Material folding mechanism of bottom crotch attaching sewing machine

A sewing machine and bottom sticking technology, applied in the field of sewing machines, can solve problems such as difficult alignment and easy distortion, and achieve the effect of improving folding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

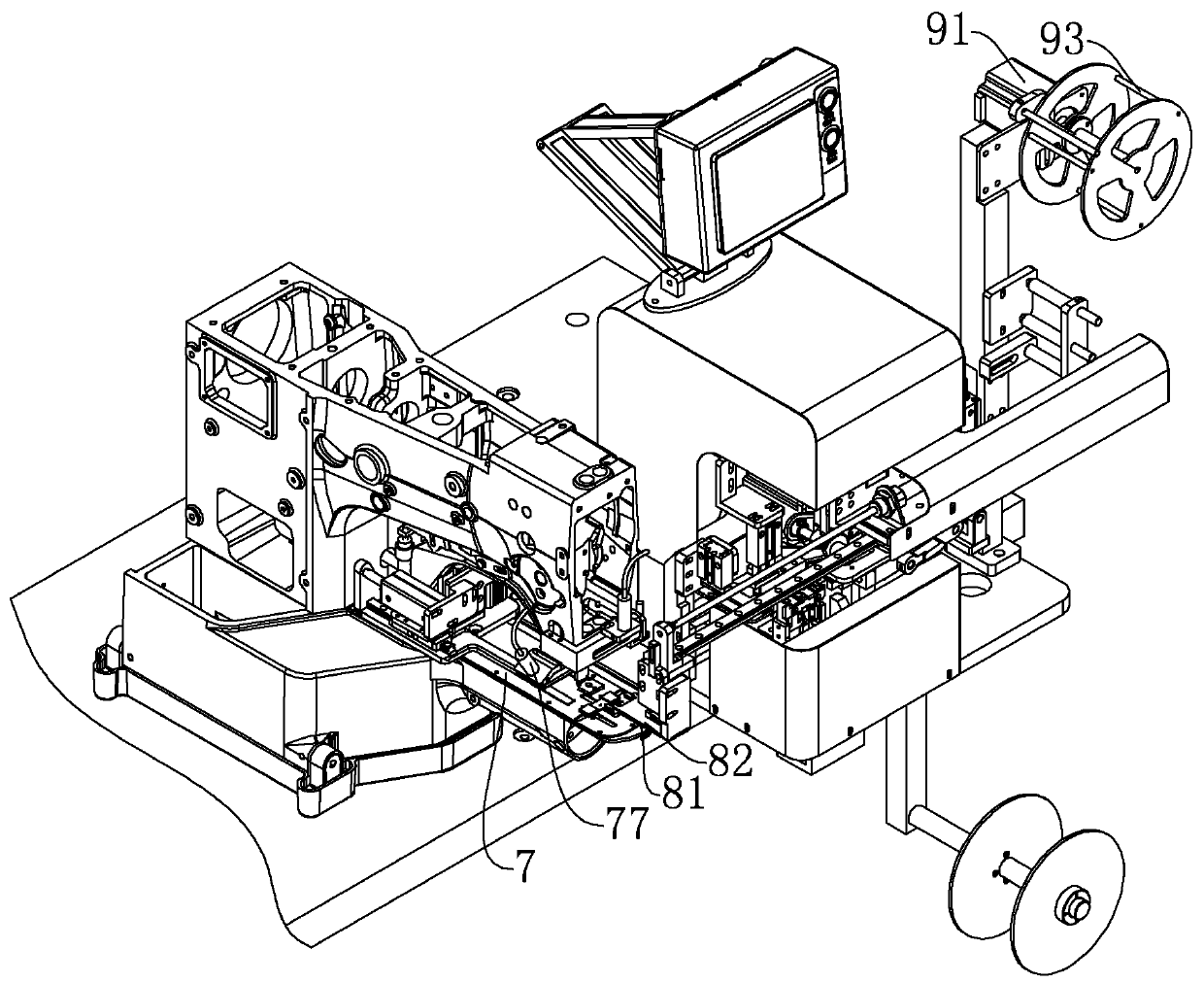

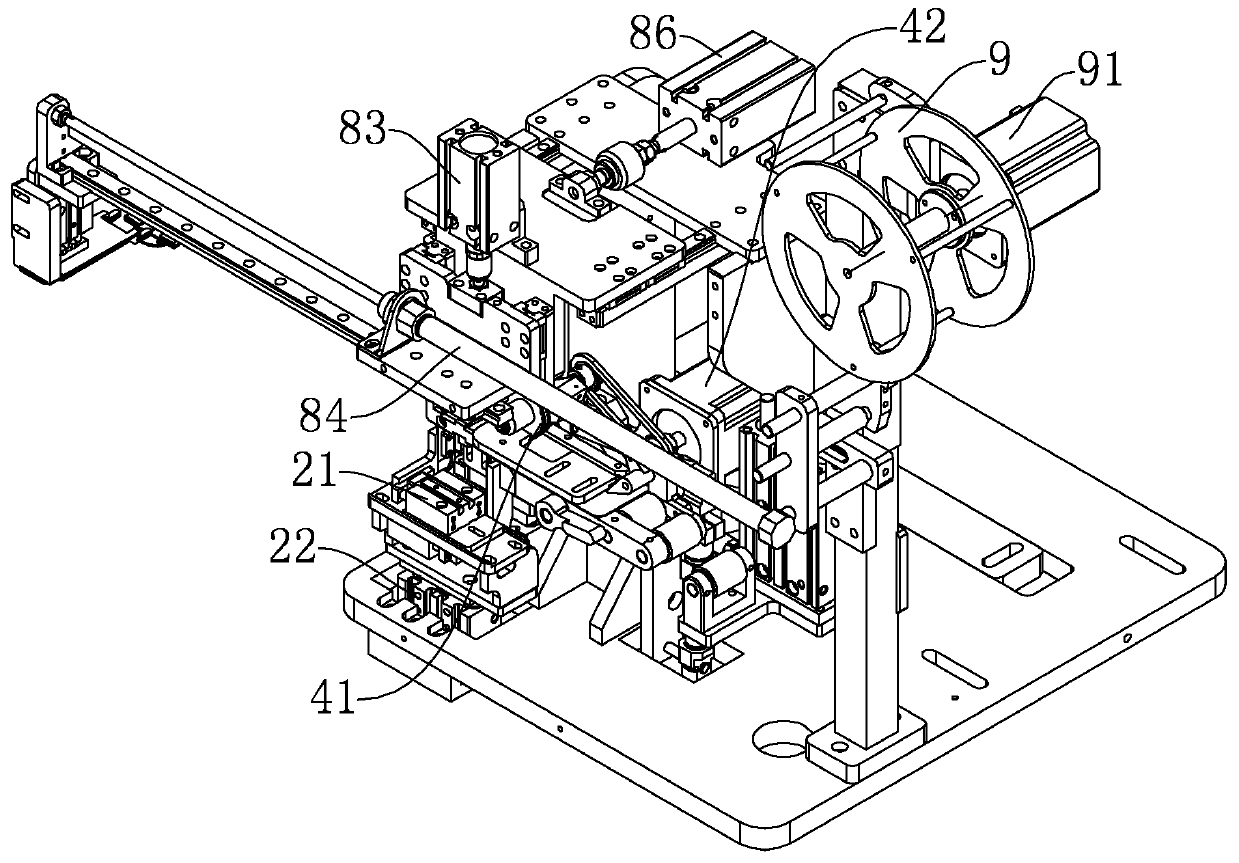

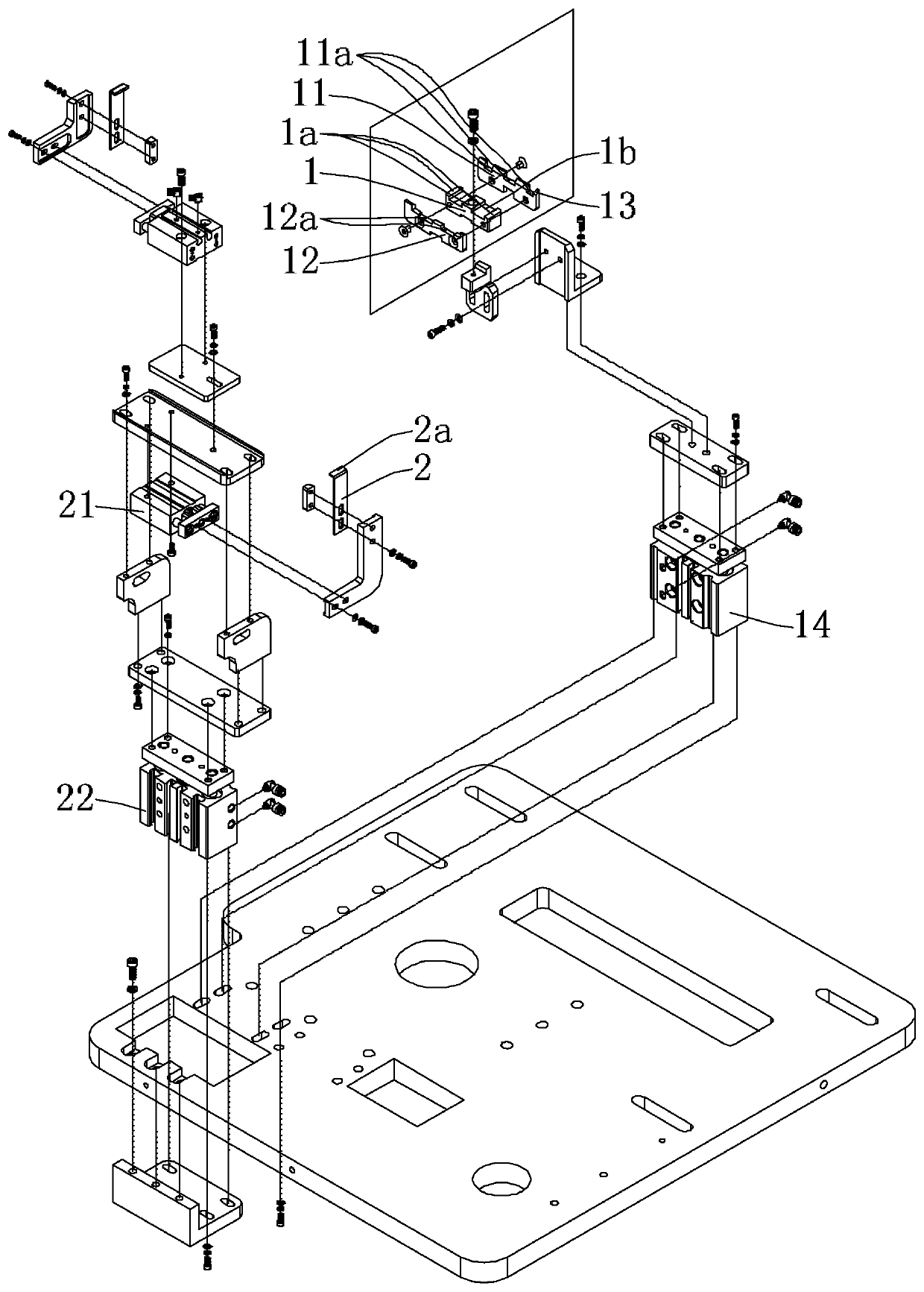

[0022] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0023] The reference signs are: support plate 1, support surface 1a, first groove 1b, first limiting plate 11, second groove 11a, second limiting plate 12, third groove 12a, folding material guide Inclined surface 13, lifting cylinder 14, folding plate 2, bending part 2a, horizontal folding driving cylinder 21, lifting folding driving cylinder 22, first pressing plate 3, pressing part 3a, fourth groove 3b, pressing Material driving cylinder 31, feeding mounting seat 4, feeding gear 41, feeding motor 42, feeding bracket 43, rotating shaft 43a, feeding tension spring 44, anti-backward plate 45, flat tip 45a, connecting handle 45b, handle 46, connecting rod 47, cutter mount 5, cutter shaft 51, cutter 52, material cutting cylinder 53, pull cylinder 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com