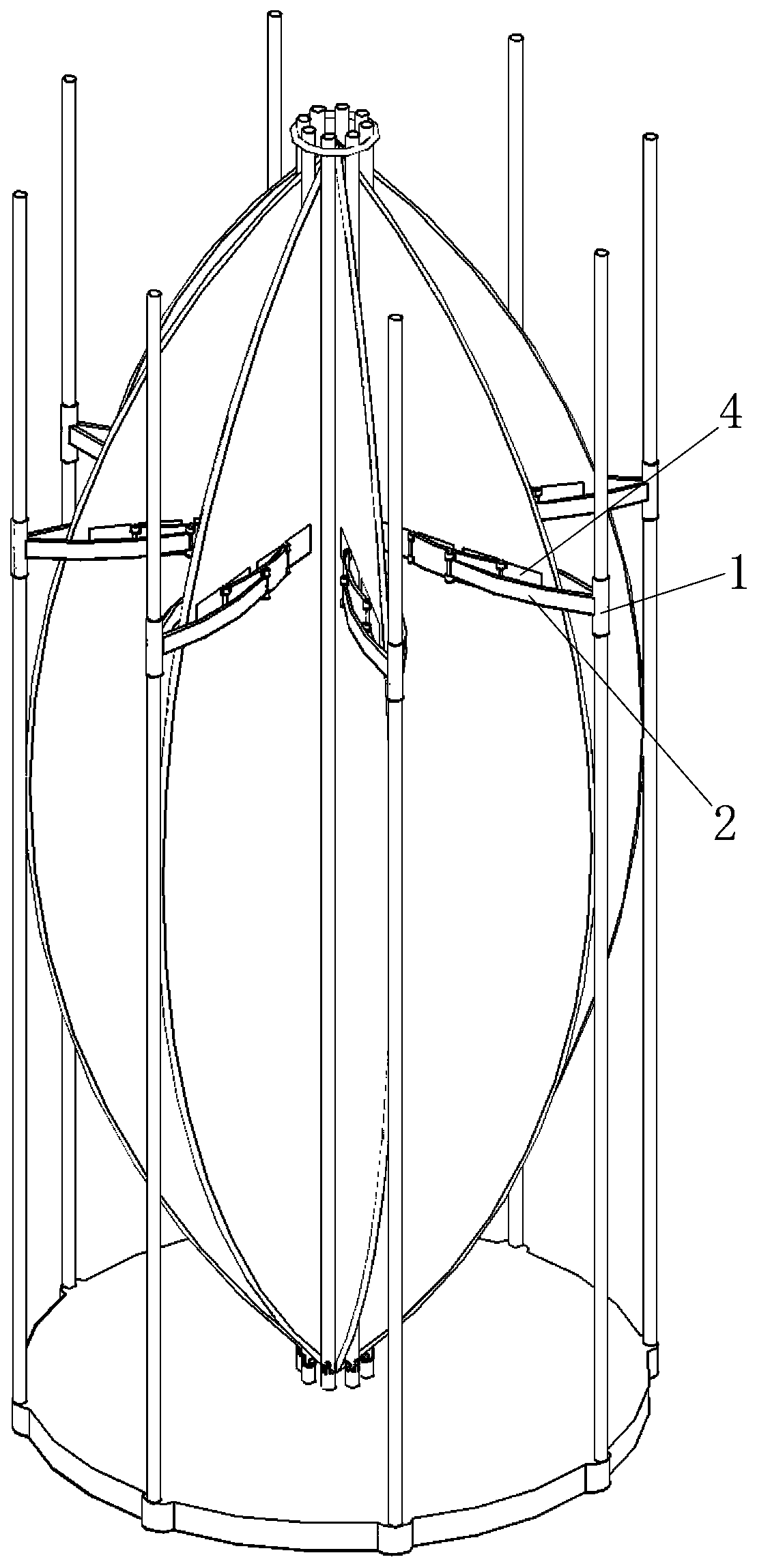

Auxiliary clamp for folding large balloon

ActiveCN106629216AFlexible useImprove folding efficiencyFolding thin materialsEngineeringMechanical engineering

The invention discloses an auxiliary clamp for folding large balloons and belongs to the technical field of large balloon folding and closing. The folding efficiency and quality of the large balloons are improved. The auxiliary clamp comprises a sleeve, elastic clamping pieces, force distribution plates and clamping plates. The two elastic clamping pieces are oppositely arranged on one side of the sleeve. One end of each elastic clamping piece is fixedly connected with the sleeve, the other end of the elastic clamping piece is provided with the corresponding arc-shaped force distribution plate. The middle of each elastic clamping piece and the middle of the corresponding force distribution plate are rotatably connected in the opening-closing direction. Concave faces of the two force distribution plates are arranged oppositely. The two ends of each force distribution plate are provided with the clamping plates correspondingly. The clamping plates and the force distribution plates are rotatably connected in the opening-closing direction or through universal spheres. The auxiliary clamp is used for folding the large balloons.

Owner:HARBIN INST OF TECH

Auxiliary gripper for folding large balloons

ActiveCN106629216BFlexible useImprove folding efficiencyFolding thin materialsEngineeringMechanical engineering

The invention discloses an auxiliary clamp for folding large balloons and belongs to the technical field of large balloon folding and closing. The folding efficiency and quality of the large balloons are improved. The auxiliary clamp comprises a sleeve, elastic clamping pieces, force distribution plates and clamping plates. The two elastic clamping pieces are oppositely arranged on one side of the sleeve. One end of each elastic clamping piece is fixedly connected with the sleeve, the other end of the elastic clamping piece is provided with the corresponding arc-shaped force distribution plate. The middle of each elastic clamping piece and the middle of the corresponding force distribution plate are rotatably connected in the opening-closing direction. Concave faces of the two force distribution plates are arranged oppositely. The two ends of each force distribution plate are provided with the clamping plates correspondingly. The clamping plates and the force distribution plates are rotatably connected in the opening-closing direction or through universal spheres. The auxiliary clamp is used for folding the large balloons.

Owner:HARBIN INST OF TECH

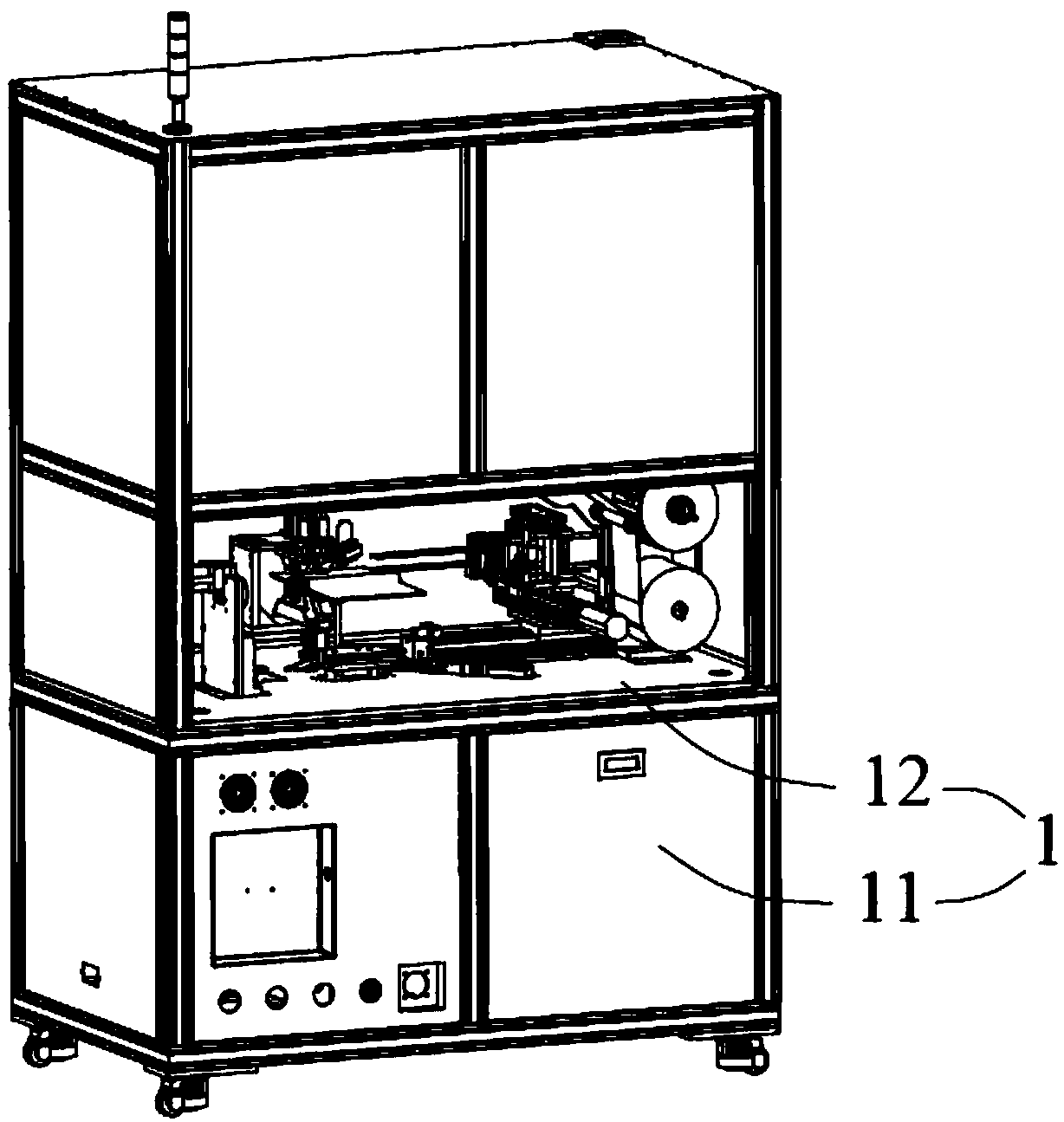

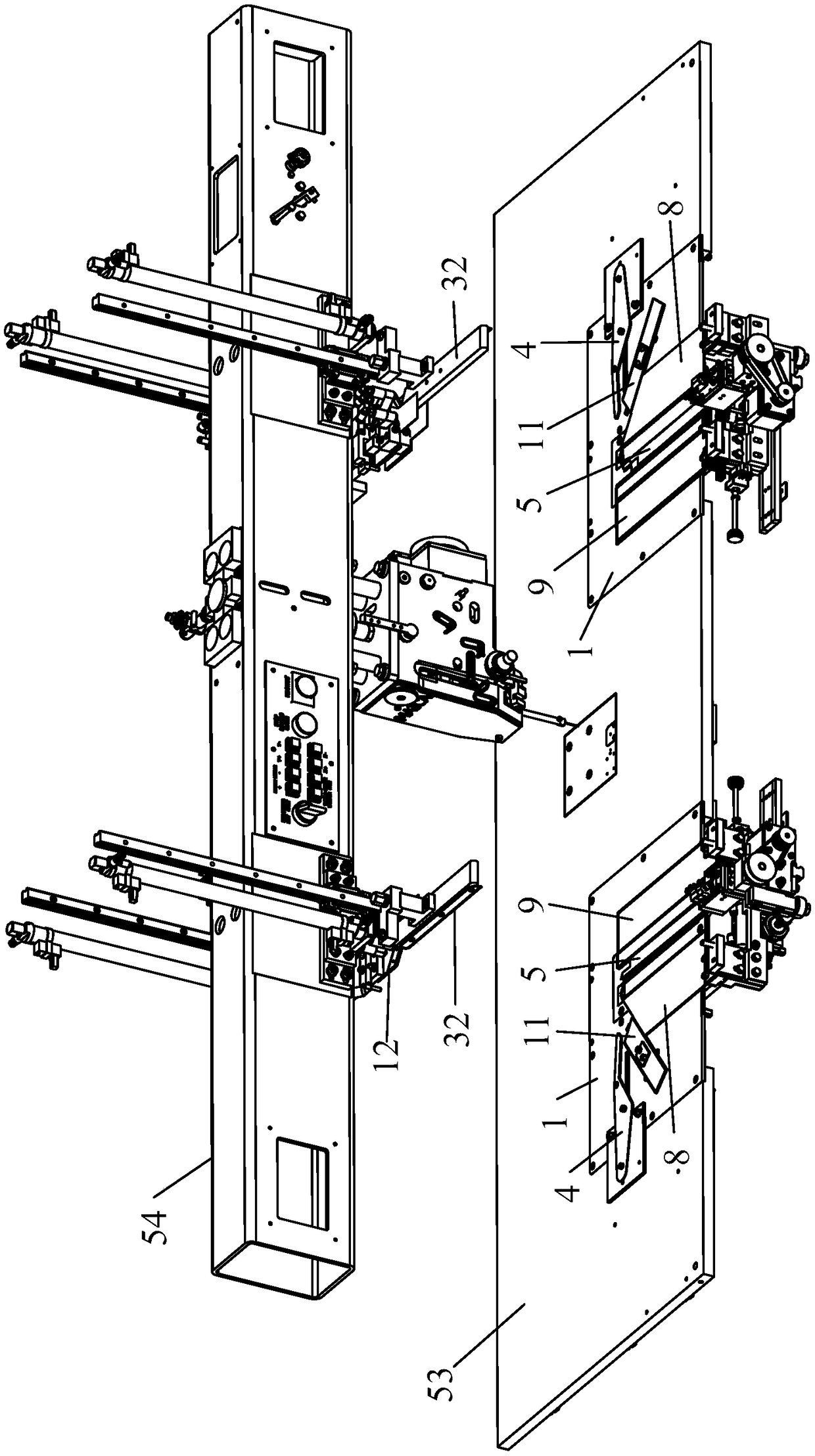

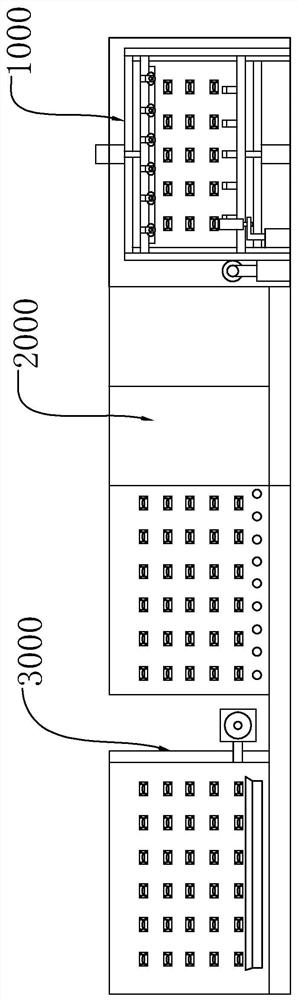

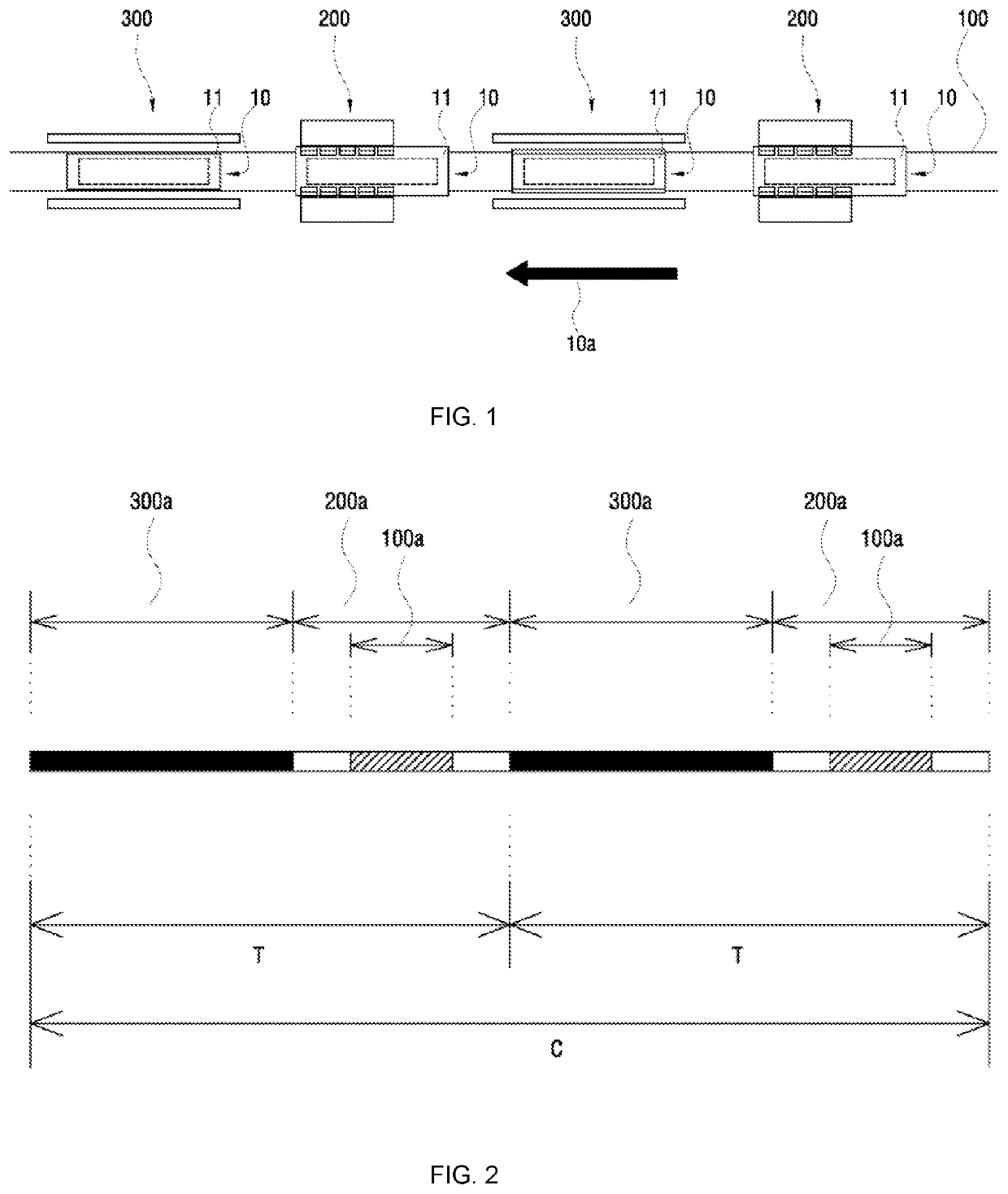

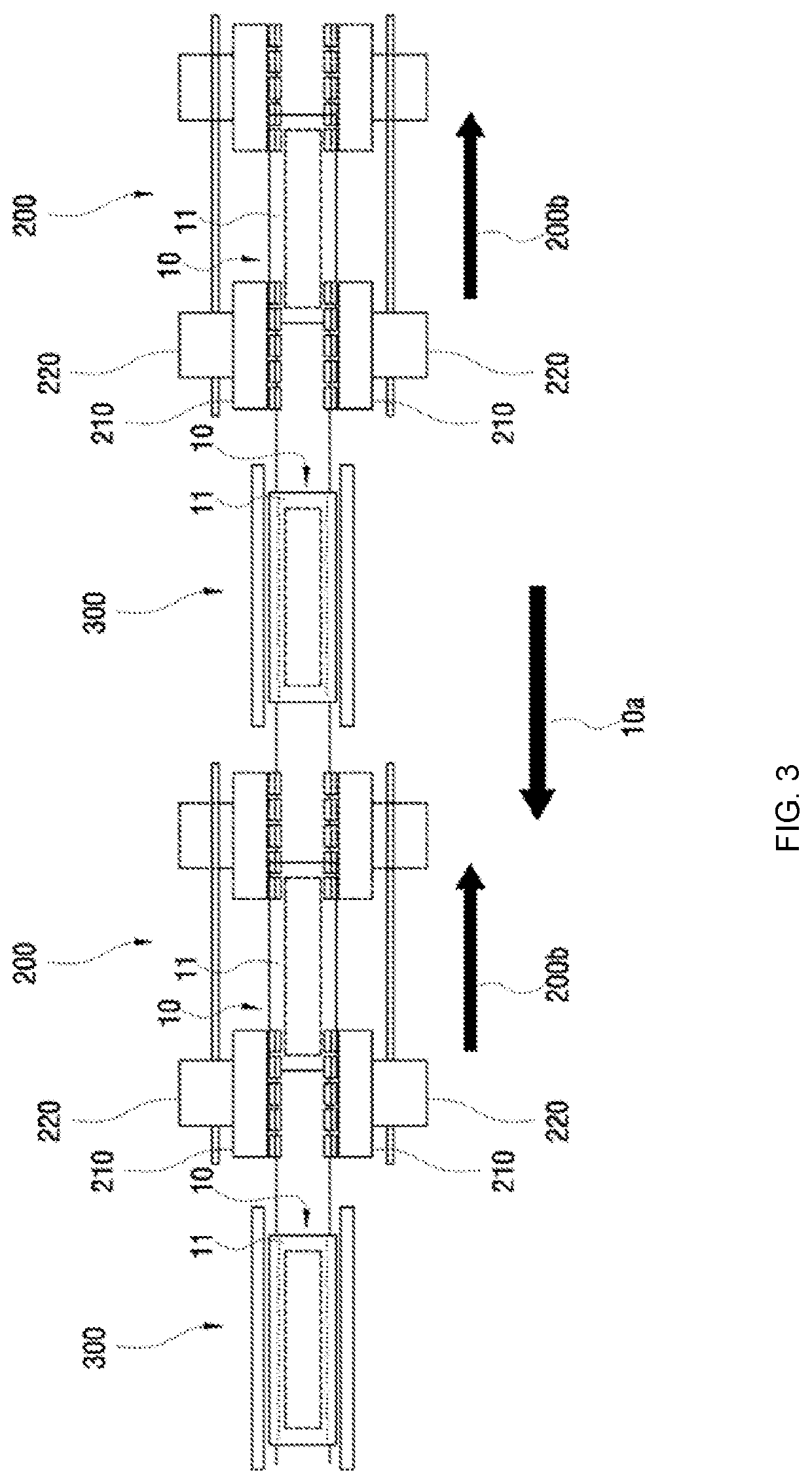

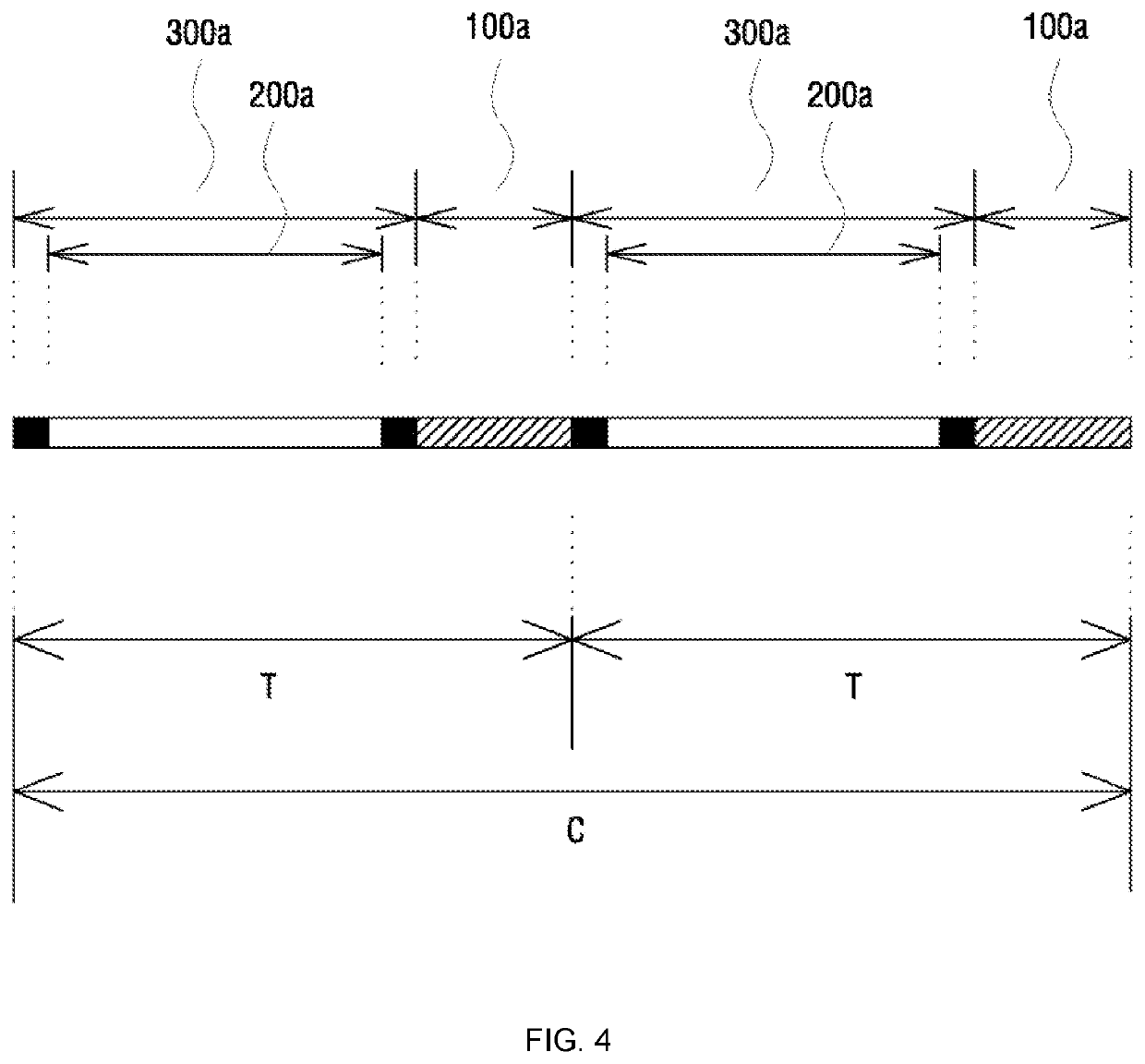

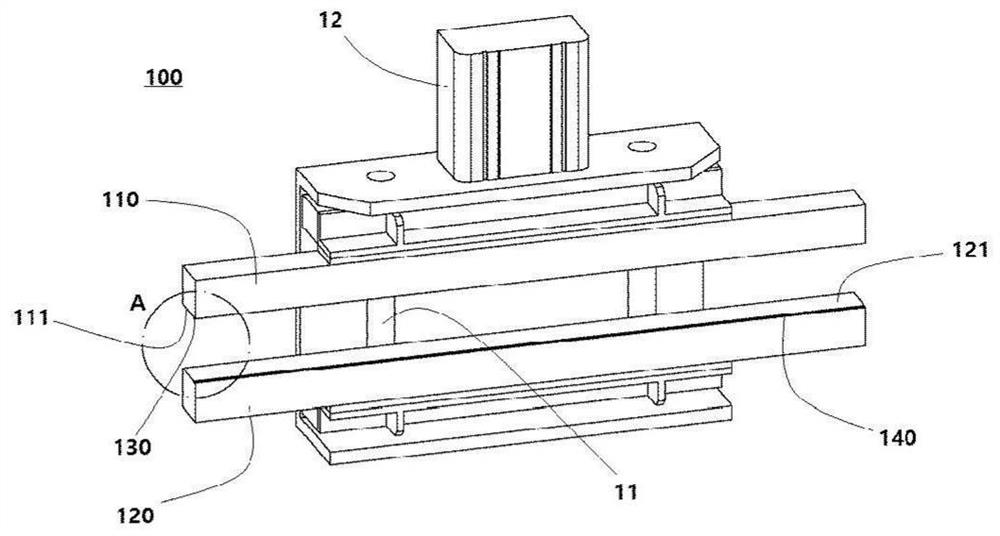

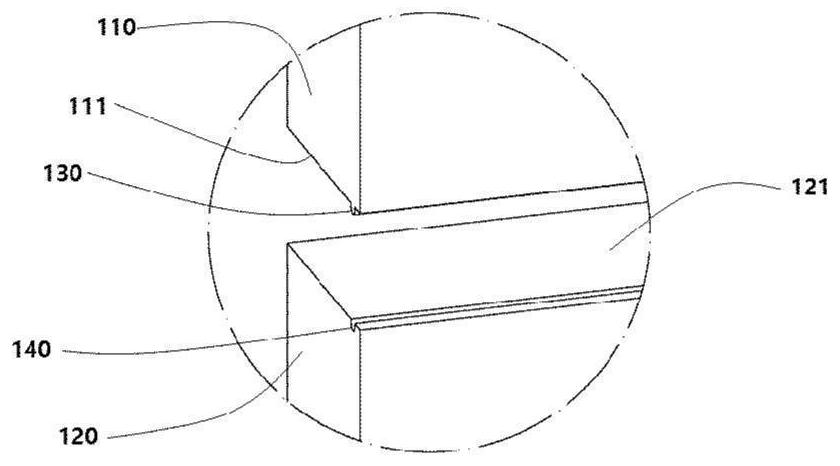

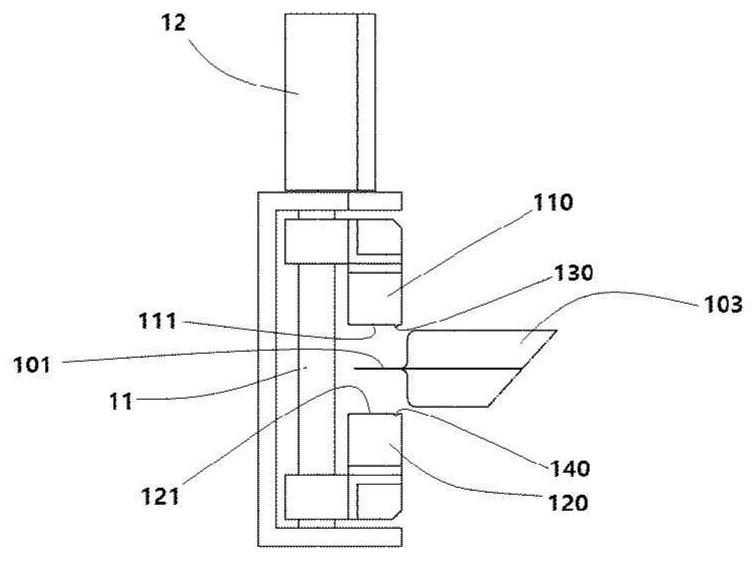

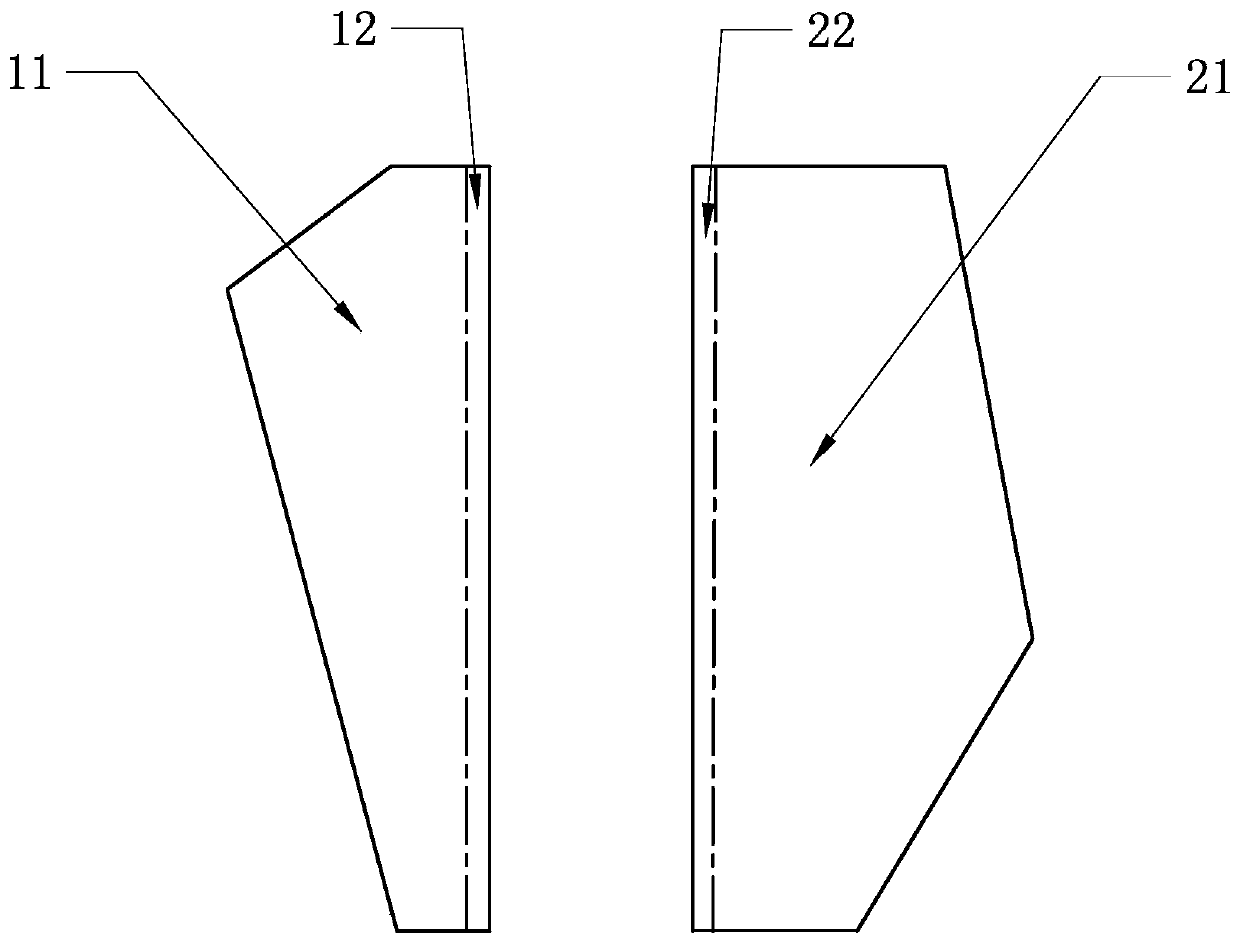

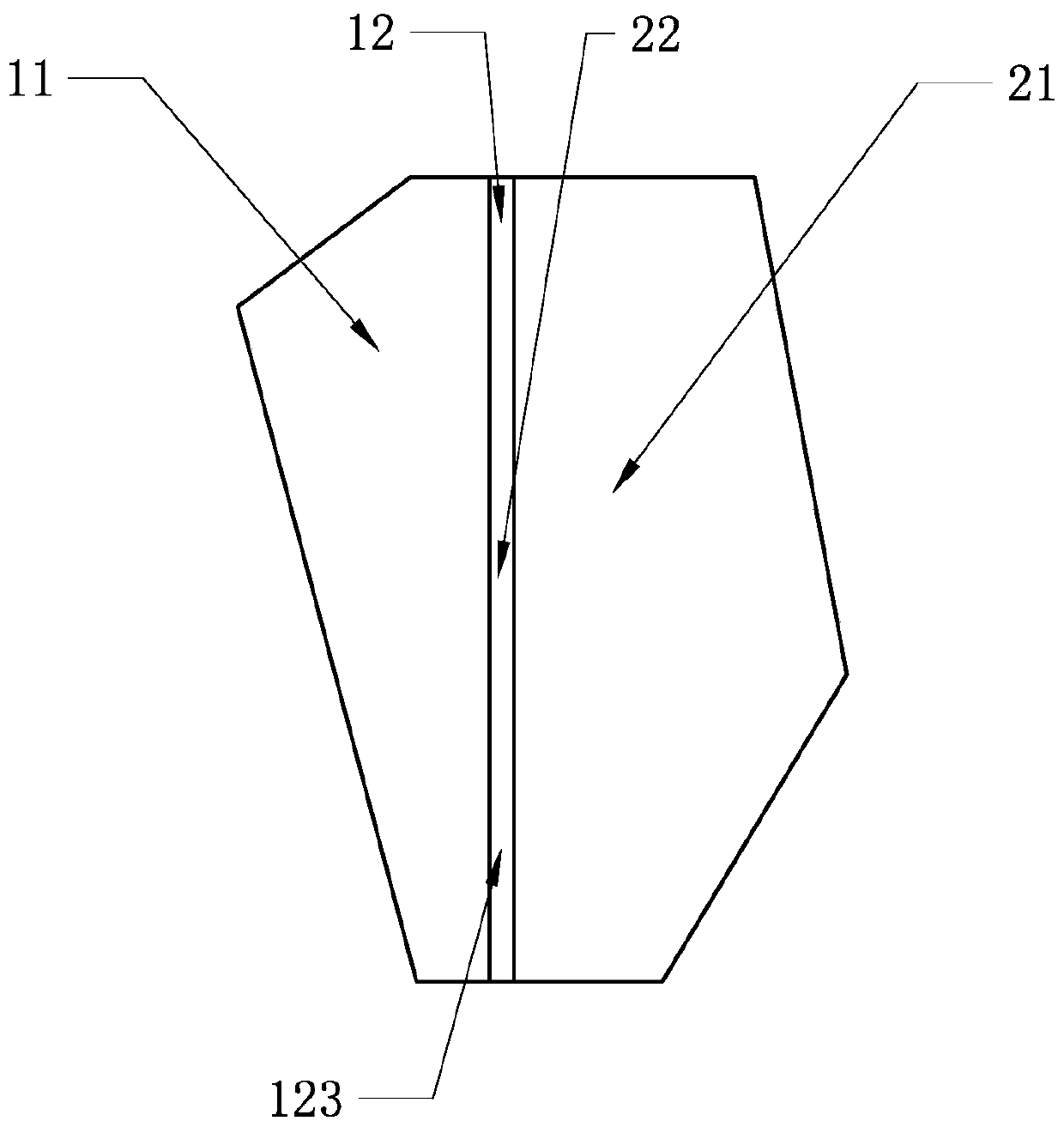

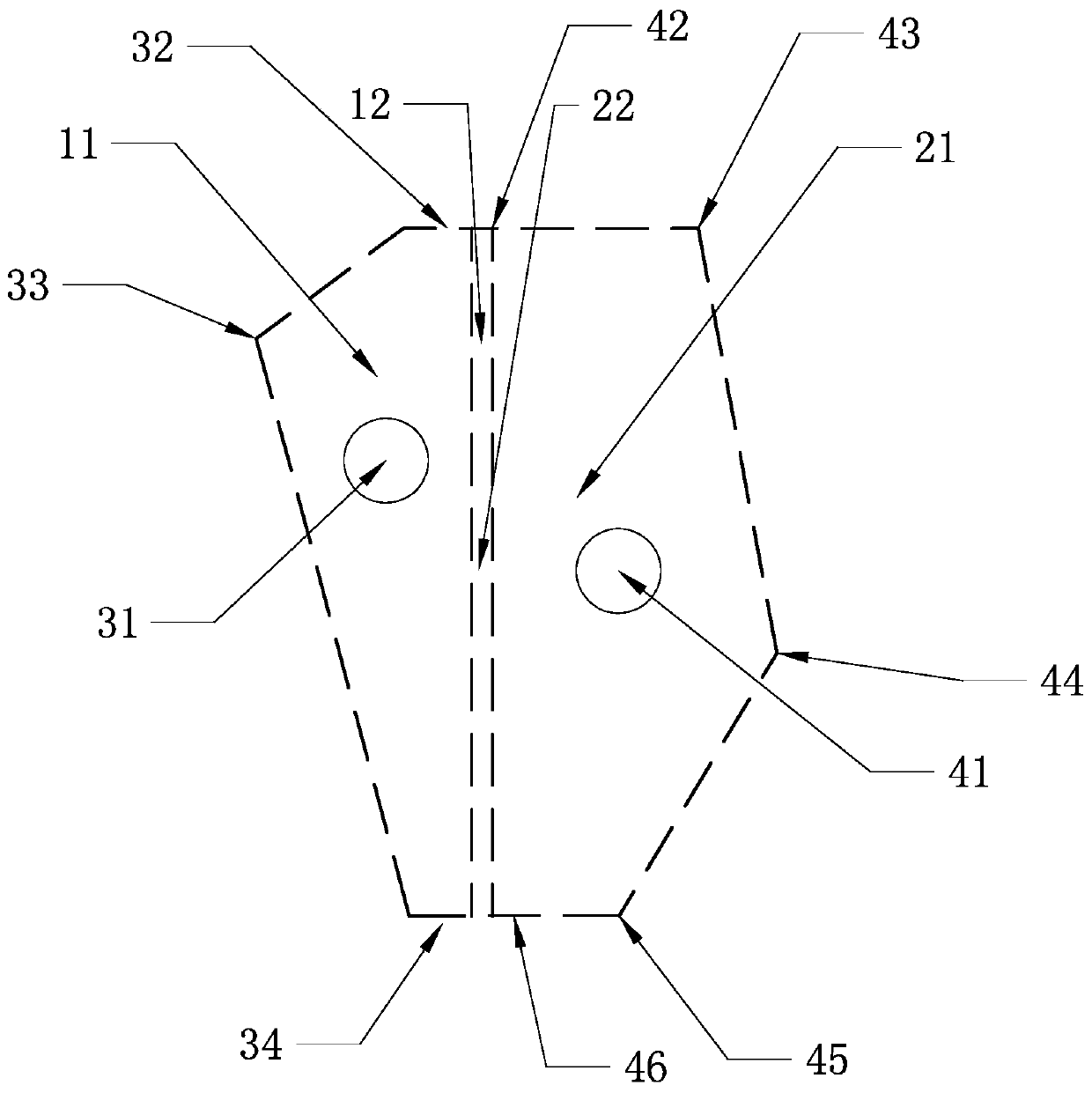

Terrace folding system of secondary battery cell

PendingUS20220227037A1Tact time can be reducedImprove fold qualityAssembling battery machinesFinal product manufactureMechanical engineeringBattery cell

Disclosed is a terrace folding system of a secondary battery cell, including a transfer unit which transports a secondary battery cell; and a folding unit which is disposed along the transfer unit and is temporally separated from the transfer unit to fold a terrace of the secondary battery cell.

Owner:CLEVER

A mechanical structure for automatic folding of long stockings and its folding method

The invention discloses a silk stocking automatic folding mechanical structure and a folding method thereof. The mechanical structure comprises conveyor belts, belt pulleys, a motor, a crank mechanism, an inner paperboard conveying rail, a vacuum adsorption disc, a guide pulley and a photoelectric sensor. The motor drives the crank mechanism so as to drive crank to rotate. An inner paperboard adding mechanism comprises the inner paperboard conveying rail, the vacuum adsorption disc and the guide pulley. The silk stocking automatic folding mechanical structure is simple and reasonable, the folding method is simple, the whole operation performance is good, and high efficiency is achieved. A silk stocking folding machine can work through complicated equipment such as manipulators, but the cost of the silk stocking folding machine is high, so that common enterprises do not have integration capability. The silk stocking automatic folding mechanical structure is low in cost, so that the enterprises can perform integrated arrangement. According to the design of the mechanical structure and by employing the mechanical structure, the labor intensity of workers can be hopefully reduced, and the folding efficiency and quality of silk stockings can be improved.

Owner:QUZHOU COLLEGE OF TECH

Single station transmission-free folding method in panty-hose automatic packing and mechanism

InactiveCN103158908BSimple folding mechanismSmall footprintPackagingStructural engineeringSingle station

The invention provides a single station transmission-free folding method in panty-hose automatic packing. The single station transmission-free folding method in panty-hose automatic packing is characterized by comprising a preparation process, a first process, a second process and a third process. The invention further provides a mechanism utilizing the method. The mechanism utilizing the method is characterized by comprising a panty-hose bending table. A clamping mechanism, a movable shaft, a first fixed shaft, a second fixed shaft, an overturn mechanism and a movable board in the overturn mechanism are arranged on the panty-hose bending table. The single station transmission-free folding method in panty-hose automatic packing and the mechanism have the advantages that folding of a panty-hose is finished on one station, a folding mechanism of a packing machine is simplified, and occupied area of the folding mechanism is reduced. Reliability of operation of equipment is improved, actions are simple in a folding process, and the length of three segments can be affirmed solely. Uniformity of the size is guaranteed after the panty-hose is folded, the utilization of a movable board in the turnover mechanism enables the method to be suitable for folding panty-hoses with different length specifications, and panty-hose conveying is not needed in the whole folding process. The phenomenon that a folding effect is affected due to deflection of the panty-hoses is avoided, and folding quality, packing efficiency and packing finished product rate are improved.

Owner:DONGHUA UNIV +1

Material folding mechanism of bottom crotch attaching sewing machine

The invention discloses a material folding mechanism of a bottom crotch attaching sewing machine. The material folding mechanism comprises a supporting plate used for placing a bottom crotch sheet, the supporting plate is provided with a supporting face used for supporting a bottom plate sheet, and a first limiting plate and a second limiting plate which are higher than the supporting face are arranged at the two sides of the supporting plate. Material folding plates used for folding the two ends of the bottom crotch sheet are arranged at the two ends of the supporting plate respectively. According to the material folding mechanism, the first limiting plate and the second limiting plate which are higher than the supporting face are arranged at the two sides of the supporting plate, the situation that the bottom crotch sheet is distorted and misaligned when placed on the supporting face is prevented, and the folding quality of the bottom crotch sheet is improved.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Folding device convenient for production of safe air bag of automobile and use method thereof

PendingCN112811244AImprove folding efficiencyImprove fold qualityFolding thin materialsDrive by wireEngineering

The invention discloses a folding device convenient for production of a safe air bag of an automobile and a use method thereof and belongs to the technical field of air bag folding. The device comprises a rack, an operating table arranged above the rack and a folding device arranged on the operating table, wherein the folding device is comprised of an X-axis linear folding mechanism and a Y-axis linear folding mechanism mounted on the operating table, the X-axis linear folding mechanism is comprised of a bidirectional linear driving mechanism and X-axis folding assemblies symmetrically mounted at driving ends of the bidirectional linear driving mechanism and arranged oppositely, each of the two Y-axis folding mechanisms is comprised of two Y-axis folding assemblies arranged oppositely and a rotary pressing mechanism located between the two Y-axis folding assemblies, and a longitudinal supporting and clamping mechanism is arranged on the rack. The folding device is matched with manpower to fold the safe air bag of the automobile via mechanical equipment, and the folding efficiency and the folding quality of the safe air bag of the automobile are improved, so that the production efficiency is improved.

Owner:WUHU RUITAI AUTO PARTS

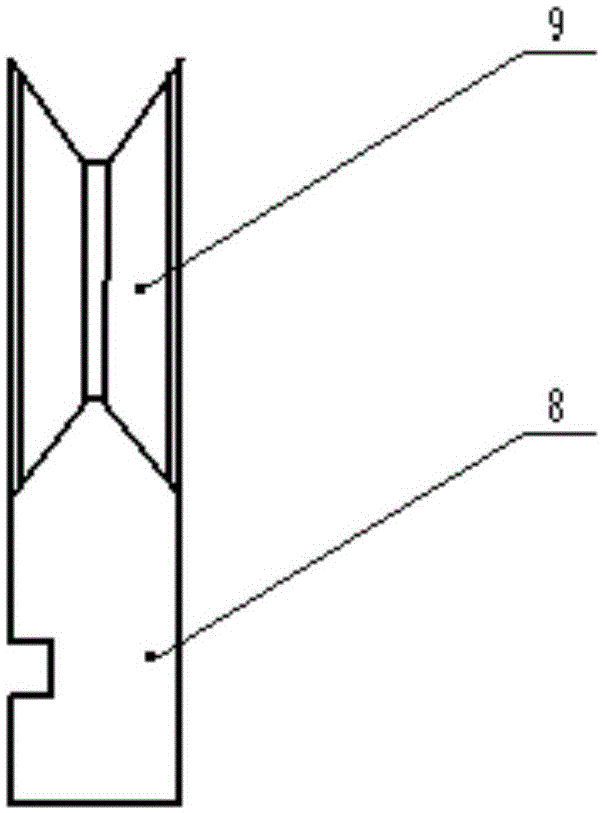

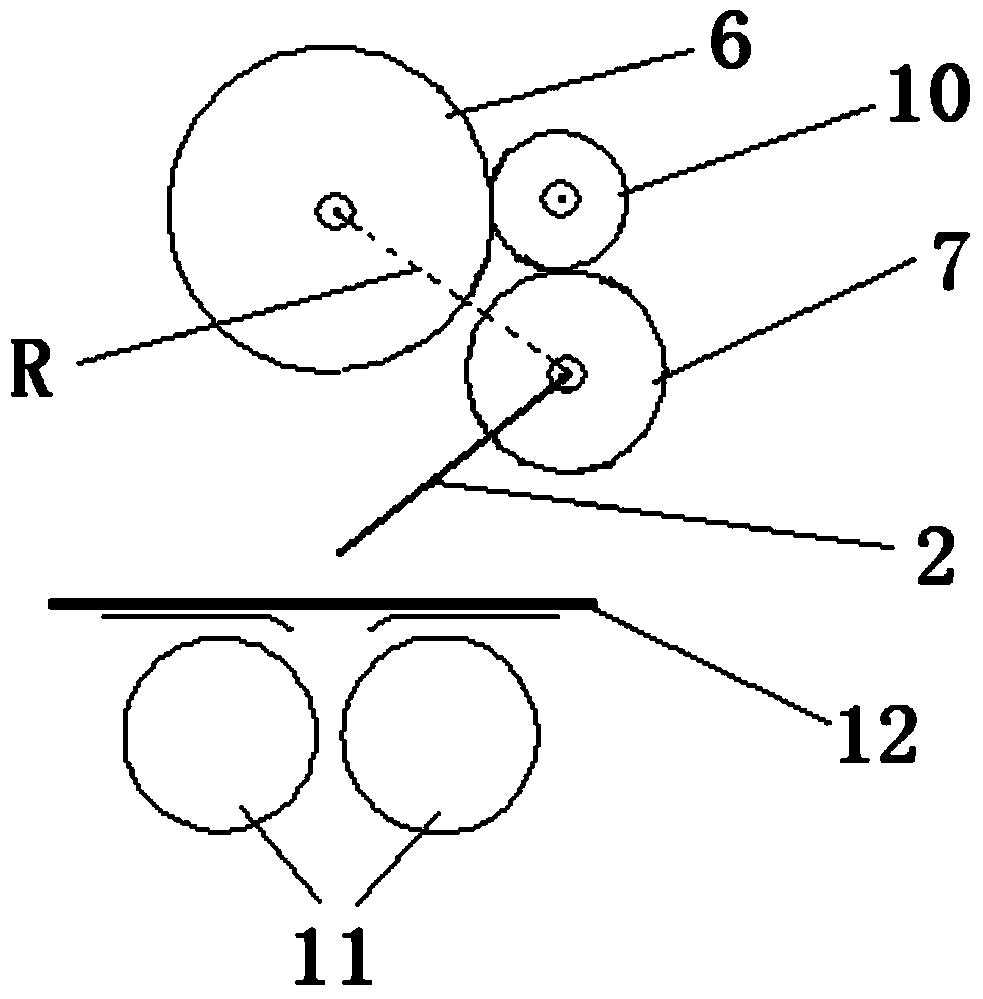

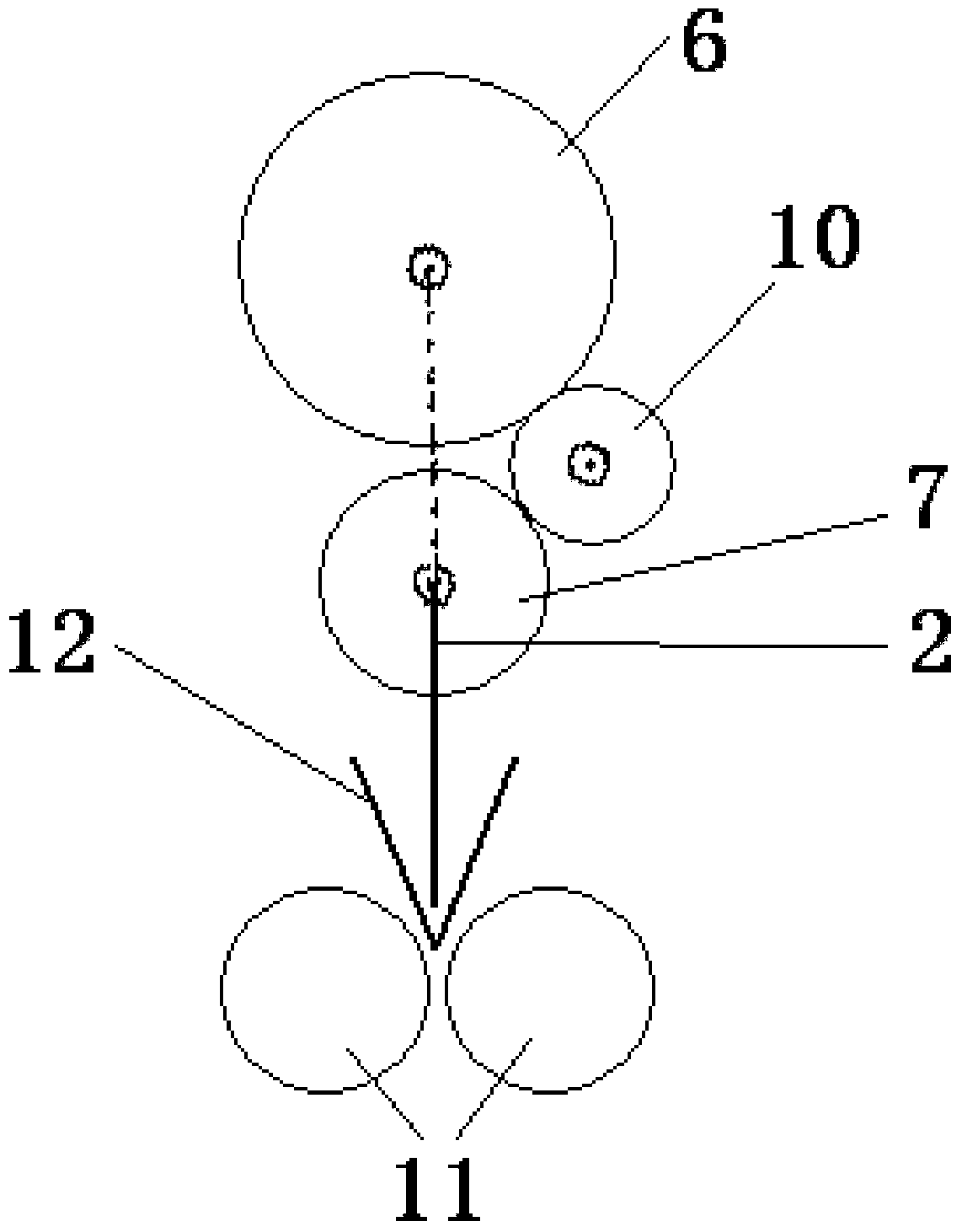

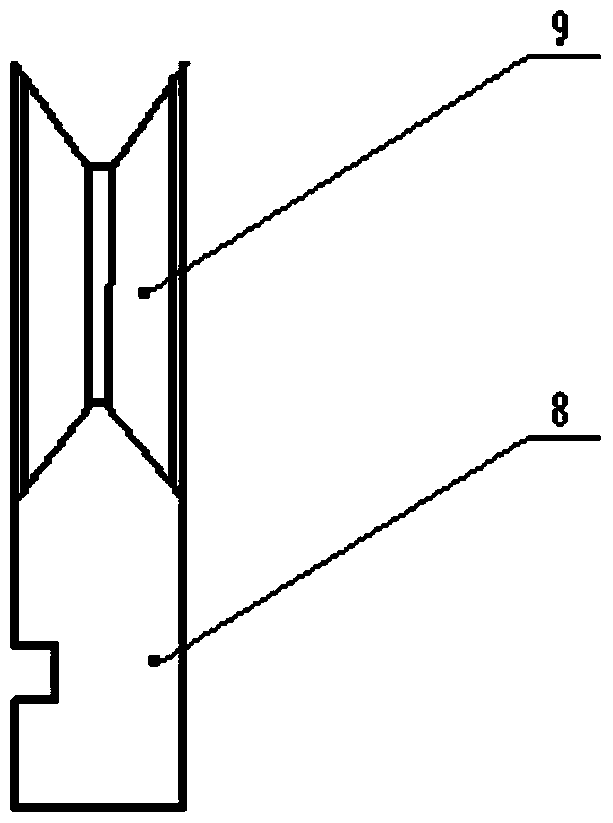

Inner frame paper folding device and system

PendingCN113247342ASolve the problem of rear conveying blockageEliminate deformation problemsPackaging cigaretteWrapper folding/bending apparatusRotational axisEngineering

The invention discloses an inner frame paper folding device and system. The inner frame paper folding device comprises two grid plates arranged in parallel, a supporting shaft, an upper rotating wheel, a belt, belt wheels, rotating shafts, a left supporting plate, a right supporting plate and lower rotating wheels, and the left supporting plate and the right supporting plate are arranged in parallel; the rotating shafts are installed between the left supporting plate and the right supporting plate, the lower rotating wheels are installed in the middles of the rotating shafts side by side, and the belt wheels are installed at one ends of the rotating shafts and sleeved with the belt; the supporting shaft is installed between the left supporting plate and the right supporting plate, one ends of the two grid plates are hinged to the middle of the supporting shaft, and the upper rotating wheels are installed between the two grid plates; and the wheel surfaces of the upper rotating wheels are in a V shape, and the wheel surfaces of the lower rotating wheels are in an inverted V shape. The problem of rear conveying blockage caused by folding deflection of inner frame paper in the forming process is solved. Te situation that the inner frame paper deforms or conveying is blocked after the inner frame paper enters a semicircular conveying device is avoided. The folding quality of the inner frame paper is improved, and the shutdown rate caused by faults of the inner frame paper is reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Sealing portion forming apparatus for folding secondary battery pouch

PendingCN113396505AImprove fold qualityPrevent springbackAssembling battery machinesFinal product manufactureElectrical batteryEngineering

The disclosed sealing portion forming apparatus for folding a secondary battery pouch comprises: first and second pressing bars that are disposed to face each other with a sealing portion for folding interposed therebetween so as to apply a pressing force for flattening the sealing portion for folding, the sealing portion being defined by the edges of the secondary battery pouch that seals an electrode assembly accommodated therein; first and second pressing surfaces provided respectively on the first and second pressing bars and disposed to face the sealing portion for folding; and a forming protrusion provided on the first pressing surface and forming a folding guide line in the sealing portion for folding by means of a pressing force from the first and second pressing bars.

Owner:株式会社快乐福

Fabric adsorbing manipulators based on industrial robot visions and fabric grabbing method

InactiveCN110552118AImprove fold qualityFully automatedProgramme-controlled manipulatorProgramme-controlled sewing machinesEngineeringManipulator

The invention relates to the technical field of sewing machines, and provides fabric adsorbing manipulators based on industrial robot visions and a fabric grabbing method. The fabric adsorbing manipulators comprise the first fabric adsorbing manipulator and the second fabric adsorbing manipulator, a first fabric is provided with a first fabric overlay part, a second fabric is provided with a second fabric overlay part, overlay portions of the first fabric overlay part and second fabric overlay part are overlay layers, a sewing machine press foot device receives press foot instructions sent bythe first fabric adsorbing manipulator and the second fabric adsorbing manipulator, a program processing terminal controls the sewing machine press foot device to perform press foot actions, and the overlay layers are pressed by the press foot. After the first fabric adsorbing manipulator and the second fabric adsorbing manipulator grab the first fabric and the second fabric in sequence, the firstfabric overlay part of the first fabric and the second fabric overlay part of the second fabric are subjected to edge overlay according to a preset overlay width, by depending on the first vision andthe second vision, the precision of the overlay layers of the first fabric overlay part and the second fabric overlay part after overlay is high, high-quality sewing is achieved, and the fabric adsorbing manipulators has higher promotion value.

Owner:QIXING INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com