Auxiliary gripper for folding large balloons

An auxiliary fixture and balloon technology, applied in the field of large-scale balloon folding, can solve the problems of no folding method, waste of carrying space, poor repeatability, etc., and achieve the effect of improving folding efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

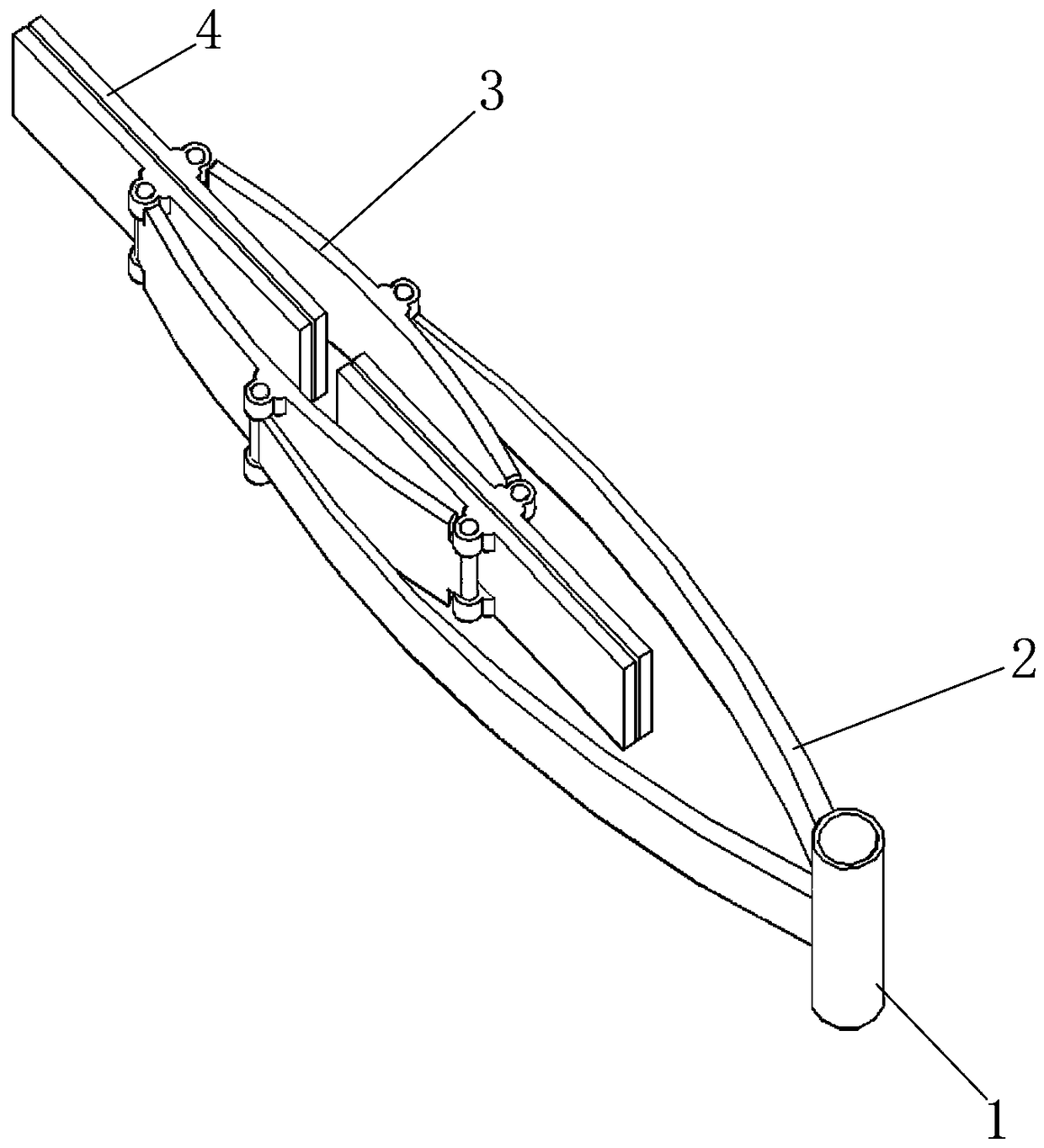

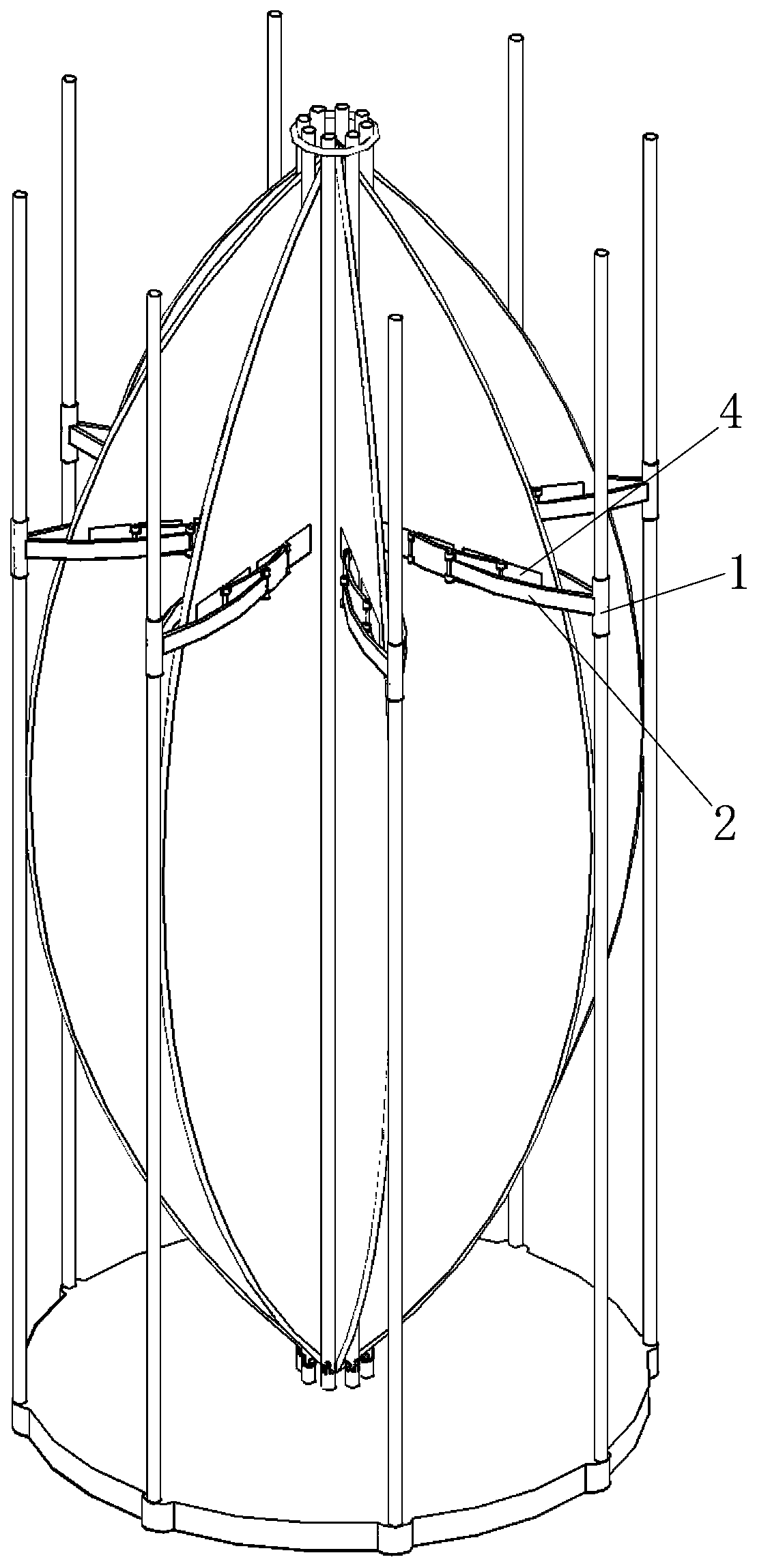

[0008] refer to figure 1 and figure 2 , an auxiliary fixture for folding a large balloon, which includes a sleeve 1, an elastic clip 2, a force component plate 3 and a splint 4; two elastic clips 2 are oppositely arranged on one side of the sleeve 1, each One end of the elastic clip 2 is fixedly connected with the casing 1, and an arc-shaped force component plate 3 is respectively provided at the other end of each elastic clip 2, and the center position of the elastic clip 2 and the force component plate 3 is opened and closed along the Direction rotation connection, the concave surfaces of the two force component plates 3 are set opposite to each other, and a splint 4 is respectively set at both ends of each force component plate 3, and the splint 4 and the force component plate 3 are connected by rotation along the opening and closing direction or through a universal ball to connect; the inner diameter of the casing 1 coincides with the outer diameter of the outer ring ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com