Single station transmission-free folding method in panty-hose automatic packing and mechanism

A technology of automatic packaging and folding methods, applied in packaging and other directions, can solve the problems of large floor space, misalignment of pantyhose, and reduced reliability of operation, and achieve the advantages of reducing floor space, simplifying folding mechanism, and improving folding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0027] The single-station non-transmission folding method in the pantyhose automatic packaging provided by the invention includes a preparation process, a first folding process, a second folding process and a third folding process.

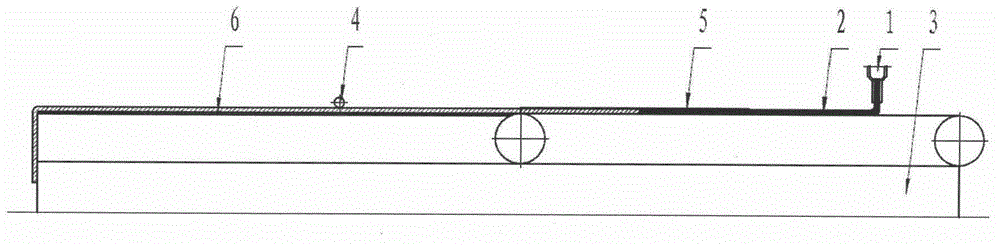

[0028] Such as figure 1 Shown is a schematic diagram of the preparation process, the steps of which are: the clamping mechanism 1 clamps the waist of the pantyhose 2 folded longitudinally and misplaced, and places it at a designated position on the sock folding table 3; Stretch out; The inner cardboard 5 is placed on the specified position on the pantyhose 2; The turning mechanism 6 is in the original state.

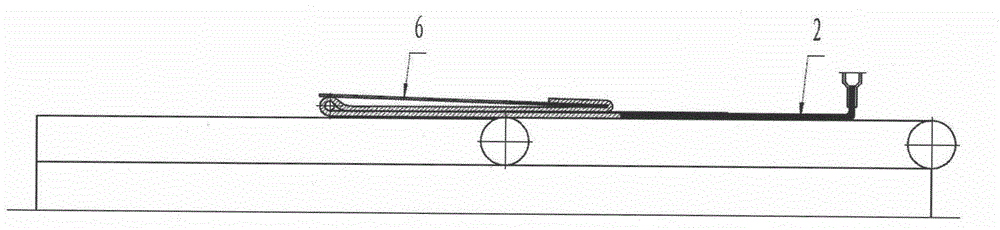

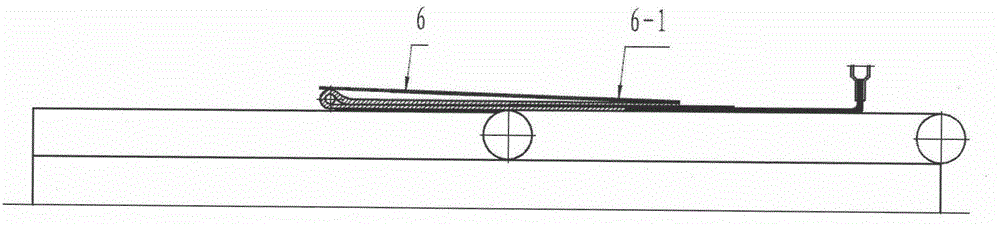

[0029] Such as Figure 2A to Figure 2D Shown is a schematic diagram of the first folding process, the steps are: the turning mechanism 6 turns over 150-180° along the longitudinal direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com