Fabric adsorbing manipulators based on industrial robot visions and fabric grabbing method

A technology of industrial robots and cloth suction manipulators, which is applied in the field of sewing machines, can solve the problems of irregular overlapping edges, low efficiency, and low degree of automation, etc., and achieve the effect of improving folding quality, high promotion value, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

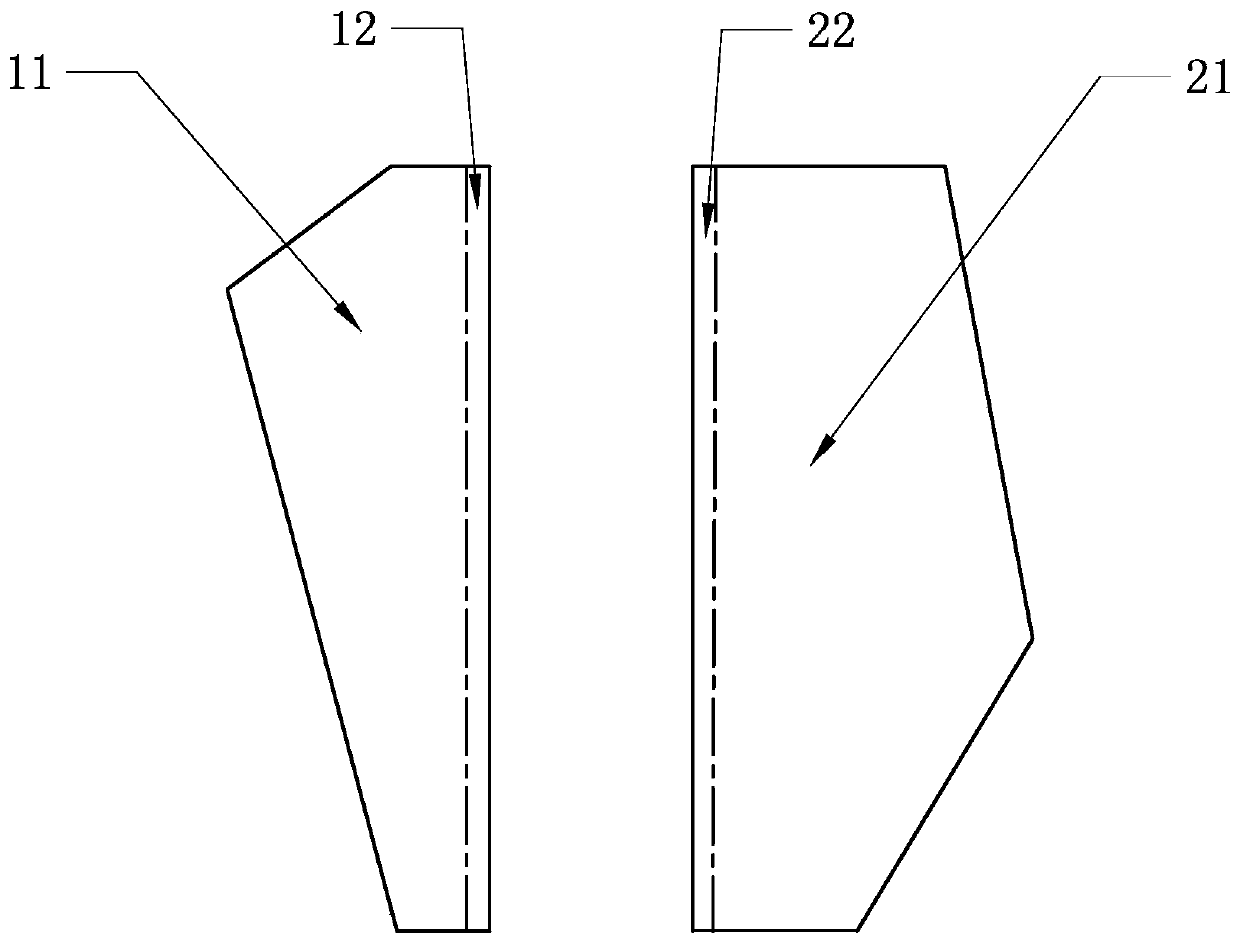

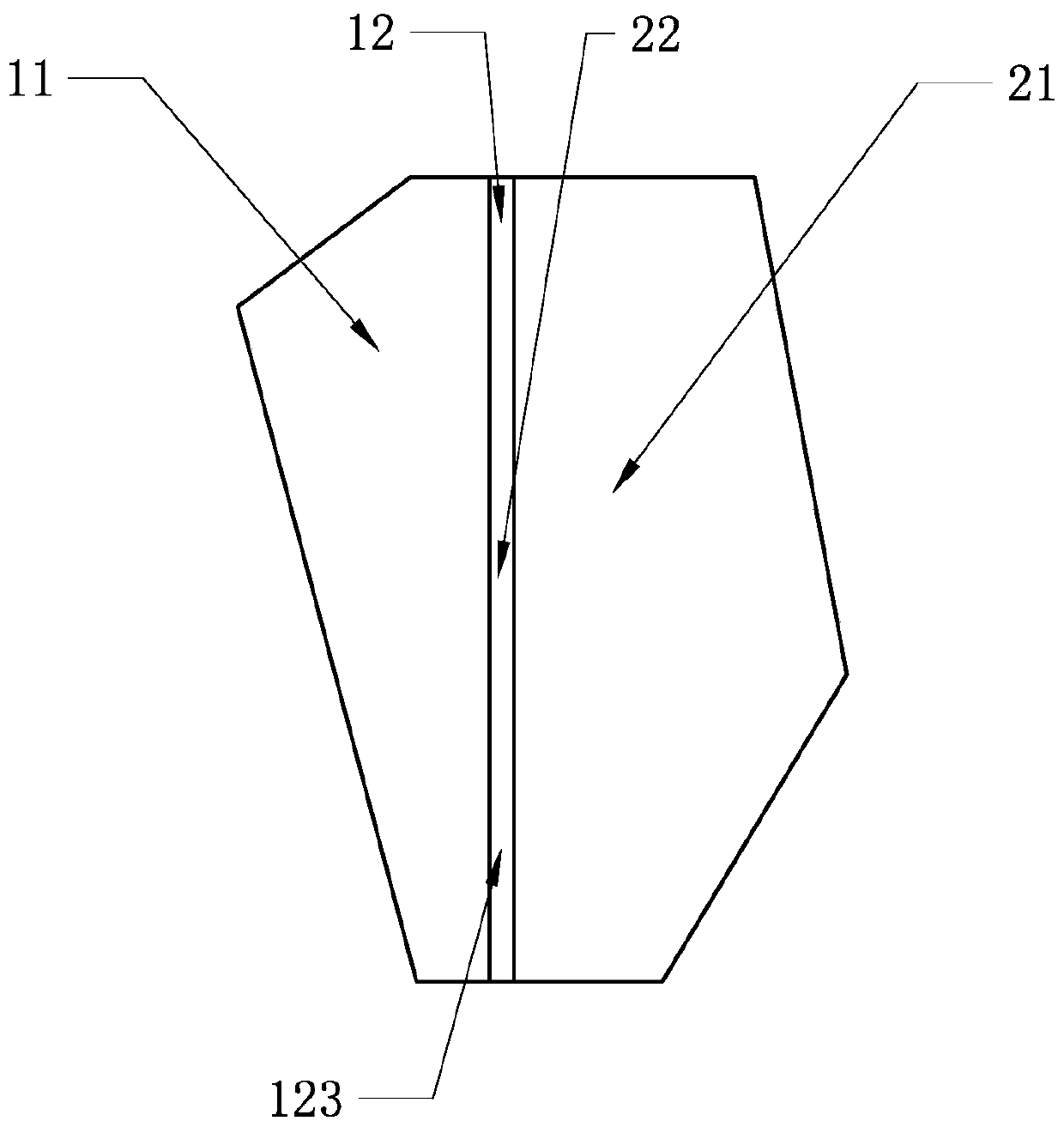

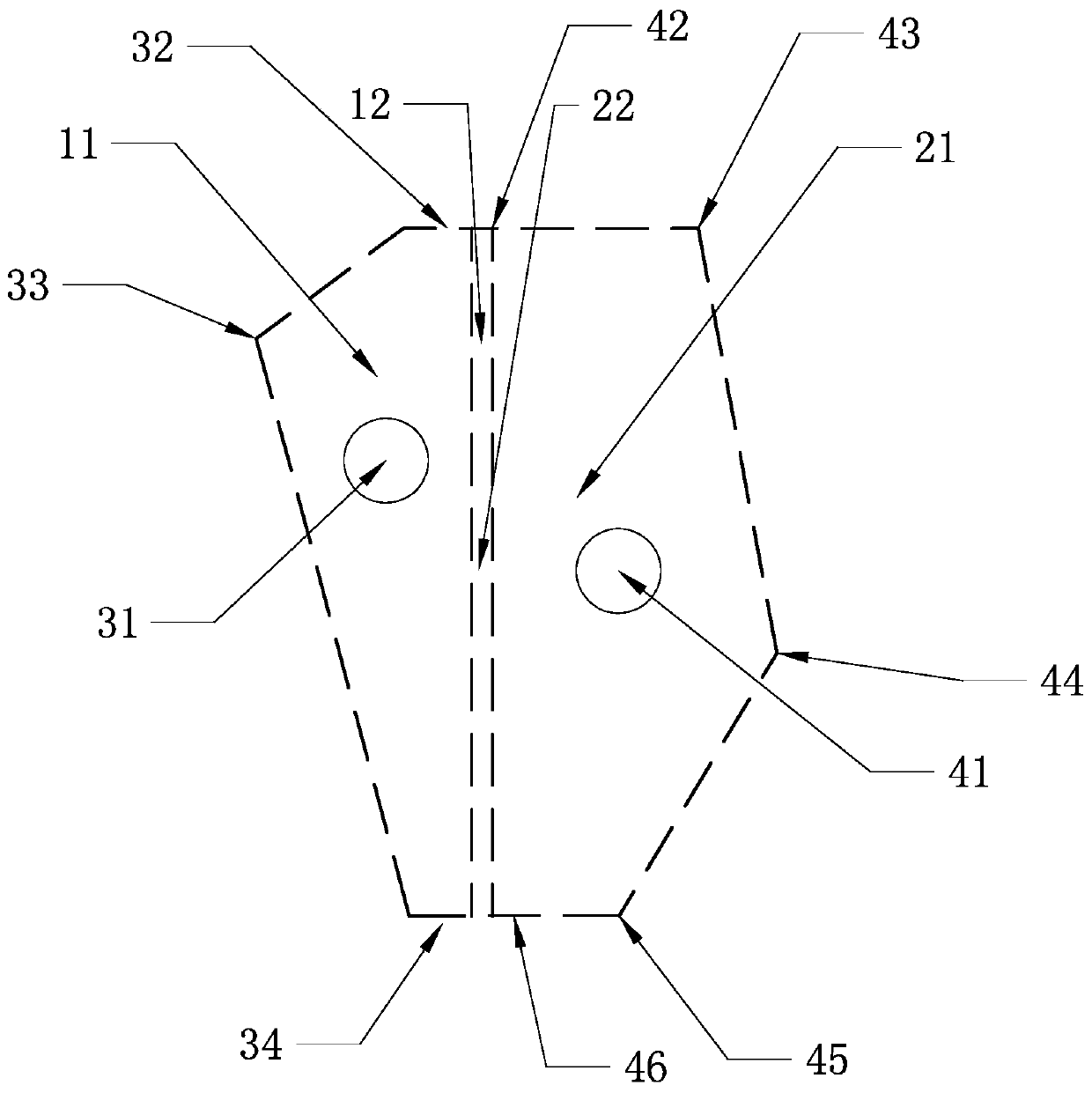

[0021] exist figure 1 and figure 2 It shows that the present invention is based on the cloth-absorbing manipulator and fabric grabbing method under the vision of an industrial robot. After the cloth-absorbing manipulator 1 and the cloth-absorbing manipulator 2 successively grab fabric 1 11 and fabric 2 21, fabric 1 11 and fabric 2 21, the material one superimposing part 12 and the material two superimposing part 22 carry out edge superimposition according to the preset superposition width, and this superimposing part is the superimposing layer 123, so that after the two fabrics of the material one superimposing part 12 and the material two super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com