Garment turning-over folding device for garment automated production line

An automatic production line and folding device technology, which is applied to folders, washing devices, laundry room devices, etc., can solve the problems of consuming manpower and material resources, increasing production costs, and manual folding, so as to reduce labor, save production costs, and speed up. The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

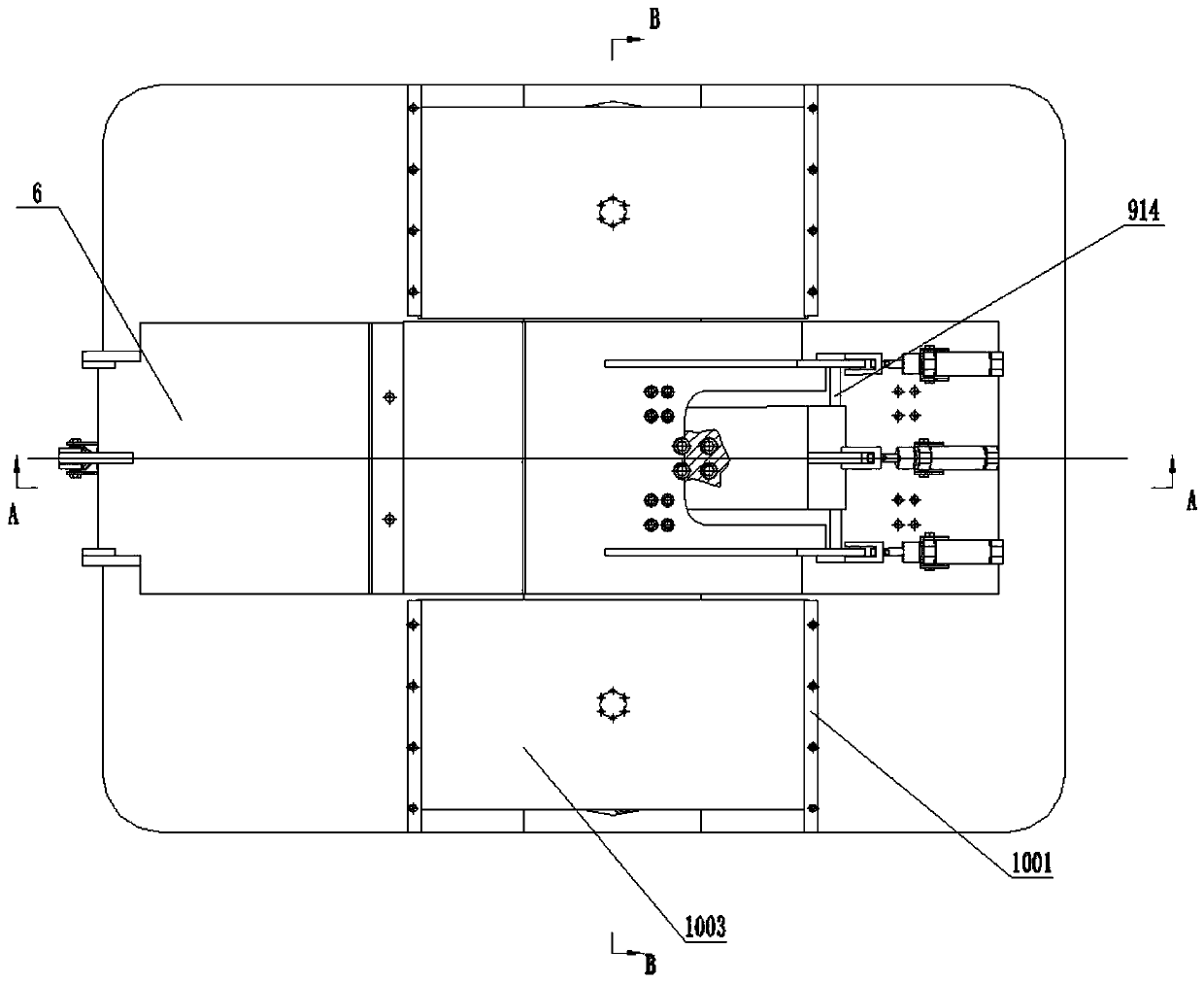

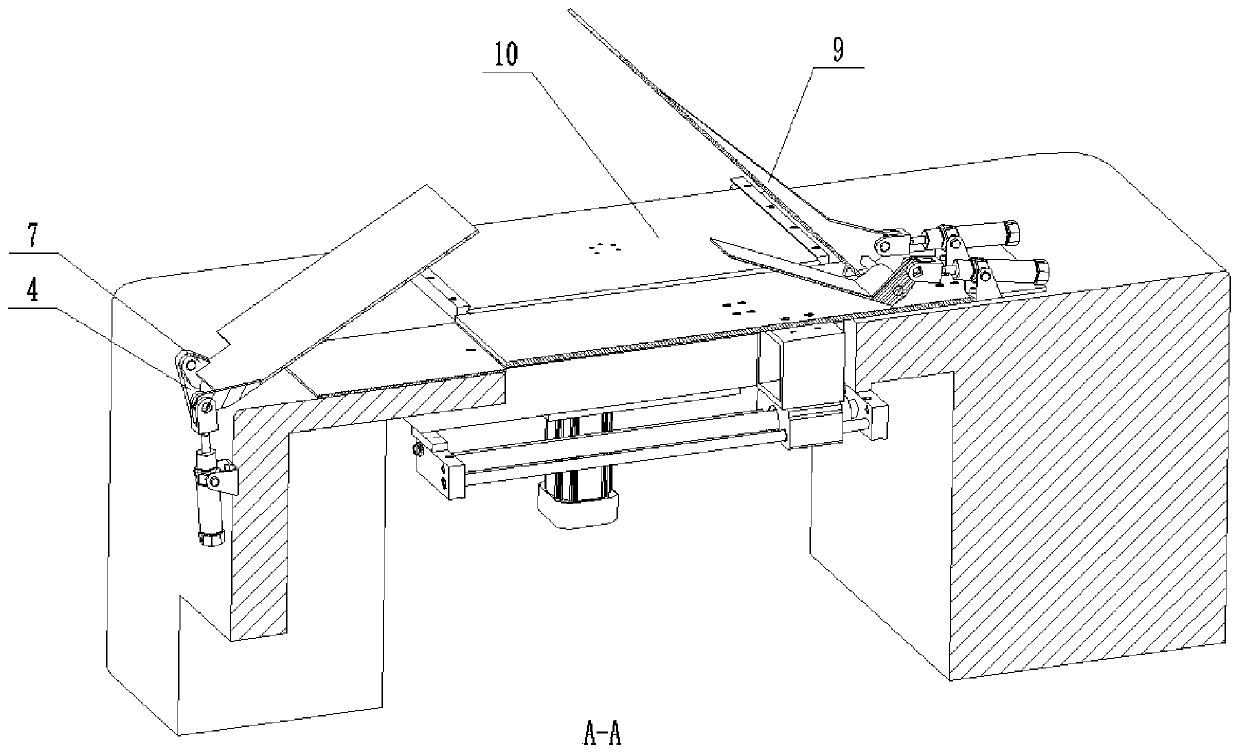

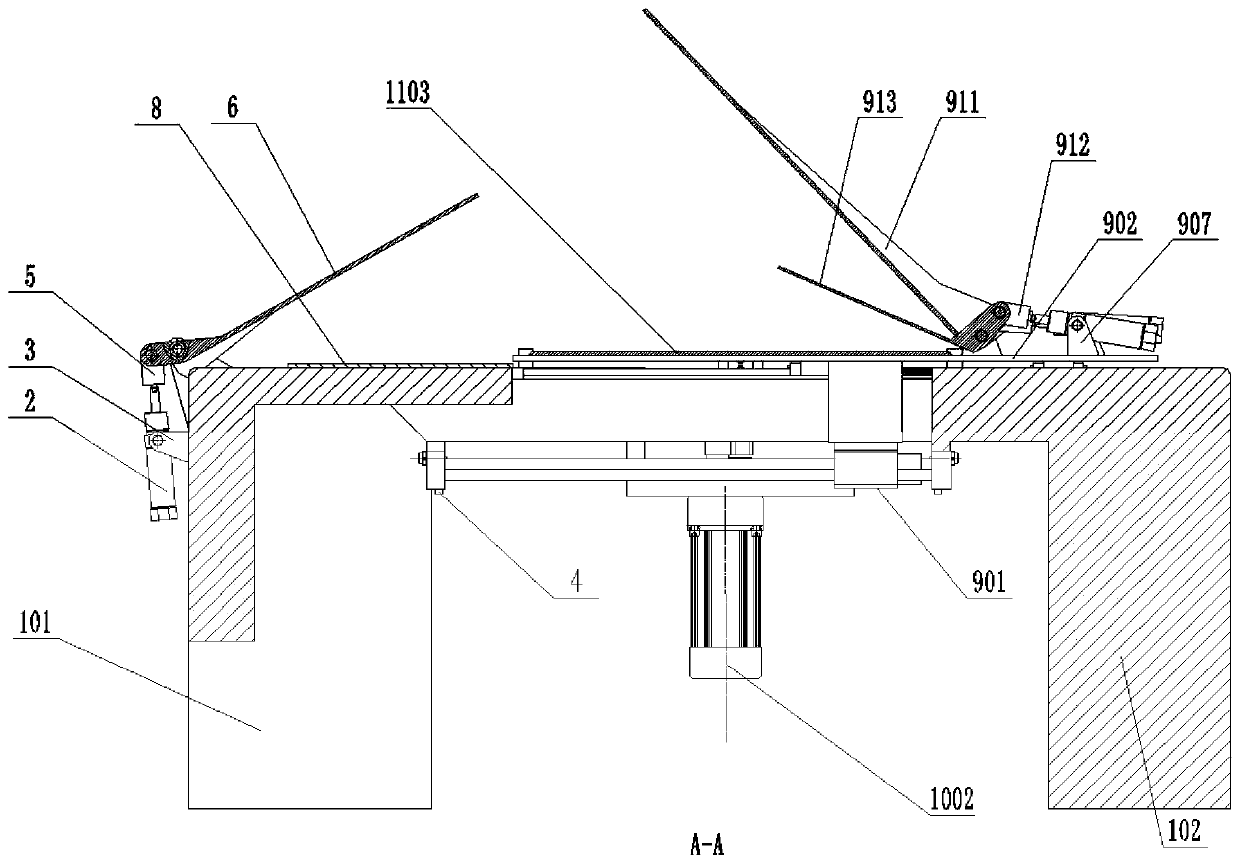

[0019] Such as Figure 1 to Figure 6 As shown, a garment turning and folding device for an automatic garment production line includes a workbench 1. In this embodiment, the length of the workbench is 1615mm, the height is 600mm, and the width is 1100mm. The workbench 1 includes a first support The part 101 and the second support part 102, the first support part 101 and the second support part 102 are connected by a U-shaped connecting plate 103, and the first supporting part 101, the second supporting part 102 and the U-shaped connecting plate 103 are integrally cast, The outer end surfaces of the two U-shaped connecting plates 103 are flush with the outer surfaces of the first supporting part 101 and the second supporting part 102, and the outer surfaces of the first supporting part 101 of the workbench 1 are respectively provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com